1. Introduction

Currently, fossil fuels are the predominant global energy consumption source, generating considerable environmental pollution. The energy consumption increases at an average of 2%. As the world’s largest energy consumer, China’s tight energy supply has become even more severe and the energy transition has received unprecedented attention. With the introduction of the carbon neutrality target, Chinese President Xi Jinping made important comments in his speech at the general debate of the 75th UN General Assembly, namely that China will increase its autonomous national contributions, adopt more solid policies and measures, strive to reach a peak of CO2 emissions by 2030, and work towards achieving carbon neutrality by 2060. Therefore, it is evident that renewable energy sources such as wind, solar, and bioenergy are receiving increasing attention in national strategies and sustainable development planning. According to the International Energy Agency (IEA), renewable energy focusing on solar power will play an important role. It will meet 80% of the incremental global electricity demand in the future, with the cumulative global installed capacity of photovoltaics forecast to reach 2000 GW by 2030. In 2002, China carried out the “delivery of electricity to the countryside” to promote the development of the photovoltaic industry in the countryside, and the annual installed capacity of photovoltaics has been transformed from the kW level to the MW level.

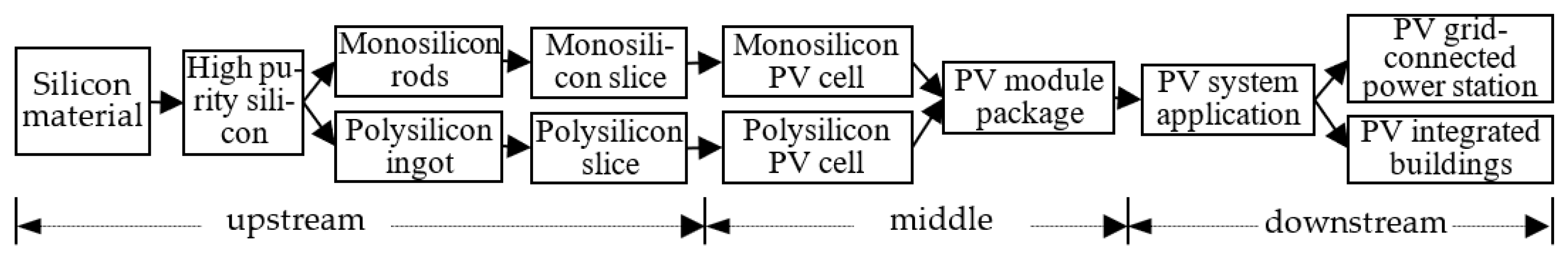

The entire PV industry chain is divided into upstream, midstream, and downstream, where upstream includes silicon raw materials and ingot/silicon wafer production, midstream refers to solar cell manufacturing and module packaging, and downstream refers to PV system applications. Solar power systems are typically “environmentally friendly at the end, polluting in the process”, especially for polysilicon companies. The overall situation in China’s PV industry is characterized by the evident duality of technology and the market, with the emerging industry development strategy encouraging clean/high-tech industries, leading to a spurt of PV industry development. Due to the industry-linked effect, many pollution links in the industry chain are laid out in China. Therefore, with the development of renewable energy generation technologies, there is a need to assess the environmental load of renewable energy generation [

1]. Due to the absence of industry-wide greening policies and the highly unbalanced structure of the PV industry chain, it is of great practical significance to select the PV industry as the research target and measure the carbon emissions of polycrystalline silicon PV systems using the life cycle assessment method.

Life Cycle Assessment (LCA) is a method of environmental management that tracks the quantitative analysis and qualitative evaluation of a product or production activity from the extraction of raw materials to their production, manufacture and use, and final disposal. The aim is to track the environmental factors and potential impacts from acquiring raw materials through production and use to the final disposal. Traditional LCA is limited to the ecological dimension. Still, as a research method to evaluate the energy consumption and environmental impact of products/services from the cradle to the grave, along with the continuous enrichment, complexity, and systematization of the evaluation objects of LCA, LCA research methods meet the diversity of evaluation needs and are also constantly improving and developing. For example, the economy-oriented whole life cycle cost assessment (LCC) and the society-oriented entire life cycle social assessment (SCCA), together with the increasing deterioration of the global ecological environment and people’s continued concern for social issues. Relevant research topics on LCA focus on life cycle sustainability assessment (LCSA) in the context of the circular economy; LCSA integrates three sustainability dimensions, that is, environmental, economic, and social dimensions [

2,

3], which cover various areas such as buildings, energy, logistics, and the environment. For the solar PV industry, a life cycle assessment system can be used to compare and analyze the carbon footprint of PV power generation throughout its life cycle at the level of the industry chain to address environmental and energy issues and to promote the sustainable development of the solar PV industry [

4].

Trina Solar is the world’s leading provider of intelligent energy solutions, with revenue of CNY 29.418 billion in 2021, up 26.14% year-on-year; total assets of CNY 45.592 billion, up 25.66% from 2020; total module shipments of 1591.5 GW, up 58.85% year-on-year; and a module production capacity of 50 GW+ in 2021 and 35 GW+ in 2021. In 2021 with a cell-planning capacity of 35 GW+, Trina Solar provided innovative distributed energy solutions including 2 GW+ of original PV systems for households, making them number one in the industry in terms of cumulative shipments 4 years in a row. They sold more than 15,000 sets of original PV systems for industrial and commercial use, making them number one in number of service outlets. By the end of December 2020, Trina Solar’s cumulative global module shipments had achieved 890,000,000 kWh of clean electricity with solar energy for the benefit of all people, equivalent to a total reduction of 88.83 million tons of carbon dioxide, 2.67 million tons of sulfur dioxide, and 24.24 million tons of carbon dust, which is equivalent to planting 4.9 billion trees. They were awarded the Global CSR Achievement Gold Award two consecutive times.

This paper measures the carbon emissions of a 280 MW polysilicon PV system from Trina Solar using the Siemens method to produce polysilicon and cell modules using a life cycle assessment method. First, the production characteristics of the whole PV industry chain are analyzed and divided into the upstream production of silicon crystals (silicon raw materials and ingots/silicon wafers), the midstream manufacturing and packaging of solar cells, and the downstream application of the PV system, with different carbon emissions at different stages. Second, carbon emission reduction involves multi-dimensionality, including environmental, economic, social, and technological indicators, and there is an urgent need to measure the carbon emissions of resources’ energy consumption, equipment inventory, and pollutant disposal in each link of the polysilicon PV system by employing the whole life cycle approach and the emissions factor approach. By measuring various carbon emission factors for industrial equipment, steel production, vehicle fuel, and pollutant disposal, the carbon emission models for the resource consumption, energy consumption, equipment lists, and pollutant disposal of polysilicon PV systems are constructed to reveal the carbon emissions in resource and energy consumption, as well as in the production process of PV installations. Finally, an example analysis is conducted with the world’s largest PV module system integrator, Trina Solar Limited (TSL) in Changzhou, China, to measure the whole life cycle carbon emissions of its 280 MW vertically integrated PV system, revealing the proportion of carbon emissions from its energy consumption, resource consumption, transport links, equipment production, and waste disposal. The key aspects of carbon emissions are identified, and valuable suggestions are made to reduce carbon emissions.

Section 2 includes a literature review related to this study to accomplish the proposed research purpose.

Section 3 provides a detailed introduction to China’s PV industry, identifying the main environmental impact categories, key processes, and essential materials.

Section 4 is the method and includes establishing a carbon emission model.

Section 5 presents a case analysis of China’s global-leading PV module company.

Section 6 is the conclusions and future work, including implications and further developments for the study.

2. Literature Review on Carbon Emissions from Photovoltaic Systems

A reasonable evaluation of carbon emissions from photovoltaic systems provides an essential basis for implementing effective carbon reduction measures. How to construct a carbon emission evaluation model has received increasing attention from scholars, among whom the whole life cycle evaluation method is a widely used analysis method. Hunt (1976) [

5] used the entire life cycle assessment method to calculate the energy payback period of monocrystalline silicon solar cells to be 11.6 years. This marked the beginning of the academic community’s environmental assessment of the whole life cycle process of the photovoltaic industry. Subsequently, scholars have carried out a series of studies on the issue of the carbon emission evaluation of photovoltaic systems. The current status of relevant research can be summarized in the following three areas.

2.1. Study on the Evaluation of the Energy Payback Time of PV Systems

Energy Payback Time (EPBT) is one of the most critical indicators in the life cycle assessment of the PV industry and refers to the total energy consumed in the production process divided by the total annual energy production of the system (electricity production). It represents the number of years required to recover the energy costs. Obviously, the shorter the energy payback period, the better the system’s environmental performance. Peng et al. (2012) [

6] summarized the relevant literature and analyzed and concluded that the EPBT for monocrystalline PV systems was 1.75–12.1 years and for polycrystalline PV systems 1.75–3.2 years. Yu et al. (2017) [

7] used the life cycle evaluation method to calculate and analyze the energy payback period of metallurgical polysilicon PV systems in China. The study obtained an energy payback period of 3.98 years for metallurgical polysilicon PV systems. Firoozzadeh et al. (2019) [

8] studied a PV power plant in the northern part of Hamedan province, Iran, and found that the energy payback period was 5.5 years. Tsuchiya et al. (2020) [

9] investigated two PV systems in rural Tanzania and calculated the energy payback period using the life cycle evaluation method and found an important conclusion, that is, that the energy payback period of the PV system in the area exceeded the lifetime of the PV panels, indicating that energy payback was not possible, in other words, the area was not suitable for a PV system. Leccisi and Fthenakis (2021) [

10] carried out a comprehensive assessment of crystalline PV systems’ life cycle sustainability status, discussing the type of crystal and considering both high and low radiation PV systems when calculating the energy payback period.

2.2. Study of GHG Emissions from PV Systems

Greenhouse Gas (GHG) emissions are the total GHG emissions generated by a company’s production process divided by the total amount of electricity generated over the lifetime of the PV system. All types of GHGs can be converted to CO

2 equivalents based on a conversion factor provided by the Intergovernmental Panel on Climate Change (IPCC) known as the Global Warming Potential (GWP). Although the operation of PV systems shows minimal pollution over their lifetime, the potential environmental impact of such systems from manufacturing to disposal cannot be ignored [

11]. Njoku and Ozioma (2020) [

12] provided a comparative analysis of Nigeria’s GHG emissions from gas-fired and PV systems. Tawalbeh et al. (2021) [

11] included a study by Maestre et al. (2021) [

13] in assessing PV systems’ GHG emissions based on input datasets from the UK and France. PV systems performed better in environmental performance than conventional residential energy systems. Maghrabie et al. (2021) [

14] argued that advances in integrated PV systems for residential and commercial buildings aim to minimize overall energy demand and associated GHG emissions. Li et al. (2018) [

15] explored the categories of solar PV systems using the life cycle theory for the Northeast UK case and found polycrystalline (p-Si) to be the best performer and the best choice.

2.3. Research on the Assessment of Environmental Effects of PV Systems

For assessing the environmental effects of PV systems, scholars usually use two life cycle evaluation methods, one is process-based and the other is a hybrid evaluation method that combines process and input–output analysis methods. Li et al. (2017) [

16] used the east of England as a case discussion to analyze the possibility of deploying solar PV combined with life cycle theory and sustainability theory. Stamford and Azapagic (2018) [

17] studied the environmental effects of silicon-based PV systems in the UK, Spain, and China based on a life cycle evaluation approach to explore PV systems’ impact on the environment. They found that the manufacturing shift from Europe to China brought adverse environmental effects to China. The value of PV is mainly dependent on improving China’s energy mix. Wang et al. (2017) [

18] calculated life-cycle CO

2 emission factors for rooftop PV systems in Beijing and discussed the carbon reduction potential of urban rooftop PV applications. Miller et al. (2019) [

19] argued that greenhouse gases from upstream emissions from PV are not negligible.

For this reason, we developed a life-cycle model that includes the emissions of all pollutants and found that PV is much less carbon-intensive than fossil-based power generation. Żelazna and Gołębiowska (2020) [

20] analyzed the environmental impact of a PV thermoelectric cooling system with heat recovery capabilities using the principles of material and energy conservation over its life cycle. In contrast to existing studies that almost always use carbon emission factors for the entire life cycle for carbon emission calculations, Pu et al. (2021) [

21] considered the variability between sub-stages. They estimated carbon emissions from the PV power industry based on the sub-stages of the life cycle and assessed the environmental impact of the PV power industry in China from 2012 to 2017.

Studies have confirmed that PV systems tend to perform better than conventional energy sources in terms of environmental performance, both in energy payback period and carbon emission indicators, except for remote rural areas with low electricity demand [

9]. Drawing on Pu et al.’s (2021) [

21] study, this paper further extends the study to investigate carbon emission evaluation issues in the upstream, midstream, and downstream stages of the whole PV industry chain and, in applying the life cycle evaluation theory, innovatively considers multiple environmental, economic, social, and technological dimensions to form a more comprehensive carbon emission evaluation system. Therefore, it is necessary to investigate the carbon emissions of the polysilicon PV systems from the selection of raw materials to the disposal of the final products. In addition, considering the differences in the PV industrial chain composition in various countries, it is crucial to include the context of the specific country. As such, in this study, considering the compositions of the PV industry in China, we specifically evaluate the carbon emissions of the polysilicon PV system at both the industry and enterprise level by applying the LCA method for three reasons. First, the polysilicon PV system is slightly different from other PV systems as it produces fewer carbon emissions. As a result, scholars have paid limited attention to investigating possible pollution and carbon emissions. Second, China’s polysilicon solar PV industry chain has unique characteristics that differ from other nations, which require detailed exploration. Third, there is a lack of case analyses to empirically understand the polysilicon PV system chain and related material and energy consumption during production at an enterprise level.

3. Identify the Composition of the Whole Industry Chain of Polysilicon Photovoltaics

According to the differences in production materials, there are two types of PV cells known as thin-film cells and crystalline silicon cells. Moreover, crystalline silicon cells are divided into monocrystalline silicon cells and polycrystalline silicon cells. Crystalline silicon cells are the most widely applied, whereas raw materials and technology restrictions hinder film cell development [

22]. The monocrystalline silicon solar cells are quite costly and there is little room for a price reduction due to the high price of monocrystalline silicon materials and the complex cell manufacturing process [

23]. As a result, in industrial production, polysilicon has replaced monocrystalline silicon. Therefore, in this section, we selected the polysilicon solar PV industry chain in the context of China. More specifically, we comprehensively explain the current situation of the PV industry in China that provides the PV industrial chain structure and the polysilicon PV system.

3.1. Current Situation of PV Industry in China

The European Commission’s Joint Research Centre (JCR) predicts that by 2030, renewable energy will account for a third of total energy consumption with approximately 10% contributed by PV electricity. In addition, the report indicated that by the end of this century, solar PV contributions would dominate the world’s energy structures due to abundant solar energy resource storage. Applying solar PV electricity will significantly improve the energy structures to maintain sustainable development.

As the third-largest country in the world, China’s vast territory means it is a nation with abundant solar energy resources and it has laid a solid foundation for developing the PV industry. According to China Meteorological Administration statistics, annual solar radiation on the ground is 1.7 × 10

14 tce, and approximately 60% of the region receives radiation over 5.02 × 10

6 kJ/m

2. In addition, the accumulated radiating time is around 2000 h. According to the National Energy Administration’s “PV power generation-related statistics”, the installed capacity of PV power generation has expanded rapidly over the past ten years. In 2021, the cumulative installed capacity of PV systems in China was 306 million kilowatts compared to 19 million kilowatts in 2013, with an average annual compound growth rate of 41%. The new installed capacity of grid-connected PV systems is 54.88 million kilowatts, reaching a record high, meaning China’s new PV installed capacity is ranked first in the world, as shown in

Table 1.

3.3. PV Industry Chain Structure

The PV industry combines an array of related industries, from the extraction of silicon materials to the production of PV cells and the application of PV systems to form an entire industrial chain [

24]. As shown in

Figure 3, there are three main steps in the PV industry chain: The upstream step is the extraction of silicon raw materials and the production of a silicon ingot. The intermediate steps are solar PV cell production and module packaging. The downstream is the application of PV systems.

Extraction of silicon: The silicon extraction industry mainly forms upstream of the solar PV industry. These industries have high energy consumption and requirements for the financial capabilities, technologies, and environmental protection approaches of enterprises [

3,

23,

25]. High purity silicon material is essential for producing solar cells, which requires enterprises to have high purification technology and capital.

Production of silicon ingots and wafers: Silicon ingot and silicon wafer production have a high dependence on technology and raw materials. Due to the large supply of polycrystalline silicon, the raw material supply of silicon ingots and wafers is not the bottleneck that hinders the industry’s development, and as such many silicon ingot production enterprises have emerged in China.

Cell manufacturing: Cell manufacturing highly depends on both financial and technological capabilities. Through continuous improvements in battery manufacturing technology in China, China’s existing technologies have reached the world’s top level, and many powerful PV enterprises have emerged.

Solar cell modules: The manufacturing and packaging of solar cell modules differ from the previous stage in that it requires a limited technology capability and capital and is a labor-intensive industry. The rapid development of this link can promote the development of the whole industry chain.

PV system application: PV system applications mainly include two categories: one is the use of solar power generation systems in remote and rural areas; the other is the use of independent systems such as PV lighting and solar PV products and PV grid-connected power generation systems.

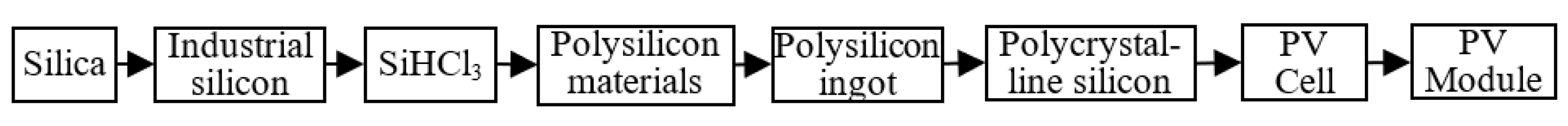

3.4. The Polysilicon PV System

The polysilicon PV system is a solar electricity system that comprises industrial silicon, polysilicon materials, polysilicon ingot, solar cells, and solar modules. In addition, related steps include the production of balance modules; plant construction; and the production, transportation, and waste treatment of consumed auxiliary materials. The specific production process from silicon raw materials to PV panels is shown in

Figure 4.

Silica is the initial raw material after adding a reducing agent, such as petroleum coke, wood, or low ash coal that melted under high-temperature conditions to derive elemental silicon and obtain industrial-grade silicone raw materials. However, the industrial-grade silicon raw material fails to reach the polycrystalline silicon’s purity for PV power generation. Therefore, further processing stages are essential.

Trichlorosilane (SiHCl3) is obtained by the reaction of industrial-grade silicon raw material with hydrochloric acid. Then, the product is rectified through a distillation column to separate it from other unrelated materials. The reduction in trichlorosilane allows for obtaining polycrystalline silicon material after distillation and separation by hydrogen.

The solar-grade polycrystalline silicon material is added into the quartz crucible sprayed with silicon nitride and the ingot is cast in the ingot furnace. After the completion of the ingot process, the polycrystalline silicon ingot is obtained and it further produces polycrystalline silicon wafers. After the production process, the extracted materials are processed through cleaning, drying, and final testing stages. Then, solar cells are produced by polysilicon chips.

The PV module production stage includes testing polycrystalline silicon cells, pretreating tinned copper strips, cleaning glass, welding, and framing.

This section formulates the PV industry chain structure and the production process from raw material silica to the final production of the PV module. It is reasonable to separate the PV industry chain by including the heterogeneity across various PV systems to understand the sources of pollution as well as the processes that generate the pollution and carbon emissions of the PV industry.

3.5. Insight into the Carbon Emission Process of PV Systems

The polysilicon PV system’s carbon emissions mainly include two types of carbon emissions: one is induced by the consumption of resources and energy, such as coal and oil combustion; the other is the carbon emissions caused by pollutants from the production of PV systems [

26]. More specifically, it includes the production and extraction of industrial silicon, the production of polysilicon ingots, solar cells, equipment, the building of PV factories, transportation tools, and transportation processes. The PV system’s main areas for producing carbon emissions caused by pollutant discharge are as follows: the production of industrial silicon, polysilicon materials, silicon ingot, polysilicon sheets, cell sheets, and cell modules.

Resource and energy analysis: The energy consumption and equipment list of each link in the polysilicon PV system are shown in

Table 2.

Pollutant discharge analysis: Pollutant discharge is mainly studied in each process of the industrial production stages. The details are shown in

Table 3.

Carbon emissions: In general, carbon emissions are greenhouse gas emissions that increase the carbon intensity of the environment. The carbon emissions in this section refer to carbon dioxide and other greenhouse gases that are converted into carbon dioxide by applying the global warming index in the subsequent calculation.

4. Methods

This paper applies the product LCA method to analyze the whole industry chain of the PV industry. After lean production, enterprises achieve sustainability by transitioning to ecological efficiency and reducing the impact of products and processes on the environment. The first step for environmental benefits is understanding a product’s environmental impact and procedures, achieved through LCA. LCA aims to identify the environmental impacts that can be assigned to a product or process. Common categories for assessing such impacts include, but are not limited to, energy consumption, consumption of minerals and fossil fuels, global warming, toxicity (air, water, land, human, and animal), ozone layer depletion, and acid rain. As such, we applied the LCA method to measure the polysilicon PV system’s carbon emissions, which adds new content to the method by constructing a whole life cycle carbon emission model of the polysilicon PV system.

4.1. Carbon Emission Model Building and Coefficient Setting

There are six crucial processes in the PV industry chain: the purification of silicon raw materials, the production of the polysilicon, the production of the polysilicon wafer, the production of the solar PV cell chip, the production of the PV cell module, and the assembly of the PV system module. It should be noted that each process will generate carbon emissions. Therefore, we should consider the following six sources of carbon emissions when building a carbon emission model. First, carbon emissions are induced by energy consumption (such as electricity, oil, coal, natural gas, etc.) during polysilicon PV cell production. Second, carbon emissions are caused by the consumption of resources (such as silver, aluminum, emery, etc.) during polysilicon PV cell production. Third, carbon emissions are generated during the transportation of batteries. Fourth, carbon emissions are caused by steel and cement consumption due to a factory’s structures. Fifth, equipment consumption (such as the polycrystalline furnace, cleaning machine, high-frequency furnace, etc.) also generates carbon emissions. Sixth, we also consider the carbon emissions generated during the disposal of wastewater. The fundamental equation of the carbon emission model is built based on the above six sources of carbon emissions.

C represents the carbon emissions of the polysilicon PV system.

E represents the carbon emissions generated by electricity consumption in the production process.

T represents the carbon emissions generated during transportation.

S represents carbon emissions generated by factory buildings.

R represents carbon emissions caused by resource consumption.

W represents carbon emissions generated from the treatment of wastewater and solid waste.

F represents carbon emissions released to the production processes of the equipment.

In the above equilibrium,

represents the electricity consumed by each production process in KWh; and

refers to the carbon emission coefficient of electricity, which is 0.62 kg CO

2/kWh.

where

is the CO

2 emission amount (kg) in the transportation stage;

is the equivalent carbon emission (kg) of CH

4 in the transportation stage;

is the equivalent carbon emission (kg) of N

2O in the transportation stage;

D is the transportation distance (km);

H is the transport weight (t);

is the potential coefficient of global warming of greenhouse gases;

is the conversion coefficient of greenhouse gas into CO

2;

is the fuel oil consumption intensity L/(t km); and

is the greenhouse gas emission coefficient of fuel oil (kg/L).

where

a is the amount of steel reinforcement required for the factory per unit area (kg/

);

b is the amount of cement needed in the workshop per unit area (kg/

);

is the workshop area required for each production stage

;

RS is the carbon emission coefficient of steel bars (kg CO

2/kg); and

RC is the carbon emission coefficient of cement (kg CO

2/kg).

where,

is the number of resources consumed in each stage (kg) and

RM is the carbon emission coefficient of resources (kg CO

2/kg).

where

Fi is the price of the equipment (CNY ten thousand) and

RF is the carbon emission coefficient of the equipment (kg/ten thousand CNY).

where

is the amount of wastewater treated in each production process (

) and

is the CO

2 emission coefficient of aerobic treatment wastewater (kg/

).

We obtained the complete carbon emission model of the PV system through the calculation models in all aspects above:

4.2. Carbon Emission Coefficient Analysis

In this section, the carbon emission coefficient analysis covers four major areas: the industrial carbon emission coefficient, the carbon emission coefficient of vehicle fuel, the carbon emission coefficient of the thermal power generation industry, and the carbon emission coefficient of pollutant treatments, respectively.

4.2.1. Industrial Carbon Emission Coefficient

The carbon emission estimation model of the industrial sector is as follows:

where

is the carbon emissions;

is standard coal consumption;

is the carbon emission conversion factor for coal consumption;

is the standard coal consumption of petroleum;

is the conversion factor for carbon emissions from petroleum consumption;

is the standard coal consumption for natural gas; and

is the carbon emission conversion factor for natural gas consumption.

According to the data on industrial production quantity related to this model in the China Statistical Yearbook (2006–2016) [

27,

28], we can obtain the national average carbon emission of different kinds of industrial equipment and steel bars. The carbon emission coefficients of fossil energies (i.e., coal, oil, and natural gas) are 0.7559, 0.5857, and 0.4483, respectively. The standard energy conversion coefficients of fossil energies (i.e., coal, oil, and natural gas) are 0.7143, 1.4286, and 1.214, respectively.

4.2.2. Carbon Emission Coefficient of the Equipment Industry

The industrial output value for general equipment, the required standard amount of the three types of fossil energy needed for the equipment, and the carbon dioxide emission unit of general equipment per unit of the industrial output value from 2006 to 2016 are shown.

The variation in the carbon dioxide emissions from general equipment over the years has the following relationship: y = 2 × 10119e−0.1384t, R2 = 0.9122, MAD = 0.33% (mean absolute deviation, MAD).

The required amount of petrol, coal, and natural gas needed for the industrial sector’s special equipment from 2006 to 2016 was calculated. More specifically, based on the industrial sector’s carbon emission coefficient method, we calculated the carbon dioxide emissions of special equipment. The trend in the carbon dioxide emissions of special equipment over the years has the following relationship: y = 8 × 10195e−0.2258t, R² = 0.9917, MAD = 0.33%.

4.2.3. Carbon Emission Coefficient in Steel Bar Production

The output and energy consumption of ferrous metals are obtained by consulting the China Statistical Yearbook (2006–2016) with the following relationship: y = 1046e−0.052t, R² = 0.909, MAD = 18.88%, MAPE = MAD/Average = 4.78% (mean absolute percentage error, MAPE).

4.2.4. Carbon Emission Coefficient of Vehicle Fuel

The combustion of vehicle fuel (gasoline) releases CO

2, N

2O, CH

4, and other gases. In the calculation of carbon emissions, CH

4 and N

2O are converted using CO

2 as the standard. The correlation coefficients are shown in

Table 4.

4.2.5. Carbon Emission Coefficient of Thermal Power Generation Industry

According to the thermal power industry standard, the carbon emission coefficient of this industry is a fixed value of 0.62 kg CO2/kWh.

4.2.6. Carbon Emission Coefficient of Pollutant Treatment

When calculating the carbon emissions from the three waste processes, such as solid waste, wastewater, and waste gases, the amount of greenhouse gases produced in the treatment process is usually calculated.

The calculation process of the carbon emission coefficient for the incineration method is as follows:

where

is the carbon emission coefficient (kg/kg) of incineration waste;

is the waste discharge (kg/kg) per unit of product; and

is the carbon content percentage of waste. In landfill mode, waste gas collection and combustion equipment are applied. The CH

4 emission coefficient is as follows:

In the above equilibrium, is the CH4 emission coefficient of the landfill disposal method (kg/kg); is the moisture percentage of waste; is the rate of the exhaust gas capture system; and is the percentage of combustion equipment efficiency.

Aerobic treatment is calculated based on the production of CO

2 and removed COD. The calculation method is as follows:

where

is the treated wastewater CO

2 emission coefficient (kg/

;

is the COD emission factor (kg/kg);

is the inlet concentration of COD, (mg/L); and

is the removal rate of COD (%). We need to calculate the CH

4 released from anaerobic decomposition for anaerobic treatment. The calculation method is as follows:

where

is the CH

4 discharge coefficient (kg/

of treated wastewater;

is the CH

4 trapping system trapping rate (%); and

is the combustion equipment efficiency (%).

5. Case Analysis of Polysilicon PV Life Cycle Carbon Emission

In this section, we selected the Changzhou Trina Solar company as the leading PV module and smart energy solutions provider. The company aims to deliver PV products, applications, and services to advocate sustainable development globally. By October 2020, Trina Solar has delivered more than 56 million kW of solar modules worldwide, ranking among the top 500 private enterprises in China. In addition, the company’s downstream businesses include solar PV project development, financing, design, construction, and operations management, providing customers with one-stop system integration solutions. The case analysis of the Changzhou Trina Solar company provides industrial insights for understanding the carbon emissions from different production links. Next, we provide a detailed description of the production process, including the production of PV cells, modules, and materials, as well as the energy consumption throughout the process.

5.1. Material Consumption and Energy Consumption

The production of PV cells and PV modules includes the consumption of both martial consumption and energy consumption. To precisely calculate the emissions of 280 MW PV cells and PV modules, we listed the material consumption in

Table 5 and the energy consumption in

Table 5. In each table, we provide the consumption list and corresponding data, model type, factory information, and important notes. The data extracted from the annual output of 280 MW of high-efficiency solar cells and photovoltaic modules project an environmental impact statement.

In terms of pollution prevention and control measures, there are two significant measures to prevent pollution: water pollution and solid waste pollution. Water pollution treatments should be discharged to the sewage treatment plant and domestic sewage after fluoride removal. It is necessary to dispose of solid waste on a case-by-case basis. If the waste is used cells, it should be sold to the public. If the waste is copper with an edge, it should be recycled by the supplier. If it is general waste, the activated carbon can be given to an industrial waste disposal company for treatment.

5.2. Calculation Results

5.2.1. Carbon Emissions from Energy Consumption

It can be seen that different production processes produce different carbon emissions, with total carbon emissions of 538,912 tons, as shown in

Table 6. According to the different production processes, carbon emissions from high-purity polysilicon amount to 490,447 tons, accounting for up to 91%, which shows that this process has the largest amount of carbon emissions and the greatest impact on the environment. The remaining two sectors have lower carbon emissions, at 16,950 tons and 31,515 tons, respectively.

5.2.2. Carbon Emission Caused by Resource Consumption

The carbon emissions generated by the materials consumed in the production process of polysilicon cells are calculated and shown in

Table 7 below, for which the energy consumption per unit of the relevant consumed substance comes from the China Energy Efficiency Analysis and International Comparative Study Report.

5.2.3. Carbon Emissions in Transportation

For a series of products in the same industrial park, the carbon emissions in the transportation stage are low, so they can hardly be counted in the final results; therefore, carbon emissions in the transportation link are not considered.

5.2.4. Carbon Emissions of Equipment

Based on the price of different production equipment and the relevant carbon emission coefficient calculated above, the carbon emissions caused by the use of the equipment to produce the system can be calculated, as shown in

Table 8.

5.2.5. Carbon Emissions from Solid Waste and Wastewater Treatment

Based on the above analysis of solid waste treatment and wastewater treatment, the calculation here applies the entire life cycle method and does not consider the carbon emissions generated when disposing of the waste that is recycled or entrusted to external treatment facilities. There are three major production stages: high-purity polysilicon production, polysilicon ingot casting and slicing production, 280 MW polysilicon solar cells production, and PV module production. Each stage produces 1.2 tons, 253.2 tons, and 0 tons of COD removal, respectively, and releases 0.825 tons, 174.075 tons, and 0 tons of carbon dioxide, respectively. Therefore, the total carbon emissions from the waste disposal of 280 MW polysilicon solar cells is 174.9 tons. Based on the calculation of the various situations mentioned above, we finalize the entire carbon emissions of the 280 MW polysilicon solar cell. What stands out in the calculation results is that the carbon emissions of the entire process of producing polysilicon solar cells with a 280 MW capacity are 734,348.1 tons. The carbon emissions of energy consumption account for up to 73.39%, which is 538,912 tons, and constitute the major carbon emissions source. The carbon emissions of resource consumption account for 26.39%, which is 193,765 tons. The carbon emissions of the production equipment are 1496.2 tons, accounting for 0.2%, whereas the carbon emissions of the production and treatment of wastewater and wastes from the equipment are minimal at only 0.02%, as shown in

Table 9.

It is apparent from the calculations that the carbon emissions of energy consumption play a vital role among several carbon emissions sources. Therefore, it is reasonable to assume that PV enterprises should optimize energy consumption to reduce carbon emissions. In the production process, we suggest improving product manufacturing technology, optimizing the production process, utilizing the equipment to produce low environmental pollution, improving the recycling and reuse rate of wastewater and waste to reduce carbon emissions, and eliminating small-scale enterprise pollution.

6. Conclusions and Future Research

The present work attempts to draw attention to the carbon emissions released from the PV industry value chain, and there is a necessity for the corresponding stages to be treated with caution by the related stakeholders. Based on the life cycle evaluation theory, we analyze the entire PV industry chain and then study the PV system’s carbon emissions in the production of polysilicon cells. From the purification of silicon raw materials to the production and assembly of polysilicon cells, a carbon emission model of the polysilicon PV system’s whole life cycle is established. This paper also demonstrates the evaluation system of polysilicon enterprises based on an analysis of the entire PV industry chain. The conclusions are as follows.

First, the whole PV industry chain is divided into the upper, middle, and lower reaches. The upper reaches include silicon raw materials and silicon ingot/silicon wafer production; the middle reaches refer to solar cell manufacturing and module packaging. The lower reaches refer to the PV system applications. A solar power generation system is a typical “terminal environmental protection, process pollution”, particularly in polysilicon production enterprises.

Second, the polysilicon PV system comprises five parts including the purification of industrial silicon, the production of polysilicon material, the production of silicon ingot, the production of polysilicon cell chips, and the production and application of polysilicon PV modules. This paper applies the LCA method to the production of polysilicon for cell modules, uses the entire LCA method to measure the polysilicon PV system’s carbon emissions, and constructs the corresponding carbon emission model. The carbon emissions from resource and energy consumption and the carbon emissions caused by pollutant emissions in the production process are studied, and resource consumption, energy consumption, equipment inventory, and pollution emission analysis are established. The polysilicon PV system’s entire life-cycle carbon emission model is built mainly using the life cycle method and the emission coefficient method. The system’s carbon emissions calculations include six areas: industrial silicon, polysilicon materials, silicon ingot, polysilicon sheets, cell sheets, and PV modules. Each area is calculated separately. The determination of the emission factors can be divided into industry, automobile fuel, thermal power industry, and pollutant emissions.

Third, the Trina Solar energy case study shows that polysilicon production plays a decisive role in accounting for 91% of total carbon emissions from energy consumption. In contrast, the polycrystalline ingot and chip production process accounted for only 3.1% and the polysilicon solar cell and PV module production process accounted for only 5.9%. Therefore, to reduce the carbon emissions of the polysilicon PV system, polysilicon enterprises should continuously improve production equipment; actively develop advanced production technologies; formulate energy conservation, environmental protection, and safety measures; reduce the resources and energy consumption of enterprises; and enhance the advantages of the polysilicon PV system. Whether in the domestic market or overseas, the global solar PV industry will have a promising future in the next few decades. As far as China is concerned, reducing coal power consumption, controlling environmental pollution, improving air quality, and establishing a benign ecological environment are essential agendas for promoting green development in the coming decades. The government must set up regulations to encourage PV-related industries and companies to consistently improve technologies to reduce carbon emissions by optimizing energy consumption.