Abstract

Reliability centered maintenance (RCM) is a new strategic framework for evaluating system maintenance requirements in its operating conditions. Some industries employ predictive maintenance strategies in addition to preventive maintenance (PM) strategies, which increase production costs. As the breakdown maintenance (BDM) technique is used, the maintenance cost increases. The RCM approach is a mixture of these maintenance strategies that can be used to optimize the maintenance costs and to ensure the availability of the system. The RCM method was applied to the steam boiler system used in the textile industries for the research work reported in this paper. The RCM methodology stated in the literature cannot be implemented, as it is in Indian textile industries due to the lack of knowledge of RCM principles, a labor-oriented nature, the use of partially computerized information systems, an inadequate maintenance database, and information about maintenance costs and production loss. To resolve these issues, a modified RCM approach involving a large number of experts is developed. To apply this RCM methodology, critical components are identified through reliability and failure mode effect and criticality analysis (FMECA). Finally, scheduled maintenance strategies and their intervals are recommended to ensure that the system continues to operate properly. According to this study, implementing the RCM technique effectively will increase boiler system reliability and availability by 28.15 percent and 0.16 percent, respectively. Additionally, up to 20.32 percent of the maintenance cost can be saved annually by applying these scheduled maintenance programs.

1. Introduction

The textile industry spins yarn from raw materials, such as cotton or wool, which is then used to make clothing. The industry involves all processes involved in converting raw material into a finished product, including textile creation, processing, manufacture and distribution. For several of these operations in the textile industry, steam is widely used as a heat transfer medium. As a result, the steam boiler is an integral part of the textile industry’s operations. In order to meet this steam requirement, maintenance policies for the steam boiler system have been established.

The reliability centered maintenance (RCM) methodology was used to develop maintenance strategies that provide an appropriate level of reliability in a cost-effective manner. Reliability centered maintenance (RCM) is not a new concept, as it has been around since the 1960s. In 1978, Stanley Nowlan and Howard Heap first introduced RCM to the aviation industry [1]. Pujadas and Chen [2] developed a new simple maintenance decision framework after making some changes and incorporating the benefits of RCM and FMECA. In 1998, Nour et al. [3], emphasized the importance of cautious analysis of mechanical component reliability in order to optimize the maintenance program. Numerous studies [4,5,6,7,8,9,10] have identified the systematic methodology for the creation of the RCM and its successful implementation. RCM can be described as a maintenance strategy that logically integrates an optimum mix of reactive, preventive, predictive, and proactive maintenance practices.

Maintenance is characterized as a set of activities that keep equipment or systems in a state where they can perform their assigned functions. Charles et al. [11] addressed the problems of preventive maintenance (PM) strategy optimization and developed an approach with the objective of minimizing maintenance costs. Maintenance cost is an important aspect to consider while deciding the optimum maintenance intervals. Taking these maintenance costs into account, Rao et al. [12] and Santos [13] proposed a model to decide the optimum preventive maintenance interval. Similarly, Das et al. [14], Smith [15], Yun et al. [16] and Macchi et al. [17] considered the Weibull failure time dispersion parameters to decide the optimum PM intervals. Jagtap et al. also improved the maintenance schedule of the turbo-generator subsystem and boiler furnace system using particle swarm optimization [18,19].

The process industries are those in which the primary production operations are either continuous or occur on an indistinguishable batch of materials. Process industries can be found all over the world and contribute significantly to a country’s economy. Many process industries rely on industrial steam boilers as a key component of their operations. As a result, the availability of the plant is dependent on the availability of the boiler. As the boiler is a complex system with various structures, there are numerous failures. In severe situations, steam boilers have been known to burst, inflicting significant damage to the plant or even the death of the operator. As a result, precise guidelines on how to clean and maintain boilers and associated systems have emerged. Furthermore, numerous failures interrupted the production process and had a financial impact. All of these problems can be avoided with inexpensive chemicals and proper maintenance.

The application of RCM in process industries enables scheduled maintenance and other steps to be done to avoid failure and the consequences of crucial components of the steam boiler system. Early detection of system failure and improving productivity of ongoing operation of the system by improving its availability is a difficult challenge. This task was taken up as a research problem and a comprehensive RCM framework is developed to detect the early failure of the steam boiler in the selected textile industries and keep the plant in healthy working condition. The availability of the critical components of the steam boiler system is improved by designing an appropriate maintenance strategy.

RCM is a logical way of defining the equipment that is expected to be maintained on a PM basis rather than on a CM basis, commonly referred to as Run-to-Failure (RTF) [20]. An effective PM policy must focus on components where failure modes will have a significant impact on safety, operations, quality, and maintenance costs. An essential issue is to reduce the maintenance costs in the direct operational costs of a process or large equipment. The main objective of this work was to develop a detailed RCM model for the steam boiler system used in textile industry (water tube boilers with capacity 03 to 05 tons), with an emphasis on maintaining system functions and system reliability. The developed reliability-centered maintenance (RCM) can be used to evaluate the optimal maintenance strategy and achieve the necessary level of reliability and availability at the lowest possible cost. The findings of this study were useful for getting a better understanding of the failure patterns that influence decision-making and system operation and maintenance planning. The paper is arranged accordingly: Section 2 developed the reliability centered maintenance (RCM) model. The results of the case study are given in Section 3. Section 4 presents results and discussions, and Section 5 eventually provides the conclusions of the study references.

2. Reliability Centered Maintenance (RCM) Model

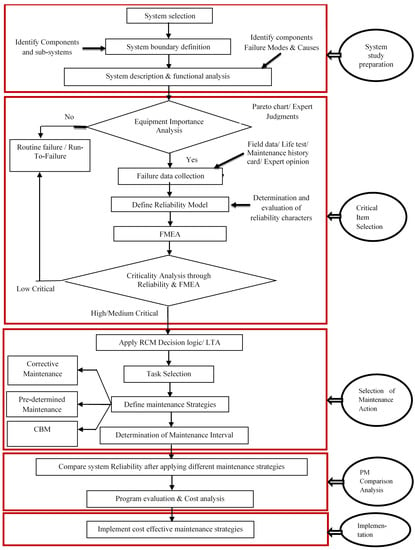

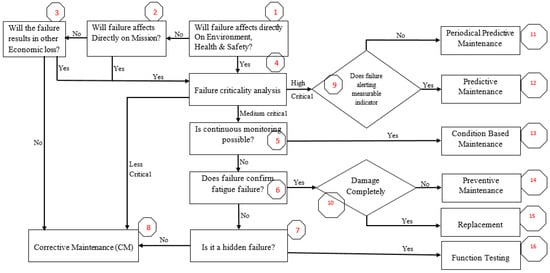

The literature reveals that the majority of frameworks are based on qualitative analysis, with only a few frameworks based on quantitative analysis of the system. From the literature, it is observed that none of the frameworks considered both quantitative and qualitative analyses of a system; so there is a need to develop a framework that can employ both qualitative and quantitative terms. The proposed RCM model allows both qualitative and quantitative analysis and is divided into five main steps: system study preparation, critical item selection, the selection of appropriate maintenance actions, the preventive maintenance cost comparison analysis, and effective implementation of the reliability-centered maintenance program. In this section, we will provide a brief overview of these steps. The RCM’s methodological definition is focused primarily by Rausand [4], Selvik and Aven [21] and Deshpande and Modak [22]. Figure 1 and Figure 2 show the developed RCM model decision framework, respectively.

Figure 1.

Modified reliability centered maintenance (RCM) model.

Figure 2.

Modified reliability centered maintenance (RCM) decision framework.

2.1. Phase I: System Study Preparation

The first phase of the developed model consists of the three main phases, i.e., selection of systems, the definition of the system boundary conditions, and system description and functional analysis. Initially, the system must be chosen taking into account the system failure frequency, preventive maintenance, corrective maintenance costs, and downtime costs incurred. Once the system has been selected for RCM analysis, the various subsystems, components and boundary conditions must be described. It is important to determine the system boundary conditions in order to maintain the RCM process under control when the system is complex. Following the selection of the boundary conditions and components/subsystems, system definition and functional analysis are needed. During the application of the RCM, the functions and their functional failures of the different components and subsystems must first be examined.

2.2. Phase II: Critical Item Selection

After selecting the system for analysis and functional failure analysis, the next phase is to identify and select the critical components and subsystems for analysis. The critical components can be identified by pareto chart analysis, FMECA, and reliability analysis. The literature-reported RCM model employs either reliability analysis or FMEA analysis. It is difficult to use a single method for criticality analysis when a system component is highly reliable, but its failure modes and effects are severe, or when the component failure does not affect system performance, but the failure frequency is high. As a result, the model presented here addresses this issue using both approaches simultaneously. Field failure data can be collected for the equipment importance analysis from maintenance history cards, life tests, and the expert opinion method. After collecting the field failure data, a reliability model can be developed and critical components identified through reliability analysis. Similarly, FMECA analysis is used to identify critical components and subsystems in terms of failure consequences. These critical components are considered to be maintenance significant items, which were later incorporated into the RCM decision logic for the planning of PM tasks.

2.3. Phase III: Selection of Maintenance Actions

The suitable PM tasks will be assigned to these maintenance significant items in this phase. This process entails applying decision logic or logic tree analysis to selected critical components, selecting the appropriate maintenance task and maintenance strategy, and determining maintenance intervals. The RCM decision logic diagram is used to evaluate the PM tasks based on the results of the reliability analysis and FMECA. This decision diagram guides the assessor in defining appropriate maintenance tasks based on a variety of YES or NO questions. After specifying the PM tasks using RCM logic, the next step is to assign maintenance intervals. The assessment of optimum maintenance intervals is a challenging task. Various mathematical models, such as Rausand and Vatn [23], Percy [24], Dekker [25], Wang and Pham [26], and Cui [27] can be used to evaluate optimum maintenance intervals. The above assessment normally results in a combination of various maintenance tasks and intervals. The PM tasks and intervals are grouped in such a way that maintenance staff can handle them effectively.

2.4. Phase IV: PM Comparison Analysis

Step IV sets out the management processes for the application of the above results. This phase involves a comparison of the reliability and maintenance costs obtained after introducing various maintenance strategies. At this point, improved system reliability following the implementation of PM tasks is compared to earlier results. Following completion of these different maintenance tasks, a cost comparison analysis must be conducted in order to reduce maintenance costs.

2.5. Phase V: Implementation of RCM

Finalize the optimum PM activities and cost-effective maintenance plans for the chosen system after a number of tests and feedback.

3. Case Study

The steam boiler is one of the most important systems in the textile industry and plays a crucial role in the production and supply of steam. Since the demand for steam is continuous, PM plays an important role in the smooth running of textile industrial operations. Maintenance costs can rise as a result of excessive PM tasks, but this can be reduced by careful task planning and scheduling. As a result, the developed RCM model is used to optimize and make cost-effective maintenance and replacement decisions for the steam boiler system used in the Indian textile industry. The main objective of the proposed model is to minimize the failure of the steam boiler subsystems and components without affecting the working environment and maintenance costs. The proposed model uses information on the failure and repair of the existing system. The following is a step-by-step description of the RCM model as applied to a steam boiler.

3.1. System Study Preperation

3.1.1. System Selection

A variety of tasks are included in the system study preparation, such as system selection, defining system boundary conditions, system description and functional failure analysis. The steam boiler system is a complex and critical system with more subsystems and components. The steam boiler ensures that the textile industry has a continuous supply of steam. Many boiler failures can interrupt the production process and create a financial impact. Therefore, a boiler system is selected for the analysis.

3.1.2. Defining System Boundary Conditions

After the selection of system, the boundary conditions were studied by defining the different subsystems and components of the system. It is important to define precise system boundaries in order to identify the major components and subsystems that lead to major failures and maintenance costs. The boiler system is therefore divided into nine separate subsystems and nearly forty-five components for study.

3.1.3. System Description and Functional Analysis

At this stage, it is important to study all the functions of the components, their operations, and all other operating and environmental conditions. The functions of all the subsystems and components of the steam boiler system have been studied. Similarly, functional failure analysis of the boiler system is carried out by identifying the failure modes and their causes.

3.2. Selection of Maintenance Significant Items/Critical Components

During this stage of maintenance, critical components are identified by criticality analysis. Criticality analysis of the boiler system is carried out using reliability analysis and FMECA.

3.2.1. Failure and Repair Data Collection

Field failure and repair data for equipment importance analysis can be collected from maintenance history cards, life tests, and by using the expert opinion method. Since many industries do not maintain maintenance history cards, real failure and repair data were not readily available. To collect the necessary information, there was continuous interaction with maintenance personnel. Finally, the expert judgment approach was used to collect as much failure data as possible.

3.2.2. Define Reliability Model

After the collection of field failure data, trend testing and goodness of fit tests were carried out [28]. Using the best-fit failure distribution parameters, a reliability analysis of the boiler system at the subsystem and components level was carried out. Finally, the critical components and subsystems of the boiler system are identified from the reliability point of view and presented in [29,30].

3.2.3. FMECA Analysis

The component failures that can weaken the main purpose of the component functions are analyzed here. The ExJ-PSI model has been developed to analyze the failure modes, causes and criticality of the components by taking into account multiple criteria. The present study takes six criteria into account: severity of the failure (SV), probability of the occurrence (O), degree of detectability (D), degree of maintainability (M), degree of safety (S), and production or quality loss (L). Critical components are identified and ranked based on the estimated criticality values. The identified critical components of the boiler system are presented in Table 1.

Table 1.

Critical components of the boiler system with their criticality index.

3.3. Selection of Maintenance Actions

Using the RCM decision logic diagram, the appropriate PM tasks will be assigned to the selected maintenance significant items. After the maintenance strategies have been established, we must use various mathematical models to determine the optimum maintenance intervals.

3.3.1. Apply RCM Decision Logic

Once critical components are identified, the next step is to apply certain maintenance tasks in order to reduce the failure rate and improve the systems’ reliability and performance. The RCM decision diagram or Logic Tree Analysis (LTA) may be used to select maintenance tasks. The LTA procedure is used to identify the most suitable, cost-effective PM tasks for a component. These suggested tasks are usually a function of component importance, design, use, and service setting. Without common guidance provided to different analysts, the use of LTA may result in different PM recommendations for similar components with the same criticality, environmental and component usage characteristics. Variations in the RCM analyst’s experience will also influence the amount of time taken to examine suitable PM tasks for a specific component type. The RCM decision diagram developed here takes into account three major categories of consequences, i.e., “Environmental Health and safety”, “Mission of the plant” and “Economic losses”. It also helps to identify the most applicable and effective PM tasks and associated task frequencies when taking multiple component characteristics into account.

3.3.2. Define Maintenance Strategies

The second phase of this analysis involves the selection of particular maintenance tasks based on the consequences of failure. The binary type of decision diagram (Yes/No Answers) can be used to select various maintenance tasks such as corrective maintenance, predictive maintenance, condition-based maintenance, preventive maintenance, replacement, and run-to-failure. The maintenance strategy selected must be efficient, reliable, and most cost-effective. The overall effectiveness of the selected maintenance task should be assessed on the basis of specific criteria’s such as reduction of operating irregularities, useful life, reduction of repair costs, usage of facilities, spare parts and tools, downtime maintenance, and the time required for repairs. The proposed model is used to select the appropriate maintenance tasks for the critical components and their failure modes of the steam boiler system and the results are presented in Table 2.

Table 2.

Maintenance task selection.

The system’s availability can be enhanced by making certain design improvements, reducing mean time to repair, and improving mean time to failure by proper maintenance task implementation. These steps are recommended based on design calculations, selection of components, maintenance policy, and discussion with experts. According to the failure analysis of the steam boiler system, the majority of boiler failures are caused by component failures, which are outsourced. Therefore, due to the early aging of these components, the reliability of the steam boiler system is difficult to ensure. Thus, the preferred components inventory should be re-formulated when designing the reliability improvement and standardized components with reliability guarantees should be chosen. All of this increases the time-to-failure and enhances the reliability of the steam boiler system.

In addition to these maintenance activities, some components with the higher mean time to failure values are recommended. Similarly, the maintenance time needed to repair these components, as well as the time required for fitting, are decreased. This significantly reduces downtime and improves system reliability. Table 3 shows the recommended components as well as their MTTF.

Table 3.

The recommended new components with their improved MTTF.

3.3.3. Determine Maintenance Intervals

In most situations, the methodology used to determine maintenance intervals is based primarily on the experience of the maintenance analyst [31]. Maintenance analysts are free to assign their own intervals for each maintenance tasks. Without quantitative modeling help, determining the maintenance interval is subjective and experience-based. This can result in a higher maintenance frequency, which will have an impact on system availability, performance, and economy. To improve the decision on interval selection, a mathematical model must be developed, and only a few researchers have used these models [32,33]. There is also a need for optimization-based decision support to enhance the ability to take correct and effective decisions on maintenance interval assignment, taking into account both reliability and cost parameters.

Maintenance intervals for each component of the boiler system were determined in consultation with the maintenance and operation staff. Real data on failure frequency and repair is obtained from different industries and optimum maintenance intervals are assigned. The periodic maintenance intervals are recommended to ensure a reliability level of approximately 75% [29] for each component of the boiler system. In particular, the maintenance team considers a 25% probability that the failure will occur before PM. If we consider higher reliability targets, maintenance intervals would be shorter and maintenance costs would be higher. Similarly, if we consider lower reliability targets, the preventive maintenance intervals would be higher and ultimately the failure frequencies and maintenance costs would be greater. Therefore, the reliability level of 75% is considered the optimum level. To estimate the time interval to perform periodic maintenance, a reliability equation of Weibull distribution is used by Mendes [34]. The estimated time interval to perform periodic maintenance is calculated from the reliability equation for a Weibull distribution as shown in Equation (1).

For reliability R(t) = 0.75 we can calculate,

where, ‘t’ is the maintenance time interval, θ is the Weibull scale parameter and β is the Weibull shape parameter. Periodic maintenance intervals of the boiler components were calculated using Equation (1) and the results of the same are presented in Table 4. It should be noted that PM should be carried out to inspect parts’ operating condition, ensure proper lubrication, cleaning and realignment of the parts and replacement of the parts whenever necessary.

Table 4.

Optimum maintenance intervals and recommended maintenance schedule.

3.4. PM Comparison Analysis

In this step along with these recommended maintenance tasks, some improvement changes in the design stage are suggested. Following these proposed changes and the implementation of these optimal maintenance tasks, a comparison of the reliability, availability, and maintenance cost results has been carried out before and after the application of these maintenance strategies.

System Reliability after Application of These Maintenance Strategies

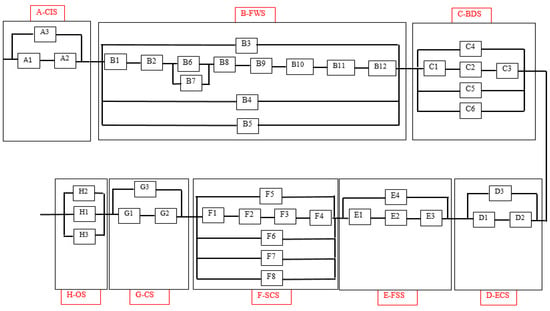

An effective implementation of the above suggested measures will enhance the component reliability, maintainability and LCC and, finally, system reliability. The reliability results of all the components evaluated by considering exponential distribution are presented in Table 5. The reliability of the entire steam boiler system is evaluated by using the reliability block diagram shown in Figure 3. The different codes used in this reliability block diagram are presented in Appendix A. The Equations (2) and (3) are the reliability models of the steam boiler system.

where RA, RB, RC, …RH, are the reliabilities of the boiler subsystems.

Table 5.

The earlier and improved reliability and maintenance cost results of boiler components.

Figure 3.

Reliability block diagram of the boiler system.

The earlier reliability of the steam boiler system after three years is calculated as follows:

Similarly, the improved reliability of the steam boiler system after three years is calculated as follows:

Therefore, the change in system reliability = improved system reliability − earlier system reliability

(ΔR)3 year = 0.3364 − 0.2625 = 0.0739 (28.15% increase)

4. Results and Discussion

The implementation of the suggested maintenance strategies and recommended new components will enhance the reliabilities of the individual components, which ultimately improves the system reliability. The time required for scheduled maintenance of the components is also calculated by considering the mean delay time for maintenance (MDT) and mean delay for supply resources (SDT). The preventive maintenance time is estimated by using the following model.

Tpm = MTTR − MDT − SDT

Therefore, the time required for scheduled maintenance is less than the time required for corrective or unscheduled maintenance. Using the improved MTTF and improved MTTR for preventive maintenance, the availability of the components is therefore estimated as follows.

Finally, the results of the earlier availability values and the improved availability values of all the components of the boiler system are presented in Table 5.

Similarly, the purpose of this study is to investigate the optimal maintenance strategies, their frequencies, and intervals with minimal maintenance cost. The average cost of maintenance due to corrective maintenance and scheduled maintenance has been assessed. Various cost measures are considered as failure cost, part cost, logistic cost, and cost of production loss in order to estimate the maintenance costs. Additionally, in order to quantify the failure cost of the component per year, the failure rate of the components, mean time to repair, labor charges, and size of the crew are taken into account. The maintenance cost model used here is shown in Equation (4).

where,

Cost of scheduled or unscheduled maintenance per year = failure cost per year + part cost per year + logistic cost per year + cost of production loss per year.

: The total maintenance cost per year.

: is number of failures per year.

: Mean time to repair for component i, in hours.

: The labor charges in Rs/hr, for component i.

: The number of labors required for maintenance.

: The part cost per year for component i, in Rs.

: Logistic cost per year for component i in Rs.

: The cost of production loss due to sudden breakdown for component i, in Rs.

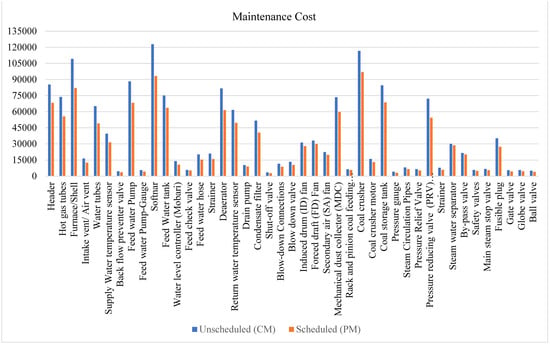

The maintenance cost with scheduled maintenance and unscheduled maintenance are estimated and summarized in Table 5 for all the selected components of the boiler system and are also shown in Figure 4.

Figure 4.

Cost comparison between scheduled and unscheduled maintenance of the boiler components.

The corrective maintenance cost of the header in the boiler system can be estimated as follows:

The mean time to failure of the header is estimated using best-fit distribution and is as follows:

The expected number of failures per year for RP are estimated as follows:

where, t is the total operating time of the component, and it is estimated by assuming 300 working days in a year. While estimating the operating time again, mean time to repair is considered.

Operating time (t) = 7200 − 34.005 = 7165.99 Hrs.

Therefore, the expected number of failures per year of the header is as follows:

The labor charges for corrective maintenance are considered as Rs. 500 per day. The part cost per year of a component is a cost of that component per year and it can be estimated as:

Therefore, the part cost of the header is

The spare logistic cost of the component is assumed to be 15% of the part cost per year. The spare logistic cost of the header is, therefore,

The cost of the production loss of the component is estimated by considering the production loss of the plant as Rs. 25,000 per hour. Therefore, the cost of production loss for the component is estimated by multiplying the number of failures per year, the mean time to repair, and the production loss of the plant per hour.

The total annual maintenance cost for the component is estimated by using Equation (4) and it is as follows:

Annual maintenance cost of the component = (the number of failures per year × mean time to repair × labor charges × no of labors) + part cost per year + logistic cost per year + cost of production loss due to that component.

Therefore, the total annual corrective maintenance cost of the header is estimated as:

Furthermore, the total annual corrective maintenance cost of the boiler system can be estimated as the sum of the corrective maintenance cost of all the components of the boiler system and is given by

A similar calculation is carried out for all selected components of the boiler system, and the results of the corrective maintenance cost estimation are shown in Table 5.

The estimated scheduled and unscheduled maintenance costs are presented in Table 5, also it is represented graphically in Figure 4. The graphical representation aids in identifying and emphasizing the most crucial components in terms of cost, as well as focusing on components whose maintenance costs may be readily lowered.

5. Conclusions

Reliability centered maintenance (RCM) is a risk and reliability management technique that can be used to evaluate and optimize PM requirements in their working environment. The RCM approach is divided into three stages: Identification of critical components and subsystems, assessment and assignment of proper maintenance tasks, and effective implementation of the PM tasks. This paper demonstrates the successful application of the developed RCM framework on a steam boiler system. The proposed RCM model focuses on the overall maintenance of the boilers, not just cleaning schedules, by taking into account availability and reliability.

In addition to determining the proper maintenance intervals, the TTF and TTR data analysis enabled the identification of critical components from a reliability perspective and provided the information required to select the most effective action to improve their performance. We have identified the components that need additional attention at the level of system reliability. Parts with a lower MTTF need to strengthen maintenance policy, while parts with a higher MTTR need to improve training and resources for the maintenance team.

To select appropriate maintenance tasks, the developed reliability-centered maintenance model and logic decision diagrams are used. For various failure modes, various maintenance tasks such as time-directed (TD), condition-directed (CD), failure findings (FF), and run-to-fail (RTF) are proposed. After deciding the appropriate maintenance tasks, a quantitative approach to determining the maintenance interval is developed based on the system reliability and time to failure model. Assuming a failure rate of 25 percent prior to the implementation of PM, a value of 0.75 is considered to be the minimum level of reliability for calculating maintenance intervals. Along with these maintenance recommendations, some design changes are also recommended. We can increase the reliability levels of the components and system and the availability of the system by making these design improvements and conducting preventive maintenance at these intervals. From this analysis, it is observed that the reliability of the steam boiler system has improved by 28.15%.

The implementation of the proposed RCM approach demonstrates its contribution towards reducing maintenance costs and improving system availability. Up to 20.32%of the maintenance cost can be saved annually by applying these scheduled maintenance programs. Additionally, it can achieve an increase in system availability of 0.16%, i.e., from 0.993282 to 0.994957.

The proposed RCM model is able to develop a methodology to determine optimum maintenance time and maintenance costs, which can be applied to other elements of the plant. The proposed model also allows to overcome limits of the classical model, which provides quantitative analysis and precise determination of maintenance costs through crew size, logistic cost, and production loss consideration.

Author Contributions

The research topic was proposed by S.S.P.; S.S.P. and A.K.B. conducted the research and drafted the methodology, also structured and wrote the final draft of the paper; R.K. took part in the validation and analysis of results; M.H.A. validated the idea and reviewed the final paper; A.K.B., M.S. and S.P. contributed to the supervision of this work. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data has been included in the paper.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| RCM | Reliability Centered Maintenance |

| PM | Preventive Maintenance |

| BM | Breakdown maintenance |

| CBM | Condition-based maintenance |

| CM | Corrective Maintenance |

| LCC | Life Cycle Cost |

| FMECA | Failure Mode Effect and Criticality Analysis |

| LTA | Logic Tree Analysis |

| MTTF | Mean Time to Failure |

| MTTR | Mean Time to Repair |

| MDT | Maintenance delay time |

| SDT | Supply delay time |

Appendix A

Table A1.

Boiler components and their codes used to define RBD of boiler system.

Table A1.

Boiler components and their codes used to define RBD of boiler system.

| Sr. No | Component | Code |

|---|---|---|

| 1 | Furnace/Combustion Chamber | A1 |

| 2 | Burner | A2 |

| 3 | Temperature Regulator | A3 |

| 4 | Water tubes | B1 |

| 5 | Feed water Pump | B2 |

| 6 | Back flow preventer valve | B3 |

| 7 | Feed water Pump-Gauge | B4 |

| 8 | Supply Water temperature sensor | B5 |

| 9 | Softener | B6 |

| 10 | Feed Water tank | B7 |

| 11 | Water level controller (Mobari) | B8 |

| 12 | Feed check valve | B9 |

| 13 | Feed water hose | B10 |

| 14 | Strainer | B11 |

| 15 | Deaerator | B12 |

| 16 | Drain pump | C1 |

| 17 | Condensate filter | C2 |

| 18 | Blow-down Connections | C3 |

| 19 | Return water temperature sensor | C4 |

| 20 | Shut-off valve | C5 |

| 21 | Blow down valve | C6 |

| 22 | Induced drum (ID) fan | D1 |

| 23 | Forced draft (FD) Fan | D2 |

| 24 | Mechanical dust collector (MDC) | D3 |

| 25 | Rack and pinion coal feeding mechanism | E1 |

| 26 | Coal crusher | E2 |

| 27 | Coal crusher motor | E3 |

| 28 | Coal storage tank | E4 |

| 29 | Header | F1 |

| 30 | Steam Circulation Pipes | F2 |

| 31 | Pressure Relief Valve (PRV) station | F3 |

| 32 | Pressure reducing valve | F4 |

| 33 | Pressure gauge | F5 |

| 34 | Steam water separator | F6 |

| 35 | By-pass valve | F7 |

| 36 | Intake vent/Air vent | F8 |

| 37 | Safety valves | G1 |

| 38 | Main steam stop valve | G2 |

| 39 | Fusible plug | G3 |

| 40 | Gate valve | H1 |

| 41 | Globe valve | H2 |

| 42 | Ball valve | H3 |

References

- Nowlan, F.S.; Heap, H.F. Reliability-Centred Maintenance. In National Technical Information Service; U.S Department of Commerce: Springfield, VA, USA, 1978. [Google Scholar]

- Pujadas, W.; Chen, F.F. A reliability centered maintenance strategy for a discrete part manufacturing facility. Comput. Ind. Eng. 1996, 31, 241–244. [Google Scholar] [CrossRef]

- Nour, G.A.; Beaudoin, H.; Ouellet, P.; Rochette, R.; Lambert, S. A reliability based maintenance policy: A case study. Comput. Ind. Eng. 1998, 35, 591–594. [Google Scholar] [CrossRef]

- Rausand, M. Reliability centered maintenance. Reliab. Eng. Syst. Saf. 1998, 60, 121–132. [Google Scholar] [CrossRef]

- Goodfellow, J.W. Applying reliability centered maintenance to overhead electric utility distribution systems. In Proceedings of the IEEE Power Engineering Society Summer Meeting, Seattle, WA, USA, 16–20 July 2000. [Google Scholar]

- Reder, W.; Flaten, D. Reliability centered maintenance for distribution underground systems. In Proceedings of the IEEE Power Engineering Society Summer Meeting, Seattle, WA, USA, 16–20 July 2000. [Google Scholar]

- Fonseca, D.J.; Knapp, G.M. An expert system for reliability centered maintenance in the chemical industry. Expert Syst. Appl. 2000, 19, 45–57. [Google Scholar] [CrossRef]

- Yssaad, B.; Khiat, M.; Chaker, A. Reliability centered maintenance optimization for power distribution systems. Electr. Power Energy Syst. 2014, 55, 108–115. [Google Scholar] [CrossRef]

- Heo, J.H.; Kim, M.K.; Lyu, J.K. Implementation of Reliability-Centered Maintenance for transmission components using Particle Swarm Optimization. Electr. Power Energy Syst. 2014, 55, 238–245. [Google Scholar] [CrossRef]

- For, S.; Mudavanhu, T. Application of RCM for a chipping and sawing mill. J. Eng. Des. Technol. 2011, 9, 204–226. [Google Scholar] [CrossRef]

- Charles, A.-S.; Floru, I.-R.; Azzaro-Pantel, C.; Pibouleau, L.; Domenech, S. Optimization of preventive maintenance strategies in a multipurpose batch plant: Application to semiconductor manufacturing. Comput. Chem. Eng. 2003, 27, 449–467. [Google Scholar] [CrossRef]

- Rao, P.N.; Srikrishna, S.; Yadava, G.S. Reliability- centered maintenance applied to power plant auxiliaries. J. Qual. Maint. Eng. 1996, 2, 3–14. [Google Scholar]

- Santos, W.B.; Colosimo, E.A.; Motta, S.B. Optimal maintenance time for repairable systems in more than one type of failure. Gest. Prod. 2007, 14, 193–202. [Google Scholar] [CrossRef]

- Das, K.; Lashkari, R.S.; Sengupta, S. Machine reliability and preventive maintenance planning for cellular manufacturing systems. Eur. J. Oper. Res. 2007, 183, 162–182. [Google Scholar] [CrossRef]

- Smith, M. Reliability Centered Maintenance; McGraw-Hill Publication: New York, NY, USA, 1993. [Google Scholar]

- Yun, C.; Chung, T.S.; Yu, C.W.; Chung, C.Y.; Ming, Z.; Xin, S. Application of reliability- centered stochastic approach and FMECA to conditional maintenance of electric power plants in China. In Proceedings of the IEEE International Conference on Electric Utility Deregulation, Restructuring and Power Technologies, Hong Kong, China, 5–8 April 2004. [Google Scholar]

- Macchi, M.; Garetti, M.; Centrone, D.; Fumagalli, L.; Pavirani, G.P. Maintenance management of railway infra structures based on reliability analysis. Reliab. Eng. Syst. Saf. 2012, 104, 71–83. [Google Scholar] [CrossRef]

- Jagtap, H.P.; Bewoor, A.K.; Kumar, R.; Ahmadi, M.H. Performance analysis and availability optimization to improve maintenance schedule for the turbo-generator subsystem of a thermal power plant using particle swarm optimization. Reliab. Eng. Syst. Saf. 2020, 204, 107130. [Google Scholar] [CrossRef]

- Jagtap, H.; Bewoor, A.K.; Kumar, R.; Ahmadi, M.H.; Lorenzini, G. Markov-based performance evaluation and availability optimization of the boiler–furnace system in coal-fired thermal power plant using PSO. Energy Rep. 2020, 6, 1124–1134. [Google Scholar] [CrossRef]

- Bloom, N.B. Reliability Centered Maintenance (RCM); McGraw-Hill Inc.: New York, NY, USA, 2006. [Google Scholar]

- Selvik, J.T.; Aven, T. A framework for reliability and risk centered maintenance. Reliab. Eng. Syst. Saf. 2011, 96, 324–331. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Modak, J.P. Application of RCM to a medium scale industry. Reliab. Eng. Syst. Saf. 2002, 77, 31–43. [Google Scholar] [CrossRef]

- Rausad, M.; Vatn, J. Reliability Centered Maintenance. In Risk and Reliability in Marine Technology; Industrial Press Inc.: New York, NY, USA, 1998; pp. 421–440. [Google Scholar]

- Percy, D. Preventive maintenance models for complex systems. In Complex System Maintenance Handbook; Springer: London, UK, 2008; pp. 179–208. [Google Scholar]

- Dekker, R. Applications of maintenance optimization models: A review and analysis. Reliab. Eng. Syst. Saf. 1996, 51, 229–240. [Google Scholar] [CrossRef]

- Wang, H.; Pham, H. Reliability and Optimal Maintenance; Springer: London, UK, 2006. [Google Scholar]

- Cui, L. Maintenance Models and Optimization. In Handbook of Performability Engineering; Springer: London, UK, 2008; pp. 789–806. [Google Scholar]

- Patil, S.S.; Bewoor, A.K.; Patil, R.B.; Mellal, M.A. Trends Based Reliability Availability and Maintainability (RAM) Assessment of a Steam Boiler. In Predictive Analytics- Modeling and Optimization; CRC Press Taylor & Francis group: Boca Raton, FL, USA, 2020; pp. 261–272. [Google Scholar]

- Patil, S.S.; Bewoor, A.K. Reliability analysis of a steam boiler system by expert judgment method and best-fit failure model method: A new approach. Int. J. Qual. Reliab. Manag. 2020, 38, 389–409. [Google Scholar] [CrossRef]

- Patil, S.S.; Bewoor, A.K.; Patil, R.B. Availability Analysis of a Steam Boiler in Textile Process Industries Using Failure and Repair Data: A Case Study. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part B Mech. Eng. 2020, 7, 021002. [Google Scholar] [CrossRef]

- Liu, M.; Zuo, H.; Ni, X.; Cai, J. Research on a Case-Based Decision Support System for Aircraft Maintenance Review Board Report; ICIC, Springer: Berlin, Germany, 2006. [Google Scholar]

- Umamaheswari, E.; Ganesan, S.; Abirami, M.; Subramanian, S. Reliability/risk centered cost effective preventive maintenance planning of generating units. Int. J. Qual. Reliab. Manag. 2018, 35, 2052–2079. [Google Scholar]

- Li, F.; Brown, R.E. Cost-Effective Approach of Prioritizing Distribution Maintenance Based on System Reliability. IEEE Trans. Power Deliv. 2004, 19, 439–441. [Google Scholar] [CrossRef]

- Mendes, A.; Ribeiro, J.D. Establishment of a maintenance plan based on quantitative analysis in the context of RCM in a JIT production scenario. Reliab. Eng. Syst. Saf. 2014, 127, 21–29. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).