1. Introduction

Over the last few decades, sustainability has become a critical aspect for organizations to maintain in the global business market. The uncertain market has further demanded a refocus on the supply chain activities and the implementation of aspects of sustainability. These aspects can be achieved effectively using several practices, including industry 4.0, digitalization, and circular, green, and lean solutions [

1]. To achieve the Sustainable Development Goals (SDGs), distribution, as well as the procurement processes within the logistics and supply chain networks, can be reengineered by implementing the sustainability concept [

2,

3]. According to Casali et al., “A well-defined business idea is essential for nascent business sustainability in the future” [

4]. The sustainable supply chains for agro-food, due to the continuous decline in the environment, have become a critical matter for government organizations, businesses, and consumers [

5]. The wastage of food is an important issue for all three dimensions of sustainability, i.e., the social, economic, and environmental aspects [

6,

7]. However, the environmental aspects of sustainability are considered as an important factor in the model of modern development [

8,

9]. Food grain packaging offers a number of issues for society and the environment. Multilayer plastic materials, which are primarily non-biodegradable, are used for a large portion of food packaging. As a result, there is a high demand for new food packaging materials that are biodegradable. These can be utilized for food packaging that aids in the fulfillment of the sustainability and CE goals in the current agro-food grain supply-chain systems.

Despite the advancements in technology, the rising demand for food and the length of the supply chain globally, increasing both the food quality, and safety-related, concerns [

10], has resulted in an upsurge in the layers of packaging and related waste. Improvement in packaging technology has become important in the area of food losses and waste reduction; however, most of the technology typically depends on the plastics used. Therefore, there is a looming requirement to take the goal seriously concerning the evolution towards considering innovative biobased food packaging materials that are biodegradable, to attain the goal of a circular bio-economy [

11]. Hence, packaging poses both opportunities and challenges to society and the environment, with implications for the costs related to the supply chain [

12], especially for food packaging. A huge part of food packaging is completed using multi-layer plastic. Such plastics cannot be recycled cost-effectively, because of the powerful tendency to employ multilayer flexible barrier packaging with the help of polyolefins and a few recyclable barrier layers, such as silicon oxide (SiOx) and aluminum oxide (AlOx) [

13]; thus, posing challenges in the circular economy (CE) context [

14]. There are many enablers of the CE for the agro-food supply chain, including digitalization, and information technology. Reducing food waste and enhancing resource efficiency to attain sustainability and CE are taking priority as the most attainable factors of the USSDG12 (US Sustainable Development Goal)—responsible production and consumption [

15]. The reduction of food packaging is a needed part of the response to address the main obstacles in the sustainable consumption of food globally, in order to reduce the environmental footprint of packaged food. A sustainable innovative packaging goal is to address a reduction in the spoilage of food and food waste by preserving the quality of food and reducing food safety problems [

16]. However, in this study, the effect of innovative packaging materials was analyzed. With innovative packaging materials, the wastage of food can be minimized.

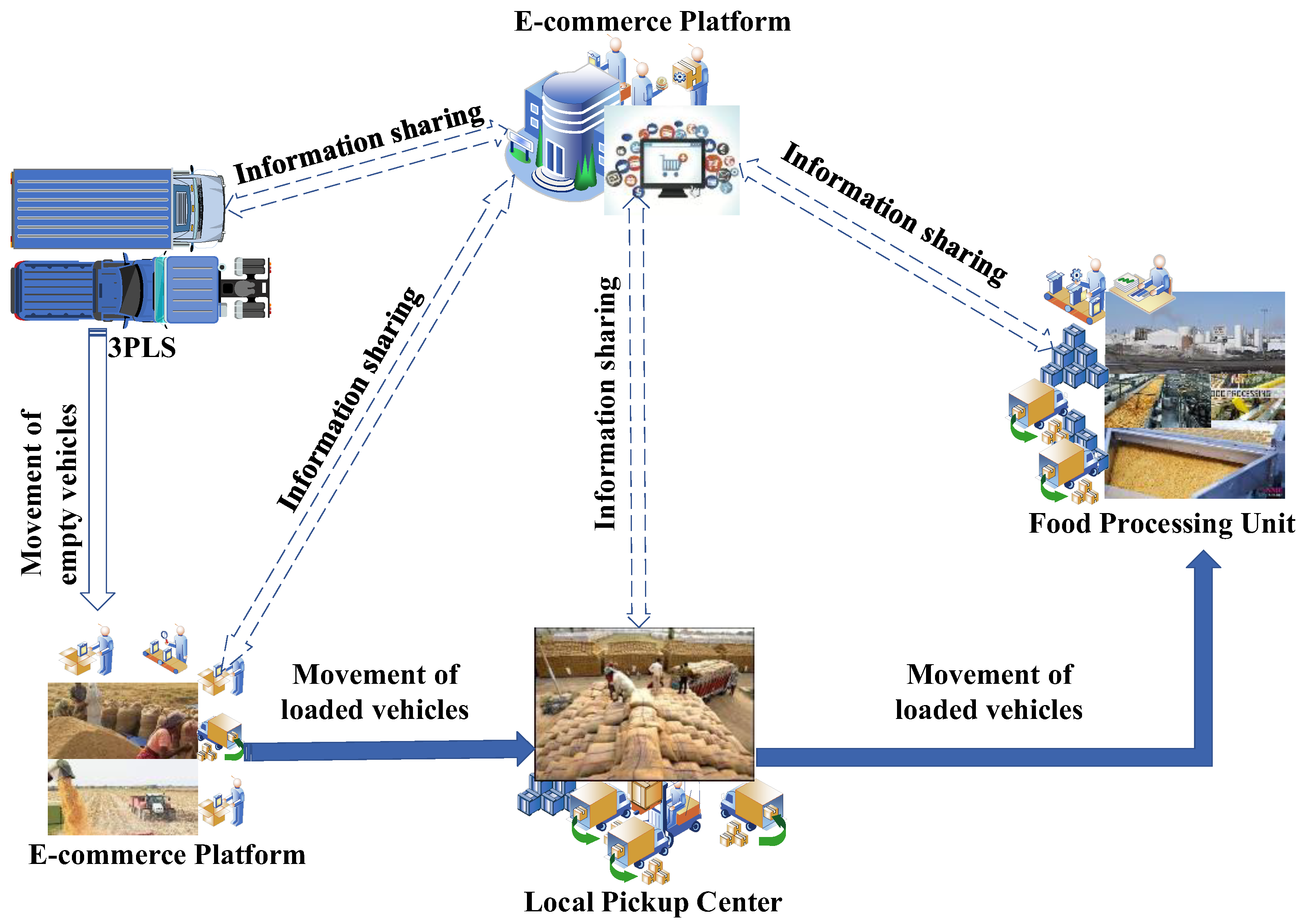

This study focused on establishing a sustainable supply chain network (SCN) design for the agro-food business in order to meet sustainability goals. To achieve sustainability, a case of agro-food grains was considered for the development of a sustainable SCN. In such a setting, it is required to collect agro-food grains from different farmers’ locations and deliver them to food processing units, via a local pickup center. The complete framework of such a sustainable supply chain is shown in

Figure 1. It can be observed that there are five significant entities in an SCN: (i) e-commerce platform; (ii) farmer location; (iii) local pickup center; (iv) food processing unit; and (v) third-party logistics service provider (3PLs). The loaded vehicles collect the grains from the farmers’ locations and deliver them to a local pickup center, and then to the food processing unit. Here, the food processing unit is considered as a buyer and the farmer as a supplier. The farmers’ business is to harvest grains and sell their harvested grains to government markets, business organizations such as food processing units, and cold storage units. The innovative packaging is processed at the Local Distribution Centers (LDCs).

A sustainable framework was developed for collecting the agro-food grains through an SCN in e-commerce towards CE. The proposed framework captured the complexities associated with packaging agro-food grains using innovative materials for packaging that enables the reduction in food waste, last-mile collections, handling, holding, and transportation. A Mixed-Integer Non-Linear Programming (MINLP) model was formulated, which helped to minimize the total costs, including the cost of innovative materials for packaging, last-mile collection costs, handling, and holding costs, and transportation costs with the environmental aspect of sustainability. This sFtudy considers only the environmental aspect of sustainability. An exact optimization approach, i.e., a global solver in LINGO 18 software package, was used to solve the proposed MINLP model and find the optimized routes for collection and delivery and the minimum total cost associated with the SCN. This study focused on answering the following research questions:

RQ.1. How to develop a framework for the collection of agro-food grains through a sustainable SCN in e-commerce towards the CE?

RQ.2. Why innovative packaging materials are taken into consideration for food packaging to reduce food wastage and environmental impacts?

RQ.3. How to capture the complexities associated with the sustainable packaging, collection, and delivery of agro-food grains in e-commerce?

RQ.4. What is the optimized transport quantity, number of vehicles assigned, and best selection of pickup points for the delivery of the required products?

RQ.5. What is the optimized value of purchasing cost of innovative food packaging materials by using the concepts of operations research and optimization techniques?

The rest of the paper is organized as follows.

Section 2 provides the past studies for making sustainable SCN. The proposed model is provided in

Section 3. The solution methodology used for the developed model is highlighted in

Section 4. In

Section 5, the computational experiments are presented to test the efficacy of the developed model. Lastly,

Section 6 provides the conclusions and the usefulness of the developed model.

2. Literature Review

The booming necessity for the involvement of sustainability in transportation planning for the agro-food supply chain is drawing the attention of academics, in the interests of the environment and stakeholders at large [

17]. The enormous quantity of generated agricultural waste is a potential feedstock for biogas creation, particularly in India. The CE concept is required to integrate agricultural-waste management, production, and the utilization of biogas and support policy [

18]. However, there is a lack of verified supply chain management frameworks with the implementation of sustainability and CE.

Kapoor et al. (2020) [

18], comprehensively discussed the power of biogas creation from agricultural waste, its utilization, and improvement accompanied by the government initiatives and policy regulations. Furthermore, they also discussed the hurdles that obstruct the growth of an efficient agri-waste to biogas-based CE, and the upcoming research opportunities to meet the increasing needs for climate change mitigation, agri-waste management, and energy production. Maiyar and Thakkar (2020) [

17], focused on developing a sustainable and robust intermodal transportation model to simplify the shipments of a single type of food grain commodity, while considering intentional hub disruption, greenhouse gas emissions, and procurement uncertainty. The study formulated a MINLP robust model related to the spoke and hub network for finding the close to optimal shipment quantity, location of the hub, and selection of routes’ decisions. Yadav et al. (2020) [

1], aimed to propose a framework that overcomes the Sustainable Supply Chain Management (SSCM) challenges through the CE and industry 4.0-based solution measures. Wang et al. (2021) [

19], studied a short food supply chain problem and delivered an empirical authentication of short food supply chains and sustainable linkages. The study explored the triple bottom line to five dimensions of sustainability towards food supply chain systems. Moghaddas et al. (2022) [

20], proposed an evaluation approach, based on the network Data Envelopment Analysis (DEA) to choose an efficient plan for each phase of a sustainable supply chain network.

Guillard et al. (2018) [

16], reviewed the major complexities that must be catered for in food packaging in the forthcoming to enter the correct circular loop bi-economy. Schmidt Rivera et al. (2019) [

15] focused on developing a framework and the key metrics for decision support that assist in advancing the selection of novel, innovative food packaging toward the CE aspect. They proposed a set of indicators, integrating both CE and techno-environmental criteria, to support decision-makers and food and packaging manufacturers and to create more sustainable products. Matthews et al. (2021) [

14] explored what was achieved and what can be achieved to lessen the risks to food safety, whilst obeying the European Union’s (EU) plastic strategy. Moreover, it has been observed that the use of plastic materials for food packaging plays an important role in minimizing food waste, extending shelf-life, and maintaining food safety. Beltran et al. (2021) [

11] examined the effort behind the variations in food packaging plastic regimes and mainly focused on understanding how sociotechnical configurations could impact the transition to a circular bio-economy, specifically biobased plastic materials that are biodegradable.

Kleine Jäger and Piscicelli (2021) [

21] worked to find out how principal organizations set up and select collaborations for food packaging within the circular economy. They used a quantitative Delphi technique to create a theoretical framework based on collaboration literature. Ojha et al. (2020) [

22] investigating the production of edible insects through the valorization of food waste, provided a unique key for locking this loop in the food value chain. They also discussed the present status of insect processing and its importance in CE. Nechita et al. (2021) [

23], analyzed the performance of hardwood xylan hemicellulose as a food packaging material, in making uniform films and as a biopolymer for paper coatings. Langley et al. (2021) [

6], focused on the perception of the consumer in the role of on-pack labeling and packaging for reducing household food waste. The study tried to find the solution to these two research questions: (1) could packaging play a significant role in reducing household food waste; (2) what are the packaging and labeling designs that make inspire the customer about reducing food waste?

Janjevic et al. (2019) [

24] provided a technique to integrate collection and delivery problems (CDPs) in the multi-echelon distribution network design. The study formulated a non-linear optimization model, that comprised the CDP location and the reason for fluctuations in demand patterns occurring with their assignment. Bergmann et al. (2020) [

25], analyzed the conflicts in route efficiency by merging first-mile collection and last-mile distribution operations in an urban delivery system. However, as stated, a SCN with sustainability implemented as part of the process still needs to be completed.

We compared the current work with the past literature, which are shown in

Table 1. From this table, we can see how the current work differs from the work completed on the agro-food supply chain-related problems in the last few years.

A comparative review based on the previous studies is presented in

Table 1.

Based on a survey of the previous studies provided in

Table 1, it was discovered that few studies have focused on the sustainable food grains supply along with the use of innovative materials for food packaging to attain the CE. This study focuses on developing a sustainable framework for the agro-food grains supply chain for the CE.

3. Problem Description

For the agro-food sector, there is a huge contribution from grain processing. A wide range of food products, including wheat, rice, and cereals, are available within the grain processing industry. In recent years, there has been an increase in cereals and cereal-related products, apart from traditional wheat and rice. With the increase in e-commerce platforms, the demand for all food grains is further rising. However, there is continuous downdrift in the sustainable agro-food supply chain. In particular, it has been observed that the packaging of these food grains poses several challenges to society and the environment. A huge part of food packaging is executed using multi-layer plastic materials that are mostly non-biodegradable. Hence, there is a strong need for innovative food packaging materials that have the ability to be biodegradable. These can be used for food packaging that helps to achieve the goals of the development of sustainability and the CE in existing agro-food grains supply chain systems.

This study aimed to develop a framework for a sustainable agro-food grains supply chain along with the circularity concept in the e-commerce platform. The proposed framework is shown in

Figure 1. A MINLP model was formulated to capture the complexities associated with the considered problem. The model aimed to find the optimal value of the quantity to be transported, vehicle assignment, and the selection of the best possible routes for collecting the food grains, in order to minimize the costs associated with the collection operation. To minimize the collection costs, we have considered these agro-food grain supply chain costs for our study: (i) last-mile pickup costs; (ii) carbon emissions taxation costs; (iii) innovative packaging materials cost, (iv) handling operational costs at farmer’s location; (v) handling operational costs at LDCs, food processing units; (vi) holding costs at the LDCs; and (vii) transportation costs between LDCs and the food processing units. It is noted that, in the developed model, the effect of innovative packaging materials has been considered by determining the packaging material costs.

3.1. Problem Statement

A mathematical model is formulated which helps to determine the minimum cost of the agro-food grains delivery with CE. The graph G (

FLi,

PCk) is shown in

Figure 2, in which FL

i, represents the set of farmer locations with index

i which belongs (

i = 1, 2, …,

I), and PC

k represents the set of food processing units with index

k, which belongs (

k = 1, 2, …,

K). LPC

j, represents the local pickup centers with index

j which belongs (

j = 1, 2, …,

J). In this graph there are two stages; the first is that the food moves from FLi to LPCj and the other is from LPCj to PCk. The availability of orders at the farmer locations is

Ai, the demand at the processing unit

Dk, and

zij and

zjk are the binary decision variables, which determine the best possible routes with an availability constraint. The number of sets and their indices, different model parameters, dependent variables, and decision variables are provided in

Table 2.

Assumptions

Availability of food grains and required transport vehicles are known and satisfy the demand of the food processing unit;

Demand is deterministic and known;

Empty vehicles returned to their starting point after delivery.

3.2. Mathematical Model Formulation

As stated above, the objective function is to minimize the total collection costs, which consist of seven different terms. These terms are, the first term is the agro-food grains handling costs at the farmers’ location and the local pickup centers. The second is the last-mile pickup costs. The third is the costs of the carbon emissions taxation employed on the vehicles used for the last-mile pickup. The fourth is the purchasing costs of the innovative food packaging materials that are both biodegradable and reusable. The fifth is the inventory-holding costs at the local pickup centers. The sixth is the handling costs of the packaged food grains at the local pickup centers, as well as the processing units. The seventh is the transportation costs, to transport the food grains from the local pickup centers to the processing units. Lastly, the costs of the carbon emissions taxation employed on the vehicles used for the long-distance delivery of the food grains. Thus, the objective function of such a model is given as:

Objective function

Minimize

Z = [(handling cost for

)

I,

j + (last-mile cost)

i→

j + (carbon emissions taxation cost)

i→

j + (innovative packaging material cost)

j + (holding cost cost)

j + (handling cost for

)

j,

k + (transportation cost)

j→

k + (carbon emissions taxation cost)

j→

k].

Equation (1) is related to the objective function that helps to minimize the total supply chain cost:

Constraint (2) is associated with the availability constraint, that ensures the total availability of food grains should be greater than or is equal to the quantity moving from the farmer’s location to the LDC. Constraints (3) and (4) ensure that the quantity delivered to any node is less than the given storage capacity. Equations (5) and (6) are related to the demand constraints. These constraints ensure that the demand for food grains at the processing unit and LDC are required to be met. Equations (7) and (8) compute the total number of small- and large-sized vehicles required for delivery purposes. Constraints (9) and (10) ensure the pickup of quantity, i.e., moving from one node to another, happens only once. Constraints (11) and (12) are binary decision variable constraints. Constraint (13) is related to the non-negativity constraint.

6. Results and Discussion

To find the complexity of the developed MINLP model, ten different case scenarios were considered with small-to-large size datasets, as given in

Table 5. For all of the case scenarios, we have used the simulated datasets that were generated randomly.

6.1. Computational Experiments

Table 5 shows the number of variables, number of constraints, total costs associated with a sustainable SCN, and computational time. In the base scenario, there are 35 variables, and 43 constraints, and the total optimized cost is Rs. 33608.21/- with a computational time of 1.21 s. However, there are 3755 variables, and 4548 constraints, and the total optimized cost in the last instance is Rs. 6046030/- and with a computational time of 2687.95 s. The complexity of the proposed model increased with an increase in the number of variables and constraints as a larger number of nodes in the logistics network. Further,

Figure 4 shows the variation, in terms of the number of variables and constraints with the number of instances. In

Figure 4, the blue line is related to the number of variables, whereas the orange line is related to the number of constraints. It means that, with an increase in the supplier and demand points, the computational time increases. The optimized value of the cost of innovative food packaging materials per unit ton is 20/-, and the mileage of the small and large-sized vehicles is 30 and 10 km, respectively, per unit fuel consumption.

6.2. Sensitivity Analysis

For the sensitivity analysis, the proposed model’s important parameter variability is taken into account. [

39,

40]. As observed in

Section 5, the cost parameters and demand significantly affect the objective function. Thus, with these two parameters, the sensitivity analysis is performed for two different settings, i.e., small-size and medium-size problems. The scenario definition and the results of the sensitivity analysis are explained next.

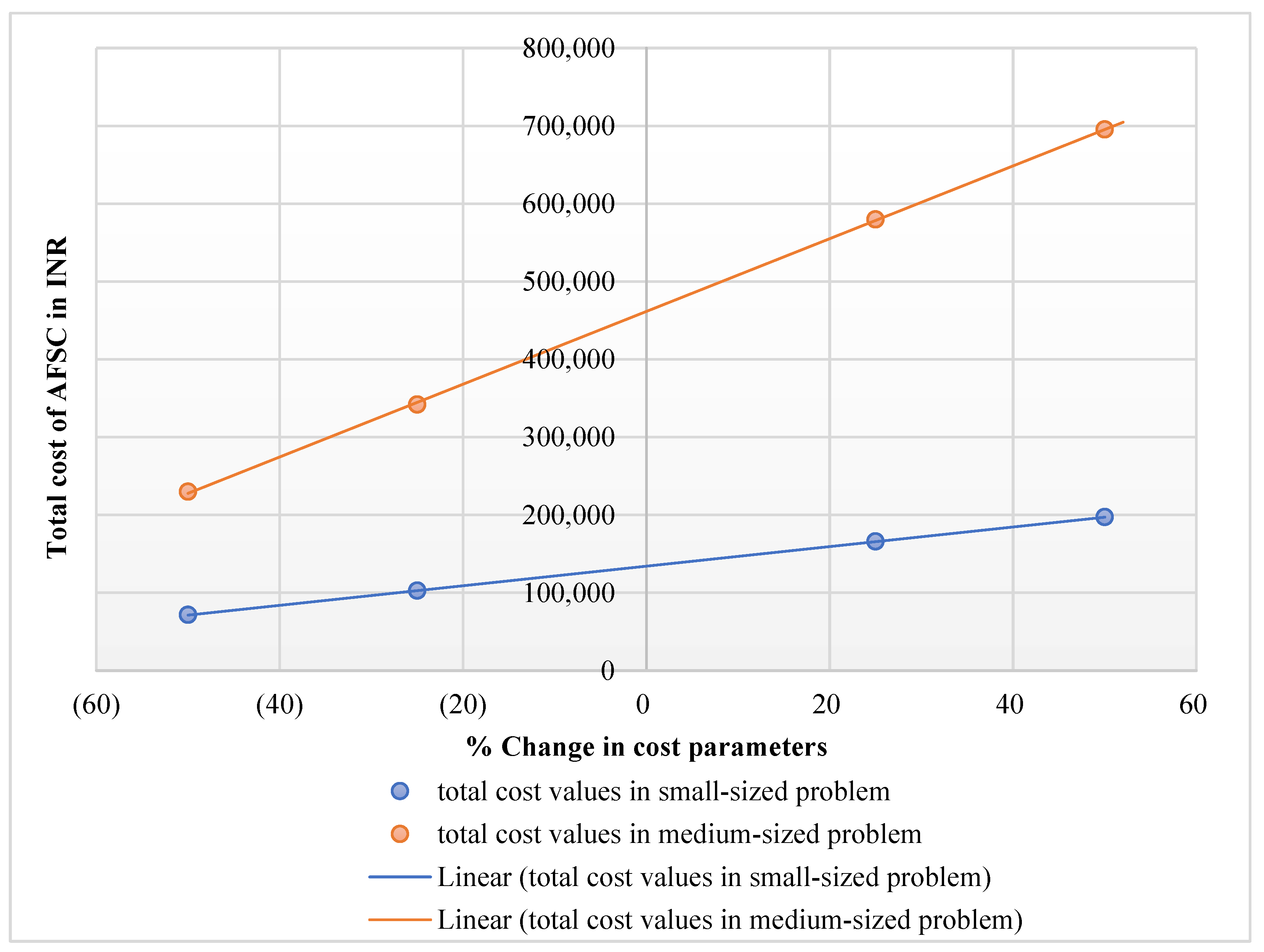

In a small size problem, firstly, the cost parameters are varied by ±25% and ±50%. Consequently, the variation in the value of the objective function, i.e., the total cost of AFSC, is ±23.72% and ±46.84%, respectively. Secondly, the demand for the products is varied by ±25% and ±50% that resulted in a −24.09% and +26.01%, and a −49.89% and +50.10% variation in the objective function.

Similarly, in the medium-size problem, the same kind of variation in the parameters is chosen. In particular, the cost parameters are varied by ±25% and ±50%, and the variation in the value of the objective function is approximately −24.99% and +27.24%, and −49.44% and +52.67%, respectively, is recorded in the objective function. Secondly, the demand for the products is varied by ±25% and ±50%, and it is observed that the variation in the objective function value is approximately −23.44% and +27.49% and −49.06% and +52.7%, respectively.

Table 6 summarizes the results of these variations. From these observations, it can be seen that there are significant variations in the objective function value by varying the values of main parameters in the model.

To find the relative comparison between the cost and demand parameters,

Figure 5 and

Figure 6 show the value of the total cost of the sustainable agro-food grains supply chain obtained in four different values for the cost and demand parameters of the model, respectively. In both of the Figures, the blue color data points and line are related to the total cost of the AFSC when applying the percentage change in the value of the cost-related parameters, whereas the orange color data points and line are related to the value of total cost of AFSC obtained when applying the percentage change in demand parameters. From

Figure 5, it can be observed that there is an almost similar change in total cost of AFSC values when only one critical parameter is varied at a time. The demand for products slightly plays a significant role comparatively in small-sized problems as shown in

Figure 5. However, in medium-sized problems, both the parameters of the model were approximately equally impactful on total cost of AFSC values, as shown in

Figure 6.

In

Figure 7, the blue color data points and line are related to total cost of AFSC obtained with varying the cost parameters in small-sized problem whereas orange color data points and line are related to total cost of AFSC obtained with varying the cost parameters in medium-sized problem. Similarly, in

Figure 8, the blue color data points and line are related to total cost of AFSC obtained with varying the demand parameters in small-sized problem whereas orange color data points and line are related to total cost of AFSC obtained with varying the demand parameters in medium-sized problem. From

Figure 7 and

Figure 8, it was observed that the slope of the trend line for the data generated (total cost AFSC values) from a medium-sized problem is greater, as compared to the slope of the trend line associated with the data generated from a small-sized problem. The effect of the critical parameters on the total cost of AFSC is seen more in enlarging the logistics network.

6.3. Discussion

To make the agro-food supply chain more sustainable, this study provided insights to the decision-makers on how innovative packaging and effective SCNs can be developed. In addition, the proposed model provided useful insights for logistics service providers and agro-food grains-related industry practitioners that are helpful in designing sustainable agro-food grains and cost-effective systems. The carbon emissions coming from the burning of fossil fuels in transport vehicles is taken into consideration as an environmental dimension of sustainability. Transportation is a major source of air pollution within the SCN. The burning of fossil fuels to power the transport vehicles emits anthropogenic gas, i.e., carbon dioxide (CO

2), which is one of the major causes of climate change. The transport sector accounts for 23% of the energy coming from CO

2 emissions. The survey reveals that 75% of the emissions related to transportation are produced by road traffic. The predicted growth of emissions from transportation is by 80% from the year 2007 to 2030, if proper actions are not taken to control the emissions. Climate change poses a threat that endangers national security and human health, and lays basic human requirements on the line [

41]. The integrated CE and techno-environmental criteria help the packaging and food manufacturing firms, as well as designers, to create products that are more sustainable [

15]. The proposed framework not only helps in the achievement of sustainability and CE goals, but also helps minimize the total costs of the collection and final delivery.

Most of the studies performed previously are based on the systematic review, surveys and interviews, and empirical analysis [

15,

21,

23,

41,

42]. Moreover, the contribution of a framework for an agro-food supply chain includes the environmental externalities and cost-based inefficiencies in a planning model providing long-term decision support. In addition, coupled with the cost efficiencies related to emissions, energy, and land-use, the framework is quantifying the concise metrics and a comparable panel that encourage decision-makers in the direction of more sustainable plans in agro-food systems [

27]. The design of a SCN provides the support for strategic decision-making relating to issues in the production of food that create an immense strain on the environment. The environmental aspect resulting from a full life-cycle approach is the most suitable option for forthcoming public and private policies for achieving sustainable agro-food supply chain systems [

29]. However, this study focused on proposing a sustainable framework for an agro-food grains supply chain for the e-commerce industry. In addition, the study formulated a mathematical model that captures the costs related to innovative food packaging, handling, inventory holding, and transportation with carbon emissions. The proposed model consists of the proposed terms relating to innovative packaging materials and carbon emissions that help to achieve both CE and sustainable development goals during the collection and delivery of agro-food grains in e-commerce. An optimization model is formulated by using the concepts of the MINLP approach, and performing computational experiments that could be applied to a real-world scenario for India. However, the proposed model could be applied to other countries as well. From the scenario results, the optimized value of the quantity to be transported is computed, as shown in

Figure 3 for the first case scenario. Further, the model also helps with vehicle assignment and selecting the best possible routes for collecting the food grains, that shows the minimum cost required for collection operation.

Packaging is an important element that helps to meet the key challenges of sustainable food consumption globally. Making microbial biodegradable polymers from the waste residues of agro-food appears to be a hopeful route to producing an innovative, productive, and more resilient waste-based food packaging economy by uncoupling the food packaging manufacturing firm from fossil feedstocks. To reply to the lack of approaches and tools to appropriately design, as well as to adapt, the food packaging to meet food requirements, mathematical modeling and simulation related to the mass transfer and reactions into food/packaging systems are promising tools [

16]. Meanwhile, this study introduced a generic mathematical model that provides the optimized value of the cost of innovative food packaging materials per unit ton of food packaging to attain sustainability and CE. Thus, the model captures the key complications to make the system more efficient and effective.

The results reflect that the developed model is scalable and flexible and provides results in a realistic time. It was seen that food grain packaging, and storage, play an important role in the developing economies as well as developed countries. Thus, our model can be useful for both developed and developing countries. For finding the computation complexity of the developed model, various case scenarios are provided. In all of these settings, the minimum value of the total cost of the supply chain for sustainable agro-food grains is calculated. It has been shown how the cost of collection varies with an increase in the number of nodes (i.e., pickup and delivery). The sensitivity analysis is performed to observe the variations in the total cost values when increasing or decreasing the values of the main parameters of the model, i.e., cost and demand. For the validation purpose, the proposed model is tested in different, two-case scenarios which are created by using simulated data.

6.4. Managerial Implications

The suggested SCN design problem is an advanced approach to design the collection systems from different farmer locations to the LPCs and, later, to selected food processing units. This research work considerably supports the businesses in designing their collection network more efficiently and effectively. This work can serve as a preliminary study to define the environmentally sustainable problems connected with the agro-food supply chain, for food grain in particular. From the results of the different scenarios, it can be proved that the findings and analysis of this study can be helpful to supply chain industries as well as policymakers. In particular, the developed model can help decision-makers find the right transportation quantity, transport vehicle assignment, and correct route selection for order pickup and delivery to minimize the total collection cost. For example, the optimized value of transport quantity, vehicle assignment, and route selection for food collection and delivery for any chosen scenario is shown in

Figure 2 (

Section 5). Additionally, with our model, the cost of innovative materials used for the agro-food grains packaging can also be considered, which helps in waste reduction and hence achieving sustainability goals. Lastly, the suggested SCN design also allows for the last-mile pickup of food grains from different farmer’s locations and delivers them at LPC and later to the selected food processing units.

The obtained findings and analysis completed in this study can be used to support chain managers, e-commerce businesses, and government organizations in creating policies to promote the development of sustainability and CE for the development of the business, as well as the development of nations.

7. Conclusions, Limitations, and Future Research

This study focused on developing a sustainable SCN design for collecting agro-food grains from farmers’ locations with last-mile pickup operation and delivering to the processing centers, i.e., the final destination in the e-commerce platform towards CE. A MINLP model is formulated to capture the complexities of food packaging, handling, last-mile pickup, holding, and final delivery problems in the considered network. The exact optimization approach used global solver in LINGO 18. These models can help find the optimal settings for various decisions, including shipping quantity, vehicle assignment, best possible pickup, and delivery routes. Moreover, the model provides the average distance travelled by transport vehicles per unit of fuel consumption. The optimized value of the fuel consumed by the transport vehicles helps in minimizing carbon emissions which supports attaining environmental sustainability. Further, the developed model also considers the costs related to the innovative food packaging materials that are able to biodegrade and are reusable, for a sustainable agro-food supply chain network with the CE.

The proposed model was tested in ten different case scenarios, i.e., small-to-medium-large sized problem. The total cost of a sustainable agro-food grains supply chain was found for each case scenario. A sensitivity analysis was conducted to observe the variations in the total cost of the SCN. From observations, the effect of the parameters was more when the size of the SCN was increased, and the values of the parameters in percentage as well.

This study has a limitation relating to the simulated datasets used for creating the instances to validate the proposed model. Furthermore, the proposed model could be validated by the use of real-life data from related e-commerce companies. Lastly, this study could be extended by considering the sustainable multi-echelon SCN design for collecting food grains and fresh foods in e-commerce towards the CE concept.