Sustainable Asphalt Rejuvenation by Using Waste Tire Rubber Mixed with Waste Oils

Abstract

1. Introduction

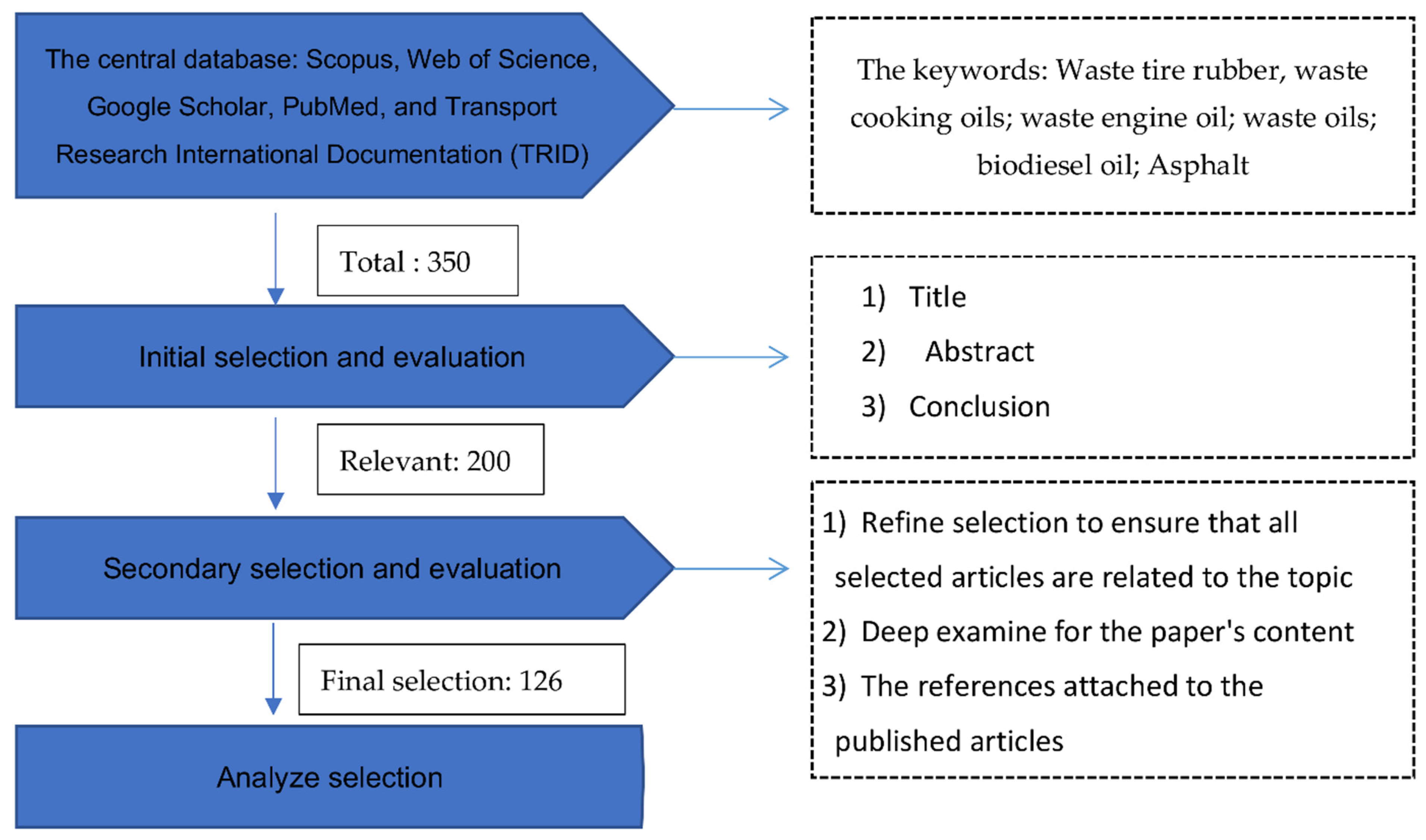

2. Methodology

- Use of rejuvenators in asphalt mixes with RAP compared to virgin bitumen.

- WTR rejuvenator and its chemical composition with the presence of waste oils.

- Changes in the physical properties of the binder due to the addition of WTR, WCO, and WEO.

- Changes in the rheological properties of the binder due to the addition of WTR, WCO, and WEO.

- Changes in the chemical properties of the binder due to WTR, WCO, and WEO.

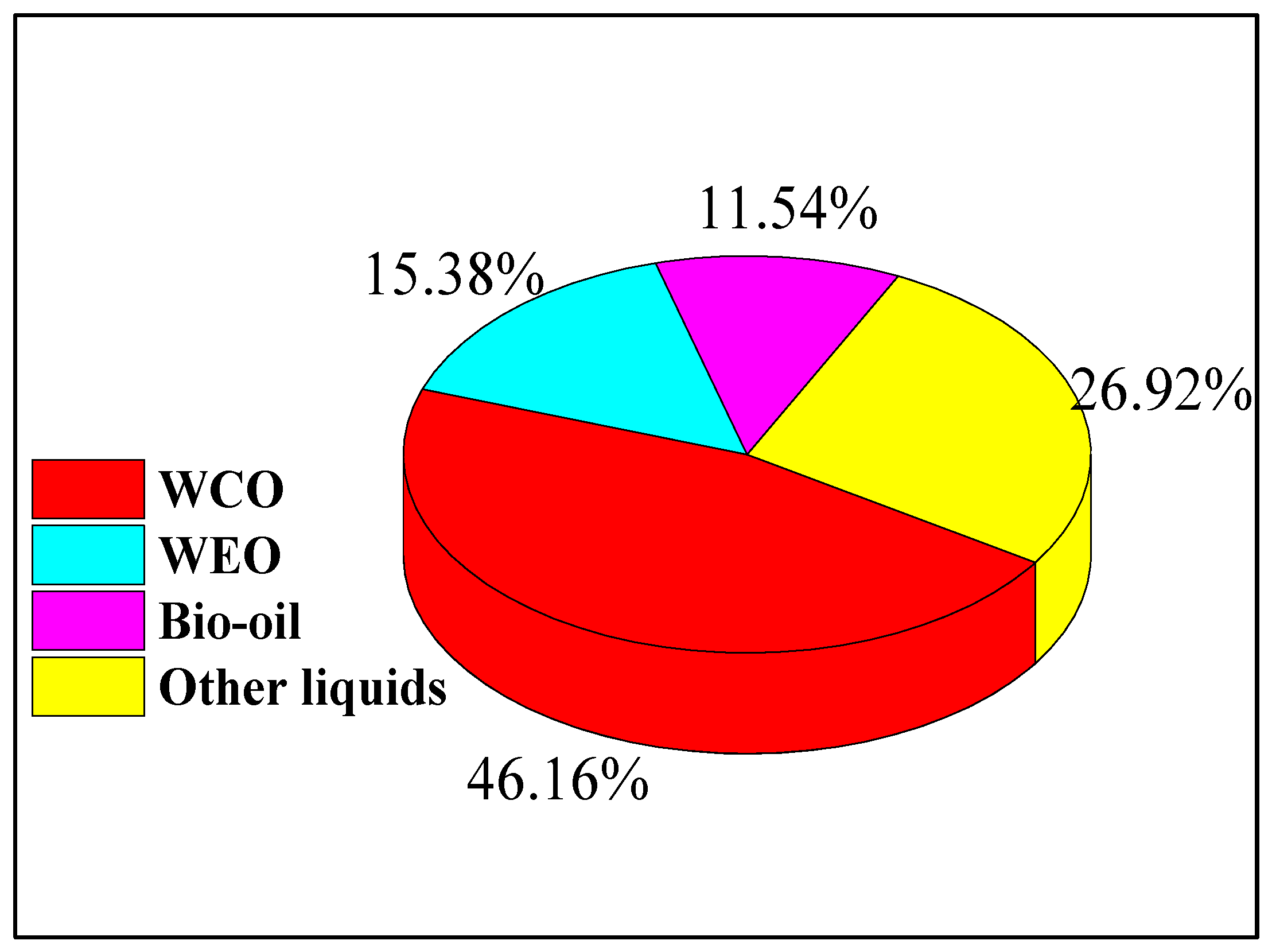

- Difference between a rejuvenator and a softener, to identify the advantages and shortcomings of the utilization of WCO. (see Figure 1).

3. Applicable Waste Materials on Rejuvenated Asphalt

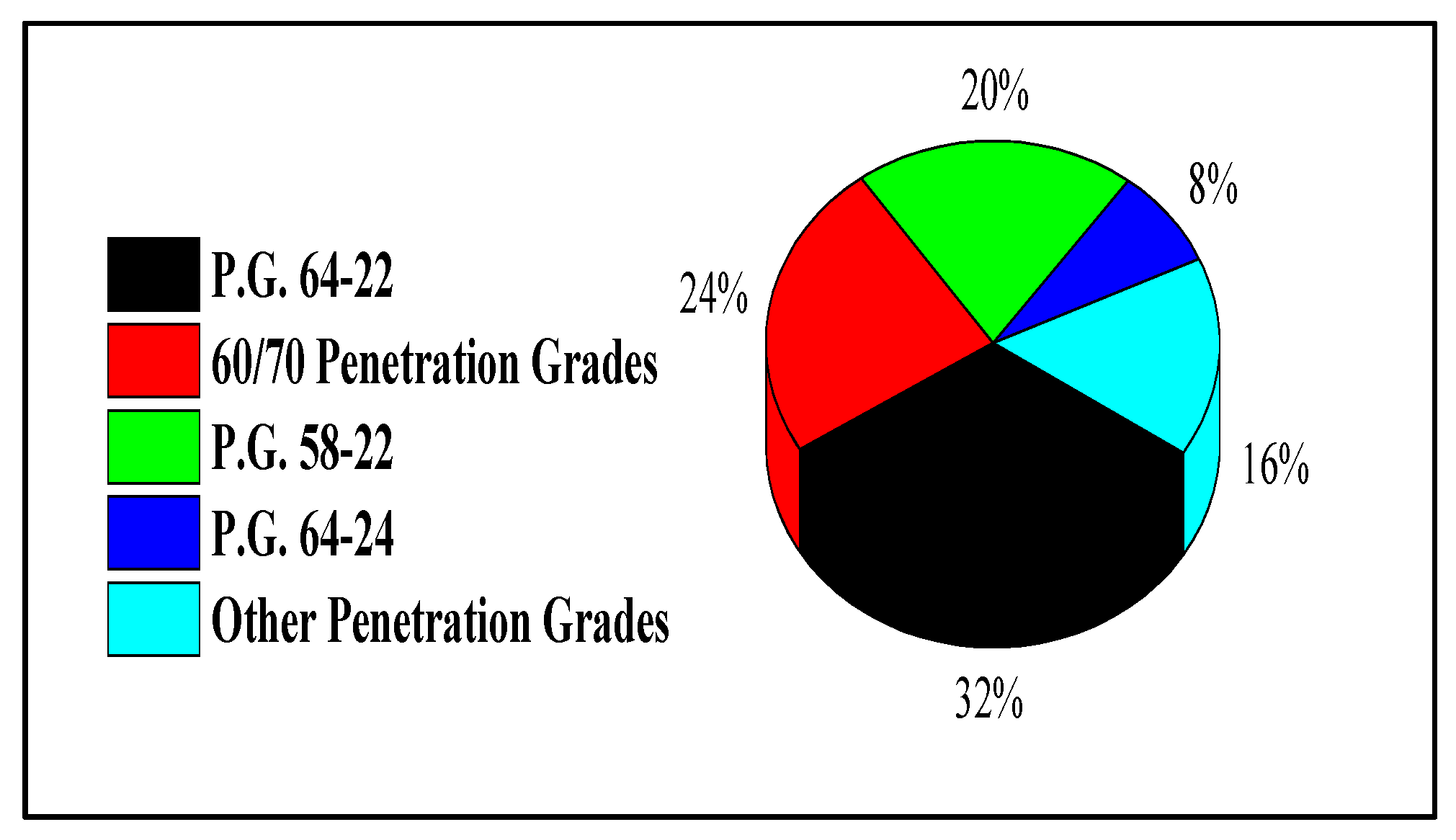

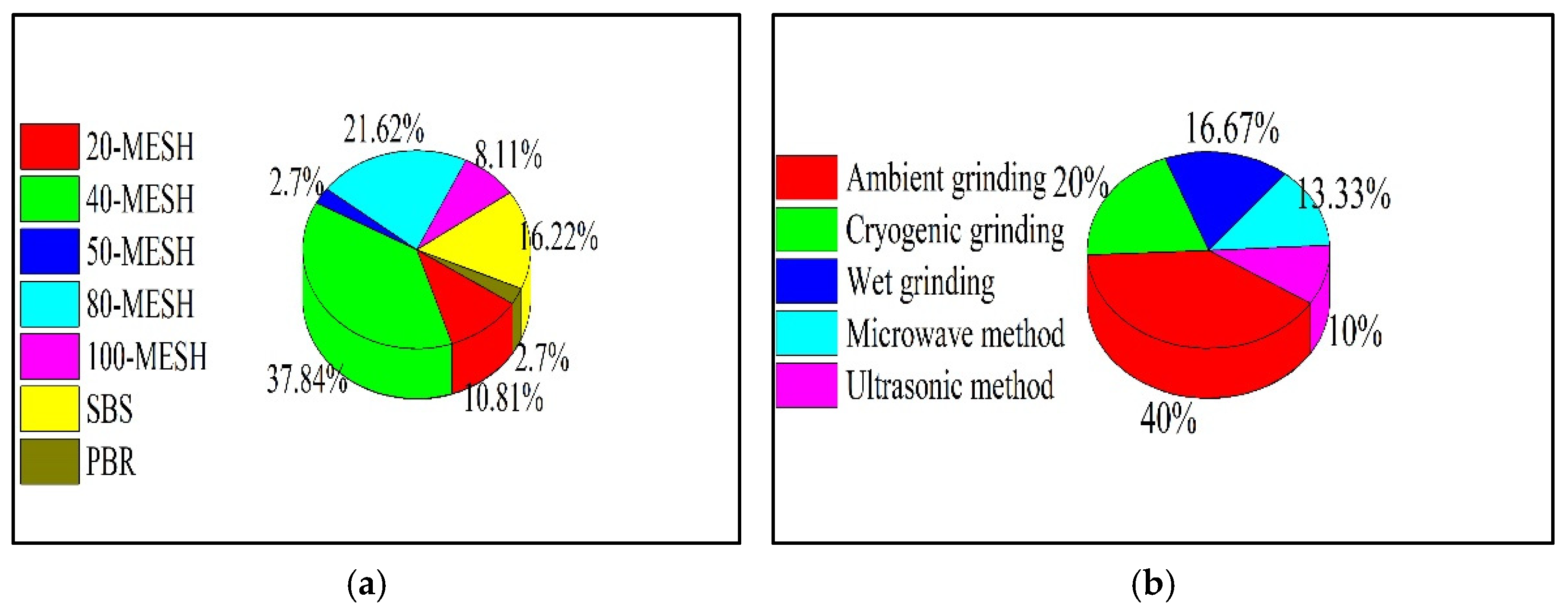

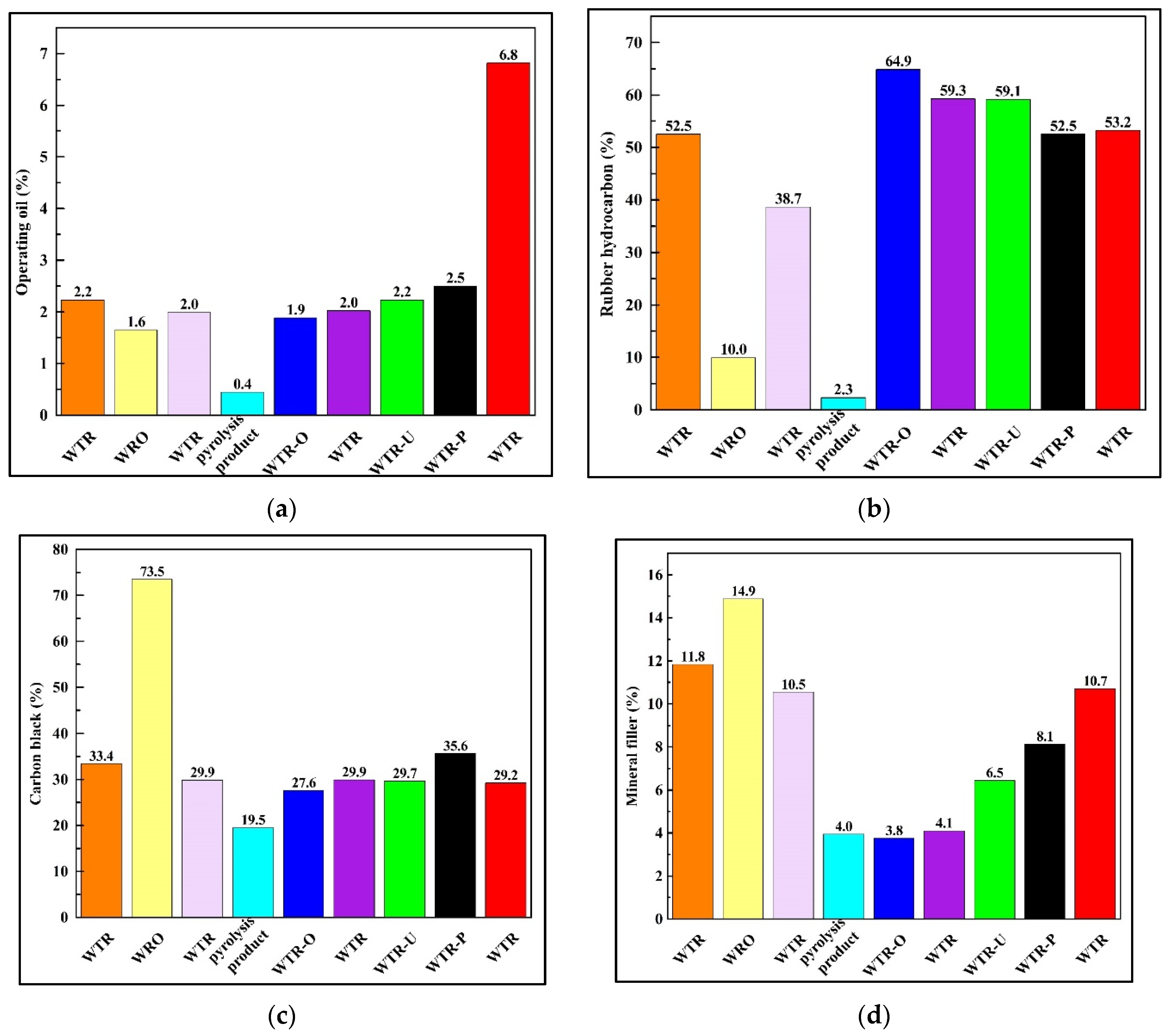

3.1. Waste Tire Rubber (WTR)

3.2. Waste Cooking Oil (WCO)

3.3. Waste Engine Oil (WEO) and Other Liquid Media

4. Effect of Waste Oils on the Characterization Properties of Rejuvenated Asphalt

4.1. Solubility

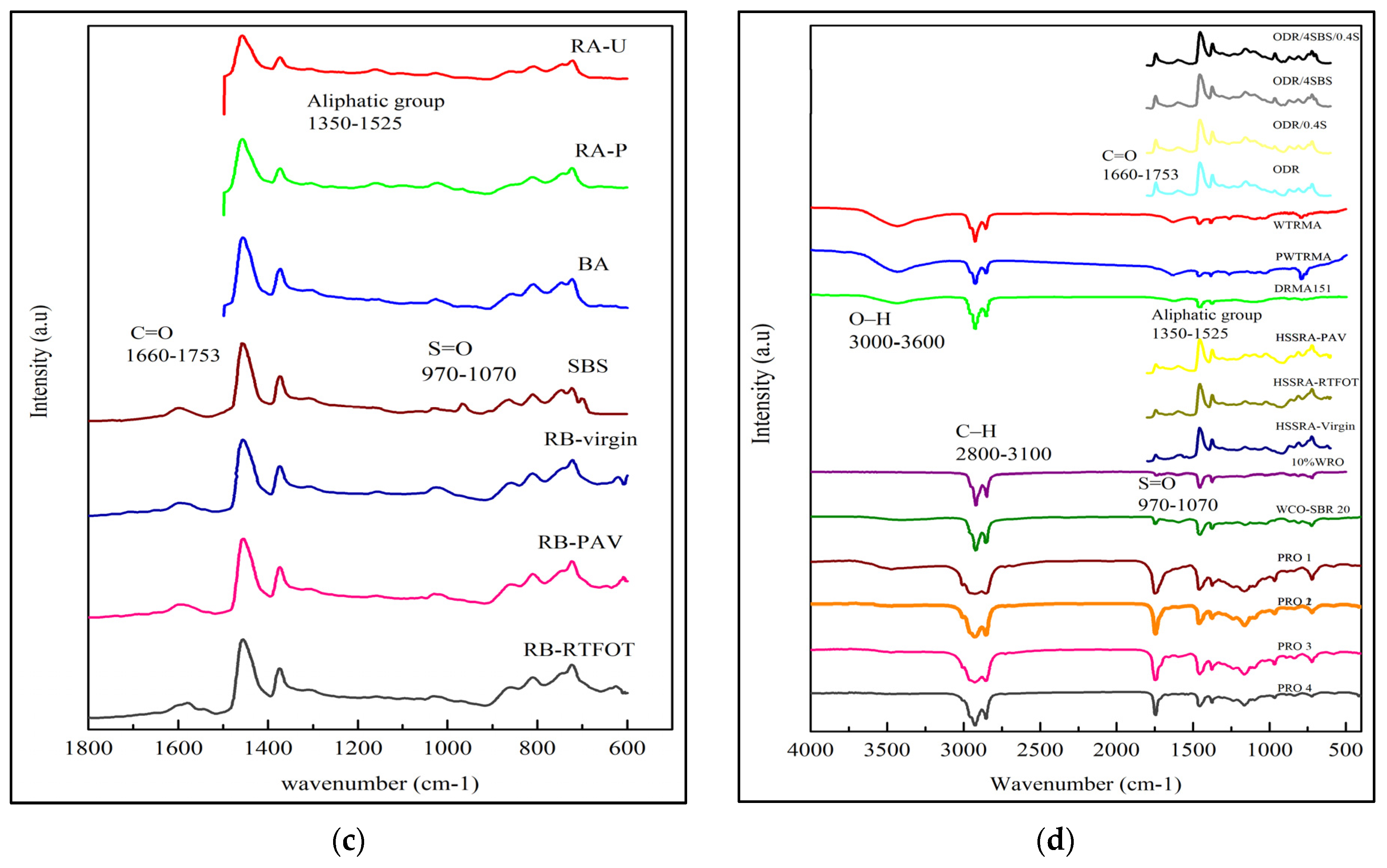

4.2. Effect of Waste Oils on Functional Groups of Rejuvenated Asphalt

4.3. Effect of Waste Oils on Elastic and Viscous Rejuvenated Asphalt

4.4. Effect of Waste Oils on Stiffness and Relaxation Characteristics of Rejuvenated Asphalt

4.5. Effect of Waste Oils on Molecular Weight of Rejuvenated Asphalt

4.6. Effect of Waste Oils on Thermal Behavior

5. Effect of Waste Oils on The Properties of Rejuvenated Asphalt

5.1. Effect of Waste oils on Conventional Physical Properties

5.1.1. Effect of Waste Oils on Penetration, Softening Point, and Ductility

5.1.2. Effect of Waste Oils on Flashing Point

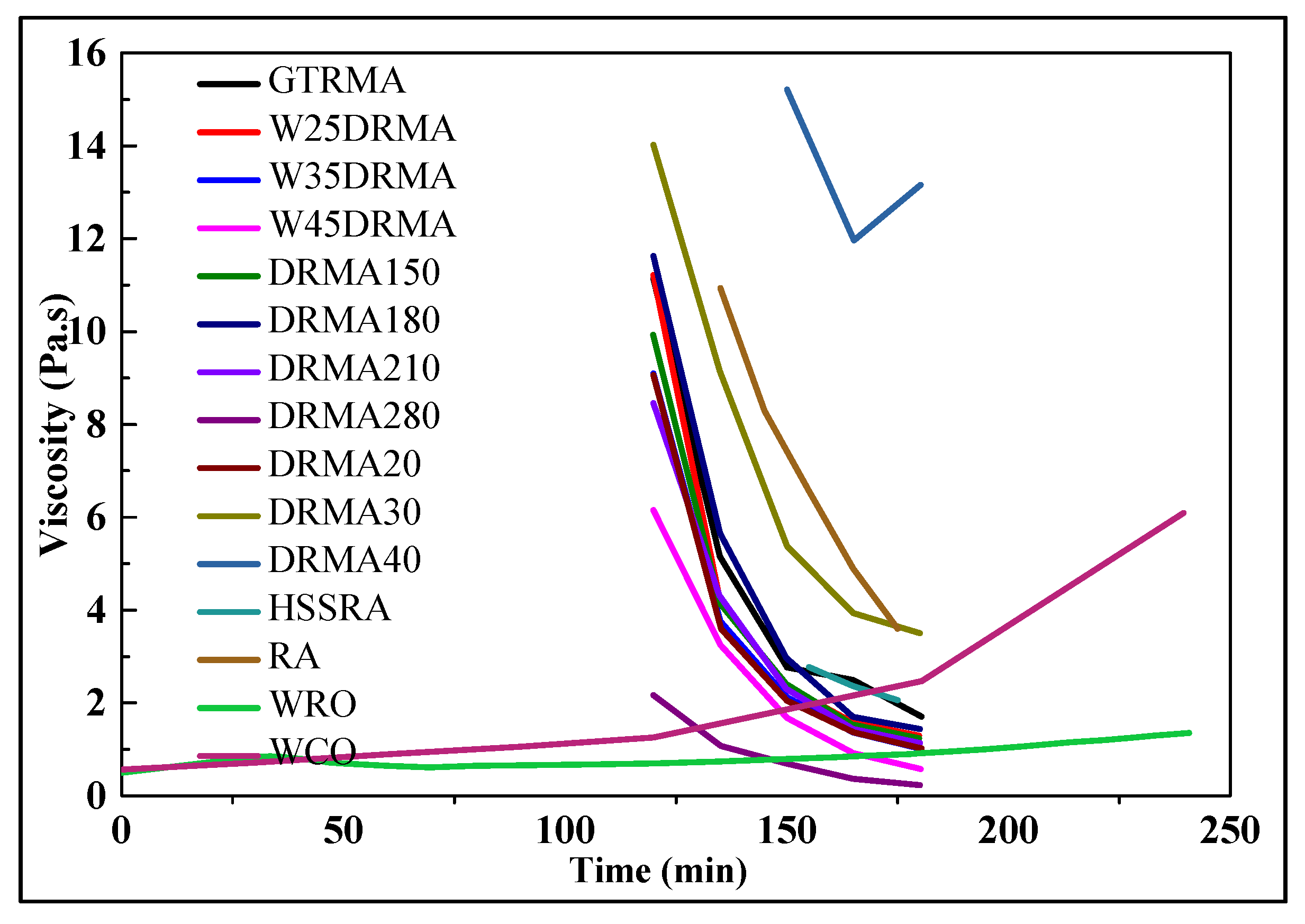

5.1.3. Effect of Waste Oils on Viscosity of Rejuvenated Asphalt

5.2. Effect of Waste Oils on High-Temperature Properties of Rejuvenated Asphalt

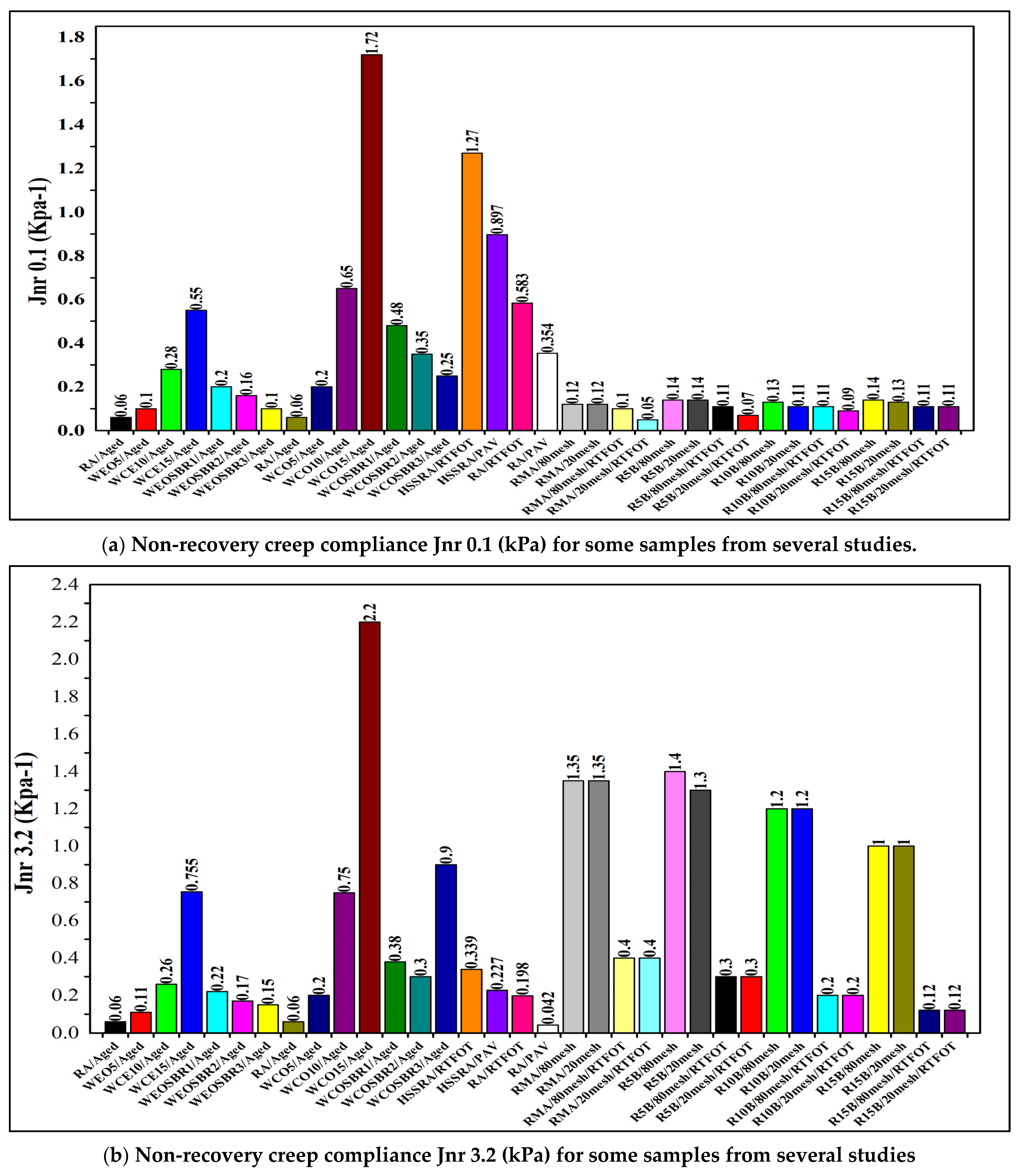

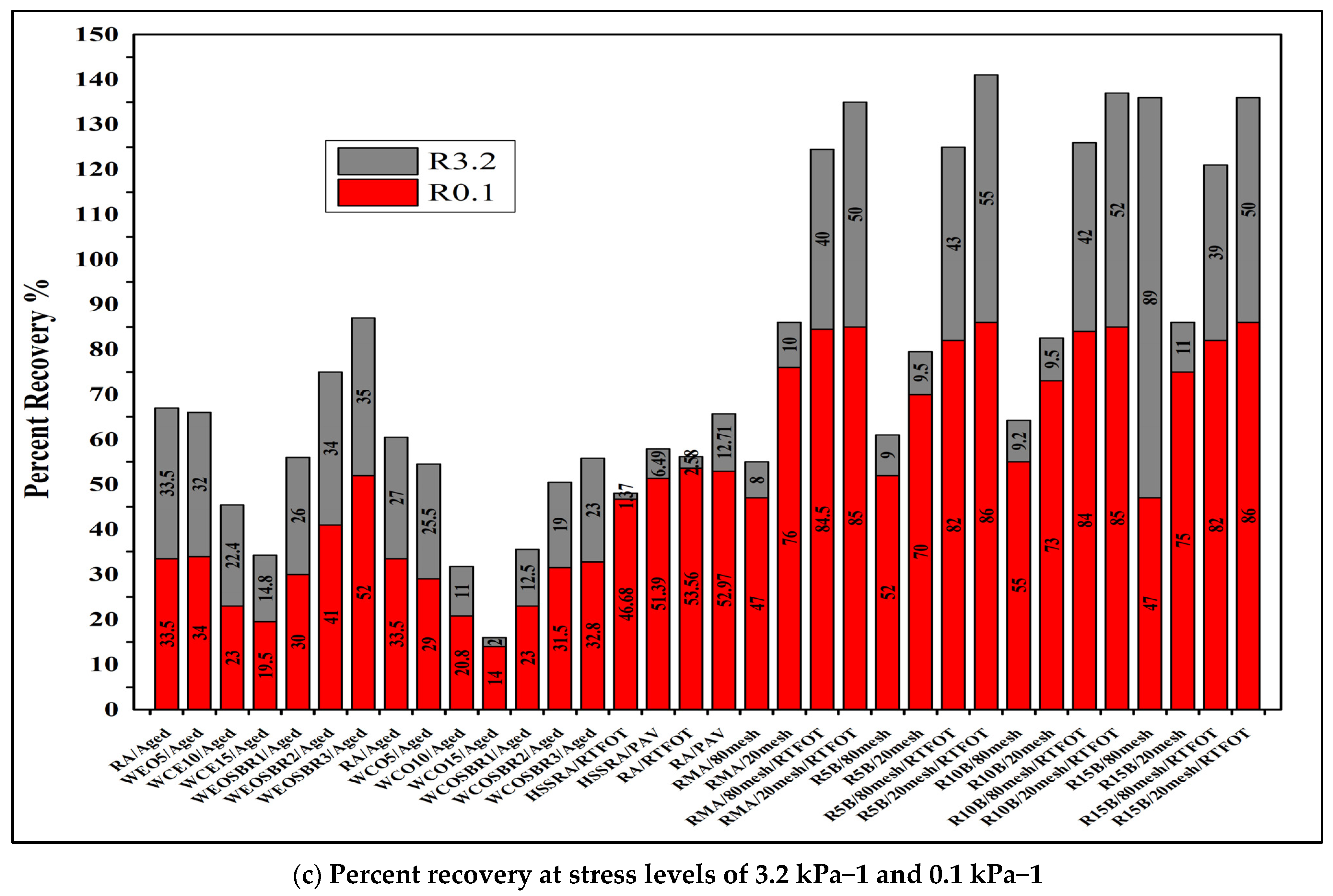

5.3. Effect of Waste Oils on Anti-Permanent Deformation Capability of Rejuvenated Asphalt

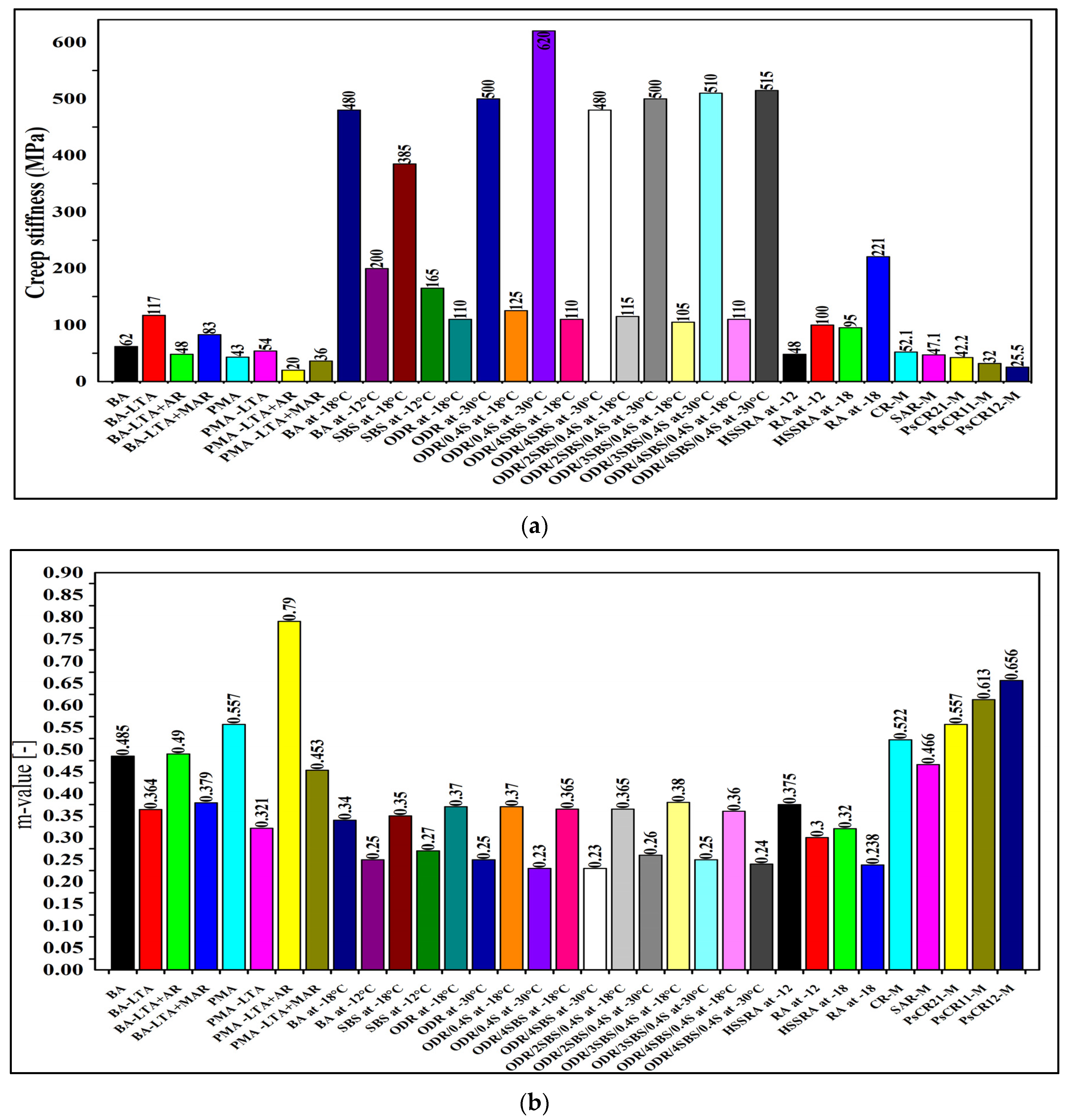

5.4. Effect of Waste Oils on Low-Temperature Properties of Rejuvenated Asphalt

5.5. Effect of Waste Oils on Aging Resistant

5.6. Effect of Waste Oils on Storage Stability of Rejuvenated Asphalt

5.7. Effect of Waste Oils on Compatibility and Morphology of Rejuvenated Asphalt

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Siddique, R.; Naik, T.R. Properties of concrete containing scrap-tire rubber—An overview. Waste Manag. 2004, 24, 563–569. [Google Scholar] [CrossRef] [PubMed]

- Shen, W.; Shan, L.; Zhang, T.; Ma, H.; Cai, Z.; Shi, H. Investigation on polymer–rubber aggregate modified porous concrete. Constr. Build. Mater. 2013, 38, 667–674. [Google Scholar] [CrossRef]

- U.S. Tire Manufacturers Association 2017. U.S. Scrap Tire Management Summary about the U.S. Tire Manufacturers; U.S. Tire Manufacturers Association: Washington, DC, USA, 2018; pp. 1–20. [Google Scholar]

- Archibong, F.N.; Sanusi, O.M.; Médéric, P.; Aït Hocine, N. An overview on the recycling of waste ground tyre rubbers in thermoplastic matrices: Effect of added fillers. Resour. Conserv. Recycl. 2021, 175, 105894. [Google Scholar] [CrossRef]

- Vijayan, S.K.; Naveena Victor, M.; Sudharsanam, A.; Chinnaraj, V.K.; Nagarajan, V. Winterization studies of different vegetable oil biodiesel. Bioresour. Technol. Rep. 2018, 1, 50–55. [Google Scholar] [CrossRef]

- De Feo, G.; Di Domenico, A.; Ferrara, C.; Abate, S.; Osseo, L.S. Evolution of waste cooking oil collection in an area with long-standing waste management problems. Sustainability 2020, 12, 8578. [Google Scholar] [CrossRef]

- PSD Online. Available online: https://apps.fas.usda.gov/psdonline/app/index.html#/app/downloads (accessed on 12 March 2021).

- Kulkarni, M.G.; Dalai, A.K. Waste Cooking OilAn Economical Source for Biodiesel: A Review. Ind. Eng. Chem. Res. 2006, 45, 2901–2913. [Google Scholar] [CrossRef]

- Kamilah, H.; Kumar, S.; Ay, T. The Management of Waste Cooking Oil: A Preliminary Survey. Health Environ. J. 2013, 4, 76–81. [Google Scholar]

- Peralta, J.; Silva, H.M.R.D.; Machado, A.V.; Pais, J.; Pereira, P.A.A.; Sousa, J.B. Changes in rubber due to its interaction with bitumen when producing asphalt rubber. Road Mater. Pavement Des. 2010, 11, 1009–1031. [Google Scholar] [CrossRef]

- Chavez, F.; Marcobal, J.; Gallego, J. Laboratory evaluation of the mechanical properties of asphalt mixtures with rubber incorporated by the wet, dry, and semi-wet process. Constr. Build. Mater. 2019, 205, 164–174. [Google Scholar] [CrossRef]

- Razmi, A.; Mirsayar, M.M. Fracture resistance of asphalt concrete modified with crumb rubber at low temperatures. Int. J. Pavement Res. Technol. 2018, 11, 265–273. [Google Scholar] [CrossRef]

- Chiu, C.T.; Lu, L.C. A laboratory study on stone matrix asphalt using ground tire rubber. Constr. Build. Mater. 2007, 21, 1027–1033. [Google Scholar] [CrossRef]

- Oliveira, J.R.M.; Silva, H.M.R.D.; Abreu, L.P.F.; Fernandes, S.R.M. Use of a warm mix asphalt additive to reduce the production temperatures and to improve the performance of asphalt rubber mixtures. J. Clean. Prod. 2013, 41, 15–22. [Google Scholar] [CrossRef]

- Ng Puga, K.L.N.; Williams, R.C. Low temperature performance of laboratory produced asphalt rubber (AR) mixes containing polyoctenamer. Constr. Build. Mater. 2016, 112, 1046–1053. [Google Scholar] [CrossRef]

- Moreno, F.; Sol, M.; Martín, J.; Pérez, M.; Rubio, M.C. The effect of crumb rubber modifier on the resistance of asphalt mixes to plastic deformation. Mater. Des. 2013, 47, 274–280. [Google Scholar] [CrossRef]

- Wang, T.; Xiao, F.; Amirkhanian, S.; Huang, W.; Zheng, M. A review on low temperature performances of rubberized asphalt materials. Constr. Build. Mater. 2017, 145, 483–505. [Google Scholar] [CrossRef]

- Han, L.; Zheng, M.; Wang, C. Current status and development of terminal blend tyre rubber modified asphalt. Constr. Build. Mater. 2016, 128, 399–409. [Google Scholar] [CrossRef]

- Feiteira Dias, J.L.; Picado-Santos, L.G.; Capitão, S.D. Mechanical performance of dry process fine crumb rubber asphalt mixtures placed on the Portuguese road network. Constr. Build. Mater. 2014, 73, 247–254. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Zhou, H.; Holikatti, S.; Vacura, P. Caltrans use of scrap tires in asphalt rubber products: A comprehensive review. J. Traffic Transp. Eng. 2014, 1, 39–48. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Review of warm mix rubberized asphalt concrete: Towards a sustainable paving technology. J. Clean. Prod. 2018, 177, 302–314. [Google Scholar] [CrossRef]

- Katman, H.Y.; Ibrahim, M.R.; Karim, M.R.; Koting, S.; Mashaan, N.S. Effect of Rubberized Bitumen Blending Methods on Permanent Deformation of SMA Rubberized Asphalt Mixtures. Adv. Mater. Sci. Eng. 2016, 2016, 4395063. [Google Scholar] [CrossRef]

- Dantas Neto, S.A.; Farias, M.M.; Pais, J.C.; Pereira, P.A.A.; Sousa, J.B. Influence of crumb rubber and digestion time on the asphalt rubber binders. Road Mater. Pavement Des. 2006, 7, 131–148. [Google Scholar] [CrossRef]

- Kök, B.V.; Çolak, H. Laboratory comparison of the crumb-rubber and SBS modified bitumen and hot mix asphalt. Constr. Build. Mater. 2011, 25, 3204–3212. [Google Scholar] [CrossRef]

- Majidifard, H.; Tabatabaee, N.; Buttlar, W. Investigating short-term and long-term binder performance of high-RAP mixtures containing waste cooking oil. J. Traffic Transp. Eng. 2019, 6, 396–406. [Google Scholar] [CrossRef]

- Elahi, Z.; Jakarni, F.M.; Muniandy, R.; Hassim, S.; Ab Razak, M.S.; Ansari, A.H.; Ben Zair, M.M. Waste cooking oil as a sustainable bio modifier for asphalt modification: A review. Sustainability 2021, 13, 11506. [Google Scholar] [CrossRef]

- Chen, Y.; Lopp, G.; Roque, R. Effects of an Asphalt Rubber Membrane Interlayer on Pavement Reflective Cracking Performance. J. Mater. Civ. Eng. 2013, 25, 1936–1940. [Google Scholar] [CrossRef]

- Lo Presti, D.; Airey, G. Tyre rubber-modified bitumens development: The effect of varying processing conditions. Road Mater. Pavement Des. 2013, 14, 888–900. [Google Scholar] [CrossRef]

- De Mello, L.G.R.; de Farias, M.M.; Kaloush, K.E. Effect of temperature on fatigue tests parameters for conventional and asphalt rubber mixes. Road Mater. Pavement Des. 2018, 19, 417–430. [Google Scholar] [CrossRef]

- Venudharan, V.; Biligiri, K.P.; Sousa, J.B.; Way, G.B. Asphalt-rubber gap-graded mixture design practices: A state-of-the-art research review and future perspective. Road Mater. Pavement Des. 2017, 18, 730–752. [Google Scholar] [CrossRef]

- Da Silva, L.; Benta, A.; Picado-Santos, L. Asphalt rubber concrete fabricated by the dry process: Laboratory assessment of resistance against reflection cracking. Constr. Build. Mater. 2018, 160, 539–550. [Google Scholar] [CrossRef]

- Wang, S.; Cheng, D.; Xiao, F. Recent developments in the application of chemical approaches to rubberized asphalt. Constr. Build. Mater. 2017, 131, 101–113. [Google Scholar] [CrossRef]

- Saberi K, F.; Fakhri, M.; Azami, A. Evaluation of warm mix asphalt mixtures containing reclaimed asphalt pavement and crumb rubber. J. Clean. Prod. 2017, 165, 1125–1132. [Google Scholar] [CrossRef]

- Zargar, M.; Ahmadinia, E.; Asli, H.; Karim, M.R. Investigation of the possibility of using waste cooking oil as a rejuvenating agent for aged bitumen. J. Hazard. Mater. 2012, 233–234, 254–258. [Google Scholar] [CrossRef] [PubMed]

- Azahar, W.N.A.W.; Jaya, R.P.; Hainin, M.R.; Bujang, M.; Ngadi, N. Mechanical performance of asphaltic concrete incorporating untreated and treated waste cooking oil. Constr. Build. Mater. 2017, 150, 653–663. [Google Scholar] [CrossRef]

- Grover Allen, R.; Little, D.N.; Bhasin, A.; Glover, C.J. The effects of chemical composition on asphalt microstructure and their association to pavement performance. Int. J. Pavement Eng. 2014, 15, 9–22. [Google Scholar] [CrossRef]

- Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Singh, D.; Girimath, S. Investigation of rheological properties and Superpave PG of PMB mixed with reclaimed asphalt pavement binders. Constr. Build. Mater. 2016, 126, 834–842. [Google Scholar] [CrossRef]

- Cao, X.; Wang, H.; Cao, X.; Sun, W.; Zhu, H.; Tang, B. Investigation of rheological and chemical properties asphalt binder rejuvenated with waste vegetable oil. Constr. Build. Mater. 2018, 180, 455–463. [Google Scholar] [CrossRef]

- Gong, M.; Yang, J.; Zhang, J.; Zhu, H.; Tong, T. Physical-chemical properties of aged asphalt rejuvenated by bio-oil derived from biodiesel residue. Constr. Build. Mater. 2016, 105, 35–45. [Google Scholar] [CrossRef]

- Yu, X.; Zaumanis, M.; Dos Santos, S.; Poulikakos, L.D. Rheological, microscopic, and chemical characterization of the rejuvenating effect on asphalt binders. Fuel 2014, 135, 162–171. [Google Scholar] [CrossRef]

- Chen, M.; Leng, B.; Wu, S.; Sang, Y. Physical, chemical and rheological properties of waste edible vegetable oil rejuvenated asphalt binders. Constr. Build. Mater. 2014, 66, 286–298. [Google Scholar] [CrossRef]

- Azahar, W.N.A.W.; Jaya, R.P.; Hainin, M.R.; Bujang, M.; Ngadi, N. Chemical modification of waste cooking oil to improve the physical and rheological properties of asphalt binder. Constr. Build. Mater. 2016, 126, 218–226. [Google Scholar] [CrossRef]

- Asli, H.; Ahmadinia, E.; Zargar, M.; Karim, M.R. Investigation on physical properties of waste cooking oil—Rejuvenated bitumen binder. Constr. Build. Mater. 2012, 37, 398–405. [Google Scholar] [CrossRef]

- Yu, J.; Ren, Z.; Gao, Z.; Wu, Q.; Zhu, Z.; Yu, H. Recycled heavy bio oil as performance enhancer for rubberized bituminous binders. Polymers 2019, 11, 800. [Google Scholar] [CrossRef]

- Qiu, Y.; Ding, H.; Rahman, A.; Wang, W. Damage characteristics of waste engine oil bottom rejuvenated asphalt binder in the non-linear range and its microstructure. Constr. Build. Mater. 2018, 174, 202–209. [Google Scholar] [CrossRef]

- Peng, C.; Guo, C.; You, Z.; Xu, F.; Ma, W.; You, L.; Li, T.; Zhou, L.; Huang, S.; Ma, H.; et al. The effect of waste engine oil and waste polyethylene on UV aging resistance of asphalt. Polymers 2020, 12, 602. [Google Scholar] [CrossRef]

- Qurashi, I.A.; Swamy, A.K. Viscoelastic properties of recycled asphalt binder containing waste engine oil. J. Clean. Prod. 2018, 182, 992–1000. [Google Scholar] [CrossRef]

- Liu, S.; Peng, A.; Wu, J.; Zhou, S.B. Waste engine oil influences on chemical and rheological properties of different asphalt binders. Constr. Build. Mater. 2018, 191, 1210–1220. [Google Scholar] [CrossRef]

- Liu, S.; Peng, A.; Zhou, S.; Wu, J.; Xuan, W.; Liu, W. Evaluation of the ageing behaviour of waste engine oil-modified asphalt binders. Constr. Build. Mater. 2019, 223, 394–408. [Google Scholar] [CrossRef]

- Jia, X.; Huang, B.; Bowers, B.F.; Zhao, S. Infrared spectra and rheological properties of asphalt cement containing waste engine oil residues. Constr. Build. Mater. 2014, 50, 683–691. [Google Scholar] [CrossRef]

- Hong, W.; Mo, L.; Pan, C.; Riara, M.; Wei, M.; Zhang, J. Investigation of rejuvenation and modification of aged asphalt binders by using aromatic oil-SBS polymer blend. Constr. Build. Mater. 2020, 231, 117154. [Google Scholar] [CrossRef]

- Kamoto, N.; Govha, J.; Danha, G.; Mamvura, T.; Muzenda, E. Production of modified bitumen from used engine oil, coal tar and waste tyre for construction applications. S. Afr. J. Chem. Eng. 2020, 33, 67–73. [Google Scholar] [CrossRef]

- Joni, H.H.; Al-Rubaee, R.H.A.; Al-zerkani, M.A. Rejuvenation of aged asphalt binder extracted from reclaimed asphalt pavement using waste vegetable and engine oils. Case Stud. Constr. Mater. 2019, 11, e00279. [Google Scholar] [CrossRef]

- Xu, P.; Gao, J.; Pei, J.; Chen, Z.; Zhang, J.; Li, R. Research on highly dissolved rubber asphalt prepared using a composite waste engine oil addition and microwave desulfurization method. Constr. Build. Mater. 2021, 282, 122641. [Google Scholar] [CrossRef]

- Mohd Hasan, M.R.; Chew, J.W.; Jamshidi, A.; Yang, X.; Hamzah, M.O. Review of sustainability, pretreatment, and engineering considerations of asphalt modifiers from the industrial solid wastes. J. Traffic Transp. Eng. 2019, 6, 209–244. [Google Scholar] [CrossRef]

- Lv, S.; Liu, J.; Peng, X.; Liu, H.; Hu, L.; Yuan, J.; Wang, J. Rheological and microscopic characteristics of bio-oil recycled asphalt. J. Clean. Prod. 2021, 295, 126449. [Google Scholar] [CrossRef]

- Zahoor, M.; Nizamuddin, S.; Madapusi, S.; Giustozzi, F. Sustainable asphalt rejuvenation using waste cooking oil: A comprehensive review. J. Clean. Prod. 2021, 278, 123304. [Google Scholar] [CrossRef]

- Zahoor, M.; Nizamuddin, S.; Madapusi, S.; Giustozzi, F. Recycling asphalt using waste bio-oil: A review of the production processes, properties and future perspectives. Process Saf. Environ. Prot. 2021, 147, 1135–1159. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Shen, P.J.; Arumdani, I.S.; Budihardjo, M.A.; Nikraz, H. The addition of a high dosage of rubber to asphalt mixtures: The effects on rutting and fatigue. Sustainability 2021, 13, 9718. [Google Scholar] [CrossRef]

- Dong, R.; Zhao, M. Research on the pyrolysis process of crumb tire rubber in waste cooking oil. Renew. Energy 2018, 125, 557–567. [Google Scholar] [CrossRef]

- Kabir, S.F.; Mousavi, M.; Fini, E.H. Selective adsorption of bio-oils’ molecules onto rubber surface and its effects on stability of rubberized asphalt. J. Clean. Prod. 2020, 252, 119856. [Google Scholar] [CrossRef]

- Yi, X.; Dong, R.; Zhao, M.; Shi, C.; Yang, J. The interaction mechanism and rejuvenation effect of crumb rubber and waste cooking oil blends. Constr. Build. Mater. 2021, 302, 124215. [Google Scholar] [CrossRef]

- Ma, J.; Hu, M.; Sun, D.; Lu, T.; Sun, G.; Ling, S.; Xu, L. Understanding the role of waste cooking oil residue during the preparation of rubber asphalt. Resour. Conserv. Recycl. 2020, 167, 105235. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Soltani, M.; Karim, M.R. Experimental Study on modified asphalt pavement by using waste. Constr. Build. Mater. 2017, 65, 141–146. [Google Scholar]

- Zhou, T.; Kabir, S.F.; Cao, L.; Luan, H.; Dong, Z.; Fini, E.H. Comparing effects of physisorption and chemisorption of bio-oil onto rubber particles in asphalt. J. Clean. Prod. 2020, 273, 123112. [Google Scholar] [CrossRef]

- Zhao, M.; Dong, R. Reaction mechanism and rheological properties of waste cooking oil pre-desulfurized crumb tire rubber/SBS composite modified asphalt. Constr. Build. Mater. 2021, 274, 122083. [Google Scholar] [CrossRef]

- Cao, W.; Wang, C. Fatigue performance characterization and prediction of asphalt binders using the linear amplitude sweep based viscoelastic continuum damage approach. Int. J. Fatigue 2019, 119, 112–125. [Google Scholar] [CrossRef]

- Jahanbakhsh, H.; Karimi, M.M.; Naseri, H.; Nejad, F.M. Sustainable asphalt concrete containing high reclaimed asphalt pavements and recycling agents: Performance assessment, cost analysis, and environmental impact. J. Clean. Prod. 2020, 244, 118837. [Google Scholar] [CrossRef]

- Zhao, M.; Dong, R.; Chi, Z.; Aljarmouzi, A.; Li, J. Effect of process variables on the chemical characteristics of crumb rubber desulfurized by waste cooking oil and its desulfurization mechanism. Constr. Build. Mater. 2021, 311, 125361. [Google Scholar] [CrossRef]

- Yang, H.; Dong, R. Investigating the properties of rejuvenated asphalt with the modified rejuvenator prepared by waste cooking oil and waste tire crumb rubber. Constr. Build. Mater. 2022, 315, 125692. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Fan, W.; Qian, C.; Nan, G.; Erkens, S. Investigating the effects of waste oil and styrene-butadiene rubber on restoring and improving the viscoelastic, compatibility, and aging properties of aged asphalt. Constr. Build. Mater. 2020, 269, 121338. [Google Scholar] [CrossRef]

- Fernandes, S.R.M.; Silva, H.M.R.D.; Oliveira, J.R.M. Developing enhanced modified bitumens with waste engine oil products combined with polymers. Constr. Build. Mater. 2018, 160, 714–724. [Google Scholar] [CrossRef]

- Fernandes, S.R.M.; Silva, H.M.R.D.; Oliveira, J.R.M. Recycled stone mastic asphalt mixtures incorporating high rates of waste materials. Constr. Build. Mater. 2018, 187, 1–13. [Google Scholar] [CrossRef]

- Dong, R.; Zhao, M.; Tang, N. Characterization of crumb tire rubber lightly pyrolyzed in waste cooking oil and the properties of its modified bitumen. Constr. Build. Mater. 2019, 195, 10–18. [Google Scholar] [CrossRef]

- Yin, J.; Wang, S.; Lv, F. Improving the short-term aging resistance of asphalt by addition of crumb rubber radiated by microwave and impregnated in epoxidized soybean oil. Constr. Build. Mater. 2013, 49, 712–719. [Google Scholar] [CrossRef]

- Rahman, M.T.; Hainin, M.R.; Bakar, W.A.W.A. Use of waste cooking oil, tire rubber powder and palm oil fuel ash in partial replacement of bitumen. Constr. Build. Mater. 2017, 150, 95–104. [Google Scholar] [CrossRef]

- Ma, J.; Sun, G.; Sun, D.; Zhang, Y.; Cannone Falchetto, A.; Lu, T.; Hu, M.; Yuan, Y. Rubber asphalt modified with waste cooking oil residue: Optimized preparation, rheological property, storage stability and aging characteristic. Constr. Build. Mater. 2020, 258, 120372. [Google Scholar] [CrossRef]

- Duan, S.; Muhammad, Y.; Li, J.; Maria, S.; Meng, F.; Wei, Y.; Su, Z.; Yang, H. Enhancing effect of microalgae biodiesel incorporation on the performance of crumb Rubber/SBS modified asphalt. J. Clean. Prod. 2019, 237, 117725. [Google Scholar] [CrossRef]

- Lei, Y.; Wang, H.; Fini, E.H.; You, Z.; Yang, X.; Gao, J.; Dong, S.; Jiang, G. Evaluation of the effect of bio-oil on the high-temperature performance of rubber modified asphalt. Constr. Build. Mater. 2018, 191, 692–701. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, F.; Yuan, X.; Kuang, M.; Song, Y.; Li, C. Usage of slurry oil for the preparation of crumb-rubber-modified asphalt emulsions. Constr. Build. Mater. 2015, 76, 279–285. [Google Scholar] [CrossRef]

- Mansourkhaki, A.; Ameri, M.; Habibpour, M.; Shane Underwood, B. Relations between colloidal indices and low-temperature properties of reclaimed binder modified with softer binder, oil-rejuvenator and polybutadiene rubber. Constr. Build. Mater. 2020, 239, 117800. [Google Scholar] [CrossRef]

- Lei, Y.; Wei, Z.; Wang, H.; You, Z.; Yang, X.; Chen, Y. Effect of crumb rubber size on the performance of rubberized asphalt with bio-oil pretreatment. Constr. Build. Mater. 2021, 285, 122864. [Google Scholar] [CrossRef]

- Yi, X.; Dong, R.; Tang, N. Development of a novel binder rejuvenator composed by waste cooking oil and crumb tire rubber. Constr. Build. Mater. 2020, 236, 117621. [Google Scholar] [CrossRef]

- Zhao, M. Interaction Mechanism and Rheological Properties Investigation of Waste Cooking Oil Pre-Desulfurized Crumb Tire Rubber Modified Asphalt 2. Ph.D. Thesis, Chongqing University, Chongqing, China, 2019. [Google Scholar]

- Dong, R.; Zhao, M.; Xia, W.; Yi, X.; Dai, P.; Tang, N. Chemical and microscopic investigation of co-pyrolysis of crumb tire rubber with waste cooking oil at mild temperature. Waste Manag. 2018, 79, 516–525. [Google Scholar] [CrossRef]

- Arabiourrutia, M.; Lopez, G.; Artetxe, M.; Alvarez, J.; Bilbao, J.; Olazar, M. Waste tyre valorization by catalytic pyrolysis—A review. Renew. Sustain. Energy Rev. 2020, 129, 109932. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Saputra, R.; Walvekar, R.; Khalid, M.; Mubarak, N.M.; Sillanpää, M. Current progress in waste tire rubber devulcanization. Chemosphere 2021, 265, 129033. [Google Scholar] [CrossRef]

- Picado-Santos, L.G.; Capitão, S.D.; Neves, J.M.C. Crumb rubber asphalt mixtures: A literature review. Constr. Build. Mater. 2020, 247, 118577. [Google Scholar] [CrossRef]

- Zareh, G.W.A. Asphalt-rubber 40 years of use in Arizona. In Proceedings of the Asphalt Rubber 2009 Conference, Nanjing, China, 2–4 November 2009. [Google Scholar]

- Kabir, S.F.; Zheng, R.; Delgado, A.G.; Fini, E.H. Use of microbially desulfurized rubber to produce sustainable rubberized bitumen. Resour. Conserv. Recycl. 2021, 164, 105144. [Google Scholar] [CrossRef]

- Asaro, L.; Gratton, M.; Seghar, S.; Aït Hocine, N. Recycling of rubber wastes by devulcanization. Resour. Conserv. Recycl. 2018, 133, 250–262. [Google Scholar] [CrossRef]

- Blumenthal, M. Scrap Tire Market in the United States: An Update. In Proceedings of the Rubber Manufacturers Association Border Meeting, Nogales, AZ, USA, 13 December 2012. [Google Scholar]

- De, S.; Isayev, A.I.; Khait, K. Rubber Recycling; CRC (Tylor& Francis): Boca Raton, FL, USA, 2002. [Google Scholar]

- Thomas, B.S.; Gupta, R.C. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Li, Y.; Shen, A.; Lyu, Z.; Wang, S.; Formela, K.; Zhang, G. Ground tire rubber thermo-mechanically devulcanized in the presence of waste engine oil as asphalt modifier. Constr. Build. Mater. 2019, 222, 588–600. [Google Scholar] [CrossRef]

- Ahmed, N.; Zeeshan, M.; Iqbal, N.; Farooq, M.Z.; Shah, S.A. Investigation on bio-oil yield and quality with scrap tire addition in sugarcane bagasse pyrolysis. J. Clean. Prod. 2018, 196, 927–934. [Google Scholar] [CrossRef]

- Ge, D.; Yan, K.; You, Z.; Xu, H. Modification mechanism of asphalt binder with waste tire rubber and recycled polyethylene. Constr. Build. Mater. 2016, 126, 66–76. [Google Scholar] [CrossRef]

- Ameri, M.; Mansourkhaki, A.; Daryaee, D. Evaluation of fatigue behavior of high reclaimed asphalt binder mixes modified with rejuvenator and softer bitumen. Constr. Build. Mater. 2018, 191, 702–712. [Google Scholar] [CrossRef]

- Liu, J.; Hao, P.; Dou, Z.; Wang, J.; Ma, L. Rheological, healing and microstructural properties of unmodified and crumb rubber modified asphalt incorporated with graphene/carbon black composite. Constr. Build. Mater. 2021, 305, 124512. [Google Scholar] [CrossRef]

- Hidayah, N.; Rosli, M.; Ezree, M. A Short Review of Waste Oil Application in Pavement Materials. In Proceedings of the 9th International Conference of Geotechnical & Transportation Engineering (GEOTROPIKA) and The 1st International Conference on Construction and Building Engineering (ICONBUILD)—GEOCON2013, Johor Bahru, Malaysia, 28 October 2013. [Google Scholar]

- Choe, E.; Min, D.B. Chemistry of deep-fat frying oils. J. Food Sci. 2007, 5, 72. [Google Scholar] [CrossRef]

- Azahar, W.N.A.W.; Bujang, M.; Jaya, R.P.; Hainin, M.R.; Ngadi, N.; Abdullah, M.E.; Mohamed, A.A. A review on application of waste cooking oil as rejuvenator in porous asphalt mixture. J. Teknol. 2016, 78, 105–109. [Google Scholar] [CrossRef][Green Version]

- Luo, W.; Zhang, Y.; Cong, P. Investigation on physical and high temperature rheology properties of asphalt binder adding waste oil and polymers. Constr. Build. Mater. 2017, 144, 13–24. [Google Scholar] [CrossRef]

- Rodrigues, C.; Capitão, S.; Picado-Santos, L.; Almeida, A. Full recycling of asphalt concrete with waste cooking oil as rejuvenator and LDPE from urban waste as binder modifier. Sustainability 2020, 12, 8222. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, M.; Wu, S.; Liu, J.; Amirkhanian, S. Analysis of the relationships between waste cooking oil qualities and rejuvenated asphalt properties. Materials 2017, 10, 508. [Google Scholar] [CrossRef] [PubMed]

- Wen, H.; Bhusal, S.; Wen, B. Laboratory Evaluation of Waste Cooking Oil-Based Bioasphalt as an Alternative Binder for Hot Mix Asphalt. J. Mater. Civ. Eng. 2013, 25, 1432–1437. [Google Scholar] [CrossRef]

- Kipkorir, D.; Nturanabo, F.; Tewo, R.; Rutto, H.; Enweremadu, C. Properties of waste-distilled engine oil and biodiesel ternary blends. Heliyon 2021, 7, e07858. [Google Scholar] [CrossRef] [PubMed]

- Ben Hassen-Trabelsi, A.; Kraiem, T.; Naoui, S.; Belayouni, H. Pyrolysis of waste animal fats in a fixed-bed reactor: Production and characterization of bio-oil and bio-char. Waste Manag. 2014, 34, 210–218. [Google Scholar] [CrossRef]

- Provenzano, M.R.; Malerba, A.D.; Pezzolla, D.; Gigliotti, G. Chemical and spectroscopic characterization of organic matter during the anaerobic digestion and successive composting of pig slurry. Waste Manag. 2014, 34, 653–660. [Google Scholar] [CrossRef]

- Liu, H.; Chen, Z.; Wang, W.; Wang, H.; Hao, P. Investigation of the rheological modification mechanism of crumb rubber modified asphalt (CRMA) containing TOR additive. Constr. Build. Mater. 2014, 67, 225–233. [Google Scholar] [CrossRef]

- Li, L.; Xin, C.; Guan, M.; Guo, M. Using molecular dynamics simulation to analyze the feasibility of using waste cooking oil as an alternative rejuvenator for aged asphalt. Sustainability 2021, 13, 4373. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, H.; Chen, Z. Improvement of short-term aging resistance of styrene-butadiene rubber modified asphalt by Sasobit and epoxidized soybean oil. Constr. Build. Mater. 2021, 271, 121870. [Google Scholar] [CrossRef]

- Kim, K.W.; Kim, K.; Doh, Y.S.; Amirkhanian, S.N. Estimation of RAP’s Binder Viscosity Using GPC without Binder Recovery. J. Mater. Civ. Eng. 2006, 18, 561–567. [Google Scholar] [CrossRef]

- Tang, N.; Huang, W.; Xiao, F. Chemical and rheological investigation of high-cured crumb rubber-modified asphalt. Constr. Build. Mater. 2016, 123, 847–854. [Google Scholar] [CrossRef]

- Zhong, L.; Zhang, Y.; Wang, T.; Ji, Y.; Norris, P.; Pan, W.P. Optimized methods for preparing activated carbon from rock asphalt using orthogonal experimental design. J. Therm. Anal. Calorim. 2019, 136, 1989–1999. [Google Scholar] [CrossRef]

- Baeta, D.A.; Zattera, J.A.; Oliveira, M.G.; Oliveira, P.J. The use of styrene-butadiene rubber waste as a potential filler in nitrile rubber: Order of addition and size of waste particles. Braz. J. Chem. Eng. 2009, 26, 23–31. [Google Scholar] [CrossRef]

- Li, H.; Dong, B.; Wang, W.; Zhao, G.; Guo, P.; Ma, Q. Effect of waste engine oil and waste cooking oil on performance improvement of aged asphalt. Appl. Sci. 2019, 9, 1767. [Google Scholar] [CrossRef]

- Compass, ASTM D7175-15 ASTM. Available online: www.astm.org (accessed on 16 March 2021).

- Li, J.; Chen, Z.; Xiao, F.; Amirkhanian, S.N. Surface activation of scrap tire crumb rubber to improve compatibility of rubberized asphalt. Resour. Conserv. Recycl. 2021, 169, 105518. [Google Scholar] [CrossRef]

| Test Items | Unit | Test Result | Technical Requirement |

|---|---|---|---|

| Ash | % | 7.39 | ≤8 |

| Acetone extract | % | 8.98 | ≤16 |

| Carbon black | % | 30.22 | ≥28 |

| Rubber hydrocarbon | % | 53.42 | ≥48 |

| Carbon C | % | 72.52 | - |

| oxygen O | % | 10.68 | - |

| Nitrogen N | % | 3.58 | - |

| Silicone Si | % | 1.84 | - |

| Sulfur S | % | 1.61 | - |

| Metal element | % | 9.76 | - |

| Performance | Actual Waste Cooking Oil | Waste Rapeseed Oil | Waste Soybean Oil | |

|---|---|---|---|---|

| Physical properties | Acid value (mg(KOH)/g) | 0.7 | 6.4 | 2.0 |

| Flash point (°C) | 304 | 298 | 301 | |

| Tetradecanic acid (wt%) | 1.41 | - | - | |

| Hexadecenoic acid (wt%) | 1.34 | 0.49 | 0.71 | |

| Fatty acid composition | Hexadecenoic acid (wt%) | 17.04 | 5.38 | 10.04 |

| Octadecenoic acid (wt%) | 80.21 | 90.98 | 88.36 | |

| Seventeen carbonic acids (wt%) | - | 3.15 | 0.69 | |

| Total Fatty Acids | Saturated fatty acid (wt%) | 18.45 | 8.53 | 10.93 |

| Unsaturated fatty acid (wt%) | 81.55 | 91.47 | 89.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aljarmouzi, A.; Dong, R. Sustainable Asphalt Rejuvenation by Using Waste Tire Rubber Mixed with Waste Oils. Sustainability 2022, 14, 8246. https://doi.org/10.3390/su14148246

Aljarmouzi A, Dong R. Sustainable Asphalt Rejuvenation by Using Waste Tire Rubber Mixed with Waste Oils. Sustainability. 2022; 14(14):8246. https://doi.org/10.3390/su14148246

Chicago/Turabian StyleAljarmouzi, Ashraf, and Ruikun Dong. 2022. "Sustainable Asphalt Rejuvenation by Using Waste Tire Rubber Mixed with Waste Oils" Sustainability 14, no. 14: 8246. https://doi.org/10.3390/su14148246

APA StyleAljarmouzi, A., & Dong, R. (2022). Sustainable Asphalt Rejuvenation by Using Waste Tire Rubber Mixed with Waste Oils. Sustainability, 14(14), 8246. https://doi.org/10.3390/su14148246