Quality-Based Supplier Selection Model for Products with Multiple Quality Characteristics

Abstract

:1. Introduction

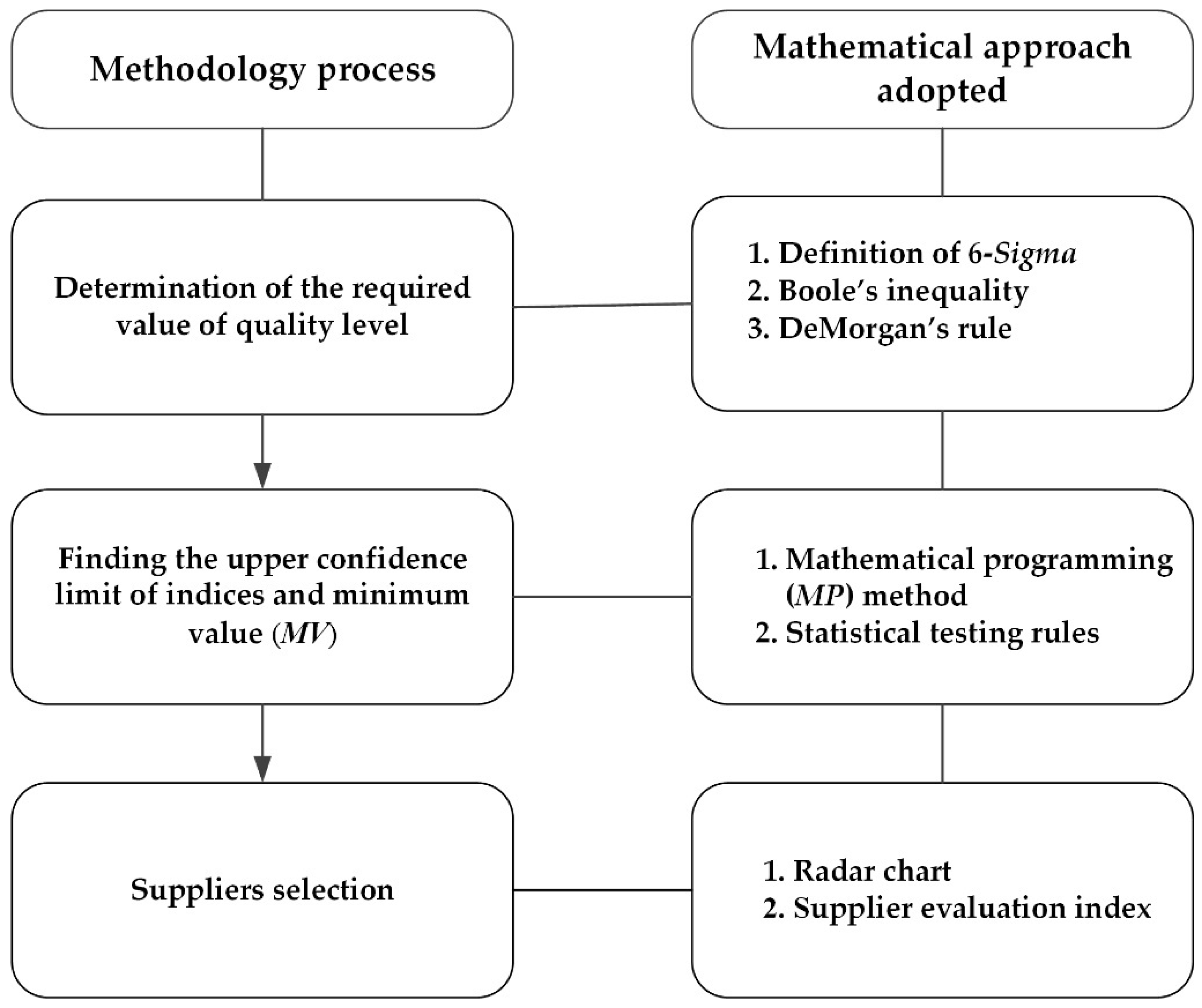

2. Research Methodology

2.1. Determination of the Required Value of Quality Level for Quality Characteristic h

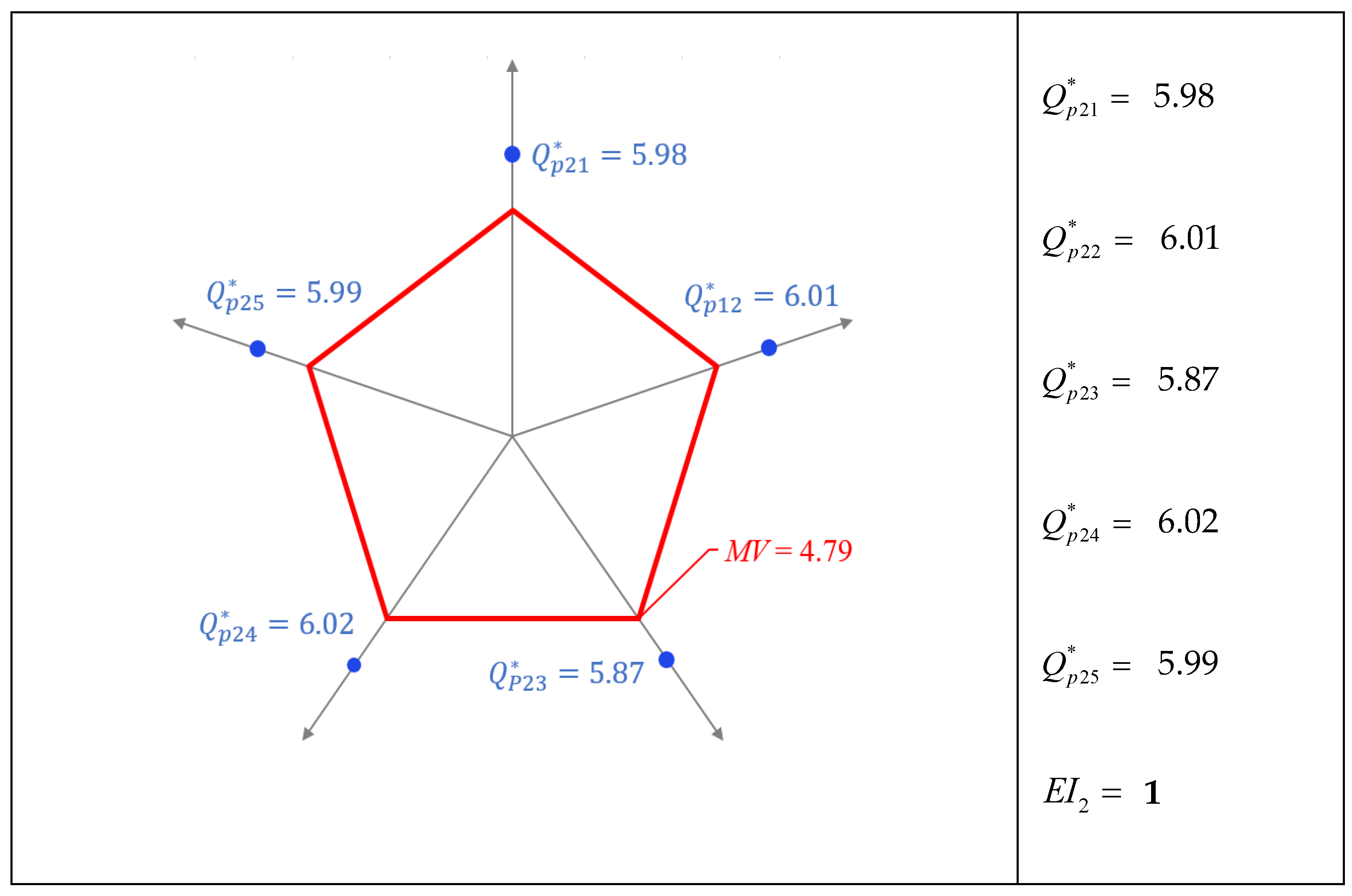

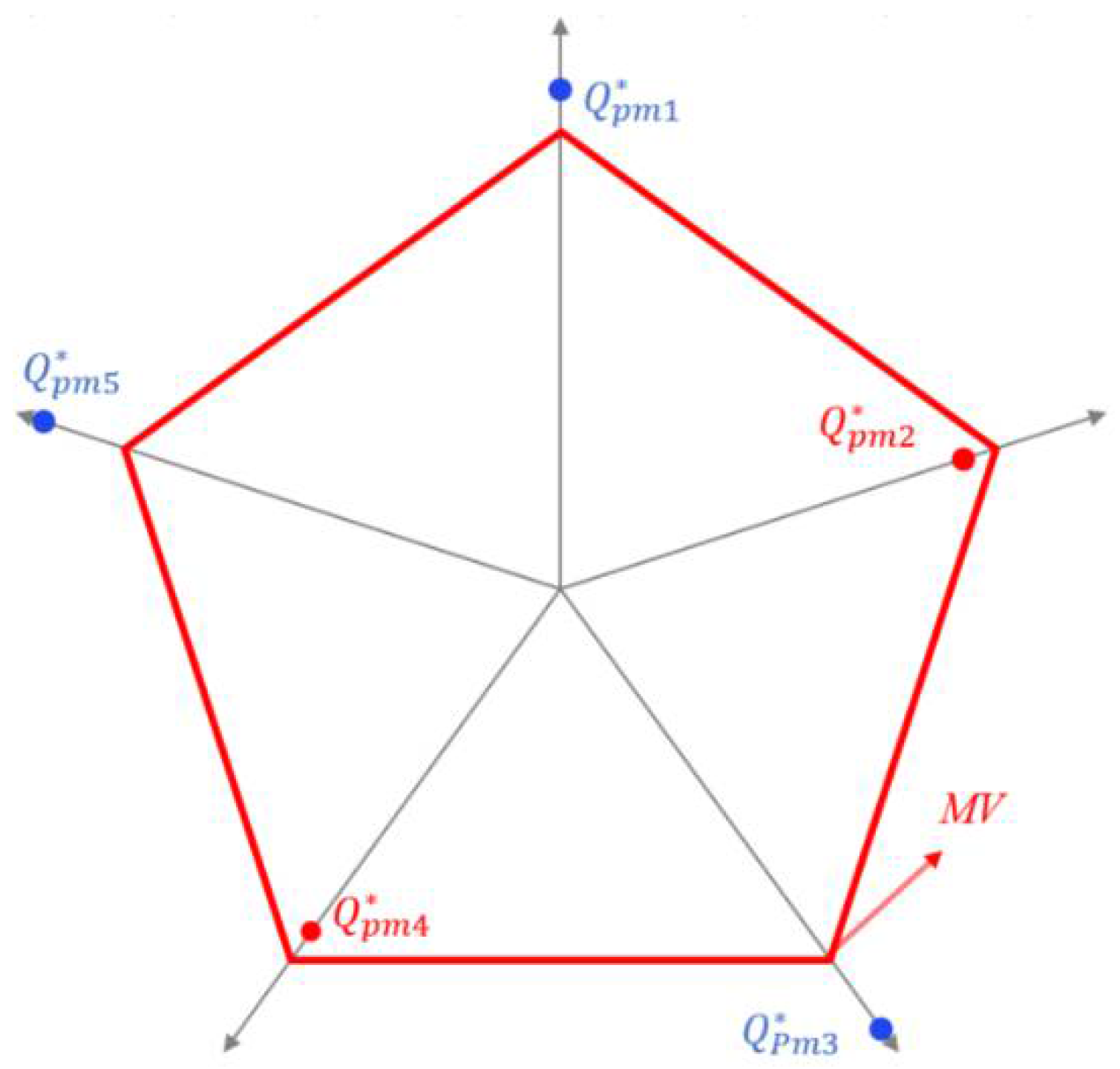

2.2. Establishing Supplier Selection Rules, Based on MV and the Radar Quality Evaluation Chart

- (1)

- Case 1:

- (2)

- Case 2: 0 ∈

- (3)

- Case 3:

- (1)

- If , then do not reject and conclude that .

- (2)

- If , then reject and conclude that .

3. An Application Example

4. Results

5. Discussion

- (1)

- (2)

- The quality evaluation radar chart offers a quality evaluation method for products with multiple quality characteristics and a selection tool for suppliers. It allows machine-tool manufacturers and suppliers to evaluate the standard of all quality characteristics at the same time and make process improvements in quality characteristics with poor quality levels [39,40].

- (3)

- When directly comparing the estimated value of the index with the minimum value, is employed to determine whether the quality level meets the requirements, which is more in line with its practical use [35].

6. Conclusions and Limitations

- (1)

- The radar quality evaluation chart assessing a supplier’s product with multiple quality characteristics was used to evaluate the standard for each quality characteristic of the supplier’s product. At a glance, we can see whether each index observation value falls into the radar chart control block and, thence, we can determine whether to carry out improvements.

- (2)

- The basis of this evaluation is to perform statistical testing using the upper confidence limit of the index, which can control the risk of rejecting otherwise excellent suppliers (producers).

- (3)

- It is possible to directly judge whether the quality for each quality characteristic has reached the required standard by comparing the point estimate of the index with , so that the opportunity for improvement can be grasped.

- (4)

- The value of was derived from the upper confidence limit and the required value of the index, which can lower the risk of misjudgments resulting from sampling error.

- (5)

- According to the evaluation results of the radar quality evaluation charts of suppliers’ products that display multiple quality characteristics, supplier evaluation indicators and selection rules were set that can help the cooperating suppliers to improve their product quality and form partnerships to ensure the quality of the final product, the machine tools.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S.D. Smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef] [Green Version]

- Huang, C.T.; Lai, K.K. Process Quality Evaluation Model with Taguchi Cost Loss Index. Appl. Sci. 2021, 11, 10182. [Google Scholar] [CrossRef]

- Chen, K.S.; Chen, H.T.; Chang, T.C. The construction and application of Six Sigma quality indices. Int. J. Prod. Res. 2017, 55, 2365–2384. [Google Scholar] [CrossRef]

- Lin, K.P.; Yu, C.M.; Chen, K.S. Production data analysis system using novel process capability indices-based circular economy. Ind. Manag. Data Syst. 2019, 119, 1655–1668. [Google Scholar] [CrossRef]

- Chen, K.S.; Yang, S.L.; Chen, H.T. Process improvement capability index with cost—A modeling method of mathematical programming. Appl. Math. Model. 2015, 39, 1577–1586. [Google Scholar] [CrossRef]

- Lei, D.; Hitt, M.A. Strategic restructuring and outsourcing: The effect of mergers and acquisitions and LBOs on building firm skills and capabilities. J. Manag. Stud. 1995, 21, 835–859. [Google Scholar] [CrossRef]

- Pearn, W.L.; Liao, M.Y.; Wu, C.W.; Chu, Y.T. Two tests for supplier selection based on process yield. J. Test. Eval. 2011, 39, 126–133. [Google Scholar] [CrossRef]

- Wu, C.W.; Liao, M.Y.; Yang, T.T. Efficient methods for comparing two process yields—Strategies on supplier selection. Int. J. Prod. Res. 2013, 51, 1587–1602. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, K.; Zeng, B.; Xu, H.; Yang, Y. Supplier selection in nuclear power industry with extended VIKOR method under linguistic information. Appl. Soft Comput. 2016, 48, 444–457. [Google Scholar] [CrossRef]

- Acerbi, F.; Sassanelli, C.; Terzi, S.; Taisch, M. A Systematic Literature Review on Data and Information Required for Circular Manufacturing Strategies Adoption. Sustainability 2021, 13, 2047. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2020, 58, 1662–1687. [Google Scholar] [CrossRef] [Green Version]

- Sassanelli, C.; Rosa, P.; Terzi, S. Supporting disassembly processes through simulation tools: A systematic literature review with a focus on printed circuit boards. J. Manuf. Syst. 2021, 60, 429–448. [Google Scholar] [CrossRef]

- Walzberg, J.; Lonca, G.; Hanes, R.J.; Eberle, A.L.; Carpenter, A.; Heath, G.A. Do We Need a New Sustainability Assessment Method for the Circular Economy? A Critical Literature Review. Front. Sustain. 2021, 1, 620047. [Google Scholar] [CrossRef]

- Sridhar, A.; Kapoor, A.; Senthil Kumar, P.; Ponnuchamy, M.; Balasubramanian, S.; Prabhakar, S. Conversion of food waste to energy: A focus on sustainability and life cycle assessment. Fuel 2021, 302, 121069. [Google Scholar] [CrossRef]

- Rajput, S.; Singh, S.P. Connecting circular economy and industry 4.0. Int. J. Inf. Manag. 2019, 49, 98–113. [Google Scholar] [CrossRef]

- Sassanelli, C.; Rossi, M.; Terzi, S. Evaluating the smart maturity of manufacturing companies along the product development process to set a PLM project roadmap. Int. J. Prod. Lifecycle Manag. 2020, 12, 185–209. [Google Scholar] [CrossRef]

- Sassanelli, C.; De Carolis, A.; Terzi, S. Initiating an industrial machinery producer to digital servitization: A case study. In Proceedings of the 18th IFIP WG 5.1 International Conference, PLM 2021, Curitiba, Brazil, 11–14 July 2021; IFIP Advances in Information and Communication Technology Virtual, Online. Springer: Cham, Switzerland, 2021; pp. 483–493. [Google Scholar] [CrossRef]

- Sassanelli, C.; De Carolis, A.; Terzi, S. Integrating Failure Mode, Effect and Criticality Analysis in the Overall Equipment Effectiveness Framework to Set a Digital Servitized Machinery: An Application Case. In Proceedings of the IFIP WG 5.7 International Conference, APMS 2021, Nantes, France, 5–9 September 2021; IFIP International Federation for Information Processing. Dolgui, A., Ed.; Springer: Cham, Switzerland, 2021; pp. 143–152. [Google Scholar] [CrossRef]

- Appolloni, A.; Chiappetta Jabbour, C.J.; D’Adamo, I.; Gastaldi, M.; Settembre-Blundo, D. Green recovery in the mature manufacturing industry: The role of the green-circular premium and sustainability certification in innovative efforts. Ecol. Econ. 2022, 193, 107311. [Google Scholar] [CrossRef]

- Chiappetta Jabbour, C.J.; Fiorini, P.D.C.; Ndubisi, N.O.; Queiroz, M.M.; Piato, É.L. Digitallyenabled sustainable supply chains in the 21st century: A review and a research agenda. Sci. Total Environ. 2020, 725, 138177. [Google Scholar] [CrossRef]

- Sharma, R.; Jabbour, C.J.C.; Lopes de Sousa Jabbour, A.B. Sustainable manufacturing and industry 4.0: What we know and what we don’t. J. Enterp. Inf. Manag. 2020, 34, 230–266. [Google Scholar] [CrossRef]

- Chang, T.C.; Chen, K.S.; Yu, C.M. Process quality assessment model of hand tools: A case study on the handle of ratchet torque wrench. Int. J. Reliab. Qual. Saf. Eng. 2016, 23, 1650017. [Google Scholar] [CrossRef]

- Yu, K.T.; Chen, K.S. Testing and analysing capability performance for products with multiple characteristics. Int. J. Prod. Res. 2016, 54, 6633–6643. [Google Scholar] [CrossRef]

- Chen, K.S.; Wang, C.H.; Tan, K.H. Developing a fuzzy green supplier selection model using Six Sigma quality indices. Int. J. Prod. Econ. 2019, 212, 1–7. [Google Scholar] [CrossRef]

- Chen, K.S.; Wang, C.H.; Tan, K.H.; Chiu, S.F. Developing one-sided specification Six-Sigma fuzzy quality index and testing model to measure the process performance of fuzzy information. Int. J. Prod. Econ. 2019, 208, 560–565. [Google Scholar] [CrossRef]

- Chiou, K.C.; Chen, K.S. Lifetime performance evaluation model based on quick response thinking. Eksploat. Niezawodn.-Maint. Reliab. 2022, 24, 1–6. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Duong, Q.D.; Mia, M. Multi-response optimization of the actively driven rotary turning for energy efficiency, carbon emissions, and machining quality. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 2155–2173. [Google Scholar] [CrossRef]

- Chen, K.S.; Yu, C.M. Dual dimensional fuzzy testing based on the upper confidence limits for supplier selection. J. Intell. Fuzzy Syst. 2021, 40, 11145–11158. [Google Scholar] [CrossRef]

- Chen, K.S.; Yu, C.M. Fuzzy decision-making model for process quality improvement of machine tool industry chain. J. Intell. Fuzzy Syst. 2022, 42, 1547–1558. [Google Scholar] [CrossRef]

- Wu, M.F.; Chen, H.Y.; Chang, T.C.; Wu, C.F. Quality evaluation of internal cylindrical grinding process with multiple quality characteristics for gear products. Int. J. Prod. Res. 2019, 57, 6687–6701. [Google Scholar] [CrossRef]

- Lin, C.J.; Pearn, W.L.; Huang, J.Y.; Chen, Y.H. Group selection for processes with multiple quality characteristics. Commun. Stat. Theory Methods 2018, 47, 3923–3934. [Google Scholar] [CrossRef]

- Weber, C.A.; Current, J.R.; Benton, W.C. Vendor selection criteria and methods. Eur. J. Oper. Res. 1991, 50, 2–18. [Google Scholar] [CrossRef]

- Chen, J.P.; Chen, K.S. Comparing the capability of two process using Cpm. J. Qual. Technol. 2004, 36, 329–335. [Google Scholar] [CrossRef]

- Li, M.; Lin, L.Y.; Chen, K.S.; Hsu, T.H. Novel service efficiency evaluation and management model. Appl. Sci. 2021, 11, 9395. [Google Scholar] [CrossRef]

- Chang, T.C.; Chen, K.S. Testing process quality of wire bonding with multiple gold wires from viewpoint of producers. Int. J. Prod. Res. 2019, 57, 5400–5413. [Google Scholar] [CrossRef]

- Chen, K.S.; Chang, T.C.; Guo, Y.Y. Selecting an optimal contractor for production outsourcing: A case study of gear grinding. J. Chin. Inst. Eng. 2020, 43, 415–424. [Google Scholar] [CrossRef]

- Yang, C.M.; Chen, K.S. Two-phase selection framework that considers production costs of suppliers and quality requirements of buyers. Int. J. Prod. Res. 2019, 57, 6351–6368. [Google Scholar] [CrossRef]

- Lo, W.; Yang, C.M.; Lai, K.K.; Li, S.Y.; Chen, C.H. Developing a novel fuzzy evaluation model by one-sided specification capability indices. Mathematics 2021, 9, 1076. [Google Scholar] [CrossRef]

- Yu, C.M.; Lai, K.K.; Chen, K.S.; Chang, T.C. Process-quality evaluation for wire bonding with multiple gold wires. IEEE Access 2020, 8, 106075–106082. [Google Scholar] [CrossRef]

- Bai, C.; Kusi-Sarpong, S.; Khan, S.A.; Vazquez-Brust, D. Sustainable buyer–supplier relationship capability development: A relational framework and visualization methodology. Ann. Oper. Res. 2021, 304, 1–34. [Google Scholar] [CrossRef]

- Wan, Y.; Cheng, K.; Liu, Z.; Ye, H. An investigation on machinability assessment of difficult-to-cut materials based on radar charts. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2013, 227, 1916–1920. [Google Scholar] [CrossRef]

- Zhang, H.; Hou, Y.; Zhang, J.; Qi, X.; Wang, F. A new method for nondestructive quality evaluation of the resistance spot welding based on the radar chart method and the decision tree classifier. Int. J. Adv. Manuf. Technol. 2015, 78, 841–851. [Google Scholar] [CrossRef]

- Chen, K.S.; Chen, K.L. Supplier selection by testing the process incapability index. Int. J. Prod. Res. 2006, 44, 589–600. [Google Scholar] [CrossRef]

- Gopalakrishnan, S.; Kumaran, M.S. Iiot framework based ml model to improve automobile industry product. Intell. Autom. Soft Comput. 2022, 31, 1435–1449. [Google Scholar] [CrossRef]

- Liu, J.; Ma, C.; Gui, H.; Wang, S. A four-terminal-architecture cloud-edge-based digital twin system for thermal error control of key machining equipment in production lines. Mech. Syst. Signal Process. 2022, 166, 108488. [Google Scholar] [CrossRef]

- Chen, K.S.; Huang, M.L.; Li, R.K. Process capability analysis for an entire product. Int. J. Prod. Res. 2001, 39, 4077–4087. [Google Scholar] [CrossRef]

- Pearn, W.L.; Cheng, Y.C. Measuring production yield for processes with multiple characteristics. Int. J. Prod. Res. 2010, 48, 4519–4536. [Google Scholar] [CrossRef]

- Wang, F.K. Quality evaluation of a manufactured product with multiple characteristics. Qual. Reliab. Eng. Int. 2006, 22, 225–236. [Google Scholar] [CrossRef]

- Chang, T.C.; Wang, K.J.; Chen, K.S. Sputtering process assessment of ITO film for multiple quality characteristics with one-sided and two-sided specifications. J. Test. Eval. 2014, 42, 196–203. [Google Scholar] [CrossRef]

- Yu, C.M.; Chen, K.S.; Lai, K.K.; Hsu, C.H. Fuzzy supplier selection method based on smaller-the-better quality characteristic. Appl. Sci. 2020, 10, 3635. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, K.-S.; Huang, M.-C.; Yu, C.-M.; Chen, H.-Y. Quality-Based Supplier Selection Model for Products with Multiple Quality Characteristics. Sustainability 2022, 14, 8532. https://doi.org/10.3390/su14148532

Chen K-S, Huang M-C, Yu C-M, Chen H-Y. Quality-Based Supplier Selection Model for Products with Multiple Quality Characteristics. Sustainability. 2022; 14(14):8532. https://doi.org/10.3390/su14148532

Chicago/Turabian StyleChen, Kuen-Suan, Ming-Chieh Huang, Chun-Min Yu, and Hsuan-Yu Chen. 2022. "Quality-Based Supplier Selection Model for Products with Multiple Quality Characteristics" Sustainability 14, no. 14: 8532. https://doi.org/10.3390/su14148532

APA StyleChen, K.-S., Huang, M.-C., Yu, C.-M., & Chen, H.-Y. (2022). Quality-Based Supplier Selection Model for Products with Multiple Quality Characteristics. Sustainability, 14(14), 8532. https://doi.org/10.3390/su14148532