Effect of Various Aqueous Mediums on the Microstructure of Compacted Bentonite–Sand Mixture Characterized by X-ray CT Investigation

Abstract

1. Introduction

2. Specimen Information and Methods

2.1. Specimen Information

2.2. Experimental Setup

2.3. Swelling Pressure and Permeability Experiment

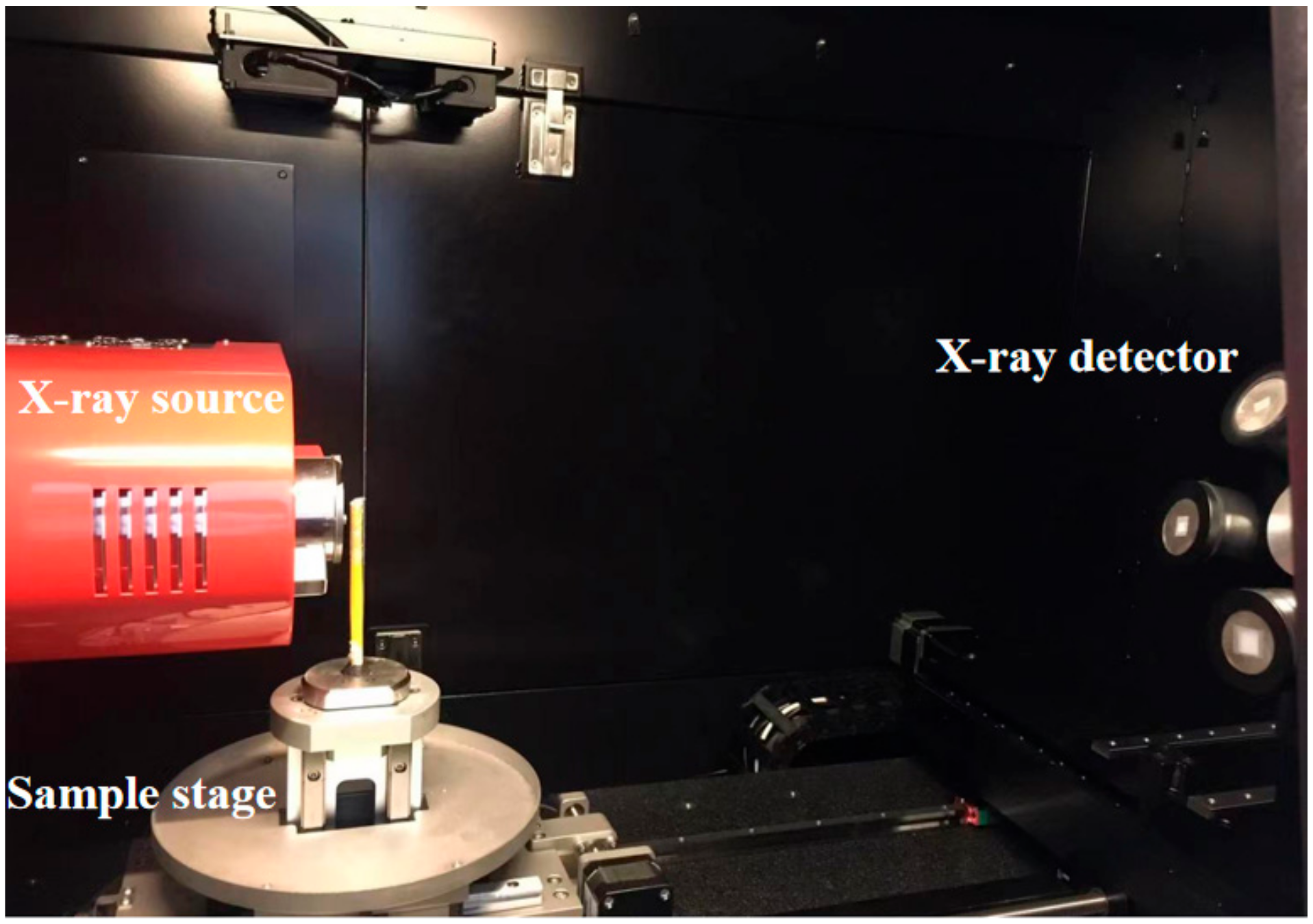

2.4. X-ray CT Scanning

3. Preprocessing of Scanned Images

4. Results and Discussion

4.1. Maximum Expansion Pressure and Hydraulic Conductivity

4.2. Pore Connectivity

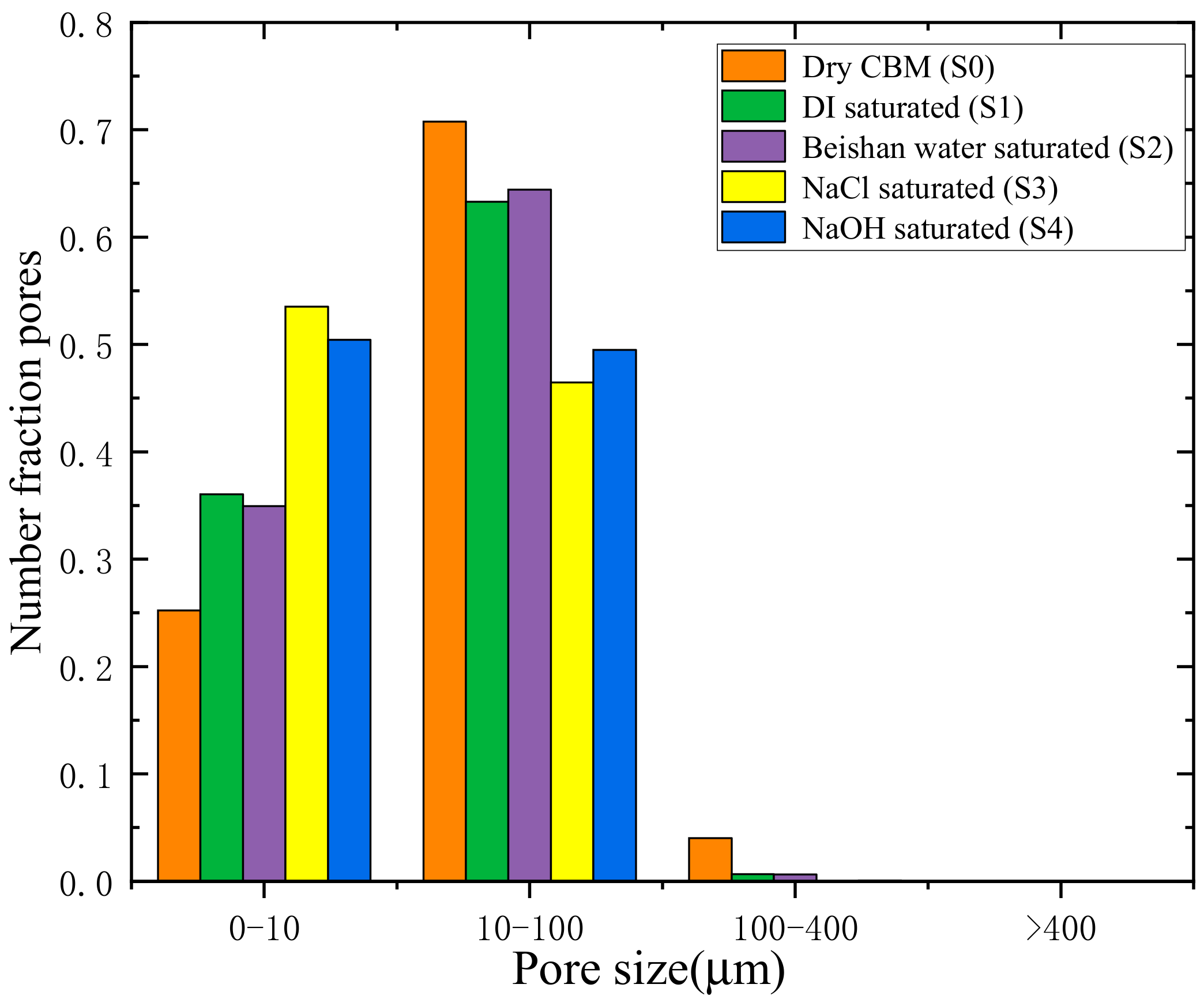

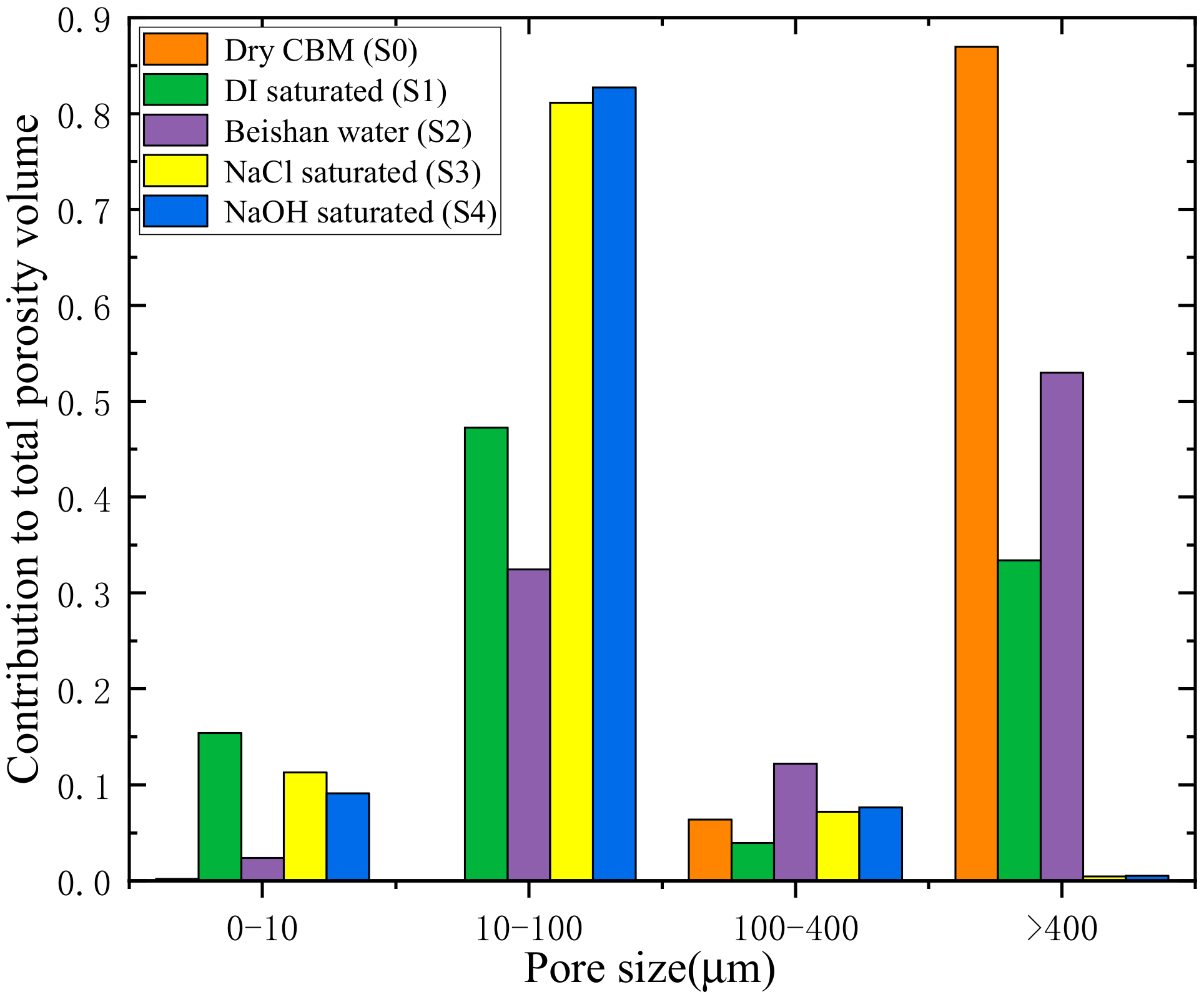

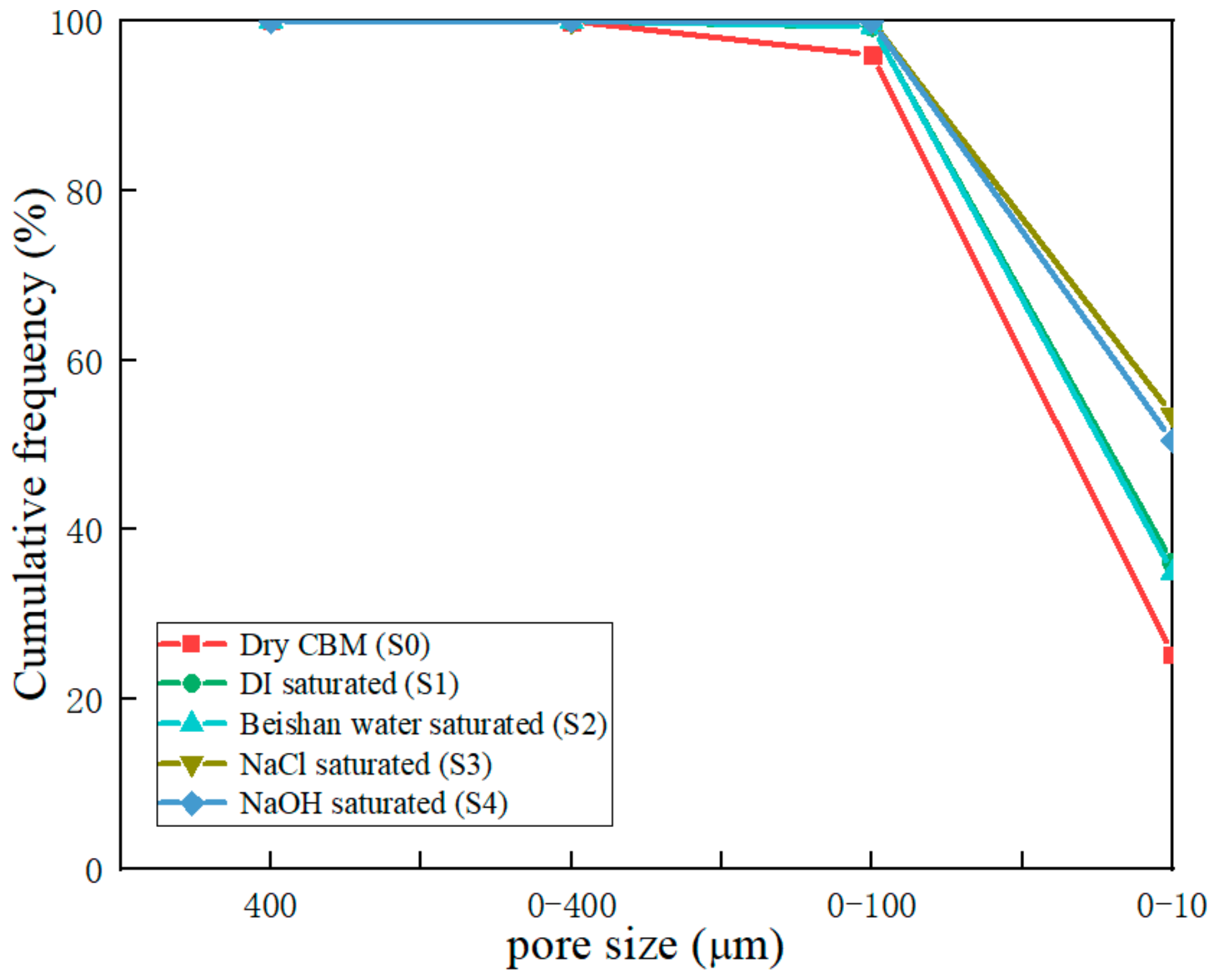

4.3. PSD and Porosity

5. Conclusions

- (1)

- The expansion and hydraulic test results showed that the expansion pressure was largest under the infiltration of DI water and smallest under the NaOH solution. The permeability coefficient of samples was NaOH > NaCl-Na2SO4 > Simulated Beishan groundwater > DI water, and the maximum expansion pressure of samples was NaOH < NaCl-Na2SO4 < Simulated Beishan groundwater < DI water. The permeability coefficient decreased with the increasing of maximum expansion pressure. In the HLW repository, the hydro-mechanical behavior between the various aqueous medium and the CBM present may raise the links among the aperture gap bringing about a higher penetration rate, emphasizing the significance of this study for designing safe HLW processing technologies.

- (2)

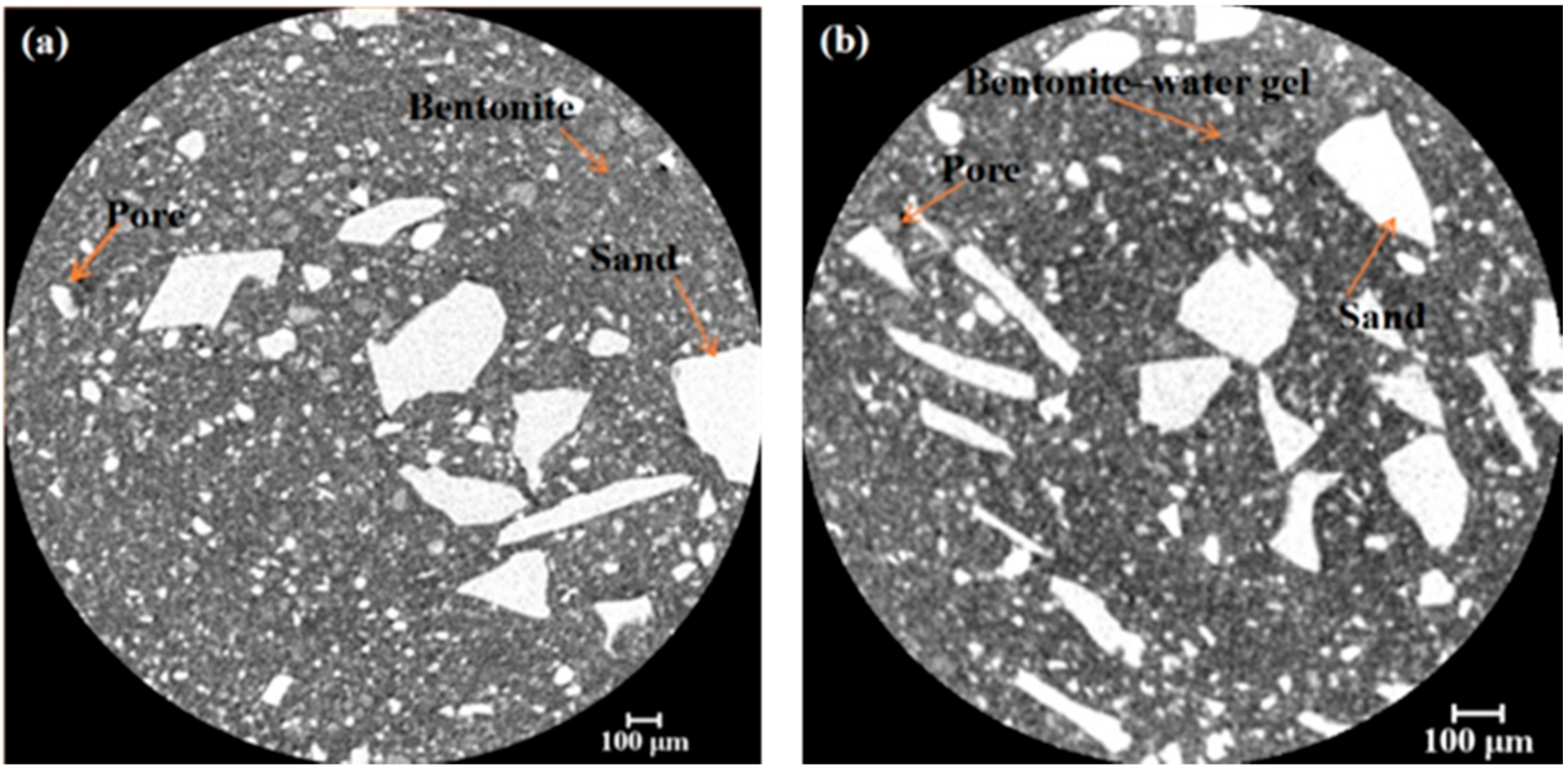

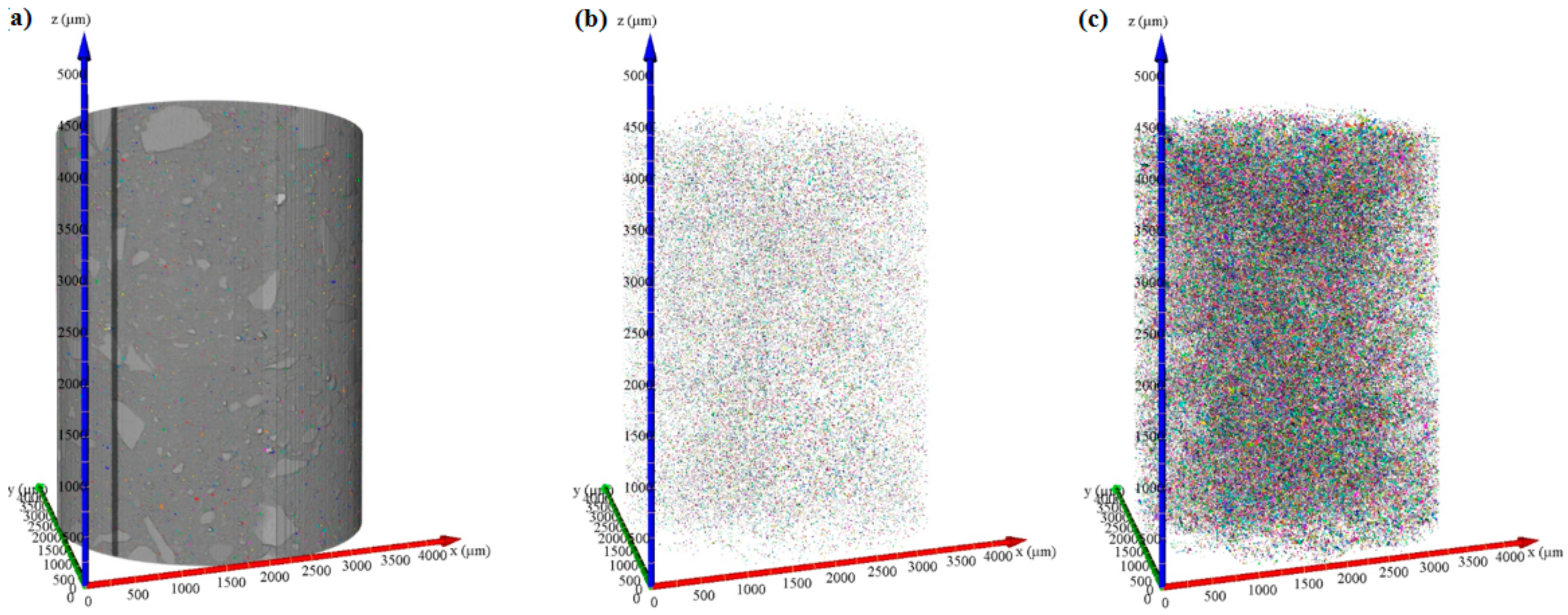

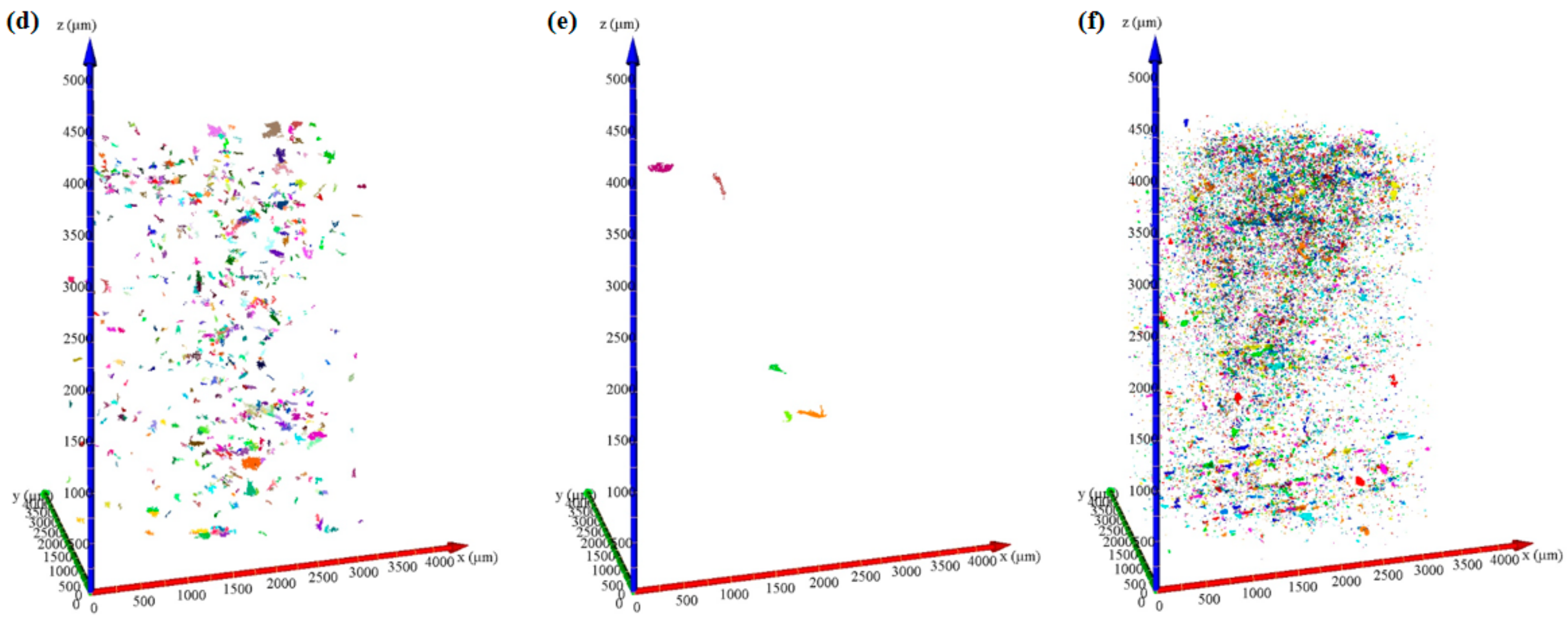

- Polyethylene pipes were used for containing the samples to prevent water evaporation from the CBM during the scanning. Pushing the flat panel detector to the farthest end and placing the sample at 2 mm away from the X-ray source can obtain high-quality images. The rebuild pictures were de-noised and segmented in order to segregate the pores and particles present in the mixture. The observations of CBMs confirmed that CT has been capable of sufficiently differentiating the bentonite from the sand in reality. The ‘pores’ and ‘bentonite–water gel’ of the mixtures after water infiltration were distinguishable in CT pictures.

- (3)

- Three-dimensional models were restructured with AVIZO software using an interactive threshold segmentation method, and porous structures were quantified and characterized. Research showed that large pore content will decrease while its small pores will increase rapidly. Contrasting with specimen S1, the pores increased under the corrosion of the NaCl-Na2SO4 and NaOH solution, and the increase in the pore size from 10 to 100 μm was more obvious, which widened the infiltration path of the solution and improved the permeability of CBM. In this study, a 3D model with real pore texture features was established using the combination of CT scanning and AVIZO. The combination of X-ray CT and AVIZO software analysis can enable high-resolution assessment of the 3D microstructures of the CBM samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharif, A.D.; Hossam, A.G.; Vahid, D.; Mohammed, A.; Isaac, H. A comprehensive review on radioactive waste cycle from generation to disposal. J. Radioanal. Nucl. Chem. 2021, 329, 15–31. [Google Scholar]

- Wang, J. Progress of geological disposal of high-level radioactive waste in China in the 21st century. Atom. Energ. Sci. Technol. 2019, 53, 2072–2082. (In Chinese) [Google Scholar]

- Jia, L.Y.; Chen, Y.G.; Ye, W.M.; Cui, Y.J. Effects of a simulated gap on anisotropic swelling pressure of compacted GMZ bentonite. J. Eng. Geol. 2019, 248, 155–163. [Google Scholar] [CrossRef]

- CAEA (China Atomic Energy Authority); Ministry of Environment Protection & Ministry of Science and Technology. Guidelines for the R&D for Geological Disposal of High-Level Radioactive Waste in China; Atomic Energy Press: Beijing, China, 2006. (In Chinese)

- Liu, Y.; Ma, L.; Ke, D.; Cao, S.; Xie, J.; Zhao, X.; Cheng, L.; Zhang, P. Design and validation of the THMC China-Mock-Up test on buffer material for HLW disposal. J. Rock Mech. Geotech. 2014, 6, 119–125. [Google Scholar] [CrossRef]

- Castellanos, E.; Villar, M.V.; Romero, E.; Lloret, A.; Gens, A. Chemical impact on the hydro-mechanical behavior of high density FEBEX bentonite. Phys. Chem. Earth 2008, 33, 516–526. [Google Scholar] [CrossRef]

- Guo, Y.H.; Yang, T.X.; Liu, S.F. Hydrogeological characteristics of Beishan preselected area, Gansu province for China’s high-level radioactive waste repository. Uranium Geol. 2001, 17, 184–189. (In Chinese) [Google Scholar]

- Chen, L.; Peng, H.; Yang, D. The microstructure and water distribution of partially saturated hard clay. Geotech. Test. J. 2018, 41, 830–835. [Google Scholar] [CrossRef]

- Alves, H.; Lima, I.; Assis, J.T.; Geraldes, M.; Lopes, R.T. Comparison of pore space features by thin sections and X-ray microtomography. Appl. Radiat. Isotopes. 2014, 94, 182–190. [Google Scholar] [CrossRef][Green Version]

- Rab, M.A.; Haling, R.E.; Aarons, S.R.; Hannah, M.; Young, I.M.; Gibson, D. Evaluation of X-ray computed tomography for quantifying macroporosity of loamy pasture soils. Geoderma 2014, 213, 460–470. [Google Scholar] [CrossRef]

- Wang, J.; Qin, Q.; Guo, L.; Feng, Y. Multi-fractal characteristics of three-dimensional distribution of reconstructed soil pores at opencast coal-mine dump based on high-precision CT scanning. Soil Till. Res. 2018, 182, 144–152. [Google Scholar] [CrossRef]

- Larsbo, M.; Koestel, J.; Jarvis, N. Relations between macropore network characteristics and the degree of preferential solute transport. Hydrol. Earth Syst. Sci. 2014, 18, 5255–5269. [Google Scholar] [CrossRef]

- Shah, S.M.; Gray, F.; Crawshaw, J.P.; Boek, E.S. Micro-computed tomography pore-scale study of flow in porous media: Effect of voxel resolution. Adv. Water Res. 2016, 95, 276–287. [Google Scholar] [CrossRef]

- Katuwal, S.; Norgaard, T.; Moldrup, P.; Lamandé, M.; Wildenschild, D.; Jonge, L.W. Linking air and water transport in intact soils to macropore characteristics inferred from X-ray computed tomography. Geoderma 2015, 238, 9–20. [Google Scholar] [CrossRef]

- Liang, L.X.; Xiong, J.; Liu, X.J. Mineralogical microstructural and physiochemical characteristics of organic-rich shales in the Sichuan Basin, China. J. Nat. Gas Sci. Eng. 2015, 26, 1200–1212. [Google Scholar] [CrossRef]

- Vogel, H.J. A numerical experiment on pore size, pore connectivity, water retention, permeability, and solute transport using network models. Eur. J. Soil Sci. 2000, 51, 99–105. [Google Scholar] [CrossRef]

- Sandin, M.; Koestel, J.; Jarvis, N.; Larsbo, M. Post-tillage evolution of structural pore space and saturated and near-saturated hydraulic conductivity in a clay loam soil. Soil Til. Res. 2017, 165, 161–168. [Google Scholar] [CrossRef]

- Liu, J.F.; Ma, S.; Ni, H.Y.; Pu, H.; Li, X.Z.; Chen, S.J. Quantitative two/three-dimensional spatial characterization and fluid transport prediction of macro/micropores in Gaomiaozi bentonite. J. Rock Mech. Geotech. 2022, in press. [CrossRef]

- Liu, J.F.; Song, S.B.; Cao, X.L.; Meng, Q.B.; Pu, H.; Wang, Y.J. Determination of full-scale pore size distribution of Gaomiaozi bentonite and its permeability prediction. J. Rock Mech. Geotech. 2020, 12, 403–413. [Google Scholar] [CrossRef]

- Song, S.B.; Liu, J.F.; Yang, D.S.; Ni, H.Y.; Huang, B.X.; Zhang, K.; Mao, X.B. Pore structure characterization and permeability prediction of coal samples based on SEM images. J. Nat. Gas Sci. Eng. 2019, 67, 160–171. [Google Scholar] [CrossRef]

- Yao, K.; Wang, W.; Li, N.; Zhang, C.; Wang, L. Investigation on strength and microstructure characteristics of nano-MgO admixed with cemented soft soil. Constr. Build. Mater. 2019, 206, 160–168. [Google Scholar] [CrossRef]

- Li, X.C.; Kang, Y.L.; Haghighi, M. Investigation of pore size distributions of coals with different structures by nuclear magnetic resonance (NMR) and mercury intrusion porosimetry (MIP). Measurement 2018, 116, 122–128. [Google Scholar] [CrossRef]

- Ando, E.; Viggiani, G.; Hall, S.; Desrues, J. Experimental micro-mechanics of granular media studies by X-ray to mography: Recent results and challenges. Geotech. Lett. 2013, 3, 142–146. [Google Scholar] [CrossRef]

- Saba, S.; Barnichon, J.D.; Cui, Y.J.; Tang, A.M.; Delage, P. Microstructure and anisotropic swelling behaviour of compacted bentonite/sand mixture. J. Rock Mech. Geotech. Eng. 2014, 6, 126–132. [Google Scholar] [CrossRef]

- Chen, L.F.; Kang, L.; Yang, D.S. Experimental investigation on drying and wetting of GMZ bentonite using X-Ray tomography and volumetric digital image correlation technique. Adv. Civ. Eng. 2020, 5, 1–8. [Google Scholar] [CrossRef]

- Gebrenegus, T.; Ghezzehei, T.A.; Tuller, M. Physicochemical controls on initiation and evolution of desiccation cracks in sand-bentonite mixtures: X-ray CT imaging and stochastic modeling. J. Contam. Hydrol. 2011, 126, 100–112. [Google Scholar] [CrossRef] [PubMed]

- Galkin, S.V.; Efimov, A.A.; Krivoshchekov, S.N.; Savitskiy, Y.V.; Cherepanov, S.S. X-ray tomography in petrophysical studies of core samples from oil and gas fields. Russ. Geol. Geophys. 2015, 56, 782–792. [Google Scholar] [CrossRef]

- Peng, D.P.; Huang, T.; He, Y.L. Application of XDMT in three-dimensional visualization of arsenic aggregates in porous media. Environ. Chem. 2012, 31, 1089–1093. [Google Scholar]

- Liu, X.J.; Zhu, H.L.; Liang, L.X. Digital rock physics of sand stone based on micro-CT technology. Chin. J. Geophys. 2014, 57, 1133–1140. [Google Scholar]

- Wang, Y.P.; Wang, Z.; Zhao, Y.; Yi, F.C.; Zhu, B.L. Swelling properties and permeability of GMZ bentonite-sand mixtures during different solutions infiltration. Sustainability 2021, 13, 1622. [Google Scholar] [CrossRef]

- Sarkar, G.; Siddiqua, S. Effect of fluid chemistry on the microstructure of light backfill: An X-ray CT investigation. Eng. Geol. 2016, 202, 153–162. [Google Scholar] [CrossRef]

- Karnland, O.; Olsson, S.; Nilsson, U.; Sellin, P. Experimentally determined swelling pressures and geochemical interactions of compacted Wyoming bentonite with highly alkaline solutions. Phys. Chem. Earth 2007, 32, 275–286. [Google Scholar] [CrossRef]

- Mishra, A.K.; Ohtsubo, M.; Li, L.Y.; Higashi, T.; Park, J. Effect of salt of various concentrations on liquid limit and hydraulic conductivity of different soil-bentonite mixtures. Environ. Geol. 2009, 57, 1145–1153. [Google Scholar] [CrossRef]

- Perret, J.; Prasher, S.O.; Kantzas, A.; Langford, C. Three-dimensional quantification of macropore networks in undisturbed soil cores. Soil Sci. Soc. Am. J. 1999, 63, 1530–1543. [Google Scholar] [CrossRef]

| Specimen No | Chemistry Solutions | Dry Density(g/cm3) | Maximum Swelling Pressure (kPa) | Permeability Coefficient (m/s) | Porosity (%) (CT) |

|---|---|---|---|---|---|

| S0 | Dry bentonite–sand | 1.70 | _ | _ | 11.77 |

| S1 | DI water | 1.70 | 1680 | 6.87 × 10−13 | 0.27 |

| S2 | Simulated Beishan groundwater | 1.70 | 1569 | 6.84 × 10−13 | 0.29 |

| S3 | NaCl-Na2SO4 | 1.70 | 1210 | 11.93 × 10−13 | 0.43 |

| S4 | NaOH | 1.70 | 769 | 15.51 × 10−13 | 0.69 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Wang, Y.; Yi, F. Effect of Various Aqueous Mediums on the Microstructure of Compacted Bentonite–Sand Mixture Characterized by X-ray CT Investigation. Sustainability 2022, 14, 9427. https://doi.org/10.3390/su14159427

Wang Z, Wang Y, Yi F. Effect of Various Aqueous Mediums on the Microstructure of Compacted Bentonite–Sand Mixture Characterized by X-ray CT Investigation. Sustainability. 2022; 14(15):9427. https://doi.org/10.3390/su14159427

Chicago/Turabian StyleWang, Zhe, Yuping Wang, and Facheng Yi. 2022. "Effect of Various Aqueous Mediums on the Microstructure of Compacted Bentonite–Sand Mixture Characterized by X-ray CT Investigation" Sustainability 14, no. 15: 9427. https://doi.org/10.3390/su14159427

APA StyleWang, Z., Wang, Y., & Yi, F. (2022). Effect of Various Aqueous Mediums on the Microstructure of Compacted Bentonite–Sand Mixture Characterized by X-ray CT Investigation. Sustainability, 14(15), 9427. https://doi.org/10.3390/su14159427