Abstract

The water–energy–food (WEF) nexus approach is gaining attention due to the challenge of better managing natural elements. Agro-industrial companies, given their environmental impacts, need to take sustainability into proper account. However, this sector lacks the novel tools needed to integrate current methodologies with additional quality frameworks, such as business excellence models (BEMs). Therefore, the present research aims to propose a sustainability-focused excellence model by integrating the principles and objectives of the WEF nexus with existing BEM and proposing its application to agro-industrial companies. For that purpose, a new conceptual model to integrate sustainability and excellence was built. The proposed novel model can become a decision-support tool in helping agro-industrial companies transition toward improved sustainability while managing existing tradeoffs and synergies.

1. Introduction

Sustainability actions are urgent in the face of the quick depletion of natural resources that are essential for humankind. There is a lack of adequate access to water, energy, and food resources for a substantial percentage of the global population: Despite efforts within the past 15 years, 800 million people are still considered food insecure, an equal number has no access to safe drinking water, and 1.2 billion people lack access to electricity [1]. In the face of this reality, new practices are needed transversally, and all industrial sectors benefit from focusing on impacts on environmental, social, and economic results. Many industries and sectors recognize the importance of better managing the aforementioned natural resources [2,3,4]. Nevertheless, the agro-industrial sector deserves to be highlighted, as it requires a huge contribution of those natural resources [5,6] and has high pollution emissions rates [7].

Given that, the good practices of natural resource management should be stimulated to overcome unsustainable practices in the agro-industrial area. In this sense, quality management (QM) could be used since it presents a framework that organizations are already familiar with and has proved to be valuable when adapted to new technologies [8]. Among them, one particular scope is business excellence models (BEMs), a framework that oversees all activities and tasks needed to maintain the desired level of performance in an organization and relate it to its external environment [9]. Given that, this approach provides the methods (tools, processes, metrics, and indicators) to do so [10]. Accordingly, and in principle, BEMs offer a useful toolset to also oversee the pursuit of organization-wide sustainability [8,11].

In this context, one important sustainability management concept used nowadays is the so-called water–energy–food (WEF) nexus. It means that the aforementioned elements are intrinsically managed together, and one action in one direction can affect both of the others [12,13]. As a result, these three issues should be considered in an integrated manner because they are connected, and their utilization may expose important tradeoffs [14]. Identifying and evaluating tradeoffs and synergies is essential for integrating other perspectives. Nevertheless, there is no clear framework to measure and assess the quality of processes and operations related to the deployment of the principles behind the WEF nexus [15]. The incorporation of the WEF nexus into an enterprise-level model is essential for integrating sustainability into efficient planning, development, and monitoring, but also for policymaking in key WEF-productive sectors of the economy [15,16].

In order to close this gap, our work highlights the use of BEMs as a possible solution for the integration of productivity and sustainability in such industries. BEMs best express the summary of different efforts and frameworks to promote the mentality of quality and continuous improvement in an organization, doing so by highlighting strategic opportunities and industry best practices [8,17]. Therefore, the objective of this work is to propose a sustainability-focused business excellence model, integrating the WEF nexus with BEM, exploring a bridge between sustainability and performance excellence, and allowing for a more complete management perspective to be made by agro-industrial companies operating according to WEF nexus principles.

2. Literature Review

2.1. Water, Food, and Energy Systems and the WEF Nexus

Concerns about water, food, and energy systems are rapidly growing due to differing regional availabilities and their impact on the interdependences amongst themselves [15,18]. WEF elements are essential for human life, sustainable development, and social equality [19]. In this sense, ensuring their security is a crucial activity concerning every individual worldwide.

Given that, the need for the integrated analysis of natural elements is not a novelty in the scientific literature. In this sense, some authors affirmed that WEF elements should be evaluated in an integrated manner. This concept is considered the first attempt at this new approach [20,21,22,23]. However, the WEF nexus concept was only launched in 2011, when it was incorporated into an international discussion on sustainable development by the Stockholm Environment Institute [12] and the World Economic Forum [13]. According to Hoff [12], the WEF nexus implies that water availability, energy production/consumption, and food security are inextricably linked. Consequently, actions in any one area have impacts on the others [19]. In addition, the World Economic Forum [13] affirms that focusing on the joint promotion of food security, in addition to water and energy accessibility, is the meaning of nexus thinking. These interlinkages, and the criticality of the scarcity of any of the three resources and its impact on the others, emphasize the need to manage them jointly and more efficiently [24].

Such a nexus approach can support the transition to implement the Sustainable Development Goals (SDGs)—Agenda 2030 [25]. In this sense, scientific literature has plenty of studies linking WEF nexus implementation with the SDGs, performing better in regional sustainability [26], for legal challenges [27], and for rural communities [28], among other uses. Furthermore, this addition should reduce environmental impacts and generate additional benefits that outweigh the integration across sectors, enhancing, for instance, circular economy implementation [29]. Such gains should appeal to national interest and encourage governments, private sectors, and civil society to engage [30]. In practical terms, this approach can represent the action required in bioeconomy to implement real solutions in sustainability actions [31].

Many scientific articles have tried to express some practical examples of how to implement this methodology. Saladini et al. [26] selected 12 indicators to monitor the Mediterranean area called the Partnership for Research and Innovation in the Mediterranean Area, based on the Sustainable Development Goals, which can be directly related to boosting sustainable business innovation [32]. Hussien et al. [33] assessed the impact of WEF elements using a risk-based method. Bijl et al. [34] showed differences in physical trade production, distance, and volume using indicators. Karan et al. [35] created indices based on the UN-Habitat’s City Prosperity Index that specifically integrate the nexus-relevant indices into a weighted equity index. El-Gafy [36] proposed six indicators in order to quantify the nexus as a strategic tool applied to crop production. AbdelHady et al. [37] proposed three output indicators, agriculture, aquaculture, and net energy production, to assess the value of different ecosystem health conditions under three water management scenarios.

Additionally, managing water, energy, and food without efficient and synergistic actions may increase the risk of shortages. Consequently, one opportunity to improve the sustainable use of these sources is investigating the integration of the water–energy–food nexus with quality and business excellence initiatives.

2.2. Quality, Excellence, and Sustainability

Given the mentioned scientific gap in integrating the WEF nexus with the principles of quality and excellence, the use of BEMs has been considered. This decision is based on the understanding that these frameworks offer a clear opportunity for the development of a quality and continuous improvement mindset that can be aligned with needs and the best sustainability practices [8,38,39]. Regarding the agro-industrial sector, they are aligned with a major impact [40], and their actions can be responsible for proper natural resource management [41]. In this sense, excellence initiatives center on meeting stakeholders’ needs and expectations, widening previous scopes of quality-oriented initiatives [42] and focusing on creating sustainable value for all “interested” parties. They have been used by organizations worldwide to improve their performance and achieve improved business results.

Excellence models are most widely used by organizations for self-assessment and improvement, including targeting sustainability [39], with companies opting to adapt and customize them in search of competitive advantages [17]. They promote a longitudinal management philosophy, highlighting a set of principles that orient managers’ and associates’ behaviors in the long-term, fostering continuous improvement [43]. BEMs focus on offering insights for organizations to manage processes, tools, or techniques, both old or new, with the goal of building value from new opportunities and achieving superior organizational results [44].

However, and regardless of their extensive use, there is still limited integration of the topic of environmental sustainability in excellence frameworks, in this particular case tackling the use of the WEF nexus approach. Despite other scientific authors cited in this research showing a growing pressure for the development of new models, the truth is that economic, social, and environmental sustainability are still often left outside of the scope of some major excellence models [45], although this situation is also changing. Thus, research on business and operational excellence does not usually include a clear focus on environmental sustainability.

Accordingly, there is a clear aim for promoting specific models for the deployment of sustainability-focused excellence in different industrial sectors. In the specific scope of this work—focusing on water, energy, and food as critical issues and looking specifically at the agro-industrial sector—this model proposes to integrate excellence and sustainability because of the WEF nexus.

Thus, in summary, the contributions of the present article are:

- Exploring possibilities and criteria for the use and selection of BEMs concerning WEF nexus elements.

- Proposing and showing the use of a theoretical and novel model to integrate the BEM and the WEF nexus approaches for agro-industrial companies.

- Stimulating and validating agro-industrial companies to perform more sustainable actions.

3. Research Methods

In the face of the interdisciplinary challenge to build a sustainability-focused excellence model, this article adopted the conceptual analysis methodology described by Jabareen [46]. This approach was extensively applied in the scientific literature, providing a comprehensive understanding of the researched phenomenon [47,48,49,50,51]. To this end, the criteria relationship interactions were highlighted throughout the following adapted steps: Selection and description of business excellence (BE) models (reading and categorizing of data); highlighting of the criteria used to evaluate them (identifying concepts); integration of the previous items, performed based on similarities that were found (deconstructivity, categorizing, synthesizing, and integrating concepts); and constructing a new conceptual model to integrate sustainability and excellence (presenting and validating the final framework) [46]. For that purpose, the researched keywords included synonyms dealing with combinations of the terms “water–energy–food nexus” or “water energy food nexus” (“WEF nexus”; “FEW nexus”), “WEF nexus analysis” (“WEF nexus”, “WEF nexus model”, “WEF nexus tools”, “WEF nexus approaches”), “Agroindustrial WEF nexus”, and “Agrifood industries WEF nexus”, resulting in a database with 241 articles (with duplicates).

Therefore, we begin by describing and selecting the major BEMs, justifying their selection and relevance to provide context and reliability to the research process, as mentioned by Silverman [52], and Yin [53]. We also looked into criteria that may be used to evaluate the aforementioned BEMs. Finally, based on the former results, the integrated models were built and presented considering their applications in the agro-industrial area. For that purpose, indicators were grouped by using the similarity analysis method to form indices [54]. In the end, similar criteria were disposed into a conceptual model. A detailed explanation will be provided assessing sustainability standards that can be applied to WEF nexus approaches targeting agro-industrial production companies [55]. Additionally, we will highlight the differences between the proposed model and the existing ones found in the scientific literature.

4. Sustainability-Focused Model Development

4.1. Benchmarked Excellence Models

Our development of a sustainability-oriented excellence model followed the logic of aligning the different needs and concerns related to sustainability (in particular, those in the agro-industrial sector and pertaining to the WEF nexus) with the different enablers of excellence. Four different BEMs were considered for this purpose. The selection of these BEMs was based on their use, reach, and proximity to areas where agro-industrial companies have important production or sales volume. Additionally, the scientific literature connects them with sustainability [8,56,57,58].

Accordingly, the European Foundation for Quality Management (EFQM) excellence model was selected due to its widespread adoption by European companies, as well as for its results in improving organizational performance [44]. Similarly, the Malcolm Baldrige National Quality Award (MBNQA) excellence model was selected due to the fact that it is the most used in the USA and its proven advantages in promoting productivity in a large number of companies [59].

The Brazilian National Quality Award Model (BNQA) not only represents one of the largest and most important economies for the agro-industrial sector in the world but has also proven to be helpful in improving companies’ performances by identifying their strengths and driving their improvement actions [60]. Likewise, the ZED Model—Zero Defect, Zero Effect scheme—from India [61] was selected. Not only is it promoted by the government, but it is also focused on the specific reality of micro, small, and medium enterprises in one of the most populated and largest economies of the world.

To better understand the contributions of each of the selected BEMs, further details are provided next.

4.1.1. EFQM—European Foundation for Quality Management (EFQM) Excellence Model

The European Foundation for Quality Management (EFQM) excellence model has been widely adopted in Europe and elsewhere. Efforts have been made to highlight the connection between the EFQM model and its impact from a management perspective [62]. Later in this article, we will focus on the importance of integration in the implementation of the EFQM model. Evidence shows that the more integrated this model is, the more effective and innovative it can be. However, we still lack mechanisms to achieve this integration [63]. One of the main impacts that is expected to demonstrate an innovation path for the purposes of its implementation.

There are eight fundamental enablers of excellence considered by the EFQM Model, which are the following: (1) achieving balanced results; (2) adding value for customers; (3) leading with vision, (4) inspiration and integrity; (5) managing by processes; (6) succeeding through people; (7) nurturing creativity and innovation; (8) building partnerships; and (9) taking responsibility for a sustainable future [44].

4.1.2. ZED—Zero Defect, Zero Effect scheme (Indian Program for MSMEs)

The “Zero Defect, Zero Effect” program was launched in 2014, as the Council of India established that companies should strive to manufacture their products with both zero defects and with zero effects on the environment. In this sense, a plan contemplating 50 parameters was designed to help micro, small, and medium enterprises pursue these objectives [61].

Its implementation includes process assessment and certification considering the corresponding maturity levels achieved. For that purpose, it includes a maturity model designed for different organizational areas. Among its specific parameters, the following can be found [61]: (1) manufacturing capabilities; (2) design capabilities; (3) quality/environment/safety assurance systems; (4) people development and engagement systems for quality and environment; (5) learning and improvement Systems; and (6) legal compliances (hygiene factors).

4.1.3. Malcolm Baldrige National Quality Award (MBNQA) Excellence Model

The MBNQA and its associated excellence model were launched in 1987 in the United States of America. It is aimed at increasing the productivity of national and international companies through the implementation of quality criteria. Indeed, many companies have improved their quality performance after applying the MBNQA [64]. A significant difference in terms of quality performance is evident when comparing organizations using the excellence model and winning the MBNQA with those that do not [65].

Therefore, the excellence model of the MBNQA is built on the following set of interrelated enablers: (1) visionary leadership; (2) customer-driven excellence; (3) organizational and personal learning; (4) valuing workforce members and partners; (5) agility; (6) focus on the future; (7) managing for innovation; (8) managing by the fact; (9) societal responsibility; (10) focus on results and creating value; and (11) a systems perspective [59].

4.1.4. Brazilian National Quality Award (BNQA)

Similar to its worldwide counterparts, the Brazilian National Quality Award is aimed at enhancing the national quality performance of industrial companies [66]. It was launched by the Brazilian National Quality Foundation (FNQ) around 1992. For the present research, we considered the following enablers of the BNQA criteria: (1) leadership; (2) strategies and plans; (3) clients; (4) society; (5) information and knowledge; (6) people; (7) processes; and, finally, (8) results [60].

4.2. Sustainability-Focused Model Presentation and Discussion

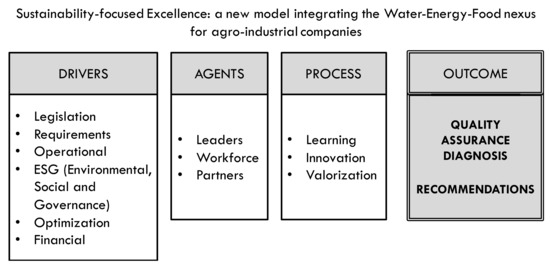

To build a sustainability-focused excellence model, several evaluation-related items have been considered. Thus, isolated efforts are no longer effective given the complexity of such an interdisciplinary research effort. In this sense, quality management systems have proved to provide a multiscale and holistic view, ranging from product production to societal challenges defined on a global level [67]. Based on this perspective, and on the previous excellence model principles explicated in Table 1, the following dimensions were considered: drivers, agents, process, and outcomes. Based on the previous discussion, our sustainability-focused model targeting agro-industrial companies is proposed based on the WEF nexus approach, as illustrated in Figure 1.

Table 1.

Enablers used by the EFQM [44], ZED [61], MBNQA [59], and BNQA [60] models with their similar correspondents on the proposed sustainability-focused model.

Figure 1.

A novel model for sustainability-focused excellence based on the WEF nexus approach for agro-industrial companies. Source: Own elaboration.

A comprehensive description of these dimensions is presented in the following topics, and the similarities between the models can be seen in Table 1.

For the fulfillment of the proposed objective, this article presents this overall conceptual model at the level of its main dimensions and criteria, but in future publications, additional details about its indicators and guidelines on how it can be used will be provided.

4.2.1. DRIVERS

Drivers guide the actions of organizations. They are the reason behind the need to change and encourage companies to transition to a more sustainable perspective. Based on the reality of the agro-industrial sector, the present research proposes a discussion that includes the following constituents: (1) legislation; (2) requirements; (3) operational drivers; (4) environmental, social, and governance drivers; (5) optimization; and (6) financial drivers.

Legislation

When it comes to environmental protection, legislation is required in order to control and limit the use and exploration of resources. In this sense, governments and national institutions play a significant role in the stimulation of better operational practices. In fact, legislation has been responsible for a positive impact on organizations regarding sustainability changes, innovation processes, and even safety and consumer protection [68]. From another perspective, inefficient legislation can cause damage to sustainable operations, for instance, when low policy measures permit non-circularity actions [69]. In this sense, many initiatives must be proposed to overcome these problems.

The previous concepts are consonant with what the WEF nexus approach targets when it calls attention to the need to reduce inequalities in natural resource uses and generate additional cost–benefit outputs. To illustrate this item, previous examples of legislative drivers being considered in excellence models can be found in the ZED model under the “Legal Compliance” criterion.

Requirements

In an agro-industrial activity, requirements rely on many factors, such as finality, food specificity, and consumer needs, among others. In this sense, for inclusion in our model, requirements are considered from two perspectives: manufacturing vision and customer behavior. Regarding the selected BE models, the following were chosen to represent this perspective: manufacturing capabilities from the ZED program, managing by the fact, and society from the MBNQA excellence model

The first consideration is directly connected to the production site, and the second one is related to the customer relationship management department. Therefore, considering the aim of the present research, those actions relate to the WEF nexus approach. When specifying the connection between quality and the management of requirements, quality management systems (QMS) and the ISO 9001 standard can be useful. ISO 9001 is a valuable tool to determine, validate, and implement the quality policy, which includes the management of information and knowledge, thus supporting the management and development of production capabilities [70].

Regarding customer behavior, it is important to highlight that this may require a transformation in the organization’s policy. In this sense, companies need to be concerned with multiple issues, not only from the environmental perspective but also economic and social ones [71]. Thus, as mentioned before, this article aims to fulfill the knowledge gap to transform the WEF nexus approach—generally used for macroanalysis—into a micro-evaluation for, in this specific case, agro-industrial companies.

Operational Drivers

Operational performance is also important when reflected in the company’s competitiveness [72]. It can be measured by many indicators, such as cost and quality, among others. This research highlights operational drivers as a result of the following excellence criteria: managing by process from the EFQM model and process from the BNQA model. Therefore, a major focus on processing activity is highlighted, as well as concerning the overall quality that will be delivered to the consumers.

We look at operational performance in this model from the point of view of external processes and operations related to supply chain management (SCM). SCM deals with all the processes, including how to go from raw material acquisition all the way to packaging disposal after consumer usage [73]. In this sense, throughout the various food processing stages, SCM-controlling tools become critical. Therefore, water, energy, and food should be included in the mentioned tools but, as stated in this research, in an integrated way. On this subject, it is important to innovate and find new indicators that can quantify the relationship between these elements [12].

Environmental, Social, and Governance (ESG)

Over the last few decades, environmental, social, and governance aspects have received increasing interest from a company perspective. Elements such as consumer behavior, policy, and emerging technologies are driving these concerns worldwide. In this scope, and in our proposition, this reflects a novel sustainability-focused excellence model; many ESG perspectives must be considered. To that end, the following excellence criteria are emphasized: taking responsibility for a sustainable future from the EFQM excellence model; quality/environment/safety assurance, people development, and engagement systems for quality and environment from the ZED program; focus on the future and societal responsibility from the MBNQA excellence model; and society from the BNQA model.

Most excellence models already have a perspective that considers environmental, social, and governance concerns. This is a consequence of the increasing interest in corporate social responsibility [74]. Agro-industrial companies are increasingly exposed to social responsibility concerns, as their operations contribute to natural resource depletion and face huge challenges to avoid and reduce waste [75]. This exposure is reinforced by changes in consumer behavior, with growing expectations for companies to adopt alternatives with less environmental damage, as well as to create the possibility for social inclusion along the production chain [76].

In the scope of the agro-industrial sector, the role of the environmental, social, and governance concerns promoted in driving the transition to a greener and more sustainable state can be easily connected to the United Nation’s Sustainable Development Goals (SDGs), whose use presents great potential. The SDGs adopted by the United Nations, and propelled by the United Nations Sustainable Development Solution Network [25], offer a suitable framework for concerns about ESGs.

It is strongly recommended that agro-industrial companies relate all of this evidence to daily production, building, for instance, indicators that are consolidated and included in their quality management systems.

Optimization

The scientific literature has a wide variety of articles tackling optimization in the agro-industrial chain. They concern important challenges, such as aiming to monitor food production [77] or the development of new products [78,79]. Nevertheless, optimization efforts are mostly concerned with a productivity perspective. In this sense, implementing integrated quality systems helps to better standardize the operational activities, with recognized positive effects on financial gains and product quality [80,81].

In our sustainability-focused excellence model, the inclusion of the optimization perspective follows criteria from the ZED program—learning and improvement systems—and the MBNQA excellence model—agility.

Financial Drivers

Financial performance is, obviously, a driver beyond any agro-industrial company. For that reason, in the present research, the inclusion of financial drivers is supported by the following criteria: Achieving balanced results from the EFQM model; focus on results and creating value and the systems perspective from the MBNQA excellence model; and, finally, results from the BNQA model. Under this scope, for the present research, two concepts will be highlighted: the production chain cost analysis and the green finance perspective.

Financial analysis is a well-known challenge in the agro-industrial production chain due to the need for a proper definition of the cost method, investments, and other economic indicators [82]. In this sense, the WEF nexus approach aims to quantify the relationship among natural elements, and one of those numbers can be expressed using cost analysis [83]. Thus, this point is a driver of sustainable change because it can stimulate more agro-industrial companies to make their own investments, considering the mentioned costs. Consequently, this action needs to be considered in the definition of a company’s subsequent steps, guiding the best ecofriendly decision and balancing it with financial imperatives.

4.2.2. AGENTS

Agents are change promoters that significantly impact the transition to sustainability. In the scope of this work, they are the stakeholders of agro-industrial companies. Agents will be divided here into the following categories: leaders, the workforce, and partners.

Leaders

Undoubtedly, sustainability driving change is a challenge typically faced by leaders, especially targeting social aspects [84]. Hence, they are responsible for promoting good conditions from which the whole organization can advance. In the present research, support for the attention given to leaders is based on the criteria leading with vision, inspiration, and integrity from the EFQM excellence model; visionary leadership from the MBNQA excellence model; and leadership from the model of the BNQA.

Organizations rely on the responsibility and impact that the leader’s vision has on the transition path. For the proposed model, this research highlights the importance of leadership in two different perspectives: climate governance leadership and leadership under the quality management systems approach.

According to Carvalho et al. [85], leaders need to make decisions based on climate governance. This means that the sustainability implications of each decision should be considered. To that end, leaders need to use diverse information and knowledge to decide what is best in the context of transitioning to sustainability. Recent studies on the WEF nexus indicate that internal policies should include, among other issues, how to deal with wastage in the production chain, as well as guidance to implement a circular economy perspective in agro-industrial companies [86].

Workforce

As in the previous agent, the workforce is also an important driver to change behavior. Efforts should be made to include more productivity by enhancing people’s knowledge. For that purpose, in the present research, this topic will be represented by the following concerns: succeeding through People (EFQM excellence model); people development and engagement systems for quality and environment (ZED program); valuing workforce members and partners (MBNQA excellence model); and people (BNQA). In practice, the proposed model will focus on evaluating the promotion of increased workforce skills, tools, and capabilities that can support the pursuit of both increased productivity and sustainability. According to Ingram [87], these skills, tools, and capabilities are aimed at improving workforce knowledge of the food processing chain’s impact on topics such as food security and safety, sustainability, and health. WEF nexus approaches should be presented from a comprehensive and educational perspective. Workforce knowledge proved to be beneficial, with evidence that it impacts the collaborators’ environmental mindset, as well as consumer behavior [88]. In this sense, continued training constitutes a critical action to help agro-industrial companies become more sustainable.

Partners

Building partnerships is required to control the agro-industrial production chain. One of the main reasons for that is the need for traceability, which is essential to ensure final product quality. Thus, it needs to be constructed with records from all processes, including origin and production processes, but also from product characteristics such as temperature, size, and color, among others. These can have a positive impact on standards audits, and, finally, they can also potentially avoid sanitary barriers [89]. According to Tomich et al. [90], partnerships are more effective when they have multiple stakeholders. In the case of the agro-industrial sector, this means that the production chain should be built upon partnerships. Specific to the present research, in order to lead to a successful implementation, all food transformation paths should be aware of the WEF nexus approach information. Quality control should become the responsibility of every actor, and all partners can become agents of sustainable change by using audits, requirements, and other requests in agro-industrial companies.

The inclusion of partners in this model is inspired by the EFQM excellence criterion building partnerships and the MBNQA excellence criterion valuing workforce members and partners.

PROCESS

In the context of sustainable excellence, continuous improvement should be a highlighted aim of any process. Agro-industrial companies should look for process improvements that can be translated into more agility, fewer costs, and, finally, more sustainability. Under this scope, the process improvement presented is based on three main objectives in the present research: learning, innovation, and valorization.

Learning

Organizational learning is required to transform the process, both in terms of productivity and sustainability. It can be defined as the recognition that society changes and that organizations should change accordingly [91]. It can also lead to more sustainable practices. The development of learning process classes is critical. In the case of the proposed model, continuous organizational learning regarding both the WEF nexus and quality and excellence are required. According to Moore et al. [92] learning those issues can avoid biased decisions, and pieces of evidence indicate that the results positively impact organizational improvement.

The focus on organizational learning is helpful for the following uses: Design capabilities in the ZED program and organizational and personal learning in the MBNQA model.

Innovation

Innovation has a strong link to excellent performance and can also support the pursuit of greener, more sustainable solutions. According to Kafetzopoulos and Gotzamani [93] enablers from some excellence models are intrinsically linked to innovation. In this sense, it is essential to provide conditions to develop such activities. In the specific case of agro-industrial companies, all actors are expected to be able to contribute to innovation, regardless of their jobs. For that purpose, it is important to highlight that there is a huge challenge in transforming the WEF nexus perspective into a feasible methodology that can be used by a company since this concept has mainly been applied at the macro level, for instance, to cities, regions, and countries, among other similar analyses [94]. Therefore, to address this concern, it is strongly recommended that the companies should include in their innovative actions the three nexus elements combined together.

In this present research, the innovation issue mainly has to do with joining the following criteria: nurturing creativity and innovation (from the excellence model of the EFQM); managing for innovation (MBNQA excellence model); and strategies and plans (from the model of the BNQA).

Valorization

Increasing the valorization of resources, as a social aspect, is a growing concern for organizations. Customers are willing to pay for differentiation in some products and then valorize them. In the specific case of agro-industrial companies, sustainability valorization is highlighted [95]. Changing customer behavior is responsible for several companies promoting a transition to greener products. Likewise, the perception that the quality of a product depends on how it is produced is changing.

In the present research, this topic is supported by covering the following topics: adding value for customers (EFQM excellence model); customer-driven excellence (MBNQA); and clients (BNQA).

4.2.3. OUTCOMES

In the context of sustainable excellence, continuous improvement should be highlighted as a major aim for any process. In particular, agro-industrial companies should look for process improvements that can be translated into more agility, fewer costs, and, finally, more sustainability. In this scope, process improvement in our present research can be related to the following main objectives: quality assurance diagnosis and sustainability recommendations.

Quality Assurance Diagnosis

One of the outcomes that is expected from the proposed model is a quality assurance diagnosis (QAD). In practical terms, companies using the model should be able to describe actual conformities and nonconformities according to an evaluation made according to an integrated vision analysis. As stated by Thrän et al. [96], environmentally integrated analysis can positively impact final products. In this case, the result will be translated into a more cost-competitive final product. Therefore, the mentioned QAD can be used as a control tool to establish indicators that should be followed. In the specific case of agro-industrial companies, it should help in the identification of impacts that deal directly with WEF nexus elements.

Sustainability Recommendations

Based on the previous QAD, recommendations should guide an action plan regarding the definition and implementation of proper corrective actions. According to Sharma et al. [73] an action plan is one of the required tools to implement sustainable performance in agro-industrial companies. The mentioned action plan should capture the experienced model results and transform the suggestions into practical terms.

Additionally, those recommendations should reflect the WEF nexus concept, which is to manage the elements in a joint manner. Likewise, those actions should enhance efforts to overcome the tradeoff in order to take the concept from a macro-perspective to a micro-perspective applied, in this case, to agro-industrial companies. These recommendations are expected to result in actions such as increases in productivity, decreases in costs, and, most critically, greener, more effective, and more sustainable production.

4.3. How Agro-Industrial Companies and WEF Nexus Aspects Can Be Targeted in the Proposed Model

The agro-industrial sector plays a significant role in feeding mankind in relation to the WEF nexus approach. However, this sector is very energy intensive, with important negative environmental impacts. In this sense, for the purpose of reducing GHG emissions, alternative energy sources (solar and wind energy for instance) and water resources (sustainable water production) should be employed [97].

Additionally, water pollution owing to agro-industrial activities is a crucial problem to human beings and the ecosystem [98]. Approximately 85% of global water consumption is used for irrigation, and the demand is still increasing [99]. In order to avoid wastage, adequate water treatment and reuse through non-pollutant methodologies are suggested [100].

The food scenario is no different. One out of nine people in the world go hungry every day according to the “State of Food Insecurity” section in the World Report [101]. Annually, one-third of food produced for human consumption is wasted in the food production chain [102]. Thus, it is a major challenge for all agro-industrial chains to produce food while avoiding food wastage.

Therefore, to implement the WEF nexus in the agro-industrial sector, these aspects should be evaluated during the model’s implementation. It means, that during its implementation, these aspects should be evaluated in each of the following aspects: drivers, agents, processes, and outcomes. In this sense, problems such as the implementation of renewable energy sources [29], the treatment of water sources [103], and actions to avoid food wastage [104] should be ranked in an evaluation model. Regarding the particular aspects of this sector, it is good to integrate with quality global standards such as the Hazard Analysis Critical Control Point (HACCP) [105], ISO 22.000 [106], and good manufacturing practices [107], among others.

5. Model Verification and Validation

To verify and validate the model, the proposed results were validated by experts. Thus, based on the citation of Carvalho et al. [108], the presented model was discussed by researchers and agro-industrial producers from Portugal, the United States of America, Italy, Brazil, and Kenya. Following that, to clarify possible uncertainties, this article highlights how to use the proposed model and a benchmark study on the diversity of evaluation models.

5.1. How to Use the Proposed Sustainability-Focused Model

Integrated management approaches have proved that organizations can become more effective, more efficient, more responsive, and enjoy better performance outcomes [109]. In this scope, the integration of productivity and sustainability also manages the perceived tradeoff that is felt by organizations regarding the need to have a superior level of business performance and the need to promote social, economic, and environmental sustainability [110]. Additionally, the proposed model has synergies spawning from this integration, and it shows that a proper balance is essential to achieve the mentioned goals. Thus, the practical deployment of this integrative vision’s model represents a well-structured approach, promoting two main visions: a framework promoting performance assessment and improvement while also ensuring an increased focus on the sustainability demanded by multiple stakeholders.

To practically apply the proposed model, it is important to highlight its constituents and interdependencies. Beginning with the drivers, these elements should be discussed after the evaluation with respect to the reasons that connections between the WEF elements are not occurring. After that, based on the previous results, agents must show how committed they are to leading these organizational changes. Following this path, the process must be evaluated from a sustainability perspective; in this sense, it could bring some ideas on how to promote innovation in agro-industrial companies by solving problems with the underscored evaluation. Finally, summarizing all the insights, the outcomes should bring, firstly, a diagnosis of the real situation; after that, it should find suggestions on how to perform better, with indications for an action plan (ideally with changing actions, employee responsibility, and dates to implement these suggestions). Accordingly, it is possible to see the interdependence between the elements completing the proposed analysis made by this model.

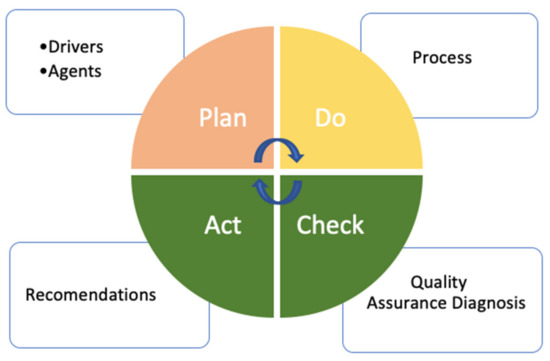

Following the previous discussion, with respect to many quality management models (ISO standards, Food Safety System Certification (FSSC), and national legislations, among others), the presented novel model can be integrated within the sequence of the Plan, Do, Check, and Act (PDCA) cycle program. The first part is represented by the driver and agent dimensions so that every analyzed item should be included in the planning stage. The application part of the program—relative to the “do part”—focuses on the process. In this case, every issue discussed before should be implemented. The check components will be credited to the quality assurance diagnosis from the outcome, highlighting the non-conformities that should be targeted. Finally, the Act part should try to overcome the previous diagnosis, thus finishing the quality cycle and restarting the evaluation. Therefore, the proposed model should be responsible for the sustainability transition that was discussed in this article. An illustrated overview can be seen in Figure 2.

Figure 2.

Illustrated overview of the sustainability-focused excellence model integrated with the PDCA cycle. Source: Own elaboration.

5.2. Benchmarking with other Evaluation Models

The scientific literature covers plenty of articles relying on the connection between quality management systems and sustainability concerns [111,112,113,114,115,116,117]. Additionally, according to Zink [113], the concept of quality management implicitly brings a sustainability perspective, especially when considering total quality management principles. In this sense, some studies rely on the efficiency of indicators, expressing items relative to these concerns [112,115]. However, a major novelty in our proposed sustainability-focused model is the fact that it aims to unite the WEF nexus approach with quality management systems models, specifically BE models. Thus, BE models can be integrated with an increasing variety of other subsystems implemented according to other standards and subsystems raised from specific standards designed for specific activity sectors [70,118]. Finally, it is important to consider that, in 2020, the EFQM model adopted a new version that reinforces sustainability indicators [92], although it is not customized to agro-industrial companies, as is the case of our suggested model.

Following the previous discussion, agro-industrial companies have been implementing many greener actions, not just because of environmental concerns, but also because of the benefits deriving from sustainable initiatives [119,120,121,122,123]. In this case, it is important to highlight that the mentioned actions are independent of company size and are trying to overcome situations such as the provision of natural resources [119]. Thus, demands for WEF nexus resources, in this sector, are increasing rapidly [124]. In this context, it is a major challenge for the overall agro-industrial chain to produce food while avoiding the excessive use of energy and water and preventing food waste. For that purpose, Table 2 lists five articles that involve WEF nexus approaches for agro-industrial companies, highlighting their objectives and evaluation methods, as well as the major differences and advantages connected with our suggested conceptual model.

Table 2.

Articles discussing the implementation of the WEF nexus approach in the agro-industrial production chain, highlighting their objectives and evaluation methods, as well as their main contributions to our sustainability-focused excellence model.

Table 2 shows the important contribution of the sustainability-focused excellence (SFE) model to the present discussion. Thus, existent WEF nexus models focus on a macro-perspective, and, in this case, we propose to focus on a microanalysis, namely, with respect to agro-industrial companies. The contents of Table 2 underscore that the use of BE models should bring other evident novelties to the system. We believe that the use of this model will be an important tool for leaders, academics, decisionmakers, and lawmakers, as well as for guiding new policies.

6. Conclusions and Future Work

This article presents a sustainability-focused excellence model by integrating the principles and objectives of the water–energy–food (WEF) nexus with existing excellence models and proposing its application for agro-industrial companies. The development of this model was based on the conceptual links between productivity and sustainability and the need to transition from one perspective together with the other. Accordingly, the novel model is presented with a focus on change, being constituted by the following dimensions (and respective evaluation criteria): drivers (legislation, requirements, operational drivers, ESG drivers, optimization, and financial drivers); agents (leaders, workforce, and partners); process (learning, innovation, and valorization); and outcome (quality assurance diagnosis, and recommendations).

We believe that this novel model can become a decision-support tool to help agro-industrial companies make the transition toward improved sustainability while managing existing tradeoffs and synergies. From this perspective, the sustainability-excellence model can be used in a dynamic and integrated way with the WEF nexus.

In terms of limitations and future research work, it is important to note that this model has not yet been tested in practice, an essential step toward complete validation. However, our aim with this publication is to perform a broader validation. Model validation can be performed in several ways. Although practical validation is often used, the theoretical validation of models through publication is notably prevalent as a first step in the validation process, with reviewers’ inputs and insights serving as a basis for improvement and scientific validation. Some authors, such as Maqsood Ahmad Sandhu and Ahm Shamsuzzoha [129], and Carvalho et. al. [108], have published their conceptual models before advancing to empirical validation. Accordingly, our aim is to use this publication to make the model available to the scientific community, which should be considered the first step in this validation process, gaining broader acceptance from academics and practitioners before advancing the model’s applicability validation in practice. Furthermore, during this time, the model can serve as a basis for the development of other models in this context of action.

As such, once the evaluation criteria and methods are defined, the next step will be to consider additional model validation with actual agro-industrial company case studies. From this perspective, the use of companies in different countries is desired since every country has different legislation and may provide different perspectives.

Author Contributions

Conceptualization, F.C., A.M.C. and P.S.; writing—original draft preparation, F.C., A.M.C. and P.S.; writing—review and editing, F.C., A.M.C., P.S. and F.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Brazilian National Council for Scientific and Technological Development—CNPq, Ministry of Science, Technology, Innovations, and Communications, Brazil—201490/2018-8.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We acknowledge the Energy for Sustainability Initiative from the University of Coimbra for academic support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Scanlon, B.R.; Ruddell, B.L.; Reed, P.M.; Hook, R.I.; Zheng, C.; Tidwell, V.C.; Siebert, S. The food-energy-water nexus: Transforming science for society. Water Resour. Res. 2017, 53, 3550–3556. [Google Scholar] [CrossRef]

- Clift, R. Climate change and energy policy: The importance of sustainability arguments. Energy 2007, 32, 262–268. [Google Scholar] [CrossRef]

- Schoenherr, T.; Talluri, S. Environmental sustainability initiatives: A comparative analysis of plant efficiencies in Europe and the US. IEEE Trans. Eng. Manag. 2013, 60, 353–365. [Google Scholar] [CrossRef]

- Yeung, S.M. UNSDGs and future quality management—Social policy for developing sustainable development mindset. Corp. Gov. Sustain. Rev. 2019, 3, 26–34. [Google Scholar] [CrossRef]

- Viles, E.; Santos, J.; Muñoz-Villamizar, A.; Grau, P.; Fernández-Arévalo, T. Lean-green improvement opportunities for sustainable manufacturing using water telemetry in agri-food industry. Sustainability 2021, 13, 2240. [Google Scholar] [CrossRef]

- Adelodun, B.; Kareem, K.Y.; Kumar, P.; Kumar, V.; Choi, K.S.; Yadav, K.K.; Yadav, A.; El-Denglawey, A.; Cabral-Pinto, M.; Son, C.T.; et al. Understanding the impacts of the COVID-19 pandemic on sustainable agri-food system and agroecosystem decarbonization nexus: A review. J. Clean. Prod. 2021, 318, 128451. [Google Scholar] [CrossRef]

- Karwacka, M.; Ciurzyńska, A.; Lenart, A.; Janowicz, M. Sustainable Development in the Agri-Food Sector in Terms of the Carbon Footprint: A Review. Sustainability 2020, 12, 6463. [Google Scholar] [CrossRef]

- Fonseca, L.; Amaral, A.; Oliveira, J. Quality 4.0: The efqm 2020 model and industry 4.0 relationships and implications. Sustainability 2021, 13, 3107. [Google Scholar] [CrossRef]

- Carvalho, A.M.; Sampaio, P.; Rebentisch, E.; Carvalho, J.A.; Saraiva, P. Operational excellence, organisational culture and agility: The missing link? Total Qual. Manag. Bus. Excell. 2019, 30, 1495–1514. [Google Scholar] [CrossRef]

- Isaksson, R. Excellence for sustainability–maintaining the license to operate. Total Qual. Manag. Bus. Excell. 2019, 32, 489–500. [Google Scholar] [CrossRef] [Green Version]

- Siltori, P.F.S.; Simon Rampasso, I.; Martins, V.W.B.; Anholon, R.; Silva, D.; Souza Pinto, J. Analysis of ISO 9001 certification benefits in Brazilian companies. Total Qual. Manag. Bus. Excell. 2020, 32, 1614–1632. [Google Scholar] [CrossRef]

- Hoff, H. Understanding the Nexus: Background Paper for the Bonn2011 Nexus Conference; Stockholm Environment Institute: Stockholm, Sweden, 2011; pp. 1–52. [Google Scholar]

- World Economic Forum. Water Security: The Water-Food-Energy-Climate Nexus: The World Economic Forum Water Initiative; Island Press: Washington, DC, USA, 2011. [Google Scholar]

- Taniguchi, M.; Endo, A.; Gurdak, J.J.; Swarzenski, P. Water-Energy-Food Nexus in the Asia-Pacific Region. J. Hydrol. Reg. Stud. 2017, 11, 1–8. [Google Scholar] [CrossRef]

- Purwanto, A.; Sušnik, J.; Suryadi, F.X.; de Fraiture, C. Water-energy-food nexus: Critical review, practical applications, and prospects for future research. Sustainability 2021, 13, 1919. [Google Scholar] [CrossRef]

- Botai, J.O.; Botai, C.M.; Ncongwane, K.P.; Mpandeli, S.; Nhamo, L.; Masinde, M.; Adeola, A.M.; Mengistu, M.G.; Tazvinga, H.; Murambadoro, M.D.; et al. A review of the water-energy-food nexus research in Africa. Sustainability 2021, 13, 1762. [Google Scholar] [CrossRef]

- Carvalho, A.M.; Sampaio, P.; Rebentisch, E.; Saraiva, P. Operational excellence as a means to achieve an enduring capacity to change—Revision and evolution of a conceptual model. Procedia Manuf. 2017, 13, 1328–1335. [Google Scholar] [CrossRef]

- Leung Pah Hang, M.Y.; Martinez-Hernandez, E.; Leach, M.; Yang, A. Designing integrated local production systems: A study on the food-energy-water nexus. J. Clean. Prod. 2016, 135, 1065–1084. [Google Scholar] [CrossRef]

- Daher, B.T.; Mohtar, R.H. Water-energy-food (WEF) Nexus Tool 2.0: Guiding integrative resource planning and decision-making. Water Int. 2015, 40, 748–771. [Google Scholar] [CrossRef]

- Koutsoyiannis, D.; Makropoulos, C.; Langousis, A.; Baki, S.; Efstratiadis, A.; Christofides, A.; Karavokiros, G.; Mamassis, N. HESS opinions: “Climate, hydrology, energy, water: Recognizing uncertainty and seeking sustainability”. Hydrol. Earth Syst. Sci. 2009, 13, 247–257. [Google Scholar] [CrossRef] [Green Version]

- Hülsmann, S.; Sušnik, J.; Rinke, K.; Langan, S.; van Wijk, D.; Janssen, A.B.; Mooij, W.M. Integrated modelling and management of water resources: The ecosystem perspective on the nexus approach. Curr. Opin. Environ. Sustain. 2019, 40, 14–20. [Google Scholar] [CrossRef]

- Benson, D.; Gain, A.K.; Rouillard, J.J. Water governance in a comparative perspective: From IWRM to a “nexus” approach? Water Altern. 2015, 8, 756–773. [Google Scholar]

- Roidt, M.; Avellán, T. Learning from integrated management approaches to implement the Nexus. J. Environ. Manag. 2019, 237, 609–616. [Google Scholar] [CrossRef]

- Weitz, N.; Strambo, C.; Kemp-Benedict, E.; Nilsson, M. Closing the governance gaps in the water-energy-food nexus: Insights from integrative governance. Glob. Environ. Chang. 2017, 45, 165–173. [Google Scholar] [CrossRef]

- UN. 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015; Volume 16301. [Google Scholar]

- Saladini, F.; Betti, G.; Ferragina, E.; Bouraoui, F.; Cupertino, S.; Canitano, G.; Gigliotti, M.; Autino, A.; Pulselli, F.M.; Riccaboni, A.; et al. Linking the water-energy-food nexus and sustainable development indicators for the Mediterranean region. Ecol. Indic. 2018, 91, 689–697. [Google Scholar] [CrossRef]

- Olawuyi, D. Sustainable development and the water-energy-food nexus: Legal challenges and emerging solutions. Environ. Sci. Policy 2020, 103, 1–9. [Google Scholar] [CrossRef]

- Cansino-Loeza, B.; Tovar-Facio, J.; Ponce-Ortega, J.M. Stochastic optimization of the water-energy-food nexus in disadvantaged rural communities to achieve the sustainable development goals. Sustain. Prod. Consum. 2021, 28, 1249–1261. [Google Scholar] [CrossRef]

- Parsa, A.; Van De Wiel, M.J.; Schmutz, U. Intersection, interrelation or interdependence? The relationship between circular economy and nexus approach. J. Clean. Prod. 2021, 313, 127794. [Google Scholar] [CrossRef]

- Garcia, D.J.; You, F. The water-energy-food nexus and process systems engineering: A new focus. Comput. Chem. Eng. 2016, 91, 49–67. [Google Scholar] [CrossRef]

- D’Adamo, I.; Gastaldi, M.; Morone, P.; Rosa, P.; Sassanelli, C.; Settembre-Blundo, D.; Shen, Y. Bioeconomy of Sustainability: Drivers, Opportunities and Policy Implications. Sustainability 2022, 14, 200. [Google Scholar] [CrossRef]

- Merino-Saum, A.; Baldi, M.G.; Gunderson, I.; Oberle, B. Articulating natural resources and sustainable development goals through green economy indicators: A systematic analysis. Resour. Conserv. Recyc. 2018, 139, 90–103. [Google Scholar] [CrossRef]

- Hussien, W.A.; Memon, F.A.; Savic, D.A. A risk-based assessment of the household water-energy-food nexus under the impact of seasonal variability. J. Clean. Prod. 2018, 171, 1275–1289. [Google Scholar] [CrossRef]

- Bijl, D.L.; Bogaart, P.W.; Dekker, S.C.; van Vuuren, D.P. Unpacking the nexus: Different spatial scales for water, food and energy. Glob. Environ. Chang. 2018, 48, 22–31. [Google Scholar] [CrossRef] [Green Version]

- Karan, E.; Asadi, S.; Mohtar, R.; Baawain, M. Towards the optimization of sustainable food-energy-water systems: A stochastic approach. J. Clean. Prod. 2018, 171, 662–674. [Google Scholar] [CrossRef]

- El-Gafy, I. Water-food-energy nexus index: Analysis of water-energy-food nexus of crop’s production system applying the indicators approach. Appl. Water Sci. 2017, 7, 2857–2868. [Google Scholar] [CrossRef] [Green Version]

- AbdelHady, R.S.; Fahmy, H.S.; Pacini, N. Valuing of Wadi El-Rayan ecosystem through water-food-energy nexus approach. Ecohydrol. Hydrobiol. 2017, 17, 247–253. [Google Scholar] [CrossRef]

- Rivera, D.E.; Piferrer, M.R.T.; Mundet, M.H.B. Measuring territorial social responsibility and sustainability using the EFQM excellence model. Sustainability 2021, 13, 2153. [Google Scholar] [CrossRef]

- Henríquez-Machado, R.; Muñoz-Villamizar, A.; Santos, J. Sustainability through operational excellence: An emerging country perspective. Sustainability 2021, 13, 3165. [Google Scholar] [CrossRef]

- Rajakal, J.P.; Ng, D.K.S.; Tan, R.R.; Andiappan, V.; Wan, Y.K. Multi-objective expansion analysis for sustainable agro-industrial value chains based on profit, carbon and water footprint. J. Clean. Prod. 2021, 288, 125117. [Google Scholar] [CrossRef]

- Amoriello, T. Sustainability: Recovery and Reuse of Brewing-Derived. Sustainability 2021, 13, 2355. [Google Scholar] [CrossRef]

- Klefsjö, B.; Bergquist, B.; Garvare, R. Quality management and business excellence, customers and stakeholders: Do we agree on what we are talking about, and does it matter? TQM J. 2008, 20, 120–129. [Google Scholar] [CrossRef] [Green Version]

- Miller, R.D.; Raymer, J.; Cook, R.; Barker, S. The Shingo Model for Operational Excellence; Logan, U., Ed.; Utah State University: Logan, UT, USA, 2013. [Google Scholar]

- EFQM. EFQM Model for Business Excellence. 2003. Available online: https://efqm.org/ (accessed on 2 December 2021).

- Asif, M.; Searcy, C.; Garvare, R.; Ahmad, N. Including sustainability in business excellence models. Total Qual. Manag. Bus. Excell. 2011, 22, 773–786. [Google Scholar] [CrossRef]

- Jabareen, Y. Building a Conceptual Framework: Philosophy, Definitions, and Procedure. Int. J. Qual. Methods 2009, 8, 49–62. [Google Scholar] [CrossRef]

- Eizenberg, E.; Jabareen, Y. Social sustainability: A new conceptual framework. Sustainability 2017, 9, 68. [Google Scholar] [CrossRef] [Green Version]

- Hong, Q.N.; Pluye, P. A Conceptual Framework for Critical Appraisal in Systematic Mixed Studies Reviews. J. Mix. Methods Res. 2019, 13, 446–460. [Google Scholar] [CrossRef]

- Khandpur, N.; Zatz, L.Y.; Bleich, S.N.; Taillie, L.S.; Orr, J.A.; Rimm, E.B.; Moran, A.J. Supermarkets in cyberspace: A conceptual framework to capture the influence of online food retail environments on consumer behavior. Int. J. Environ. Res. Public Health 2020, 17, 8639. [Google Scholar] [CrossRef]

- Kørnøv, L.; Lyhne, I.; Davila, J.G. Linking the UN SDGs and environmental assessment: Towards a conceptual framework. Environ. Impact Assess. Rev. 2020, 85, 106463. [Google Scholar] [CrossRef]

- Hidayati, A.N.; Riadi, I.; Ramadhani, E.; Amany, S.U. Al Development of conceptual framework for cyber fraud investigation. Regist. J. Ilm. Teknol. Sist. Inf. 2021, 7, 125–135. [Google Scholar] [CrossRef]

- Silverman, D. Doing Qualitative Research: A Practical Guide; Sage: London, UK, 2000. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; Sage: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Nardi, P.C.C.; da Silva, R.L.M.; Ribeiro, E.M.S.; de Oliveira, S.V.W.B. Proposal for a methodology to monitor sustainability in the production of soft drinks in Ref PET. J. Clean. Prod. 2017, 151, 218–234. [Google Scholar] [CrossRef]

- Mohr, M.; Renz, P. Naga City: Septage treatment and wastewater concept for Del Rosario. Fraunhofer IGB Report. 2014. Available online: https://www.unescap.org/sites/default/files/Report_PH_Naga_SeptageAndWastewater_2014.pdf (accessed on 15 January 2022).

- Khalil, M.K.; Muneenam, U. Total quality management practices and corporate green performance: Does organizational culture matter? Sustainability 2021, 13, 21. [Google Scholar] [CrossRef]

- Adapa, S. Factors influencing consumption and anti-consumption of recycled water: Evidence from Australia. J. Clean. Prod. 2018, 201, 624–635. [Google Scholar] [CrossRef]

- Jamal, C.M.C.; Albrecht Anversa, M.V.; De Souza Chacon, P.A. A conexão do Sistema de Gestão da Qualidade Total (SGQ) com a Gestão da Inovação (GI). Sist. Gestão 2021, 16, 3–10. [Google Scholar] [CrossRef]

- Baldrige Performance Excellence Program Criteria for Performance Excellence, US, NIST, Gaithersburg, MD. Available online: https://www.nist.gov/baldrige (accessed on 15 January 2022).

- Brazilian National Quality Award Foundation FPNQ—Performance Excellence Criteria. Available online: https://fnq.org.br/empresas-reconhecidas-em-gestao-meg-e-pnq-de-1992-a-2020/ (accessed on 3 November 2021).

- Ministry of Micro Small and Medium Enterprises. ZED Zero Deffect Zero Effect Statement. Available online: https://zed.msme.gov.in/ (accessed on 2 December 2021).

- Criado-García, F.; Calvo-Mora, A.; Martelo-Landroguez, S. Knowledge management issues in the EFQM excellence model framework. Int. J. Qual. Reliab. Manag. 2019, 37, 781–800. [Google Scholar] [CrossRef]

- Davies, J. Integration: Is it the key to effective implementation of the EFQM Excellence Model? Int. J. Qual. Reliab. Manag. 2008, 25, 383–399. [Google Scholar] [CrossRef] [Green Version]

- Miller, J.; Parast, M.M. Learning by Applying: The Case of the Malcolm Baldrige National Quality Award. IEEE Trans. Eng. Manag. 2019, 66, 337–353. [Google Scholar] [CrossRef]

- Tettey, A.; Sampson, G.; Mesmer, B. Exploratory Analysis of the Malcolm Baldrige National Quality Award Model. J. Manag. Eng. Integr. 2019, 12, 2019. [Google Scholar]

- Cauchick Miguel, P.A. Comparing the Brazilian national quality award with some of the major prizes. TQM Mag. 2001, 13, 260–272. [Google Scholar] [CrossRef]

- Sampaio, P.; Saraiva, P.; Rodrigues, A.G. ISO 9001 certification research: Questions, answers and approaches. Int. J. Qual. Reliab. Manag. 2009, 26, 38–58. [Google Scholar] [CrossRef]

- Leialohilani, A.; de Boer, A. EU food legislation impacts innovation in the area of plant-based dairy alternatives. Trends Food Sci. Technol. 2020, 104, 262–267. [Google Scholar] [CrossRef]

- Canali, M.; Amani, P.; Aramyan, L.; Gheoldus, M.; Moates, G.; Östergren, K.; Silvennoinen, K.; Waldron, K.; Vittuari, M. Food waste drivers in Europe, from identification to possible interventions. Sustainability 2017, 9, 37. [Google Scholar] [CrossRef] [Green Version]

- Sampaio, P.; Saraiva, P.; Rodrigues, A.G. The economic impact of quality management systems in Portuguese certified companies: Empirical evidence. Int. J. Qual. Reliab. Manag. 2011, 28, 929–950. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, N.; Johnson, L.W. Consumer behaviour and environmental sustainability. J. Consum. Behav. 2020, 19, 2020–2022. [Google Scholar] [CrossRef]

- Gupta, S.; Dangayach, G.S.; Singh, A.K.; Meena, M.L.; Rao, P.N. Adoption of sustainable supply operation quality practices and their impact on stakeholder’s performance and sustainable performance for sustainable competitiveness in Indian manufacturing companies. Int. J. Intell. Enterp. 2018, 5, 125–140. [Google Scholar] [CrossRef]

- Sharma, V.K.; Chandna, P.; Bhardwaj, A. Green supply chain management related performance indicators in agro industry: A review. J. Clean. Prod. 2017, 141, 1194–1208. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Jafarian, A. A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach. J. Clean. Prod. 2013, 47, 345–354. [Google Scholar] [CrossRef]

- Dania, W.A.P.; Xing, K.; Amer, Y. Collaboration behavioural factors for sustainable agri-food supply chains: A systematic review. J. Clean. Prod. 2018, 186, 851–864. [Google Scholar] [CrossRef]

- Doukidis, G.I.; Matopoulos, A.; Vlachopoulou, M.; Manthou, V.; Manos, B. A conceptual framework for supply chain collaboration: Empirical evidence from the agri-food industry. Supply Chain Manag. Int. J. 2007, 12, 177–186. [Google Scholar] [CrossRef] [Green Version]

- Gao, T.; Tian, Y.; Zhu, Z.; Sun, D.W. Modelling, responses and applications of time-temperature indicators (TTIs) in monitoring fresh food quality. Trends Food Sci. Technol. 2020, 99, 311–322. [Google Scholar] [CrossRef]

- Estevão, S.T.; Batista de Almeida e Silva, J.; Lourenço, F.R. Development and optimization of beer containing malted and non-malted substitutes using quality by design (QbD) approach. J. Food Eng. 2020, 289, 110182. [Google Scholar] [CrossRef]

- Zayed, A.; Farag, M.A. Valorization, extraction optimization and technology advancements of artichoke biowastes: Food and non-food applications. Lwt 2020, 132, 109883. [Google Scholar] [CrossRef]

- Costa, L.B.M.; Godinho Filho, M.; Fredendall, L.D.; Ganga, G.M.D. The effect of Lean Six Sigma practices on food industry performance: Implications of the Sector’s experience and typical characteristics. Food Control 2020, 112, 107110. [Google Scholar] [CrossRef]

- Purwanto, A.; Asbari, M.; Santoso, P.B. Does Culture, Motivation, Competence, Leadership, Commitment Influence Quality Performance? Inovbiz J. Inov. Bisnis 2019, 7, 201. [Google Scholar] [CrossRef]

- Villalva-Catano, A.; Ramos-Palomino, E.; Provost, K.; Casal, E. A Model in Agri-Food Supply Chain Costing Using ABC Costing: An Empirical Research for Peruvian Coffee Supply Chain. In Proceedings of the 7th International Engineering, Sciences and Technology Conference (IESTEC), Panama City, Panama, 9–11 October 2019; pp. 1–6. [Google Scholar] [CrossRef]

- McCarl, B.A.; Yang, Y.; Schwabe, K.; Engel, B.A.; Mondal, A.H.; Ringler, C.; Pistikopoulos, E.N. Model Use in WEF Nexus Analysis: A Review of Issues. Curr. Sustain. Energy Rep. 2017, 4, 144–152. [Google Scholar] [CrossRef]

- Blanco-Portela, N.; R-Pertierra, L.; Benayas, J.; Lozano, R. Sustainability leaders’ perceptions on the drivers for and the barriers to the integration of sustainability in Latin American Higher Education Institutions. Sustainability 2018, 10, 2954. [Google Scholar] [CrossRef] [Green Version]

- Carvalho, A.M.; Sampaio, P.; Rebentisch, E.; Carvalho, J.Á.; Saraiva, P. The influence of operational excellence on the culture and agility of organizations: Evidence from industry. Int. J. Qual. Reliab. Manag. 2020, 38, 1520–1549. [Google Scholar] [CrossRef]

- Del Borghi, A.; Moreschi, L.; Gallo, M. Circular economy approach to reduce water-energy-food nexus. Curr. Opin. Environ. Sci. Health 2020, 13, 23–28. [Google Scholar] [CrossRef]

- Ingram, J.; Ajates, R.; Arnall, A.; Blake, L.; Borrelli, R.; Collier, R.; de Frece, A.; Häsler, B.; Lang, T.; Pope, H.; et al. A future workforce of food-system analysts. Nat. Food 2020, 1, 9–10. [Google Scholar] [CrossRef] [Green Version]

- Uhrin, A.; Bruque-Camara, S.; Moyano-Fuentes, J. Lean production, workforce development and operational performance. Manag. Decis. 2017, 55, 103–118. [Google Scholar] [CrossRef]

- Shuvo, S.D. Assessing food safety and associated food hygiene and sanitary practices in food industries: A cross-sectional study on biscuit industry of Bangladesh. Nutr. Food Sci. 2015, 45, 39–53. [Google Scholar] [CrossRef]

- Tomich, T.P.; Lidder, P.; Dijkman, J.; Coley, M.; Webb, P.; Gill, M. Agri-food systems in international research for development: Ten theses regarding impact pathways, partnerships, program design, and priority-setting for rural prosperity. Agric. Syst. 2019, 172, 101–109. [Google Scholar] [CrossRef]

- Argote, L.; Miron-Spektor, E. Organizational learning: From experience to knowledge. Organ. Sci. 2011, 22, 1123–1137. [Google Scholar] [CrossRef] [Green Version]

- Moore, A.A.; Weckauf, R.; Accouche, W.F.; Black, S.A. The value of consensus in rapid organisation assessment: Wildlife programmes and the Conservation Excellence Model. Total Qual. Manag. Bus. Excell. 2020, 31, 666–680. [Google Scholar] [CrossRef]

- Kafetzopoulos, D.; Gotzamani, K. Investigating the role of EFQM enablers in innovation performance. TQM J. 2019, 31, 239–256. [Google Scholar] [CrossRef]

- Kurian, M. Monitoring versus modelling of water–energy–food interactions: How place-based observatories can inform research for sustainable development. Curr. Opin. Environ. Sustain. 2020, 44, 35–41. [Google Scholar] [CrossRef]

- Aschemann-Witzel, J.; Giménez, A.; Ares, G. Convenience or price orientation? Consumer characteristics influencing food waste behaviour in the context of an emerging country and the impact on future sustainability of the global food sector. Glob. Environ. Chang. 2018, 49, 85–94. [Google Scholar] [CrossRef]

- Thrän, D.; Schaldach, R.; Millinger, M.; Wolf, V.; Arendt, O.; Ponitka, J.; Gärtner, S.; Rettenmaier, N.; Hennenberg, K.; Schüngel, J. The Milestones modeling framework: An integrated analysis of national bioenergy strategies and their global environmental impacts. Environ. Model. Softw. 2016, 86, 14–29. [Google Scholar] [CrossRef] [Green Version]

- Pashangpour, R.; Faghihi, F.; Soleymani, S. Optimized scheduling for electric lift trucks in a sugarcane agro-industry based on thermal, biomass and solar resources. Int. J. Environ. Sci. Technol. 2018, 15, 2349–2358. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, F.; Duan, L.; Yang, H.; Gao, J. Tetracycline adsorption onto rice husk ash, an agricultural waste: Its kinetic and thermodynamic studies. J. Mol. Liq. 2016, 222, 487–494. [Google Scholar] [CrossRef]

- Zou, Y.; Duan, X.; Xue, Z.; Mingju, E.; Sun, M.; Lu, X.; Jiang, M.; Yu, X. Water use conflict between wetland and agriculture. J. Environ. Manag. 2018, 224, 140–146. [Google Scholar] [CrossRef]

- Mo, J.; Yang, Q.; Zhang, N.; Zhang, W.; Zheng, Y.; Zhang, Z. A review on agro-industrial waste (AIW) derived adsorbents for water and wastewater treatment. J. Environ. Manag. 2018, 227, 395–405. [Google Scholar] [CrossRef] [PubMed]

- FAO; IFAD; WFP. Strengthening the Enabling Environment for Food Security and Nutrition; FAO: Rome, Italy, 2014. [Google Scholar]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Emanuelsson, A. The Methodology of the FAO Study: Global Food Losses and Food Waste—Extent, Causes and Prevention; SIK Report; FAO: Rome, Italy, 2011; Volume 2013. [Google Scholar]

- Sagbansua, L.; Balo, F. Ecological impact & financial feasibility of Energy Recovery (EIFFER) Model for natural insulation material optimization. Energy Build. 2017, 148, 1–14. [Google Scholar] [CrossRef]

- Ghedini, G.; Loreau, M.; White, C.R.; Marshall, D.J. Testing MacArthur’s minimisation principle: Do communities minimise energy wastage during succession? Ecol. Lett. 2018, 21, 1182–1190. [Google Scholar] [CrossRef]

- Pardo, J.E.; Zied, D.C.; Alvarez-Ortí, M.; Peñaranda, J.Á.; Gómez-Cantó, C.; Pardo-Giménez, A. Application of hazard analysis and critical control points (HACCP) to the processing of compost used in the cultivation of button mushroom. Int. J. Recycl. Org. Waste Agric. 2017, 6, 179–188. [Google Scholar] [CrossRef] [Green Version]

- Purwanto, A.; Putri, R.S.; Ahmad, A.H.; Asbari, M.; Bernarto, I.; Santoso, P.B.; Sihite, O.B. The effect of implementation integrated management system ISO 9001, ISO 14001, ISO 22000 and ISO 45001 on Indonesian food industries performance. Test Eng. Manag. 2020, 82, 14054–14069. [Google Scholar]

- Malavi, D.N.; Abong, G.O.; Muzhingi, T. Effect of food safety training on behavior change of food handlers: A case of orange-fleshed sweetpotato purée processing in Kenya. Food Control 2021, 119, 107500. [Google Scholar] [CrossRef]

- Rebentisch, E.; Prusak, L. Integrating Program Management and Systems Engineering: Methods, Tools, and Organizational Systems for Improving Performance; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Melnyk, S.A.; Sroufe, R.P.; Calantone, R. Assessing the impact of environmental management systems on corporate and environmental performance. J. Oper. Manag. 2003, 21, 329–351. [Google Scholar] [CrossRef]

- Reed, R.; Lemak, D.J.; Mero, N.P. Total quality management and sustainable competitive advantage. J. Qual. Manag. 2000, 5, 5–26. [Google Scholar] [CrossRef]

- Isaksson, R. Total quality management for sustainable development: Process based system models. Bus. Process Manag. J. 2006, 12, 632–645. [Google Scholar] [CrossRef]

- Klaus, J. Zink from total quality management to corporate sustainability based on a stakeholder management. J. Manag. Hist. 2007, 13, 394–401. [Google Scholar]

- Bastas, A.; Liyanage, K. Sustainable supply chain quality management: A systematic review. J. Clean. Prod. 2018, 181, 726–744. [Google Scholar] [CrossRef] [Green Version]

- Souza, J.P.E.; Alves, J.M. Lean-integrated management system: A model for sustainability improvement. J. Clean. Prod. 2018, 172, 2667–2682. [Google Scholar] [CrossRef]

- Chen, R.; Lee, Y.D.; Wang, C.H. Total quality management and sustainable competitive advantage: Serial mediation of transformational leadership and executive ability. Total Qual. Manag. Bus. Excell. 2020, 31, 451–468. [Google Scholar] [CrossRef]

- Abbas, J. Impact of total quality management on corporate sustainability through the mediating effect of knowledge management. J. Clean. Prod. 2020, 244, 118806. [Google Scholar] [CrossRef]

- Sampaio, P.; Saraiva, P.; Domingues, P. Management systems: Integration or addition? Int. J. Qual. Reliab. Manag. 2012, 29, 402–424. [Google Scholar] [CrossRef] [Green Version]

- Namagembe, S. Enhancing environmentally friendly practices in SME agri-food upstream chains. Int. J. Qual. Reliab. Manag. 2020, 38, 505–527. [Google Scholar] [CrossRef]

- Serhan, H.; Yannou-Lebris, G. The engineering of food with sustainable development goals: Policies, curriculums, business models, and practices. Int. J. Sustain. Eng. 2020, 14, 12–25. [Google Scholar] [CrossRef]

- Gaddis, J.E.; Jeon, J. Sustainability transitions in agri-food systems: Insights from South Korea’s universal free, eco-friendly school lunch program. Agric. Hum. Values 2020, 37, 1055–1071. [Google Scholar] [CrossRef]

- Cao, Y.; Tao, L.; Wu, K.; Wan, G. Coordinating joint greening efforts in an agri-food supply chain with environmentally sensitive demand. J. Clean. Prod. 2020, 277, 123883. [Google Scholar] [CrossRef]

- Fortunati, S.; Morea, D.; Mosconi, E.M. Circular economy and corporate social responsibility in the agricultural system: Cases study of the Italian agri-food industry. Agric. Econ. 2020, 66, 489–498. [Google Scholar] [CrossRef]

- Tortorella, M.M.; Di Leo, S.; Cosmi, C.; Fortes, P.; Viccaro, M.; Cozzi, M.; Pietrapertosa, F.; Salvia, M.; Romano, S. A methodological integrated approach to analyse climate change effects in agri-food sector: The TIMES water-energy-food module. Int. J. Environ. Res. Public Health 2020, 17, 7703. [Google Scholar] [CrossRef]

- Ngammuangtueng, P.; Jakrawatana, N.; Nilsalab, P.; Gheewala, S.H. Water, energy and food nexus in rice production in Thailand. Sustainability 2019, 11, 5852. [Google Scholar] [CrossRef] [Green Version]

- Seeliger, L.; De Clercq, W.P.; Hoffmann, W.; Cullis, J.D.S.; Horn, A.M.; De Witt, M. Applying the water-energy-food nexus to farm profitability in the middle breede catchment, South Africa. S. Afr. J. Sci. 2018, 114, 1–10. [Google Scholar] [CrossRef]

- De Castro Sobrosa Neto, R.; Berchin, I.I.; Magtoto, M.; Berchin, S.; Xavier, W.G.; de Andrade Guerra, J.B.S.O. An integrative approach for the water-energy-food nexus in beef cattle production: A simulation of the proposed model to Brazil. J. Clean. Prod. 2018, 204, 1108–1123. [Google Scholar] [CrossRef]

- Martinez-hernandez, E.; Samsatli, S. ScienceDirect Biorefineries and the food, energy, water nexus—Towards a whole systems approach to design and planning. Curr. Opin. Chem. Eng. 2017, 18, 16–22. [Google Scholar] [CrossRef]

- Sandhu, M.A.; Ahm Shamsuzzoha, P.H. Business excellence in a volatile, uncertain, complex and ambiguous environment (BEVUCA). TQM J. 2016, 34, 1–5. [Google Scholar] [CrossRef]