Unlocking Barriers to Circular Economy: An ISM-Based Approach to Contextualizing Dependencies

Abstract

:1. Introduction

How can interpretive structural modelling be used as an approach to contextualize barrier interdependencies toward a circular economy?

2. Theoretical Background

2.1. Context-Dependency of CE Barriers

2.2. Interpretive Structural Modelling in a CE Context

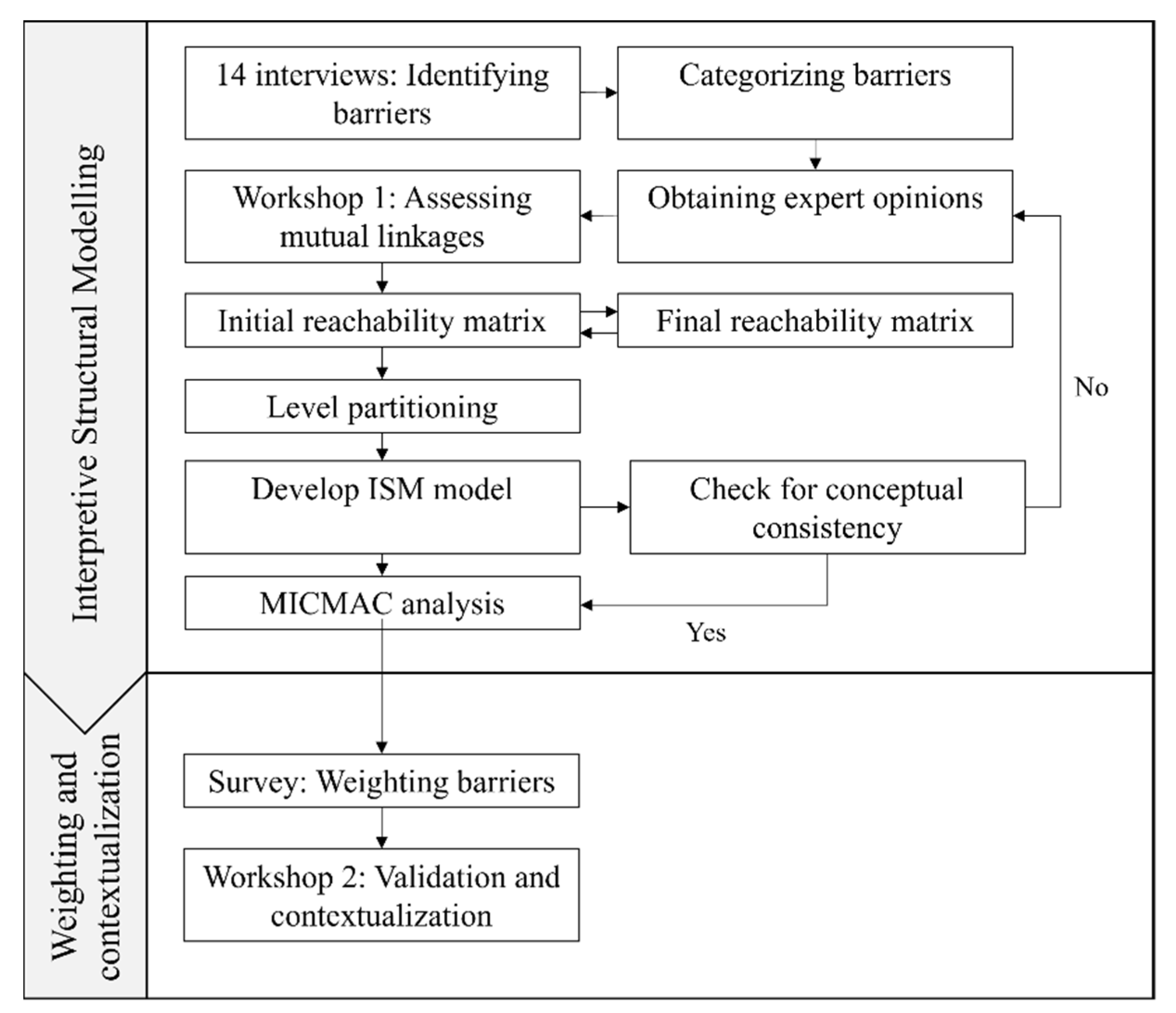

3. Empirical Foundation and Methods

3.1. Step 1: Identifying Barriers and Mutual Dependencies

3.2. Step 2: Weighting and Contextualization

4. Model Development

4.1. Identifying Barriers

4.2. Structural Self-Interaction Matrix

4.3. Reachability Matrix

- If the (i,j) entry in the SSIM is V, then the (i,j) entry in the reachability matrix becomes 1, and the (j,i) entry becomes 0.

- If the (i,j) entry in the SSIM is A, then the (i,j) entry in the reachability matrix becomes 0, and the (j,i) entry becomes 1.

- If the (i,j) entry in the SSIM is X, then the (i,j) entry in the reachability matrix becomes 1, and the (j,i) entry becomes 1.

- If the (i,j) entry in the SSIM is O, then the (i,j) entry in the reachability matrix becomes 0, and the (j,i) entry becomes 0.

4.4. Partitioning into Levels

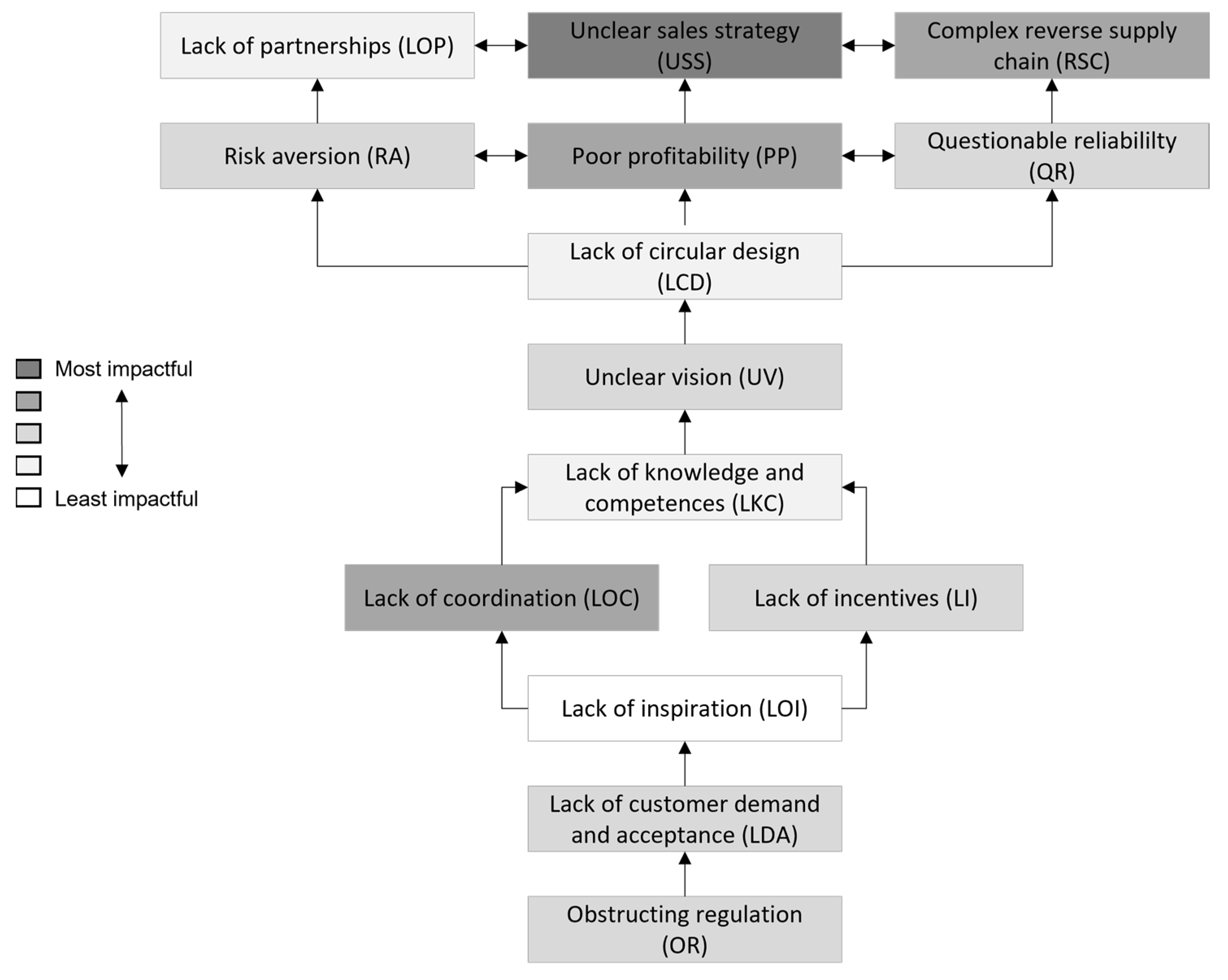

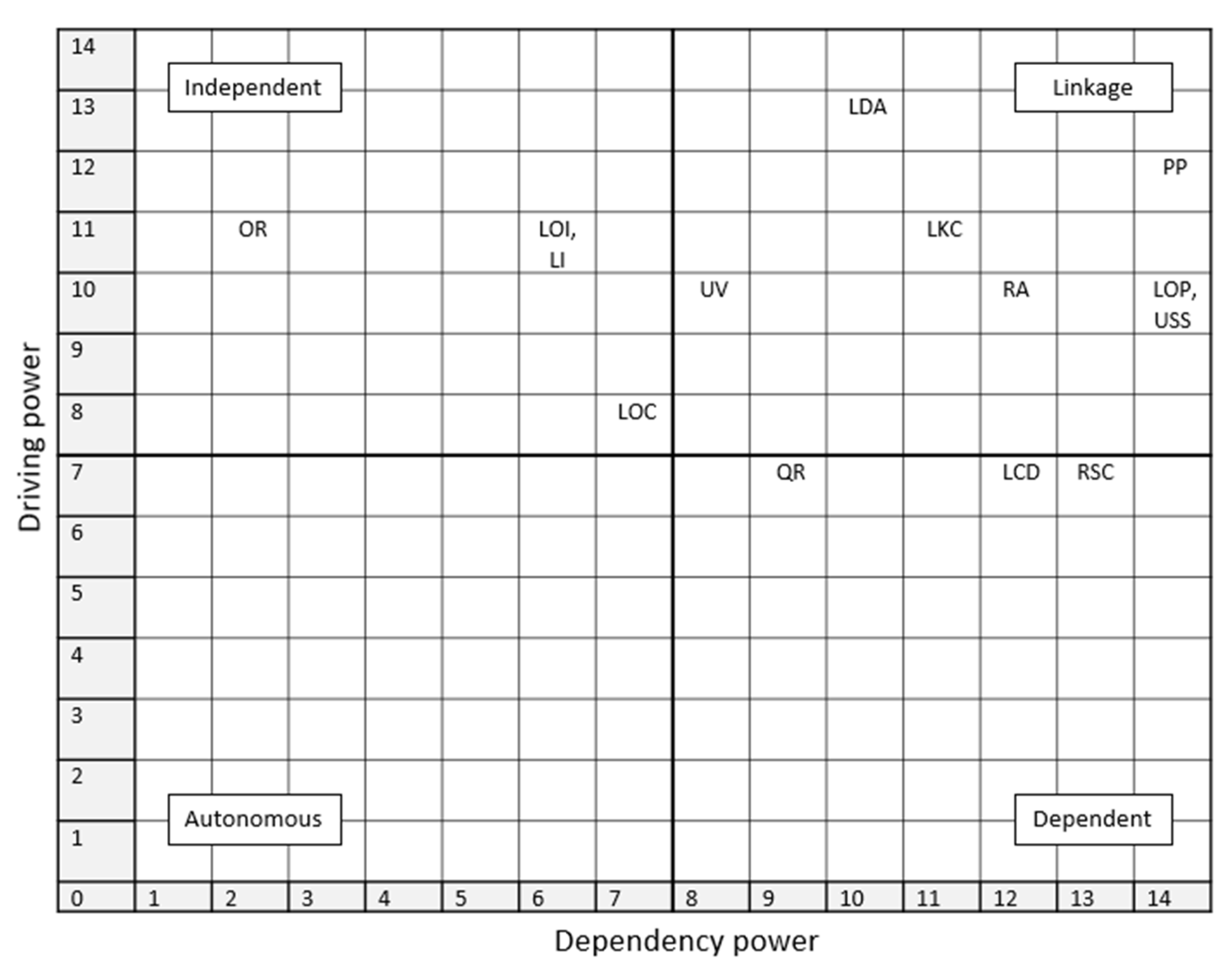

4.5. MICMAC Analysis

5. Results

6. Discussion

6.1. Managerial Implications

6.2. Academic Contribution

7. Conclusions and Limitations

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef] [Green Version]

- Geissdoerfer, M.; Pieroni, M.P.; Pigosso, D.C.; Soufani, K. Circular business models: A review. J. Clean. Prod. 2020, 277, 123741. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Z.; Bi, J.; Moriguichi, Y. The Circular Economy: A New Development Strategy in China. J. Ind. Ecol. 2006, 10, 4–8. [Google Scholar] [CrossRef] [Green Version]

- European Commission. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe; 98 Final; European Commission: Brussels, Belgium, 2020.

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Business model innovation for circular economy and sustainability: A review of approaches. J. Clean. Prod. 2019, 215, 198–216. [Google Scholar] [CrossRef]

- Lahti, T.; Wincent, J.; Parida, V. A definition and theoretical review of the circular economy, value creation, and sustainable business models: Where are we now and where should research move in the future? Sustainability 2018, 10, 2799. [Google Scholar] [CrossRef] [Green Version]

- Uhrenholt, J.N.; Kristensen, J.H.; Rincón, M.C.; Jensen, S.F.; Waehrens, B.V. Circular economy: Factors affecting the financial performance of product take-back systems. J. Clean. Prod. 2022, 335, 130319. [Google Scholar] [CrossRef]

- Duflou, J.R.; Sutherland, J.W.; Dornfeld, D.; Herrmann, C.; Jeswiet, J.; Kara, S.; Hauschild, M.Z.; Kellens, K. Towards energy and resource efficient manufacturing: A processes and systems approach. CIRP Ann. 2012, 61, 587–609. [Google Scholar] [CrossRef] [Green Version]

- Govindan, K.; Hasanagic, M. A systematic review on drivers, barriers, and practices towards circular economy: A supply chain perspective. Int. J. Prod. Res. 2017, 56, 278–311. [Google Scholar] [CrossRef]

- Ayati, S.M.; Shekarian, E.; Majava, J.; Wæhrens, B.V. Toward a circular supply chain: Understanding barriers from the perspective of recovery approaches. J. Clean. Prod. 2022, 359, 131775. [Google Scholar] [CrossRef]

- Urbinati, A.; Franzò, S.; Chiaroni, D. Enablers and Barriers for Circular Business Models: An empirical analysis in the Italian automotive industry. Sustain. Prod. Consum. 2021, 27, 551–566. [Google Scholar] [CrossRef]

- de Jesus, A.; Mendonça, S. Lost in Transition? Drivers and Barriers in the Eco-innovation Road to the Circular Economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef] [Green Version]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef] [Green Version]

- Grafström, J.; Aasma, S. Breaking circular economy barriers. J. Clean. Prod. 2021, 292, 126002. [Google Scholar] [CrossRef]

- Attri, R.; Dev, N.; Sharma, V. Interpretive Structural Modelling (ISM) approach: An Overview. Res. J. Manag. Sci. 2013, 2, 3–8. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Guldmann, E.; Huulgaard, R.D. Barriers to circular business model innovation: A multiple-case study. J. Clean. Prod. 2019, 243, 118160. [Google Scholar] [CrossRef]

- García-Quevedo, J.; Jové-Llopis, E.; Martínez-Ros, E. Barriers to the circular economy in European small and medium-sized firms. Bus. Strat. Environ. 2020, 29, 2450–2464. [Google Scholar] [CrossRef]

- Ormazabal, M.; Prieto-Sandoval, V.; Puga-Leal, R.; Jaca, C. Circular Economy in Spanish SMEs: Challenges and opportunities. J. Clean. Prod. 2018, 185, 157–167. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; Van Der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of Circular Economy Business Models by Small and Medium-Sized Enterprises (SMEs): Barriers and Enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef] [Green Version]

- Kumar, V.; Sezersan, I.; Garza-Reyes, J.A.; Gonzalez, E.D.; Al-Shboul, M.A. Circular economy in the manufacturing sector: Benefits, opportunities and barriers. Manag. Decis. 2019, 57, 1067–1086. [Google Scholar] [CrossRef] [Green Version]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F. Heavy vehicles on the road towards the circular economy: Analysis and comparison with the automotive industry. Resour. Conserv. Recycl. 2018, 135, 108–122. [Google Scholar] [CrossRef]

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hvass, K.K.; Pedersen, E.R.G. Toward circular economy of fashion: Experiences from a brand’s product take-back initiative. J. Fash. Mark. Manag. Int. J. 2019, 23, 345–365. [Google Scholar]

- Jia, F.; Yin, S.; Chen, L.; Chen, X. The circular economy in the textile and apparel industry: A systematic literature review. J. Clean. Prod. 2020, 259, 120728. [Google Scholar] [CrossRef]

- Ahmad, N.; Qahmash, A. SmartISM: Implementation and Assessment of Interpretive Structural Modeling. Sustainability 2021, 13, 8801. [Google Scholar] [CrossRef]

- Sharma, S.K.; Panda, B.N.; Mahapatra, S.S.; Sahu, S. Analysis of Barriers for Reverse Logistics: An Indian Perspective. Int. J. Model. Optim. 2011, 1, 101–106. [Google Scholar] [CrossRef]

- Bilal, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R. Current state and barriers to the circular economy in the building sector: Towards a mitigation framework. J. Clean. Prod. 2020, 276, 123250. [Google Scholar] [CrossRef]

- Manoharan, S.; Pulimi, V.S.K.; Kabir, G.; Ali, S.M. Contextual relationships among drivers and barriers to circular economy: An integrated ISM and DEMATEL approach. Sustain. Oper. Comput. 2021, 3, 43–53. [Google Scholar] [CrossRef]

- Patel, M.N.; Pujara, A.A.; Kant, R.; Malviya, R.K. Assessment of circular economy enablers: Hybrid ISM and fuzzy MICMAC approach. J. Clean. Prod. 2021, 317, 128387. [Google Scholar] [CrossRef]

- Kumar, S.; Raut, R.D.; Nayal, K.; Kraus, S.; Yadav, V.S.; Narkhede, B.E. To identify industry 4.0 and circular economy adoption barriers in the agriculture supply chain by using ISM-ANP. J. Clean. Prod. 2021, 293, 126023. [Google Scholar] [CrossRef]

- Pham, T.T.; Kuo, T.-C.; Tseng, M.-L.; Tan, R.R.; Tan, K.; Ika, D.S.; Lin, C.J. Industry 4.0 to Accelerate the Circular Economy: A Case Study of Electric Scooter Sharing. Sustainability 2019, 11, 6661. [Google Scholar] [CrossRef] [Green Version]

- Rajput, S.; Singh, S.P. Industry 4.0—Challenges to implement circular economy. Benchmarking Int. J. 2019, 28, 1717–1739. [Google Scholar] [CrossRef]

- Abdul-Hamid, A.-Q.; Ali, M.H.; Tseng, M.-L.; Lan, S.; Kumar, M. Impeding challenges on industry 4.0 in circular economy: Palm oil industry in Malaysia. Comput. Oper. Res. 2020, 123, 105052. [Google Scholar] [CrossRef]

- Nika, C.-E.; Expósito, A.; Kisser, J.; Bertino, G.; Oral, H.V.; Dehghanian, K.; Vasilaki, V.; Iacovidou, E.; Fatone, F.; Atanasova, N.; et al. Validating Circular Performance Indicators: The Interface between Circular Economy and Stakeholders. Water 2021, 13, 2198. [Google Scholar] [CrossRef]

- Govindan, K.; Palaniappan, M.; Zhu, Q.; Kannan, D. Analysis of third party reverse logistics provider using interpretive structural modeling. Int. J. Prod. Econ. 2012, 140, 204–211. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods; SAGE: Newcastle upon Tyne, UK, 2009. [Google Scholar]

- Mura, M.; Longo, M.; Zanni, S. Circular economy in Italian SMEs: A multi-method study. J. Clean. Prod. 2019, 245, 118821. [Google Scholar] [CrossRef]

- Gravagnuolo, A.; Angrisano, M.; Girard, L.F. Circular Economy Strategies in Eight Historic Port Cities: Criteria and Indicators towards a Circular City Assessment Framework. Sustainability 2019, 11, 3512. [Google Scholar] [CrossRef] [Green Version]

- Chouinard, U.; Pigosso, D.C.; McAloone, T.C.; Baron, L.; Achiche, S. Potential of circular economy implementation in the mechatronics industry: An exploratory research. J. Clean. Prod. 2019, 239, 118014. [Google Scholar] [CrossRef]

- Taherdoost, H. Sampling Methods in Research Methodology; How to Choose a Sampling Technique for Research. SSRN Electron. J. 2016, 5, 18–27. [Google Scholar] [CrossRef]

- Warfield, J.N. Developing Interconnection Matrices in Structural Modeling. IEEE Trans. Syst. Man Cybern. 1974, SMC-4, 81–87. [Google Scholar] [CrossRef] [Green Version]

- Malone, D. An introduction to the application of interpretive structural modeling. Proc. IEEE 1975, 63, 397–404. [Google Scholar] [CrossRef]

- Abuzeinab, A.; Arif, M.; Qadri, M.A. Barriers to MNEs green business models in the UK construction sector: An ISM analysis. J. Clean. Prod. 2017, 160, 27–37. [Google Scholar] [CrossRef]

- Boer, H.; Holweg, M.; Kilduff, M.; Pagell, M.; Schmenner, R.W.; Voss, C. Making a meaningful contribution to theory. Int. J. Oper. Prod. Manag. 2015, 35, 1231–1252. [Google Scholar] [CrossRef] [Green Version]

- Desing, H.; Brunner, D.; Takacs, F.; Nahrath, S.; Frankenberger, K.; Hischier, R. A circular economy within the planetary boundaries: Towards a resource-based, systemic approach. Resour. Conserv. Recycl. 2020, 155, 104673. [Google Scholar] [CrossRef]

- Ravi, V.; Shankar, R. Analysis of interactions among the barriers of reverse logistics. Technol. Forecast. Soc. Chang. 2005, 72, 1011–1029. [Google Scholar] [CrossRef]

- Makki, A.; Alidrisi, H.; Iqbal, A.; Al-Sasi, B. Barriers to Green Entrepreneurship: An ISM-Based Investigation. J. Risk Financ. Manag. 2020, 13, 249. [Google Scholar] [CrossRef]

- Uhrenholt, J.N.; Kristensen, J.H.; Rincón, M.C.; Adamsen, S.; Jensen, S.F.; Waehrens, B.V. Maturity Model as a Driver for Circular Economy Transformation. Sustainability 2022, 14, 7483. [Google Scholar] [CrossRef]

| Characteristics | |

|---|---|

| Size (employees) | 35,000+ |

| Industry | Mechatronics |

| Business model | Product-based |

| Customer segment | Industrial |

| Production strategy | Manufacture-to-order |

| Product customization | Functional customization |

| Product value | High |

| Product lifetime | 10–15 years |

| Participants for Data Collection | |||||

|---|---|---|---|---|---|

| Title | Experience | Interview | Workshop 1 | Survey | Workshop 2 |

| Vice President | 15+ years | X | X | X | X |

| Senior Director (Engineering) | 15+ years | X | X | X | X |

| Standardization Manager | 0–5 years | X | X | X | X |

| People Leader | 15+ years | X | X | ||

| Head of Mechanics | 5–15 years | X | X | X | |

| Senior Director (Quality) | 15+ years | X | |||

| Head of Global Sales | 15+ years | X | |||

| Head of Sales (Marketing) | 5–15 years | X | |||

| Engineering Director | 5–15 years | X | X | ||

| Process Excellence Manager | 5–15 years | X | |||

| Senior Manager | 15+ years | X | X | X | |

| Project Manager | 5–15 years | X | X | X | X |

| Project Manager | 5–15 years | X | X | X | |

| Cluster | Barrier | Description |

|---|---|---|

| Managerial | Risk aversion (RA) | Managers are inclined to favor a complete overview of the circular transition. As this overview is often absent due to high uncertainties, managers are hesitant to take risks. |

| Lack of internal coordination (LOC) | The ability to effectively undertake a circular transition requires a coordinative effort across functions, including but not limited to service centers, logistics, production, quality, and sales. This has proven particularly challenging. | |

| Lack of inspiration (LOI) | As CE is new to the case company, they are actively seeking inspiration from other companies. However, demonstration projects are scarce. | |

| Unclear visions (UV) | Circular economy has caught the awareness of the case company. Yet, visions for the transition are unclear. | |

| Lack of knowledge and competences (LKC) | Employees experience a lack of knowledge about the principles of a circular economy as well as the competences to integrate them into their daily operations. | |

| Market | Lack of partnerships (LOP) | The case company acknowledges that a circular transition requires partnerships with customers, suppliers, third-party service partners, and/or waste handlers as well as universities in ways that differ from past collaborative efforts. However, little is known about the required capabilities from partners. |

| Unclear sales strategy (USS) | Selling refurbished products is difficult due to fluctuating availability. As the product return flow is unstable, availability of products cannot be guaranteed. Furthermore, questions are raised concerning sales channels. | |

| Lack of customer demand and acceptance (LDA) | Customer demand remains weak. Furthermore, it is questionable as to what degree customers are willing to accept changes, e.g., for the visual appearance of refurbished products. | |

| Financial | Poor profitability (PP) | It is difficult for a take-back program to generate a profitable business case in the short term. Long-term profitability is considered probable but with high uncertainty. |

| Technical | Complex reverse supply chain (RSC) | Complexity of developing a reverse supply chain is high due to difficulties of acquiring products as well as product disassembly. |

| Lack of circular design (LCD) | As products on the market have not been designed for a circular economy, disassembly of products is significantly hampered. | |

| Questionable reliability (QR) | As the case company produces high-quality products, concerns are raised about the reliability of refurbished products. | |

| Regulative | Obstructing regulation (OR) | Obstructing regulation hampers take-back. To exemplify, end-of-life products are sometimes considered waste, which makes it difficult to import/export across borders. |

| Lack of incentives (LI) | Few incentives are provided by national or international regulations. |

| LI | OR | QR | LCD | RSC | PP | LDA | USS | LOP | LKC | UV | LOI | LOC | RA | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA | A | A | X | O | X | X | X | X | V | X | X | X | A | |

| LOC | O | O | O | V | X | X | A | V | X | V | A | A | ||

| LOI | O | O | V | V | V | V | A | V | X | X | X | |||

| UV | A | O | O | V | V | X | A | X | V | X | ||||

| LKC | A | A | V | V | V | X | X | X | X | |||||

| LOP | X | A | A | X | X | X | X | X | ||||||

| USS | X | A | A | X | X | X | X | |||||||

| LDA | V | A | X | X | X | X | ||||||||

| PP | X | A | X | X | X | |||||||||

| RSC | A | A | O | A | ||||||||||

| LCD | A | A | X | |||||||||||

| QR | A | A | ||||||||||||

| OR | X | |||||||||||||

| LI |

| LI | OR | QR | LCD | RSC | PP | LDA | USS | LOP | LKC | UV | LOI | LOC | RA | Driv. Power | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 10 |

| LOC | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 8 |

| LOI | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 11 |

| UV | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 10 |

| LKC | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 11 |

| LOP | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 10 |

| USS | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 10 |

| LDA | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 13 |

| PP | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 12 |

| RSC | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 7 |

| LCD | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 7 |

| QR | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 7 |

| OR | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 11 |

| LI | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 11 |

| Depend. Power | 6 | 2 | 9 | 12 | 13 | 14 | 10 | 14 | 14 | 11 | 8 | 6 | 7 | 12 |

| LI | OR | QR | LCD | RSC | PP | LDA | USS | LOP | LKC | UV | LOI | LOC | RA | Driv. Power | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA | 1 * | 1 * | 1 | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 | 14 |

| LOC | 1 * | 1 * | 1 * | 1 | 1 | 1 | 1 * | 1 | 1 | 1 | 1 * | 1 * | 1 | 1 | 14 |

| LOI | 1 * | 1 * | 1 | 1 | 1 | 1 | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 14 |

| UV | 1 * | 1 * | 1 * | 1 | 1 | 1 | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 14 |

| LKC | 1 * | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 | 14 |

| LOP | 1 | 1 * | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 | 1 | 1 * | 14 |

| USS | 1 | 1 * | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 | 14 |

| LDA | 1 | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 14 |

| PP | 1 | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 | 1 | 14 |

| RSC | 1 * | 1 * | 1 * | 1 * | 1 | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 * | 1 | 1 | 14 |

| LCD | 1 * | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 * | 1 * | 1 * | 14 |

| QR | 1 * | 1 * | 1 | 1 | 1 * | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 * | 1 * | 1 | 14 |

| OR | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 * | 1 | 14 |

| LI | 1 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 | 14 |

| Depend. Power | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 |

| Barriers | Reachability | Antecedent | Intersection | Level |

|---|---|---|---|---|

| RA | RA,QR,RSC,PP,LDA, USS,LOP,LKC,UV,LOI | RA,LOC,LOI,UV,LKC,USS, LDA,PP,RSC,QR,OR,LI | RA,QR,RSC,PP,LDA, USS,LKC,UV,LOI | II |

| LOC | LOC,LCD,RSC,PP,USS, LOP,LKC,RA | LOC,LOI,UV,LOP,LDA,PP, RSC | LOC,RSC,PP,LOP | VI |

| LOI | LOI,QR,LCD,RSC,PP, USS,LOP,LKC,UV, LOC,RA | LOI,RA,UV,LKC,LDA | LOI,LKC,UV,RA | VI |

| UV | UV,LCD,RSC,PP,USS, LOP,LKC,LOI,LOC,RA | UV,RA,LOI,LKC,USS,LDA, PP,LI | UV,PP,USS,LKC,UV, LOI,RA | IV |

| LKC | LKC,QR,LCD,RSC,PP, LDA,USS,LOP,UV,LOI, RA | LKC,RA,LOC,LOI,UV,LOP, USS,LDA,PP,OR,LI | LKC,PP,USS,LOP,UV, LOI,RA | V |

| LOP | LOP,LI,LCD,RSC,PP, LDA,USS,LKC,LOI,LOC, RA | LOP,RA,LOC,LOI,UV,LKC, USS,LDA,PP,RSC,LCD,QR, OR,LI | LOP,LI,LCD,RSC,PP, LDA,USS,LKC,LOI, LOC,RA | I |

| USS | USS,LI,LCD,RSC,PP, LDA,LOP,LKC,UV,RA | USS,RA,LOC,LOI,UV,LKC, LOP,LDA,PP,RSC,LCD,QR, OR,LI | USS,LI,LCD,RSC,PP, LDA,LOP,LKC,UV,RA | I |

| LDA | LDA,LI,QR,LCD,RSC,PP, USS,LOP,LKC,UV,LOI, LOC,RA | LDA,RA,LKC,LOP,USS,PP, RSC,LCD,QR,OR,LI | LDA,LI,QR,LCD,RSC, PP,USS,LOP,LKC,RA | VIII |

| PP | PP,LI,QR,LCD,RSC,LDA, USS,LOP,LKC,UV,LOC, RA | PP,RA,LOC,LOI,UV,LKC, LOP,USS,LDA,RSC,LCD, QR,OR,LI | PP,LI,QR,LCD,RSC, LDA,USS,LOP,LKC,UV, LOC,RA | II |

| RSC | RSC,PP,LDA,USS,LOP, LOC,RA | RSC,RA,LOC,LOI,UV,LKC, LOP,USS,LDA,PP,LCD,OR, LI | RSC,PP,LDA,USS,LOP, LOC,RA | I |

| LCD | LCD,QR,RSC,PP,LDA, USS,LOP | LCD,LOC,LOI,UV,LKC, LOP,USS,LDA,QR,OR,LI | LCD,QR,LDA,USS,LOP | III |

| QR | QR,LCD,PP,LDA,USS, LOP,RA | QR,RA,LOI,LKC,LDA,PP, LCD,OR,LI | QR,LCD,PP,LDA,RA | II |

| OR | OR,LI,QR,LCD,RSC,PP, LDA,USS,LOP,LKC,RA, | OR,LI | OR,LI | IX |

| LI | LI,OR,QR,LCD,RSC,PP, USS,LOP,LKC,UV,RA | LI,LOP,UDD,LFS,PP,OR | LI,OR,PP,USS,LOP | VII |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jensen, S.F.; Kristensen, J.H.; Uhrenholt, J.N.; Rincón, M.C.; Adamsen, S.; Waehrens, B.V. Unlocking Barriers to Circular Economy: An ISM-Based Approach to Contextualizing Dependencies. Sustainability 2022, 14, 9523. https://doi.org/10.3390/su14159523

Jensen SF, Kristensen JH, Uhrenholt JN, Rincón MC, Adamsen S, Waehrens BV. Unlocking Barriers to Circular Economy: An ISM-Based Approach to Contextualizing Dependencies. Sustainability. 2022; 14(15):9523. https://doi.org/10.3390/su14159523

Chicago/Turabian StyleJensen, Steffen Foldager, Jesper Hemdrup Kristensen, Jonas Nygaard Uhrenholt, Maria Camila Rincón, Sofie Adamsen, and Brian Vejrum Waehrens. 2022. "Unlocking Barriers to Circular Economy: An ISM-Based Approach to Contextualizing Dependencies" Sustainability 14, no. 15: 9523. https://doi.org/10.3390/su14159523

APA StyleJensen, S. F., Kristensen, J. H., Uhrenholt, J. N., Rincón, M. C., Adamsen, S., & Waehrens, B. V. (2022). Unlocking Barriers to Circular Economy: An ISM-Based Approach to Contextualizing Dependencies. Sustainability, 14(15), 9523. https://doi.org/10.3390/su14159523