A Comparative Life Cycle Assessment of Palm Kernel Shell in Ceramic Tile Production: Managerial Implications for Renewable Energy Usage

Abstract

:1. Introduction

2. Materials and Methods

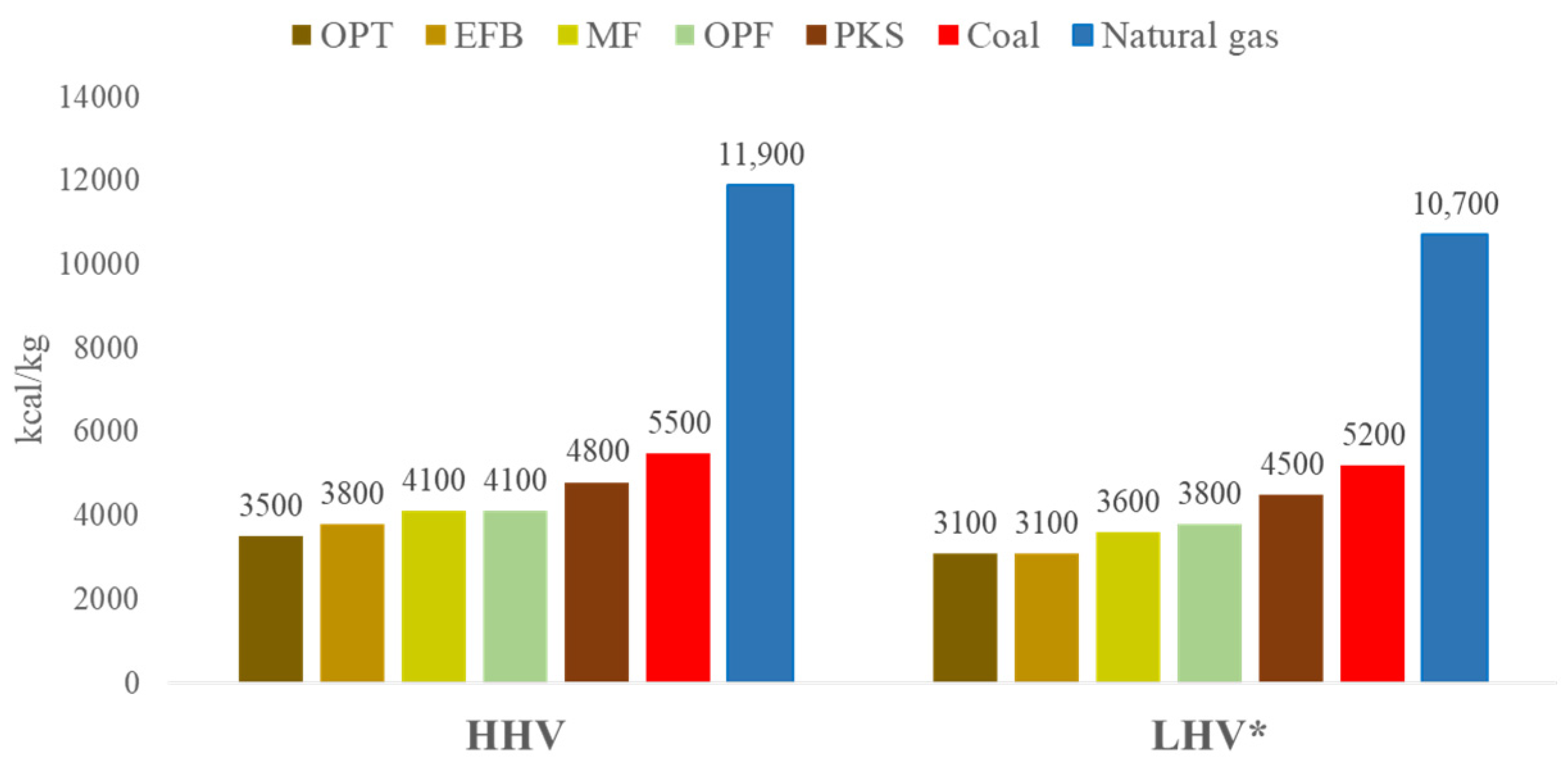

2.1. Palm Kernel Shell, Other Oil Palm Biomass, and Comparison Fuels

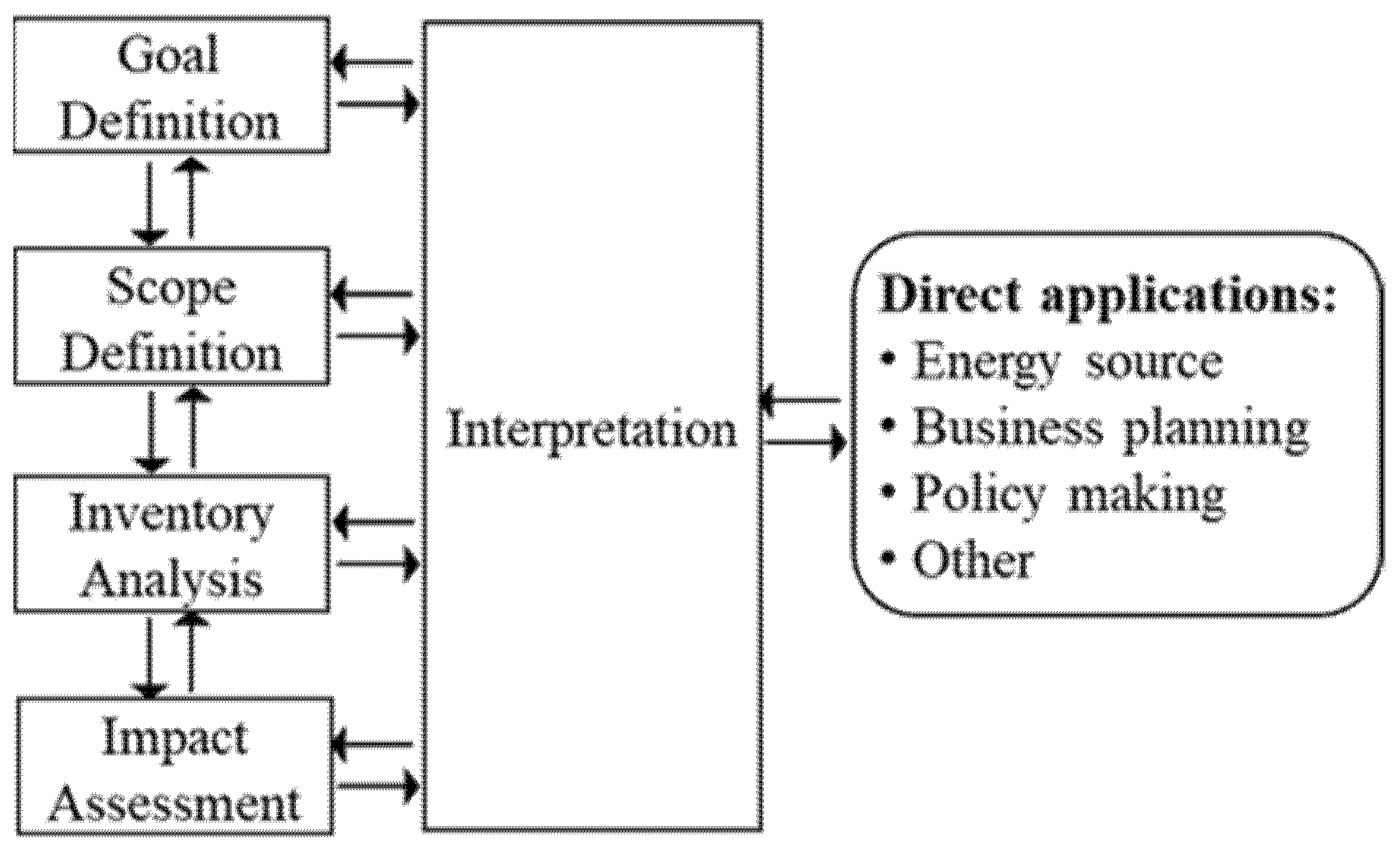

2.2. Life Cycle Assessment

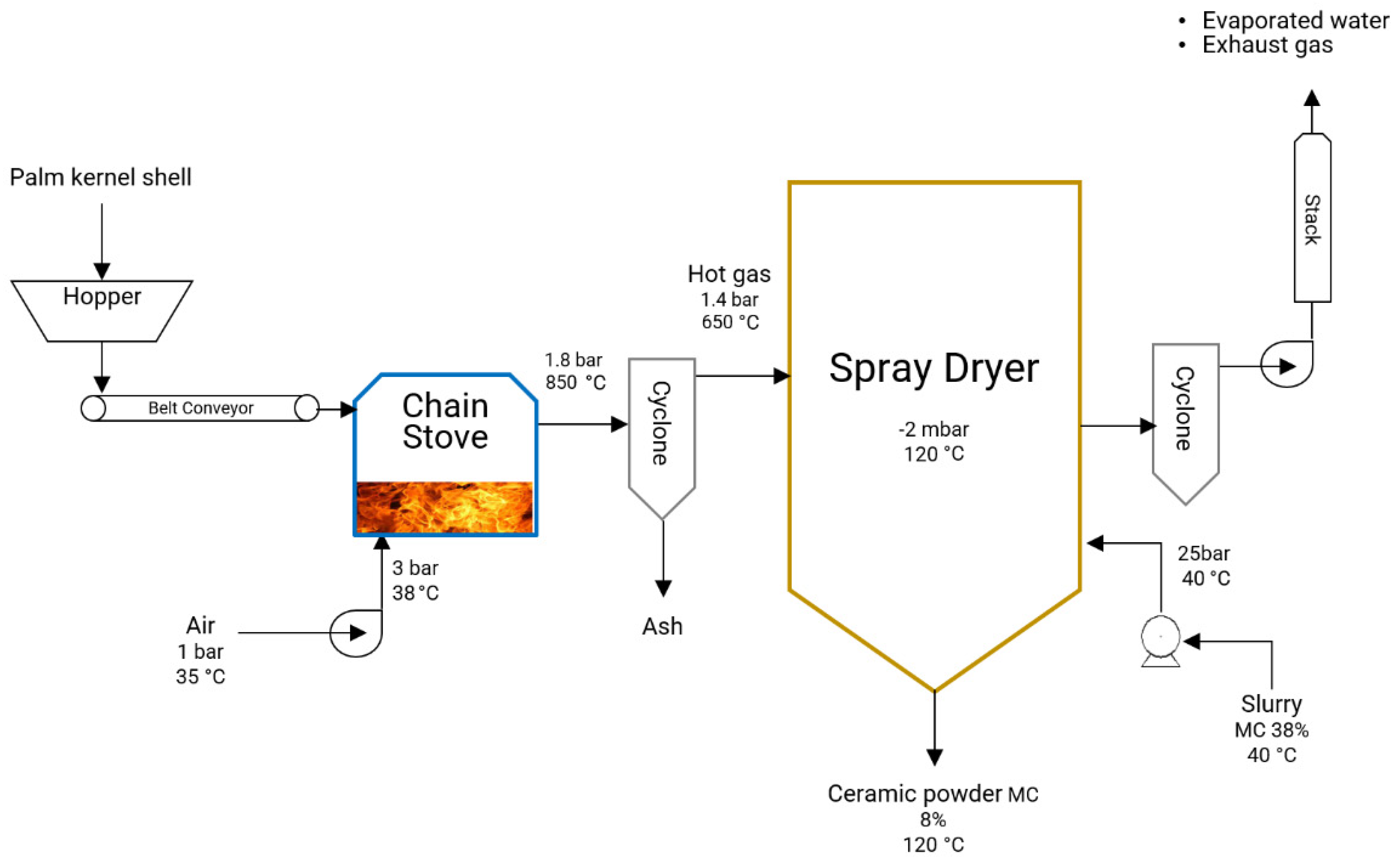

2.3. Spray Drying Process

- ηTh = thermal efficiency, %;

- Qu = net heat used, kcal;

- = fuel consumption, kg;

- LHVfuel = lower heating value of fuel, kcal·kg−1;

- HHVfuel = higher heating value of fuel, kcal·kg−1;

- = weight of water in feed, kg;

- = weight of water evaporated, kg;

- = specific heat capacity of water, kcal·kg−1·°C−1;

- = latent evaporation heat of water, kcal·kg−1;

- Tslurry = temperature of feed, °C;

- %Hfuel = fuel hydrogen content, %;

- %MCfuel = moisture content, %.

3. Results

3.1. Goal Definition and Scope

| to compare environmental impacts of industrial fuels among PKS and alternate fossil fuels, i.e., coal and natural gas, for application in industries with thermal processes by utilizing combustion technology. |

| the study only covers impacts to climate change referred to as carbon footprint, which are measured as CO2 equivalent generation throughout the entire supply chain of the respective fuels. |

| supporting decision makers with recommendations for environmentally preferred fuel selection related to GHG emissions in industrial applications, whilst other aspects of environmental superiority and social impacts are out of context. |

| the study is intended for corporate decision makers to convince the usage of more environmentally friendly materials than fossil fuels and the academic community. |

| comparisons are made among life cycle assessment studies of alternative fuels from the combination of literature study and field observations. |

| the study is self-funded with no conflict of interest and is commissioned by experts with the appropriate academic background. |

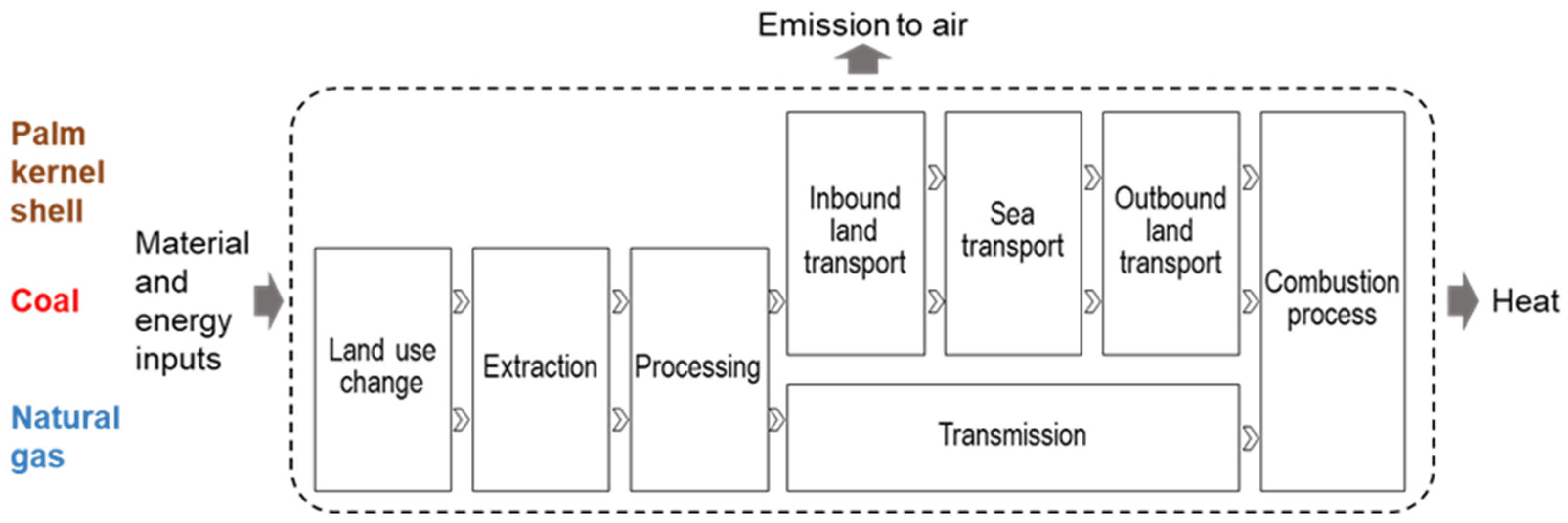

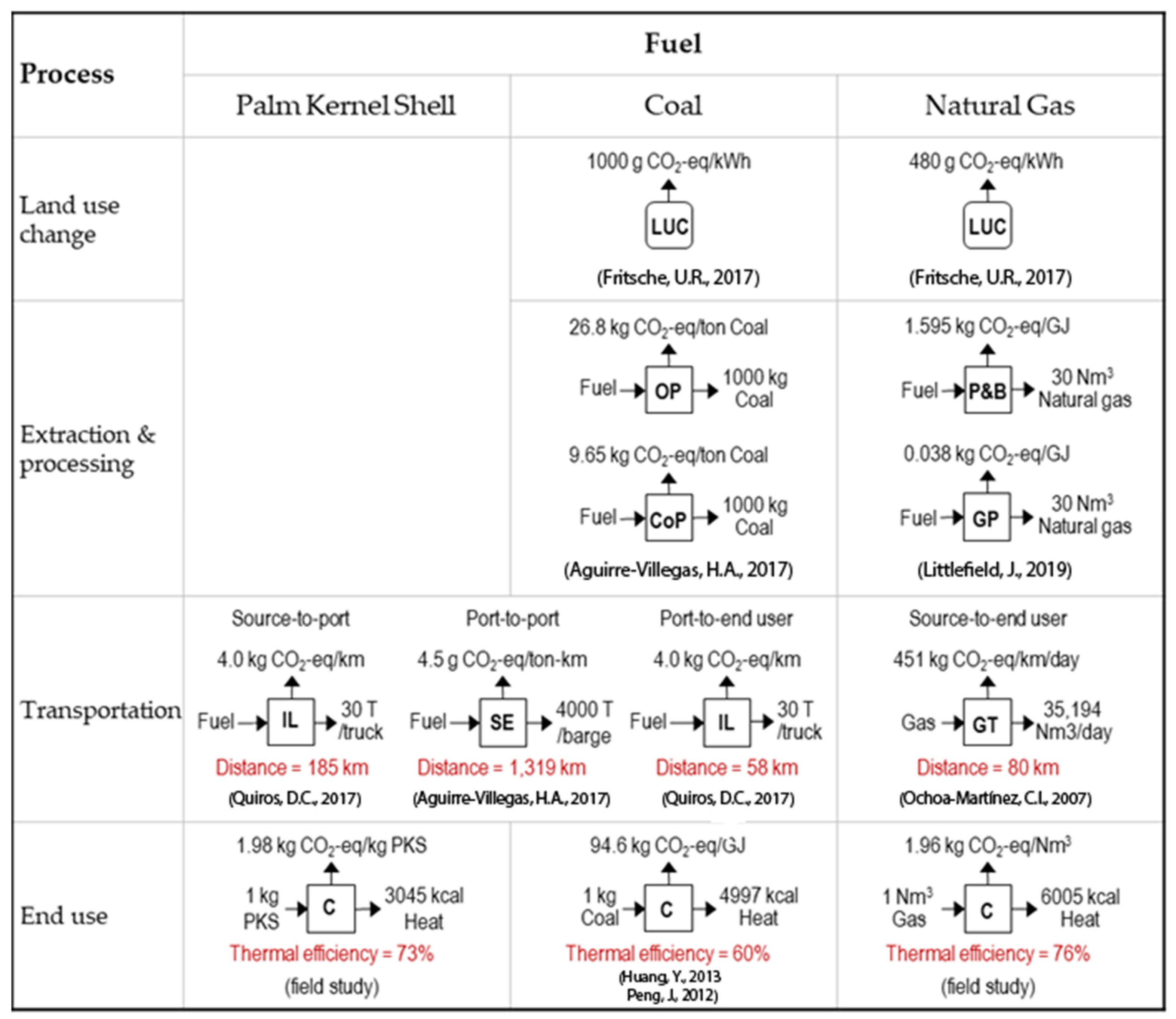

3.2. Life Sycle Inventory Analysis

3.3. Life Cycle Impact Assessment

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Conrad, J.M. Resource Economics, 2nd ed.; Cambridge University Press: New York, NY, USA, 2010; pp. 1–5. [Google Scholar]

- Cramb, R.; McCarthy, J.F. Characterising oil palm production in Indonesia and Malaysia. In The Oil Palm Complex: Smallholders, Agribusiness, and the State in Indonesia and Malaysia; Cramb, R., McCharty, J.F., Eds.; National University of Singapore Press: Singapore, 2018; pp. 27–77. [Google Scholar]

- Simadiputra, W.; Lim, R.W.; Khor, M. Indonesian palm oil: Tight supply to help prices. DBS Asian Insights 2018, 68. Available online: https://www.dbs.com.sg/treasures/aics/pdfController.page?pdfpath=/content/article/pdf/AIO/102018/181031_insights_tight_supply_to_help_prices.pdf (accessed on 7 February 2020).

- Handaya, H.; Susanto, H.; Indrawan, D.; Marimin, M. Supply and demand characteristics of palm kernel shell as a renewable energy source for industries. Int. J. Renew. Energy Dev. 2022, 11, 481–490. [Google Scholar] [CrossRef]

- Faaij, A.; Junginger, M.; Goh, C.S. A general introduction to international bioenergy trade, In International Bioenergy Trade—History, Status and Outlook on Securing Sustainable Bioenergy Supply, Demand and Markets; Junginger, M., Goh, C.S., Faaij, A., Eds.; Springer: Dordrecht, The Netherlands, 2014; pp. 1–15. [Google Scholar]

- Azar, C.; Lindgreen, K.; Larson, E.; Möllersten, K. Carbon-capture and storage from fossil fuels and biomass—Costs and potential role in stabilizing the atmosphere. Clim. Chang. 2006, 74, 47–79. [Google Scholar] [CrossRef]

- Chen, C.K.; Kamba, M.; Shie, A.J.; Dahlgaard, J. Greenhouse gas management model—A triple cause-effect logic. Int. J. Quality Service Sci. 2016, 8, 412–427. [Google Scholar] [CrossRef]

- Yatim, P.; Mamat, M.N.; Mohammad-Zailani, S.H.; Ramlee, S. Energy policy shifts towards sustainable energy future for Malaysia. Clean Technol. Environ. Policy 2016, 18, 1685–1695. [Google Scholar] [CrossRef]

- EIA. International Energy Outlook 2019 with Projection to 2050; US Energy Information Administration: Washington, DC, USA, 2019.

- Hambali, E.; Rivai, M. The potential of palm oil waste biomass in Indonesia in 2020 and 2030. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017; Volume 65, p. 012050. [Google Scholar]

- Harahap, H.; Leduc, S.; Mesfun, S.; Khatiwada, D.; Kraxner, F.; Silveira, S. Opportunities to optimize the palm oil supply chain in Sumatra, Indonesia. Energies 2019, 12, 420. [Google Scholar] [CrossRef]

- Nasution, M.A.; Wulandari, A.; Ahamed, T.; Noguchi, R. Alternative POME treatment technology in the implementation of Roundtable on Sustainable Palm Oil, Indonesian Sustainable Palm Oil (ISPO), and Malaysian Sustainable Palm Oil (MSPO) standards using LCA and AHP methods. Sustainability 2020, 12, 4101. [Google Scholar] [CrossRef]

- BPS. Indonesian Oil Palm Statistics 2020; Indonesia Central Bureau of Statistics: Jakarta, Indonesia, 2021. [Google Scholar]

- Abnisa, F.; Wan Daud, W.M.A.; Husin, W.N.W.; Sahu, J.N. Utilization possibilities of palm shell as a source of biomass energy in Malaysia by producing bio-oil in pyrolysis process. Biomass Bioenergy 2011, 35, 1863–1872. [Google Scholar] [CrossRef]

- Okoroigwe, E.C.; Li, Z.; Unachukwu, G.; Stuecken, T.; Saffron, C. Thermochemical conversion of palm kernel shell (pks) to bio-energy. Energy Sustain. 2011, 54686, 1183–1191. [Google Scholar]

- Schmidt, J.; De Rosa, M. Certified palm oil reduces greenhouse gas emissions compared to non-certified. J. Clean. Prod. 2020, 277, 124045. [Google Scholar] [CrossRef]

- Yahayu, M.; Abas, F.Z.A.; Zulkifli, S.E.; Ani, F.N. Utilization of oil palm fiber and palm kernel shell in various applications. In Sustainable Technologies for the Management of Agricultural Wastes; Zakaria, Z.A., Ed.; Springer Nature Singapore Ltd.: Singapore, 2018; pp. 45–56. [Google Scholar]

- Mahlia, T.M.I.; Ismail, N.; Hossain, N.; Silitonga, A.S.; Shamsuddin, A.H. Palm oil and its wastes as bioenergy sources: A comprehensive review. Environ. Sci. Pollut. Res. 2019, 26, 14849–14866. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Luo, J.; Xia, B. Application of cleaner production as an important sustainable strategy in the ceramic tile plant—A case study in Guangzhou China. J. Clean. Prod. 2013, 43, 113–121. [Google Scholar] [CrossRef]

- Peng, J.; Zhao, Y.; Jiao, L.; Zheng, W.; Zeng, L. CO2 Emission calculation and reduction options in ceramic tile manufacture— The Foshan case. Energy Procedia 2012, 16, 467–476. [Google Scholar] [CrossRef]

- Statista. Available online: https://www.statista.com/statistics/1275511/global-ceramic-tile-production-volume/ (accessed on 6 August 2022).

- Bird, N.; Cowie, A.; Cherubini, F.; Jungmeier, G. Using a life cycle assessment approach to estimate the net greenhouse gas emissions of bioenergy. In IEA Bioenergy Strategic Report; IEA Bioenergy: Rotarua, New Zealand, 2011. [Google Scholar]

- Hoppe, W.; Bringezu, S.; Thonemann, N. Comparison of global warming potential between conventionally produced and CO2-based natural gas used in transport versus chemical production. J. Clean. Prod. 2016, 121, 231–237. [Google Scholar] [CrossRef]

- Olofsson, J.; Börjesson, P. Residual biomass as resource—Life-cycle environmental impact of wastes in circular resource system. J. Clean. Prod. 2018, 196, 997–1006. [Google Scholar] [CrossRef]

- Nduagu, E.I.; Yadav, D.; Bhardwaj, N.; Elango, S.; Biswas, T.; Banerjee, R.; Rajagopalan, S. Comparative life cycle assessment of natural gas and coal-based directly reduced iron (DRI) production: A case study for India. J. Clean. Prod. 2022, 347, 131196. [Google Scholar] [CrossRef]

- Kar, S.; Billen, P.; Björnebo, L.; Katz, B.; Yang, S.; Volk, T.A.; Spatari, S. Effects of greenhouse gas emissions timing on alternative biomass and fossil energy sources for district heating. GCB Energy 2021, 13, 1785–1799. [Google Scholar] [CrossRef]

- Nudri, N.A.; Bachmann, R.T.; Ghani, W.A.W.A.K.; Ng, D.K.S.; Azni, A.A. Characterization of oil palm trunk biocoal and its suitability for solid fuel applications. Biomass Convers. Biorefinery 2020, 10, 45–55. [Google Scholar] [CrossRef]

- Loh, S.K. The potential of the Malaysian oil palm biomass as a renewable energy source. Energy Convers. Manag. 2017, 141, 285–298. [Google Scholar] [CrossRef]

- Ghugare, S.B.; Tiwary, S.; Elangovan, V.; Tambe, S.S. Prediction of higher heating value of solid biomass fuels using artificial intelligence formalisms. Bioenergy Res. 2013, 7, 681–692. [Google Scholar] [CrossRef]

- Jameel, H.; Keshwani, D.R. Thermochemical conversion of biomass to power and fuels. In Biomass to Renewable Energy Processes, 2nd ed.; Cheng, J.J., Ed.; CRC Press: New York, NY, USA, 2018; pp. 375–421. [Google Scholar]

- Samiran, N.A.; Jaafar, M.N.M.; Cheng, T.C.; Ng, J.H. A review of palm oil biomass as a feedstock for syngas fuel technology. J. Teknol. 2015, 72, 13–18. [Google Scholar] [CrossRef]

- Kabir, G.; Din, A.T.M.; Hameed, B.H. Pyroysis of oil palm mesocarp fiber and palm frond in a slow-heating fixed-bed reactor: A comparative study. Bioresour. Technol. 2017, 241, 561–572. [Google Scholar] [CrossRef] [PubMed]

- Guangul, F.M.; Sulaiman, S.A.; Ramli, A. Gasifier selection, design and gasification of oil palm fronds with preheated and unheated gasifying air. Bioresour. Technol. 2012, 126, 224–232. [Google Scholar] [CrossRef]

- Kristiani, A.; Abimanyu, H.; Setiawan, A.H.; Aulia, F. Effect of pretreatment process by using diluted acid to characteristic of oil palm’s frond. Energy Procedia 2013, 32, 183–189. [Google Scholar] [CrossRef]

- Ahmad, Z.; Saman, H.M.; Tahir, P.M. Oil palm trunk fiber as a bio-waste resource for concrete reinforcement. Int. J. Mechanical Mater. Eng. 2010, 5, 199–207. [Google Scholar]

- Speight, J.G. The Chemistry and Technology of Coal; CRC Press: Boca Raton, FL, USA, 2013; pp. 226+238+269. [Google Scholar]

- Mokhatab, S.; Poe, W.A.; Mak, J.Y. Handbook of Natural Gas Transmission and Processing—Principles and Practices, 4th ed.; Gulf Professional Publishing: Cambridge, MA, USA, 2019; pp. 35–36. [Google Scholar]

- Ninduangdee, P.; Kuprianov, V.I. Combustion of PKS in a fluidized bed—Optimization of biomass particle size and operating conditions. Energy Convers. Manag. 2014, 85, 800–808. [Google Scholar] [CrossRef]

- Vamvuka, D. Overview of solid fuels combustion technologies. In Handbook of Combustion; Lackner, M., Winter, F., Agarwal, A.K., Eds.; Wiley-VCH Verlag GmbH & Co.: Weinheim, Germany, 2010; Volume 4, pp. 31–84. [Google Scholar]

- Quiros, D.C.; Smith, J.; Thiruvengadam, A.; Huat, T.; Hu, S. Greenhouse gas emissions from heavy-duty natural gas, hybrid, and conventional diesel on-road trucks during freight transport. Atmos. Environ. 2017, 168, 36–45. [Google Scholar] [CrossRef]

- Herdzik, J. Energy efficiency operational indicator as an index of carbon dioxide emission from marine transport. Annu. Set Environ. Protect. 2020, 22, 549–560. [Google Scholar]

- Fritsche, U.R.; Berndes, G.; Cowie, A.L.; Dale, V.H.; Kline, K.L.; Johnson, F.X.; Langeveld, H.; Sharma, N.; Watson, H.; Woods, J. Energy and Land Use. Global Land Outlook Working Paper; United Nations Convention to Combat Desertification (UNCCD): Bonn, Germany, 2017. [Google Scholar]

- Aguirre-Villegas, H.A.; Benson, C.H. Case history of environmental impacts of an Indonesian coal supply chain. J. Clean. Prod. 2017, 157, 47–56. [Google Scholar] [CrossRef]

- Littlefield, J.; Roman-White, S.; Augustine, D.; Pegallapati, A.; Zaimes, G.G.; Rai, S.; Cooney, G.; Skone, T.J. Life Cycle Analysis of Natural Gas Extraction and Power Generation; US National Energy Technology Laboratory: Pittsburgh, PA, USA, 2019.

- Dianita, C.; Saputra, A.H. Estimating greenhouse gas emissions level of a natural gas pipeline—Case study from A to B point in West Java-Indonesia. MATEC Web Conf. 2016, 58, 01011. [Google Scholar] [CrossRef]

- CEN. ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. European Committee for Standardization: Brussels, Belgium, 2006.

- Rabl, A.; Benoist, A.; Dron, D.; Peuportier, B.; Spadaro, J.V.; Zoughaib, A. How to account for CO2 emissions from Biomass in an LCA. Int. J. Life Cycle Assess. 2007, 12, 281. [Google Scholar] [CrossRef]

- Laurent, A.; Espinosa, N.; Hauschild, M.Z. LCA of energy systems. In Life Cycle Assessment: Theory and Practice; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer International Publishing AG: Cham, Switzerland, 2018; pp. 633–668. [Google Scholar]

- Jha, G.; Soren, S.; Mehta, K.D. Life cycle assessment of sintering process for carbon footprint and cost reduction: A comparative study for coke and biomass-derived sintering process. J. Clean. Prod. 2020, 259, 120889. [Google Scholar] [CrossRef]

- Pryshlakivsky, J.; Searcy, C. Life cycle assessment as a decision-making tool: Practitioner and managerial considerations. J. Clean. Prod. 2021, 309, 127344. [Google Scholar] [CrossRef]

- Loo, S.; van Koppejan, J. The Handbook of Biomass Combustion and Co-Firing; Earthscan: London, UK, 2008; pp. 28–29. [Google Scholar]

- McDermott, S.M.; Howarth, R.B.; Lutz, D.A. Biomass energy and climate neutrality: The case of the northern forest. Land Econ. 2015, 91, 197–210. [Google Scholar] [CrossRef]

- Pfaltzgraff, L.A.; Clark, J.H. Green chemistry, biorefineries and second generation strategies for re-use of waste: An overview. In Advances in Biorefineries: Biomass and Waste Supply Chain Exploitation; Waldron, K., Ed.; Woodhead Publishing: Cambridge, UK, 2014; pp. 7–9. [Google Scholar]

- Gagarin, H.; Sridhar, S.; Lange, I.; Bazilian, M.D. Considering non-power generation uses of coal in the United States. Renew. Sustain. Energy Rev. 2020, 124, 109790. [Google Scholar] [CrossRef]

- DitjenEBTKE. Directorate General of New Energy, Renewable and Conservation of Energy Strategic Plan 2020–2024; Directorate General of New Energy, Renewable and Conservation of Energy—Ministry of Energy and Mineral Resources of the Republic of Indonesia: Jakarta, Indonesia, 2020. [Google Scholar]

- Anwar, Z.; Gulfraz, M.; Irshad, M. Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: A brief review. J. Radiat. Res. Appl. Sci. 2014, 7, 163–173. [Google Scholar] [CrossRef]

- Pfau, S.F.; Hanssen, S.V.; Straatsma, M.W.; Koopman, K.R.; Leuven, R.S.E.W.; Huijbregts, M.A.J. Life cycle greenhouse gas benefits or burdens of residual biomass from landscape management. J. Clean. Prod. 2019, 220, 698–706. [Google Scholar] [CrossRef]

- Dani, S.; Wibawa, A. Challenges and Policy for Biomass Energy in Indonesia. Int. J. Bus. Econ. Law 2018, 15, 41–47. [Google Scholar]

- Tasri, A.; Susilawati, A. Selection among renewable energy alternatives based on a fuzzy analytic hierarchy process in Indonesia. Sustain. Energy Technol. Assess. 2014, 7, 34–44. [Google Scholar] [CrossRef]

| Oil Palm Biomass | C | H | O | N | S | FC | VM | Ash | MC | Reference |

|---|---|---|---|---|---|---|---|---|---|---|

| Palm kernel shell | 50 | 5 | 45 | 0.1 | 0.2 | 22 | 76 | 2 | 11 | [14] |

| Empty fruit bunch | 41 | 6 | 43 | 0.2 | 1.0 | 19 | 73 | 8 | 70 | [31] |

| Mesocarp fiber | 46 | 9 | 50 | 0.4 | 0.0 | 28 | 71 | 1 | 5 | [32] |

| Fronds | 45 | 5 | 49 | 0.7 | 0.1 | 15 | 81 | 4 | 8 | [33,34] |

| Trunks | 62 | 9 | 51 | 1.3 | 0.1 | 4 | 77 | 19 | 76 | [27,28,35] |

| Coal | 66 | 5 | 19 | 1.0 | 0.8 | 49 | 28 | 23 | 3 | [36] |

| Natural gas | 73 | 24 | 0.4 | 0.1–1.5 | <5 ppm | [37] |

| Fuel | Process | Specificity | Type | Source | ||||

|---|---|---|---|---|---|---|---|---|

| Very High | High | Medium | Low | Very Low | ||||

| Palm kernel shell | Inbound land transport | X | Emission per km | [40] | ||||

| Sea transport | X | Emission per km | [41] | |||||

| Outbound land transport | X | Emission per km | [40] | |||||

| Combustion process | X | Concentration | field study | |||||

| Coal | Land-use change | X | Complete unit | [42] | ||||

| Overburden processing | X | Concentration | [43] | |||||

| Coal processing | X | Concentration | [43] | |||||

| Inbound land transport | X | Emission per km | [40] | |||||

| Sea transport | X | Emission per km | [41] | |||||

| Outbound land transport | X | Emission per km | [40] | |||||

| Combustion process | X | Concentration | [19,20] | |||||

| Natural gas | Land-use change | X | Complete unit | [42] | ||||

| Production and boosting | X | Concentration | [44] | |||||

| Processing | X | Concentration | [44] | |||||

| Transmission | X | Emission per km | [45] | |||||

| Combustion process | X | Concentration | field study | |||||

| Variables/Parameters | PKS (1) | Coal (2) | Natural Gas (1) | |||

|---|---|---|---|---|---|---|

| Basis of powder | 1000 | kg/h | 000 | kg/h | 1000 | kg/h |

| Powder moisture content | 7.3 | % | 7.0 | % | 8.0 | % |

| Slurry moisture content | 36.0 | % | 30.9 | % | 36.0 | % |

| Slurry temperature | 30 | °C | 30 | °C | 30 | °C |

| Fuel HHV | 4750 | kcal/kg | 5002 | kcal/kg | 9170 | kcal/Nm3 |

| 22 | % | 8 | % | 0 | % |

| 9 | % | 5 | % | 24 | % |

| Fuel LHV | 4194 | kcal/kg | 4716 | kcal/kg | 8004 | kcal/Nm3 |

| Fuel consumption | 91 | kg | 75 | kg | 45 | Nm3 |

| Heat consumed | 278,657 | kcal/h | 210,984 | kcal/h | 272,475 | kcal/h |

| Net heat used | 3065 | kcal/kg | 2813 | kcal/kg | 6055 | kcal/Nm3 |

| Thermal efficiency | 73 | % | 60 | % | 76 | % |

| Stage | Fuel | ||

|---|---|---|---|

| Palm Kernel Shell | Coal | Natural Gas | |

| Source | Riau Province, Sumatera | Subang, West Java | |

| Distribution | Inland Riau—Riau port to Jakarta port— inland Jakarta to Cikarang, West Java | Piping from Subang to Cikarang | |

| Use | Cikarang, West Java | ||

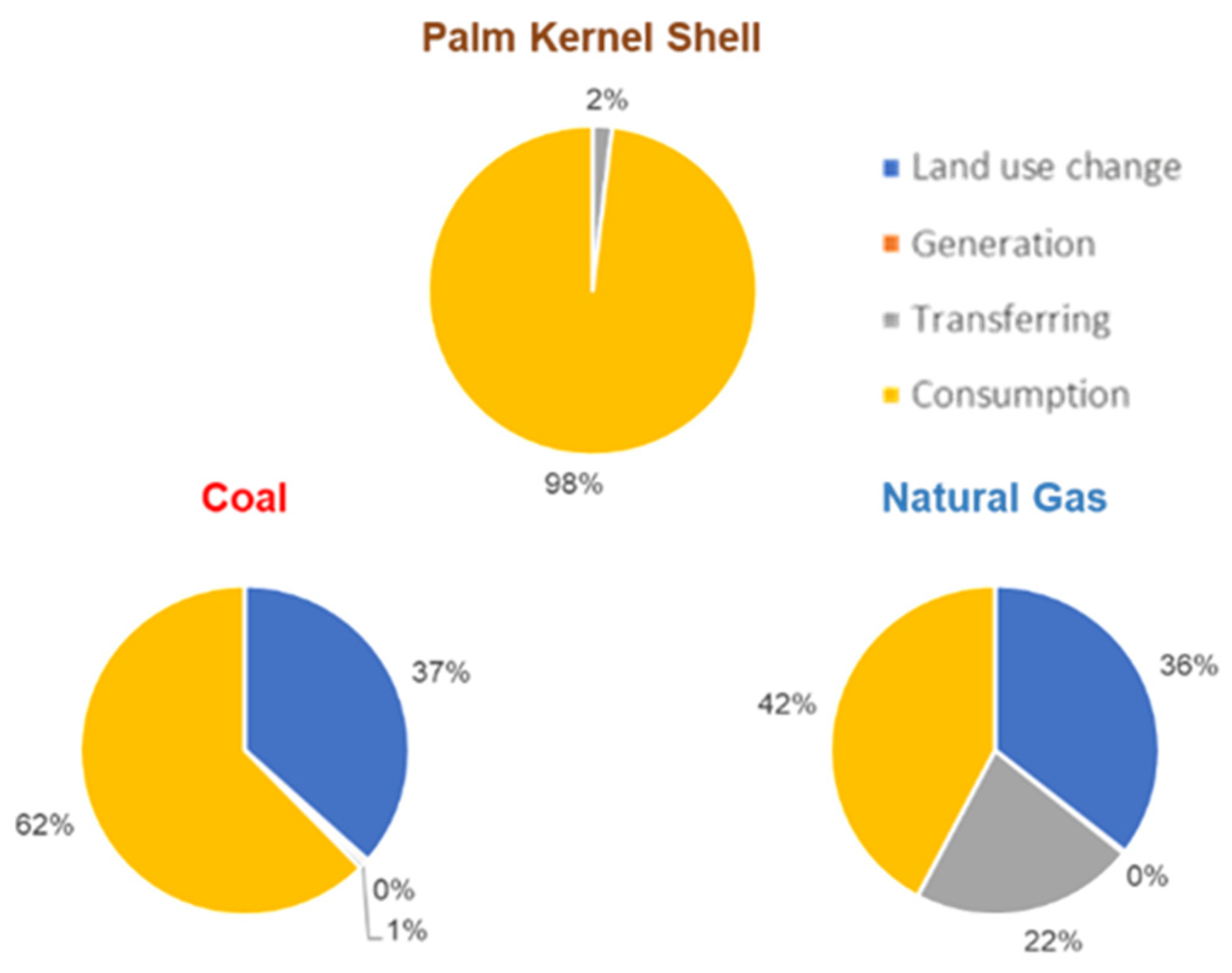

| Activity | Fuel | ||

|---|---|---|---|

| Palm Kernel Shell | Coal | Natural Gas | |

| Land-use change | 0.355 | 0.239 | |

| Generation | 0.005 | 0.001 | |

| Transferring | 0.011 | 0.005 | 0.149 |

| Consumption | 0.566 | 0.605 | 0.284 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Handaya; Marimin; Indrawan, D.; Susanto, H. A Comparative Life Cycle Assessment of Palm Kernel Shell in Ceramic Tile Production: Managerial Implications for Renewable Energy Usage. Sustainability 2022, 14, 10100. https://doi.org/10.3390/su141610100

Handaya, Marimin, Indrawan D, Susanto H. A Comparative Life Cycle Assessment of Palm Kernel Shell in Ceramic Tile Production: Managerial Implications for Renewable Energy Usage. Sustainability. 2022; 14(16):10100. https://doi.org/10.3390/su141610100

Chicago/Turabian StyleHandaya, Marimin, Dikky Indrawan, and Herri Susanto. 2022. "A Comparative Life Cycle Assessment of Palm Kernel Shell in Ceramic Tile Production: Managerial Implications for Renewable Energy Usage" Sustainability 14, no. 16: 10100. https://doi.org/10.3390/su141610100

APA StyleHandaya, Marimin, Indrawan, D., & Susanto, H. (2022). A Comparative Life Cycle Assessment of Palm Kernel Shell in Ceramic Tile Production: Managerial Implications for Renewable Energy Usage. Sustainability, 14(16), 10100. https://doi.org/10.3390/su141610100