Study of the Air Leakage Mechanism and the Suitable Gas Drainage Volume with the Upper Tunnel

Abstract

:1. Introduction

2. Site Conditions

3. Development of Air Leakage

3.1. Formation of Air Leakage Channel

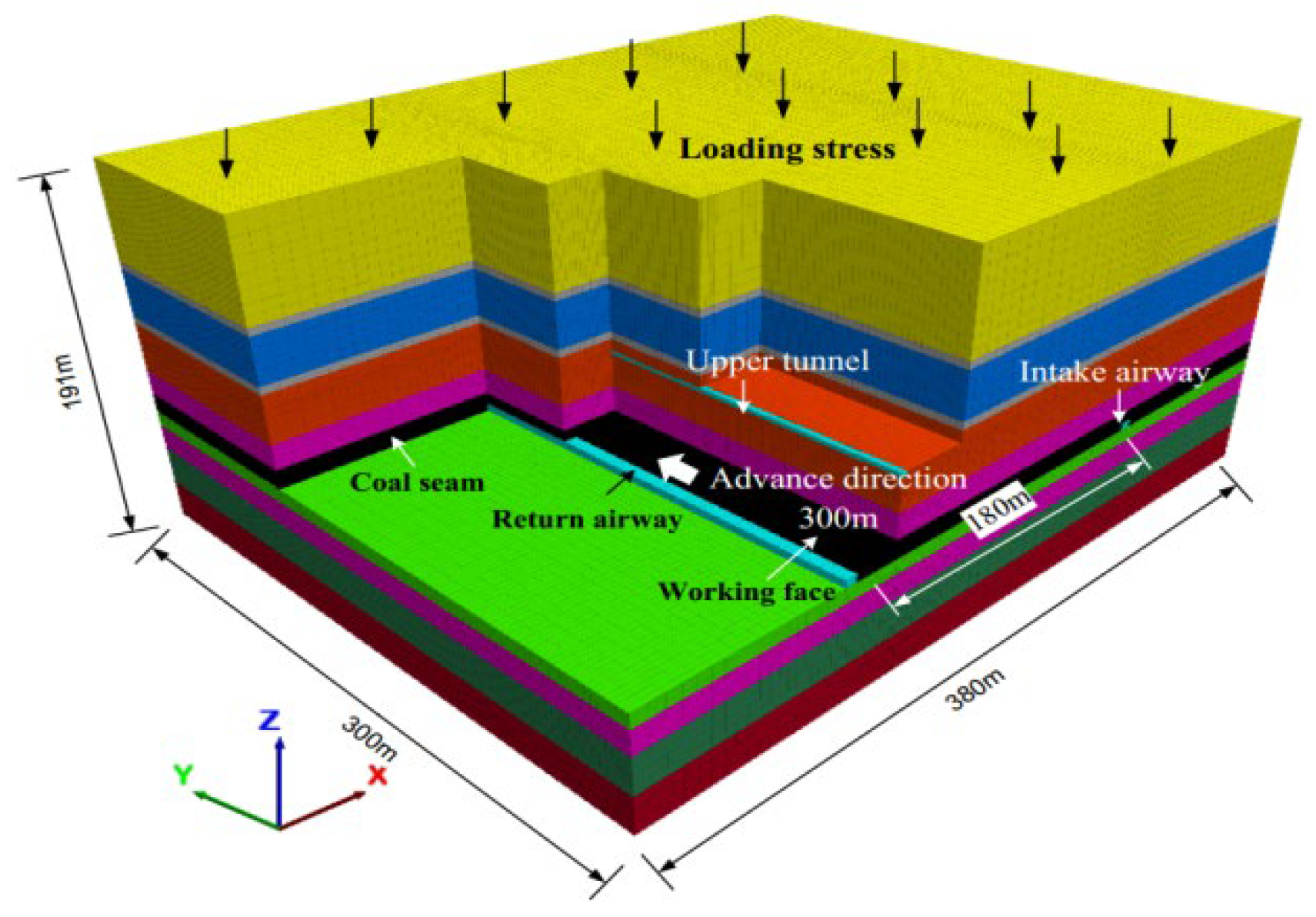

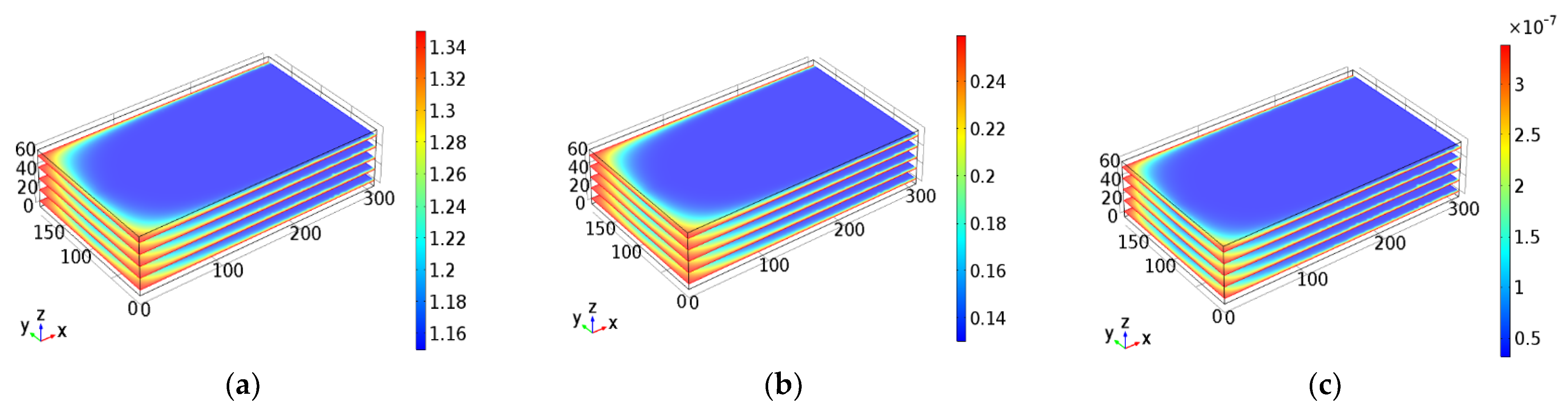

3.1.1. Model Settings

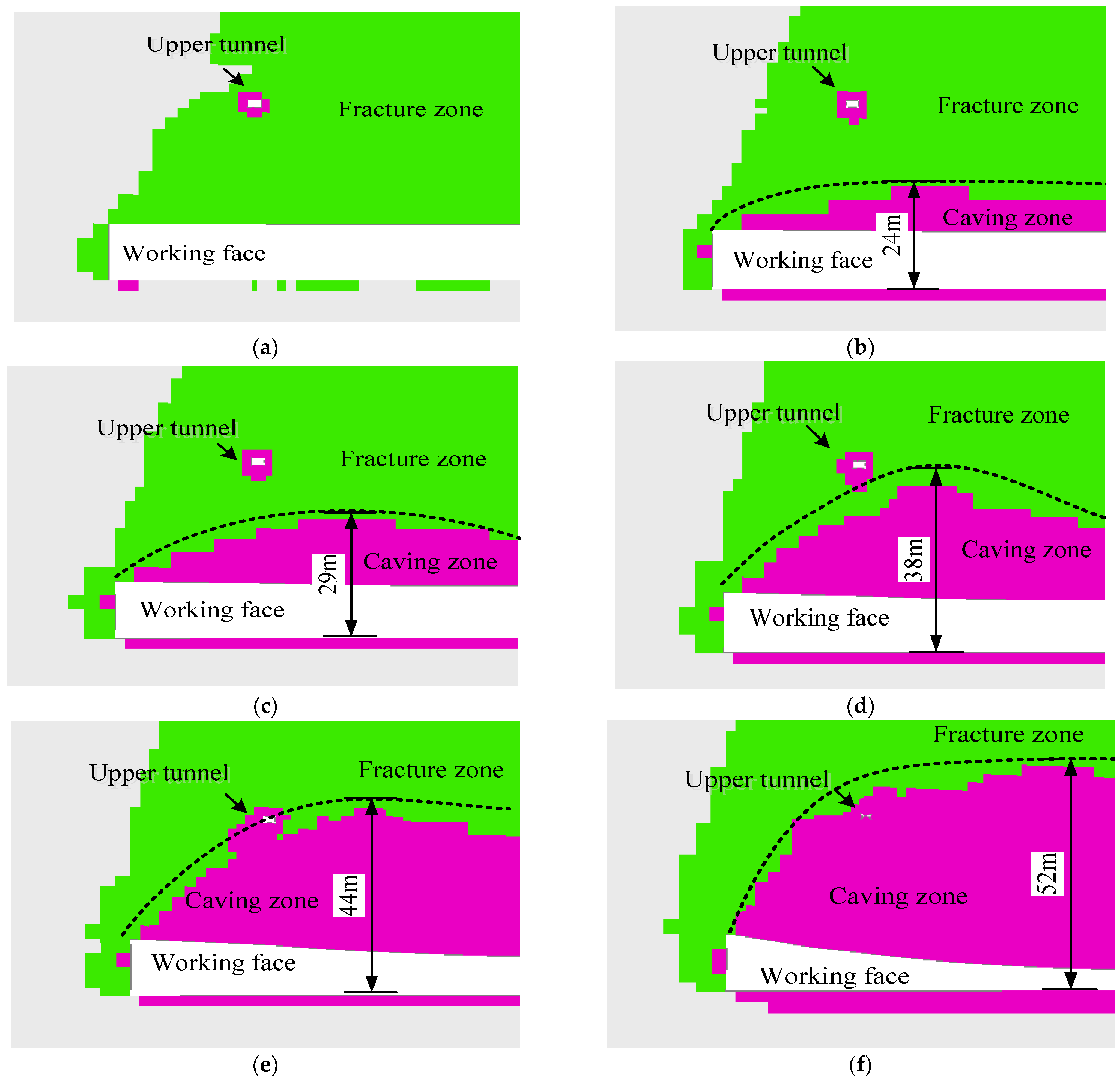

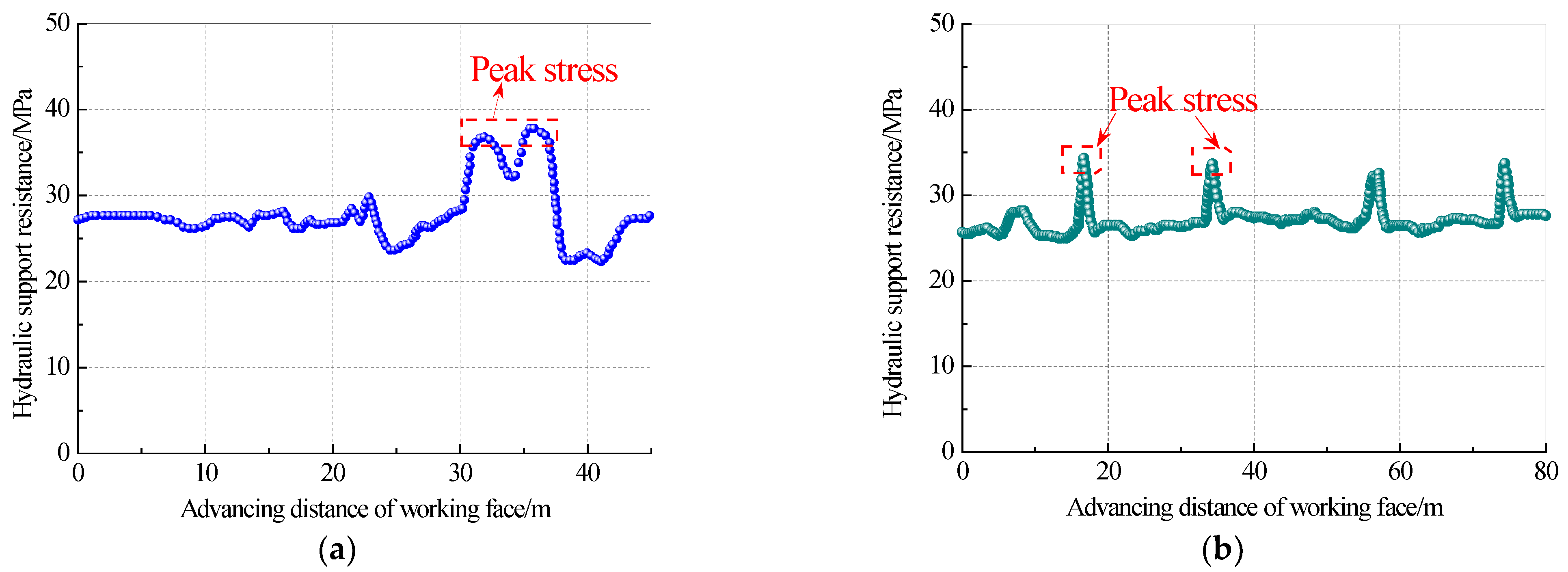

3.1.2. Breaking Process of Upper Tunnel

3.1.3. Effective Drainage Section of Upper Tunnel

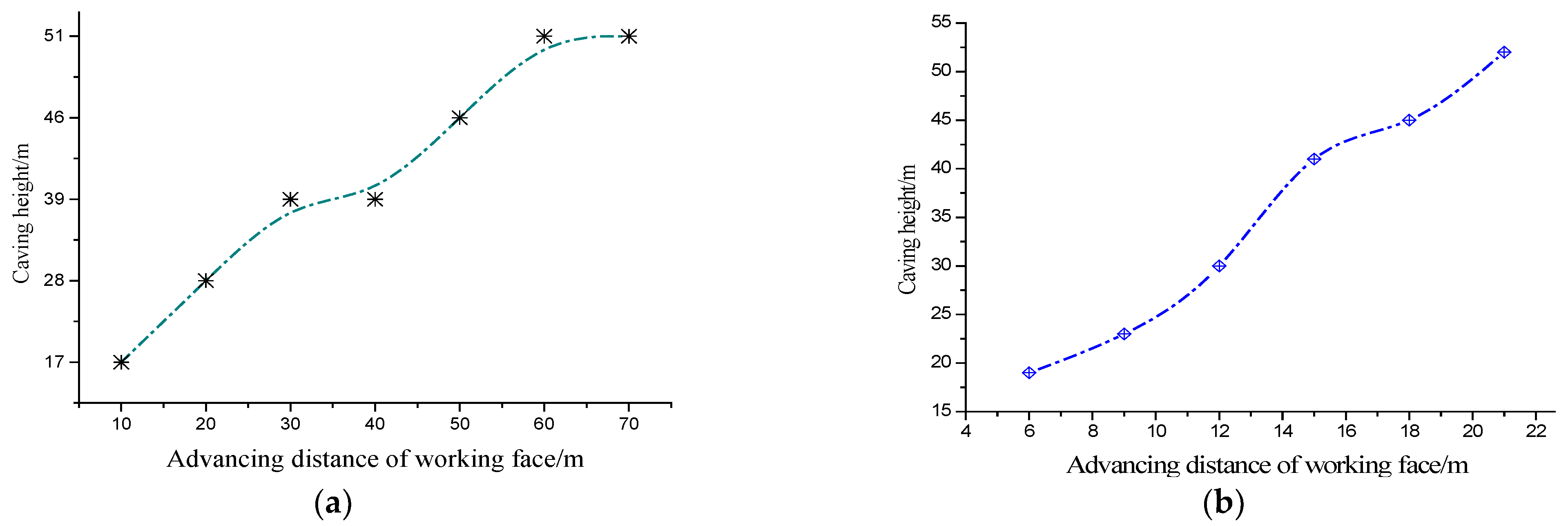

3.1.4. Model Test by Weighting Interval

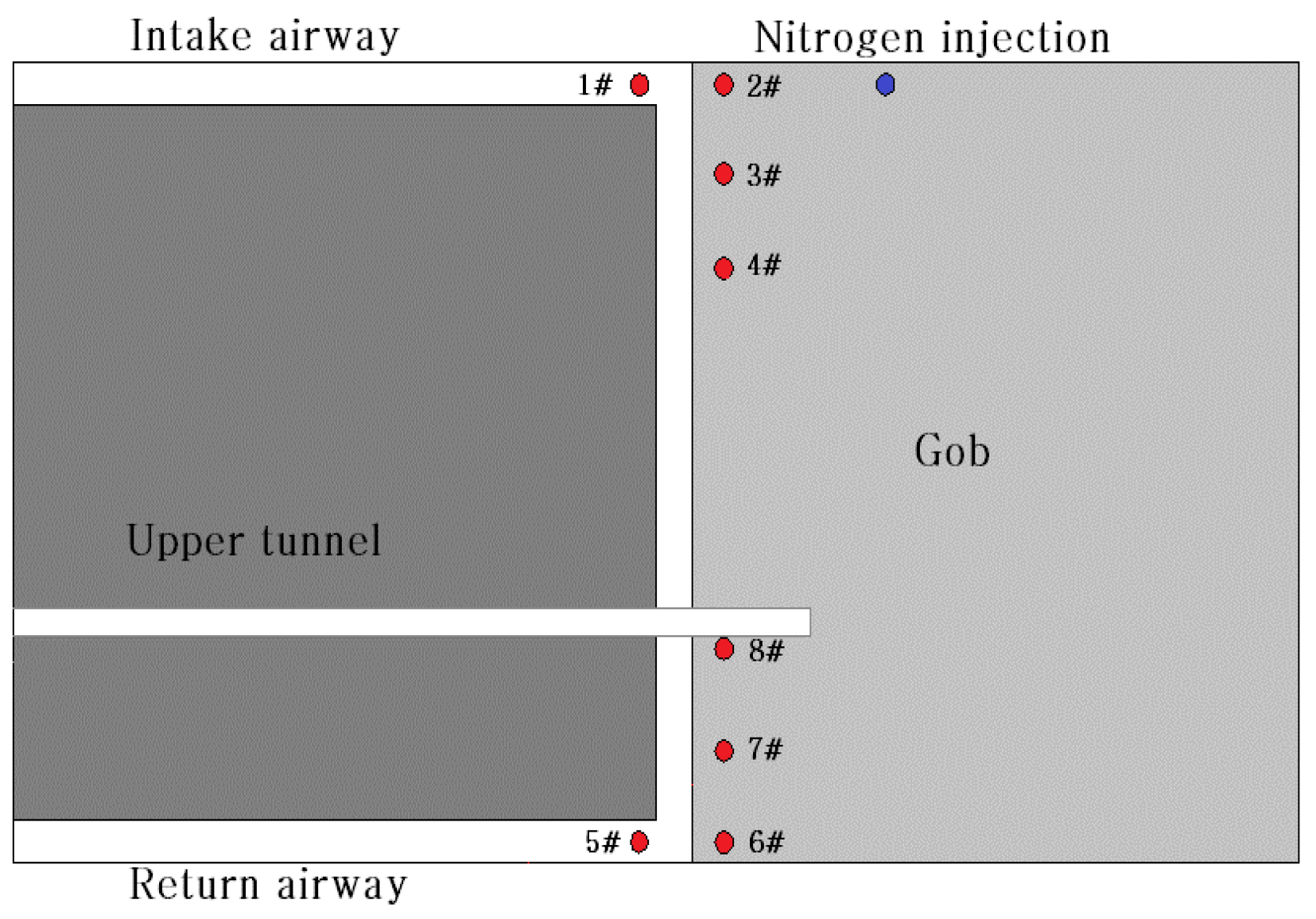

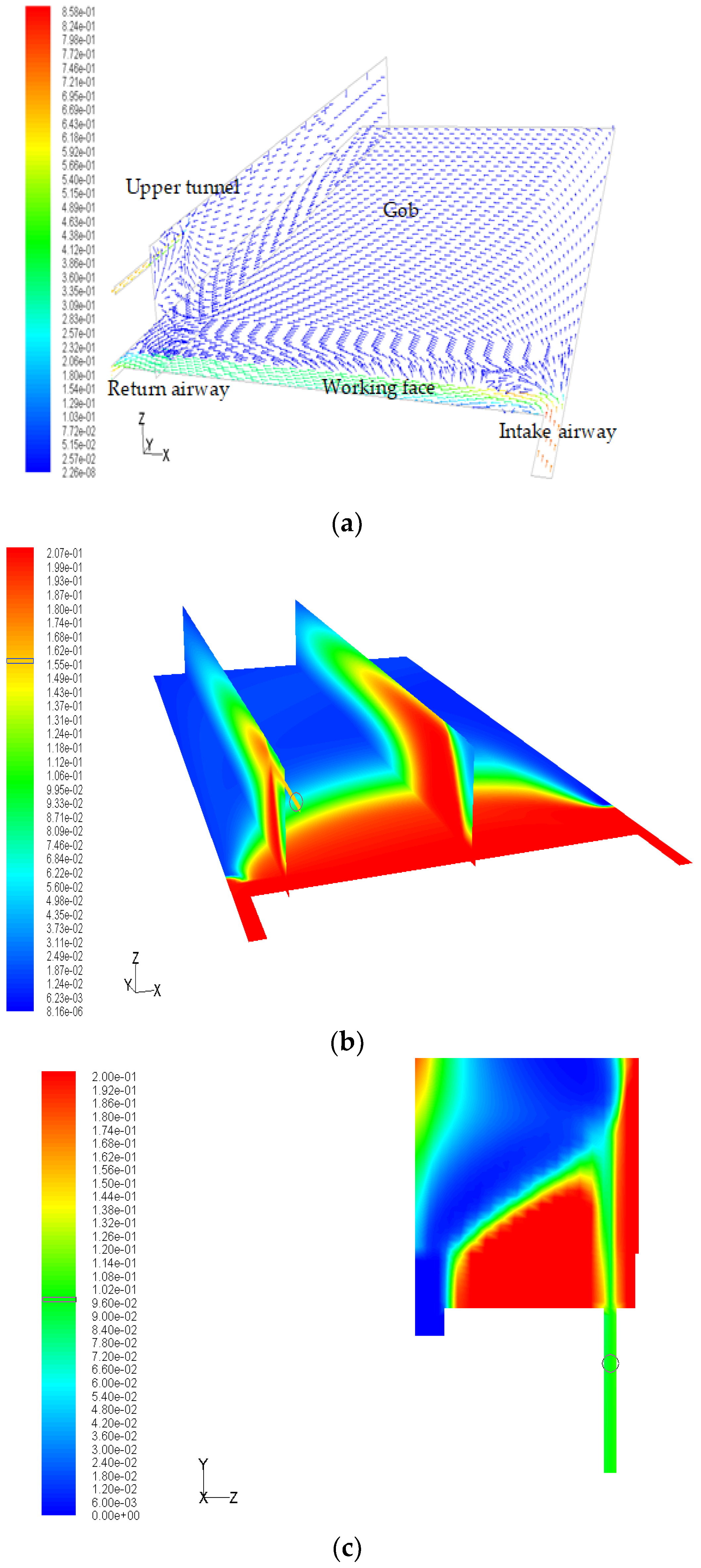

3.2. Flow Field of Air Leakage

3.2.1. Governing Equations

3.2.2. Boundary Conditions

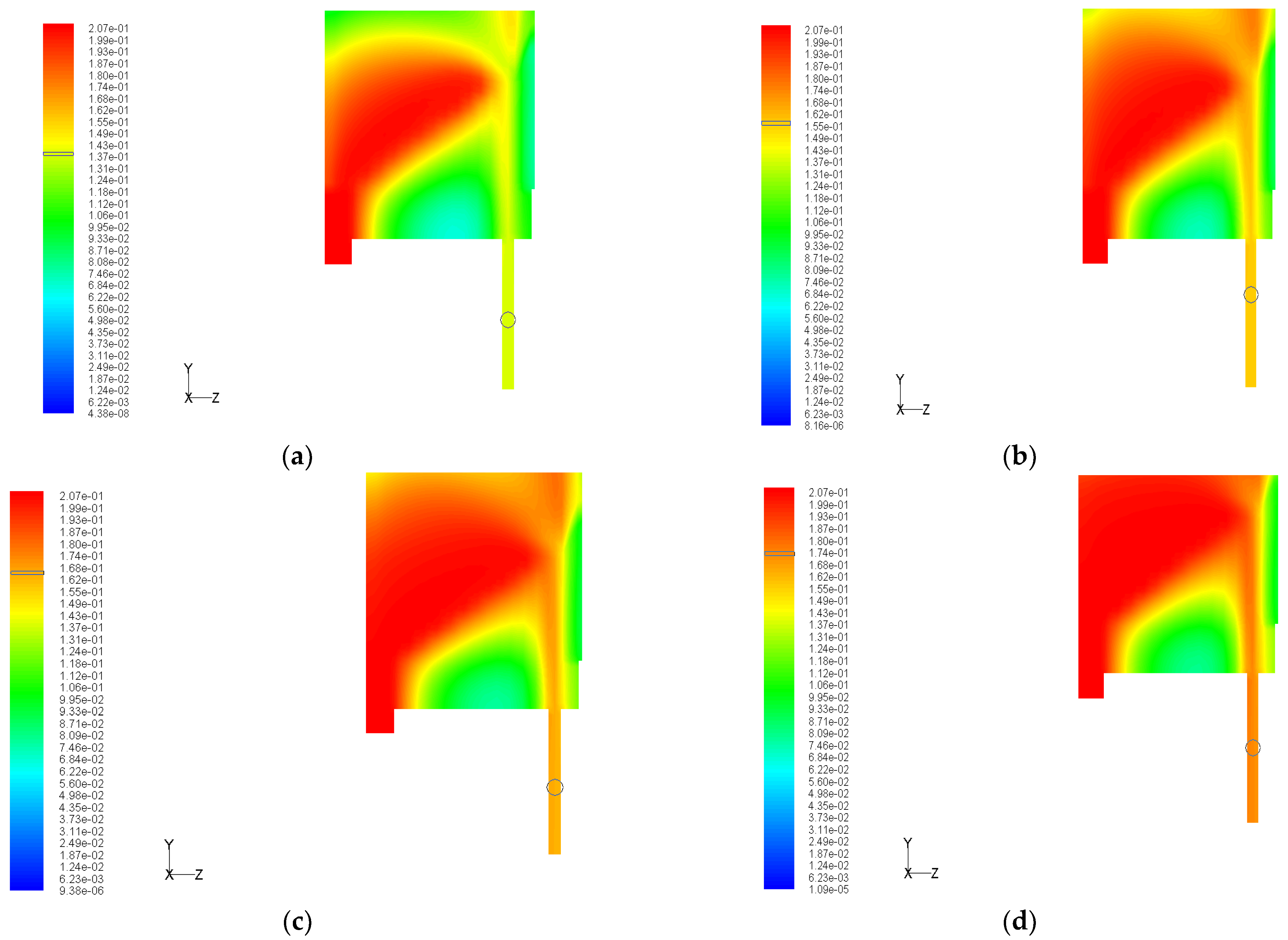

3.2.3. Flow Field Characteristics

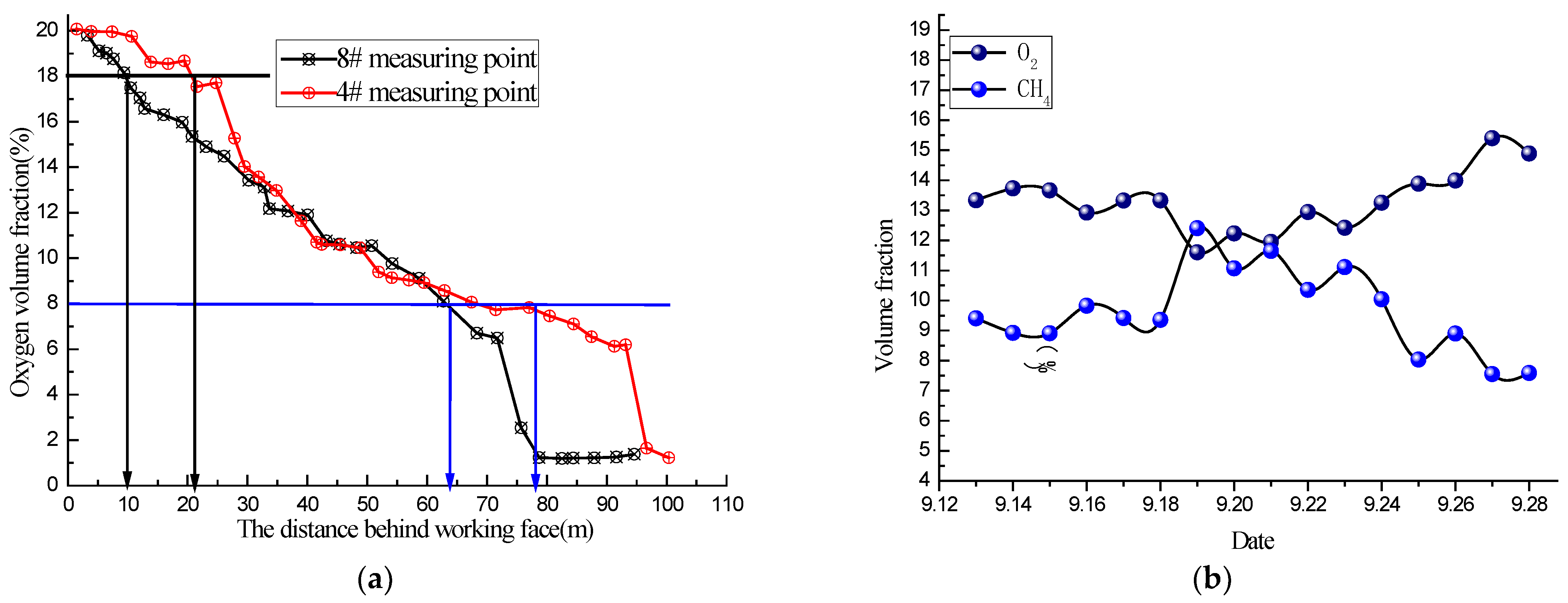

3.2.4. Verification of CFD Modelling

4. Determination of the Suitable Gas Drainage Volume

5. Conclusions

- (1)

- The breaking process and the location of the effective drainage section of the upper tunnel were determined. With the advance of the working face, the upper tunnel was finally located at the junction of the caving zone and fracture zone. The upper tunnel showed periodic deformation and breaking, and the developing fractures provided channels for air leakage. The location of the effective drainage section was 18 m behind the working face of the gob.

- (2)

- The characteristics of air leakage influenced by the upper tunnel were identified. The air leakage was segmented into two parts, high-position air leakage and low-position air leakage, which were stereoscopic distributions.

- (3)

- The influences of the gas extraction amount on gas emission and the distribution of the spontaneous combustion danger area in the goaf were clarified. Increasing the gas drainage volume led to an increase in the distribution of the spontaneous combustion danger area, which was adverse to the prevention of self-heating in coal. However, the gas concentration in the upper corner decreased with the increase in the extraction quantity. According to the simulation results, the actual gas extraction parameters of the mine were guided by comparing and analyzing the gas emission and spontaneous combustion of coal with different extraction quantities. The safe gas drainage volume was determined. This method effectively prevents spontaneous coal seam combustion in the goaf and gas accumulation in the upper corner; it lays the foundation for safe and efficient mine mining.

6. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Diamond, W.P.; Garcia, F. Prediction of Longwall Methane Emissions: An Evaluation of the Influence of Mining Practices on Gas Emissions and Methane Control Systems; Report of Investigations No.9649; National Institute for Occupational Safety and Health: Pittsburgh, PA, USA, 1999. [Google Scholar]

- Karacan, C.Ö.; Esterhuizen, G.S.; Schatzel, S.J.; Diamond, W.P. Reservoir simulation based modelling for characterizing longwall methane emissions and gob gas venthole production. Int. J. Coal Geol. 2007, 71, 225–245. [Google Scholar] [CrossRef]

- Qin, Z.Y.; Yuan, L.; Guo, H.; Qu, Q.D. Investigation of longwall gob gas flows and borehole drainage performance by CFD simulation. Int. J. Coal Geol. 2015, 150–151, 51–63. [Google Scholar] [CrossRef]

- Zhou, F.B.; Xia, T.Q.; Wang, X.X.; Zhang, Y.F.; Sun, Y.N.; Liu, J.S. Recent developments in coal mine methane drainage and utilization in China: A review. J. Nat. Gas Sci. Eng. 2016, 31, 437–458. [Google Scholar] [CrossRef]

- Chu, T.X.; Jiang, D.Y.; Yu, M.G.; Chen, Y.X. Study on mechanism of inducing coal spontaneous combustion and safe gas drainage volume under roof tunnel gas drainage. J. China Coal Soc. 2016, 41, 1701–1710. (In Chinese) [Google Scholar] [CrossRef]

- Xie, S.R.; Zhao, Y.J.; Zhang, S.B.; Yang, H.Z.; Xiao, D.C.; Tian, C.Y. Mechanism and experiment of substituting high drainage roadway with directional long drilling group to extract pressure-relief gas. J. Cent. South Univ. 2012, 19, 2591–2597. [Google Scholar] [CrossRef]

- Chu, T.X. Research on the coupling effects between stereo gas drainage and coal spontaneous combustion. In Proceedings of the 1st International Symposium on Mine Safety Science and Engineering (ISMSSE), Beijing, China, 21–23 September 2011; pp. 218–227. [Google Scholar] [CrossRef] [Green Version]

- Chu, T.X.; Li, P.; Chen, Y.X. Risk assessment of gas control and spontaneous combustion of coal under gas drainage of an upper tunnel. Int. J. Min. Sci. Technol. 2019, 29, 491–498. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, Y.P.; Li, F.R.; Wang, H.F.; Liu, H.B. Fracture evolution and pressure relief gas drainage from distant protected coal seams under an extremely thick key stratum. J. China Univ. Min. Technol. 2008, 18, 182–186. (In Chinese) [Google Scholar] [CrossRef]

- Liu, H.Y.; Cheng, Y.P.; Zhou, H.X.; Wang, H.F.; Chen, H.D. Fissure evolution and evaluation of pressure-relief gas drainage in the exploitation of super-remote protected seams. Min. Sci. Technol. 2010, 20, 178–182. [Google Scholar] [CrossRef]

- Guo, H.; Adhikary, D.P.; Craig, M.S. Simulation of mine water inflow and gas emission during longwall mining. Rock Mech. Rock Eng. 2009, 42, 25–51. [Google Scholar] [CrossRef]

- Li, S.G.; Xiao, P.; Pan, H.Y.; Lin, H.F.; Cheng, L.H. Experimental investigation on the seepage law of pressure-relieved gas under the influence of mining. Saf. Sci. 2012, 50, 614–617. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, S.G.; Wang, L.Y.; Wu, Z.Y. Bulking factor of the strata overlying the gob and a three-dimensional numerical simulation of the air leakage flow field. Min. Sci. Technol. 2011, 21, 261–266. [Google Scholar] [CrossRef]

- Wu, J.J.; Liu, X.C. Risk assessment of underground coal fire development at regional scale. Int. J. Coal Geol. 2011, 86, 87–94. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Yang, S.Q.; Qin, Y.; Hu, X.C.; Cheng, J.W. Experimental study on the gob flow field of the ‘‘U+I” type ventilation system for a comprehensive mechanized mining face. Min. Sci. Technol. 2015, 74, 603–622. [Google Scholar] [CrossRef]

- Zhang, C.; Jiao, D.; Zhang, M.; Huang, G. Study on multipoint and zoning coordinated prevention of gas and coal spontaneous combustion in highly gassy and spontaneous combustion-prone coal seam. ACS Omega 2022, 7, 17305–17329. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Yuan, L.; Shen, B.; Qu, Q.D.; Xue, J. Mining-induced strata stress changes, fractures and gas flow dynamics in multi-seam longwall mining. Int. J. Rock Mech. Min. Sci. 2012, 54, 129–139. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, P.; Zhang, Y.; Tu, S.; Wang, J.; Hao, Z. Distribution characteristic and migration mechanism of toxic gases in goafs during close-distance coal seam mining: A case study of shaping coal mine. ACS Omega 2022, 7, 7403–7413. [Google Scholar] [CrossRef]

- Guo, H.; Todhunter, C.; Qu, Q.; Qin, Z.Y. Longwall horizontal gas drainage through goaf pressure control. Int. J. Coal Geol. 2015, 150–151, 276–286. [Google Scholar] [CrossRef]

- Qin, C.; Huang, Q.; Wang, S.; Li, J.; Ju, S.; Wang, G. Prevention and control of spontaneous combustion of residual coals in acid-soaked goaf in gas drainage condition. Adv. Civ. Eng. 2022, 1668952. [Google Scholar] [CrossRef]

- Chen, L.; Qi, X.; Li, Y.; Xin, H.; Liang, Z. Coupling relation between the location of cross-cut negative pressure and injecting nitrogen into coal mine goaf. ACS Omega 2021, 6, 8189–8198. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.H.; Wu, S.Y.; Wang, Y.W. Research and application of drainage parameters for gas accumulation zone in overlying strata of gob area. Saf. Sci. 2012, 50, 778–782. [Google Scholar] [CrossRef]

- Hu, X.; Yang, S.; Zhou, X.; Yu, Z.; Hu, C. Coal spontaneous combustion prediction in gob using chaos analysis on gas indicators from upper tunnel. J. Nat. Gas Sci. Eng. 2015, 26, 461–469. [Google Scholar] [CrossRef]

- Tang, M.; Jiang, B.Y.; Zhang, R.Q.; Yin, Z.Q.; Dai, G.L. Numerical analysis on the influence of gas drainage on air leakage in the gob. J. Nat. Gas Sci. Eng. 2016, 33, 278–286. [Google Scholar] [CrossRef]

- Schatzel, S.J.; Karacan, C.Ö.; Dougherty, H.; Goodman, G.V. An analysis of reservoir conditions and responses in longwall panel overburden during mining and its effect on gob gas well performance. Eng. Geol. 2012, 127, 65–74. [Google Scholar] [CrossRef]

- Macdonald, M.J.; Chu, C.F.; Guilloit, P.P. A generalized Blake-Kozeny equation for multisized spherical particles. AlChE J. 1991, 37, 1583–1588. [Google Scholar] [CrossRef]

- Luo, H.; Quintard, M.; Debenest, G.; Laouafa, F. Properties of a diffuse interface model based on a porous medium theory for solid-liquid dissolution problems. Comput. Geosci. 2012, 16, 913–932. [Google Scholar] [CrossRef]

- Byon, C.; Kim, S.J. The effect of the particle size distribution and packing structure on the permeability of sintered porous wicks. Int. J. Heat Mass Transf. 2013, 61, 499–504. [Google Scholar] [CrossRef]

- Xia, T.Q.; Zhou, F.B.; Wang, X.X.; Zhang, Y.F.; Li, Y.M.; Kang, J.H.; Liu, J.S. Controlling factors of symbiotic disaster between coal gas and spontaneous combustion in longwall mining gobs. Fuel 2016, 182, 886–96. [Google Scholar] [CrossRef]

- Guo, G.L.; Miu, X.X.; Zhang, Z.N. Study of old goaf rupture rock deformation properties. Sci. Technol. Eng. 2002, 2, 44–47. (In Chinese) [Google Scholar] [CrossRef]

| Strata | Thickness/m | Density/kg/m3 | Bulk Modulus/GPa | Shear Modulus/GPa | Internal Friction Angle/(°) | Cohesion/MPa | Tensile Strength/MPa |

|---|---|---|---|---|---|---|---|

| Sandy mudstone | 47.51 | 2350 | 6.304 | 3.425 | 32 | 4.2 | 0.50 |

| Muddy intercalations | 3.54 | 1850 | 5.093 | 2.083 | 26 | 3.0 | 0.28 |

| Mudstone | 24.20 | 1950 | 5.519 | 2.519 | 28 | 3.5 | 0.35 |

| Muddy intercalations | 4.12 | 1850 | 5.093 | 2.083 | 26 | 3.0 | 0.28 |

| Fine grain sandstone | 25.32 | 2600 | 7.963 | 5.244 | 36 | 5.5 | 1.00 |

| Sandy mudstone | 14.50 | 2350 | 6.304 | 3.425 | 32 | 4.2 | 0.50 |

| Coal | 15.62 | 1700 | 4.529 | 1.742 | 25 | 2.5 | 0.20 |

| Mudstone | 5.75 | 1950 | 5.519 | 2.519 | 28 | 3.5 | 0.35 |

| Sandy mudstone | 10.57 | 2350 | 6.304 | 3.425 | 32 | 4.2 | 0.50 |

| Medium grain sandstone | 21.25 | 2700 | 9.226 | 6.352 | 39 | 7.6 | 1.20 |

| Siltstone | 18.62 | 2500 | 7.021 | 4.256 | 34 | 4.9 | 0.80 |

| Type | Intake Airway (a) | Return Airway (c) | Upper Tunnel (b) | |

|---|---|---|---|---|

| Boundary Condition | Velocity-inlet | Out-flow | Out-flow | |

| 1.64 m/s | Default | 0.75 m/s | ||

| Source item | Gob gas emission | Nitrogen injection | ||

| 23.5 m3/min | 50 m3/min | |||

| Interior wall | Working face  gob, gob

gob, gob  upper tunnel upper tunnel | |||

| Evaluation | Meets the Gas Emission Control? | Exceeds the Max Acceptable Oxidation Zone Width? | Suitable or Not? | |

|---|---|---|---|---|

| Drainage Volume | ||||

| 120 m3/min | NO | YES | NO | |

| 180 m3/min | YES | YES | YES | |

| 240 m3/min | NO | NO | NO | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Chu, T.; Liu, S.; Ni, X. Study of the Air Leakage Mechanism and the Suitable Gas Drainage Volume with the Upper Tunnel. Sustainability 2022, 14, 8614. https://doi.org/10.3390/su14148614

Zhang C, Chu T, Liu S, Ni X. Study of the Air Leakage Mechanism and the Suitable Gas Drainage Volume with the Upper Tunnel. Sustainability. 2022; 14(14):8614. https://doi.org/10.3390/su14148614

Chicago/Turabian StyleZhang, Chao, Tingxiang Chu, Shanjun Liu, and Xin Ni. 2022. "Study of the Air Leakage Mechanism and the Suitable Gas Drainage Volume with the Upper Tunnel" Sustainability 14, no. 14: 8614. https://doi.org/10.3390/su14148614

APA StyleZhang, C., Chu, T., Liu, S., & Ni, X. (2022). Study of the Air Leakage Mechanism and the Suitable Gas Drainage Volume with the Upper Tunnel. Sustainability, 14(14), 8614. https://doi.org/10.3390/su14148614