“Eco”, “safe”, “intelligent”, and “efficient” are the requirements for the sustainable development of the mining industry. China is rich in mineral resources, and open-pit mining is the most commonly used mining method. In recent years, due to the continuous expansion of the scale of open-pit mining and greater investment in large-scale equipment, open-pit mining has gradually developed in the direction of mechanization, automation, and intelligence, which has greatly improved the mining efficiency of mineral resources and improved the economic benefits of mining enterprises. Truck transportation has outstanding advantages, such as strong environmental adaptability, as well as flexible and convenient scheduling. Therefore, it is still the most common transportation method used in open-pit mines in China, and the transportation cost of open-pit mining accounts for more than 50% of the production cost of the entire mine [

1]. For this reason, strengthening the management of transportation equipment and improving the working efficiency of transportation equipment has become the key for mining enterprises to control costs. With the continuous development and application of new-generation information technologies such as big data, artificial intelligence technology, and the Internet of things, as well as the continuous advancement of intelligent mine construction, more and more large-scale open-pit mines have established truck dispatching systems. The establishment of a truck dispatching system fully realizes the optimal planning, optimal design, optimal management, and optimal control of the mine, and also conforms to the requirements of the new era. In the production and transportation process of open-pit mines, the dispatching system can dispatch vehicles in real time according to real-time data, which can significantly improve transportation efficiency; moreover, it can save and control operating costs for enterprises [

2]. In the truck dispatching system, it is necessary to make the truck freight the lowest and the waiting time the shortest at the same time. In the transportation equipment route planning, the optimal route aiming at the shortest transportation distance and the lowest transportation consumption can better meet the actual needs of the mine. Although the open-pit mine truck dispatching system can fully improve the benefits of mining enterprises in general, it is particularly urgent for mining enterprises to establish a suitable, efficient, and economic dispatching system and continuously improve the intelligence level of the dispatching system. Accordingly, for mining enterprises, it is of great practical significance and value to carry out the evaluation of open-pit mine truck dispatching systems and continuously improve the functions of the dispatching system, as well as continuously promote the optimization and upgrading of the system.

Many experts and scholars have studied the optimal design and comprehensive evaluation of the truck dispatching system in open-pit mines, achieving a series of research results, which have greatly promoted the intelligent development of truck dispatching systems. In terms of truck dispatching system optimization, some algorithms improved the economy of the operation of the dispatching system, such as the artificial fish swarm neural network optimization algorithm [

3], improved quantum particle swarm optimization algorithm based on genetic algorithm [

4], and combined optimization algorithm from simulated annealing algorithm and genetic algorithm [

5]. In terms of truck dispatching system evaluation, Zhao Bin et al. constructed a matter–element extension comprehensive evaluation model for truck dispatching systems in open-pit mines and calculated weight factors using the weighting method [

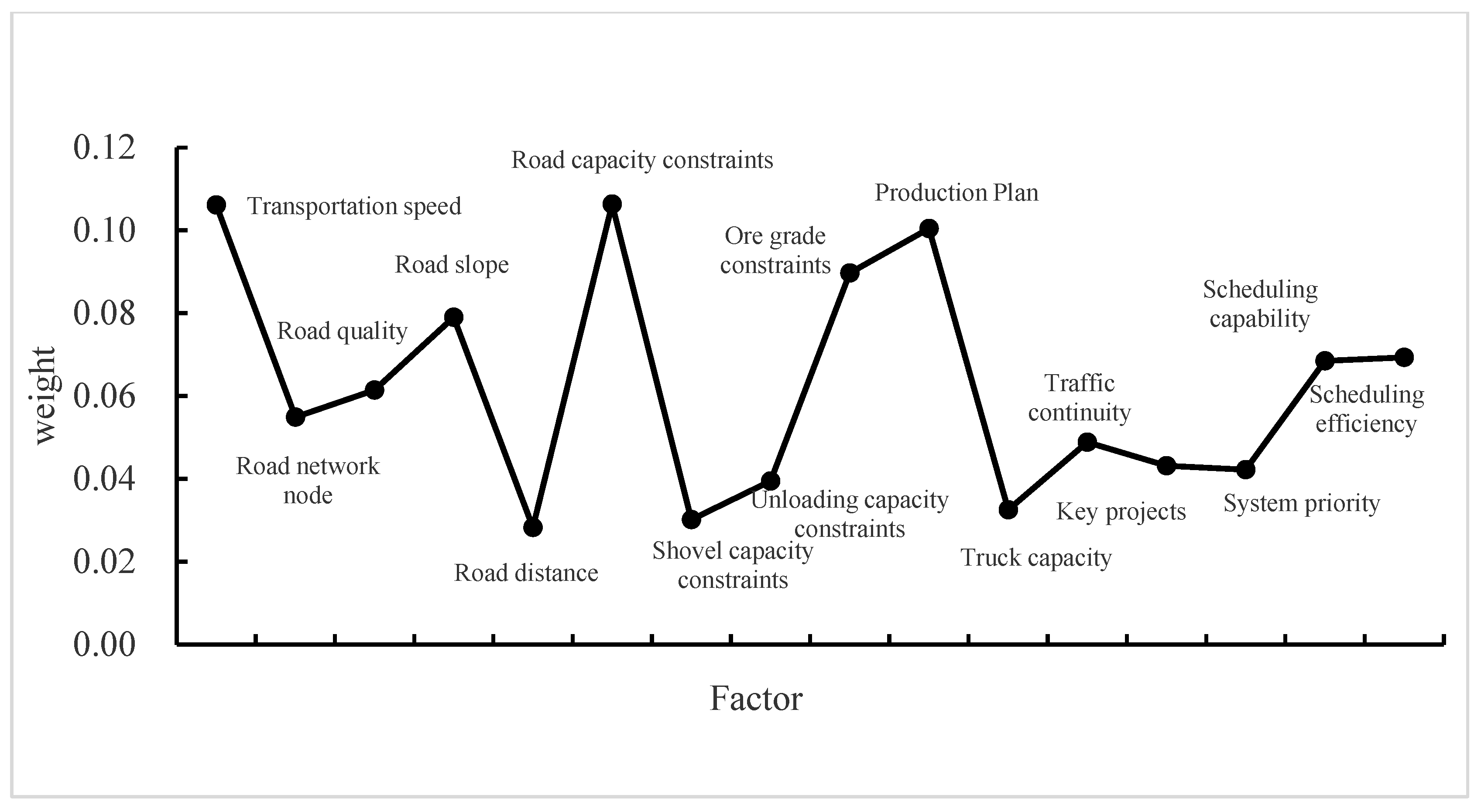

6]. Furthermore, using the combined weighting method, which realized the dynamic evaluation of the truck dispatching system in open-pit mines, on the basis of establishing an optimization factor system for truck dispatching in open pit mines, Zhao Songsong et al. used the improved AHP to analyze the weights of optimization factors [

7]. The research shows that road network conditions, operation time, and transportation factors have the greatest impact on the truck scheduling process, which provides theoretical guidance for the research on truck scheduling in open-pit mines. Through comparison, it was found that several studies have been conducted on the optimization of the truck dispatching system, while only few studies have been conducted on the comprehensive evaluation of the truck dispatching system. Therefore, a relatively mature theoretical system, a perfect evaluation factor system, and an effective comprehensive evaluation model have not yet been formed, making it difficult to truly guide practice. The optimization of the truck dispatching system in open pit mines mainly focuses on three aspects: route optimization, traffic flow planning, and real-time dispatching. Besides, the influencing factors involved in each optimization aspect are different. Therefore, after in-depth research on the theory and process of truck scheduling in open pit mines, a comprehensive evaluation model for truck dispatching systems in open-pit mines is built in this paper. The three aspects of optimal route, traffic flow planning, and real-time dispatching have been taken into consideration in this model. The evaluation of the truck dispatching system in open-pit mines is a multi-attribute decision problem, with the need to consider many factors that are incompatible. Furthermore, qualitative factors are mainly used, which increases the difficulty of evaluation to a certain extent. In the research of multi-attribute decision-making problems, the technique for order of preference by similarity to ideal solution (TOPSIS) is a relatively widely used theoretical model. It evaluates the pros and cons by calculating the closeness of each decision plan to the positive and negative ideal solutions, with the advantages of relatively simple calculation and strong operability. The TOPSIS method has been widely used in system feasibility evaluation [

8], system risk assessment [

9], alternative optimization [

10], and so on, achieving satisfactory effects. However, studies have shown that the traditional TOPSIS method only considers the Euclidean distance between factors when making decisions, and it is difficult to truly and objectively reflect the overall dynamic trend [

11]. Gray relational analysis (GRA) is a model for systematic decision making based on the gray relational degree [

12]. Therefore, a GRA-TOPSIS comprehensive evaluation model was established by coupling these two theoretical models: TOPSIS and GRA. The GRA-TOPSIS comprehensive evaluation model can give full play to the advantages of the GRA model and make up for the shortcomings of TOPSIS, thus making the decision more scientific and reliable. When applying the GRA-TOPSIS model for comprehensive evaluation and decision making, a systematic and comprehensive multilevel comprehensive evaluation factor system needs to be established first, before calculating the factor weights. The rationality and objectivity of the factor weights directly affect the reliability of the evaluation results. Weight calculation methods are mainly divided into two categories: subjective weighting methods and objective weighting methods. Subjective weighting methods mainly rely on the subjective experience of the evaluator, ignoring the true reflection of the objective facts; hence, the weight has strong subjectivity. On the other hand, objective weighting methods are based on the attributes of the factor data, which can fully reflect their essential characteristics. However, objective weighting methods ignore the subjective initiative of people, and they are not ideal for application to situations with poor or limited information. Therefore, purely adopting subjective or objective weighting methods is not conducive to comprehensive evaluation results [

13,

14].

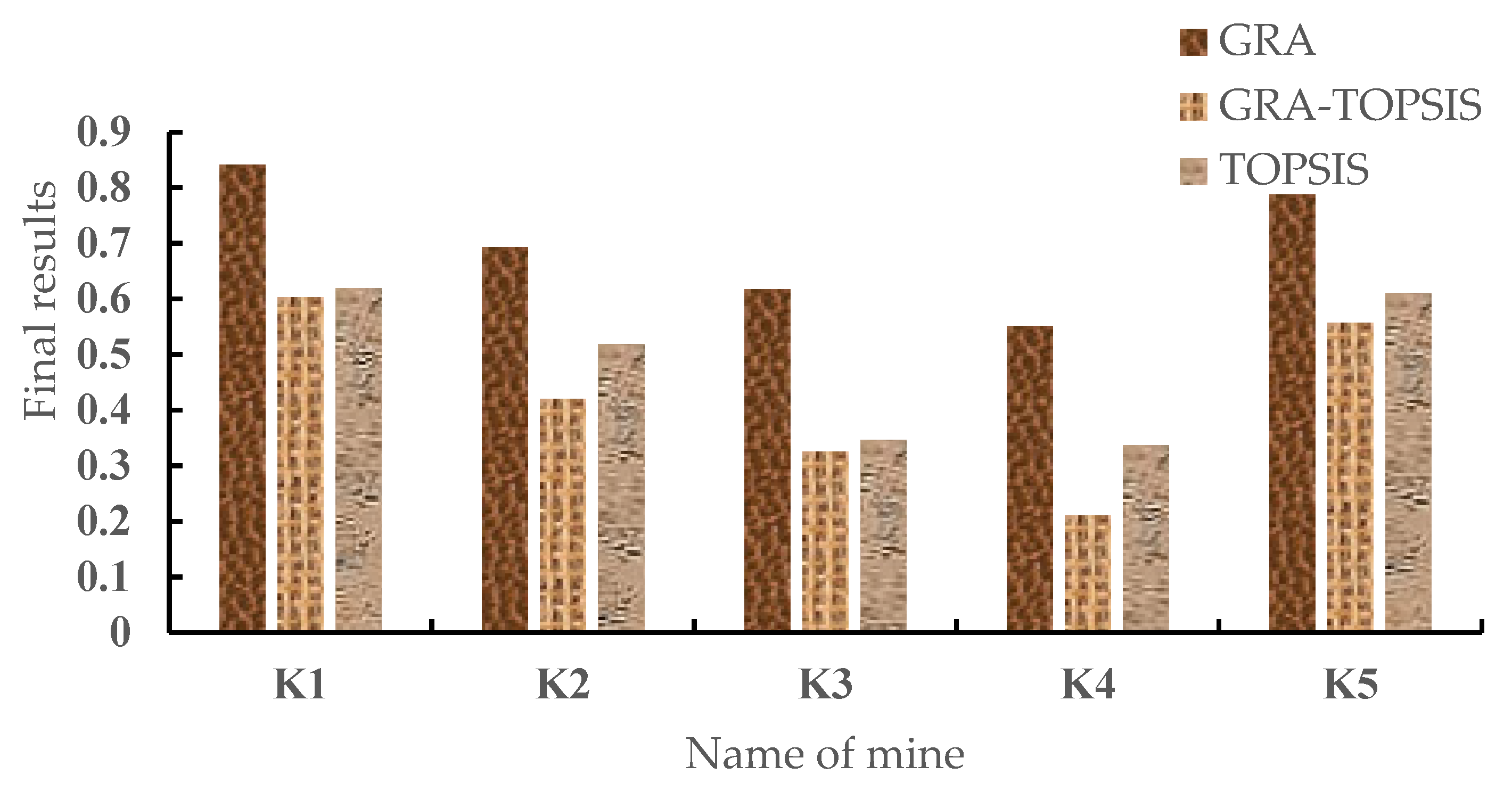

In this paper, an evaluation model based on GRA-TOPSIS was established in order to improve the comprehensive evaluation of the truck dispatching system. Through this evaluation model, the existing truck dispatching system can be evaluated. In addition, the existing system can be optimized, upgraded, and improved according to the evaluation results, which can further improve the production efficiency and management level of open-pit mining enterprises, and further control the operating costs of enterprises. By constructing a comprehensive evaluation factor system of the truck dispatching system, the G1 method, the improved CRITIC method, and game theory were used in this paper to determine the final weights of factors. Since the evaluation factors were qualitative, the assignment of factors was mainly based on expert scoring. Considering the subjective blindness and uncertainty of experts in scoring, it was difficult to directly give an exact scoring standard. Therefore, blind number theory was introduced. The blind number matrix was constructed to process the factor scores, further reducing the influence of subjective factors on the evaluation results. Lastly, taking the truck dispatching system of five open-pit mines as the research background, a comprehensive evaluation of the truck dispatching system was carried out to verify the applicability of the model.