Immobilization of Metals in Fired Clay Brick Incorporated with Aluminium-Rich Electroplating Sludge: Properties and Leaching Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material Preparation

2.2. Geotechnical and Chemical Properties of the Raw Materials

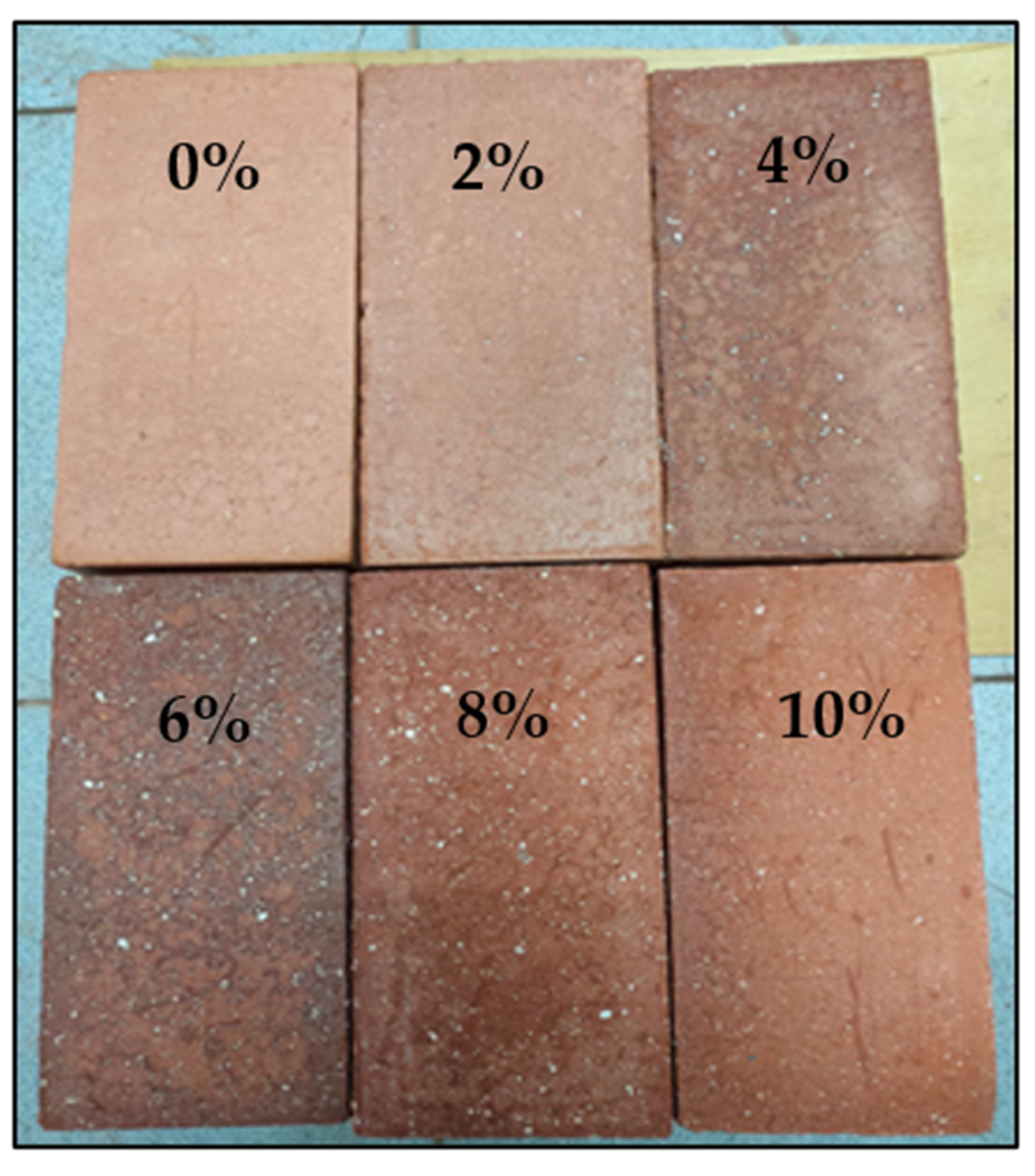

2.3. Manufacturing of Brick Samples

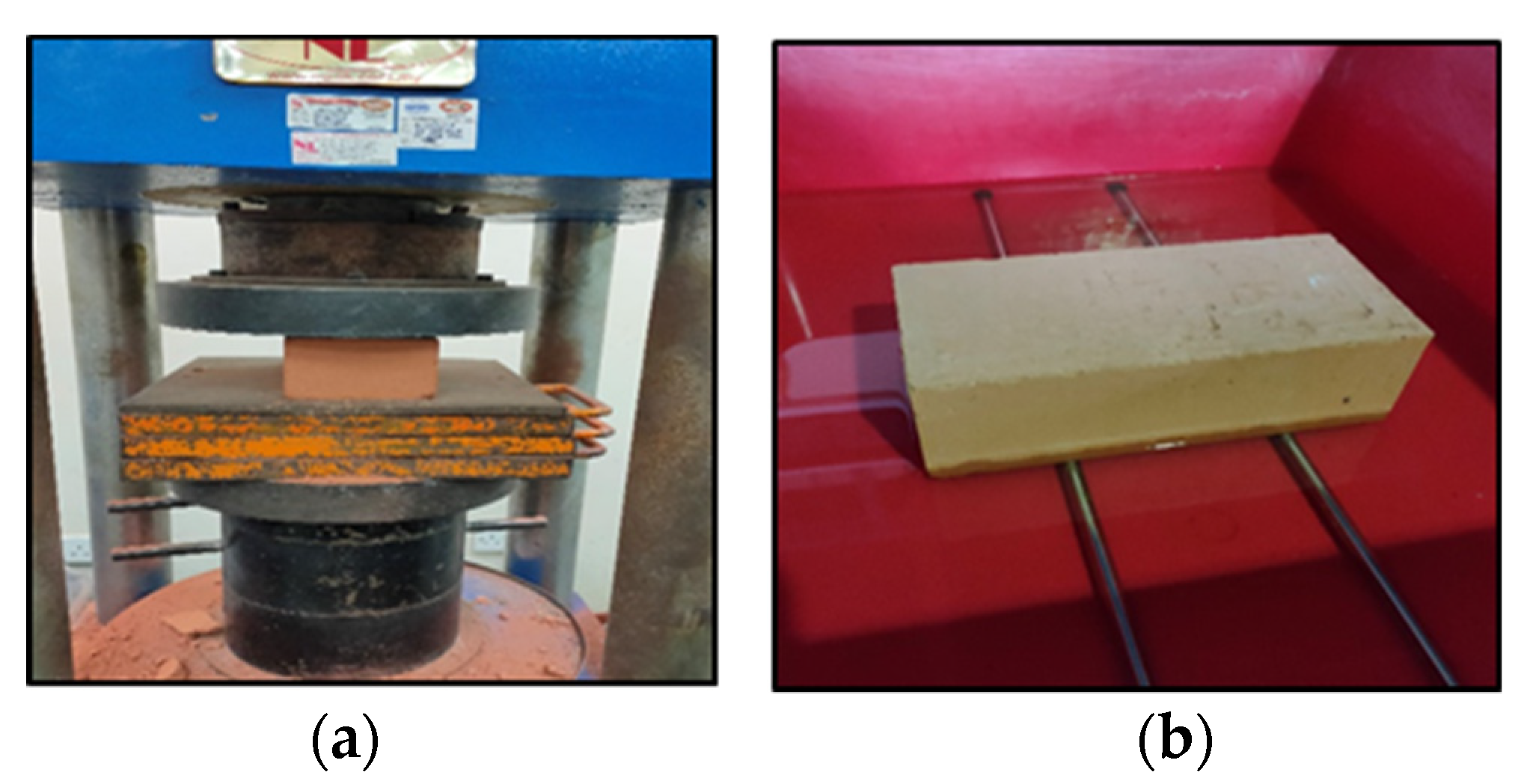

2.4. Physical and Mechanical Testing of the Brick Samples

2.5. Leachability Test of Metals

3. Results and Discussion

3.1. Chemical Compositions of Raw Materials

3.2. Physical and Mechanical Properties of Bricks

3.2.1. Firing Shrinkage

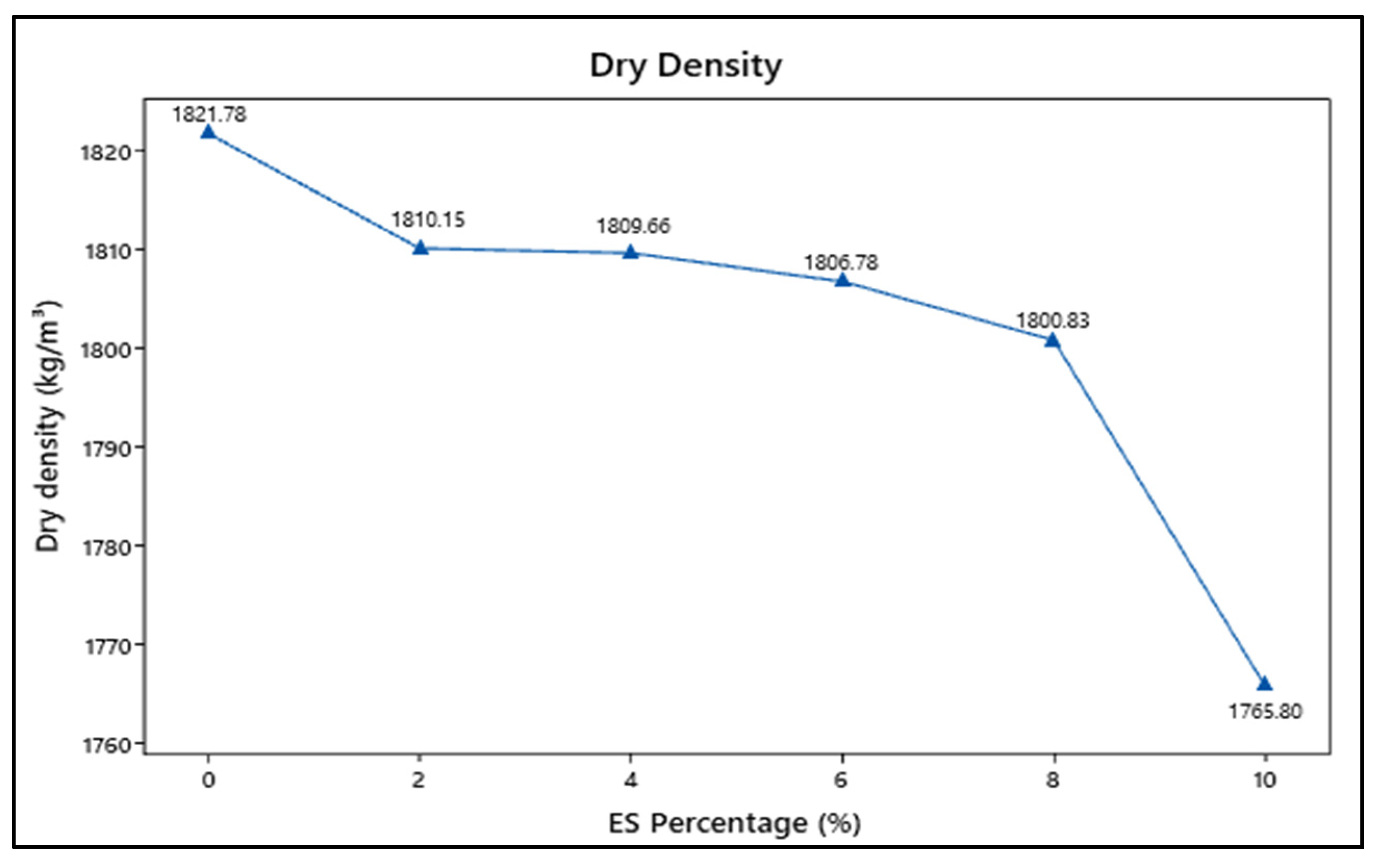

3.2.2. Dry Density

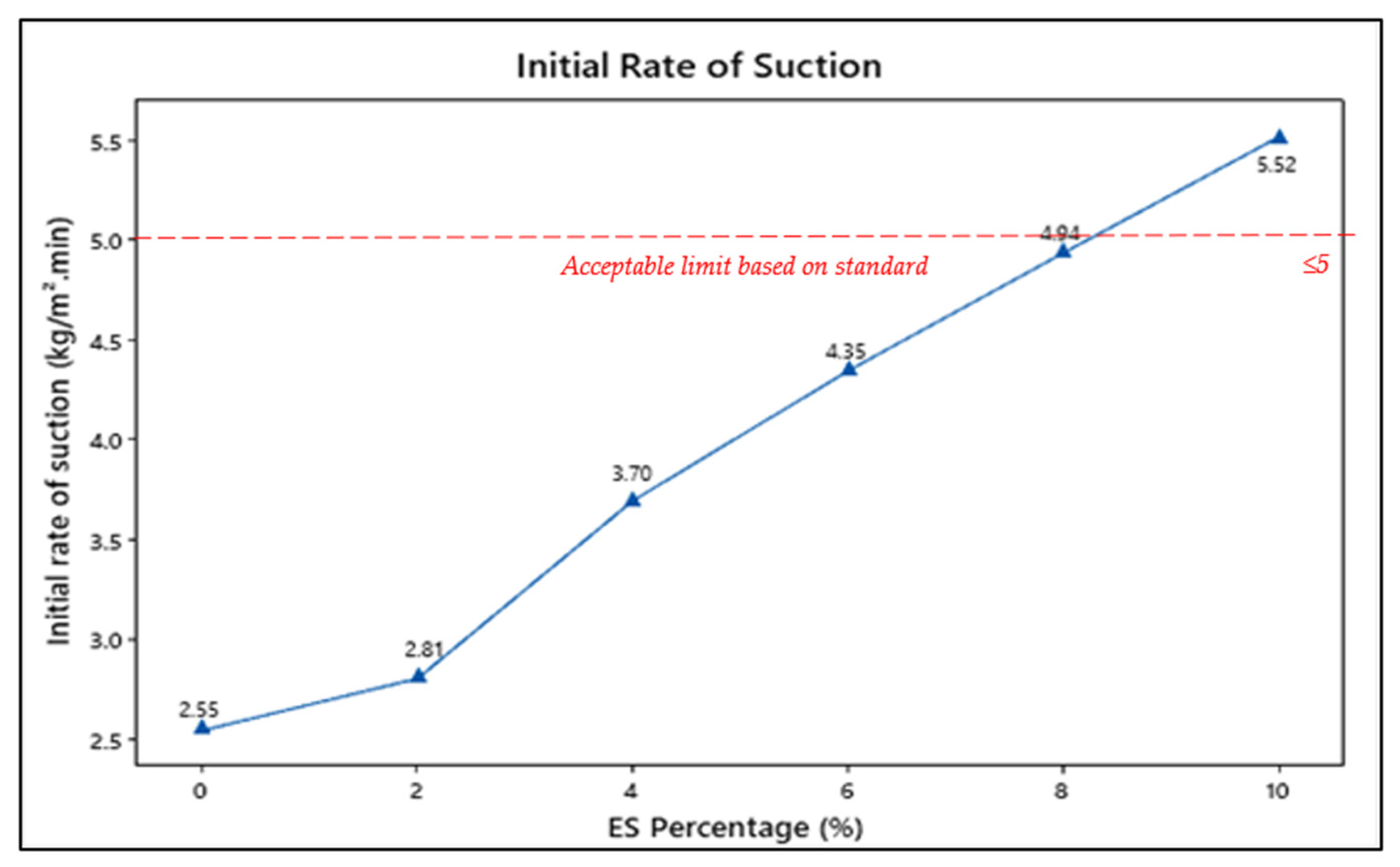

3.2.3. Initial Rate of Suction

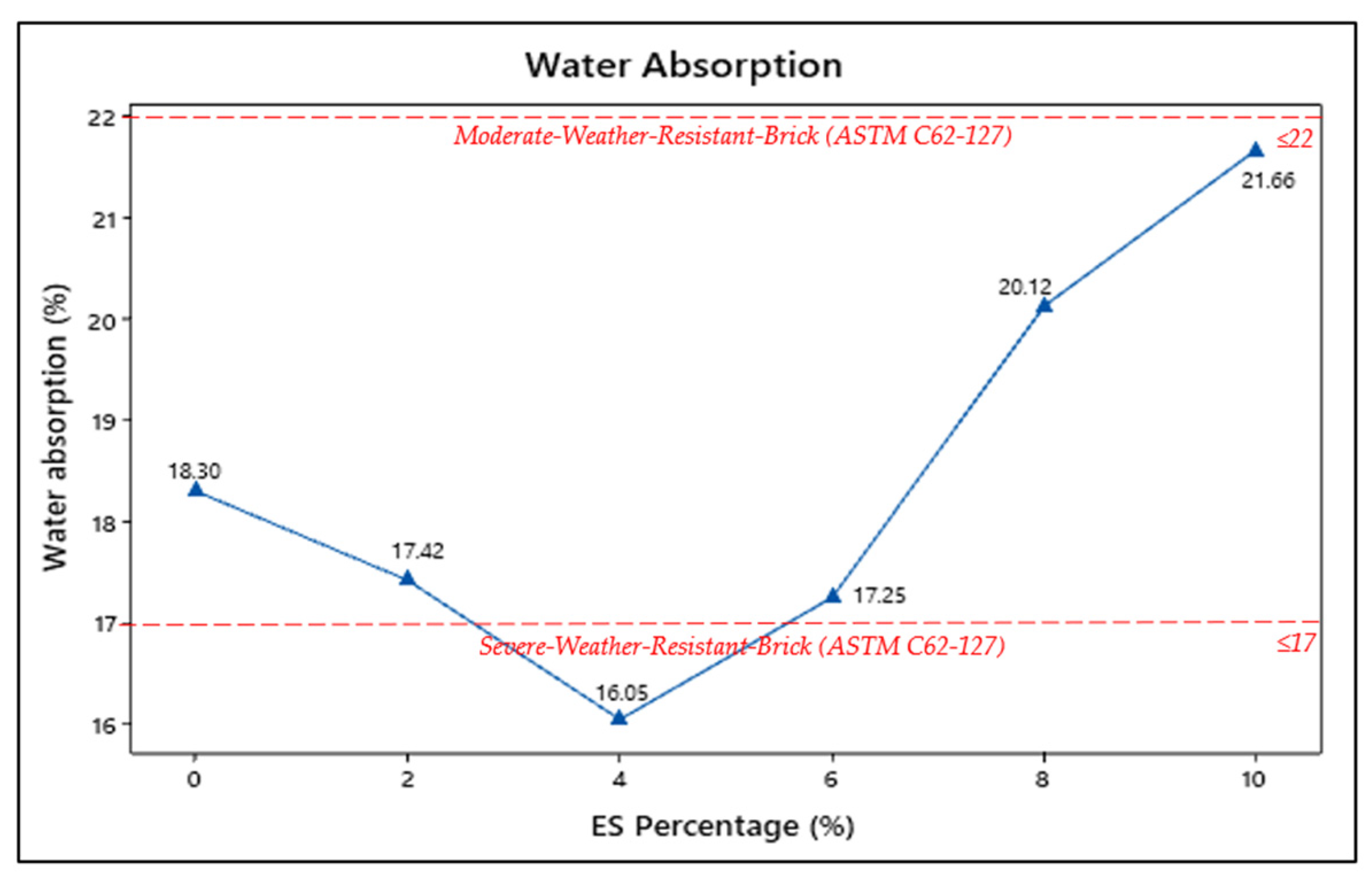

3.2.4. Water Absorption

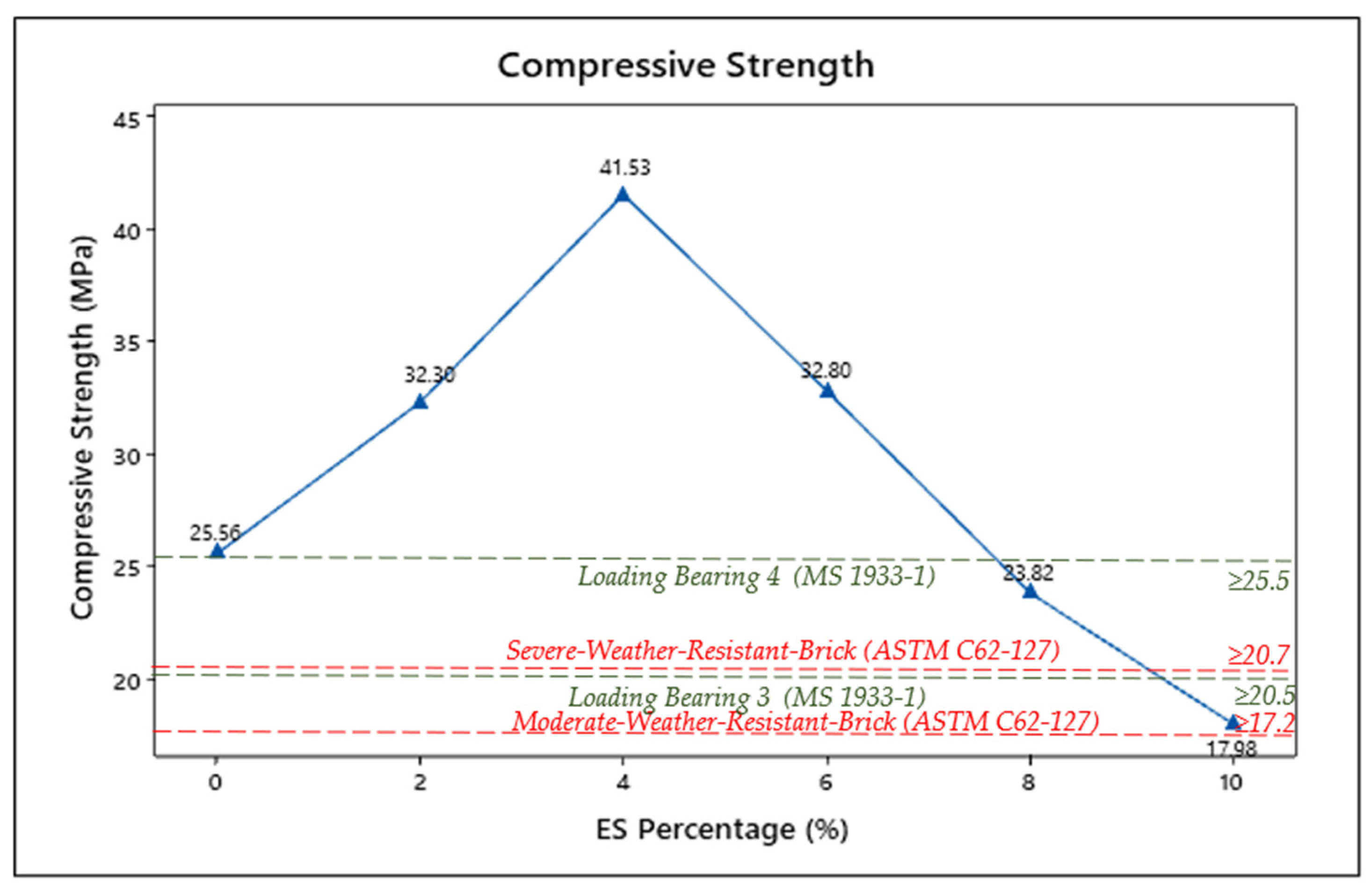

3.2.5. Compressive Strength

3.3. Leachability of Metals

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Department of Environment Malaysia (DOE). Current Practice of Recycling and Treatment of Hazardous Wastes in Malaysia; DOE: Putrajaya, Malaysia, 2011; pp. 1–35. Available online: www.doe.gov.my (accessed on 25 January 2022).

- Dai, Z.; Zhou, H.; Zhang, W.; Hu, L.; Huang, Q.; Mao, L. The improvement in properties and environmental safety of fired clay bricks containing hazardous waste electroplating sludge: The role of Na2SiO3. J. Clean. Prod. 2019, 228, 1455–1463. [Google Scholar] [CrossRef]

- Al-Sibahy, A.; Edwards, R. Characterization of the clay masonry units and construction technique at the ancient city of Nippur. Eng. Struct. 2019, 147, 517–529. [Google Scholar] [CrossRef] [Green Version]

- Vieira, C.M.F.; Pinheiro, R.M.; Rodriguez, R.J.S.; Candido, V.S.; Monteiro, S.N. Clay bricks added with effluent sludge from paper industry: Technical, economical and environmental benefits. Appl. Clay Sci. 2016, 132–133, 753–759. [Google Scholar] [CrossRef]

- Eliche-Quesada, D.; Azevedo-Da Cunha, R.; Corpas-Iglesias, F.A. Effect of sludge from oil refining industry or sludge from pomace oil extraction industry addition to clay ceramics. Appl. Clay Sci. 2015, 114, 202–211. [Google Scholar] [CrossRef]

- Magalhães, J.M.; Silva, J.E.; Castro, F.P.; Labrincha, J.A. Effect of experimental variables on the inertization of galvanic sludges in clay-based ceramics. J. Hazard. Mater. 2004, 106, 139–147. [Google Scholar] [CrossRef]

- Gencel, O. Characteristics of fired clay bricks with pumice additive. Energy Build. 2015, 102, 217–224. [Google Scholar] [CrossRef]

- Sutcu, M. Influence of expanded vermiculite on physical properties and thermal conductivity of clay bricks. Ceram. Int. 2015, 41, 2819–2827. [Google Scholar] [CrossRef]

- Bories, C.; Aouba, L.; Vedrenne, E.; Vilarem, G. Fired clay bricks using agricultural biomass wastes: Study and characterization. Constr. Build. Mater. 2015, 91, 158–163. [Google Scholar] [CrossRef] [Green Version]

- BS 1377-2; British Standard (BS). Methods of Test for Soils for Civil Engineering Purposes, Part 2—Chemical and Electro-Chemical Tests. The British Standards Institution: London, UK, 1990.

- BS 1377-3; British Standard (BS). Methods of Test for Soils for Civil Engineering Purposes, Part 3—Classification Tests. The British Standards Institution: London, UK, 1990.

- BS 3921; British Standard Specification for Clay Bricks. The British Standards Institution: London, UK, 1985.

- Environment Protection Agency. Method 1311: Toxicity Characteristic Leaching Procedure; Environment Protection Agency: Washington, DC, USA, 1992.

- United States Environmental Protection Agency (USEPA). Hazardous Waste Characteristics Coping Study; USEPA: Washington, DC, USA, 1996.

- Zhang, M.; Chen, C.; Mao, L.; Wu, Q. Use of electroplating sludge in production of fired clay bricks: Characterization and environmental risk evaluation. Constr. Build. Mater. 2018, 159, 27–36. [Google Scholar] [CrossRef]

- Pérez-Villarejo, L.; Martínez-Martínez, S.; Carrasco-Hurtado, B.; Eliche-Quesada, D.; Ureña-Nieto, C.; Sánchez-Soto, P.J. Valorization and inertization of galvanic sludge waste in clay bricks. Appl. Clay Sci. 2015, 105–106, 89–99. [Google Scholar] [CrossRef] [Green Version]

- Muñoz, P.; Morales, M.P.; Letelier, V.; Mendívil, M.A. Fired clay bricks made by adding wastes: Assessment of the impact on physical, mechanical and thermal properties. Constr. Build. Mater. 2016, 165, 112–125. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Alexandre, J.; Margem, J.I.; Sánchez, R.; Vieira, C.M.F. Incorporation of sludge waste from water treatment plant into red ceramic. Constr. Build. Mater. 2008, 22, 1281–1287. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Vieira, C.M.F. On the production of fired clay bricks from waste material: A critical update. Constr. Build. Mater. 2014, 68, 97–107. [Google Scholar] [CrossRef]

- Mao, L.; Gao, B.; Deng, N.; Zhai, J.; Zhao, Y.; Li, Q.; Cui, H. The role of temperature on Cr (VI) formation and reduction during heating of chromium-containing sludge in the presence of CaO. Chemosphere 2015, 138, 197–204. [Google Scholar] [CrossRef] [PubMed]

- Pillay, K.; Von Blottnitz, H.; Perersen, J. Ageing of chromium (III) bearing slag and its relation to the atmospheric oxidation of solid chromium (III)-oxide in the presence of calcium oxide. Chemosphere 2003, 52, 1771–1779. [Google Scholar] [CrossRef]

- Karaman, S.; Ersahin, S.; Gunal, H. Firing temperature and firing time influence on mechanical and physical properties of clay bricks. J. Sci. Ind. Res. 2006, 65, 153–159. [Google Scholar]

- Dai, Z.; Wu, Y.; Hu, L.; Zhang, W.; Mao, L. Evaluating physical–mechanical properties and long periods environmental risk of fired clay bricks incorporated with electroplating sludge. Constr. Build. Mater. 2019, 227, 116716. [Google Scholar] [CrossRef]

- Cusidó, J.A.; Cremades, L.V.; Soriano, C.; Devanta, M. Incorporation of paper sludge in clay brick formulation: Ten years of industrial experience. Appl. Clay Sci. 2015, 108, 191–198. [Google Scholar] [CrossRef]

- Kurmus, H.; Mohajerani, A. Recycling of cigarette butts in fired clay bricks: A new laboratory investigation. Materials 2020, 13, 790. [Google Scholar] [CrossRef] [Green Version]

- Kayali, O. High performance bricks from fly ash. In Proceedings of the 2005 World of Coal Ash (WOCA), Lexington, KY, USA, 11–15 April 2005; pp. 1–6. [Google Scholar]

- Eliche-Quesada, D.; Corpas-Iglesias, F.A.; Pérez-Villarejo, L.; Iglesias-Godino, F.J. Recycling of sawdust, spent earth from oil filtration, compost and marble residues for brick manufacturing. Construction and Building Materials 2012, 34, 275–284. [Google Scholar] [CrossRef]

- Arsenovic, M.; Radojevic, Z.; Stankovic, S. Removal of toxic metals from industrial sludge by fixing in brick structure. Constr. Build. Mater. 2012, 37, 7–14. [Google Scholar] [CrossRef]

- BS EN 772-1; British Standard (BS). Methods of Test for Masonry Units Part 1: Determination of Compressive Strength. The British Standards Institution: London, UK, 2000.

- MS 1933-1; Malaysian Standard (MS). Methods of Test for Masonry Units Part 1: Determination of Compressive Strength. Department of Standard Malaysia: Selangor, Malaysia, 2017.

- ASTM C62-12; American Society for Testing Material (ASTM). Standard Specification for Building Brick (Solid Mansory Units Made from Clay or Shale). ASTM: West Conshohocken, PA, USA, 2017.

- Phonpuak, N.; Chindaprasirt, P. Types of waste, properties, and durability of pore-forming waste-based fired masonry bricks. In Eco-Efficient Masonry Bricks and Blocks; Elsevier: Amsterdam, The Netherlands, 2016; pp. 103–127. [Google Scholar]

- Singh, I.B.; Chaturvedi, K.; Yegneswaran, A.H. Thermal immobilization of Cr, Cu and Zn of galvanizing wastes in the presence of clay and fly ash. Environ. Technol. 2008, 28, 713–721. [Google Scholar] [CrossRef] [PubMed]

- Lin, D.F.; Weng, C.H. Use of sewage sludge ash as brick material. J. Environ. Eng. 2001, 2001, 127. [Google Scholar] [CrossRef]

- Taha, Y.; Benzaazoua, M.; Hakkou, R.; Mansori, M. Natural clay substitution by calamine processing wastes to manufacture fired bricks. J. Clean. Prod. 2016, 135, 847–858. [Google Scholar] [CrossRef]

- Kuo, Y.M.; Lin, T.C.; Tsai, P.J. Effect of SiO2 on immobilization of metals and encapsulation of a glass network in slag. J. Air Waste Manag. 2003, 53, 1412–1416. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Guidelines for Drinking Water Quality. 2006. Available online: https://www.who.int (accessed on 5 January 2022).

- Environmental Protection Agency. Chemical Contaminant Rules in Drinking Water. 2001. Available online: www.epa.gov.my (accessed on 5 December 2021).

| Amount of Electroplating Sludge (%) | Amount of Clay Soil (kg) | Amount of Electroplating Sludge (kg) | Amount of Water (mL) |

|---|---|---|---|

| 0 | 3.053 | 0.000 | 427.5 |

| 2 | 2.992 | 0.056 | 458.0 |

| 4 | 2.931 | 0.111 | 488.5 |

| 6 | 2.870 | 0.167 | 519.0 |

| 8 | 2.809 | 0.222 | 549.5 |

| 10 | 2.748 | 0.278 | 580.0 |

| Chemical Elements | Concentration (%) | |

|---|---|---|

| Clay Soil | Electroplating Sludge | |

| Sodium oxide | - | 14.70 |

| Magnesium oxide | 1.87 | - |

| Aluminium oxide | 19.7 | 67.20 |

| Silicon dioxide | 67.6 | 3.02 |

| Phosphorus (V) oxide | 0.12 | 0.06 |

| Sulphur trioxide | 0.01 | 11.00 |

| Potassium oxide | 2.54 | 0.08 |

| Calcium oxide | 0.07 | 0.41 |

| Strontium oxide | 0.01 | - |

| Iron (III) oxide | 5.82 | 0.58 |

| Titanium oxide | 1.02 | 0.10 |

| Copper (II) oxide | 0.01 | 0.11 |

| Chromium (III) oxide | 0.01 | 0.02 |

| Zinc oxide | 0.01 | 0.03 |

| Nickel oxide | - | 0.05 |

| Manganese (II) oxide | 0.03 | 0.03 |

| Cobalt oxide | 0.03 | 0.01 |

| Loss on Ignition | 9.27 | 35.44 |

| Metals | Concentration (ppm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CB | ESB2% | ESB4% | ESB6% | ESB8% | ESB10% | Raw Clay | Raw ES | TCLP | Permissible Limit for Drinking Water | |||

| USEPA | USEPA 1996 [14] | WHO 2006 [37] | EPA 2001 [38] | |||||||||

| Cu | 0.0266 | 0.0461 | 0.0754 | 0.1300 | 0.0702 | 0.0634 | 94.00 | 1320.00 | 100 | 2 | 1 | 0.0266 |

| Pb | 0.0013 | 0.0016 | 0.0015 | 0.0048 | 0.0101 +++ | 0.0073 +++ | 16.60 | 91.00 | 5 | 0.01 | 0.005 | 0.0013 |

| Zn | 0.2160 | 0.2080 | 0.1080 | 0.1070 | 0.2750 | 0.1010 | 559.00 | 385.00 | 500 | 3 | 5 | 0.2160 |

| Mn | 0.0347 | 0.0282 | 0.0304 | 0.0380 | 0.3100 +++ | 0.3340 +++ | 1260.00 | 902.00 | - | 0.4 | 0.05 | 0.0347 |

| Ni | 0.0028 | 0.0108 | 0.0133 | 0.0219 | 0.0063 | 0.0030 | 59.90 | 308.00 | 1.34 | 0.07 | 0.1 | 0.0028 |

| Al | 0.0939 | 0.1372 | 0.1725 | 0.1814 | 4.3588 +++ | 6.5481 +++ | 3480.00 | 46,100.00 | - | - | 0.20 | 0.0939 |

| Cr | 0.0065 | 0.0024 | 0.0019 | 0.0023 | 0.0098 | 0.0040 | 7.97 | 171.00 | 5 | 0.05 | - | 0.0065 |

| Fe | 0.1440 | 0.2300 | 0.1450 | 0.2000 | 0.3610 +++ | 0.8730 +++ | 154.00 | 459.00 | - | - | 0.3 | 0.1440 |

| Co | 0.0003 | 0.0006 | 0.0000 | 0.0014 | 0.0002 | 0.0000 | 23.00 | 8.63 | - | - | - | 0.0003 |

| As | 0.0020 | 0.0023 | 0.0033 | 0.0073 | 0.0024 | 0.0003 | 0.55 | 19.70 | 5 | 0.01 | 0.01 | 0.0020 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashim, A.A.; Abdul Kadir, A.; Sarani, N.A.; Hassan, M.I.H.; Kersnansamy, A.; Abdullah, M.M.A.B. Immobilization of Metals in Fired Clay Brick Incorporated with Aluminium-Rich Electroplating Sludge: Properties and Leaching Analysis. Sustainability 2022, 14, 8732. https://doi.org/10.3390/su14148732

Hashim AA, Abdul Kadir A, Sarani NA, Hassan MIH, Kersnansamy A, Abdullah MMAB. Immobilization of Metals in Fired Clay Brick Incorporated with Aluminium-Rich Electroplating Sludge: Properties and Leaching Analysis. Sustainability. 2022; 14(14):8732. https://doi.org/10.3390/su14148732

Chicago/Turabian StyleHashim, Azini Amiza, Aeslina Abdul Kadir, Noor Amira Sarani, Mohd Ikhmal Haqeem Hassan, Arunraj Kersnansamy, and Mohd Mustafa Al Bakri Abdullah. 2022. "Immobilization of Metals in Fired Clay Brick Incorporated with Aluminium-Rich Electroplating Sludge: Properties and Leaching Analysis" Sustainability 14, no. 14: 8732. https://doi.org/10.3390/su14148732

APA StyleHashim, A. A., Abdul Kadir, A., Sarani, N. A., Hassan, M. I. H., Kersnansamy, A., & Abdullah, M. M. A. B. (2022). Immobilization of Metals in Fired Clay Brick Incorporated with Aluminium-Rich Electroplating Sludge: Properties and Leaching Analysis. Sustainability, 14(14), 8732. https://doi.org/10.3390/su14148732