High-Temperature Rheological Properties of Crumb Rubber Composite Modified Asphalt

Abstract

:1. Introduction

2. Objectives and Scope

3. Materials

3.1. Asphalt

3.2. Crumb Rubber and Reacted and Activated Rubber

3.3. Composite Additives

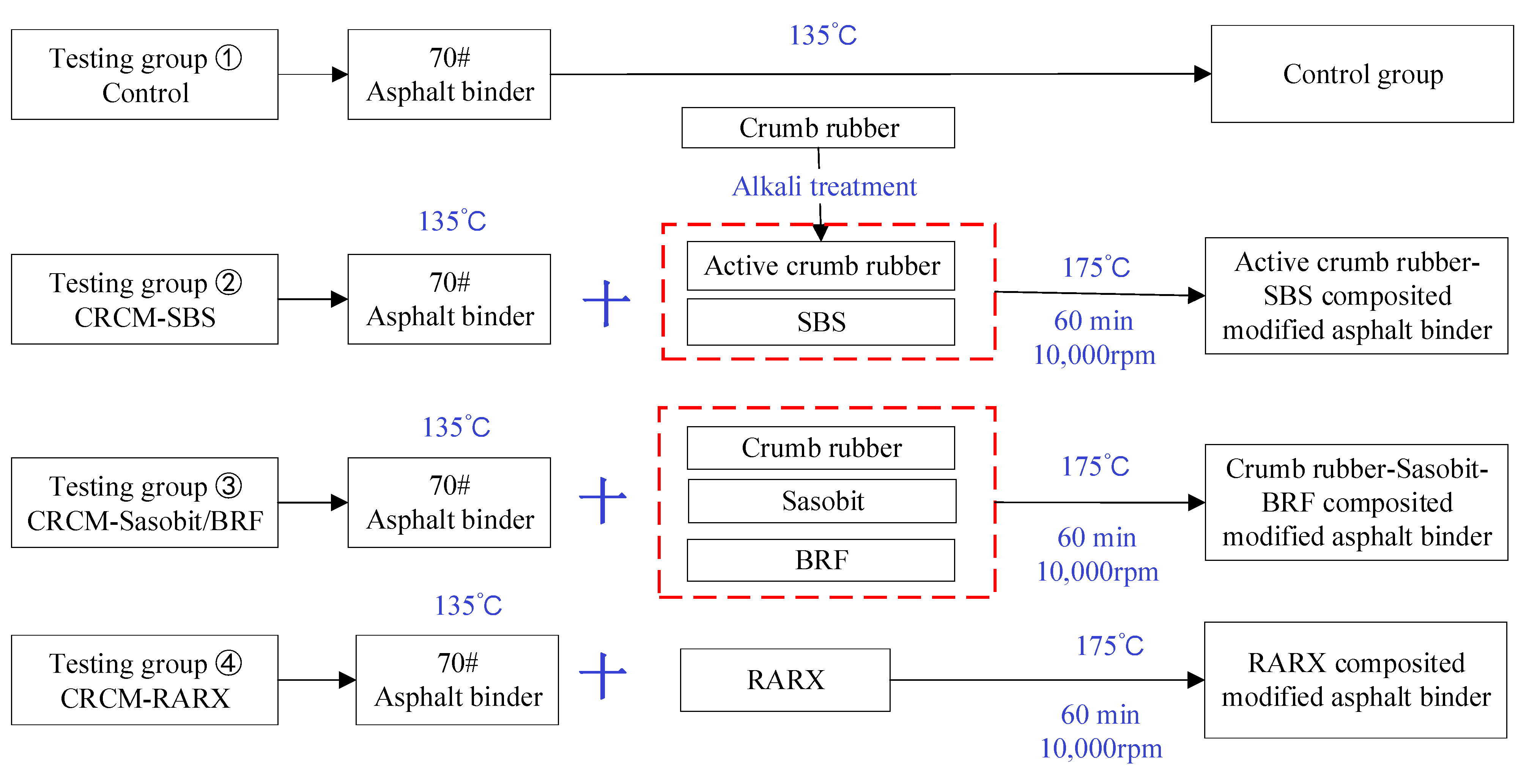

3.4. Preparation of Composite Modified Asphalt

4. Experiment Design and Testing Methods

4.1. Design of Experiment

4.2. Rotational Viscometer (RV)

4.3. Dynamic Shear Rheometer (DSR)

4.4. Multiple Stress Creep Recovery (MSCR) Test

4.5. Fourier Transform Infrared Spectroscopy (FTIR) Test

5. Results and Discussion

5.1. Rotational Viscosity

5.2. Temperature Sweep

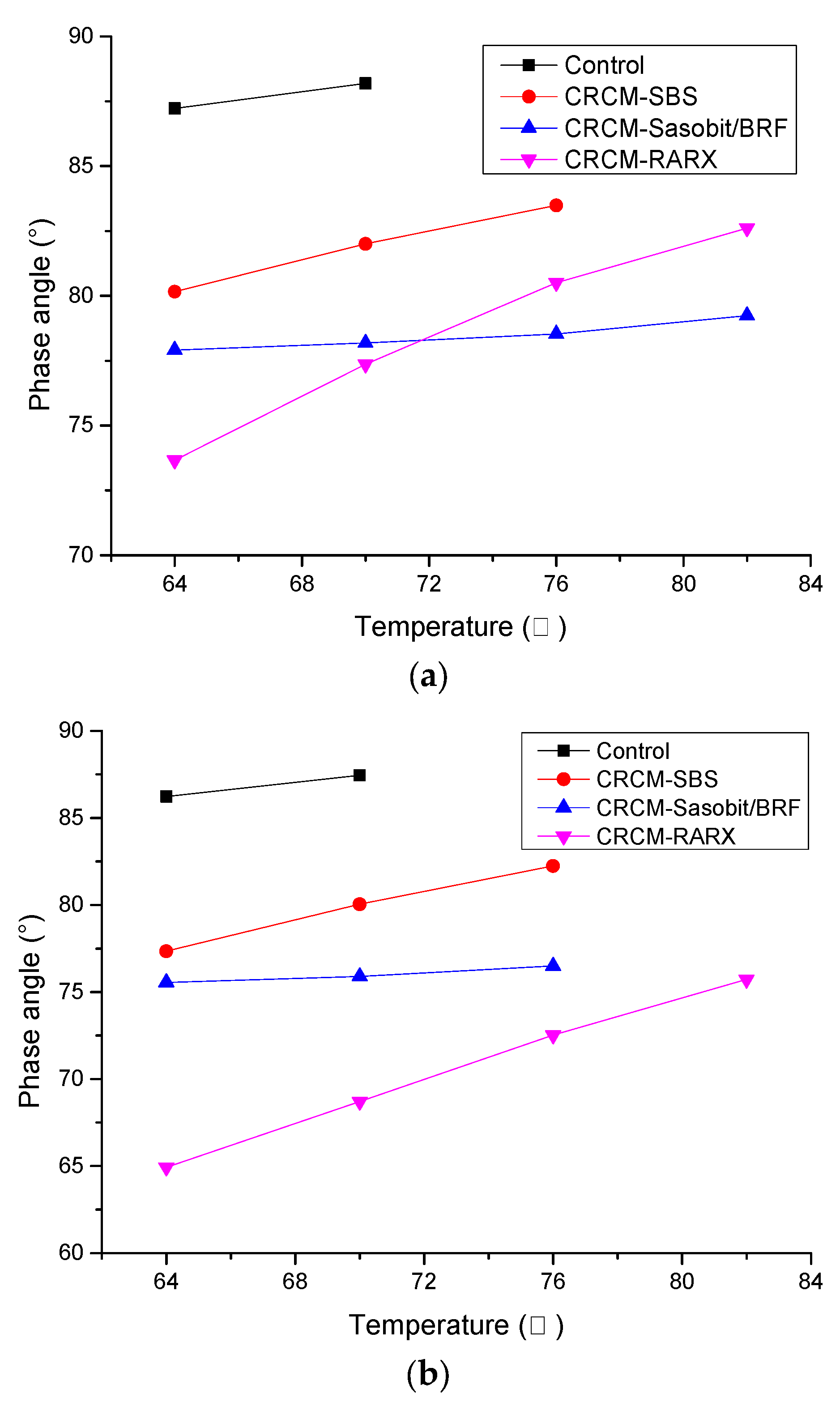

5.2.1. Variation Rule of Phase Angle

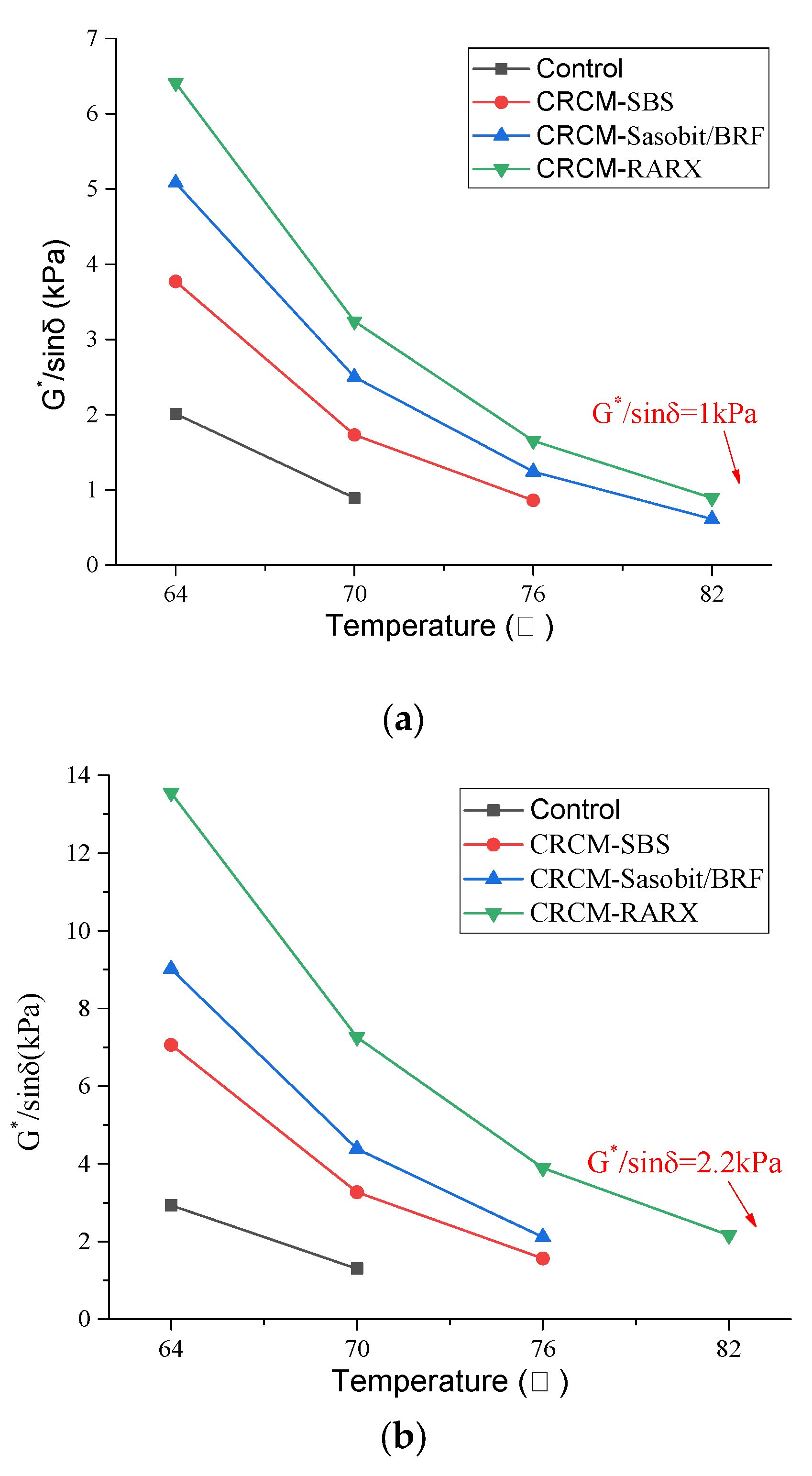

5.2.2. Variation Rule of Rutting Factor

5.2.3. Critical Temperature

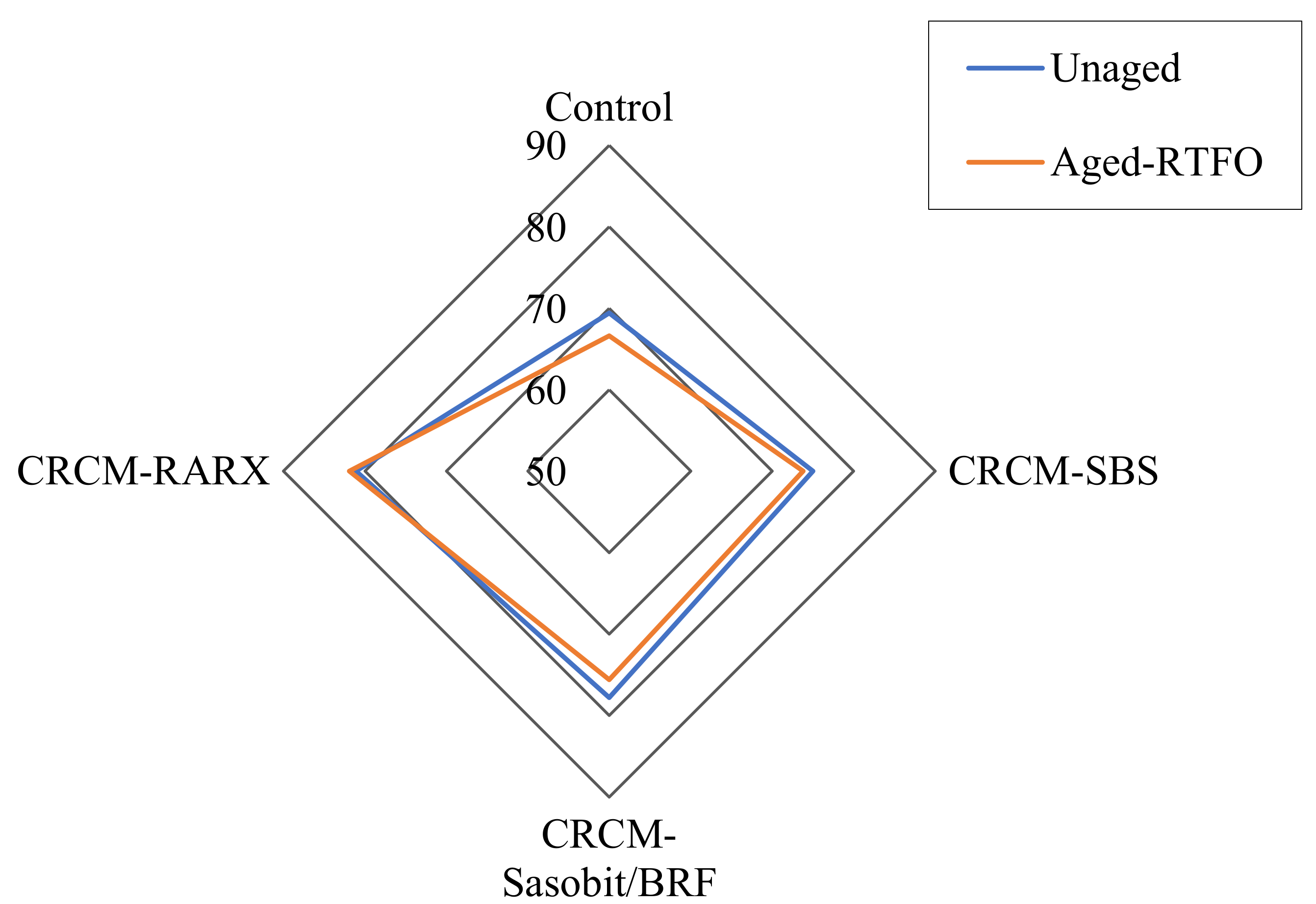

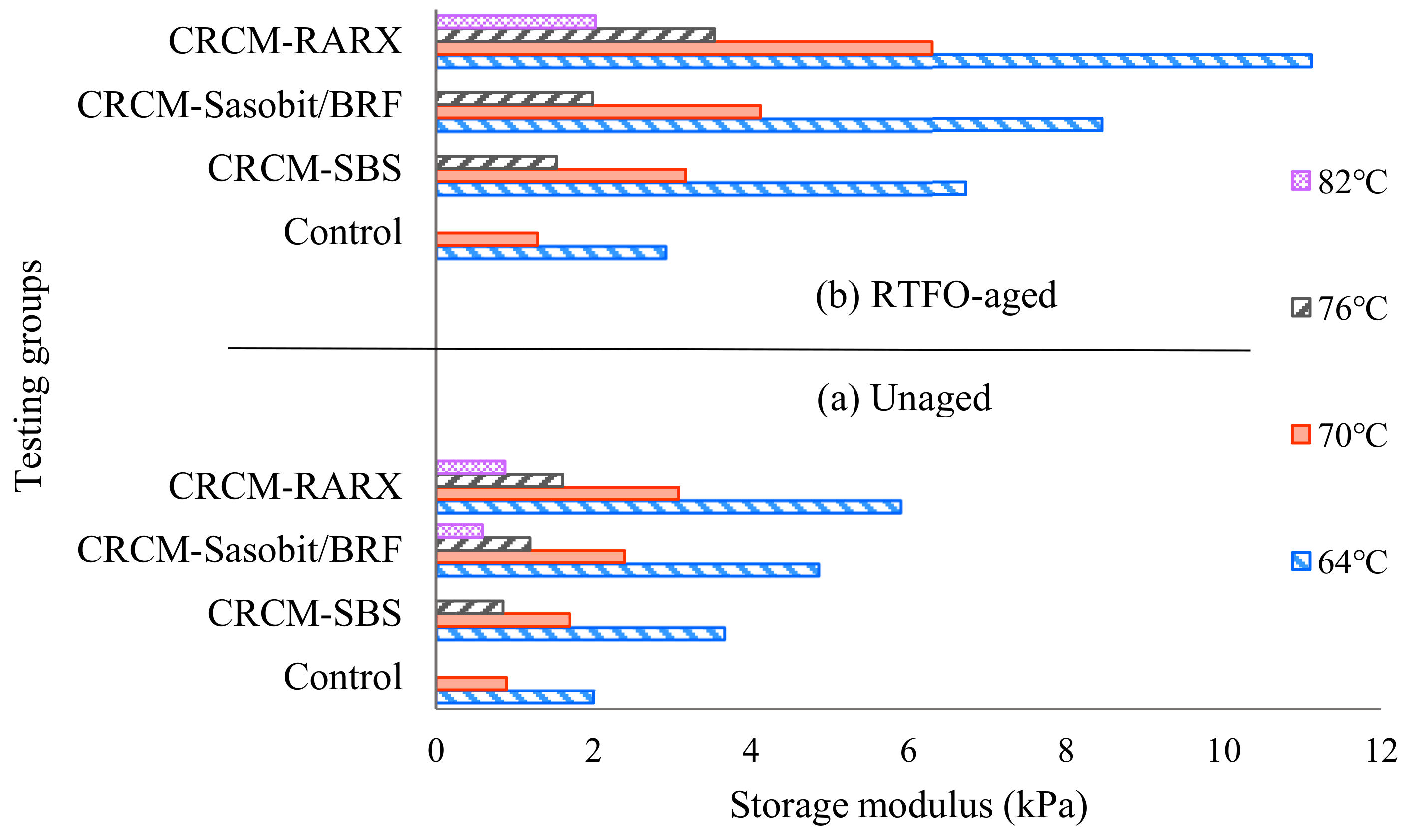

5.2.4. Storage Modulus of Asphalt in Unaged and FTFO-Aged Condition

5.3. MSCR Test

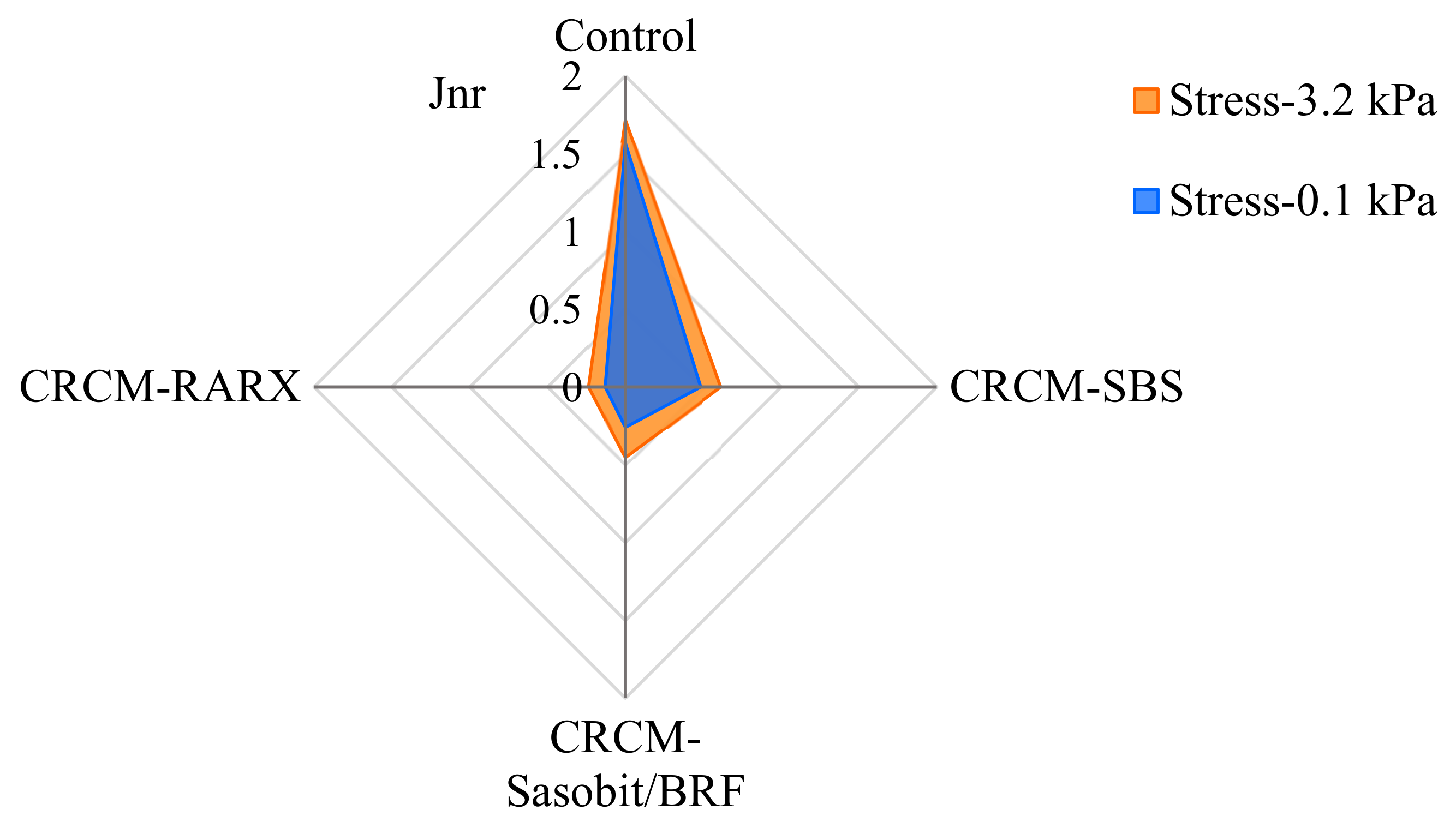

5.3.1. Non-Recoverable Creep Compliance

5.3.2. Percent Recovery

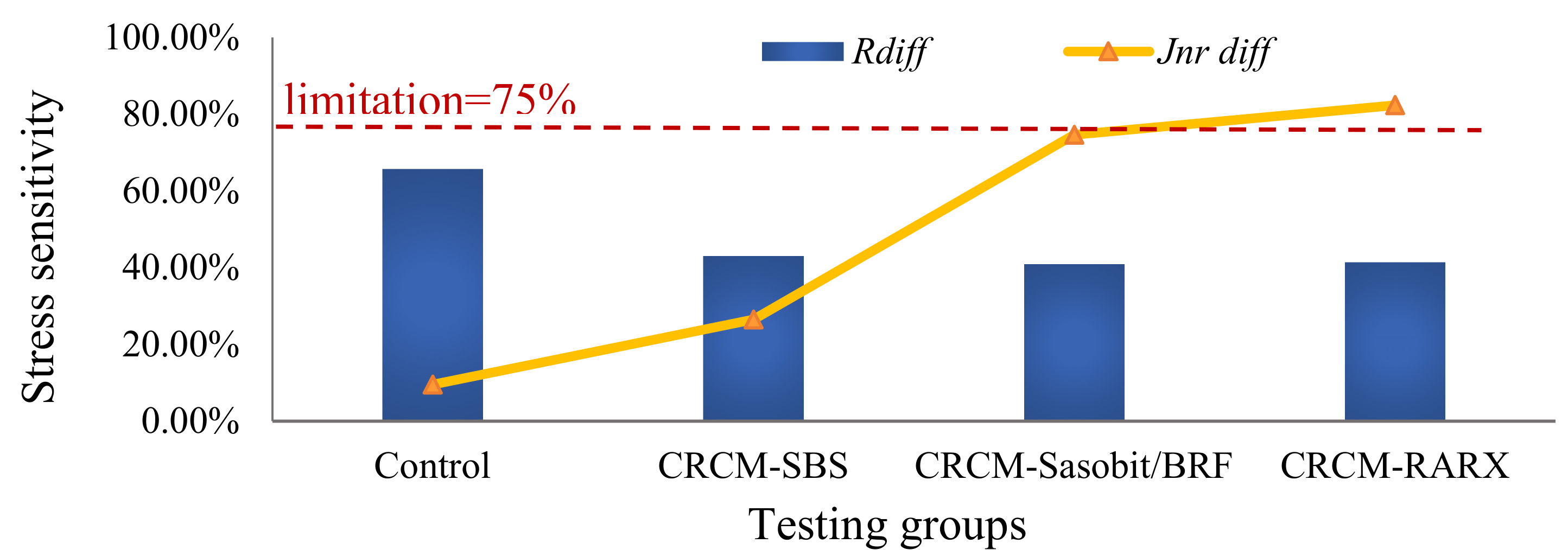

5.3.3. Stress Sensitivity

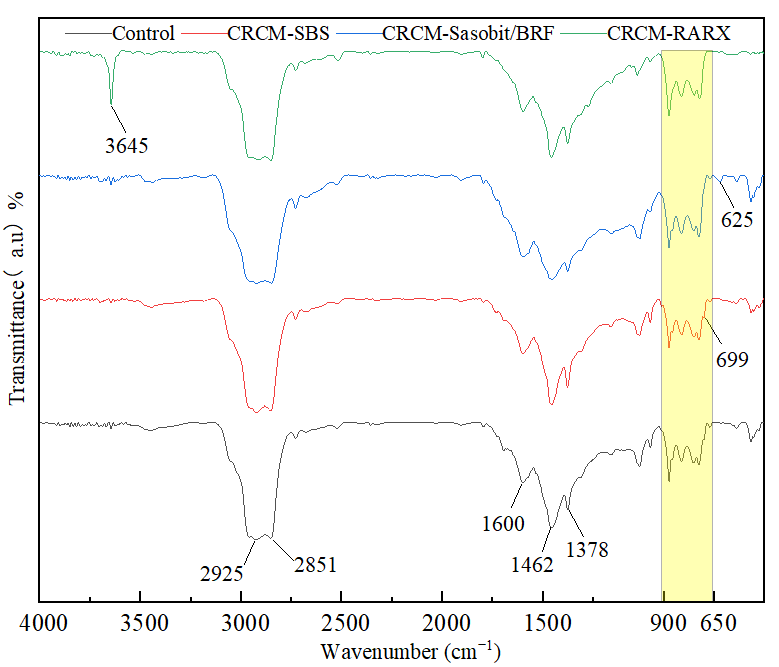

5.4. FTIR Test

6. Conclusions

- The addition of rubber particles and composite additives increased the viscosity of the virgin asphalt at different testing temperatures and rotational speeds. However, the consequence was highly related to the types of composite additives. Concurrently, the viscosity of crumb rubber composite modified asphalt could still be adequately flowable for the workability and mixability during the construction.

- Crumb rubber composite modified asphalt presented lower non-recoverable creep compliance and higher percent recovery. Additionally, the crumb rubber composite modified asphalt reduced the stress sensitivity of percent difference in recovery, while improving the difference in the non-recoverable creep compliance compared with the virgin binder.

- For the evaluation of high-temperature performance for crumb rubber composite modified asphalt, the conclusions of the rutting factor and MSCR test were in agreement with each other, and the results in a diminishing sequence were: CRCM-RARX, CRCM-Sasobit/BRF, and CRCM-SBS.

- From the results of the microscopic test, a strong absorption peak caused by the O-H stretching vibration exists in CRCM-RARX. Due to the improving activation degree of rubber, the high-temperature performance of CRCM-RARX is effectively enhanced.

Author Contributions

Funding

Conflicts of Interest

References

- Yang, X.; You, Z.; Hasan, M.R.M.; Diab, A.; Shao, H.; Chen, S.; Ge, D. Environmental and mechanical performance of crumb rubber modified warm mix asphalt using Evotherm. J. Clean. Prod. 2017, 159, 346–358. [Google Scholar] [CrossRef]

- Diab, A.; You, Z.; Yang, X.; Wahaballa, A.M. Multi-scale characterization of hydrated lime mastics. Can. J. Civ. Eng. 2017, 44, 985–993. [Google Scholar] [CrossRef]

- Chen, S.; You, Z.; Sharifi, N.P.; Yao, H.; Gong, F. Material selections in asphalt pavement for wet-freeze climate zones: A review. Constr. Build. Mater. 2019, 201, 510–525. [Google Scholar] [CrossRef]

- Riekstins, A.; Haritonovs, V.; Straupe, V. Economic and environmental analysis of crumb rubber modified asphalt. Constr. Build. Mater. 2022, 335, 127468. [Google Scholar] [CrossRef]

- Kaloush, K.E. Asphalt rubber: Performance tests and pavement design issues. Constr. Build. Mater. 2014, 67, 258–264. [Google Scholar] [CrossRef]

- Presti, D.L. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Xiao, F.; Zhao, P.W.; Amirkhanian, S.N. Fatigue behavior of rubberized asphalt concrete mixtures containing warm asphalt additives. Constr. Build. Mater. 2009, 23, 3144–3151. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, J.; Xiao, F.; Li, Z.; Wang, J.; Xu, Z. Performance investigation and sustainability evaluation of multiple-polymer asphalt mixtures in airfield pavement. J. Clean. Prod. 2018, 189, 67–77. [Google Scholar] [CrossRef]

- Kedarisetty, S.; Biligiri, K.P.; Sousa, J.B. Advanced rheological characterization of Reacted and Activated Rubber (RAR) modified asphalt binders. Constr. Build. Mater. 2016, 122, 12–22. [Google Scholar] [CrossRef]

- Ziari, H.; Goli, A.; Amini, A. Effect of Crumb Rubber Modifier on the Performance Properties of Rubberized Binders. J. Mater. Civ. Eng. 2016, 28, 04016156. [Google Scholar] [CrossRef]

- Gong, F.; Guo, S.; Chen, S.; You, Z.; Liu, Y.; Dai, Q. Strength and durability of dry-processed stone matrix asphalt containing cement pre-coated scrap tire rubber particles. Constr. Build. Mater. 2019, 214, 475–483. [Google Scholar] [CrossRef]

- Chen, S.; Ge, D.; Gong, F.; You, Z.; Diab, A.; Ye, M. Rheological properties and chemical characterisation of reacted and activated rubber modified asphalt binder. Road Mater. Pavement Des. 2020, 21, S140–S154. [Google Scholar] [CrossRef]

- Ghabchi, R.; Zaman, M.; Arshadi, A. Use of Ground Tire Rubber (GTR) in Asphalt Pavements: Literature Review and DOT Survey. 2016. Available online: https://www.semanticscholar.org/paper/USE-OF-GROUND-TIRE-RUBBER-(GTR)-IN-ASPHALT-REVIEW/1d05887c26cc086e3eb032a887c3387f03d6fee5 (accessed on 21 June 2022).

- Lin, W. Research on the Performance of Crumb Rubber Composite Modified Asphalt Based on Rheological Properties; South China University of Technology: Guangzhou, China, 2020. [Google Scholar]

- Rath, P.; Love, J.E.; Buttlar, W.G.; Reis, H. Performance Analysis of Asphalt Mixtures Modified with Ground Tire Rubber Modifiers and Recycled Materials. Sustainability 2019, 11, 1792. [Google Scholar] [CrossRef] [Green Version]

- Fontes, L.P.T.L.; Pereira, P.A.A.; Pais, J.C.; Trichês, G. Performance of Wet Process Method Alternatives: Terminal or Continuous Blend. In Proceedings of the Asphalt Rubber Conference, Palm Springs, CA, USA, 25–27 October 2006; pp. 545–562. Available online: http://repositorium.sdum.uminho.pt/handle/1822/7194 (accessed on 21 June 2022).

- Del Barco-Carrión, A.J.; García-Travé, G.; Moreno-Navarro, F.; Martínez-Montes, G.; Rubio-Gámez, M.C. Comparison of the effect of recycled crumb rubber and polymer concentration on the perfor-mance of binders for asphalt mixtures. Mater. De Constr. 2016, 66, 90. [Google Scholar]

- Sousa, J.B.; Vorobiev, A.; Rowe, G.M.; Ishai, I. Reacted and activated rubber: Elastomeric asphalt extender. Transp. Res. Rec. 2013, 2371, 32–40. [Google Scholar] [CrossRef]

- Ye, F.; Yin, W.; Lu, H.; Dong, Y. Property improvement of Nano-Montmorillonite/SBS modified asphalt binder by naphthenic oil. Constr. Build. Mater. 2020, 243, 118200. [Google Scholar] [CrossRef]

- You, L.; Yan, K.; Wang, D.; Ge, D.; Song, X. Use of amorphous-poly-alpha-olefin as an additive to improve terminal blend rubberized asphalt. Constr. Build. Mater. 2019, 228, 116774. [Google Scholar] [CrossRef]

- Bocoum, A.; Hosseinnezhad, S.; Fini, E.H. Investigating effect of amine based additives on asphalt rubber rheological properties. In Proceedings of the 12th International Conference on Asphalt Pavements, ISAP 2014, Raleigh, NC, USA, 1–5 June 2014; Taylor and Francis-Balkema: Abingdon, UK, 2014. [Google Scholar]

- Güngör, A.; Akbay, I.K.; Özdemir, T. Waste walnut shell as an alternative bio-based filler for the EPDM: Mechanical, thermal, and kinetic studies. J. Mater. Cycles Waste Manag. 2019, 21, 145–155. [Google Scholar] [CrossRef]

- Mokhothu, T.H.; John, M.J. Bio-Based Fillers for Environmentally Friendly Composites; Structure and Chemistry Handbook of Composites from Renewable Materials. 2017. pp. 243–270. Available online: https://www.researchgate.net/profile/Thabang-Mokhothu/publication/318510717_Bio-Based_Fillers_for_Environmentally_Friendly_Composites/links/59e84af60f7e9bc89b50c146/Bio-Based-Fillers-for-Environmentally-Friendly-Composites.pdf (accessed on 21 June 2022).

- Razmi, A.; Mirsayar, M. Fracture resistance of asphalt concrete modified with crumb rubber at low temperatures. Int. J. Pavement Res. Technol. 2018, 11, 265–273. [Google Scholar] [CrossRef]

- Wang, Y.; Zhan, B.; Cheng, J. Study on preparation process of SBS/crumb rubber composite modified asphalt. Adv. Mater. Res. 2012, 450–451, 417–422. [Google Scholar] [CrossRef]

- Wu, C.; Sousa, J.B.; Li, A.; Zhao, Z. Activated minerals as binder stabilizers in middle course’s asphalt concrete paving mixtures. In Proceedings of the Transportation Research Board 91st Annual Meeting, Washington, DC, USA, 22–26 January 2012; Transportation Research Board: Washington, DC, USA, 2012. [Google Scholar]

- Sousa, D.B. Elastomeric Asphalt Extender@ a New Frontier on Asphalt Rubber Mixes. 2012. Available online: http://www.ra-foundation.org/wp-content/uploads/2013/02/009-FormatoAR2012-Elastomeric-Asphalt-Extender.pdf (accessed on 21 June 2022).

- Hurley, G.C.; Prowell, B.D. Evaluation of Sasobit for Use in Warm Mix Asphalt; NCAT Report; 2005; Volume 5, pp. 1–27. Available online: http://www.doc88.com/p-70459576828616.html (accessed on 21 June 2022).

- Jamshidi, A.; Hamzah, M.O.; Zahed, M.A. Rheological Evaluation and Modeling of Sasobit®-Modified Asphalt Binder at High Temperatures. Pet. Sci. Technol. 2013, 31, 1574–1584. [Google Scholar] [CrossRef]

- Becker, Y.; Méndez, M.; Rodríguez, Y. Polymer modified asphalt. Vis. Tecnol. 2000, 9, 39–50. [Google Scholar]

- Wang, H.; Dang, Z.; You, Z.; Cao, D. Effect of warm mixture asphalt (WMA) additives on high failure temperature properties for crumb rubber modified (CRM) binders. Constr. Build. Mater. 2012, 35, 281–288. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixture for Highway Engineering. Ministry of Communications of People’s Republic of China: Beijing, China, 2011.

- AASHTO T 316-13; Viscosity Determination of Asphalt Binder Using Rotational Viscometer. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013.

- Wang, M.; Li, R.; Wen, Y.; Pei, J.; Xing, X.; Chen, Z. Rheological and aging behaviors of liquid rubber modified asphalt binders. Constr. Build. Mater. 2019, 227, 116719. [Google Scholar] [CrossRef]

- Wasage, T.L.; Stastna, J.; Zanzotto, L. Rheological analysis of multi-stress creep recovery (MSCR) test. Int. J. Pavement Eng. 2011, 12, 561–568. [Google Scholar] [CrossRef]

- Chen, Z.; Pei, J.; Wang, T.; Amirkhanian, S. High temperature rheological characteristics of activated crumb rubber modified asphalts. Constr. Build. Mater. 2018, 194, 122–131. [Google Scholar] [CrossRef]

- Mitchell, M.R.; Link, R.E.; Amirkhanian, A.N.; Xiao, F.; Amirkhanian, S.N. Evaluation of High Temperature Rheological Characteristics of Asphalt Binder with Carbon Nano Particles. J. Test. Eval. 2011, 39, 583–591. [Google Scholar] [CrossRef]

- Nien, Y.-H.; Yeh, P.-H.; Chen, W.-C.; Liu, W.-T.; Chen, J.-H. Investigation of flow properties of asphalt binders containing polymer modifiers. Polym. Compos. 2008, 29, 518–524. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- AASHTO M320; Standard Specification for Performance-Grade Asphalt Binder. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2017.

- Liu, L.; Xiao, F.; Zhang, H.; Amirkhanian, S. Rheological characteristics of alternative modified binders. Constr. Build. Mater. 2017, 144, 442–450. [Google Scholar] [CrossRef]

- Lv, S.; Liu, C.; Yao, H.; Zheng, J. Comparisons of synchronous measurement methods on various moduli of asphalt mixtures. Constr. Build. Mater. 2018, 158, 1035–1045. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; Liu, C.; Ge, D.; You, Z.; Yu, M. High-temperature rheological behavior and fatigue performance of lignin modified asphalt binder. Constr. Build. Mater. 2019, 230, 117063. [Google Scholar] [CrossRef]

| Property | Unit | Result | Specification | Method |

|---|---|---|---|---|

| Penetration at 25 °C | 0.1 mm | 63.5 | 60–80 | T0604-2011 |

| Penetration index | - | −1.37 | −1.5~+1.0 | T0604-2011 |

| Softening point (ring & ball method) | °C | 48.9 | ≥46 | T0606-2011 |

| Density at 15 °C | g/cm−3 | 1.038 | measured records | T0603-2011 |

| Ductility at 10 °C | cm | 31.2 | >20 | T0605-2011 |

| Ductility at 15 °C | cm | >150 | >100 | T0605-2011 |

| Dynamic viscosity at 60 °C | Pa.s | 208 | ≥180 | T0620-2011 |

| Wax content | % | <2.1 | <2.2 | T0615-2011 |

| Solubility (TCE) | % | >99.5 | >99.5 | T0607-2011 |

| Flash point (COC) | °C | >260 | >260 | T0611-2011 |

| After RTFO (163 °C, 85 min) | ||||

| Mass loss | % | 0.03 | ≤±0.8 | T0610-2011 |

| Residual penetration ratio (25 °C) | % | 67 | ≥61 | T0604-2011 |

| Residual ductility (10 °C) | cm | 6.9 | ≥6 | T0605-2011 |

| Residual ductility (15 °C) | cm | 18 | ≥15 | T0605-2011 |

| Chemical Properties of Crumb Rubber (by Weight of Crumb Rubber) | |

|---|---|

| Property | Percentage (wt. %) |

| Moisture content | 0.6 |

| Ash content | 5.11 |

| Carbon black content | 28.43 |

| Acetone content | 9.85 |

| Fiber content | 0.0.1 |

| Sulfur content | 1.47 |

| Technical properties of Reacted and Activated Rubber (RAR) | |

| Item | Technique information |

| Physical state | Solid, Black/grey powder |

| Odor and appearance | Mild rubber, black/grey with brownish color granules |

| Bulk density (g/cm−3) | 0.6 ± 0.03 |

| Specific gravity | 1.031 ± 0.03 |

| Flash point (°C) | >300 |

| Solubility | Insoluble in water |

| Chemical stability | Incompatible with strong oxidizing |

| Item | Technique Information |

|---|---|

| Technical information of BRF | |

| Physical state | Black with brownish color powders |

| PH value | 7.0~7.5 |

| Moisture content | 0~50 |

| Particle size D90 (μm) | ≤13 |

| Organic content (%) | 25~35 |

| Inorganic content (%) | 35~45 |

| Technical information of Sasobit | |

| Physical state/odor and appearance | White/yellowish prills (small pellets), odorless |

| Density at 25 ℃ (g/cm−3) | 0.94 |

| Flash point (℃) | ≥285 |

| Drop melting point (℃) | Around 115 °C |

| Chemical composition | Long-chain aliphatic hydrocarbon |

| Technical information of SBS | |

| Structure type | Star-shaped SBS |

| Styrene/butadiene (S/B) | 31/69 |

| Molecular weight (×104) | 23~28 |

| Tensile strength (kg·cm−2) | 330 |

| Hardness (shore A) | 76 |

| Specific gravity | 0.94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, F.; Lin, W.; Chen, Z.; Shen, T.; Hu, C. High-Temperature Rheological Properties of Crumb Rubber Composite Modified Asphalt. Sustainability 2022, 14, 8999. https://doi.org/10.3390/su14158999

Gong F, Lin W, Chen Z, Shen T, Hu C. High-Temperature Rheological Properties of Crumb Rubber Composite Modified Asphalt. Sustainability. 2022; 14(15):8999. https://doi.org/10.3390/su14158999

Chicago/Turabian StyleGong, Fangyuan, Weijie Lin, Zhenkan Chen, Tao Shen, and Chichun Hu. 2022. "High-Temperature Rheological Properties of Crumb Rubber Composite Modified Asphalt" Sustainability 14, no. 15: 8999. https://doi.org/10.3390/su14158999

APA StyleGong, F., Lin, W., Chen, Z., Shen, T., & Hu, C. (2022). High-Temperature Rheological Properties of Crumb Rubber Composite Modified Asphalt. Sustainability, 14(15), 8999. https://doi.org/10.3390/su14158999