Mechanical Properties, Durability and Leaching Toxicity of Cement-Stabilized Macadam Incorporating Reclaimed Clay Bricks as Fine Aggregate

Abstract

:1. Introduction

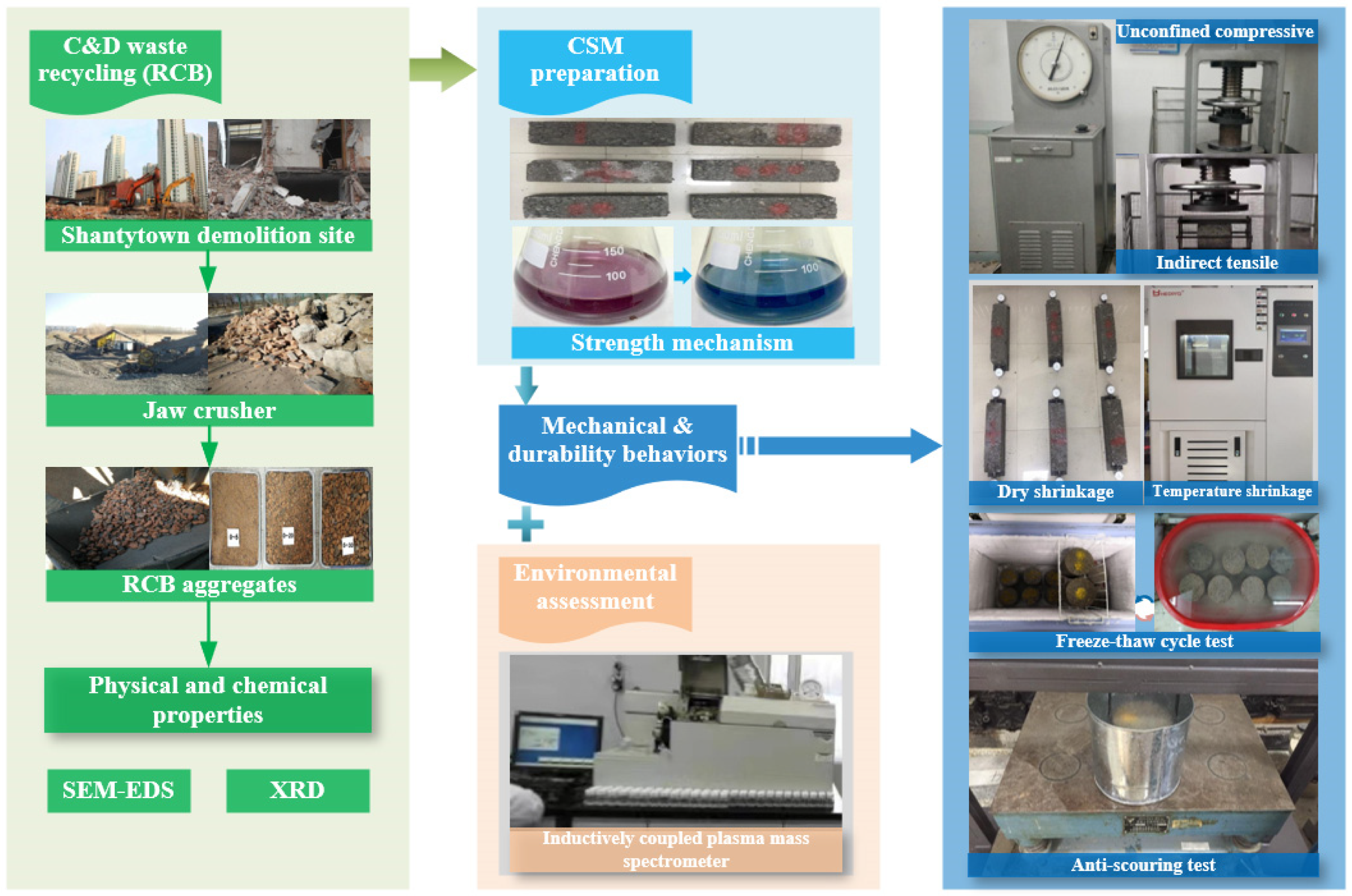

2. Goal and Scope

3. Experimental Program

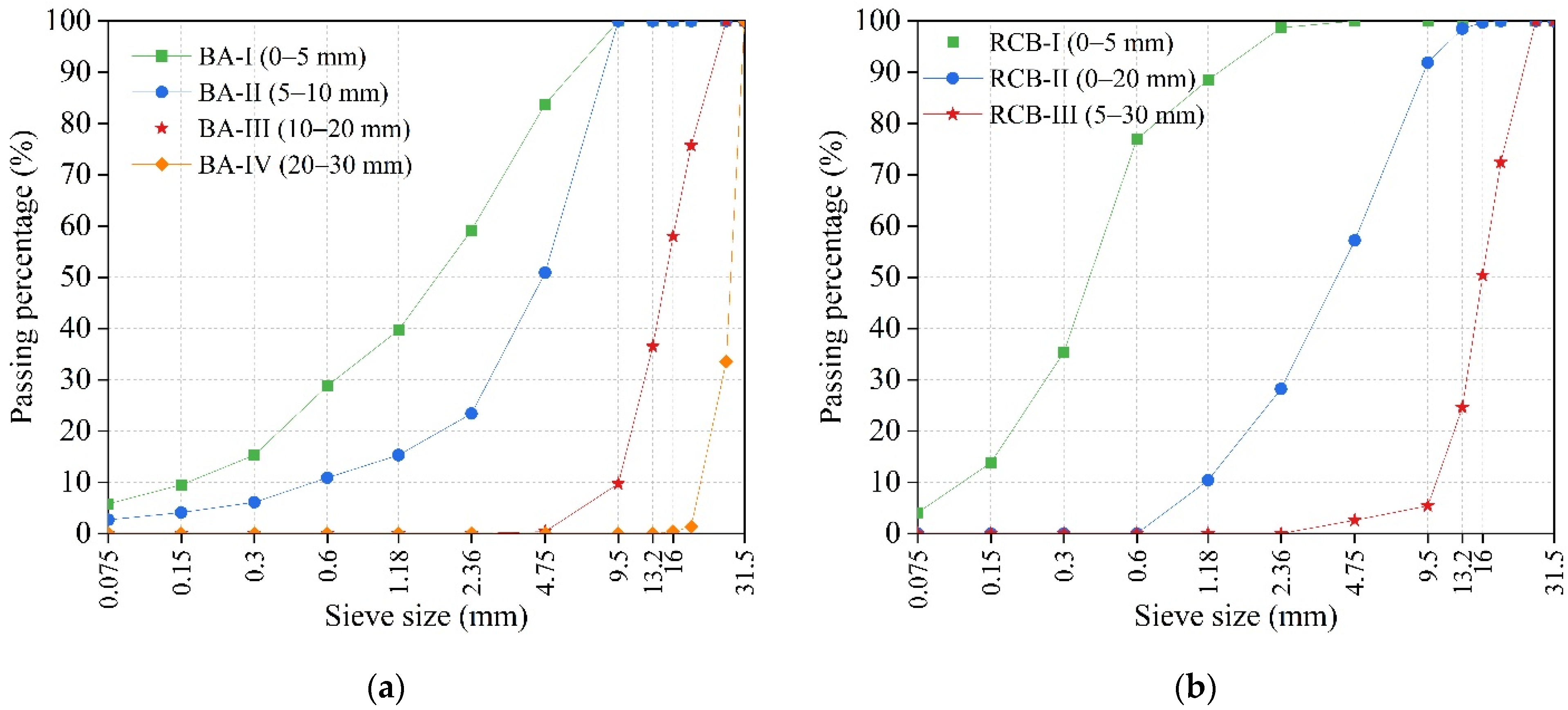

3.1. Materials

3.2. Mixture Design

3.3. Specimen Preparation

3.4. Testing Procedure

4. Results and Discussion

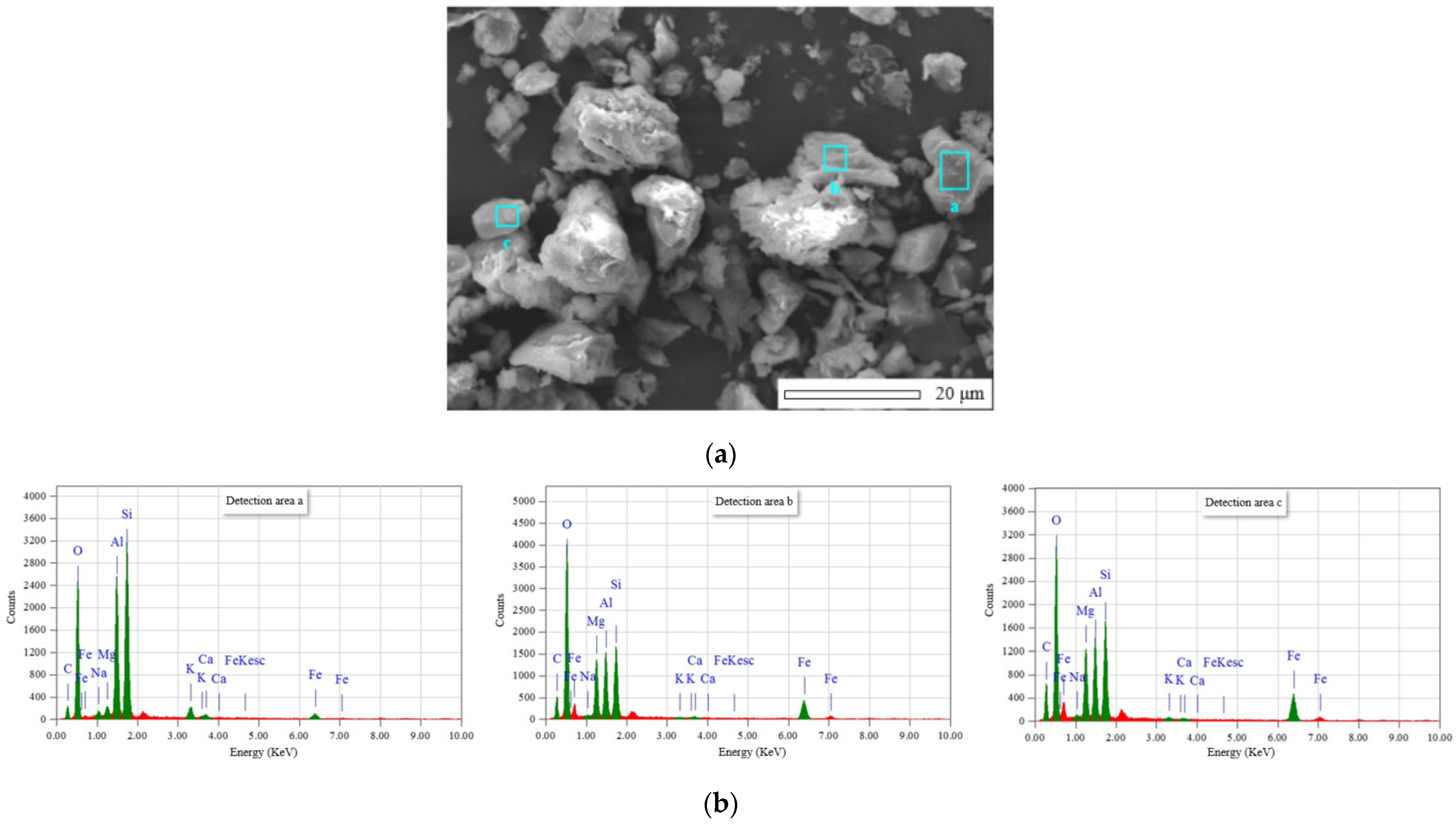

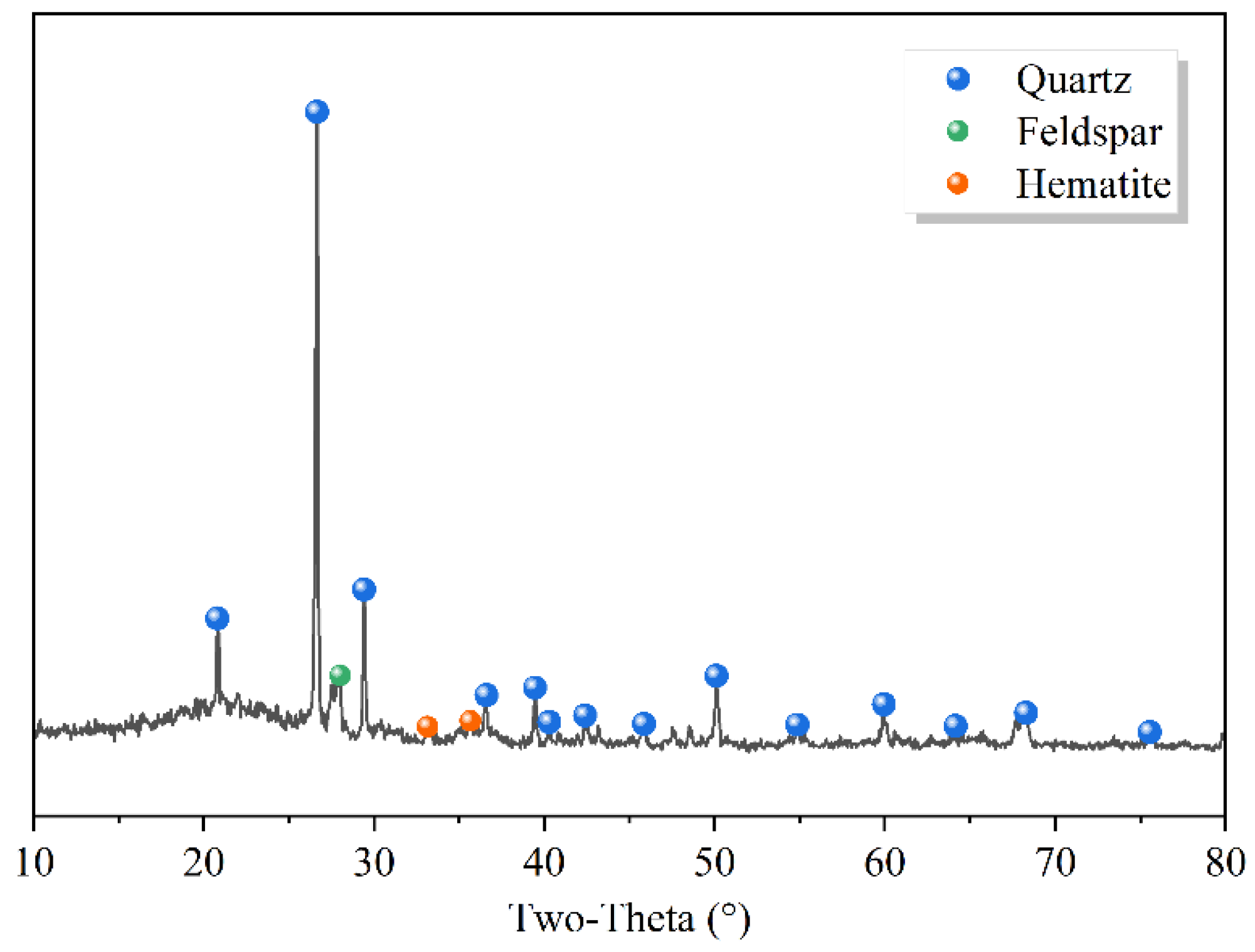

4.1. Physical and Chemical Properties of RCB

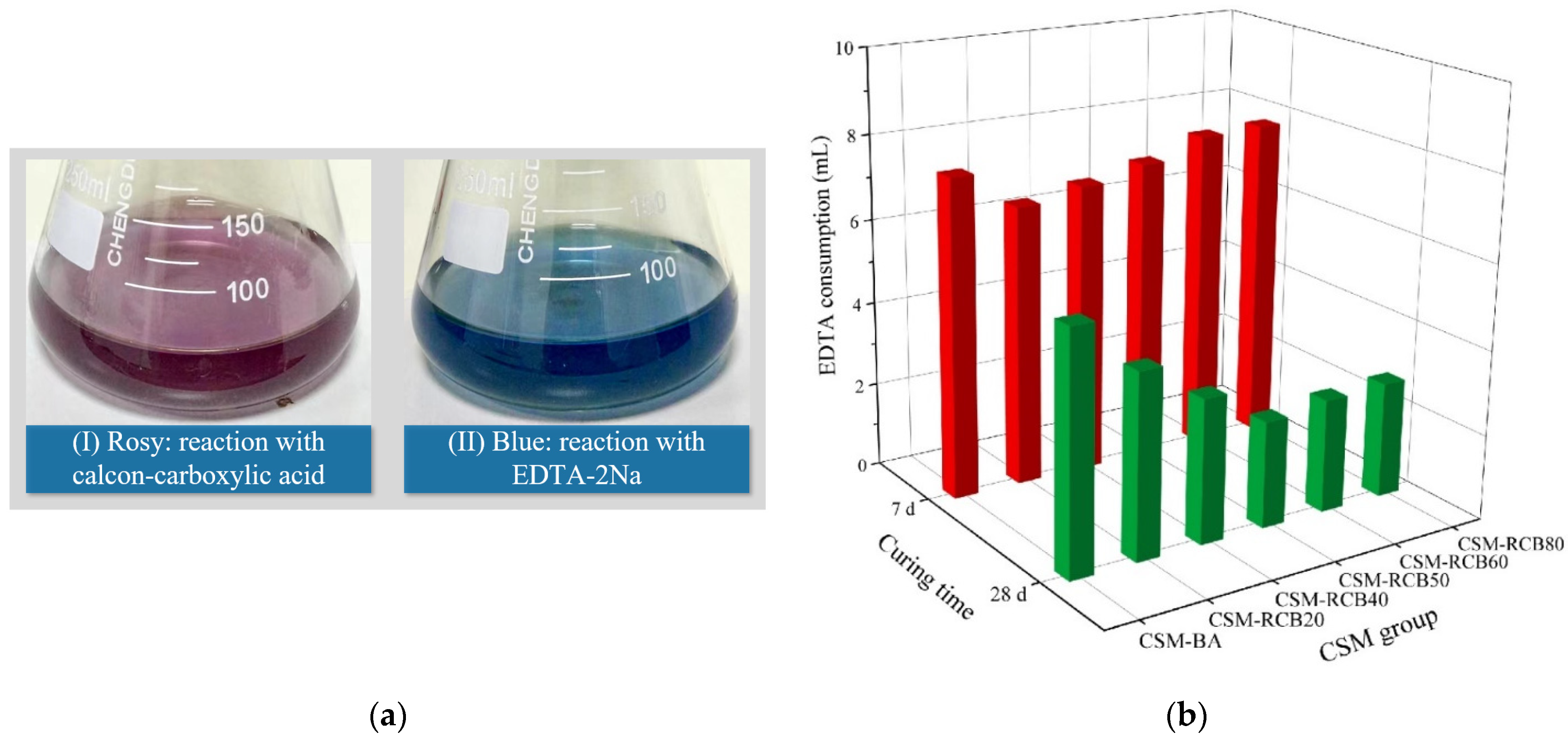

4.2. Strength Mechanism Analysis Using EDTA-2Na

4.3. Mechanical Properties

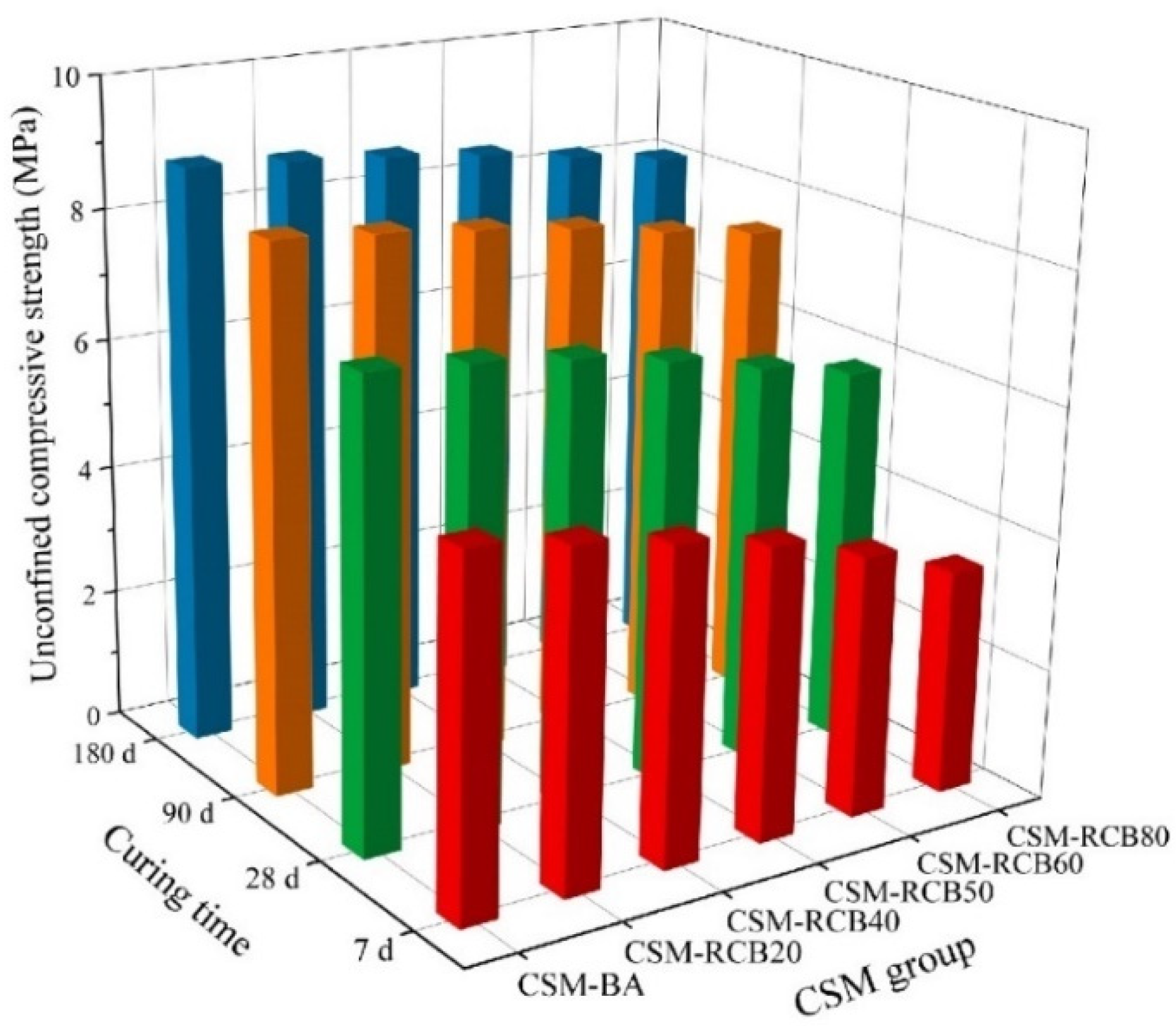

4.3.1. Unconfined Compressive Strength

4.3.2. Indirect Tensile Strength

4.4. Durability Properties

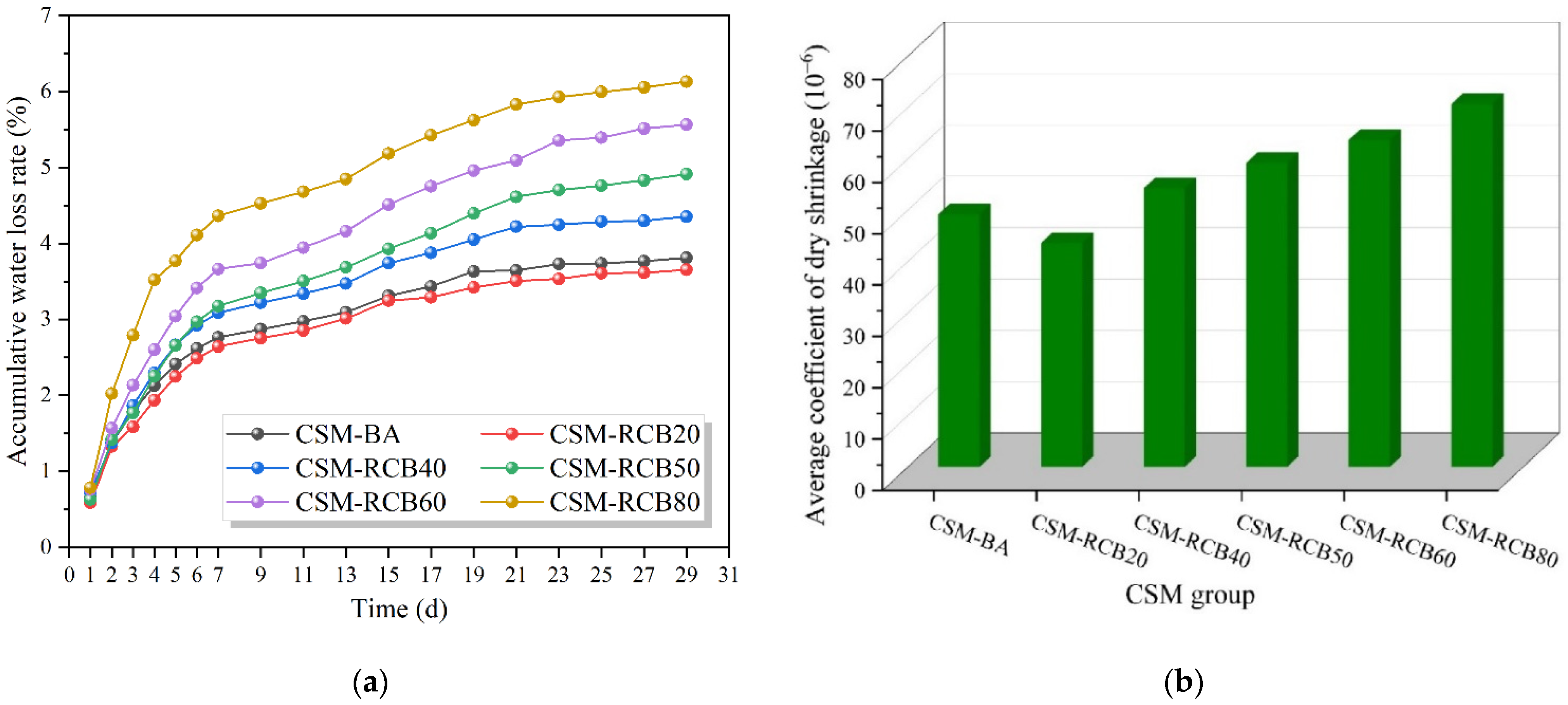

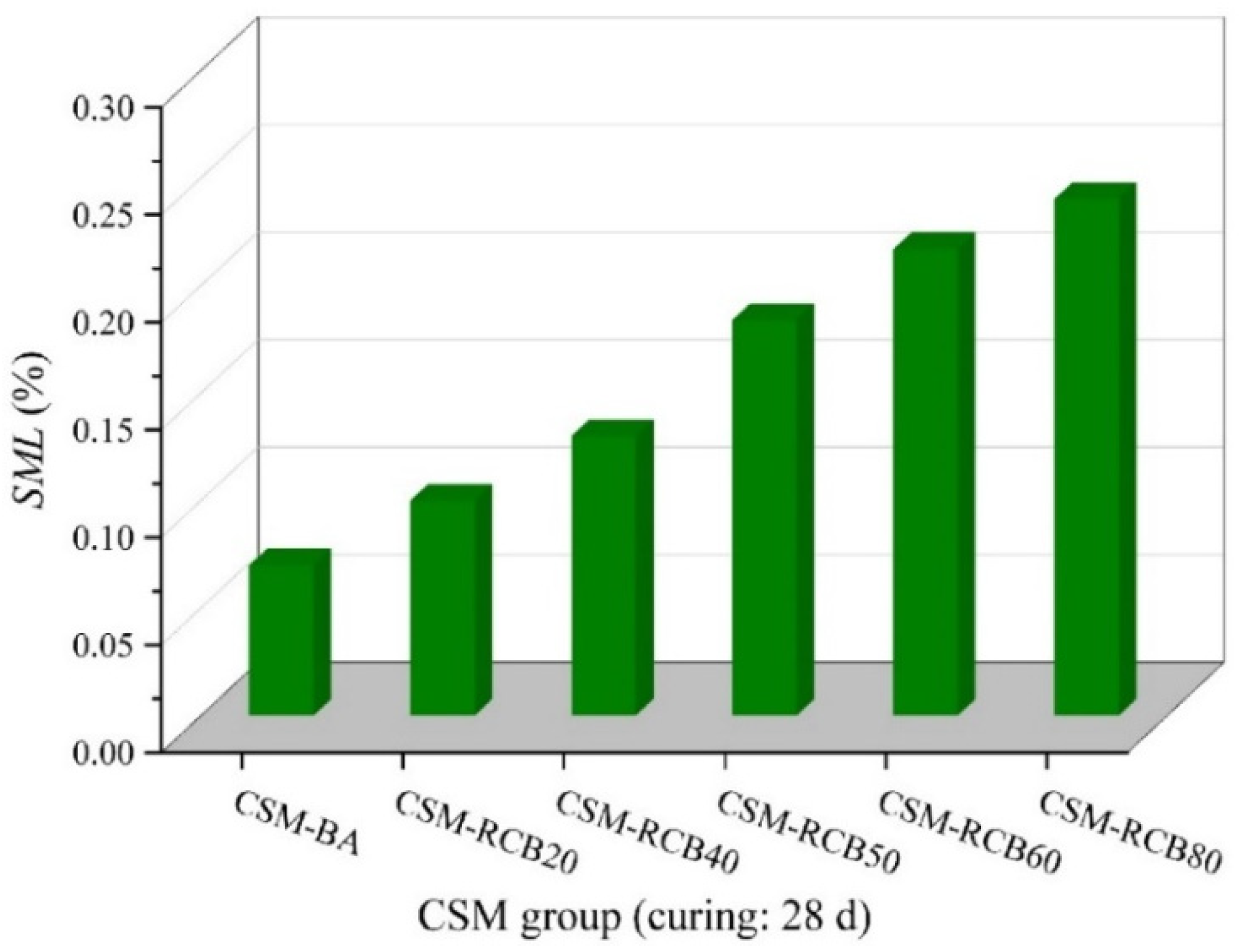

4.4.1. Dry Shrinkage Behavior

4.4.2. Temperature Shrinkage Behavior

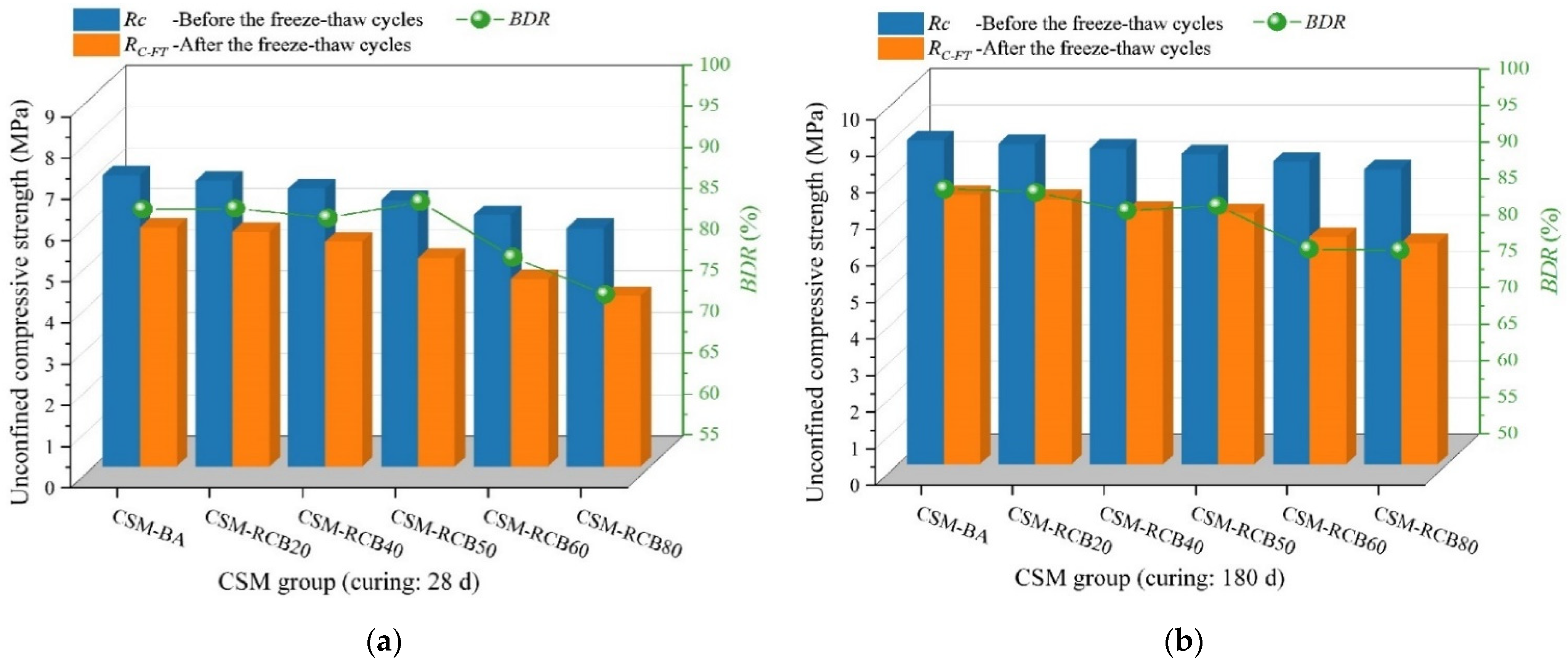

4.4.3. Freeze-Thaw Resistance Behavior

4.4.4. Anti-Scouring Behavior

4.5. Environmental Impact Based on the Leaching Toxicity

5. Conclusions

- (1)

- A higher substitution ratio results in lower unconfined compressive strength as for the lower inherent strength and inconspicuous angularity of RCB compared with natural aggregate. The higher the RCB substitution ratio is, the larger the indirect tensile strength of the late curing period is.

- (2)

- RCB negatively impacts upon the freeze-thaw resistance of CSM, and the increase in CSM curing time can promote its freeze-thaw resistance, since the pozzolanic reaction would produce cementitious materials to fill internal pores. RCB has a smaller aggregate size and poorer angularity compared with natural aggregate, causing a negative influence on the anti-scouring property of CSM.

- (3)

- Substituting RCB for natural aggregate resulted in an overall increasing accumulative water loss rate, the average coefficient of dry shrinkage and temperature shrinkage. Moreover, the coefficient of temperature shrinkage has a relatively gentle variation in the temperature range of 10–20 °C.

- (4)

- CSM incorporating RCB with pozzolanic activity reacts very slowly to form the crystal structure, which has a positive effect on the strength of modified CSM mainly at later stages. The leaching concentrations of several heavy metal elements were far lower than the threshold values of identification for extraction toxicity, which also meet the standard requirements of surface water and groundwater referring to the Chinese standard.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wong, C.L.; Mo, K.H.; Yap, S.P.; Alengaram, U.J.; Ling, T.C. Potential use of brick waste as alternate concrete-making materials: A review. J. Clean. Prod. 2018, 195, 226–239. [Google Scholar] [CrossRef]

- Fatta, D.; Papadopoulos, A.; Avramikos, E.; Sgourou, E.; Moustakas, K.; Kourmoussis, F.; Mentzis, A.; Loizidou, M. Generation and management of construction and demolition waste in greece-an existing challenge. Resour. Conserv. Recycl. 2003, 40, 81–91. [Google Scholar] [CrossRef]

- Asensio, E.; Medina, C.; Frias, M.; de Rojas, M.I.S. Fired clay-based construction and demolition waste as pozzolanic addition in cements. Design of new eco-efficient cements. J. Clean. Prod. 2020, 265, 121610. [Google Scholar] [CrossRef]

- Zheng, L.N.; Wu, H.Y.; Zhang, H.; Duan, H.B.; Wang, J.Y.; Jiang, W.P.; Dong, B.Q.; Liu, G.; Zuo, J.; Song, Q.B. Characterizing the generation and flows of construction and demolition waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.H.; Ding, L.; Li, F.; Peng, J.H. Recycled aggregates from construction and demolition wastes as alternative filling materials for highway subgrades in China. J. Clean. Prod. 2020, 255, 120223. [Google Scholar] [CrossRef]

- Xin, J.; Liu, L.; Xu, L.; Wang, J.; Yang, P.; Qu, H. A preliminary study of aeolian sand-cement-modified gasification slag-paste backfill: Fluidity, microstructure, and leaching risks. Sci. Total Environ. 2022, 830, 154766. [Google Scholar] [CrossRef]

- Tang, D.W.; Zhang, X.B.; Hu, S.S.; Liu, X.Y.; Ren, X.; Hu, J.X.; Feng, Y. The reuse of red brick powder as a filler in styrene-butadiene rubber. J. Clean. Prod. 2020, 261, 120966. [Google Scholar] [CrossRef]

- Zhang, J.H.; Li, C.; Ding, L.; Li, J. Performance evaluation of cement stabilized recycled mixture with recycled concrete aggregate and crushed brick. Constr. Build. Mater. 2021, 296, 123596. [Google Scholar] [CrossRef]

- Fang, Y.; Yang, X.; Lin, Y.L.; Shi, J.Y.; Prominski, A.; Clayton, C.; Ostroff, E.; Tian, B.Z. Dissecting biological and synthetic soft-hard interfaces for tissue-like systems. Chem. Rev. 2022, 122, 5233–5276. [Google Scholar] [CrossRef]

- Lin, Y.L.; Fang, Y.; Yue, J.P.; Tian, B.Z. Soft-hard composites for bioelectric interfaces. Trends Chem. 2020, 2, 519–534. [Google Scholar] [CrossRef]

- Fang, Y.; Han, E.D.; Zhang, X.X.; Jiang, Y.W.; Lin, Y.L.; Shi, J.Y.; Wu, J.B.; Meng, L.Y.; Gao, X.; Griffin, P.J.; et al. Dynamic and programmable cellular-scale granules enable tissue-like materials. Matter 2020, 2, 948–964. [Google Scholar] [CrossRef]

- Fang, Y.; Tian, B.Z. Curving neural nanobioelectronics. Nat. Nanotechnol. 2019, 14, 733–735. [Google Scholar] [CrossRef] [PubMed]

- Afshinnia, K.; Poursaee, A. The potential of ground clay brick to mitigate alkali-silica reaction in mortar prepared with highly reactive aggregate. Constr. Build. Mater. 2015, 95, 164–170. [Google Scholar] [CrossRef]

- Filho, R.D.T.; Goncalves, J.P.; Americano, B.B.; Fairbairn, E.M.R. Potential for use of crushed waste calcined-clay brick as a supplementary cementitious material in brazil. Cem. Concr. Res. 2007, 37, 1357–1365. [Google Scholar] [CrossRef]

- Li, Z.D.; Zhang, T.; Wang, Y.M.; Yue, X.J.; Yang, D.Y.; Qiu, F.X. Waste-to-resource strategy to fabricate functionalized material from waste brick. Sci. Total Environ. 2020, 703, 135032. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.A.; Du, Q.A.; Bao, Y.W. Concrete with recycled concrete aggregate and crushed clay bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Sun, Y.; Li, L.H. Strength assessment and mechanism analysis of cement stabilized reclaimed lime-fly ash macadam. Constr. Build. Mater. 2018, 166, 118–129. [Google Scholar] [CrossRef]

- Contessi, S.; Dalconi, M.C.; Pollastri, S.; Calgaro, L.; Meneghini, C.; Ferrari, G.; Marcomini, A.; Artioli, G. Cement-stabilized contaminated soil: Understanding pb retention with xanes and raman spectroscopy. Sci. Total Environ. 2021, 752, 141826. [Google Scholar] [CrossRef]

- Chhabra, R.S.; Ransinchung, G.D.R.N.; Islam, S.S. Performance analysis of cement treated base layer by incorporating reclaimed asphalt pavement material and chemical stabilizer. Constr. Build. Mater. 2021, 298, 123866. [Google Scholar] [CrossRef]

- Lv, S.T.; Peng, X.H.; Yuan, J.; Liu, H.F.; Hu, L.; Yang, S.; Liu, J. Stress path investigation of fatigue characteristics of cement stabilized macadam. Constr. Build. Mater. 2021, 292, 123446. [Google Scholar] [CrossRef]

- Lepakshi, R.; Reddy, B.V.V. Shear strength parameters and mohr-coulomb failure envelopes for cement stabilised rammed earth. Constr. Build. Mater. 2020, 249, 118708. [Google Scholar] [CrossRef]

- Kasinikota, P.; Tripura, D.D. Evaluation of compressed stabilized earth block properties using crushed brick waste. Constr. Build. Mater. 2021, 280, 122520. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Bo, M.W.; Sivakugan, N. Geotechnical characteristics of recycled crushed brick blends for pavement sub-base applications. Can. Geotech. J. 2012, 49, 796–811. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D.X. Paving blocks made with recycled concrete aggregate and crushed clay brick. Constr. Build. Mater. 2006, 20, 569–577. [Google Scholar] [CrossRef]

- Adamson, M.; Razmjoo, A.; Poursaee, A. Durability of concrete incorporating crushed brick as coarse aggregate. Constr. Build. Mater. 2015, 94, 426–432. [Google Scholar] [CrossRef] [Green Version]

- Zong, L.; Fei, Z.Y.; Zhang, S.P. Permeability of recycled aggregate concrete containing fly ash and clay brick waste. J. Clean. Prod. 2014, 70, 175–182. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, S.Y.; Ren, J.L.; Wang, Y.; Wang, C.G. Fatigue characteristics and prediction of cement-stabilized cold recycled mixture with road-milling materials considering recycled aggregate composition. Constr. Build. Mater. 2021, 301, 124122. [Google Scholar] [CrossRef]

- Silva, J.; de Brito, J.; Veiga, R. Incorporation of fine ceramics in mortars. Constr. Build. Mater. 2009, 23, 556–564. [Google Scholar] [CrossRef]

- Bektas, F.; Wang, K.; Ceylan, H. Effects of crushed clay brick aggregate on mortar durability. Constr. Build. Mater. 2009, 23, 1909–1914. [Google Scholar] [CrossRef]

- Shao, J.; Gao, J.; Zhao, Y.; Chen, X. Study on the pozzolanic reaction of clay brick powder in blended cement pastes. Constr. Build. Mater. 2019, 213, 209–215. [Google Scholar] [CrossRef]

- Ortega, J.M.; Letelier, V.; Solas, C.; Moriconi, G.; Climent, M.Á.; Sánchez, I. Long-term effects of waste brick powder addition in the microstructure and service properties of mortars. Constr. Build. Mater. 2018, 182, 691–702. [Google Scholar] [CrossRef] [Green Version]

- Turanli, L.; Bektas, F.; Monteiro, P.J.M. Use of ground clay brick as a pozzolanic material to reduce the alkali–silica reaction. Cem. Concr. Res. 2003, 33, 1539–1542. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Liang, C.Y.; Wang, Y.; Song, W.Z.; Tan, G.J.; Li, Y.L.; Guo, Y.M. Potential activity of recycled clay brick in cement stabilized subbase. Appl. Sci. 2019, 9, 5208. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Wang, Z.; Li, Y.; Shang, J. Cold recycling of lime-fly ash stabilized macadam mixtures as pavement bases and subbases. Constr. Build. Mater. 2018, 169, 306–314. [Google Scholar] [CrossRef]

- Wu, J.D.; Guo, L.P.; Qin, Y.Y. Preparation and characterization of ultra-high-strength and ultra-high-ductility cementitious composites incorporating waste clay brick powder. J. Clean. Prod. 2021, 312, 127813. [Google Scholar] [CrossRef]

- Zhang, S.P.; Zong, L. Properties of concrete made with recycled coarse aggregate from waste brick. Environ. Prog. Sustain. Energy 2014, 33, 1283–1289. [Google Scholar] [CrossRef]

- Yan, X.; Jiang, L.; Guo, M.; Chen, Y.; Zhu, P.; Jin, W.; Zha, J. Using edta-2na to inhibit sulfate attack in slag cement mortar under steam curing. Constr. Build. Mater. 2020, 265, 120324. [Google Scholar] [CrossRef]

- Yan, K.Z.; Li, G.K.; You, L.Y.; Zhou, Y.B.; Wu, S.H. Performance assessments of open-graded cement stabilized macadam containing recycled aggregate. Constr. Build. Mater. 2020, 233, 117326. [Google Scholar] [CrossRef]

- Yan, K.Z.; Sun, H.; Gao, F.Q.; Ge, D.D.; You, L.Y. Assessment and mechanism analysis of municipal solid waste incineration bottom ash as aggregate in cement stabilized macadam. J. Clean. Prod. 2020, 244, 118750. [Google Scholar] [CrossRef]

- Yan, K.; Gao, F.; Sun, H.; Ge, D.; Yang, S. Effects of municipal solid waste incineration fly ash on the characterization of cement-stabilized macadam. Constr. Build. Mater. 2019, 207, 181–189. [Google Scholar] [CrossRef]

- Guo, Y.; Yao, C.; Shen, A.; Chen, Q.; Wei, Z.; Yang, X. Feasibility of rapid-regeneration utilization in situ for waste cement-stabilized macadam. J. Clean. Prod. 2020, 263, 121452. [Google Scholar] [CrossRef]

- Raavi, S.S.D.; Tripura, D.D. Predicting and evaluating the engineering properties of unstabilized and cement stabilized fibre reinforced rammed earth blocks. Constr. Build. Mater. 2020, 262, 120845. [Google Scholar] [CrossRef]

- Bakhshi, M.; Mobasher, B.; Soranakom, C. Moisture loss characteristics of cement-based materials under early-age drying and shrinkage conditions. Constr. Build. Mater. 2012, 30, 413–425. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Chen, H.; Wan, C. Microstructure-based modelling of drying shrinkage and microcracking of cement paste at high relative humidity. Constr. Build. Mater. 2016, 126, 410–425. [Google Scholar] [CrossRef]

- Tai, B.W.; Wu, Q.B.; Yue, Z.R.; Xu, H.B. Ground temperature and deformation characteristics of anti-freeze-thaw embankments in permafrost and seasonal frozen ground regions of China. Cold Reg. Sci. Technol. 2021, 189, 103331. [Google Scholar] [CrossRef]

- Tai, B.W.; Yue, Z.R.; Sun, T.C.; Qi, S.C.; Li, L.; Yang, Z.H. Novel anti-frost subgrade bed structures a high speed railways in deep seasonally frozen ground regions: Experimental and numerical studies. Constr. Build. Mater. 2021, 269, 121266. [Google Scholar] [CrossRef]

- Çelik, M.Y.; Akbulut, H.; Ergül, A. Water absorption process effect on strength of ayazini tuff, such as the uniaxial compressive strength (ucs), flexural strength and freeze and thaw effect. Environ. Earth Sci. 2013, 71, 4247–4259. [Google Scholar] [CrossRef]

- Miao, Y.; Yu, W.; Hou, Y.; Liu, C.; Wang, L. Influences of clay brick particles on the performance of cement stabilized recycled aggregate as pavement base. Sustainability 2018, 10, 3505. [Google Scholar] [CrossRef] [Green Version]

- Wei, H.; Zhang, Y.; Cui, J.; Han, L.; Li, Z. Engineering and environmental evaluation of silty clay modified by waste fly ash and oil shale ash as a road subgrade material. Constr. Build. Mater. 2019, 196, 204–213. [Google Scholar] [CrossRef]

- Li, X.-G.; Lv, Y.; Ma, B.-G.; Chen, Q.-B.; Yin, X.-B.; Jian, S.-W. Utilization of municipal solid waste incineration bottom ash in blended cement. J. Clean. Prod. 2012, 32, 96–100. [Google Scholar] [CrossRef]

- Li, H.; Dong, L.; Jiang, Z.; Yang, X.; Yang, Z. Study on utilization of red brick waste powder in the production of cement-based red decorative plaster for walls. J. Clean. Prod. 2016, 133, 1017–1026. [Google Scholar] [CrossRef]

- Hu, J.; Wang, K.; Gaunt, J.A. Recycling lead-based paint contaminated deconstructed masonry materials as aggregate for portland cement concrete—A cost effective and environmental friendly approach. Resour. Conserv. Recycl. 2010, 54, 1453–1460. [Google Scholar] [CrossRef]

| Fine Aggregates | Apparent Specific Density | Water Absorption (%) | Liquid Limit (%) | Plasticity Index |

|---|---|---|---|---|

| BA | 2.689 | 1.73 | 18.06 | 4.34 |

| RCB | 2.116 | 17.60 | 37.91 | 8.50 |

| Group No. | CSM-BA | CSM-RCB20 | CSM-RCB40 | CSM-RCB50 | CSM-RCB60 | CSM-RCB80 |

|---|---|---|---|---|---|---|

| MDD (g/cm3) | 2.362 | 2.215 | 2.167 | 2.143 | 2.122 | 2.152 |

| OWC (%) | 5.11 | 6.87 | 7.04 | 7.35 | 8.17 | 8.31 |

| Fitting Models | RCB Substitution Ratio (%) | |||||

|---|---|---|---|---|---|---|

| 0 | 20 | 40 | 50 | 60 | 80 | |

| a | 3.3378 | 2.9941 | 2.5979 | 2.1251 | 1.5063 | 0.7652 |

| b | 1.0873 | 1.1369 | 1.1918 | 1.2541 | 1.3333 | 1.4467 |

| R2 | 0.9939 | 0.9919 | 0.9912 | 0.9926 | 0.9967 | 0.9899 |

| Specimens | Concentration of Leaching Toxicity Heavy Metal Elements (mg/L) | |||||||

|---|---|---|---|---|---|---|---|---|

| Zn | Cu | Cr | Cd | Ni | Pb | As | ||

| CSM-BA | 0.0033 | 0.0071 | 0.0087 | ND | 0.0055 | 0.0013 | ND | |

| CSM-RCB20 | 0.0037 | 0.0084 | 0.0096 | ND | 0.0064 | 0.0021 | ND | |

| CSM-RCB40 | 0.0039 | 0.0098 | 0.0105 | 0.0010 | 0.0069 | 0.0032 | ND | |

| CSM-RCB50 | 0.0046 | 0.0111 | 0.0124 | 0.0013 | 0.0071 | 0.0039 | ND | |

| CSM-RCB60 | 0.0052 | 0.0120 | 0.0140 | 0.0017 | 0.0071 | 0.0044 | ND | |

| CSM-RCB80 | 0.0065 | 0.0132 | 0.0172 | 0.0021 | 0.0073 | 0.0057 | ND | |

| Extraction toxicity (GB 5085.3-2007) | 100 | 100 | 5 | 1 | 5 | 5 | 5 | |

| Surface water (GB 3838-2002) | I | 0.05 | 0.01 | 0.01 | 0.001 | / | 0.01 | 0.05 |

| II | 1 | 1 | 0.05 | 0.005 | / | 0.01 | 0.05 | |

| Groundwater (GB/T 14848-2017) | I | 0.05 | 0.01 | 0.005 | 0.0001 | / | 0.005 | 0.001 |

| II | 0.5 | 0.05 | 0.01 | 0.001 | / | 0.005 | 0.001 | |

| III | 1 | 1 | 0.05 | 0.005 | / | 0.01 | 0.01 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, E.; Wang, X.; Wang, W.; Wang, H. Mechanical Properties, Durability and Leaching Toxicity of Cement-Stabilized Macadam Incorporating Reclaimed Clay Bricks as Fine Aggregate. Sustainability 2022, 14, 8432. https://doi.org/10.3390/su14148432

Zhang E, Wang X, Wang W, Wang H. Mechanical Properties, Durability and Leaching Toxicity of Cement-Stabilized Macadam Incorporating Reclaimed Clay Bricks as Fine Aggregate. Sustainability. 2022; 14(14):8432. https://doi.org/10.3390/su14148432

Chicago/Turabian StyleZhang, Ermao, Xirui Wang, Wensheng Wang, and Haoyun Wang. 2022. "Mechanical Properties, Durability and Leaching Toxicity of Cement-Stabilized Macadam Incorporating Reclaimed Clay Bricks as Fine Aggregate" Sustainability 14, no. 14: 8432. https://doi.org/10.3390/su14148432

APA StyleZhang, E., Wang, X., Wang, W., & Wang, H. (2022). Mechanical Properties, Durability and Leaching Toxicity of Cement-Stabilized Macadam Incorporating Reclaimed Clay Bricks as Fine Aggregate. Sustainability, 14(14), 8432. https://doi.org/10.3390/su14148432