An Emerging Solution for Medical Waste: Reuse of COVID-19 Protective Suit in Concrete

Abstract

:1. Introduction

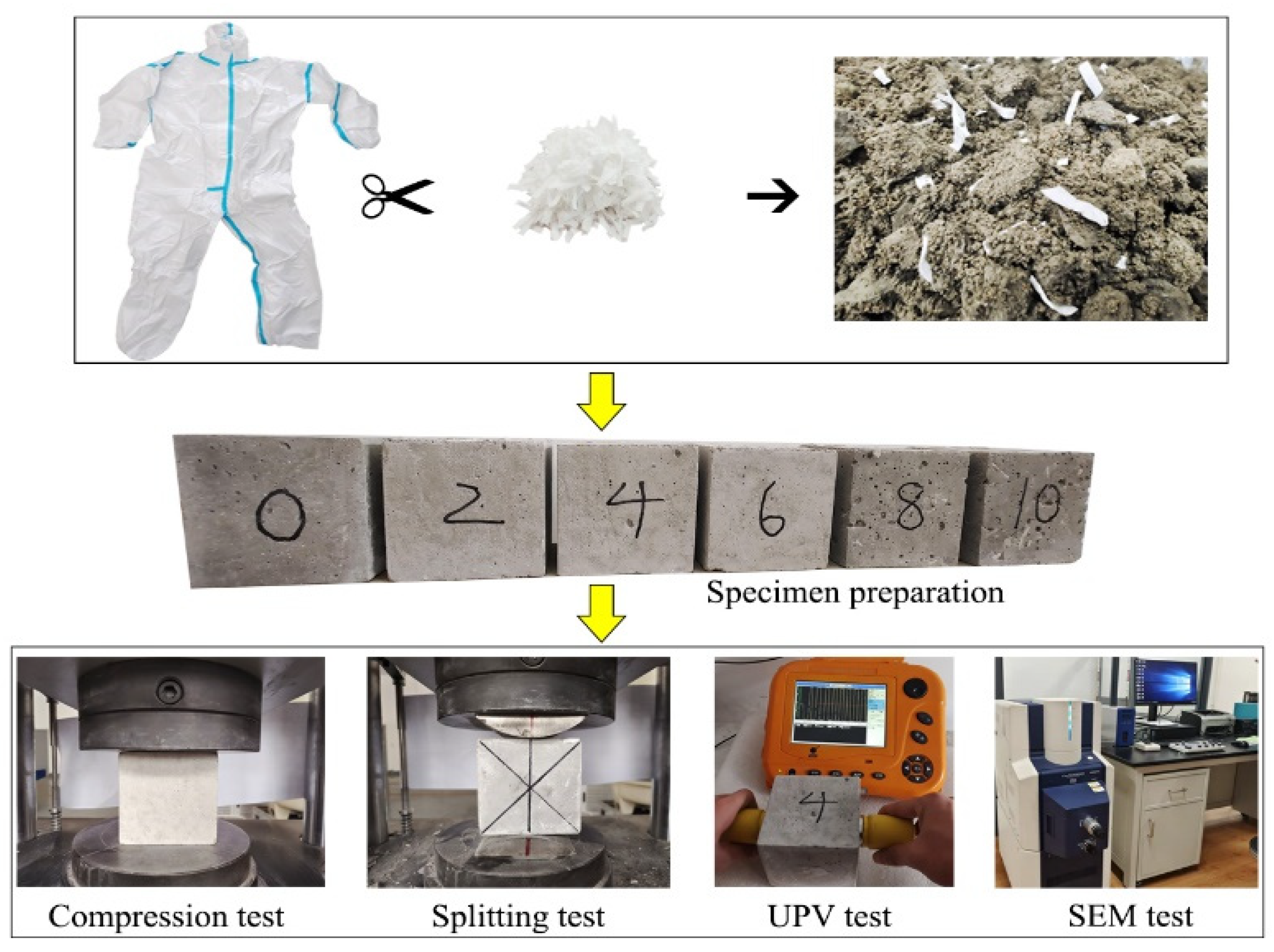

2. Materials and Methods

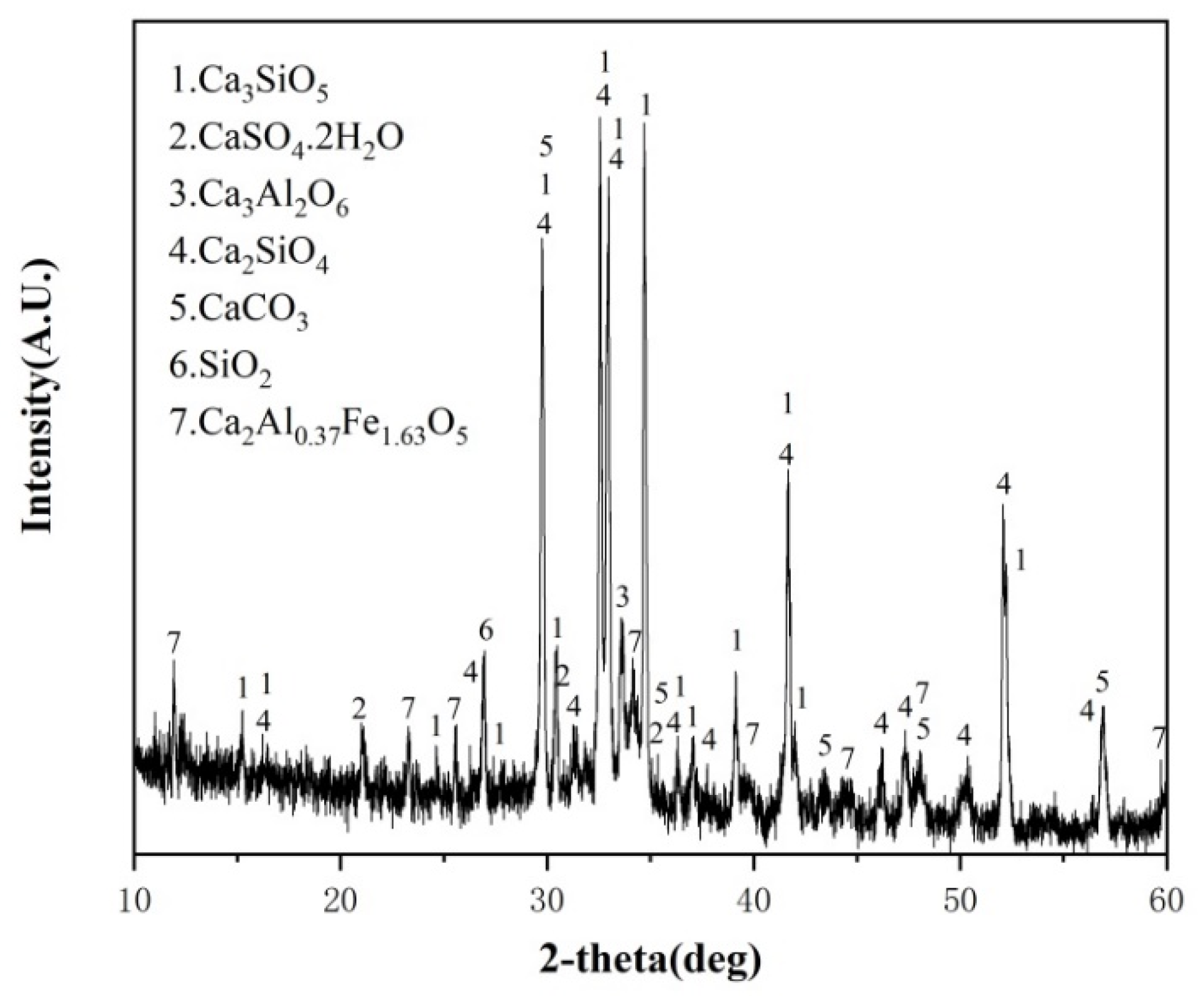

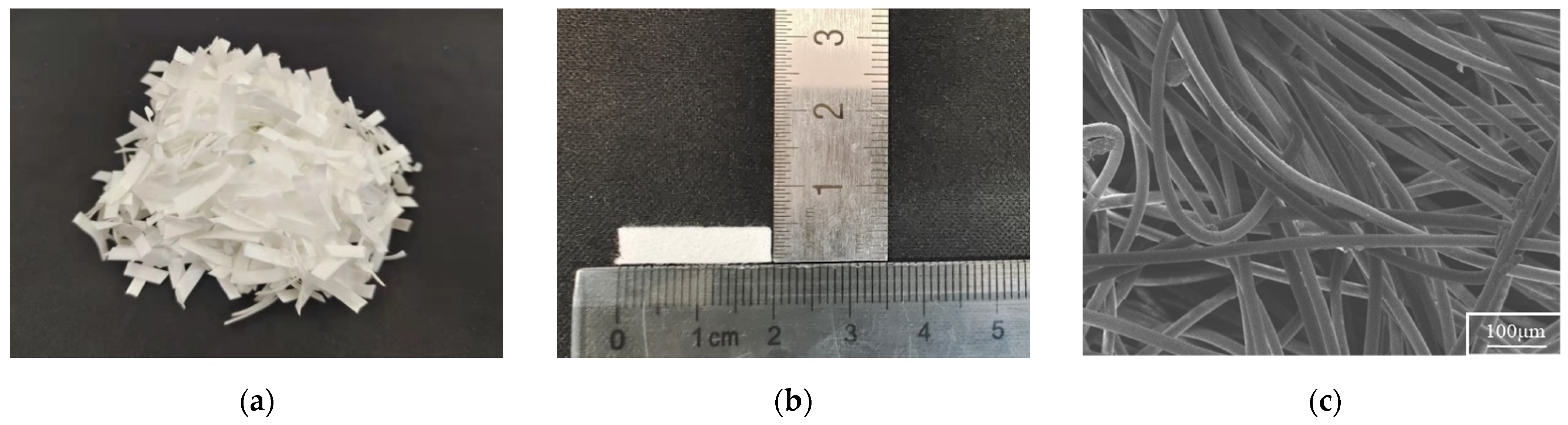

2.1. Materials

2.2. Mix Design, Casting Procedures, and Specimen-Making

2.3. Testing Methods

2.3.1. Strength Test

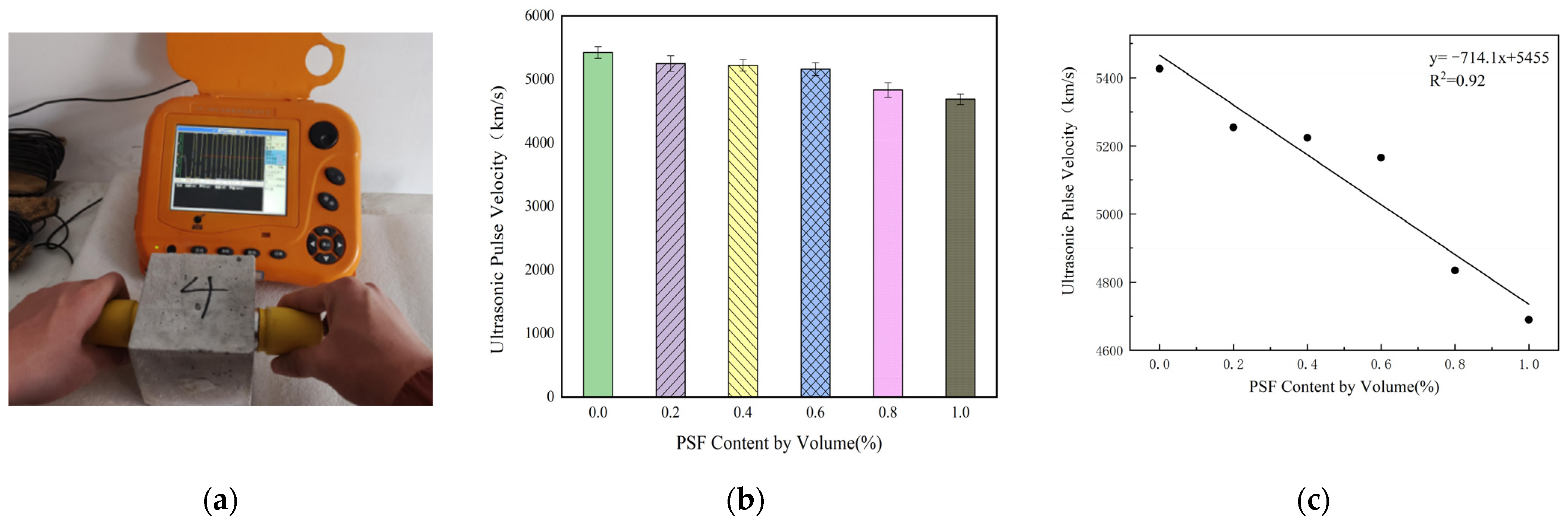

2.3.2. Ultrasonic Pulse Velocity (UPV)

2.3.3. Scanning Electron Microscope Test

3. Results and Discussion

3.1. Physical Parameters

3.2. Ultrasonic Pulse Velocity

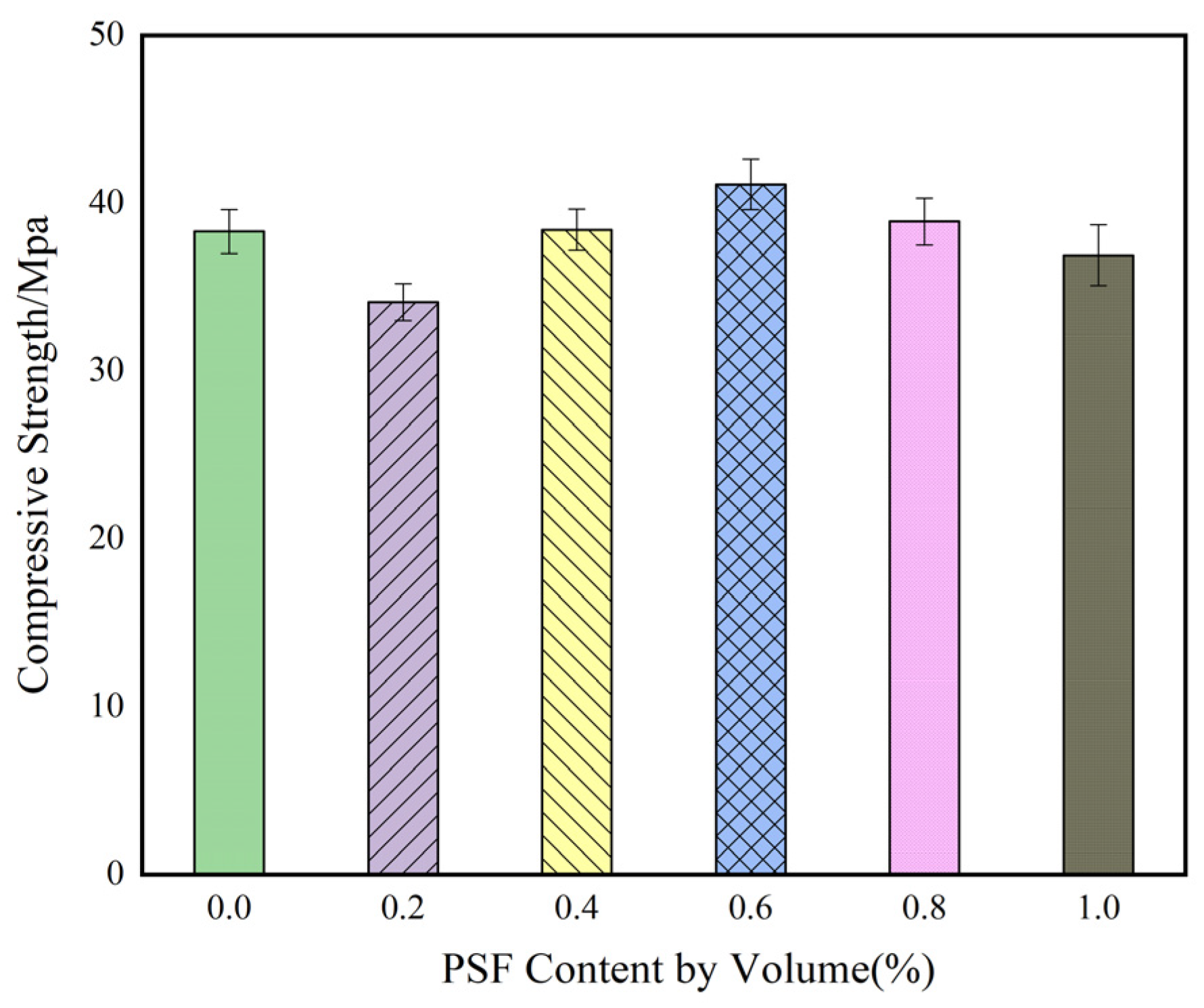

3.3. Compressive Strength

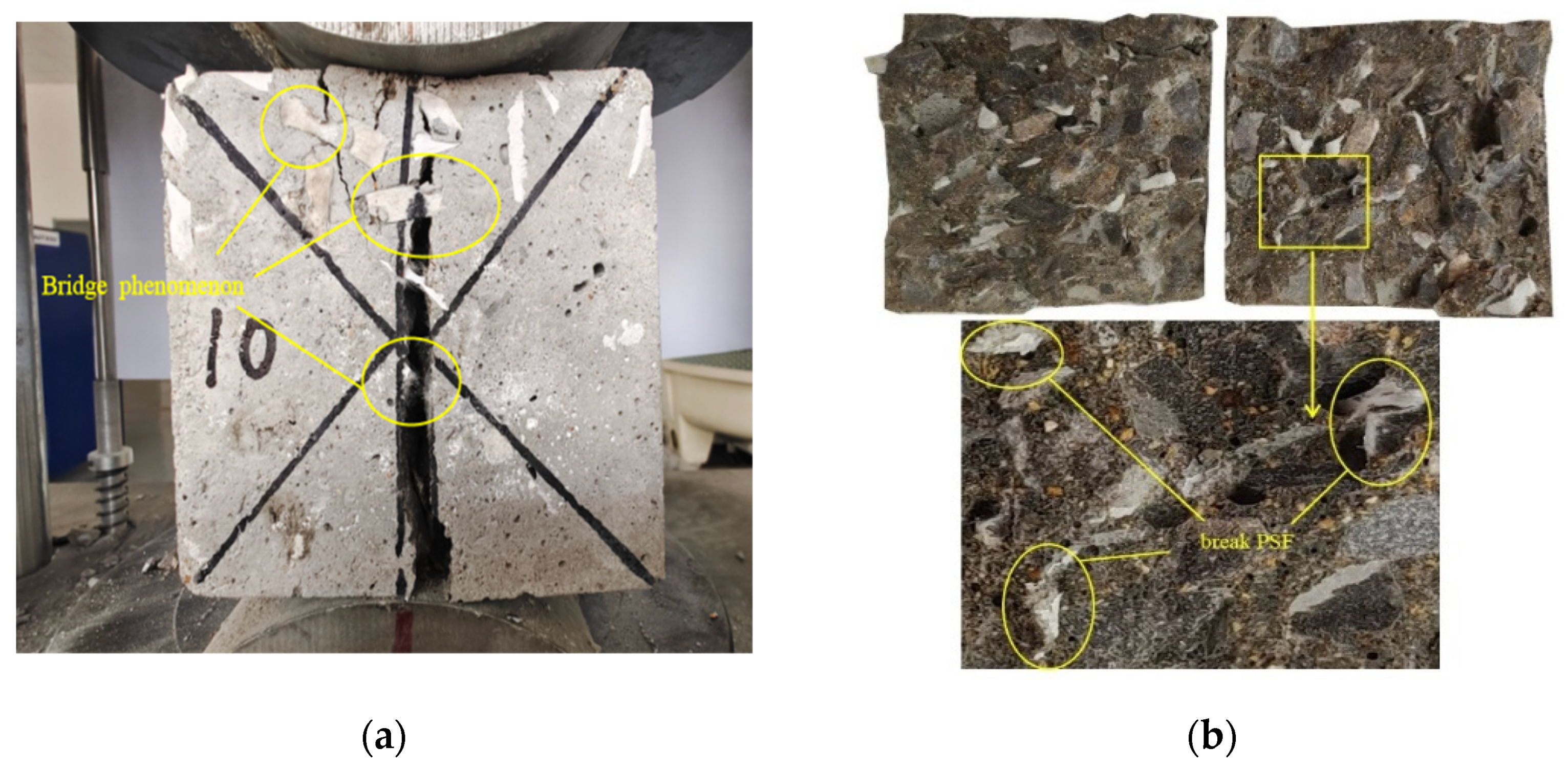

3.4. Splitting Tensile Strength

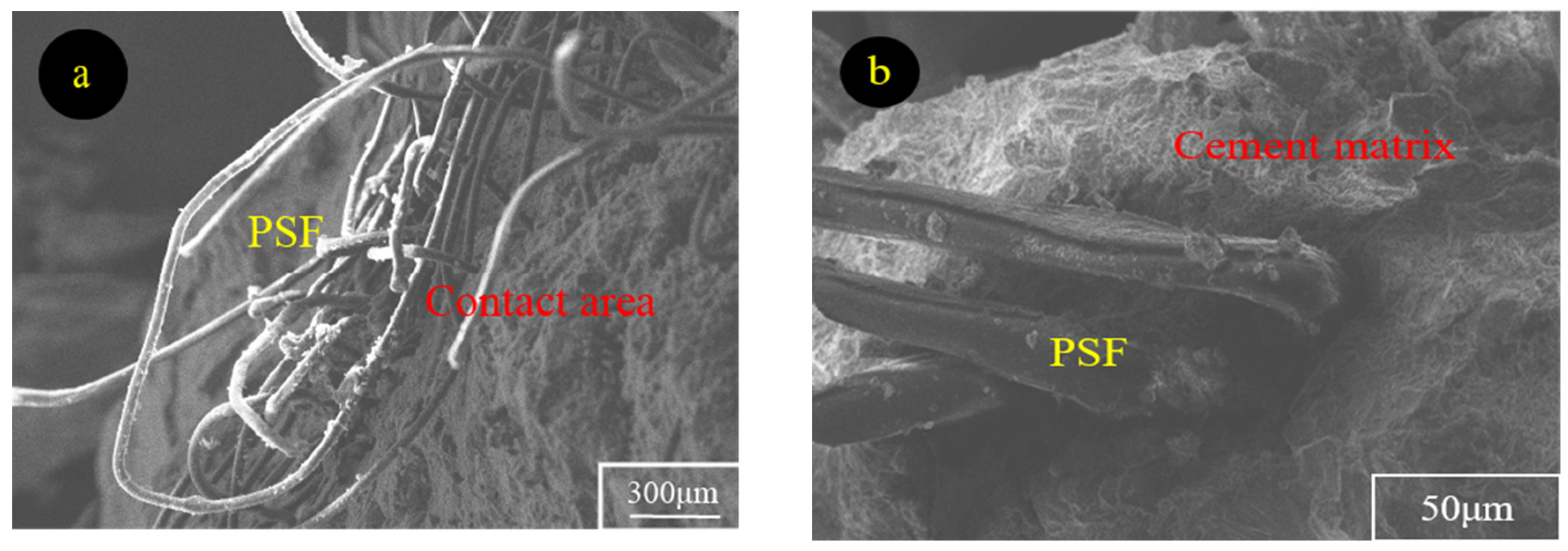

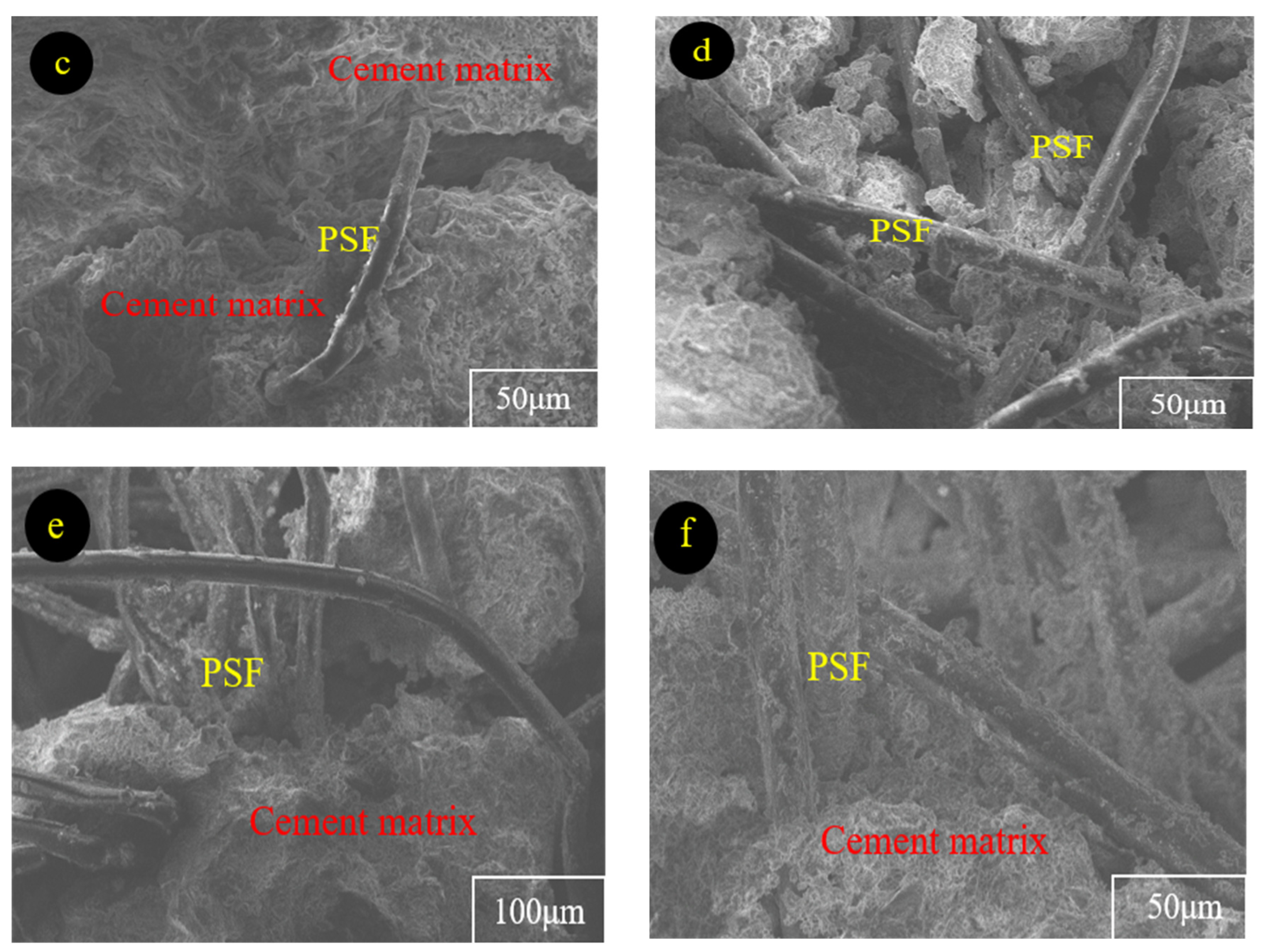

3.5. Microscopic Electron Microscope Analysis

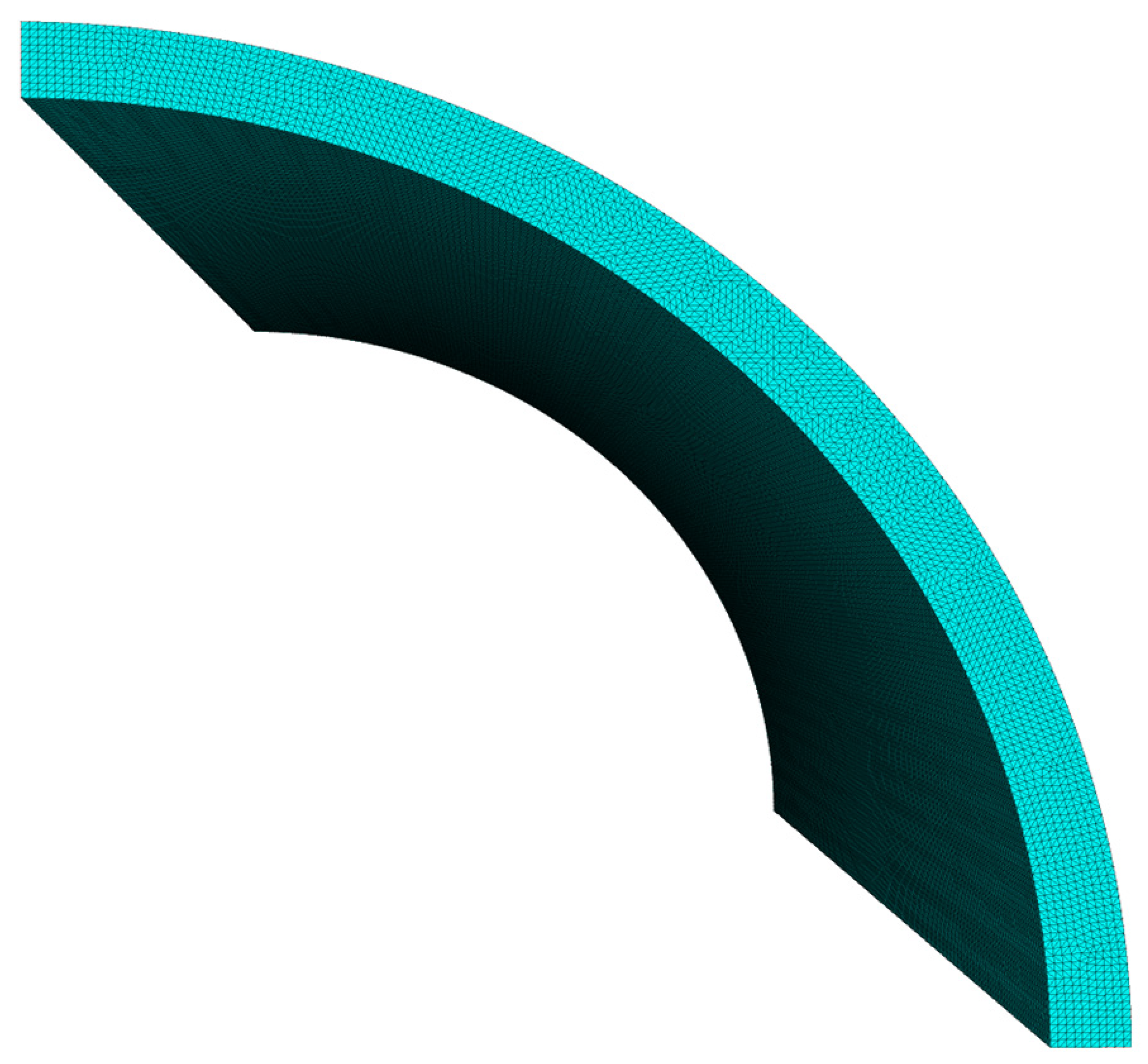

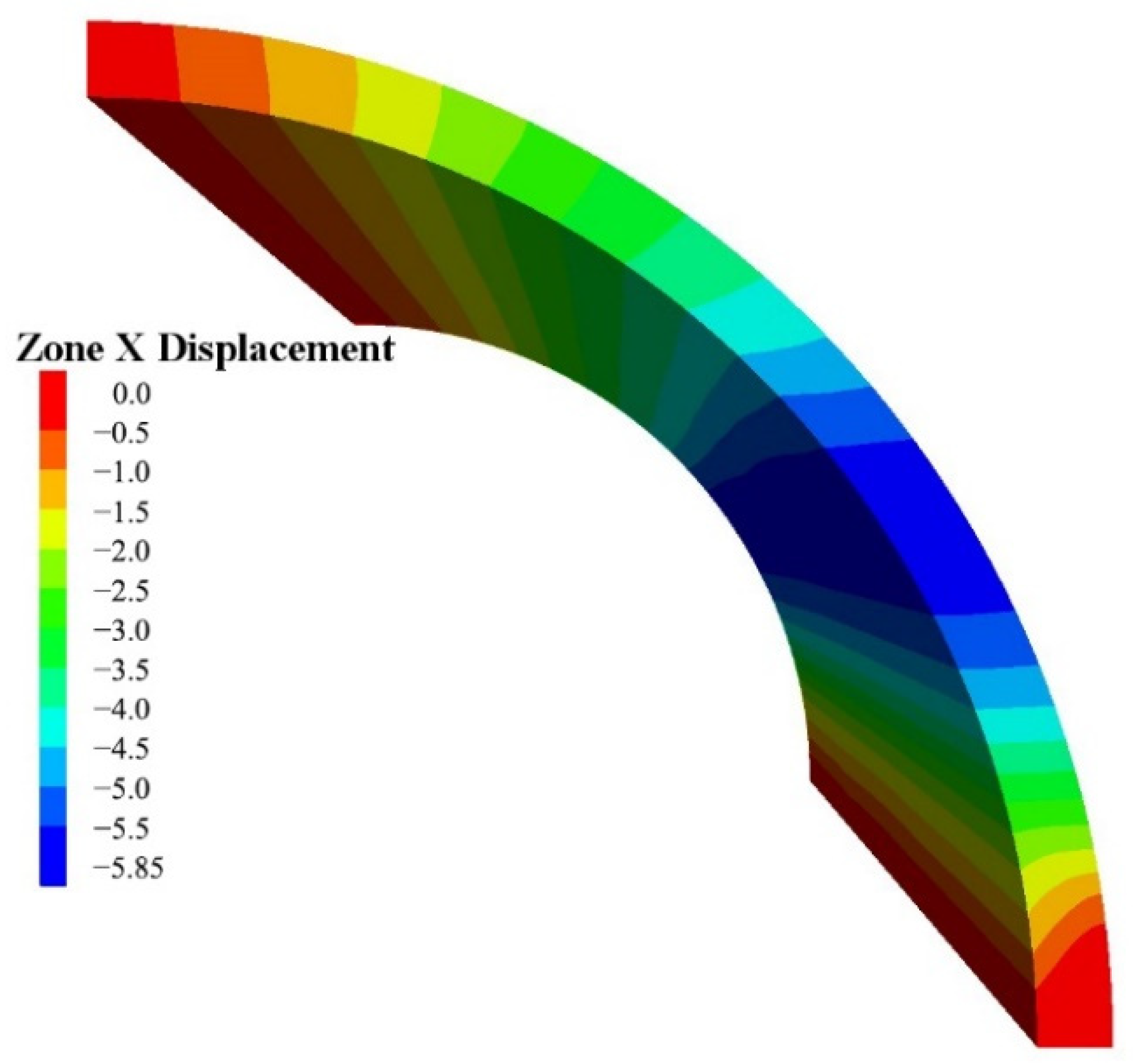

4. Finite Element Simulation

5. Treatment Methods and Cost Analysis of PS

6. Conclusions

- The inclusion of PSF improved the compressive and tensile strength of concrete, and the tensile strength increased by 43.6% compared with the control mix. The mechanical properties of concrete containing PSF have been significantly improved because of the influence of PSF in transferring stress, absorbing energy, and confining behavior on cracks.

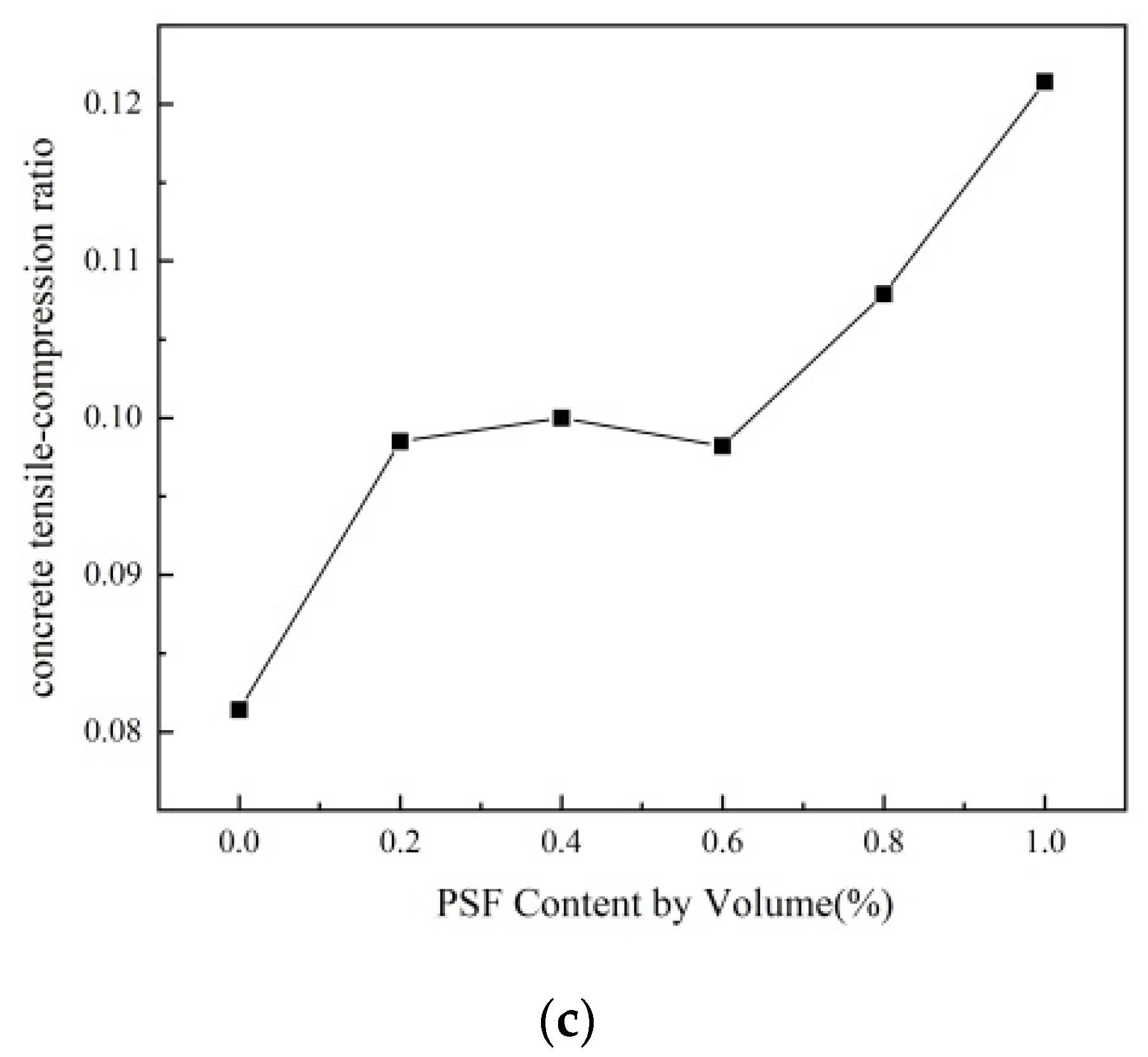

- With the gradual increase of the PSF content, the tensile–compression ratio of concrete showed an upward trend, which was 20.6–49.1% higher than the control group. It indicated that the toughness of this concrete has been improved obviously.

- According to the SEM images, PSF had good contact with the cement matrix and hindered the propagation of micro-cracks. The introduction of PSF leads to the enhancement of the overall microstructure of concrete.

- The finite element simulation results prove that PSF shotcrete has good use value in the construction of underground lining structures.

- Applying COVID-19 protective suits to the production of high-quality concrete has the potential to show great environmental and economic benefits. The findings of this paper may help in the management of COVID-19 medical waste.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- World Health Organization. WHO Coronavirus (COVID-19) Dashboard. Available online: https://covid19.who.int/ (accessed on 10 May 2022).

- Yang, L.; Yu, X.; Wu, X.; Wang, J.; Yan, X.; Jiang, S.; Chen, Z. Emergency response to the explosive growth of health care wastes during COVID-19 pandemic in Wuhan, China. Resour. Conserv. Recycl. 2021, 164, 105074. [Google Scholar] [CrossRef]

- Kahlert, S.; Bening, C.R. Plastics recycling after the global pandemic: Resurgence or regression? Resour. Conserv. Recycl. 2020, 160, 104948. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; You, F. Can decontamination and reuse of N95 respirators during COVID-19 pandemic provide energy, environmental, and economic benefits? Appl. Energy 2021, 304, 117848. [Google Scholar] [CrossRef] [PubMed]

- Amuah, E.E.Y.; Agyemang, E.P.; Dankwa, P.; Fei-Baffoe, B.; Kazapoe, R.W.; Douti, N.B. Are used face masks handled as infectious waste? Novel pollution driven by the COVID-19 pandemic. Resour. Conserv. Recycl. Adv. 2022, 13, 200062. [Google Scholar] [CrossRef]

- Prata, J.C.; Silva, A.L.P.; Walker, T.R.; Duarte, A.C.; Rocha-Santos, T. COVID-19 Pandemic Repercussions on the Use and Management of Plastics. Environ. Sci. Technol. 2020, 54, 7760–7765. [Google Scholar] [CrossRef]

- Chen, C.; Chen, J.; Fang, R.; Ye, F.; Yang, Z.; Wang, Z.; Shi, F.; Tan, W. What medical waste management system may cope with COVID-19 pandemic: Lessons from Wuhan. Resour. Conserv. Recycl. 2021, 170, 105600. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Cheng, Y.; Liu, T.; Huang, S.; Yin, L.; Pu, Y.; Liang, G. Impact of waste of COVID-19 protective equipment on the environment, animals and human health: A review. Environ. Chem. Lett. 2022, 2022, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, G.M.S.; El Aal, A.A. Assessment of the reuse of Covid-19 healthy personal protective materials in enhancing geotechnical properties of Najran’s soil for road construction: Numerical and experimental study. J. Clean. Prod. 2021, 320, 128772. [Google Scholar] [CrossRef]

- Uddin, M.A.; Afroj, S.; Hasan, T.; Carr, C.; Novoselov, K.S.; Karim, N. Environmental Impacts of Personal Protective Clothing Used to Combat COVID-19. Adv. Sustain. Syst. 2022, 6, 2100176. [Google Scholar] [CrossRef]

- Fadare, O.O.; Okoffo, E.D. Covid-19 face masks: A potential source of microplastic fibers in the environment. Sci. Total Environ. 2020, 737, 140279. [Google Scholar] [CrossRef] [PubMed]

- Dimoudi, A.; Tompa, C. Energy and environmental indicators related to construction of office buildings. Resour. Conserv. Recycl. 2008, 53, 86–95. [Google Scholar] [CrossRef]

- Arena, A.P.; De Rosa, C. Life cycle assessment of energy and environmental implications of the implementation of conservation technologies in school buildings in Mendoza–Argentina. Build. Environ. 2003, 38, 359–368. [Google Scholar] [CrossRef]

- Liang, N.; You, X.; Yan, R.; Miao, Q.; Liu, X. Experimental Investigation on the Mechanical Properties of Polypropylene Hybrid Fiber-Reinforced Roller-Compacted Concrete Pavements. Int. J. Concr. Struct. Mater. 2022, 16, 3. [Google Scholar] [CrossRef]

- Behfarnia, K.; Behravan, A. Application of high performance polypropylene fibers in concrete lining of water tunnels. Mater. Des. 2014, 55, 274–279. [Google Scholar] [CrossRef]

- Zia, A.; Ali, M. Behavior of fiber reinforced concrete for controlling the rate of cracking in canal-lining. Constr. Build. Mater. 2017, 155, 726–739. [Google Scholar] [CrossRef]

- Hussain, I.; Ali, B.; Akhtar, T.; Jameel, M.S.; Raza, S.S. Comparison of mechanical properties of concrete and design thickness of pavement with different types of fiber-reinforcements (steel, glass, and polypropylene). Case Stud. Constr. Mater. 2020, 13, e00429. [Google Scholar] [CrossRef]

- Alani, A.M.; Beckett, D. Mechanical properties of a large scale synthetic fibre reinforced concrete ground slab. Constr. Build. Mater. 2013, 41, 335–344. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Effectiveness of hair and wave polypropylene fibers for concrete roads. Constr. Build. Mater. 2018, 166, 581–591. [Google Scholar] [CrossRef]

- Bhogayata, A.C.; Arora, N.K. Workability, strength, and durability of concrete containing recycled plastic fibers and styrene-butadiene rubber latex. Constr. Build. Mater. 2018, 180, 382–395. [Google Scholar] [CrossRef]

- Foti, D. Use of recycled waste pet bottles fibers for the reinforcement of concrete. Compos. Struct. 2013, 96, 396–404. [Google Scholar] [CrossRef]

- Fraternali, F.; Spadea, S.; Berardi, V.P. Effects of recycled PET fibres on the mechanical properties and seawater curing of Portland cement-based concretes. Constr. Build. Mater. 2014, 61, 293–302. [Google Scholar] [CrossRef]

- Won, J.P.; Jang, C.I.; Lee, S.W.; Lee, S.J.; Kim, H.Y. Long-term performance of recycled PET fibre-reinforced cement composites. Constr. Build. Mater. 2010, 24, 660–665. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Recycling woven plastic sack waste and PET bottle waste as fiber in recycled aggregate concrete: An experimental study. Waste Manag. 2018, 78, 79–93. [Google Scholar] [CrossRef] [PubMed]

- Kilmartin-Lynch, S.; Saberian, M.; Li, J.; Roychand, R.; Zhang, G. Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete. J. Clean. Prod. 2021, 296, 126460. [Google Scholar] [CrossRef] [PubMed]

- Solís-Carcaño, R.; Moreno, E.I. Evaluation of concrete made with crushed limestone aggregate based on ultrasonic pulse velocity. Constr. Build. Mater. 2008, 22, 1225–1231. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, X.; Chai, J.; Xu, Z.; Li, S. Experimental study of compressive behavior of polypropylene-fiber-reinforced and polypropylene-fiber-fabric-reinforced concrete. Constr. Build. Mater. 2019, 194, 216–225. [Google Scholar] [CrossRef]

- Cavdar, A.; Bingöl, S. Suggestion of new formulations for schmidt hammer and UPV test methods for concrete. Acta Phys. Pol. A 2014, 125, 402–404. [Google Scholar] [CrossRef]

- Carrillo, J.; Ramirez, J.; Lizarazo-Marriaga, J. Modulus of elasticity and Poisson’s ratio of fiber-reinforced concrete in Colombia from ultrasonic pulse velocities. J. Build. Eng. 2019, 23, 18–26. [Google Scholar] [CrossRef]

- Abdulridha, S.Q.; Nasr, M.S.; Al-Abbas, B.H.; Hasan, Z.A. Mechanical and structural properties of waste rope fibers-based concrete: An experimental study. Case Stud. Constr. Mater. 2022, 16, e00964. [Google Scholar] [CrossRef]

- Akhmetov, D.; Akhazhanov, S.; Jetpisbayeva, A.; Pukharenko, Y.; Root, Y.; Utepov, Y.; Akhmetov, A. Effect of low-modulus polypropylene fiber on physical and mechanical properties of self-compacting concrete. Case Stud. Constr. Mater. 2022, 16, e00814. [Google Scholar] [CrossRef]

- Orouji, M.; Zahrai, S.M.; Najaf, E. Effect of glass powder & polypropylene fibers on compressive and flexural strengths, toughness and ductility of concrete: An environmental approach. Structures 2021, 33, 4616–4628. [Google Scholar] [CrossRef]

- Dharan, D.S.; Lal, A. Study the Effect of Polypropylene Fiber with Steel Slag Aggregate in Concrete. Int. J. Sci. Res. 2016, 5, 1539–1543. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M. Characteristics of recycled polypropylene fibers as an addition to concrete fabrication based on portland cement. Materials 2020, 13, 1827. [Google Scholar] [CrossRef] [PubMed]

- Mohammadhosseini, H.; Tahir, M.M.; Sam, A.R.M. The feasibility of improving impact resistance and strength properties of sustainable concrete composites by adding waste metalized plastic fibres. Constr. Build. Mater. 2018, 169, 223–236. [Google Scholar] [CrossRef]

- Peled, A.; Mobasher, B.; Cohen, Z. Mechanical properties of hybrid fabrics in pultruded cement composites. Cem. Concr. Compos. 2009, 31, 647–657. [Google Scholar] [CrossRef]

- Jiang, P.W.; Fang, J.H.; Pang, J.Y.; Su, Q.; Xia, X. Experimental Study and Engineering Application of Polypropylene Fiber Shotcrete for Bored Tunnels in Water-Rich Strata. Arab. J. Sci. Eng. 2020, 45, 8655–8666. [Google Scholar] [CrossRef]

- Al-Omran, K.; Khan, E.; Ali, N.; Bilal, M. Estimation of COVID-19 generated medical waste in the Kingdom of Bahrain. Sci. Total Environ. 2021, 801, 149642. [Google Scholar] [CrossRef] [PubMed]

- Saadat, S.; Rawtani, D.; Hussain, C.M. Environmental perspective of COVID-19. Sci. Total Environ. 2020, 728, 138870. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Shao, L.M.; He, P.J. Tracing source and migration of Pb during waste incineration using stable Pb isotopes. J. Hazard. Mater. 2017, 327, 28–34. [Google Scholar] [CrossRef]

- Liao, L.; Xiao, W.; Zhao, M.; Yu, X.; Wang, H.; Wang, Q.; Chu, S.; Cui, Y. Can N95 Respirators Be Reused after Disinfection? How Many Times? ACS Nano 2020, 14, 6348–6356. [Google Scholar] [CrossRef]

- Li, D.F.; Cadnum, J.L.; Redmond, S.N.; Jones, L.D.; Pearlmutter, B.; Haq, M.F.; Donskey, C.J. Steam treatment for rapid decontamination of N95 respirators and medical face masks. Am. J. Infect. Control 2020, 48, 855–857. [Google Scholar] [CrossRef] [PubMed]

- Kampf, G.; Todt, D.; Pfaender, S.; Steinmann, E. Persistence of coronaviruses on inanimate surfaces and their inactivation with biocidal agents. J. Hosp. Infect. 2020, 104, 246–251. [Google Scholar] [CrossRef] [PubMed]

- Barcelo, D. An environmental and health perspective for COVID-19 outbreak: Meteorology and air quality influence, sewage epidemiology indicator, hospitals disinfection, drug therapies and recommendations. J. Environ. Chem. Eng. 2020, 8, 104006. [Google Scholar] [CrossRef]

- Hamzavi, I.H.; Lyons, A.B.; Kohli, I.; Narla, S.; Parks-Miller, A.; Gelfand, J.M.; Lim, H.W.; Ozog, D.M. Ultraviolet germicidal irradiation: Possible method for respirator disinfection to facilitate reuse during the COVID-19 pandemic. J. Am. Acad. Dermatol. 2020, 82, 1511–1512. [Google Scholar] [CrossRef]

| Composition Content (%) | Cement |

|---|---|

| SiO2 | 22.60 |

| Al2O3 | 5.03 |

| Fe2O3 | 4.38 |

| CaO | 63.11 |

| MgO | 1.46 |

| SO3 | 2.24 |

| Loss on Ignition | 1.18 |

| Fiber Properties | PSF |

|---|---|

| Breaking force (N) | 183 |

| Elongation at break (%) | 42 |

| Specific gravity | 0.93 |

| Water absorption | 7.6% |

| Aspect radio | 5 |

| Group Number | Cement (Kg) | Sand (Kg) | Limestone (Kg) | Water (Kg) | Water Reducer (Kg) | PSF (% by Volume) |

|---|---|---|---|---|---|---|

| PS0 | 445 | 641 | 1139 | 178 | 3.9 | 0 |

| PS2 | 445 | 641 | 1139 | 178 | 3.9 | 0.2 |

| PS4 | 445 | 641 | 1139 | 178 | 3.9 | 0.4 |

| PS6 | 445 | 641 | 1139 | 178 | 3.9 | 0.6 |

| PS8 | 445 | 641 | 1139 | 178 | 3.9 | 0.8 |

| PS10 | 445 | 641 | 1139 | 178 | 3.9 | 1.0 |

| Group Number | Water–Cement Ratio W/C | SAND Ratio b1 (%) | Slump (mm) | Density (Kg/m3) |

|---|---|---|---|---|

| PS0 | 0.4 | 36.01 | 34 | 2402 |

| PS2 | 0.4 | 36.01 | 30 | 2399 |

| PS4 | 0.4 | 36.01 | 28 | 2392 |

| PS6 | 0.4 | 36.01 | 24 | 2383 |

| PS8 | 0.4 | 36.01 | 22 | 2377 |

| PS10 | 0.4 | 36.01 | 17 | 2364 |

| Group Number | Compressive Strength/MPa | Splitting Tensile Strength/MPa |

|---|---|---|

| PS0 | 38.3 | 3.12 |

| PS2 | 34.1 | 3.36 |

| PS4 | 38.4 | 3.84 |

| PS6 | 41.1 | 4.04 |

| PS8 | 38.9 | 4.21 |

| PS10 | 36.9 | 4.48 |

| Properties | PSF Concrete | Ordinary Concrete |

|---|---|---|

| Modulus of Elasticity (GN/m2) | 28 | 30 |

| Poisson’s ratio | 0.2 | 0.2 |

| C (kN/m2) | 6780 | 5440 |

| ϕ (degree) | 53.42 | 58.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ran, T.; Pang, J.; Zou, J. An Emerging Solution for Medical Waste: Reuse of COVID-19 Protective Suit in Concrete. Sustainability 2022, 14, 10045. https://doi.org/10.3390/su141610045

Ran T, Pang J, Zou J. An Emerging Solution for Medical Waste: Reuse of COVID-19 Protective Suit in Concrete. Sustainability. 2022; 14(16):10045. https://doi.org/10.3390/su141610045

Chicago/Turabian StyleRan, Tao, Jianyong Pang, and Jiuqun Zou. 2022. "An Emerging Solution for Medical Waste: Reuse of COVID-19 Protective Suit in Concrete" Sustainability 14, no. 16: 10045. https://doi.org/10.3390/su141610045

APA StyleRan, T., Pang, J., & Zou, J. (2022). An Emerging Solution for Medical Waste: Reuse of COVID-19 Protective Suit in Concrete. Sustainability, 14(16), 10045. https://doi.org/10.3390/su141610045