1. Introduction

The current global context of sustainable development urges all countries to mitigate the consequences of climate change. It is also a time when the current trend of societies in developed countries is to concentrate the population in huge metropolia. The railway sector plays a vital role in transporting people between these large metropolitan areas. Its immediate future lies in making the train more attractive to potential users. In this regard, high-speed railways (HSR) has been an advance, providing a fast and comfortable transport mode for long-distance services. HSR is considered an efficient transport mode and is part of the strategy to avoid the pollution produced by the massive use of private vehicles. Europe is leading among the developed countries in managing decarbonisation in all sectors with imminent effect. In this way, the Sustainable Development Goals (SDGs) are the main framework in which measures have to be taken. Therefore, the most immediate action to carry through by society, administrations, and companies is to develop technology by making it more efficient in terms of emissions of greenhouse gases.

This rational use of energy is particularly relevant for the transport sector because of the massive amount of energy required in developed countries [

1,

2], especially when the trend is towards unification into an electrified system. In this manner, railway transport is the most efficient in energy consumption and pollution emission. Railway operations account for a low percentage of energy consumption, but, even so, it is a large consumer and, therefore, its efficiency is susceptible to being improved [

3]. Railway operators, national infrastructure managers, and other companies in the sector apply all kinds of technological developments in order to minimise the energy consumption associated with train operations, always considering the comfort and safety requirements.

Eco-driving is one of the most popular methods for optimising energy consumption in railway operations because it can be applied in the short term, providing important energy reduction results [

4]. Eco-driving is the obtention of the speed profile with the minimum energy consumption associated. The eco-driving speed profile is calculated for a specific target running time considering the previously designed timetable [

3,

5,

6,

7,

8,

9,

10,

11].

Different eco-driving strategies have been analysed in the academic literature. In some simple scenarios, driving through speed regulation has been simulated [

1,

12,

13,

14]. Other studies have proposed design by coast-remotoring cycles, having upper and lower speed limits [

15,

16,

17] or considering coasting points along the railway line [

18,

19,

20,

21,

22]. Previous strategies are appropriate for short routes on metro lines but are not very efficient for longer railway lines as the HSR lines. The speed regulation without braking has been demonstrated as an efficient and easily executed eco-driving strategy for high-speed railway lines [

23,

24].

The production of speed profiles with the minimum energy consumption requires an optimisation model that can return the best combination of eco-driving strategies. In study [

18], the initial study on eco-driving was developed. This work applies Pontryagin’s Maximum Principle to a simplified train dynamics model, obtaining optimal driving modes as maximum acceleration, cruising, coasting, and maximum braking. The studies developed subsequently to [

18] have improved the dynamic model of simulation, and the different optimisation techniques implemented are classified in study [

25] as analytical and numerical methods.

Most of the analytical methods are developed based on the optimal control theory. Pontryagin’s Maximum Principle is used in these methods to find the best energy efficiency solutions and apply algorithms to obtain the optimal switching points between the efficient regimes. These algorithms are based on Dynamic Programming [

26,

27,

28,

29], constructive algorithms [

1,

21,

30,

31], Sequential Quadratic Programming [

32], and the method of Lagrange Multipliers over the discretised problem [

33]. Other methods transform the situation into a non-linear problem [

34]. The analytical methods are used to provide the optimal solution but, considering the complexity of the problem to be solved, a series of simplifications have to be made in the train model. Due to the simplifications, inaccuracies can be obtained in the results generated, and may require recalculations in real applications [

13].

On the other hand, numerical methods have been used for solving the problem of efficient driving in railway operations as well. These methods are flexible enough to be used without reducing the complexity of the train model by using detailed simulation models, adjusting the comfort and driving requirements. Thus, these methods can be used to fulfil any need or constraint in real situations.

Among these numerical methods are Artificial Neural Networks, being used for the optimisation of the coasting points [

35], the optimisation of the coasting speed for a Mass Rapid Transit System considering energy cost and travelling time cost [

36], and for calculating a new indicator to characterise a railway traffic driving smoothness [

37]. Nature-inspired optimisation algorithms such as Genetic Algorithm (GA) have been widely applied for determining the speed profile which minimise the energy consumption [

2], the optimal coasting points [

19], and the optimum train speed along the journey [

27]. A single optimise train trajectory considering net energy between adjacent DC substations is described in [

38]. In study [

39], it is jointly optimised by means of a GA for the timetable and the speed profile. A coasting point control method is developed in [

40,

41,

42] based on GA to determine its number and position. Multi-population Genetic Algorithm (GA) is used in [

43] to reduce energy consumption in a subway system with multiple stations, and in [

44] in order to determine the acceleration, cruising and coasting points. GA combined with fuzzy logic is used in [

16] to optimise energy traction by trading-off reductions in energy against time, in study [

23] to find the economical pattern for an HSR balancing energy and running time, and used in studies [

45,

46] to calculate optimal speed profiles considering uncertainty in manual driving. Direct search algorithms have been applied to minimise energy traction in [

47] while Brute Force algorithm is used in [

48] to minimise energy consumption in substations. A Monte Carlo Simulation model was proposed to determine the system energy flow considering regenerative braking trains [

49]. Differential Evolution has been presented in [

50] to optimise railway operation. Optimisation by minimising energy traction is carried out by Simulated Annealing in [

51] and searching optimal coasting points in [

52]. On the other hand, multi-objective models have been developed using numerical methods. Among them, Indicator Based Evolutionary Algorithm (IBEA) was proposed to optimise both the running time and energy consumption [

53]. Non-dominated Sorting Genetic Algorithm II (NSGA-II) is used in [

54] to design ATO CBTC speed profiles to minimise energy traction and in [

55], its performance is compared with Multi-Objective Particle Swarm Optimisation (MOPSO) generating the Pareto curve for real cases of the Madrid Underground. Ant Colony Optimisation can be seen in [

27], proposing a distance-based train trajectory optimising the train trajectory, and in [

56] to achieve the optimal driving strategy. Finally, a MOPSO algorithm is used in [

57] to design efficient speed profiles for the ATO of the trains of a metro line.

With the purpose to obtain accurate results, it is important not only to use detailed simulation models but also to take into account the possible uncertainties that emerge from the HSR operation. These uncertainties can be classified in three groups: limitations in the movement authority produced by signals or preceding trains [

58,

59], variability in the manual operation of the train [

45], and the climate conditions. While the first two uncertainty sources have been widely studied, climate conditions have not been deeply considered in the eco-driving problem.

Most academic works focus on winter scenarios in Northern Europe to forecast delays or disruptions in traffic operation. Some studies have reviewed the issues during winter railway operations caused by snow and ice in Nordic countries [

60]. In study [

61], impact of humidity, temperature, ice, and snow depth on the occurrence of delays in high-speed operation in Sweden has been analysed through a Cox model and Markov chain model. A train delay prediction model with weather data has been designed in [

62] and tested on two high-speed railway lines in China. The Nordland railway line has been assessed in [

63], where extreme cold weather is a crucial factor related to delays and low punctuality. Other papers have focused on service delay time and its exposure time to bad weather [

64]. A combination of fuzzy theory and rough sets under adverse weather conditions has been used to contribute to the forewarning method for train operation in [

65]. Causal relationships between extreme weather patterns and derailments on railway turnouts have been investigated by means of Fuzzy Bayesian Network model [

66]. The impact on freight railways in winter weather in Northern Europe has been discussed [

67]. In study [

68], an estimation of the effects of weather conditions on railway operator performance of passenger train services has been carried out, focusing on infrastructure disruptions. In study [

69], a model to capture the cascade dynamics of delay propagation on railway networks under inclement weather has been presented.

As a general rule, climatological factors are considered random variables and instantly excluded from the models considered by railway operators. However, in HSR, the running resistance is the major factor determining the trains’ energy consumption. Climatic conditions such as wind or air density can produce significant variations in running resistance value. Therefore, climatology plays an important role in the energy that high-speed trains demands. Previous reasons motivate this paper to generate a new model to quantify the climatological affection in railway operation, both in energy consumption and in running time. Climatology has a great variability due to the impossibility of having complete knowledge of all the variables that model its behaviour. Therefore, climatic conditions such as pressure, temperature, and wind have been modelled by means of fuzzy logic [

70]. This way, this affection is included in the running resistance, given the vagueness in the knowledge of these variables.

The main advantage of fuzzy logic modelling is the ability to handle imprecise or incomplete information. Additionally, a positive feature is its flexibility and simplicity to be developed and implemented to obtain efficient calculations. That is why many studies have applied fuzzy logic in train operation models. In study [

71], the train service provider and the infrastructure provider have been modelled as software agents, and the negotiation for a train schedule and the associated track access charge as a prioritised fuzzy constrain satisfaction problem. In study [

72], predictive fuzzy control is used for carrying out the train dwell-time control in an event-driven framework. A methodology for predictive fuzzy control in an event-driven environment for multi-objective decision making on DC railway systems has been presented in [

73]. In study [

74], an approach within the fuzzy framework for tackling the complexity of multidimensional service evaluations and the judgment on the goodness of the schedule has been proposed. In study [

75], the authors investigated a passenger train timetable problem with fuzzy passenger demand. The paper presented by [

76] exposed a framework to evaluate the logistics performance of intermodal freight transportation by applying fuzzy set techniques. A multilevelled distributed railway traffic fuzzy control system is proposed in [

77]. An assistant support system for railway traffic control is described in [

78] making use of fuzzy knowledge. A fuzzy optimisation model for rescheduling high-speed timetables is proposed in [

11], focusing this work on punctuality and passengers’ affection without considering energy minimisation. In studies [

79,

80], a fuzzy model is proposed for an Automatic Train Control system. In studies [

45,

59], uncertainty in the manual driving application of the speed regulation command is modelled using fuzzy numbers. In study [

16], the optimal speed profile in urban DC railways is found with a GA, where the energy consumption and the running time are the fuzzy results. A fuzzy model of delays and punctuality constraints is proposed in [

46] for the offline design of timetables when efficient driving is applied. The algorithm proposed in [

54] is used for urban ATO operation including uncertainty in the mass, generating optimal energy–time Pareto curves of speed profiles. Fuzzy logic is applied in [

81] to detect the railway wheelset conicity as a measure of the deterioration. In study [

82], a fuzzy model is used to evaluate the potential risks of railway crossings. As can be seen, climatological parameters and their associated uncertainty have not been modelled previously; therefore, this possible affection to the railway operation has not been considered.

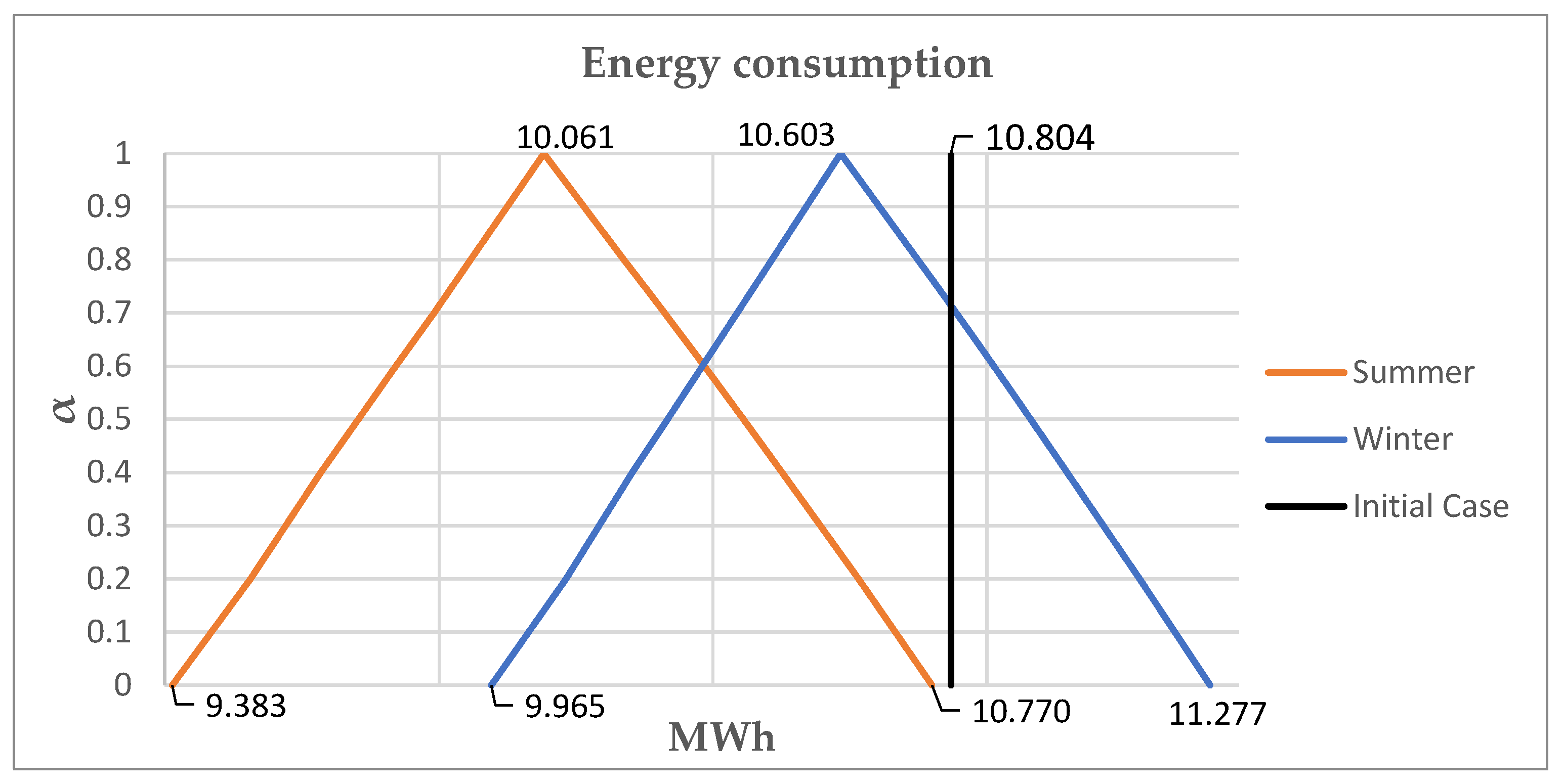

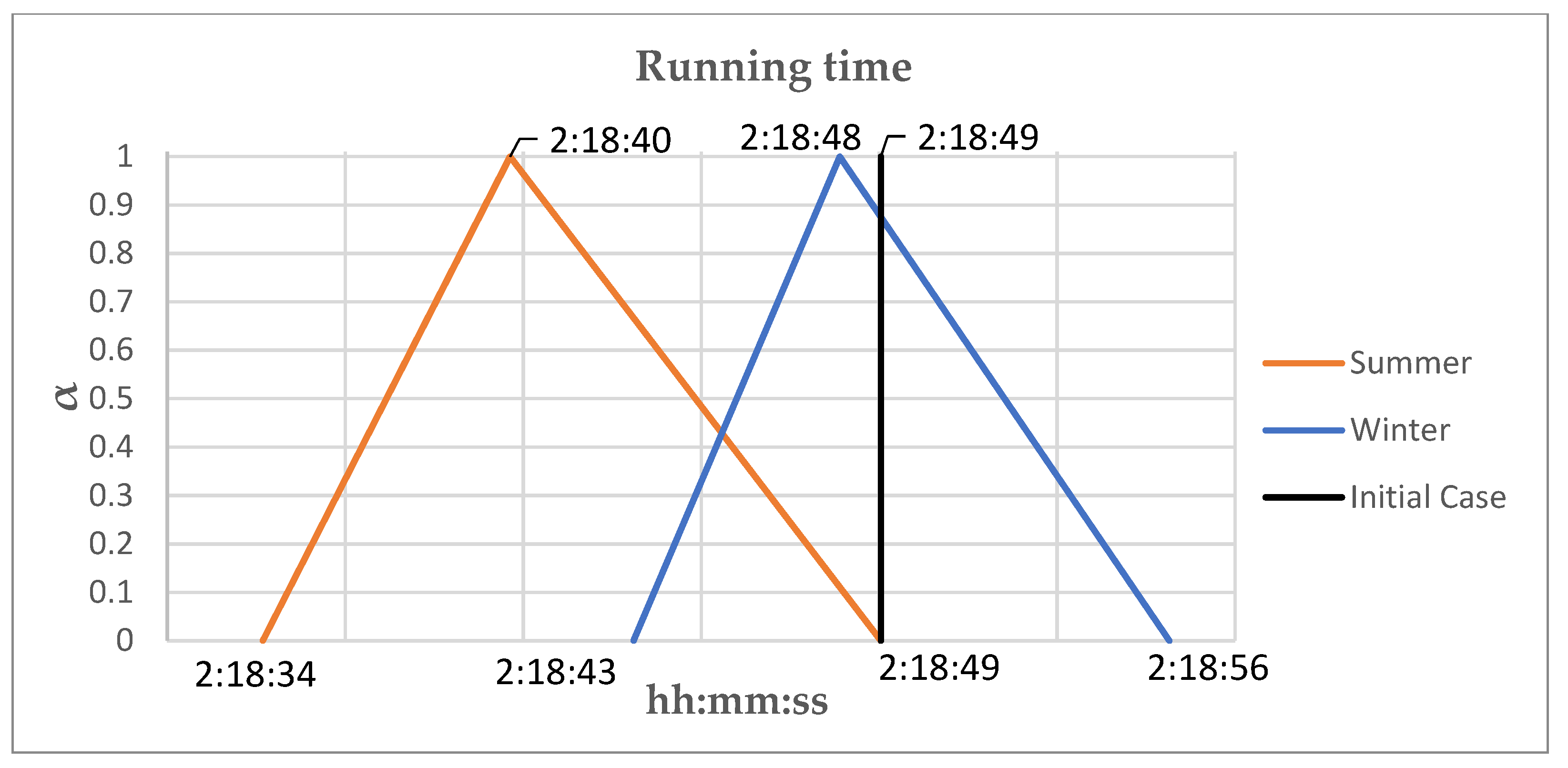

The main contribution of this paper is the introduction of climatological parameters in the eco-driving optimisation model. The proposed model allows an efficient driving design considering the uncertainty due to climate conditions by means of fuzzy modelling. Climatological parameters are not typically considered in the design of speed profiles, and they could affect the running time and energy consumption.

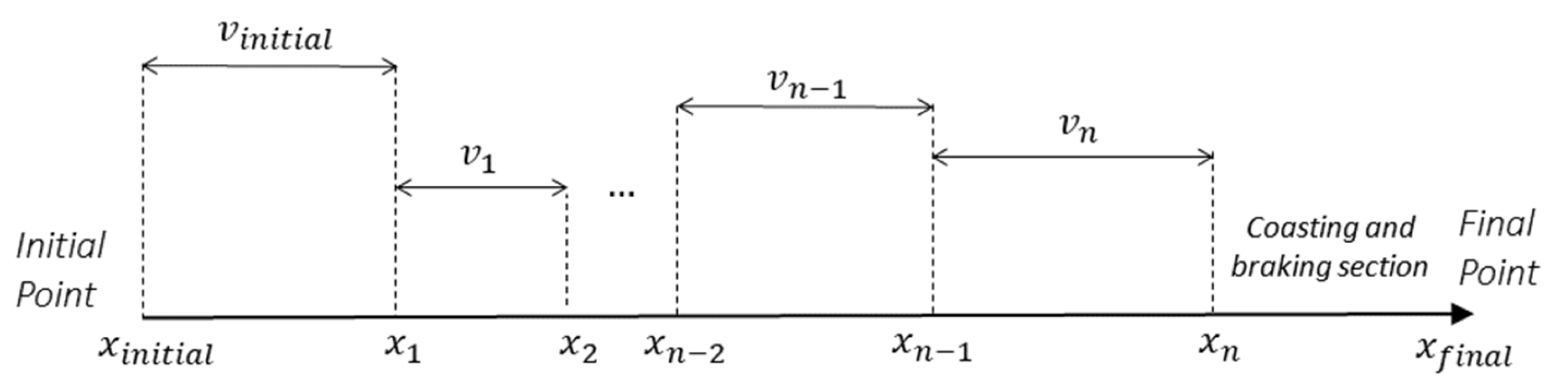

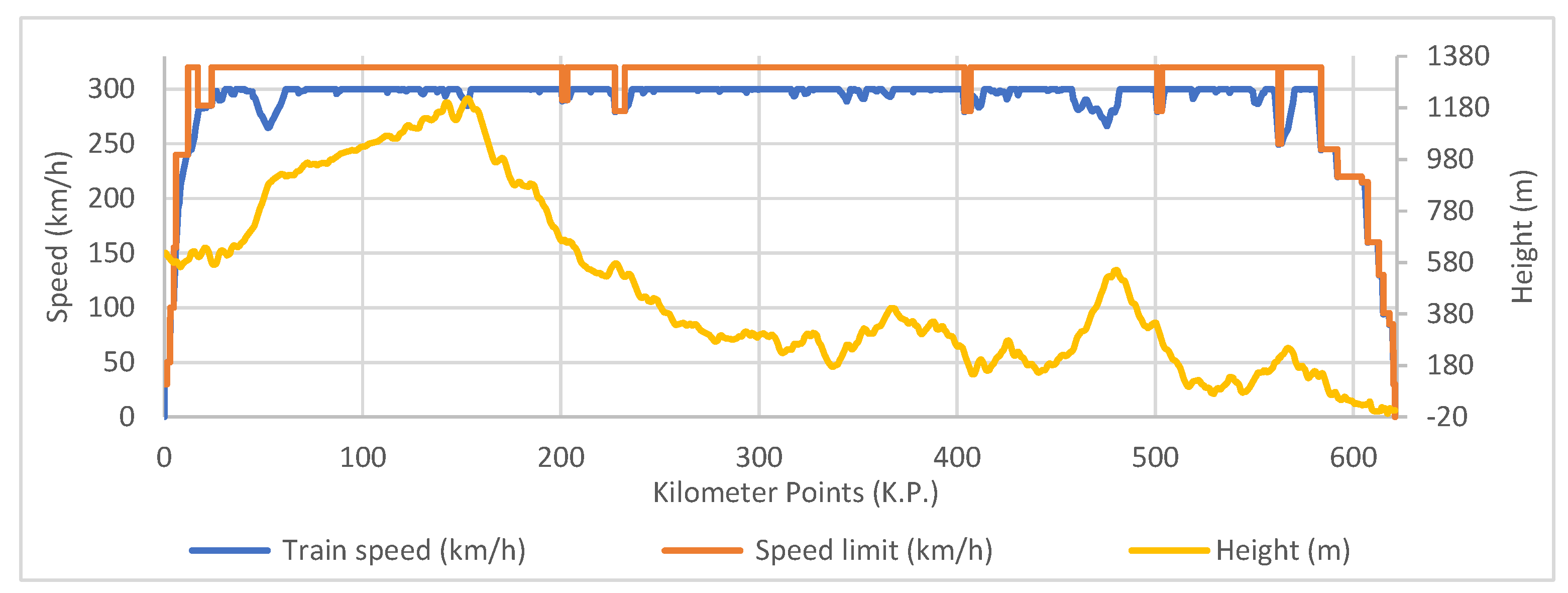

The optimisation model is based on a Genetic Algorithm combined with fuzzy parameters. This algorithm applies a search process that optimises a driving holding speed without a braking commands set that can be easily applied by human drivers. Applying these commands generates the efficient driving with punctuality requirements at the destination. Using a detailed simulation platform makes solving all possible scenarios possible when the climatological parameters vary according to the proposed model. This methodology can also be applied to quantify the error obtained in the expected energy saving if climate conditions are not initially considered in the optimisation of the railway operation. The model has been applied in a simulation test based on real data of a Spanish HSR, to compare scenarios where different wind and air pressure conditions are considered.

The paper is organised as follows:

Section 2 describes the simulation model in which the weather parameters are included. The uncertainty associated with the climatological parameters is modelled in

Section 3.

Section 4 is a description of the optimisation model developed to generate efficient driving.

Section 5 analyses the case study and presents the results obtained for a real high-speed railway line using the models proposed in previous sections. A discussion of the proposed procedure and the results are presented in

Section 6. At the end of the document, the bibliographical references and previous academic studies from which information for the present analysis has been obtained are presented.

2. Simulation

2.1. Simulation Model

The simulation model is described in this section. This model is detailed in [

45], and the results provided by the simulation were compared with real data of a Spanish HSR to validate the simulator. Differences of 1.2% for the running time and differences of 0.4% when compared with the energy consumption were shown. The model was used from [

45] to design eco-driving in a high-speed line, and measurements were recorded. As a result, energy savings between 20% and 34% were measured in commercial services. It was a detailed discrete event deterministic simulation model, that combines next-event and fixed-discrete time steps for advancing the simulation clock [

83,

84]. The simulation model takes several input data related to the rolling stock involved in the operation and related to the railway line:

- ❖

Rolling stock.

- i.

Physical parameters: mass of the train, the mass of the load, length, maximum speed, rotatory inertia, and adhesion traction.

- ii.

Traction effort curve, braking effort curve, running resistance coefficients, energetic and power systems and auxiliary systems consumptions.

- ❖

Railway line. Includes Kilometric Points of relevant information as stations (K.P.), grades, track curvatures, speed limits, tunnels, and grade transitions considering the length of the train and the electric neutral zones.

The equation that models the motion of the train at each simulation step considering the forces acting on the train is:

where

a is the acceleration of the train.

Fm is the motor force.

R is the running resistance of the train defined by the Davis formula (Equation (7)).

Fg is the force due to the railway grades.

Fr is the force due to track curvature.

meq is the equivalent mass.

By definition, the acceleration of the train in every step of the simulation is:

The equivalent mass, effective mass or inertial mass can be calculated by:

where

Force due to gradient (Equation (4)) shows acceleration due to gravity effect, considering uphill or downhill motion. Therefore, the force due to gradient profile can be written as:

where

Given the small values of slope angle in typical railway tracks, Equation (4) can be written as:

where

• p is the gradient of the track (mm/m or ‰).

Likewise, the force due to the track curvature can be expressed as follows:

where

The traction effort or motor force (Fm) is bounded by a maximum value of the electrical traction effort curve and a maximum electrical braking effort curve both dependent on the train speed. The simulation model considers at every moment the speed limits established along the rail track by the railway administration. Speed limits are defined by stretches along the railway where the train must drive respecting the maximum speed limit considering the total length of the train. When a train passes through a neutral zone, auxiliary systems cannot be fed from a catenary, and motors apply at least a constant braking effort to maintain the charge of the batteries that feed auxiliary systems along neutral zones.

Running resistance is the model that defines and groups a series of resistances opposing the train’s movement. These include mechanical resistances (rolling and internal friction), air intake resistances (for engine cooling and passenger air renewal), and aerodynamic resistance [

85]. The running resistance is modelled with a second-degree equation dependent on the instantaneous velocity and defined by the Davis expression [

86]:

where

a is a constant related to the mechanical resistance to the motion.

b is a constant related to the resistance due to the air inlet in the train.

c is a constant related to the aerodynamic resistance.

k is the tunnel factor.

vtrain is the velocity of the train.

The Davis formulae and similar expressions of a polynomial nature are models of reality. Each term of this equation refers to different physical components of the total running resistance. However, it must be considered that these polynomials are fitted models of highly complex phenomena that interact themselves. Therefore, although for general purposes certain approximations can be estimated, in reality, they are not completely accurate and do not represent reality in its entirety. Likewise, within the running resistance model, there are parameterised coefficients (a, b and c) that represent different oppositions to the movement of the train. These values are experimental, complex to define, and depend on the physical characteristics of the rolling stock. In order to obtain them, manufacturers test their trains and their relationships with the resistances generated. These coefficients are the nominal values, so they have been evaluated under standard conditions of pressure and temperature given by the International Standard Atmosphere, ISA (ISO, 1975: T = 15 °C; ρ = 1.225 kg/m3).

The term of the running resistance model (Equation (7)) that is not related to the effect of the air outside the train is called mechanical resistance. In this term, the coefficient a is involved. In the most general case, it is derived from the frictional resistance between mechanical components, rail-to-wheel contact, track irregularities, and energy losses in the traction and suspension equipment of the vehicles due to the oscillating or parasitic movements of the suspended mass.

The term of the train speed-dependent running resistance corresponds, mainly, to the resistance caused by the air intake of the train. In trains, there is a constant and noticeable air flow, necessary for cooling engines and other equipment as well as that required for air renewal for passengers. This term is related to the b coefficient of the running resistance model.

The so-called aerodynamic running resistance is the longitudinal force that opposes the train’s movement as a consequence of the interaction between the train and the surrounding air with which it collides and envelops it. The coefficient c is responsible for modelling this resistance.

The tunnel factor k increases the quadratic term of the running resistance model when the train runs through a tunnel due to the increased air friction against the outer surface of the train. When a tunnel is not involved in the simulation, the factor takes the value 1.

Equations (1)–(7) describe the motion of the train in next-event and fixed-discrete simulation steps, limited by speed limits, calculating braking curves to stop at the arrival point or station point with comfort and safety requirements.

The model related to the energy consumed by the train measured at the pantograph

Epantograph is expressed as shown in Equation (8) while the train energy consumption estimated at the electrical substation (

Esubstation) is defined by means of Equation (9):

where

Previous calculus requires some other equations to complete the model:

where

Pmec is the mechanical power.

Paux is the power consumed by the auxiliary systems.

ηT is the electrical chain efficiency for the traction case.

ηB is the electrical chain efficiency for the braking case.

V is the nominal line voltage.

cos φ is the power factor.

r(s) is the electrical line resistance.

nzstart and nzend are the initial and final position of every neutral electrical zone.

2.2. Climatological Model

The following section focuses on the running resistance variation when the railway operation is developed under real climatological circumstances. Initially, the influence of the variation of density along the railway line due to altitude changes has been modelled. Then, the wind’s influence on the running resistance model is incorporated. When motion equations are applied (Equations (1)–(7)) for simulating the train’s driving in a railway line, it is supposed that pressure and temperature values are constant along the whole line under standard conditions, given by the International Standard Atmosphere [

87]. Thus, Equation (7) is just modified by the velocity of the train and it incorporates coefficients,

b and

c given by the manufacturer. For that reason, previous coefficients are also constant along the railway operation in absence of wind and they are always the same for each line, no matter the geographical location and the season of the year considered for the railway operation. The purpose of this section is to include in the simulation model the influences on the running resistance with climatological considerations of pressure, temperature, and wind.

The railway operation can occur between points of different altitudes, and it is, therefore, to be expected that the model must deal with this variation along the railway line. In summary, throughout the journey, the air density will vary due to the change in altitude and this variation will modify the running resistance equation according to the model described below. When the train runs on a line without wind, the running resistance term can be defined by Equation (7). In the running resistance model, lineal and quadratic terms vary as a function of train speed. In the quadratic term, the coefficient

can be defined by the general aerodynamics equation as shown below, according to the quasi-steady theory [

88]:

where

From Equation (15), it is deduced that factor

c of the Davis formula is dependent on the density of the air and, therefore, on its variation. Finally, with the previous information, the coefficient

c is parameterised as follows, varying with density and considering standard weather conditions as a reference [

89]:

Finally, when all information related is considered, the running resistance model can be written as follows. However, this equation models the situation where the train is running without being influenced by the wind:

In this manner, a main and essential task is to know the air density at every point or analyse the stretch along the railway line. The density is a function of the temperature and pressure of the air, and its relationship can be expressed by the equation of state defined in the ideal gas law as follows:

where

Pressure and temperature values strongly depend on the meteorological conditions given a specific area due to its geographical characteristics and the year’s season. Therefore, considering the climatological model, they can be significantly different from one area to another. This work analyses these differences, which are present in the variations along the railway line.

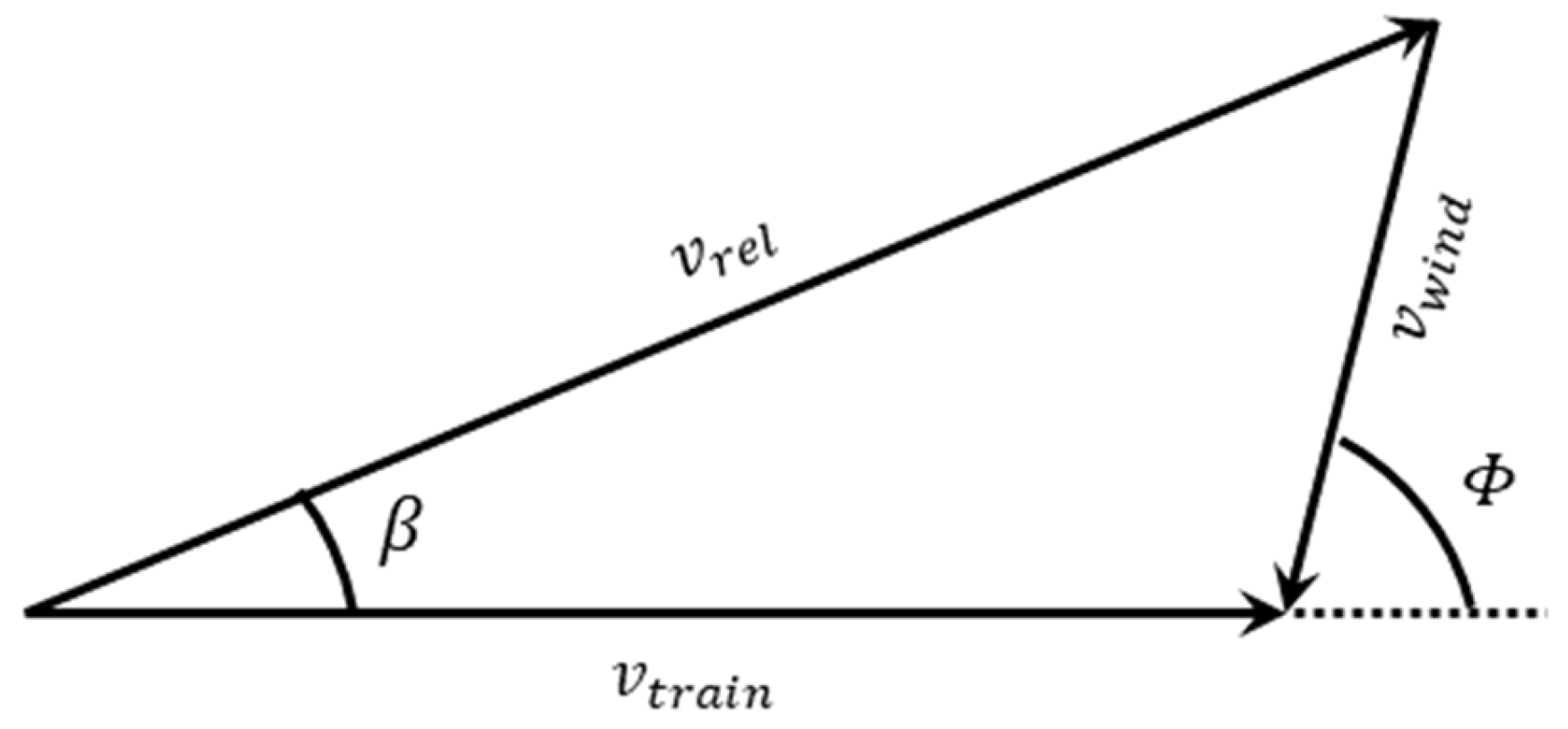

On the other side, the running resistance force is also significantly affected by the wind and its variation along the route. The influence of the wind is modelled by the combination of its intensity, or wind speed, and the angle of incidence in each stretch relative to the train (

) [

88,

89,

90]. The train speed relative to the wind is the train speed minus the wind speed vectors, as it can be seen in

Figure 1.

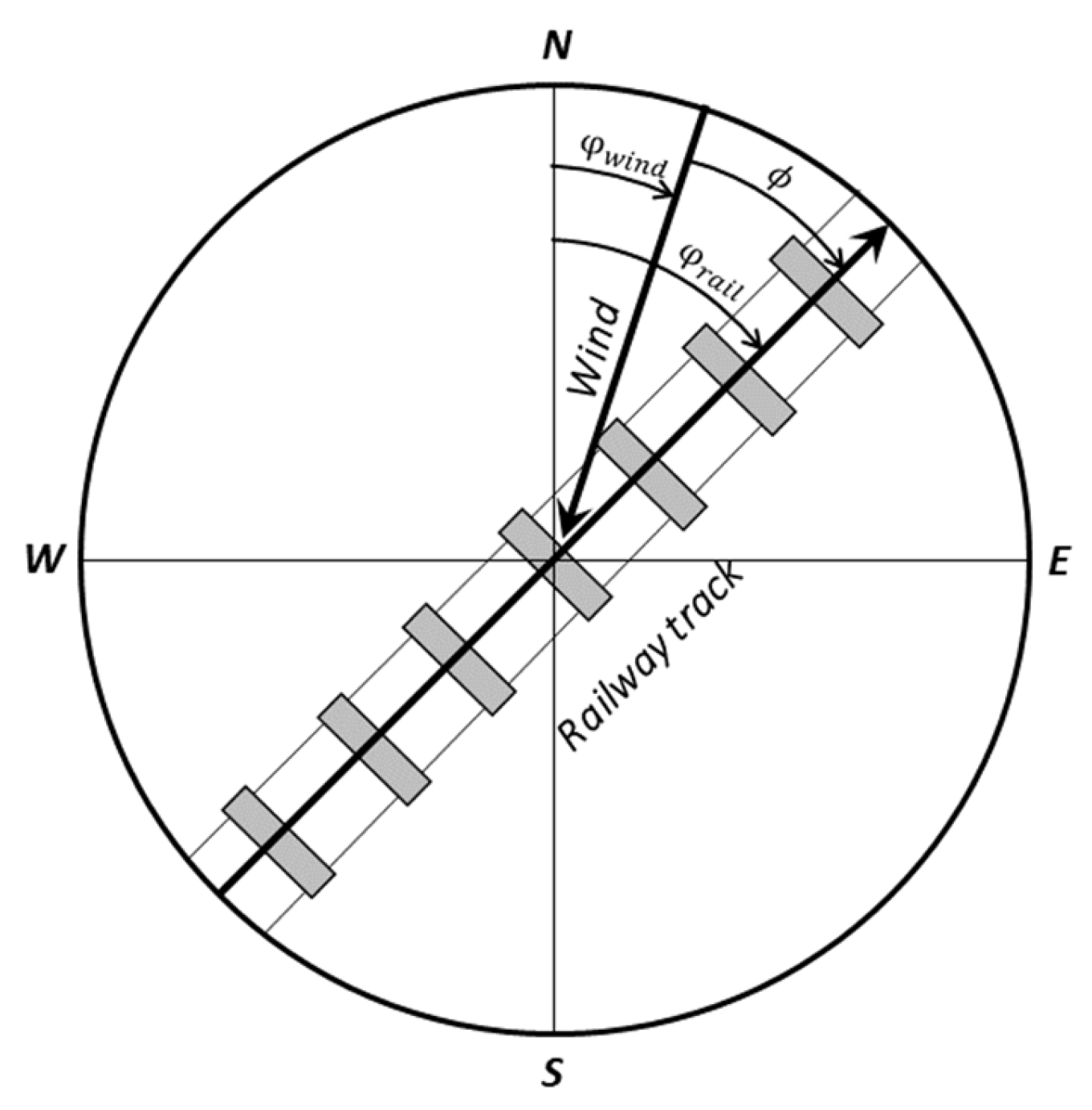

Figure 2 shows the reference frame considered in this work where angle

(Equation (19)) is the principal parameter to model the wind influence in the railway operation.

where

Running resistance model, given by Equation (7), is valid just when the wind has not been considered, so the model has to be modified, now influenced by the speed of the train and wind vectors, as shown in

Figure 1. The modification consists of replacing the train speed in Equation (7) by the train speed relative to the wind, which is equivalent to considering zero wind in the original equation:

Besides and in addition to the previous model, it has to be considered that factor

c also depends on the angle

β as shown in

Figure 1. Yaw angle can be calculated using Equation (21).

To get the final model for the running resistance of a train, the relative train speed must be calculated, determining the simulation model as follows:

Equation (23) is proposed in [

91]. This expression establishes the variation of the constant

according to the angle

β. This is an empirical expression and becomes meaningless when

β > 30°. An angle with such magnitude for typical speed values in operation would imply extreme winds, which would affect the train operation or could lead to the total suspension of the service.

where

• c(ρ) is the value of c when density variation is considered according to Equation (16).

Finally, the variable running resistance considering climatological factors is modelled as:

When the train runs through a tunnel, the force exerted by the influence of the wind shall not be considered. Therefore, for the sections simulated in a tunnel, the expression for the running resistance must be modelled with an expression that considers the train speed as input data, including the tunnel factor in the quadratic term. As applicable, it is used a

k parameter as the tunnel factor:

Pressure, temperature and wind models have been discretised along the railway line. If the altitude suffers any variation along the journey, the model can deal with the change by measuring the impact of the air density variance. Two different reasons have justified the division or discretisation along the railway line. Firstly, the variability of the wind makes necessary a partition along the line where the climatological and geographical characteristics determine the main direction in which the wind blows. And secondly, the change of directions taken by the train along the railway line has been dealt implementing stretches where it can be supposed that the relative angle between the wind and the train movement is approximately constant along a straight line. Hence, the proposed wind model considers both the railway track angle and the incidence wind angle to be parametrised. In conclusion, previous considerations allow the simulation model of the train movement to deal with the wind behaviour’s complexity without compromising the final results’ accuracy.

3. Fuzzy Climatological Model

This paper quantifies the relevance of the climatological factors and their variation by modelling them with their associated uncertainty during railway operation by means of a climate fuzzy model.

The parameters modelled by fuzzy numbers [

92] are defined in

Section 2.2: the pressure and temperature defining, consequently, the density, and the intensity and the angle of incidence of the wind.

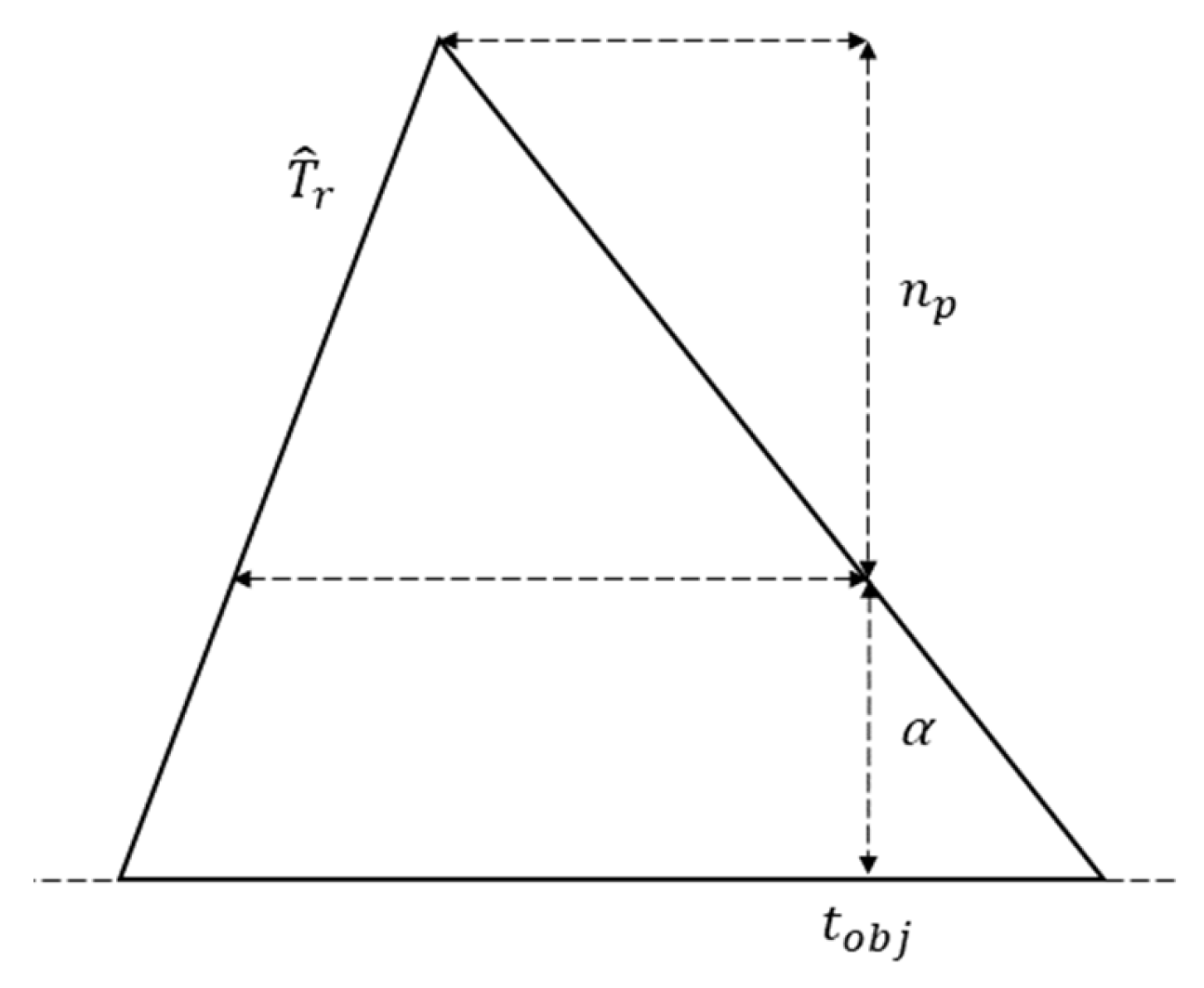

Among the many possibilities for the membership function of the fuzzy numbers: piece-wise linear [

93], linear, hyperbolic, exponential and S-shaped [

94,

95], climatological factors have been defined as triangular fuzzy numbers. But the model proposed in this paper would be applicable if any other shape is utilised to model climatological parameters’ uncertainty. Each of the fuzzy numbers, the temperature, barometric pressure, air density, wind intensity (or speed) and the angle of incidence of wind are defined by the shape shown in

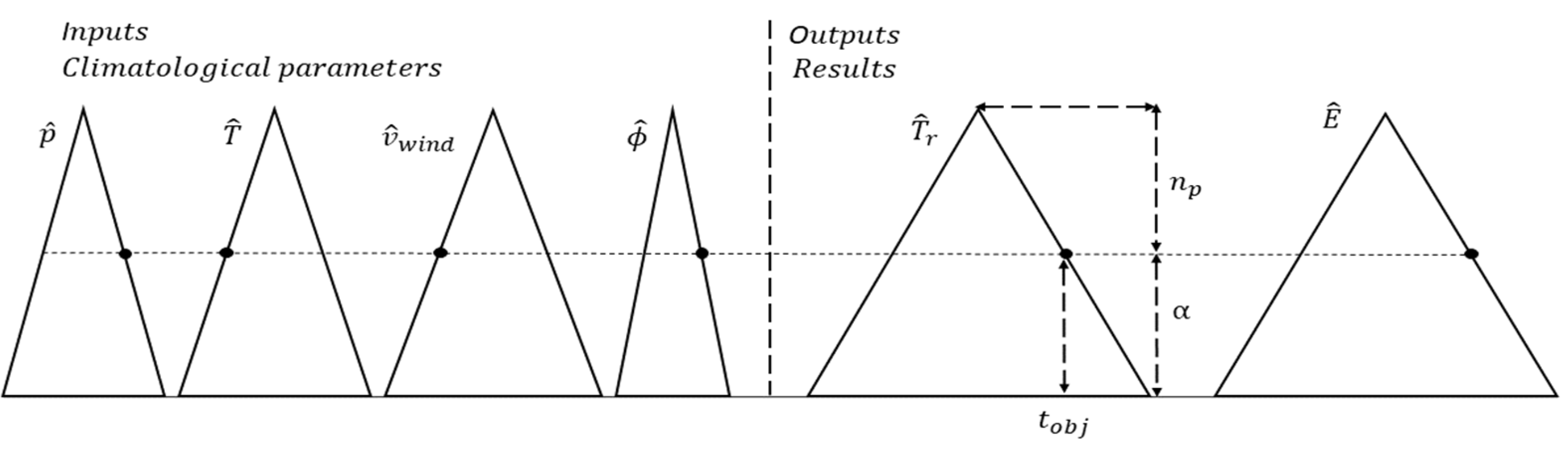

Figure 3. Therefore, a fuzzy number is defined by its core, its lower limit and its upper limit of the support.

Fuzzy pressure (

), fuzzy temperature (

), fuzzy wind speed (

) and fuzzy angle of incidence (

) have been defined for every division realised along the railway line in order to get a more detailed climatological model on railway track sections as explained in

Section 2.2.

The running time is calculated from the indicated fuzzy parameters and the model input data (train and railway line,

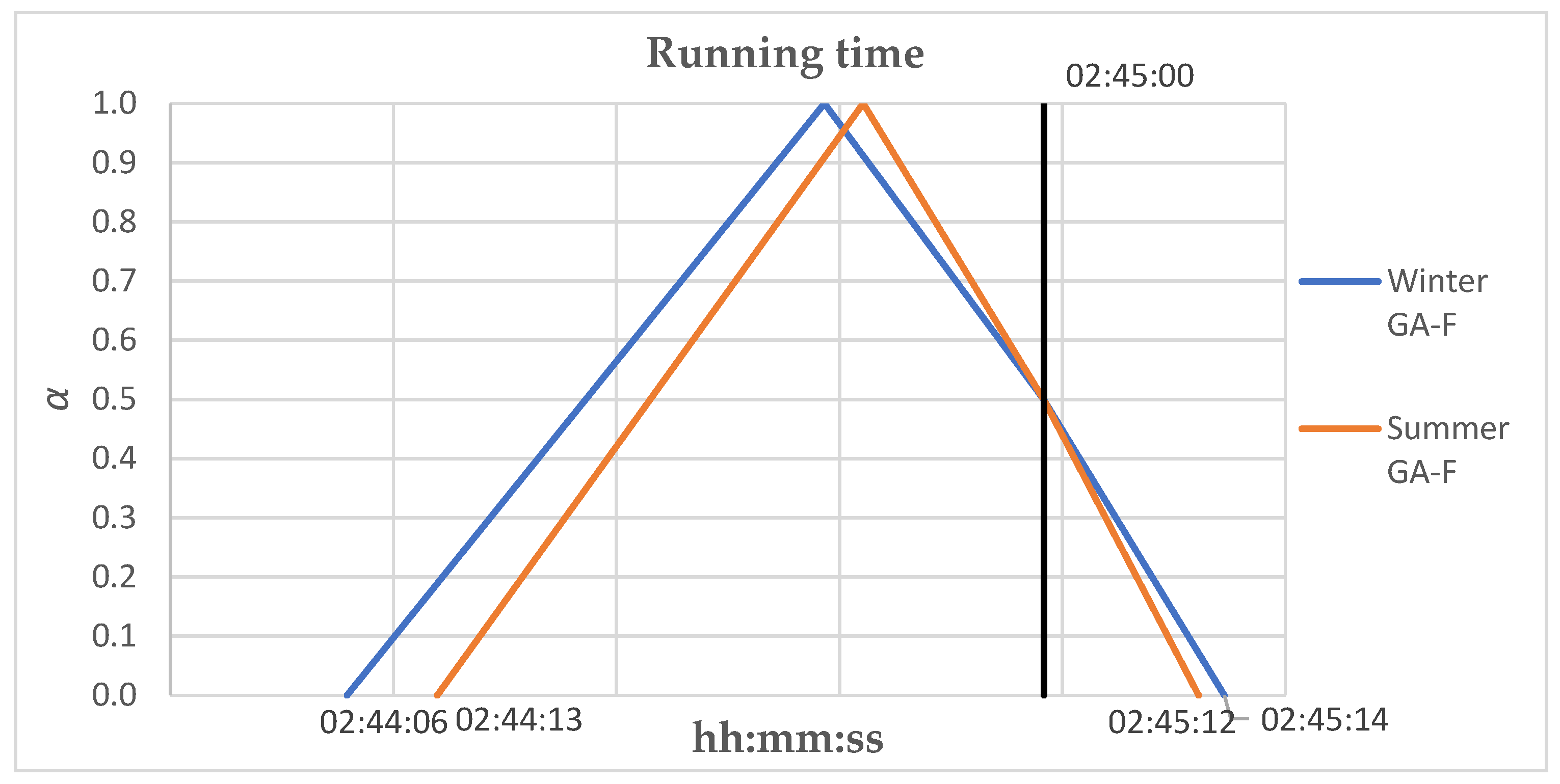

Section 2.1). This result will be a fuzzy parameter due to the uncertainty associated with some of the calculation parameters. In the proposed fuzzy model, the punctuality constraint is imposed on the fuzzy running time, which must be less or equal to the objective running time:

The punctuality constraint can be expressed either as a measure of the possibility of arriving at the scheduled time or as a measure of the necessity of fulfiling that objective. Thus, if it is expressed as a measure of the possibility α

ρ, the expression is:

The corresponding necessity measure, in this case, is 0:

If the punctuality constraint is expressed as a measure of the required necessity

, (

Figure 4) the expression is:

The corresponding possibility measure, in this case, is 1: