1. Introduction

Remanufacturing is a green manufacturing technology that can effectively utilize used products and has become an important contributor to the development of a circular economy [

1]. The remanufacturing of used products provides products of the same quality as new ones, and effectively reduces economic input, resource consumption and environmental pollution [

2]. However, the current raw materials for remanufacturing (cores) are mainly derived from scrapped products, which denotes typical end-of-life cycle remanufacturing [

3]. The quality of these cores varies widely due to uncertainty and variation in the degree of damage forms in the service process of products, leading to a difficult remanufacturing craftsmanship and inefficient process, which limits the remanufacturing industry’s growth. [

4]. Therefore, it is essential to start from a life-cycle perspective, progressing through comprehensive decision-making, to choose the best time to implement active remanufacturing during the service period of the product, so as to prevent the “remanufacturing in advance” or “overuse” of cores, and realize the comprehensive optimization of technology, economy and environment in the product life cycle.

A lot of research has been conducted in the field of the timing for active remanufacturing. Ke et al. [

5] identified the active-remanufacturing-timing domain decision method by analyzing the life-cycle service value of electromechanical products. By defining the energy-consumption characteristic as the main index, they were able to determine the ideal active remanufacturing timing. Wang et al. [

6] obtained the best active-remanufacturing temporal arrangement by analyzing the dependability changes in a mechanical device product in commission. Liu et al. [

7] considered the value-per-unit temporal order to minimize services because of the improvement objective, and acquired the best remanufacturing recovery temporal order. Gong et al. [

8] proposed a non-empirical hybrid multi-attribute decision-making method, which mitigates well the influence of the subjective factors of designers. Zhang et al. [

9] presented the remanufacturing timing computing method with the optimal carbon-emission reduction benefit in engines, and the ideal active remanufacturing timing for carbon-emission reduction benefit was discovered by studying the system boundaries of engines. In view of the problems of energy scarcity and the environment, Ma et al. [

10,

11] proposed an energy-efficiency-rating (ege) method based on energy-efficiency rating (IEE) and a processing system energy-assessment method based on the data-processing grouping method (GMDH), which is helpful for the energy management decisions of manufacturing enterprises. Song et al. [

12] comprehensively considered the fatigue and wear of crankshafts, and obtained the best active remanufacturing temporal arrangement of crankshafts. Wang et al. [

13] provided an online monitoring signals model to analyze the optimal timing of the active remanufacturing of the crankshafts.

The aforementioned studies provide a useful reference for the timing decision of active remanufacturing. Nevertheless, a large portion of the research [

14,

15] has either focused only a certain damaged characteristic of the product, or only taken cost, energy consumption, carbon emissions and other single factors into consideration to determine the timing of active remanufacturing. Few studies [

12,

16] on the timing of active remanufacturing consider both economic and environmental factors, and appropriate integration methodologies are still lacking. To this end, based on the 3E analysis of product life cycle, a multi-objective optimization model of active remanufacturing timing decisions is established, and the particle swarm algorithm is used to ascertain the ideal remanufacturing timing for economic and environmental benefits, which provides methodological support for the remanufacturing of used engines.

The remainder of this paper is organized as follows: the second part introduces the method of this article, including two stages of product-life-cycle 3E analysis and multi-objective optimization solutions. The third part is the case study. The fourth part summarizes the conclusions and future work.

2. Methodology

Active remanufacturing is for products in service, according to the failure rule of products over time, the bathtub curve (as shown in

Figure 1). According to the different time points of active remanufacturing, it can be divided into “remanufacturing in advance” and “overuse”. There will also be an optimal time for active remanufacturing between these two stages. The implementation of remanufacturing at this moment can effectively prevent the core from being remanufactured in advance or overused.

In this paper, economic, energy and environmental (3E) analysis is used as the performance indicators of the active-remanufacturing-timing research. However, they have different curves over time. If the 3E parameters are also used as the basis for the active-remanufacturing timing decision, three different active-remanufacturing time points

will be obtained. Therefore, conflict resolution is needed first, and then the active remanufacturing timing is obtained from a comprehensive perspective, as shown in

Figure 2.

2.1. 3E Analysis of Product Life Cycle

Product-life-cycle 3E analysis is a method to quantify the economic, energy, and environmental impact of a product during its life cycle [

17]. Its advantages include full-process analysis and extensive coverage. When researching the timing of active remanufacturing, the manufacturing-stage, service-stage, and remanufacturing-stage cost, energy consumption and environmental emissions in the product life cycle are important factors that need to be considered. By analysing the functional relationship between them and time, one will offer effective steering for the choice of active-remanufacturing temporal arrangements.

2.1.1. LCA and LCC Methods

Life-cycle assessment (LCA) is used to evaluate the environmental factors of the product life cycle and its potential impact technology. It can quantitatively analyze and calculate the energy consumption consumed throughout the life cycle of a product (e.g., mining raw materials, product processing and manufacturing, transportation, recycling and recycling, etc.) and material consumption and discharged waste, to achieve a series of processes with the best environmental impact [

18,

19]. As the performance of products varies in different stages of the life cycle, LCA needs to be used to analyze the environmental and energy impacts of each stage. Life-cycle cost (LCC) is a method of systematically evaluating all the related costs of a project, product, or service in the life cycle. This includes all costs from the design stage, raw material processing, product manufacturing, transportation and end-of-life, and even the recycling phase. It is a guideline for evaluating the economic benefits of a product or making decisions on the modification of the plan by analyzing and calculating the cost of each stage of the product [

20,

21]. Through the combination of LCA and LCC, from the perspective of life-cycle impact assessment and economic analysis, the practicability of traditional LCA is improved, and the importance of balancing economic and environmental benefits is reflected.

2.1.2. Energy Analysis

The function of product energy consumption with time has strong regularity, which can effectively reflect the quality degradation law of products in service, and is an important index to be considered in the timing decision of active remanufacturing.

- (1)

Manufacturing stage

The product producing stage includes: material mining, extraction, forging, machining, and assembly, etc. In line with the method sort, the energy consumption within the producing stage includes: energy usage of materials processing , and energy consumption of core processing .

Taking into account that the categories of raw material is

, the mass of the processed

th raw material is

and the energy consumption per unit mass is

. Consequently, the energy needed to process raw materials is:

Suppose the primary processing step is

and the specific energy depletion of the

th process is

, Each procedure’s quality of material eliminated is

. Therefore, the energy consumption of core processing is:

The amount of energy used throughout the production process

is:

- (2)

Service stage

The energy loss produced by the wear of critical engine parts accounts for the majority of the energy consumption during the servicing stage. By recording the consumption of multiple energy types under different usage times, the energy consumption of the service phase can be linear fitted.

where

is

th type energy-consumption function, which is related to time and

is

th type energy-consumption factor.

- (3)

Remanufacturing stage

The remanufacturing process of used products includes: disassembly, cleaning, repair, subsequent processing, inspection, reassembly, etc. The remanufacturing process of products under different service periods is very different. The energy consumption in the remanufacturing period can be calculated depended on the energy-consumption checklist when the product is completely scrapped:

where

is the total energy used by various procedures throughout the remanufacturing step,

is the energy conversion rate, which is the percentage of the energy consumption of the

th process in the

th year of service to the energy consumption of the

th process when it is scrapped.

The average annual energy-consumption function is:

2.1.3. Economic Analysis

Controlling the cost of the product’s life cycle is of great significance for maximizing economic benefits, and it is also a key factor that cannot be ignored in the study of active remanufacturing timing.

- (1)

Manufacturing stage

The cost of the product-manufacturing stage includes the purchase cost of raw materials and the cost of electricity consumption. Suppose the unit quality raw material price is

, and the unit power consumption cost is

. The cost of the product in the manufacturing stage is:

- (2)

Service stage

As the cost of products in the service period mainly includes the cost of using energy such as electric energy or chemical energy. Suppose the price per unit of energy is

. The cost of products in the service phase is:

- (3)

Remanufacturing stage

The cost of the remanufacturing stage mainly includes the cost of using electric energy. Assuming the price of unit electric energy is

, the cost of the product in the remanufacturing stage is:

The annual-average-cost function is:

2.1.4. Environmental Analysis

In the face of depletion of natural resources and environmental damage, environmental benefits have received increasing attention from enterprises. Environmental emissions are also one of the important indicators to be considered when making active remanufacturing timing decisions.

- (1)

Manufacturing stage

The consumption of crude oil, coal, and natural gas contributes to environmental emissions during the product-manufacturing stage, while the consumption of electricity contributes to environmental emissions during the raw-material-processing stage. Assuming

is the total amount of the

th contaminant generated by the

th energy per unit mass, the amount of electricity energy expended during core processing is

, and

is the mass of the

th contaminant created by an electricity-generating unit; there are

categories of environmental emissions.

- (2)

Service stage

Assuming that there are

types of environmental emissions produced by the product during service,

is the mass of pollutants produced by the combustion of unit mass energy. The environmental emissions during the service stage are:

- (3)

Remanufacturing stage

The main energy consumption in the remanufacturing craft of used products is electrical energy;

is the quality of pollutants generated per unit of electricity energy. The environmental emissions at the remanufacturing stage are:

The annual average environmental emission function is:

2.2. Modeling and Solving the Multi-Objective Optimization Problem

Multi-objective optimization problems are common in various subject areas. They usually use multiple criteria or multiple objectives as research objects. In the actual decision-making process, each goal is constrained or affected by other goals. Therefore, most multi-objective optimizations cannot achieve the best results at the same time. The objective function, decision variables, and constraints are the three major elements of a multi-objective optimization problem [

22].

2.2.1. Normalization of Multiple Objective Functions

For linear function models, converting multiple objective functions into a single objective function is an effective solution method. In this paper, the cost, energy-consumption and environmental-emission functions can all be fitted as linear functions. Before the normalization of multi-objective functions, the functions should be dimensionless so that they are in the same order of magnitude.

where

is processed function,

is the function before processing,

is the maximum value of the

th function, and

is the minimum value of the

th function.

The multiply–divide method is used to construct the multi-objective function into a one-objective function, which can optimize the complex models and reduce the calculation amount.

where

is processed function,

is the

th function,

is weight value,

.

2.2.2. Objective Function of Optimization

The goal of optimization is to minimize the normalized function value within the whole service cycle stage of the used products, so the optimized function model can be expressed as:

where

is the normalized function,

is service time of the product,

is the minimum service time of the used products, and

is the maximum service time of the used products.

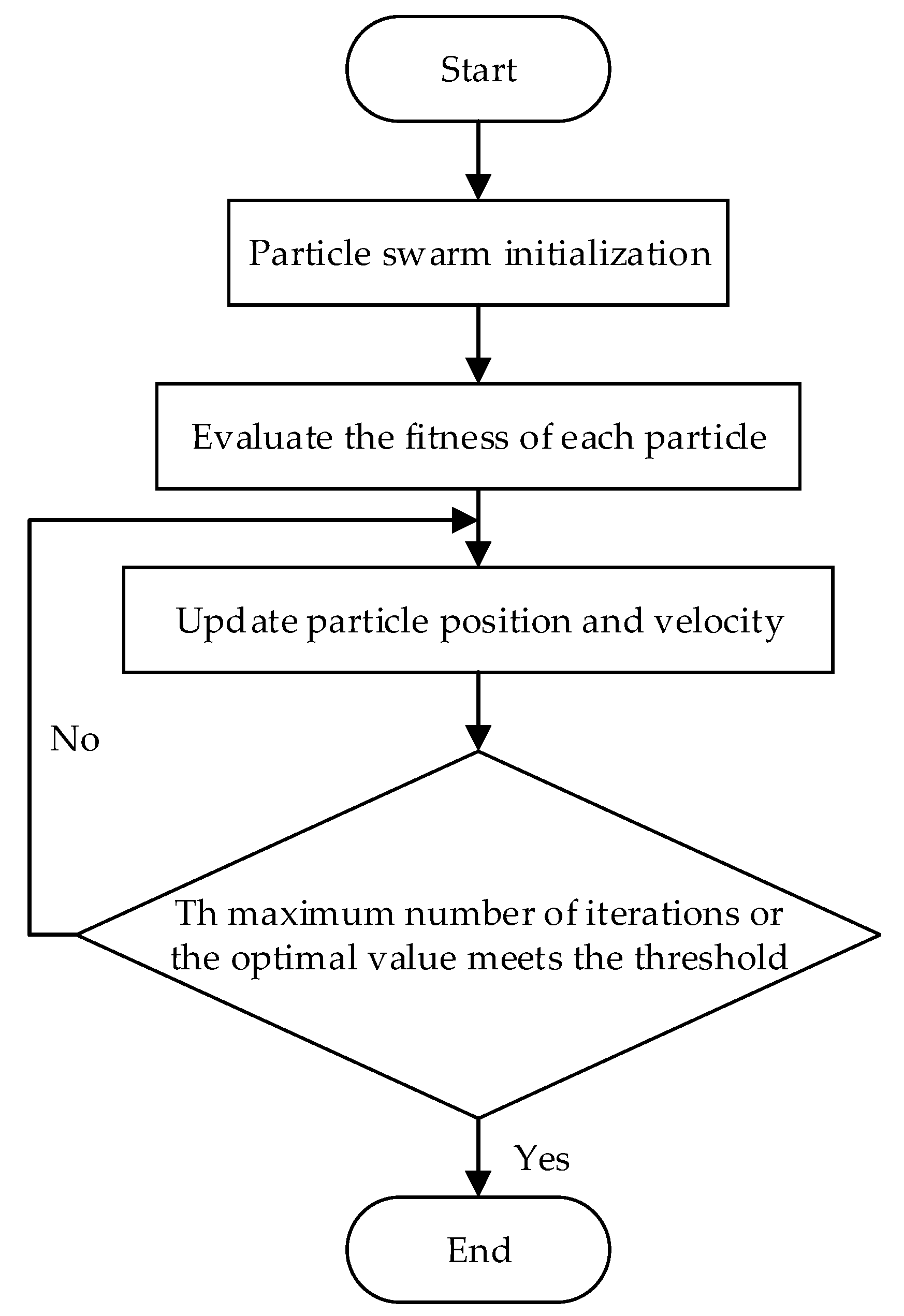

2.2.3. Model Solving with Particle Swarm Optimization

Some global optimization algorithms, such as tabu search, a simulated annealing algorithm, are limited by their respective mechanisms and structures. Therefore, it is difficult for them to optimize complex multi-objective functions efficiently [

23]. Particle swarm optimization is inspired by animal foraging behavior, and its group assistance and random search can effectively solve complex function-optimization problems. Particle swarm optimization algorithms address the basic characteristics of biological behavior in nature using universal, simple survival rules, and then convert these characteristics and rules into a computer language, achieving the goal of simulating the behavior of individual organisms and solving complex problems in practice [

24,

25]. This method has been widely used in the field of engineering. As a result, to optimize the solution, this work uses the particle swarm optimization algorithm. The flowchart of particle swarm optimization is shown in

Figure 3.

3. Case Study

The object of this study is the used engine; its service life is defined as . If the active remanufacturing is implemented early, the service value of the product cannot be fully utilized, so the engine service time is set as the first active remanufacturing timing. In addition, the system boundary is limited to that not involving the secondary remanufacturing of the engine.

3.1. Annual Average Energy Consumption

- (1)

Manufacturing stage

This is the list of raw-material-processing energy usage (as shown in

Table 1), and parts-manufacturing process energy-consumption list (as shown in

Table 2).

According to the data in the table and Formulas (12) and (13), the production stage’s energy usage is:

- (2)

Service stage

With the increase in service time, the wear of the key parts of the engine becomes more and more serious, which leads to the deterioration of engine performance. In order to ensure enough torque output, the engine’s fuel consumption will rise. When the engine rated speed is

, and annual mileage is

, the energy consumption during the service stage of the engine is:

- (3)

Remanufacturing stage

The energy consumption of the engine remanufacturing stage depends on the processing technology of each key part. The remanufacturing process of the crankshaft is: cleaning, testing, remanufacturing, subsequent processing, inspection, etc.; the remanufacturing course of the cylinder adopts the course of replacement method; the remanufacturing course of the connecting rod is the replacement of the small end bushing, honing, boring cutting, milling, etc. The list of energy consumption during the remanufacturing of key engine components is shown in

Table 3.

The energy consumption in the remanufacturing phase of the engine is obtained by fitting:

Therefore, the average annual energy consumption function is:

3.2. Annual Average Cost

- (1)

Manufacturing stage

The cost of the manufacturing stage includes raw-material purchase cost, processing cost and energy-consumption cost. According to current market prices, a ton of coal is

, a barrel of crude oil is

, a cubic meter of natural gas is

, the price of industrial electricity is

per kilowatt hour, and a ton of steel is

. Therefore, the cost of the manufacturing stage is:

- (2)

Service stage

The additional fuel consumption caused by performance degradation during the service stage of the engine is the maintenance cost of the engine-maintenance stage. The present market price of one ton of diesel is

. The cost during the service stage of the engine is:

- (3)

Remanufacturing stage

The cost of the engine-remanufacturing stage primarily includes the use cost of electric energy, and the purchase cost of nickel chromium and nickel. According to the current market price, the price of a ton of nickel is

, and the price of a ton of nickel–chromium alloy is

. The cost during the remanufacturing stage of the engine is:

Therefore, the average annual cost function is:

3.3. Annual Average Environmental Emissions

- (1)

Manufacturing stage

Coal, crude oil, natural gas, and other raw materials are used in the raw-material processing process, the core-processing process consumes electricity; these processes will produce

,

,

,

,

. Environmental emissions during the manufacturing stage are:

- (2)

Service stage

The environmental emissions generated by each ton of diesel consumed by the engine are shown in

Table 4.

During the service stage of the engine, the main consumption is diesel. The environmental emissions generated are

,

,

,

,

- (3)

Remanufacturing stage

The environmental emissions produced during the engine-remanufacturing stage are mainly related to the electrical-energy consumption.

Therefore, the average annual environmental emission function is:

3.4. Multi-Objective Optimization Solution

First, the three functions are characterized so that they are of the same magnitude, as follows:

Second, the multi-objective function is transformed to a one-objective function by the multiply–divide method. In this paper, the weight coefficients of energy consumption, cost, and environmental emissions were chosen as 0.25, 0.50, 0.25, respectively. Therefore, the optimization model is:

To put the particle swarm algorithm into practice, a program is written in MATLAB; the particle swarm algorithm’s parameters are as follows: population size

, particle dimension

, the number of evolution

, maximum flying speed of particles

, minimum flying speed of particles

. The minimum timing for active remanufacturing is

; the maximum timing for active remanufacturing is

. The above data and functions were incorporated into the particle swarm algorithm, and an iterative flowchart of optimal timing for active remanufacturing based on the particle swarm algorithm was finally obtained, as shown in

Figure 4.

The iterative flowchart of the particle swarm algorithm shows that the optimal solution reaches stability at the 30th generation of the population. The optimal timing for active remanufacturing is .

4. Conclusions

This work proposes an active-remanufacturing-timing research method based on a 3E analysis of product life cycle, which effectively prevents remanufactured cores from being remanufactured in advance or overused. The LCA and LCC are integrated in this model to analyze the energy, economic and environmental impacts of the product manufacturing stage, service stage, and remanufacturing stage. For the active-remanufacturing timing of average annual energy consumption, a multi-objective optimization model was also constructed, including cost and environmental emissions, and the model was solved using a particle swarm approach. A diesel engine of the X15 series manufactured by a company is used as an example; the efficacy of the proposed strategy was demonstrated. According to the diesel-engine design manual and the actual working condition of the X15 series diesel engine, the overhaul time of the general diesel engine is about the third year after service, and the active-remanufacturing time obtained by the product life cycle 3E analysis is 3.381 years, which is close to the overhaul time of a diesel engine and can be applied to other diesel engines. The work presented here not only introduces a timing decision-making method for proactive remanufacturing, but it also provides methodological support for a 3E analysis of a product life cycle, which may play an important role in the cleaner production of enterprises.

In future work, the stages of the life cycle can be analyzed in more detail, covering topics such as the product transportation process and scrap process. In addition, more efficient algorithms can be developed to enhance the correctness of outcomes when solving the model.