1. Introduction

The energy supply to charge electric vehicles plays a vital role in sustainability with the large-scale introduction of electric vehicles (EV). Electric mobility contributes directly to reducing greenhouse gases, noise, and visual pollution compared to traditional mobility. Human mobility plays a vital role in the development and growth of society; on the contrary, with classic mobility, the environmental cost becomes severe and unfavorable for future generations due to the current climate change [

1].

In this sense, replacing fuel-based vehicles with battery-electric vehicles arises, with deployment being a challenging issue. Proper planning is required to locate the correct number of charging stations (CS) in optimal locations. Different methods have been proposed to identify and size CS without considering factors such as traffic flow, road networks, structures, capacity constants, and geographical considerations. For this reason, to choose candidate sites for the optimization process, conventional gas stations (fossil fuels), bus stops, and parking lots are considered [

2].

Through a literature review,

Table 1 is elaborated, and three criteria for the location of CS can be observed, among which include: model, approach, and trajectory. This article addresses the design methodologies for CS for EV and details the technical considerations based on international standards.

The current progress in the number of scientific articles published shows the high contemporary relevance. Part of the existing publications and research projects studies trends and challenges, such as the reduced charging infrastructure, as a limiting factor in achieving greater EV market integration. Much of the literature presents various strategies for localizing CS. From there, several authors raise the questions of where the CS should be located within a given area, the number, and what type of CS should be installed [

3]. Industry standards raise some aspects of electric vehicle CS, but some features may be standard or optional so these stations may vary by vehicle model and manufacturer. Understanding the different elements of CS will help choose the best application option [

4].

Through a bibliometric analysis, this article aims to establish and design a charging infrastructure for electric vehicles considering bibliometric study (Web of Science and Scopus) and regulations based on the electrical code for incorporation into an intelligent grid. Therefore, two objectives are proposed: the first is to identify design methodologies for electric vehicle charging stations. The second objective is to detail the technical considerations for the design of charging stations for electric cars from international standards based on the electrical code.

Figure 1 shows the importance of designing a charging infrastructure for an EV; in the first instance, prior knowledge of the regulations must be established at all design stages. When referring to rules, emphasize the design’s international standards, from terminology to charging, battery, safety and security, communication, and quality.

This article is organized as follows: the work related to the research is described in

Section 2. The problem formulation is presented in

Section 3. The analysis of the results is provided in

Section 4. Finally, some conclusions are given in

Section 5.

2. Related Works

The gradual, orderly, and planned deployment of electric vehicle charging centers is part of the smart grid concept and facilitates the system’s efficiency, reliability, and resilience [

1,

5]. In addition, contemplate other stages such as the smart metering of electric energy, the communications system to send information from electric meters [

6,

7], the allocation of communication channels, and the behavior of the electricity consumption pattern until reaching the demand response that leads to the objective of reducing energy losses.

Whether technical or regulatory considerations require a charging station for electric vehicles, the need arises to know the location of charging stations to facilitate long-distance travel and meet urban demands. Therefore, the types of charging market and the main variables, such as travel behavior and electric vehicle characteristics, and how it influences assessing demand or the quality of time spent setting, are determined.

The demand for charging stations may be due to population growth, increasing per capita gross domestic product (GDP). Growing demand generally requires additional costs, e.g., investment, operating, and maintenance costs. Using the city of Shanghai as an example, the demanding times to charge and wait at each existing charging station are estimated; the result shows that the probability of drivers charging at public stations is 39.6.

The use of renewable energy sources such as solar power is more widespread due to the falling cost of photovoltaic (PV) panels. The rationale is to maximize PV use for electric vehicle charging with minimal energy exchange with the grid. Industrial sites and office buildings in the Netherlands harbor the excellent potential for PV panels with their large area on flat roofs. Solar-powered on-site charging of electric vehicles provides a sustainable gateway for transportation in the future [

8].

Modeling electric vehicle charging fleets provides insight into electric vehicle charging capacity and the potential for electric vehicle demand response in power systems. The approach allows for simulating assessing profiles and finding how many chargers are needed to meet the approximate electric vehicle charging demand from traffic characteristics such as arrival time, charging duration, and maximum charging power. One of the main obstacles in modeling future scenarios is the uncertainty in the behavioral patterns of electric vehicle owners [

9].

Building public charging stations is not enough; due to the expected increase in electric vehicles, owners will require parking and charging convenience similar to owners’ garages or private parking spaces. Sharing seems to be an innovative and simple solution to ensure many charging stations for electric cars. Charging electric vehicles with energy-efficient chargers contributes to the efficient use of the transformer station potential; by reserving parking spaces in a parking garage during evening hours, it is possible to achieve efficiency of their service and simultaneously create charging conditions and a price per kWh comparable to home charging [

10,

11].

As an essential part of planning for integrating electric vehicles in smart cities, considering the long charging time of electric cars, there will be congestion during peak periods and idle equipment during off-peak periods. Taking the case of Chengdu, China, the results show that the introduction of a backup service can not only reduce the total social cost but also reduce the waiting time of users, resulting in increased convenience for customers and reduced waiting times at charging stations [

12,

13].

In [

14], it proposes a model with a novel formulation to design and manage electric vehicle charging stations, considering both long-term planning decisions and short-term operational decisions in a pre-specified planning horizon and under stochastic energy demand. In the model, the electricity demand at the charging station from four different energy sources can be supplied: (i) direct from the grid; (ii) batteries stored at the charging stations; (iii) renewable (e.g., solar energy); and power discharge from electric vehicles to the grid through V2G connection capabilities.

Major entities must adopt commercial models for solar-powered charging stations (SPCE) to address the current electric vehicle charging infrastructure. These SPCEs should be located in parking lots to produce electricity for the grid and provide an integrated infrastructure for charging electric cars. In addition, the charging infrastructure should be integrated with existing physical infrastructure, such as shopping malls and workplaces, to allow drivers to charge their vehicles while performing other tasks [

15].

The best topology for electric vehicle routing decisions is achieved by looking at road capacity, vehicle flow, and spacing variables. The heuristics have proven to be scalable and have been validated through iterative processes to address contingency concepts for predicting peak vehicular traffic density in roadway networks [

1]. Therefore, the objective is to solve multiple resource allocation problems in a geo-referenced area of NP-hard computational complexity, supported by optimization tools, graph theory, and routing algorithms.

Proper planning of charging station sites and scales is critical to reducing adverse impacts and improving the quality of service for electric vehicles. Therefore, to capture real-world travel patterns of electric vehicles, large-scale cellular signaling data were collected and processed to generate travel demand in addition to daily trips. Through comparative analysis, charging station sites derived from the K-means approach provide better performance than other approaches in terms of the service area, scale, and assessing station accessibility [

16].

In 2015, the Thai government created technology-push policies to boost investment in the electric vehicle charging station business (such as subsidies for charging stations, setting a temporary selling price for electricity, and creating an electric vehicle charging consortium). As for the Thai competition landscape between 2015 and 2020, no single company can dominate the electric vehicle charging market. However, Energy Absolute seems to be the most active company that can expand the charging network to many places [

17].

In [

18], it proposes a novel model for the plug-in electric vehicle charging station planning problem by considering users’ daily trips. Aiming to minimize the total cost, including the cost of charging stations (including installation cost and management cost) and the cost of users (including station access cost and charging cost), the proposed model simultaneously handles the problems of where to locate the charging stations and how many chargers to be installed at each charging station.

Ref. [

19] presents an approach that integrates Geographic Information Systems (GIS) techniques and Multi-Criteria Decision Making (MCDM) methods. Moreover, the optimal site is selected among predetermined alternative locations using GIS techniques, and the appropriate places of charging stations are determined using semantic information and benefiting from the integration of spatial and semantic information.

In the location concept, as a starting point for the general idea, a methodology was developed based on theoretical concerns and stakeholder consultations. The approach included different work steps, starting with the locations’ planning, then elaborating technical and contractual requirement definitions for implementing the charging infrastructure and its integration into the overall traffic system. In addition, this approach uses empirical mobility data, traffic models, user groups, and usage patterns to indicate a spatial distribution of charging points in the city that matches the demand [

20].

Ref. [

21] presents the cloud model used first to predict the charging behavior of drivers; a charging station optimization model is proposed, which is based on waiting time; the objective of this optimization model is to minimize the time cost for electric vehicle drivers, and the SCE-UA algorithm is employed to solve the optimization model.

Electric vehicle drivers choose among charging stations according to various factors, including distance, charging rate, and queue conditions. In [

22], a behavioral model is first proposed to capture the decision-making of EV drivers in choosing charging stations, from which an optimal charging station location model is presented to minimize the social cost (defined as the congestion at charging stations suffered by all EV).

A heuristic methodology for urban transportation networks is presented in [

23], which considers the deployment of charging stations for coverage purposes and the fulfillment of user preferences and constraints as two separate processes. This methodology uses a reallocation algorithm to prioritize selecting locations of interest and reducing the number of stations with overlapping coverage areas. The method results are compared with those extracted from a greedy algorithm based on multi-path consideration in an extensive metropolitan transportation network.

The following

Table 1 was prepared through a literature review. Three criteria are observed to guide the sizing and implementation of charging stations for electric vehicles. Some authors consider models based on planning and optimization to locate a minimum number of charging stations to meet the needs of electric cars, as restrictions focus on vehicular traffic behavior through simulations to verify the impact it has on the proposed models. Several studies involve a proposal on the location of the charging station; however, the regulations for its design are not contemplated. Consequently, this work will contribute to a methodology for creating a charging station considering international standards.

Table 1.

Summary of articles related to the sizing and implementation of electric vehicle charging stations.

Table 1.

Summary of articles related to the sizing and implementation of electric vehicle charging stations.

| Scientific Article | Problem | Constraint | Proposal |

|---|

| Author | Planning | Optimization | Charging Time | Traffic | Autonomy | Electrical Network | Location | Design | Standards |

|---|

| Morán, 2022 [2] | | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() | | | ![Sustainability 14 08248 i001]() | | |

| Rajendran, 2021 [24] | | | | | | | | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() |

| Campaña, 2021 [1] | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() | | ![Sustainability 14 08248 i001]() | | ![Sustainability 14 08248 i001]() | | | |

| Luo, 2020 [12] | | | ![Sustainability 14 08248 i001]() | | | | ![Sustainability 14 08248 i001]() | | |

| Xiong, 2020 [22] | | ![Sustainability 14 08248 i001]() | | | | | ![Sustainability 14 08248 i001]() | | |

| Das, 2020 [25] | | | | | | ![Sustainability 14 08248 i001]() | | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() |

| Quddus, 2019 [14] | ![Sustainability 14 08248 i001]() | | | ![Sustainability 14 08248 i001]() | | ![Sustainability 14 08248 i001]() | | ![Sustainability 14 08248 i001]() | |

| Jia, 2019 [16] | | ![Sustainability 14 08248 i001]() | | ![Sustainability 14 08248 i001]() | | | ![Sustainability 14 08248 i001]() | | |

| Zhu, 2018 [18] | | ![Sustainability 14 08248 i001]() | | | | | ![Sustainability 14 08248 i001]() | | |

| Qiao, 2018 [26] | | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() | | | | ![Sustainability 14 08248 i001]() | | |

| Tian, 2018 [21] | | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() | | | | ![Sustainability 14 08248 i001]() | | |

| Csonka, 2017 [27] | ![Sustainability 14 08248 i001]() | | | ![Sustainability 14 08248 i001]() | | | ![Sustainability 14 08248 i001]() | | |

| Hardinghaus, 2016 [20] | ![Sustainability 14 08248 i001]() | | | ![Sustainability 14 08248 i001]() | | | ![Sustainability 14 08248 i001]() | | |

| Proposal Authors | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() | ![Sustainability 14 08248 i001]() |

2.1. Bibliometric Analysis

In recent years, the number of publications about CS and EV has grown dramatically; such is the case that a search in Scopus for the keywords “electric vehicle charging station” gives a total of 5719 articles as results for the period (2001–2021); similarly, a search in Web Of Science (WoS) for the keywords “electric vehicle charging station” gives a total of 2285 articles as results for the period (2001–2021). We used the VOSviewer software for the data analysis, which allows us to make a graphical representation of the papers with the highest impact from the bibliographic information. Consequently, VOSviewer creates a map that suggests the weight of each article and the distance between each one, defined by the degree of co-occurrence of terms. In addition, the larger the element’s size in the graph, the higher the frequency of occurrence in the literature investigated. The smaller the distance between one part and another, the higher the degree of co-occurrence.

With the information obtained from WoS,

Figure 2 and

Table 2 below show the countries’ participation according to the number of publications, and countries such as the People’s Republic of China, the United States, Canada, and England prevail. Additionally, China appears as the country with more publications and participation of 23%, followed by the USA with 18%, Canada with 4%, and England with 3%.

Figure 3 shows the leading institutions that have published scientific articles. At the top of the list is China, with three universities with the highest scientific production (Tsinghua, North China Electric Power, and Zhejiang), in fourth place in the USA (University of Berkeley), and fifth place in Australia (University of Sydney). These results indicate the importance of the research topic in Asia, particularly China.

Figure 4 shows the authors’ contributions’ according to the number of publications related to the keywords “electric vehicle charging station.” The authors that stand out the most are Zhang Hongcai, Hu Zechun, He Fang, and Song Yonghua, who belong to the University of Macau, Tsinghua University, Western University, and University of Macau institutions, respectively. This information strengthens the value of research on this topic in the Asian continent.

Similarly, the analysis is performed with the information obtained in Scopus.

Figure 5 below shows the countries’ participation according to the number of publications, where countries such as China have 24%. The United States has 15%, Canada with 4%, and the United Kingdom with 3% prevail. The publications by country are presented in

Table 3.

Figure 6 shows the leading institutions that have published scientific articles. Topping the list is China, with two institutions with the highest scientific production (State Grid Zhejiang Electric Power Company and Tsinghua University), in fourth and fifth place in Latvia (Institute of Physical Energetic).

Figure 7 shows the authors’ contributions’ according to the number of publications related to the keywords “electric vehicle charging station.” The authors that stand out the most are Zhang Yongjun (South China University of Technology), Zhang Jianhua (North China Electric Power University), Liu Hengchang (University of Science and Technology), and Liu Yujun (Southeast University). These results show the importance of the researched topic, particularly in China.

2.2. Electric Vehicle Charging Infrastructure Standards

There are many regulations about EV and their repercussions on society and transport users in the global environment. Generally, and thanks to the trend towards massification of transport in certain European territories, standards were developed and adopted to establish measures to ensure the safety of individuals and the proper handling of vehicle elements. Standardization concerning EV charging can be divided into three areas: standards for EV charging components (International Organization for Standardization (ISO)), criteria for EV grid integration (Institute of Electrical and Electronics Engineers (IEEE) and Underwriters Laboratories (UL)), and standards for safety (National Fire Protection Association (NFPA) and the National Electrical Code (NEC) [

11,

25].

Several standards are available; manufacturers use the society of Automotive Engineers (SAE) and IEEE in the US, and IEC is used in much of Europe. Japan and China have their standards with Chademo and Guobiao (GB/T).

Table 4 presents the voltage and current levels of IEC62196, SAEJ1772, and GB/T-20234 standards in charge of EV charging. In SAE, the term “level” of power is considered, while IEC believes the term “mode” to indicate the power level [

28,

29].

As evidenced in

Table 4, the only charging mode that includes 120 V is the SAE J1772 standard, unlike the other standards with higher charging voltages even in their lowest charging modes. SAE J1772 offers a lower voltage (500 V) in the full charging mode than 1000 V of the other standards. The lowest current is the GB/T-20234 standard at 10 A, compared to 16A for the different standards. SAE J1772 supports a maximum current of 200 A, GB/T-20234 with 250 A, and IEC 62196 with 400 A. In alternating current charging modes, SAE J1772 has a charging power of 1.9 kW, the lowest, compared to GB/T-20234 with 27.7 kW and IEC 62196 with 3.8 kW. In direct current charging modes, IEC 62196 offers 400 kW, the highest, compared to 250 kW offered by GB/T-20234 and 100 kW by SAE J1772.

Safety is an essential part of electric vehicle charging and grid integration. NFPA and NEC focus specifically on safety and security. The NFPA 70 standard addresses grid integration and electric vehicles, providing instructions for equipment wiring and customer safety at the point of connection to the grid. NEC 625 “Electric Vehicle Charging Systems” addresses installation for EV charging infrastructure. NEC 626 “Truck Parking” manages the parking area and external infrastructure for EV charging.

2.3. Charging Station Design

The criteria and recommendations described in the NEC 2020 national electrical code are considered to design the charging station for EVs.

In the case of the power supply equipment that makes up the charging station, it must contemplate an adequate nominal voltage for the load to be supplied; then, EV recharging operation is assumed to be a continuous load if the manufacturer does not specify a nominal voltage, the voltages presented in

Figure 8 will be considered. The EV cable for power supply for EV shall be of the types EV, EVJ, EVE, EVJE, EVT, or EVJT flexible; the length of the line shall not exceed 7.5 m (25 ft) unless equipped with a suitable management system.

Installation

Outlets installed for EV charging shall be fed by a single circuit and may not have branch circuits. The overcurrent protection of the charging station equipment shall be designed for continuous service and shall not be less than 125% of the maximum load of the equipment. In the case of discontinuous shipments taken from the same feeder, the overcurrent device shall be not be less than the sum of the intermittent loads plus 125% of the continuous loads.

Back-feeding energy through the electric vehicle and supply equipment to the primary system shall be avoided during a loss of prime source unless the system has been designed for that purpose. The charging station coupling shall be located at a height of not less than 450 mm (18 in) from the floor for indoor locations; for outdoor areas, the size shall be 600 mm (24 in) from the floor.

Suppose electric vehicle charging is performed indoors and the charging equipment requires ventilation. In that case, the ventilation shall include the supply and exhaust air equipment, mechanical fans with direct ventilation to the outside shall be used, and positive pressure ventilation is considered in buildings. The mechanical ventilation equipment shall be electrically connected to the EV charging equipment and remain in operation during the entire EV charging cycle. The methods specified in Section 625 of the NEC 2020 determine the required mechanical ventilation.

3. Problem Formulation and Methodology

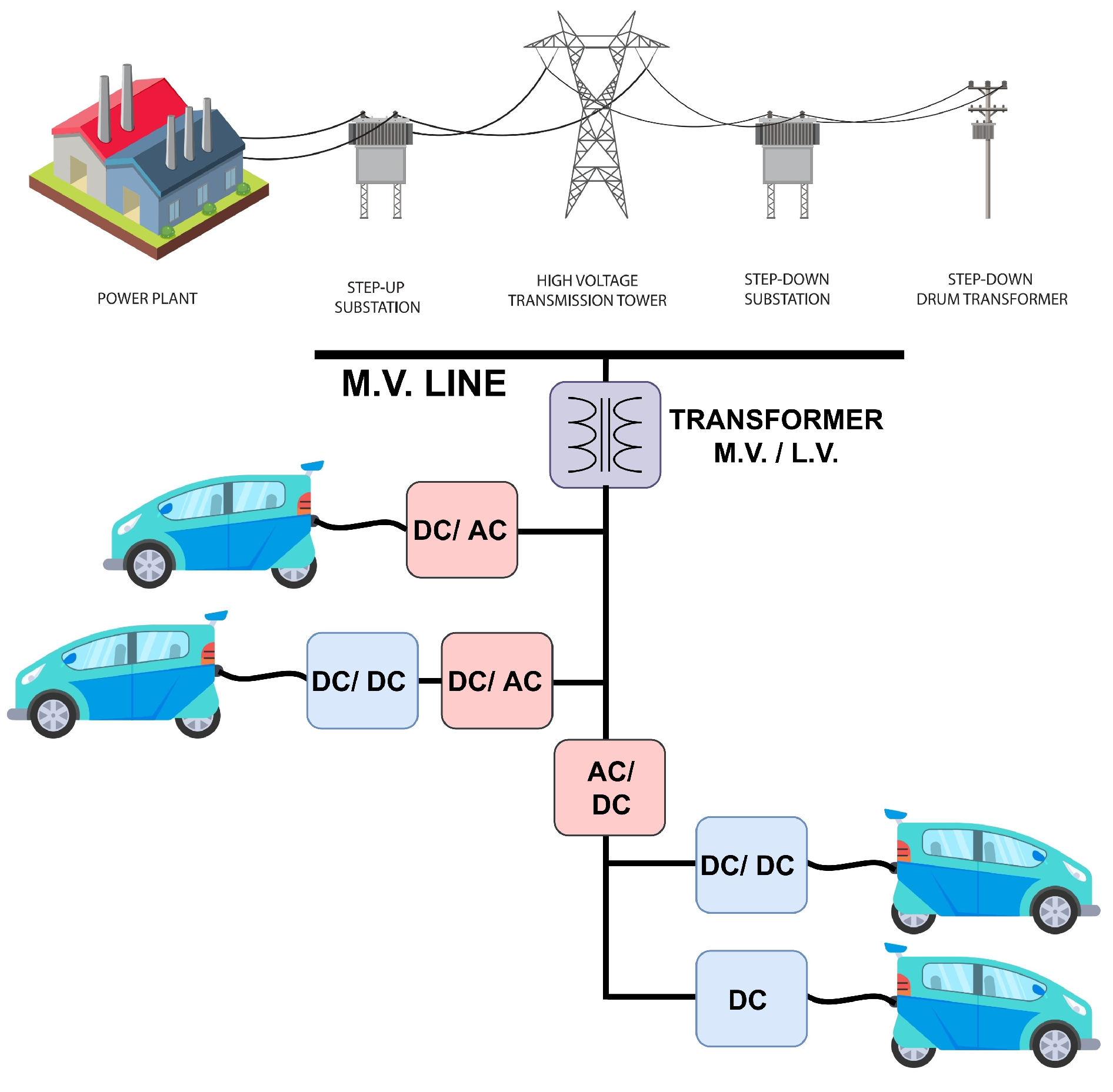

This article has a descriptive approach since it seeks to propose a methodological model for the design of charging stations considering restrictions and recommendations based on international standards. Finally, a design proposal will be constructed that contemplates the technical framework required to be considered for the deployment of charging infrastructure for electric vehicles according to the requirements of a smart grid. The EV charging infrastructure is organized according to the type of energy used, the location of the charging circuit, the physical connection requirements, and the direction of energy flow, which is presented in

Figure 9.

International standards cover a wide range of aspects related to EV, from terminology, charging, storage, and communication, to the protection and safety of people, according to

Figure 10.

The vocabulary and terminology for electric propulsion vehicles and their batteries can be defined by ISO/IEC Guide 2:2004, whose official languages are English, French, and Russian. ISO/TR 8713:2019 and SAE J 1715:2021-05-28 establish a vocabulary of terms and definitions for EV, BEV (Battery Electric Vehicle), HEV (Hybrid Electric Vehicle), PHEV (Plug-in Hybrid Electric Vehicle), FCEV (Fuel Cell Electric Vehicle), and FCHEV (Fuel Cell Hybrid Electric Vehicle). In contrast, SAE J1715/2:2021-08-09 provides reports related to energy storage and batteries.

The present paper focuses on the conductive charging method, one of the most frequently used techniques nowadays. IEC 61851-1:2017 sets out the requirements for conductive charging and applies to charging systems inside and outside the EV with supply voltages of 1000 V AC or up to 1500 V DC, further classifies AC supply voltages, setting modes, as well as requirements for connector, plug, and socket, among others. IEC 62196-2:2016 applies to plugs and connectors possessing a rated operating voltage not exceeding 480V in AC, 50 Hz to 60 Hz, and a rated current not exceeding 63A three-phase or 70A single-phase for the conductive load. In addition, it is possible to have ANSI/UL 2202, ANSI/UL 25942, UL 9741, and ANSI/UL 22512 standards addressing charging systems.

The state, duration, charge and discharge cycle, and charge level become a fundamental part of the EV; below in

Table 5, the standards established by the main standardization entities are presented:

For the design and subsequent construction of the EV charging infrastructure, it is mandatory to consider the standards to safeguard the devices, equipment, and operating personnel, due to the risk involved in this technology, as shown in

Table 6 with the standards established by the main standardization entities:

For the communication between the different components of the system, it will be necessary to consider whether the current flow is one-way (V1G) or bidirectional V2G.

Table 7 below shows the standards established by the main standardization entities:

The charging system for EV requires a stable and undisturbed power quality, including harmonic distortion, voltage fluctuations, interruptions, outages, and noise. The standards established by the main standardization entities are shown in

Table 8 below:

Figure 11 presents the structure of the conductive charging station for EV; for AC charging, an AC/DC converter is required, which is integrated into the onboard charger. In the DC card, an AC/DC converter is installed at the output of the M.V/ L.V, 22 kV/ (277/480) V distribution transformer; the AC/DC power electronic converters provide rectification, voltage control, and power factor correction, isolation, DC power supply to the EV connection port. DC/DC converters isolate the DC supply to the EV connection port.

Figure 12 presents the scheme for installing an EV charging station, which must comply with the manufacturer’s provisions, standards, and specifications. The electrical power must be selected according to the load foreseen for the EV load, indicated in

Table 4. The supply voltage for EV charging can be single-phase at (230–240) V, (16–32) A, or three-phase at (277/480) V, (32–250) A in alternating current, in the case of direct current, (600–1000) V, (250–400) A.

The EV charging circuit is for exclusive use, counting the auxiliary services of the charging system. It is not used for any other electrical connection; the charging point can be supplied individually and collectively, protected against overloads and short circuits. The connection point shall be of a conductive type and feed only one EV at a time; it shall be equipped with the appropriate connectors according to the charging mode, thus avoiding using couplers.

For the simulation of the proposed system, the DIgSILENT PowerFactory software is used; the charging stations have been designed for Charging Modes 1, 2, and 3 described in

Table 4, and, similarly, the maximum power and supply voltage have been selected. The proposed charging station system is designed exclusively for charging electric vehicles and will not be able to supply electric power to users for uses other than the setting.

The power supply conductor will be chosen according to IEC 60364-5-52, which is included in the PowerFactory DIgSILENT library. It is connected to a transformer of 180 kW at 22 kV/480 V. A low voltage bus bar will be in charge of integrating the different charging stations. The integration of the charging station to the grid is simulated through an external grid source of 150 kW at 22 kV.

Figure 13 shows the system modeled in DIgSILENT PowerFactory.

A C-curve circuit breaker must protect all connection points within the charging station system against overloads and short circuits (tripping between 5 to 10 times the rated current) for protection against direct and indirect contacts with a 30 mA differential switch according to IEC 60364-7-722. An available circuit breaker is considered for the general protection of all circuits, from which the individual circuits will start. As it is regarded as a collective load system used simultaneously, a diversity factor of 1 is considered, according to IEC 60364.

A circuit breaker with a maximum current of 16 A, 32 A, and 200 A will be used for the 7.6 kW, 15.3 kW, and 120 kW charging stations, respectively, while the primary protection will be set at 250 A, taking into consideration NEC 210.20 (A) Continuous and non-continuous loads. For Charging Modes 1 and 2, a type B differential protection with a sensitivity not exceeding 30 mA is available; for Charging Mode 3, a type B differential protection with a sensitivity not exceeding 30 mA is used, and a type F differential protection with a sensitivity not exceeding 30 mA is considered, combined with a residual current detection device (RDC-DD) against leakage of 6 mA DC.

For the design of the charging station, the installation of a three-phase (277/480) V, 3 kW generator set has been considered, which will be in charge of supplying electrical energy to the lighting, power, and accounting systems when there is a power interruption from the network. The generator may not work parallel to the low voltage network, for which a switching system is installed to prevent simultaneous connection. The ISO 8528-1 standard defines the application, classification, and performance of the generator set driven by a combustion engine; the IEC 60034 standard provides us with different variables related to the operation of rotating machines. Sections 430.14 and 445 of the NEC 2020 provide us with the requirements for the installation and location that the Genset must have.

4. Analysis of Results

This section presents the results obtained from the simulation performed in the DIgSILENT PowerFactory environment, being software for the simulation of Electrical Power Systems.

Table 9 shows the simulation parameters used to validate and evaluate the proposed design based on international standards.

Figure 14 shows the simulation of the model through a power flow; the variables shown are active power, reactive power, and system voltage. The green color in the heat diagram indicates no voltage losses in any of the connection points of the proposed system.

In the system’s initial conditions, the power assigned to the transformer is as indicated, supporting the loads transferred to the proposed method, in this case, the load stations CE1, CE2, and CE3.

Figure 15 shows the metrics of the active power of the elements mentioned above, the operational management of the transformer reaches 95.58 kW, while 5.06 kW, 10.2 kW, and 79.99 kW for loads CE1, CE2, and CE3, respectively, were obtained at 8 ms of simulation, indicating no overload in the system elements versus their nominal design powers.

For the fault analysis in the system, a single-phase short circuit to ground is inserted in phase A of load CE1 at 0.5 s, shown in

Figure 16, resulting in a short circuit current of 8.71 kA, causing instability in the system, at 0.6 s, the protection in load CE1 releases the fault, returning to the regular operation of the system.

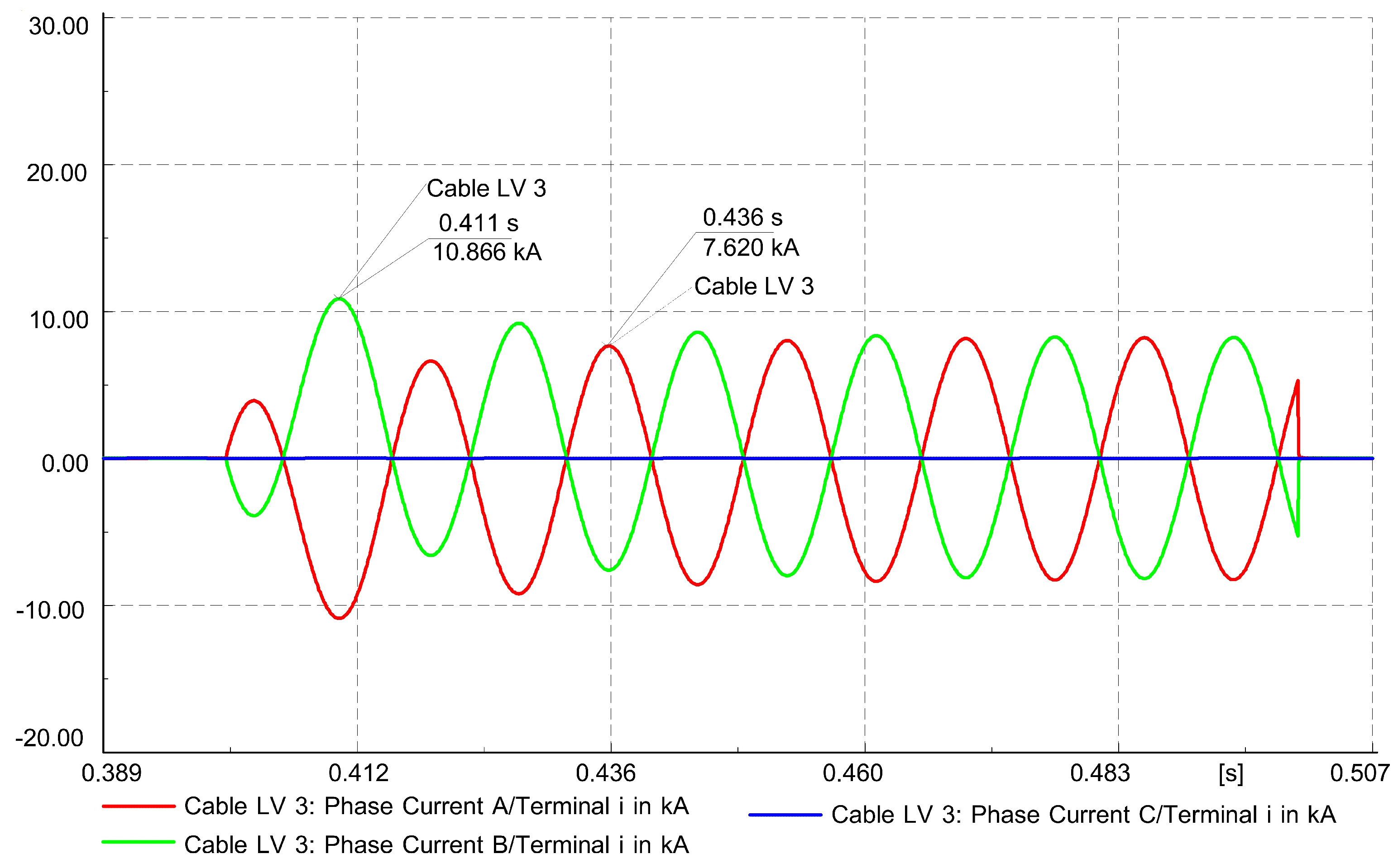

Figure 17 shows the result for a phase-to-phase short circuit between phase A and B for load CE2 at 0.4 s, showing a short circuit current of 7.62 kA in phase A; in phase B, there is a short circuit current of 10.86 kA; at 0.5 s, the fault is released by the load protection, reaching system stability.

For the fault analysis of load CE3, a three-phase short circuit has been inserted between phases A, B, and C at 0.3 s and being released at 0.325 s, shown in

Figure 18, phases A, B, and C present a short circuit current of 9.23 kA, 15.45 kA, and 5.39 kA, respectively.

Unlike the faults presented above, the three-phase fault is the most severe fault for the system, with a current of 15.45 kA; therefore, since the CE3 load is the largest with 120 kW, consequently, an operating current of 0.145 kA.

6. Conclusions

This paper has designed an electric vehicle charging infrastructure considering bibliometric analysis and regulations based on the electrical code for incorporation into a smart grid. In addition, design methodologies for electric vehicle charging stations have been identified. Finally, the technical considerations for designing electric vehicle charging stations based on international standards have been detailed.

The charging infrastructure for electric vehicles has been established and designed considering bibliometric analysis and regulations based on the electrical code for its incorporation into a smart grid. In addition, it is understood that several international standards are universally followed if the incorporation of electric vehicles into the network is desired.

The IEC and SAE standards are responsible for conductive charging, communication, and power quality; these documents are founded on standards such as ISO and IEC, which are accountable for the communication interface between the smart grid and the electric vehicle. The safety and protection of the person become fundamental, and the NFPA 70 standard establishes the requirements that every charging system must have.

The present work has identified design methodologies for electric vehicle charging stations. Consequently, the model can find low power charging stations with low current consumption from the network; it also has high power charging stations with high current consumption from the grid; having this high consumption, the upstream elements of the system will have to be more robust, i.e., can operate without being affected in their performance.

The study details the technical considerations for designing charging stations for electric vehicles based on international standards. Therefore, performing a system stability analysis is essential to determine that the design parameters are adequate.

In the first instance, it is verified that, if there is no overload in the elements of the designed circuit, then tests are performed to determine whether the system can cope with a contingency; in this case, inserted short circuits in the system, resulting in a momentary instability of the system since the protections designed correctly make this disturbance evident.