Explaining the Differences between the Environmental Impacts of 44 French Artisanal Cheeses

Abstract

:1. Introduction

2. Materials and Methods

2.1. Goal and Scope

2.1.1. Product Selection

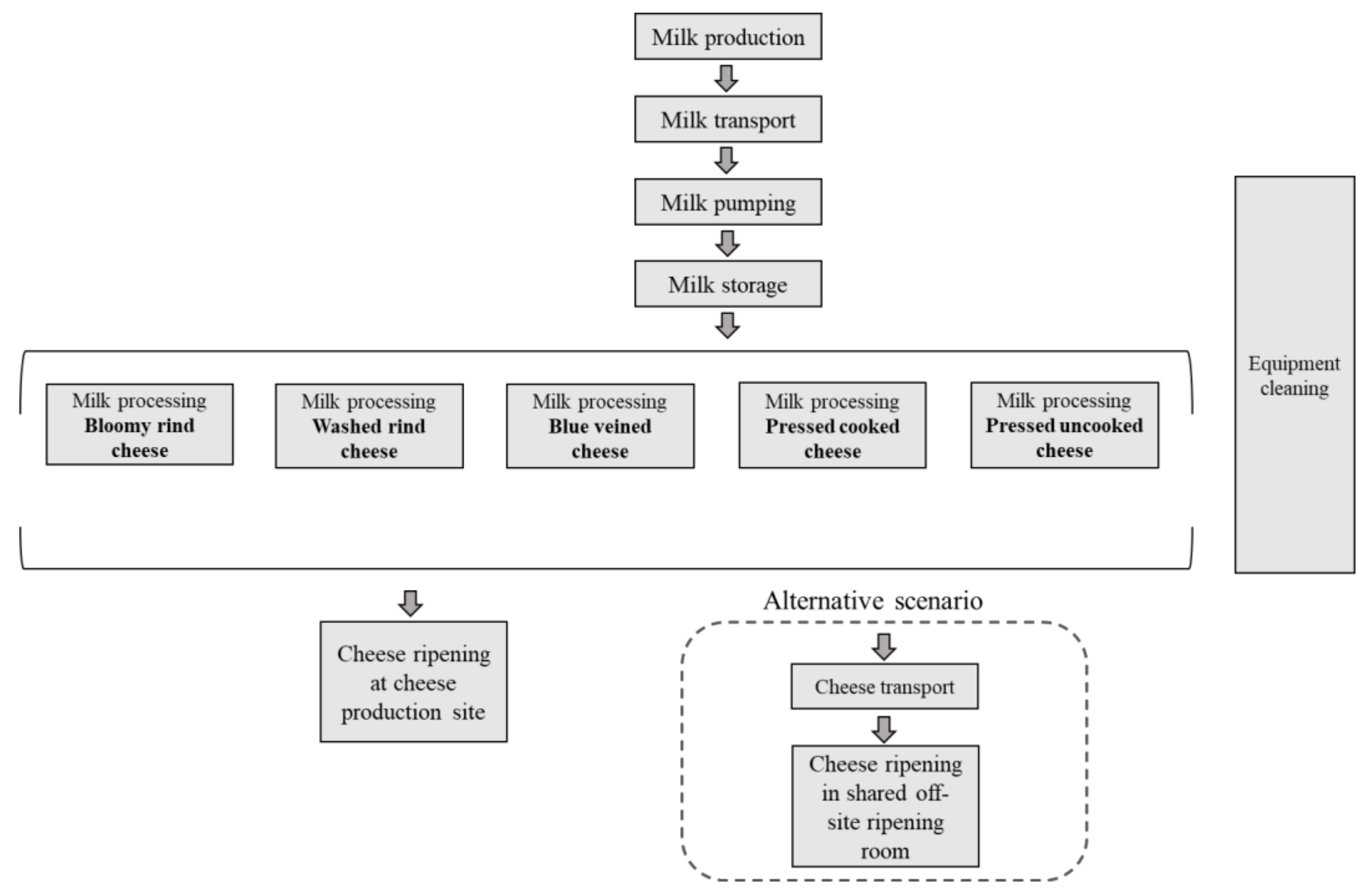

2.1.2. System Boundaries

2.1.3. Functional Unit

2.2. Inventory Analysis

2.2.1. Data Collection

2.2.2. Dry Matter Basis Allocation

2.3. Life Cycle Impact Assessment

2.4. Interpretation of Results

3. Results and Discussion

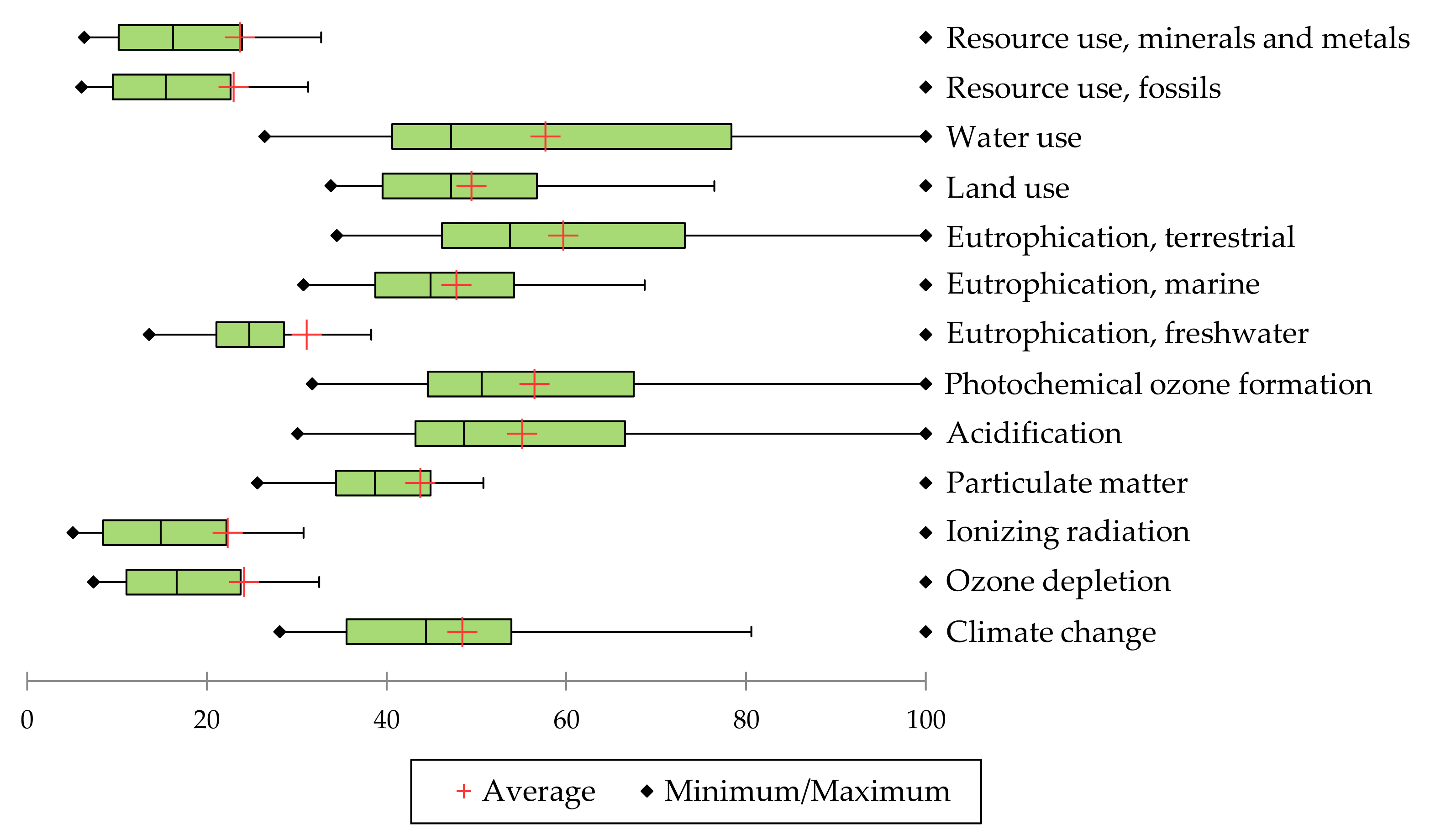

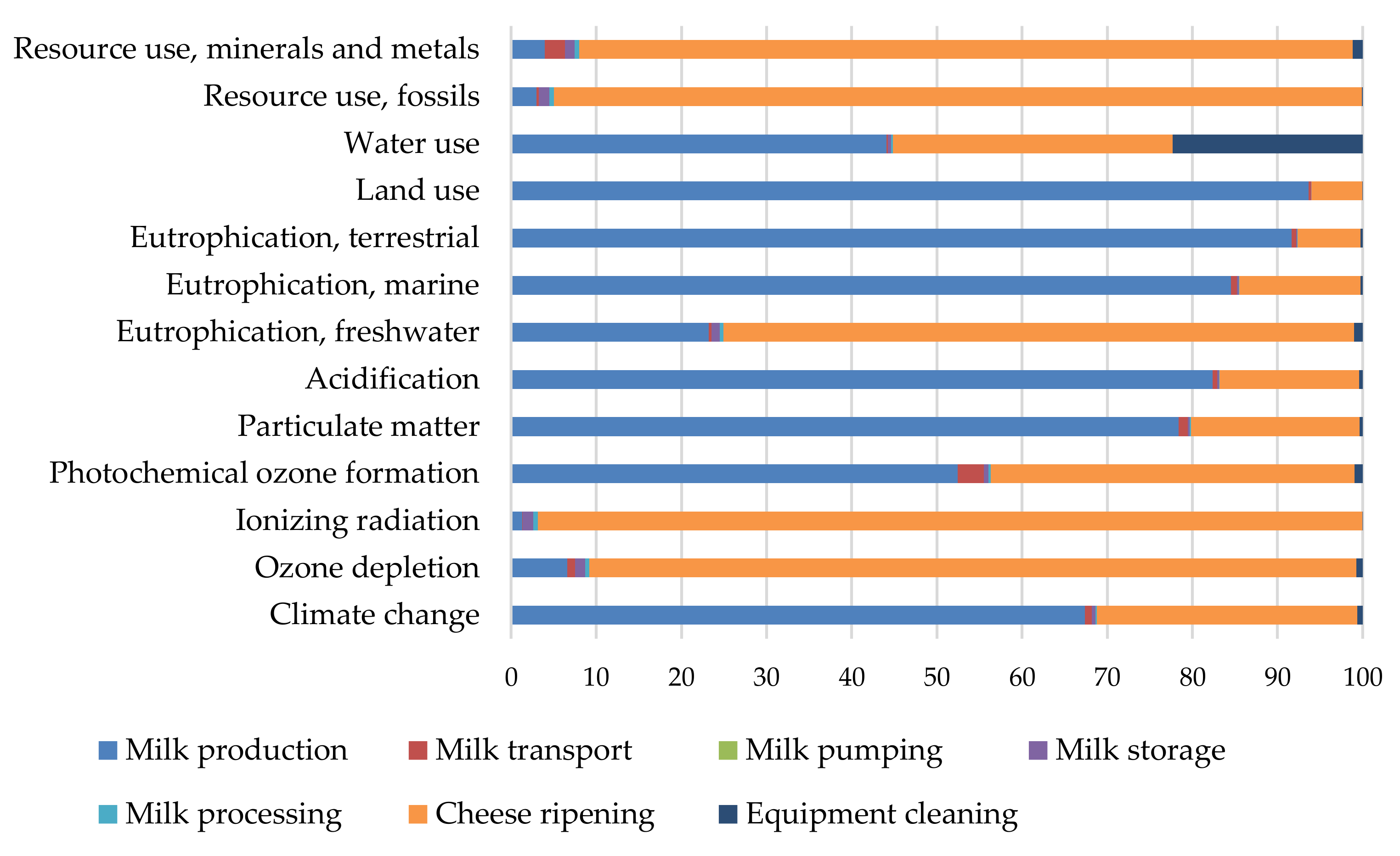

3.1. Base Scenario—Analysis of Environmental Impacts Variability, Identification of Hotspots

3.2. Alternative Scenario—Analysis of Environmental Impacts Variability, Identification of Hotspots

3.3. Comparative Analysis of the Base and Alternative Scenarios

3.4. Influence of Cheese Characteristics on Environmental Impacts

3.4.1. Base Scenario—Influence of Qualitative Characteristics of Cheeses on Their Environmental Impacts

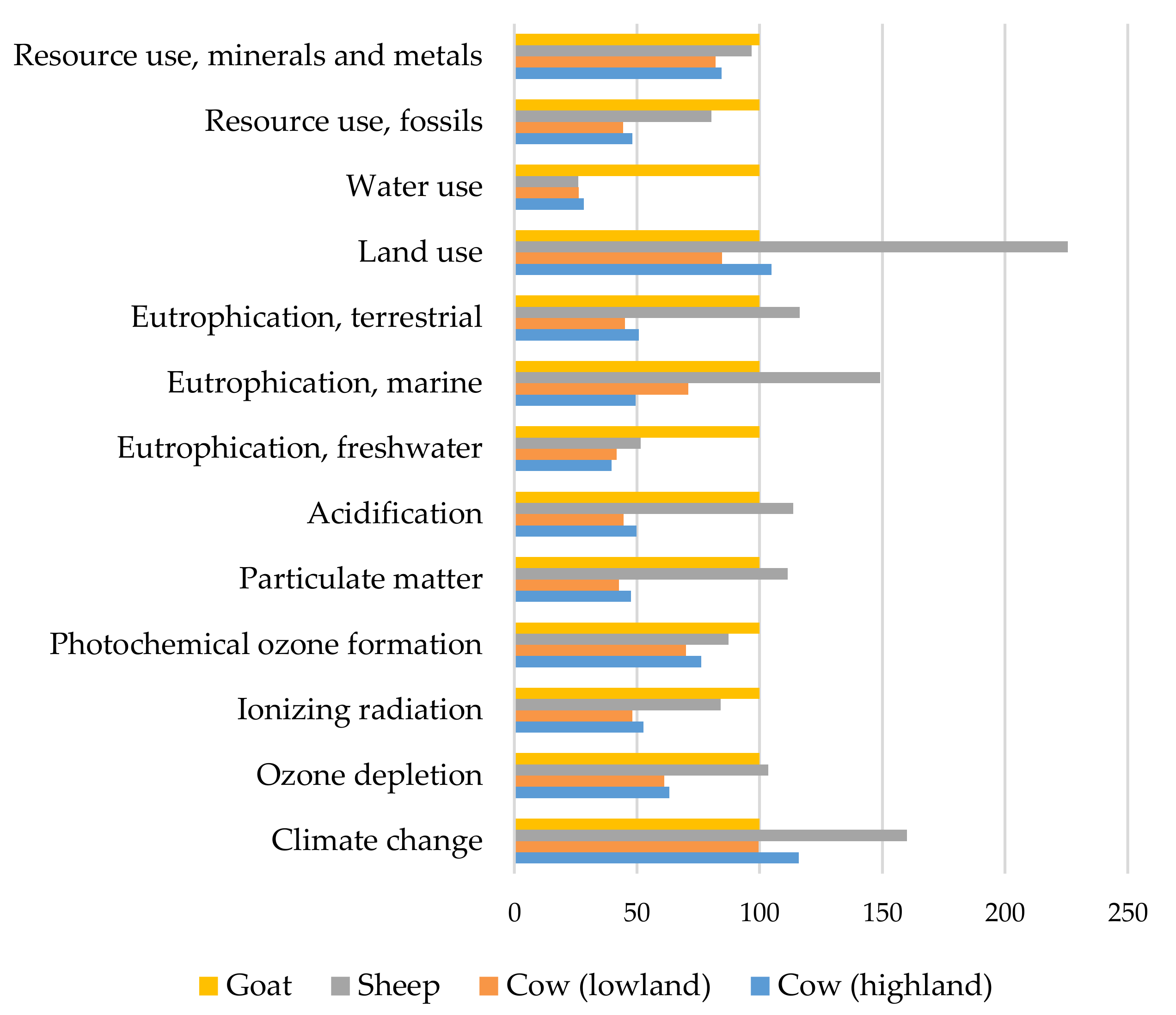

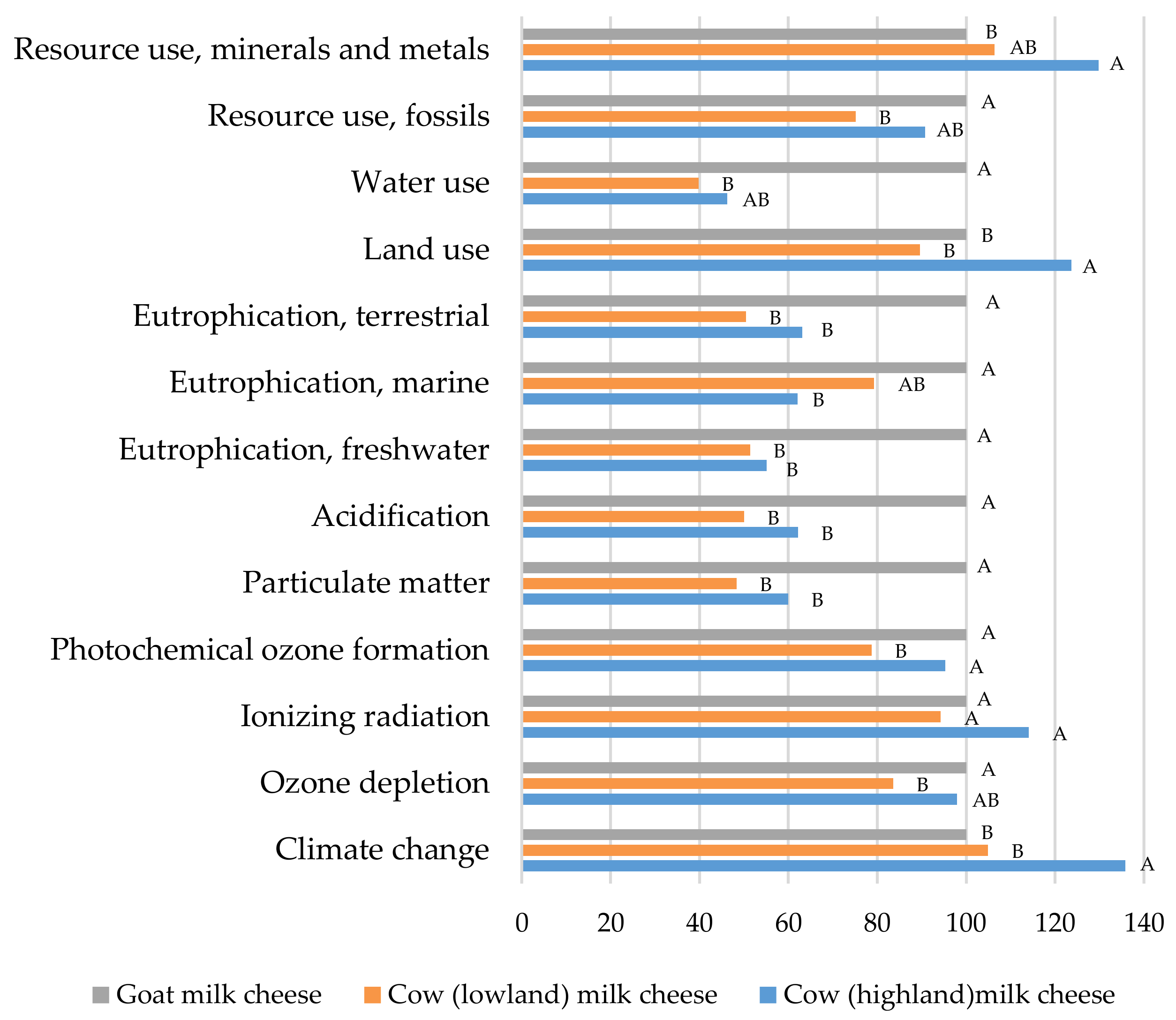

Comparison of the Environmental Impacts of Cheeses Made from Different Types of Milk

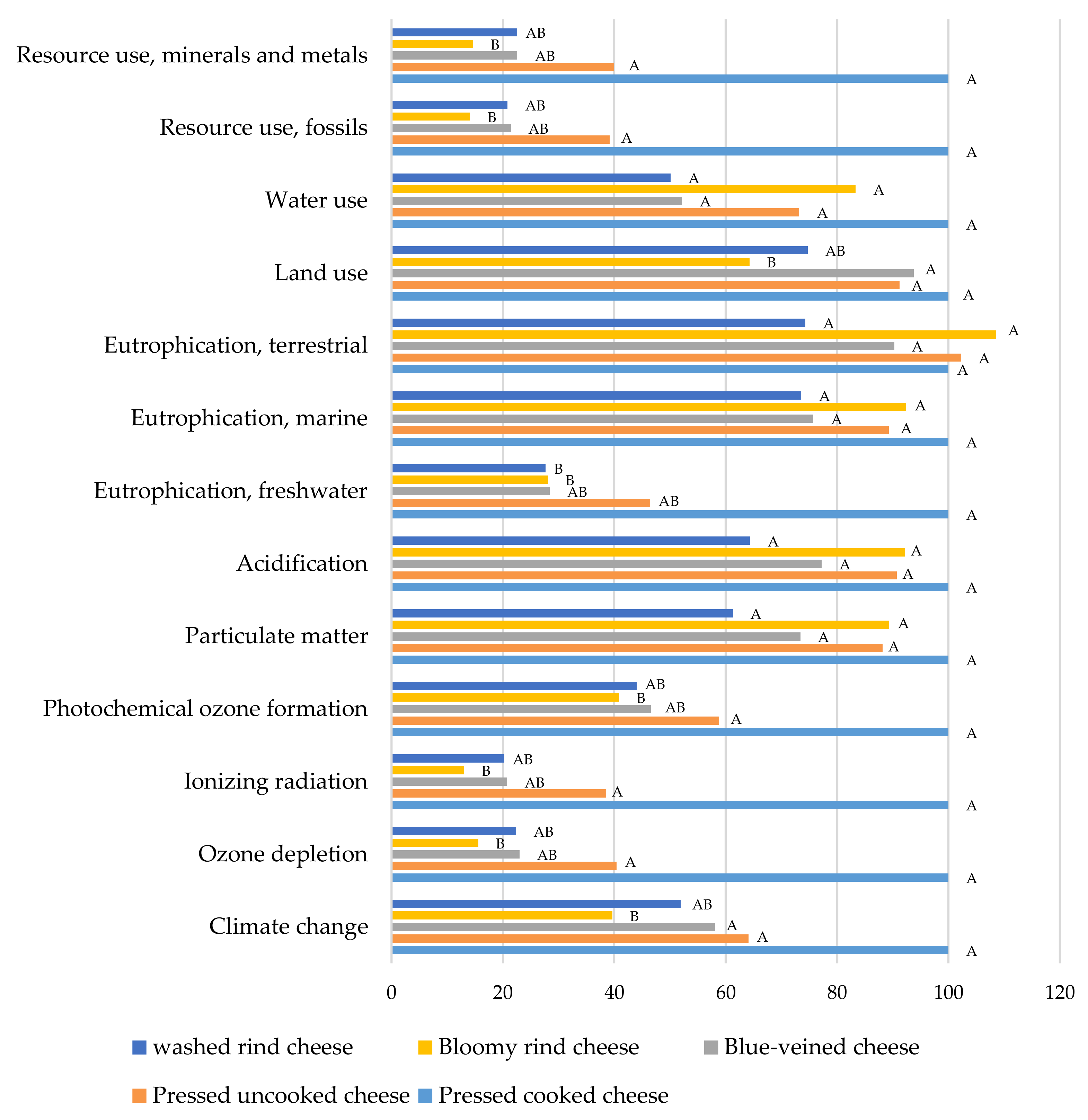

Comparison of the Environmental Impact of Cheeses Made Using Different Cheese Technologies

3.4.2. Base Scenario—Influence of Quantitative Cheese Characteristics on Their Environmental Impacts

3.4.3. Alternative Scenario—Influence of Cheese Characteristics on Environmental Impacts under the Alternative Scenario

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Milk and Milk Product Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Milk_and_milk_product_statistics#Milk_products (accessed on 28 July 2021).

- L’économie Laitière en Chiffres–Edition 2022. Available online: https://presse.filiere-laitiere.fr/assets/leconomie-laitiere-en-chiffres-edition-2022-f33b-ef05e.html?lang=fr (accessed on 22 July 2022).

- EN ISO 14044:2006; Environmental Management. Life Cycle Assessment. Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Cucurachi, S.; Scherer, L.; Guinée, J.; Tukker, A. Life Cycle Assessment of Food Systems. One Earth 2019, 1, 292–297. [Google Scholar] [CrossRef] [Green Version]

- Finnegan, W.; Yan, M.; Holden, N.M.; Goggins, J. A Review of Environmental Life Cycle Assessment Studies Examining Cheese Production. Int. J. Life Cycle Assess. 2018, 23, 1773–1787. [Google Scholar] [CrossRef]

- Üçtuğ, F.G. The Environmental Life Cycle Assessment of Dairy Products. Food Eng. Rev. 2019, 11, 104–121. [Google Scholar] [CrossRef]

- La France: Pays des Fromages par Excellence! Available online: https://www.filiere-laitiere.fr/fr/fromages (accessed on 14 November 2021).

- Soares, B.B.; Alves, E.C.; de Almeida Neto, J.A.; Rodrigues, L.B. Chapter 8-Environmental Impact of Cheese Production. In Environmental Impact of Agro-Food Industry and Food Consumption; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 169–187. ISBN 978-0-12-821363-6. [Google Scholar]

- Appellation D’origine Protégée/Contrôlée (AOP/AOC). Available online: https://www.inao.gouv.fr/Les-signes-officiels-de-la-qualite-et-de-l-origine-SIQO/Appellation-d-origine-protegee-controlee-AOP-AOC (accessed on 28 April 2021).

- Chiffres Clés 2020 des Produits Laitiers AOP et IGP. Available online: https://www.inao.gouv.fr/eng/content/download/3919/34426/version/1/file/Cnaol%20Chiffres%20Cles%202020_BD%20%28002%29.pdf (accessed on 14 January 2021).

- Cortesi, A.; Dijoux, L.; Yannou-Le Bris, G.; Pénicaud, C. Data related to the Life Cycle Assessment of 44 artisanally produced French Protected Designation of Origin (PDO) cheeses. Data Brief 2022, 43, 108403. [Google Scholar] [CrossRef] [PubMed]

- Corrieu, G.; Perret, B.; Kakouri, A.; Pappas, D.; Samelis, J. Positive Effects of Sequential Air Ventilation on Cooked Hard Graviera Cheese Ripening in an Industrial Ripening Room. J. Food Eng. 2018, 222, 162–168. [Google Scholar] [CrossRef]

- Product Environmental Footprint Category Rules for Dairy Products. Available online: https://ec.europa.eu/environment/eussd/smgp/pdf/PEFCR-DairyProducts_2018-04-25_V1.pdf (accessed on 26 February 2022).

- Fazio, S.; Castellani, V.; Sala, S.; Schau, E.; Secchi, M.; Zampori, L.; Diaconu, E. Supporting Information to the Characterisation Factors of Recommended EF Life Cycle Impact Assessment Method; Ispra: Lombardy, Italy, 2018; p. 42. [Google Scholar]

- Sala, S.; Cerutti, A.K.; Pant, R. Development of a Weighting Approach for the Environmental Footprint (No. EUR 28562); Publications Office of the European Unio: Luxembourg, 2018; p. 146. [Google Scholar]

- Dollé, J.-B.; Agabriel, J.; Peyraud, J.-L.; Faverdin, P.; Manneville, V.; Raison, C.; Gac, A.; Le Gall, A. Greenhouse Gases in Cattle Breeding: Evaluation and Mitigation Strategies [Les Gaz à Effet de Serre En Élevage Bovin: Évaluation et Leviers d’action]. Prod. Anim. 2011, 24, 415–432. [Google Scholar] [CrossRef] [Green Version]

- Le Moal, M.; Gascuel-Odoux, C.; Ménesguen, A.; Souchon, Y.; Étrillard, C.; Levain, A.; Moatar, F.; Pannard, A.; Souchu, P.; Lefebvre, A.; et al. Eutrophication: A New Wine in an Old Bottle? Sci. Total Environ. 2019, 651, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Frischknecht, R.; Braunschweig, A.; Hofstetter, P.; Suter, P. Human Health Damages Due to Ionising Radiation in Life Cycle Impact Assessment. Environ. Impact Assess. Rev. 2000, 20, 159–189. [Google Scholar] [CrossRef]

- Poinssot, C.; Bourg, S.; Ouvrier, N.; Combernoux, N.; Rostaing, C.; Vargas-Gonzalez, M.; Bruno, J. Assessment of the Environmental Footprint of Nuclear Energy Systems. Comparison between Closed and Open Fuel Cycles. Energy 2014, 69, 199–211. [Google Scholar] [CrossRef] [Green Version]

- González-García, S.; Hospido, A.; Moreira, M.T.; Feijoo, G.; Arroja, L. Environmental Life Cycle Assessment of a Galician cheese: San Simon da Costa. J. Clean. Prod. 2013, 52, 253–262. [Google Scholar] [CrossRef]

- Bava, L.; Bacenetti, J.; Gislon, G.; Pellegrino, L.; D’Incecco, P.; Sandrucci, A.; Tamburini, A.; Fiala, M.; Zucali, M. Impact assessment of traditional food manufacturing: The case of Grana Padano cheese. Sci. Total Environ. 2018, 626, 1200–1209. [Google Scholar] [CrossRef] [PubMed]

- Nigri, E.M.; de Barros, A.C.; Rocha, S.D.F.; Romeiro Filho, E. Assessing Environmental Impacts Using a Comparative LCA of Industrial and Artisanal Production Processes: “Minas Cheese” Case. Food Sci. Technol. 2014, 34, 522–531. [Google Scholar] [CrossRef] [Green Version]

| Cheese Name | Milk Origin | Cheese Technology |

|---|---|---|

| Abondance | Cow (highland) | Pressed cooked cheese |

| Banon | Goat | Bloomy rind cheese |

| Beaufort | Cow (highland) | Pressed cooked cheese |

| Bleu d’Auvergne | Cow (highland) | Blue veined cheese |

| Bleu de Gex Haut-Jura | Goat | Blue veined cheese |

| Bleu des Causses | Cow (highland) | Blue veined cheese |

| Bleu du Vercors-Sassenage | Cow (highland) | Blue veined cheese |

| Brie de Meaux | Cow (lowland) | Bloomy rind cheese |

| Bries de Melun | Cow (lowland) | Bloomy rind cheese |

| Camembert de Normandie | Cow (lowland) | Bloomy rind cheese |

| Cantal | Cow (highland) | Pressed uncooked cheese |

| Chabichou de Poitou | Goat | Bloomy rind cheese |

| Chaource | Cow (lowland) | Bloomy rind cheese |

| Charolais | Goat | Bloomy rind cheese |

| Chavignol | Goat | Bloomy rind cheese |

| Chevrotin | Goat | Pressed uncooked cheese |

| Comté | Cow (highland) | Pressed cooked cheese |

| Epoisses | Cow (highland) | Washed rind cheese |

| Fourme d’Ambert | Cow (highland) | Blue veined cheese |

| Fourme de Montbrisson | Cow (highland) | Blue veined cheese |

| Laguiole | Cow (highland) | Pressed uncooked cheese |

| Langres | Cow (highland) | Washed rind cheese |

| Livarot | Cow (lowland) | Washed rind cheese |

| Mâconnais | Goat | Bloomy rind cheese |

| Maroilles | Cow (lowland) | Washed rind cheese |

| Mont d’Or | Cow (highland) | Washed rind cheese |

| Morbier | Cow (highland) | Pressed uncooked cheese |

| Munster | Cow (highland) | Washed rind cheese |

| Neufchâtel | Cow (lowland) | Bloomy rind cheese |

| Ossau Iraty | Sheep | Pressed uncooked cheese |

| Pélardon | Goat | Bloomy rind cheese |

| Picodon | Goat | Bloomy rind cheese |

| Pont l’Evêque | Cow (lowland) | Washed rind cheese |

| Pouligny Saint-Pierre | Goat | Bloomy rind cheese |

| Reblochon | Cow (highland) | Pressed uncooked cheese |

| Rigotte de Condrieu | Goat | Bloomy rind cheese |

| Rocamadour | Goat | Bloomy rind cheese |

| Roquefort | Sheep | Blue veined cheese |

| Saint-Nectaire | Cow (highland) | Pressed uncooked cheese |

| Sainte-Maure-de-Touraine | Goat | Bloomy rind cheese |

| Salers | Cow (highland) | Pressed uncooked cheese |

| Selles sur Cher | Goat | Bloomy rind cheese |

| Tome de Bauges | Cow (highland) | Pressed uncooked cheese |

| Valençay | Goat | Bloomy rind cheese |

| Contribution of Milk Production (%) | Contribution of Cheese Ripening (%) | |||||

|---|---|---|---|---|---|---|

| Maximum | Minimum | Average | Maximum | Minimum | Average | |

| Climate change | 90 | 45 | 78 | 53 | 7 | 20 |

| Ozone depletion | 37 | 2 | 15 | 96 | 52 | 78 |

| Ionizing radiation | 13 | 0.5 | 4 | 99 | 78 | 91 |

| Photochemical ozone formation | 86 | 30 | 66 | 68 | 8 | 28 |

| Particulate matter | 97 | 59 | 87 | 40 | 2 | 11 |

| Acidification | 98 | 65 | 89 | 35 | 1 | 9 |

| Eutrophication, freshwater | 78 | 9 | 42 | 90 | 18 | 54 |

| Eutrophication, marine | 97 | 57 | 87 | 42 | 2 | 11 |

| Eutrophication, terrestrial | 99 | 82 | 95 | 18 | 1 | 4 |

| Land use | 99 | 89 | 96 | 11 | 1 | 3 |

| Water use | 86 | 26 | 60 | 61 | 3 | 20 |

| Resource use, fossils | 27 | 1 | 9 | 98 | 64 | 86 |

| Resource use, minerals and metals | 19 | 1 | 8 | 97 | 61 | 81 |

| Milk Production | Milk Transport | Milk Pumping | Milk Storage | Milk Processing | Cheese Transport | Cheese Ripening | Equipment Cleaning | |

|---|---|---|---|---|---|---|---|---|

| Climate change | 97 (94–98) | 1 (0–3) | 0 | 0 (0–1) | 0 | 0 (0–1) | 0 (0–2) | 1 |

| Ozone depletion | 63 (47–77) | 7 (1–22) | 0 | 11 (0–20) | 4 (0–6) | 2 (0–6) | 7 (2–26) | 6 (4–8) |

| Ionizing radiation | 39 (18–62) | 1 (0–2) | 0 | 31 (0–49) | 10 (0–17) | 0 | 19 (5–50) | 1 (0–1) |

| Photochemical ozone formation | 91 (96–83) | 4 (1–11) | 0 | 1 (0–2) | 0 (0–1) | 1 (0–3) | 1 (0–3) | 1 (1–2) |

| Particulate matter | 98 (99–96) | 1 (0–2) | 0 | 0 (0–1) | 0 | 0 (0–1) | 0 (0–1) | 0 |

| Acidification | 99 (99–97) | 0 (0–1) | 0 | 0 (0–1) | 0 | 0 | 0 (0–1) | 0 (0–1) |

| Eutrophication, freshwater | 87 (95–77) | 1 (0–5) | 0 | 4 (0–7) | 1 (0–3) | 0 (0–1) | 3 (0–11) | 3 (2–4) |

| Eutrophication, marine | 98 (99–95) | 1 (0–3) | 0 | 0 | 0 | 0 (0–1) | 0 (0–1) | 0 |

| Eutrophication, terrestrial | 99 (100–98) | 0 (0–1) | 0 | 0 | 0 | 0 | 0 | 0 |

| Land use | 99 (100–95) | 0 (0–0) | 0 | 0 | 0 | 0 | 0 (0–4) | 0 |

| Water use | 74 (88–65) | 0 (0–0) | 0 | 1 (0–1) | 0 (0–1) | 0 | 0 (0–2) | 25 (11–34) |

| Resource use, fossils | 55 (76–32) | 4 (0–11) | 0 | 20 (0–34) | 6 (0–10) | 1 (0–3) | 12 (2–39) | 2 (1–3) |

| Resource use, minerals and metals | 40 (53–18) | 20 (4–52) | 0 | 13 (0–22) | 4 (0–7) | 5 (1–14) | 8 (2–28) | 10 (5–14) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cortesi, A.; Dijoux, L.; Yannou-Le Bris, G.; Pénicaud, C. Explaining the Differences between the Environmental Impacts of 44 French Artisanal Cheeses. Sustainability 2022, 14, 9484. https://doi.org/10.3390/su14159484

Cortesi A, Dijoux L, Yannou-Le Bris G, Pénicaud C. Explaining the Differences between the Environmental Impacts of 44 French Artisanal Cheeses. Sustainability. 2022; 14(15):9484. https://doi.org/10.3390/su14159484

Chicago/Turabian StyleCortesi, Adeline, Laure Dijoux, Gwenola Yannou-Le Bris, and Caroline Pénicaud. 2022. "Explaining the Differences between the Environmental Impacts of 44 French Artisanal Cheeses" Sustainability 14, no. 15: 9484. https://doi.org/10.3390/su14159484

APA StyleCortesi, A., Dijoux, L., Yannou-Le Bris, G., & Pénicaud, C. (2022). Explaining the Differences between the Environmental Impacts of 44 French Artisanal Cheeses. Sustainability, 14(15), 9484. https://doi.org/10.3390/su14159484