A Novel Sustainable Processing Mode for Burr Classified Prediction of Weak Rigid Drilling Process Using a Fusion Modeling Method

Abstract

:1. Introduction

2. Literature Review

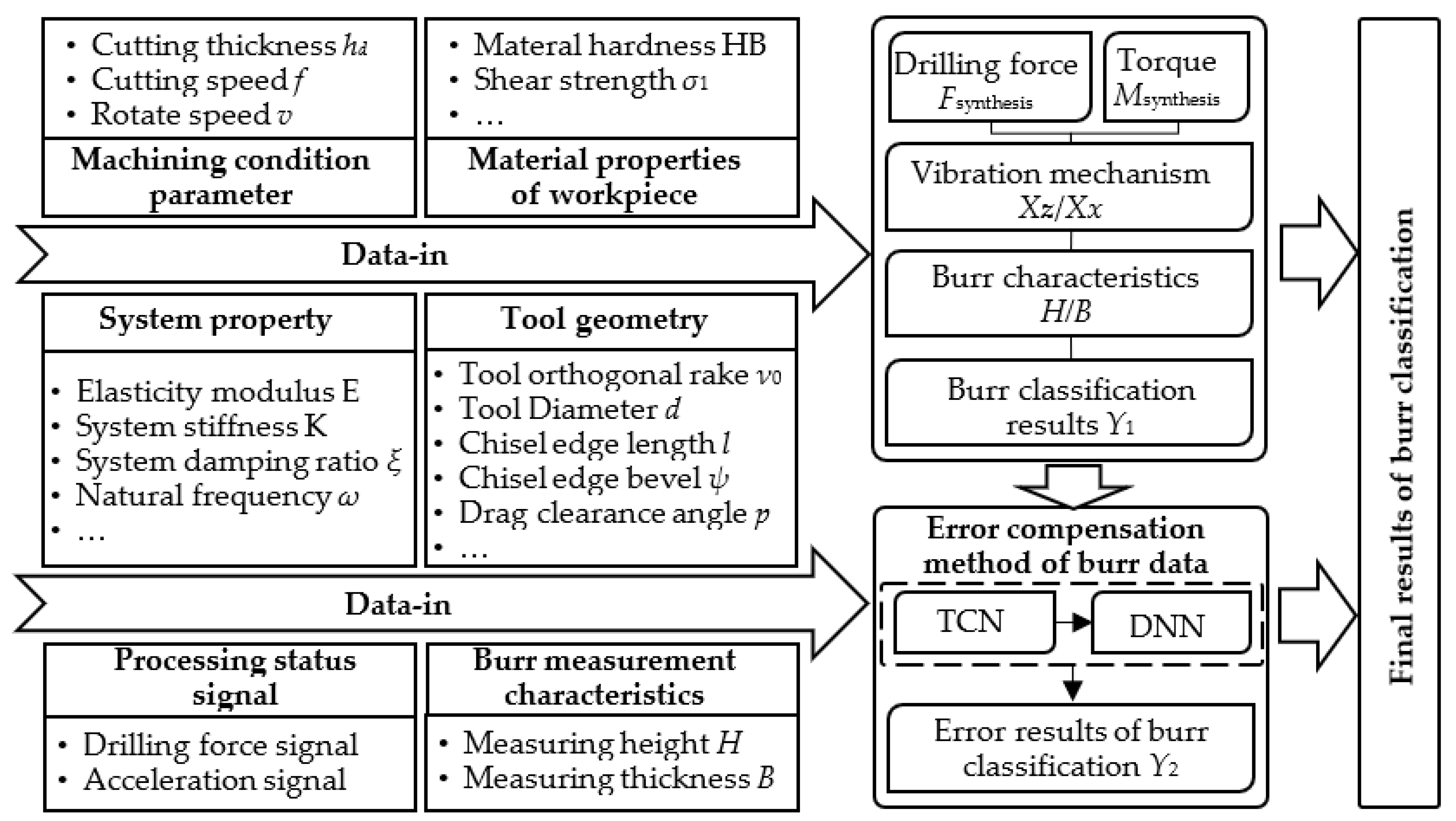

3. Mechanism Model for Drilling Burr Forming

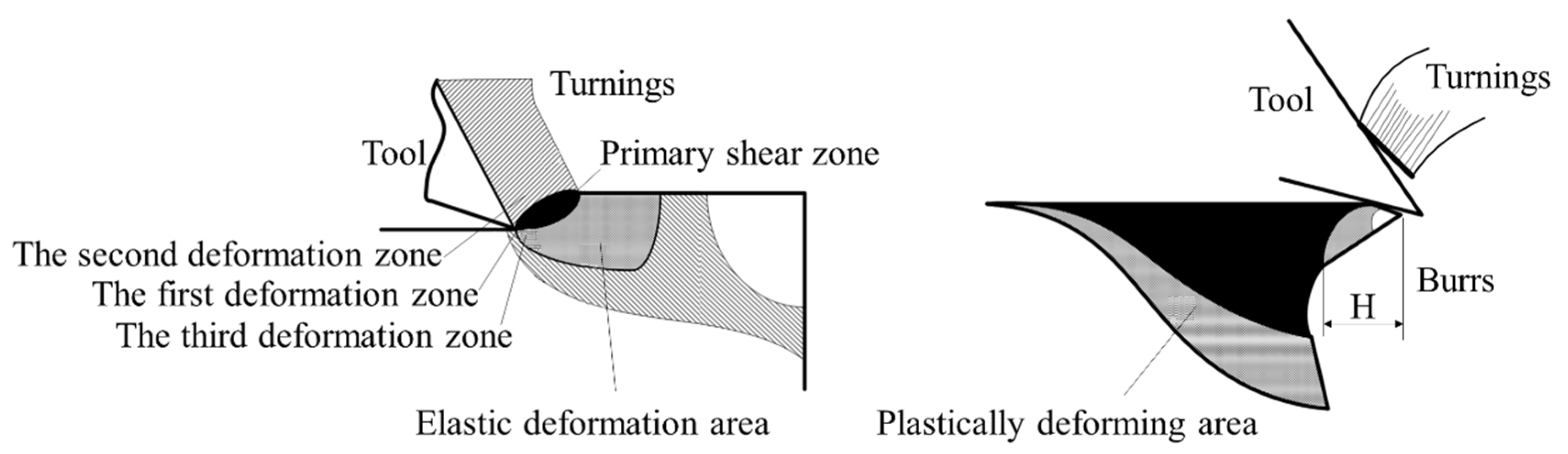

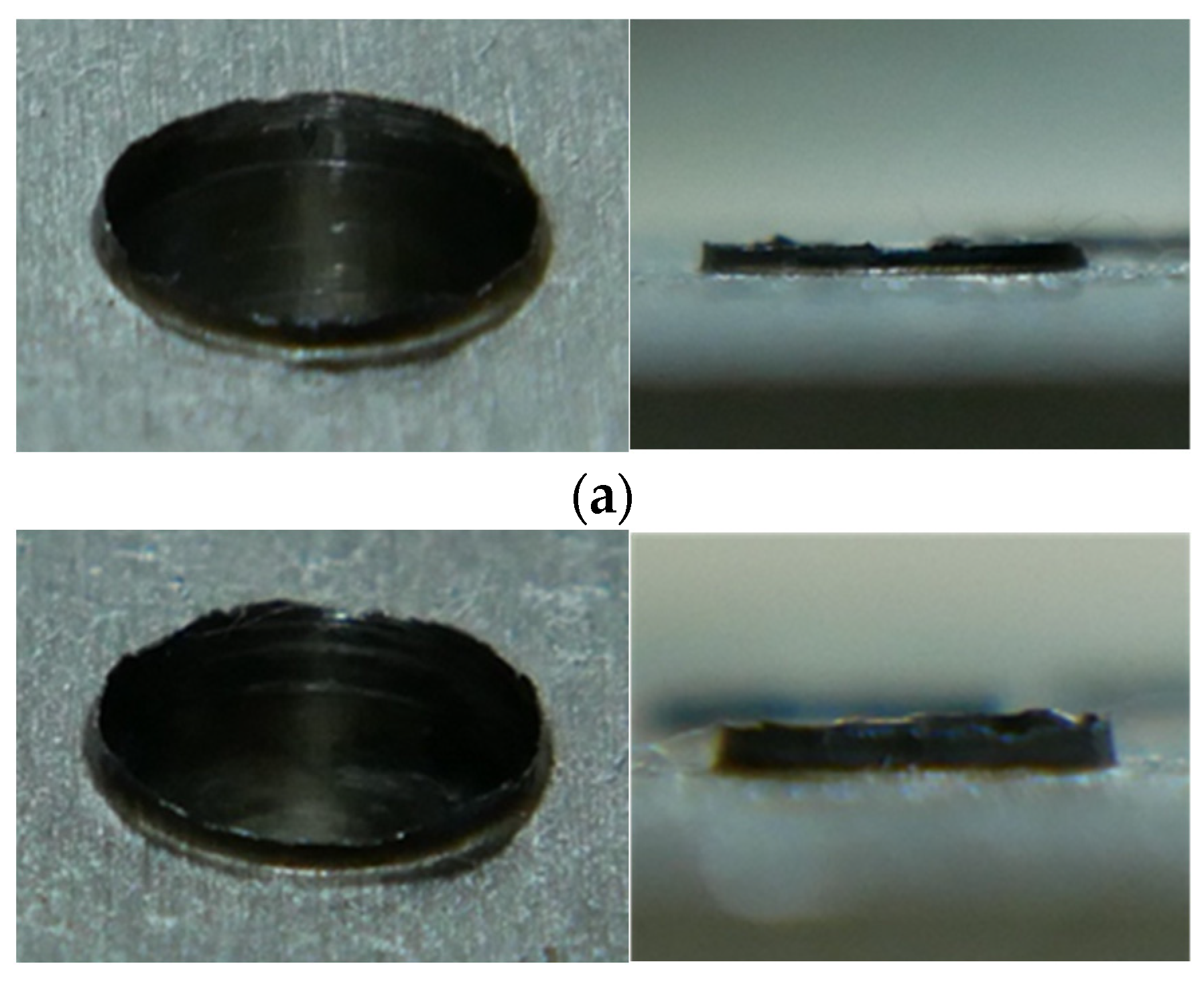

3.1. Burr Formation Mechanism and Feature Selection

3.2. Prediction Mechanism Model of Drilling Burr Scale

- (1)

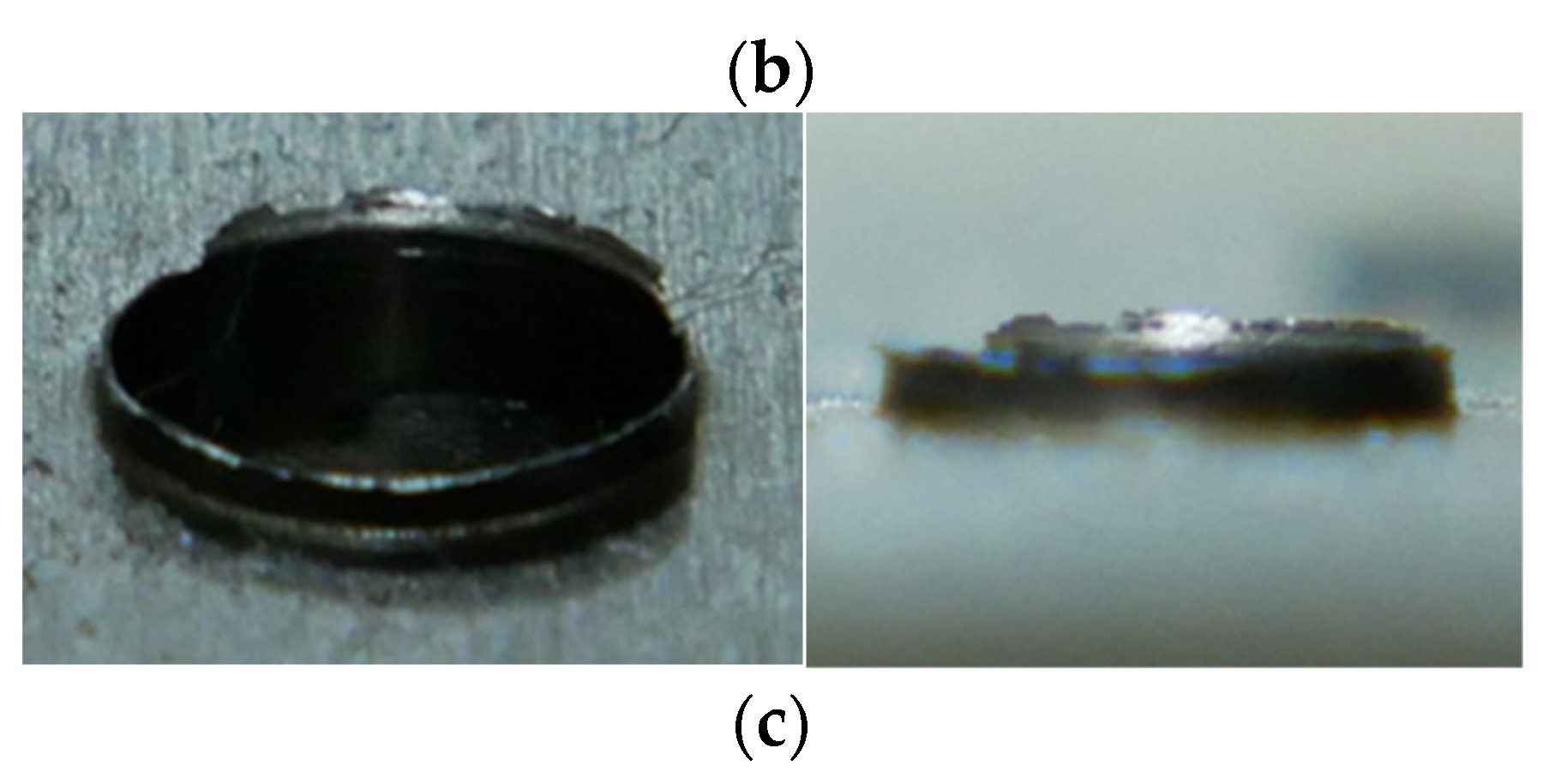

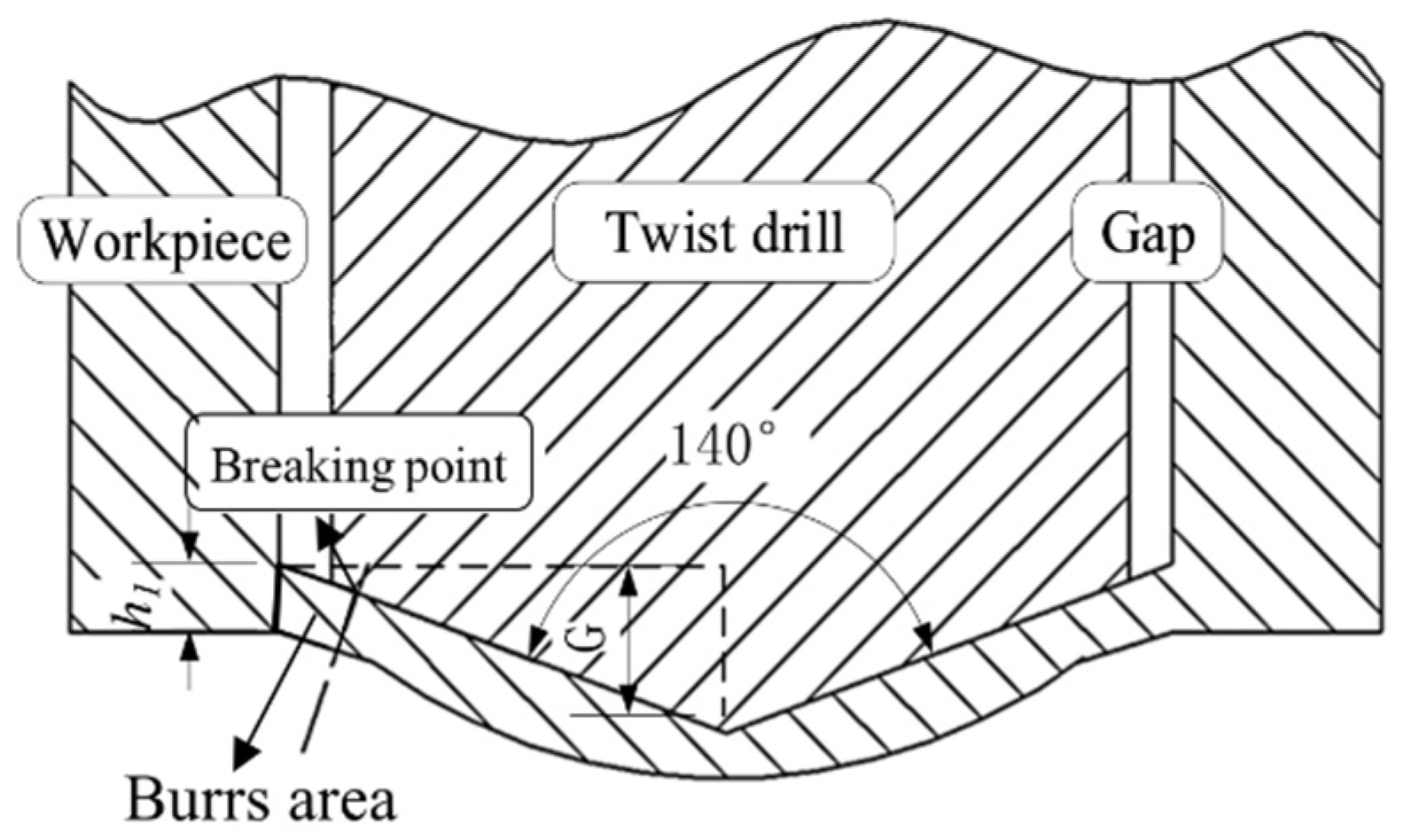

- The tool penetrates workpiece: When the drill bit breaks through the workpiece material, the burr on the edge can be regarded as pure plastic deformation. Because of the radial vibration, there is an equivalent gap in the hole, similar to the blanking process, and this gap has a certain effect on the generation of burrs. As shown in Figure 3, assuming that the equivalent clearance is δs, which is equal to the amplitude of vibration, the expression of burr height Hpenetrate is shown in Equation (1) based on rigid plastic assumptions [42]. Figure 3 shows the h1 and δs schematics for the bit breaking through the workpiece material.

- (2)

- The tool does not penetrate the workpiece: At this point, the formation of burrs firstly appears as large plastic deformation and then as elastic fracture, as shown in Figure 4. Due to elastic backflow at the fracture [43], burr height only needs to be considered in terms of plastic elongation and the location of the danger point. At the moment before the workpiece material fracture, the strain rate εf reaches 0.3 to 0.5. At this point, the height curve of the burr edge can be approximately linearized. On this basis, the modified burr height H can be obtained by further considering the area shrinkage rate of material attributes, as shown in Equation (2).

- (3)

- Equivalent height of burrs: The burr in real environments is the reconstruction of these two kinds of burrs under different energy ratios. The details are shown in Equation (3).

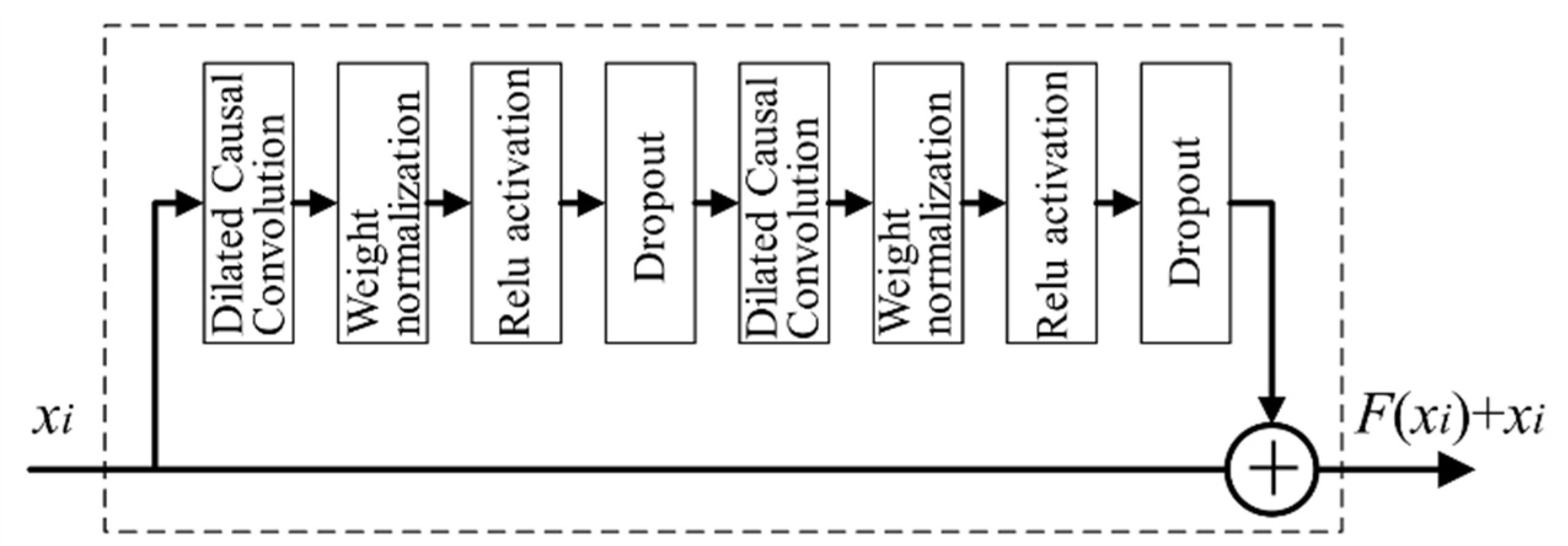

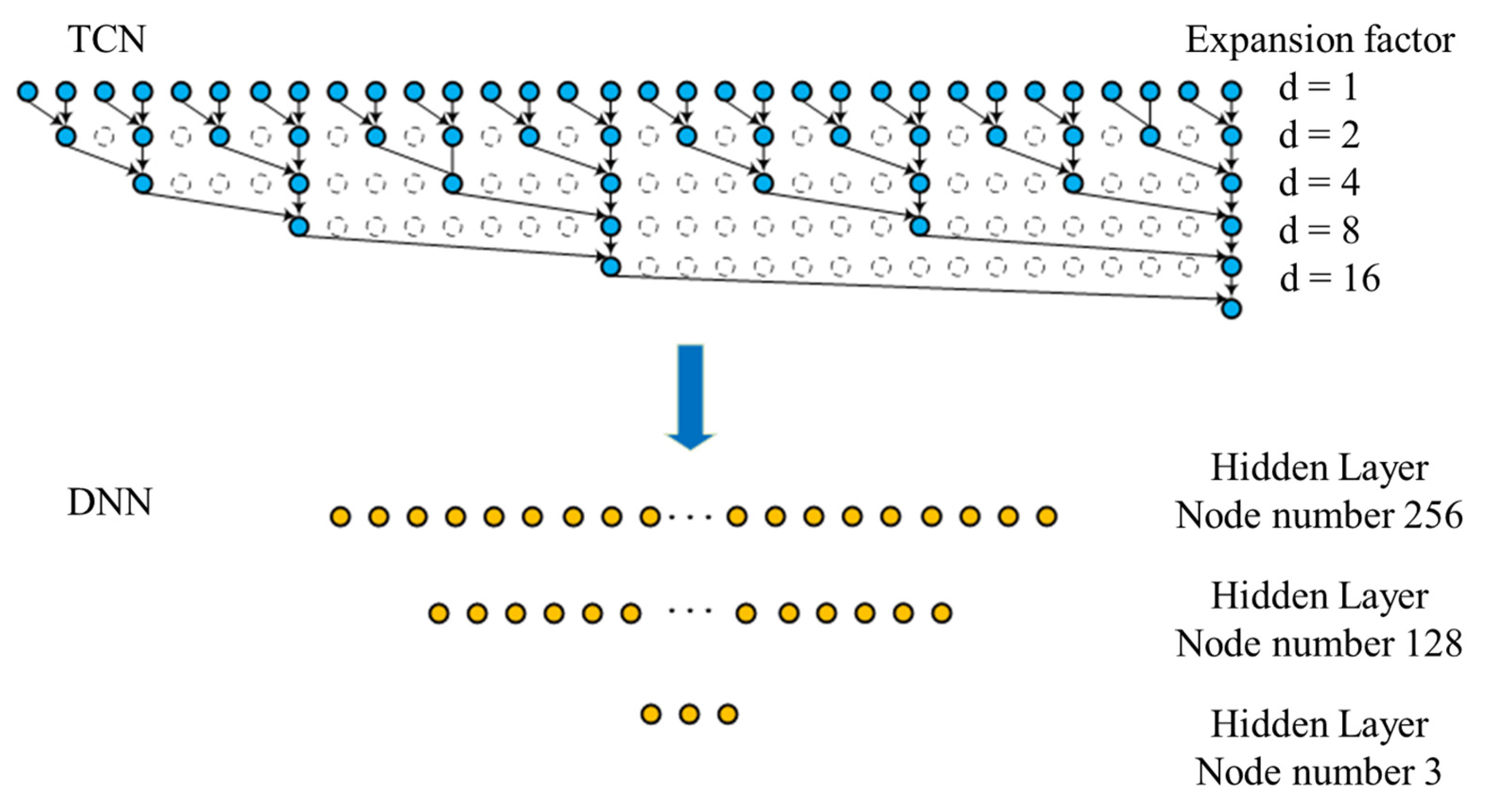

4. Error Compensation for Drilling Process by the Data-Driven Approach

- CNN: Convolutional Neural Network

- RNN: Recurrent Neural Network

- TCN: Temporal Convolutional Network

- DNN: Deep Neural Network

- TCN–DNN: Temporal Convolutional Network–Deep Neural Network

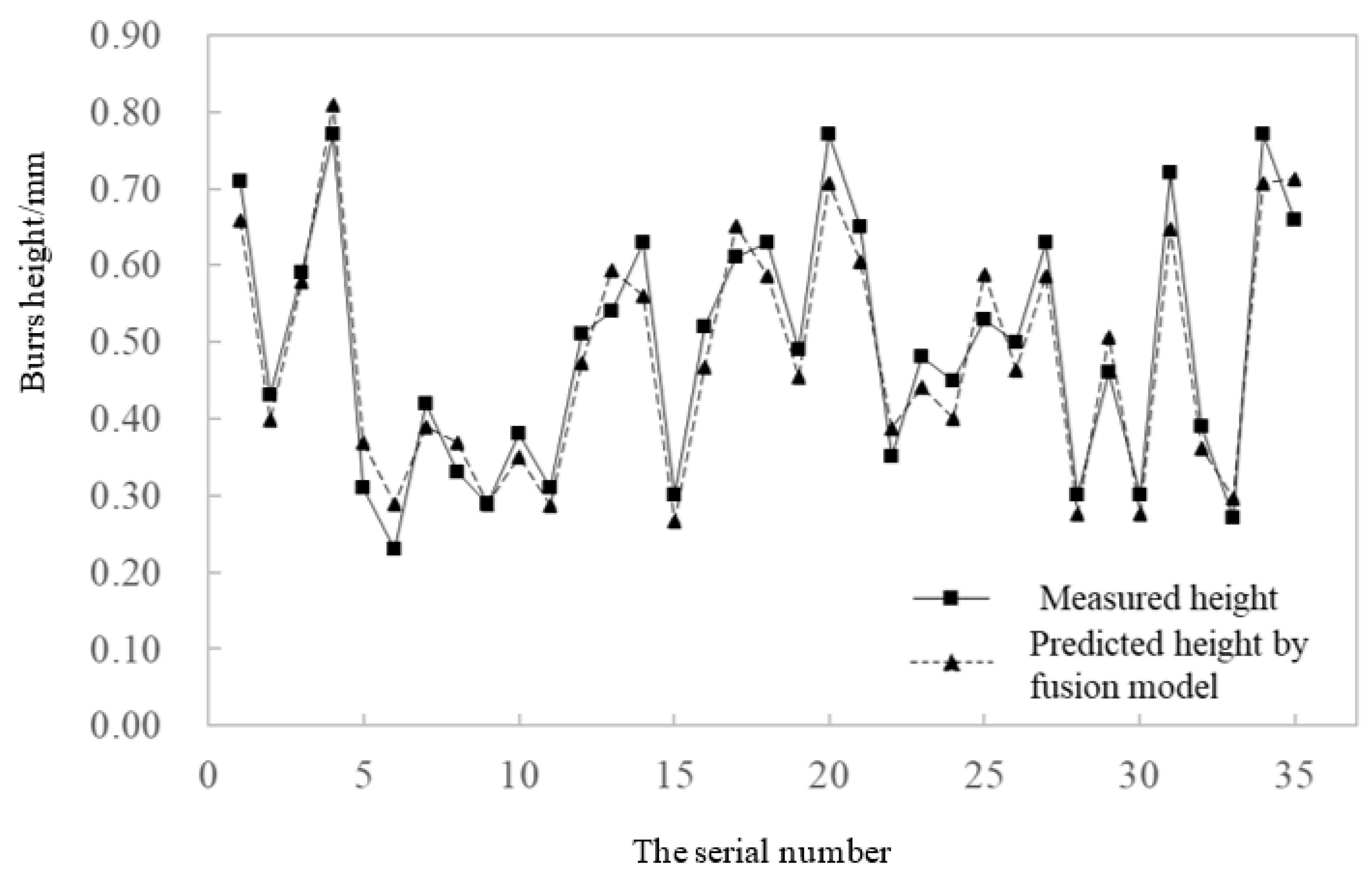

5. Fusion Modelling of Mechanism and Data

6. Borehole Testing and Burr Scale Prediction

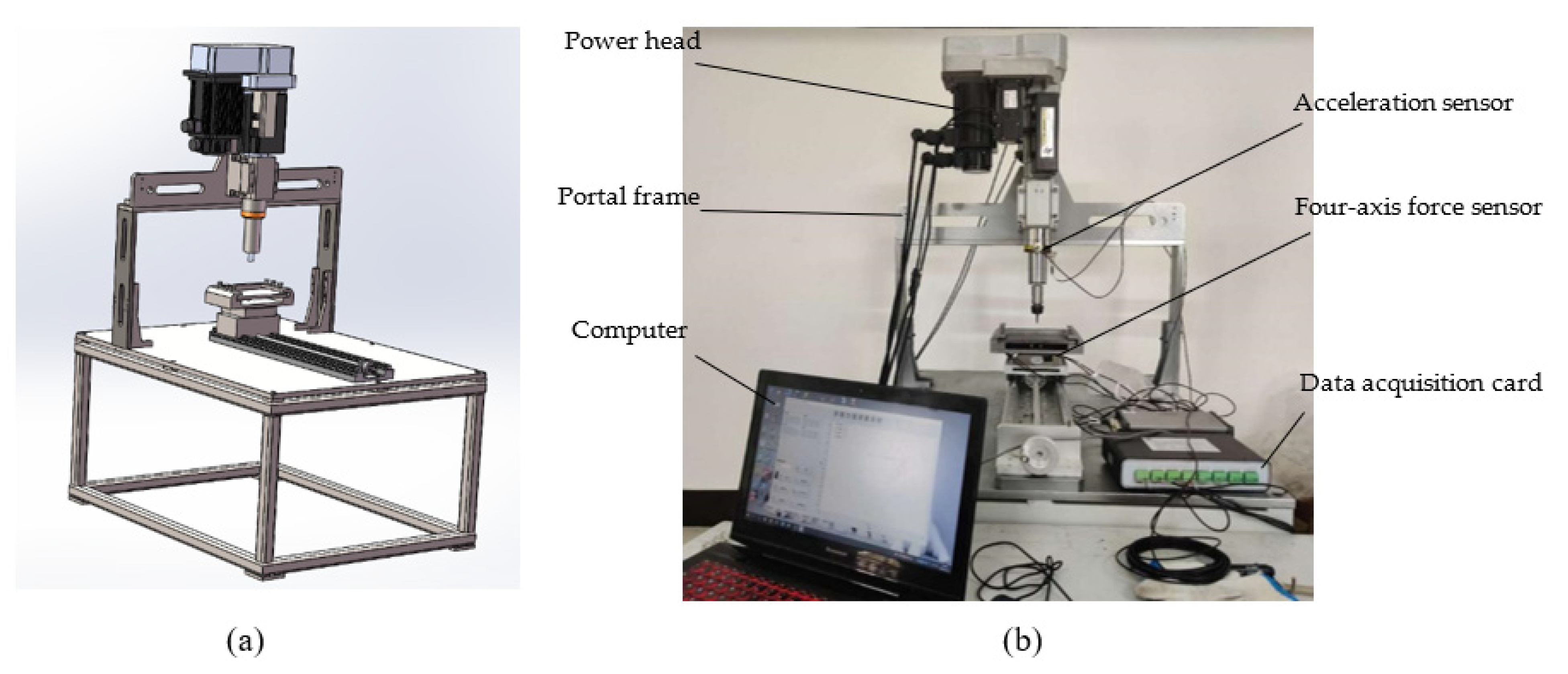

6.1. Experimental Design

- (1)

- Frame: A self-designed gantry frame and a metal platform for installing the gantry frame were used. A one-dimensional slide table was installed on it to adjust the machining position of the experimental workpiece, so that a piece of workpiece could be tested many times, and reliable experimental results could be obtained.

- (2)

- Power head: A double servo tapping and drilling machine was selected and connected to the gantry frame through the installation base. A laser level meter and other related equipment were used to adjust the frame to ensure its shape and position deviation meets the requirements. The power head was controlled by a Galil control card, model is DMC-B140-M, which adopts the control mode of C# language of the upper computer. In addition, the spindle rotation servo motor used has a rated power of 1.8 kw and torque of 6 Nm. The feed servo motor used has a rated power of 0.4 kw and torque of 1.27 Nm.

- (3)

- Sensor: An acceleration sensor (INV3062T) was installed on the power head, and a four-axis sensor (NOS-C906) was mounted on the slide platform to collect the parameters of axial force and torque during the machining process. Its rated load was 1 KN/1 KN/2 KN/200 Nm, and its sensitivity was 1%.

- (4)

- Fixture: An ER20 collet was installed at the end of the power head with a 6 mm clip. By self-design, it was mounted on the four-axis sensor. Thus, the data collected by the sensor was more stable and reliable. An alloy steel straight shank twist drill was selected for the drilling tool.

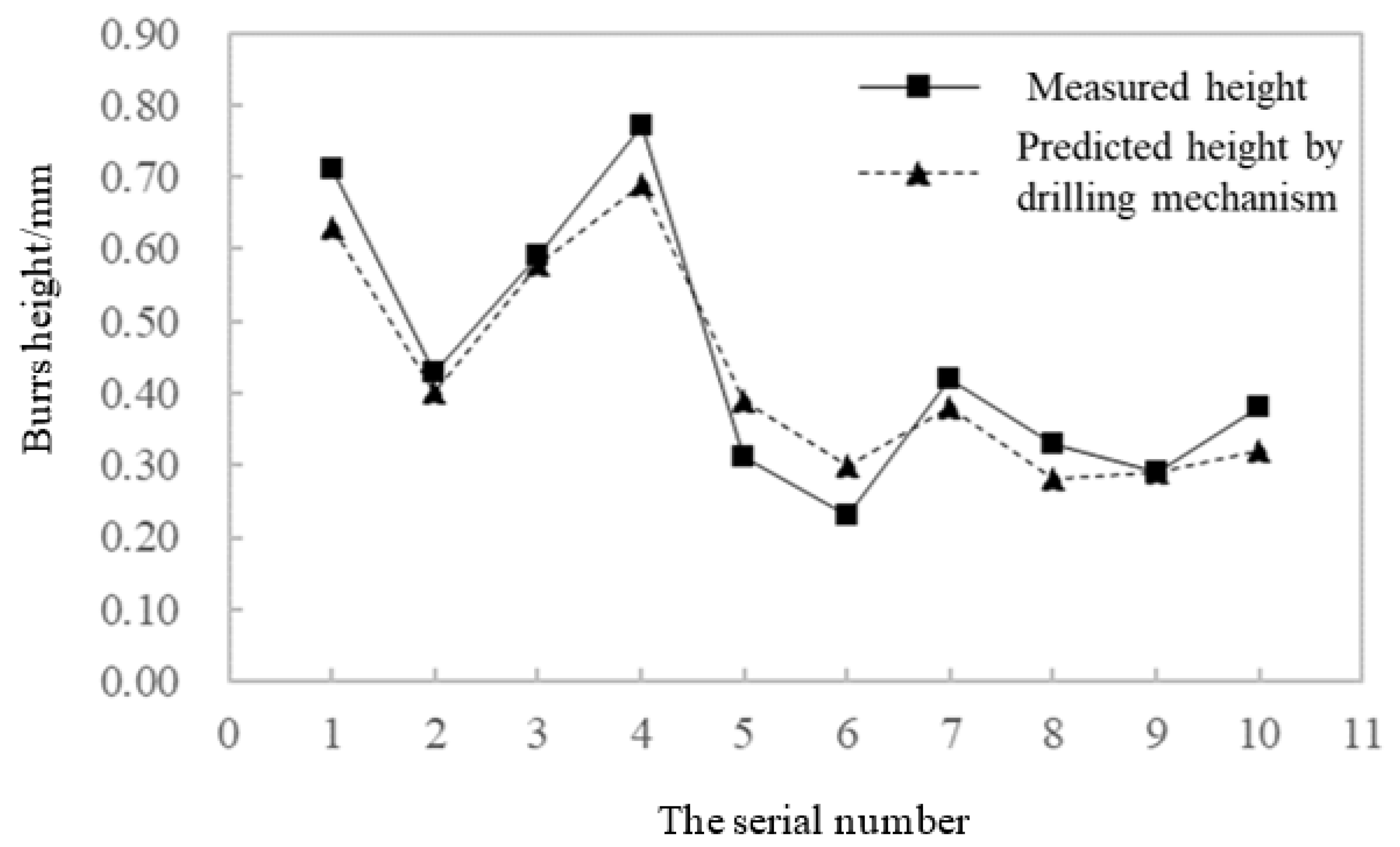

6.2. Predictive Analytics

7. Conclusions

- (1)

- The proposed burr classified prediction method can integrate the burr formation mechanism and data-driven error compensation model, which fully considers the mechanical characteristics of the drilling process. The overall calculation accuracy has improved by 25% compared with that of the traditional drilling mechanism model.

- (2)

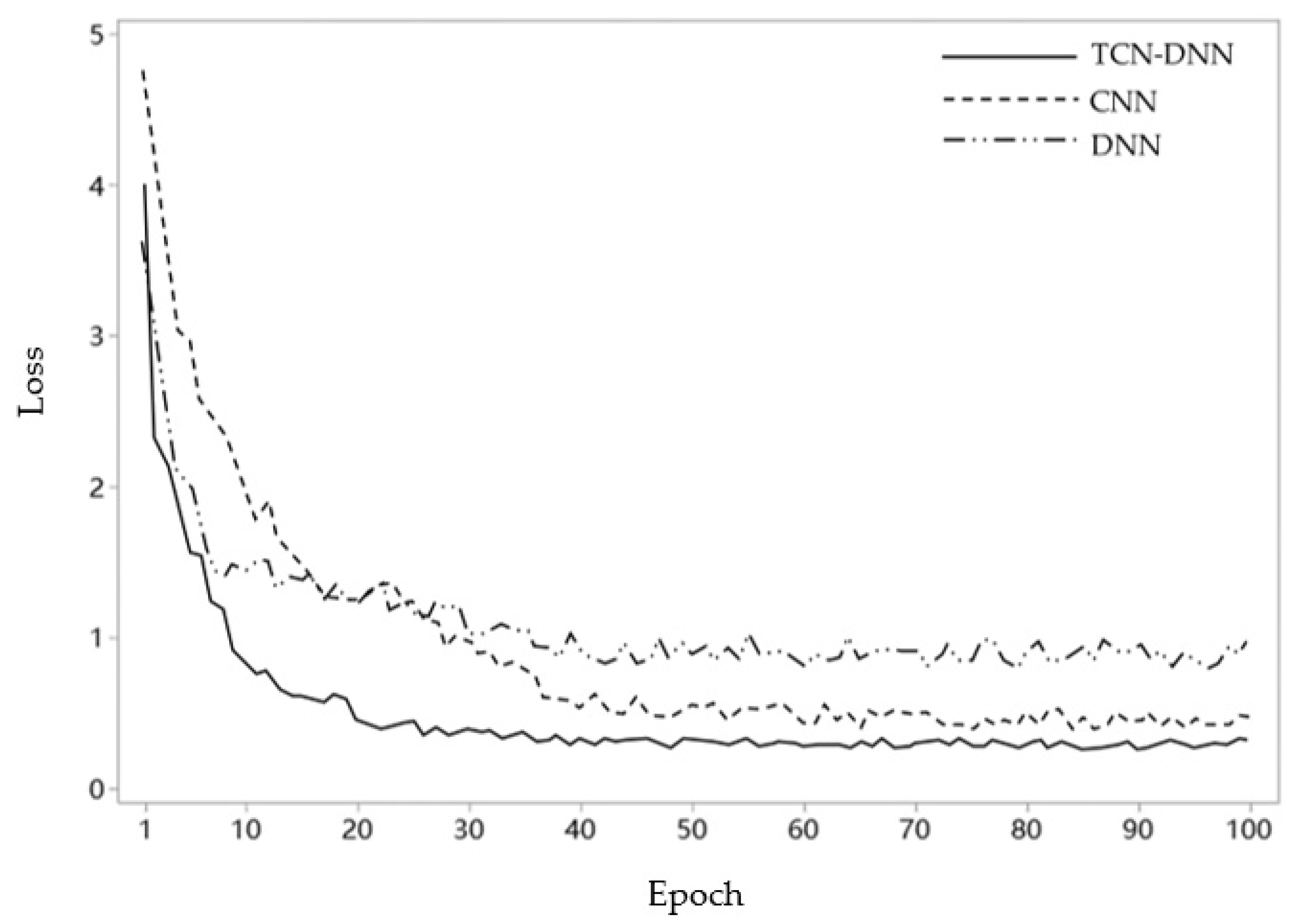

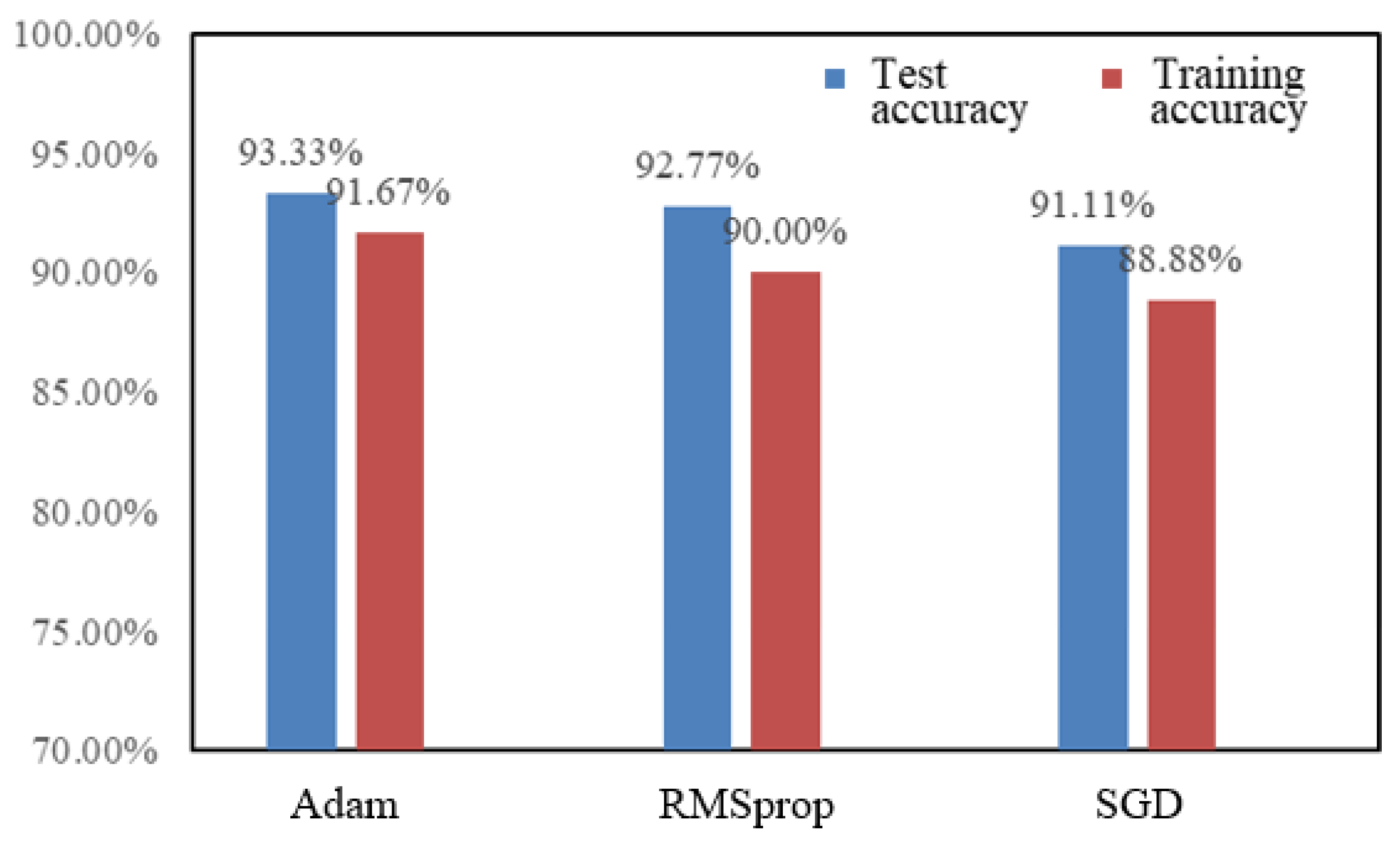

- An effective error compensation model based on the fusion of machine learning techniques is established, which involves the temporal convolutional network and deep neural network. The trained network fully explores the timing regularity of machining state parameters and can both accurately harmonize the past data and precisely predict the burr quality. The algorithm has the highest accuracy, reaching 91.67%, which is higher than that of traditional networks, and a satisfactory convergence speed.

- (3)

- The accuracy and feasibility of the proposed method are further verified by a realistic case originating in a weak rigid hole-making system. Experimental results show that the Adam optimizer has the best prediction accuracy and can be adopted in the proposed prediction model. The research has strong practical significance and theory-guiding sense. It can be widely used in automatic hole-making systems, such as in aerospace, military, and other fields.

Author Contributions

Funding

Conflicts of Interest

Appendix A

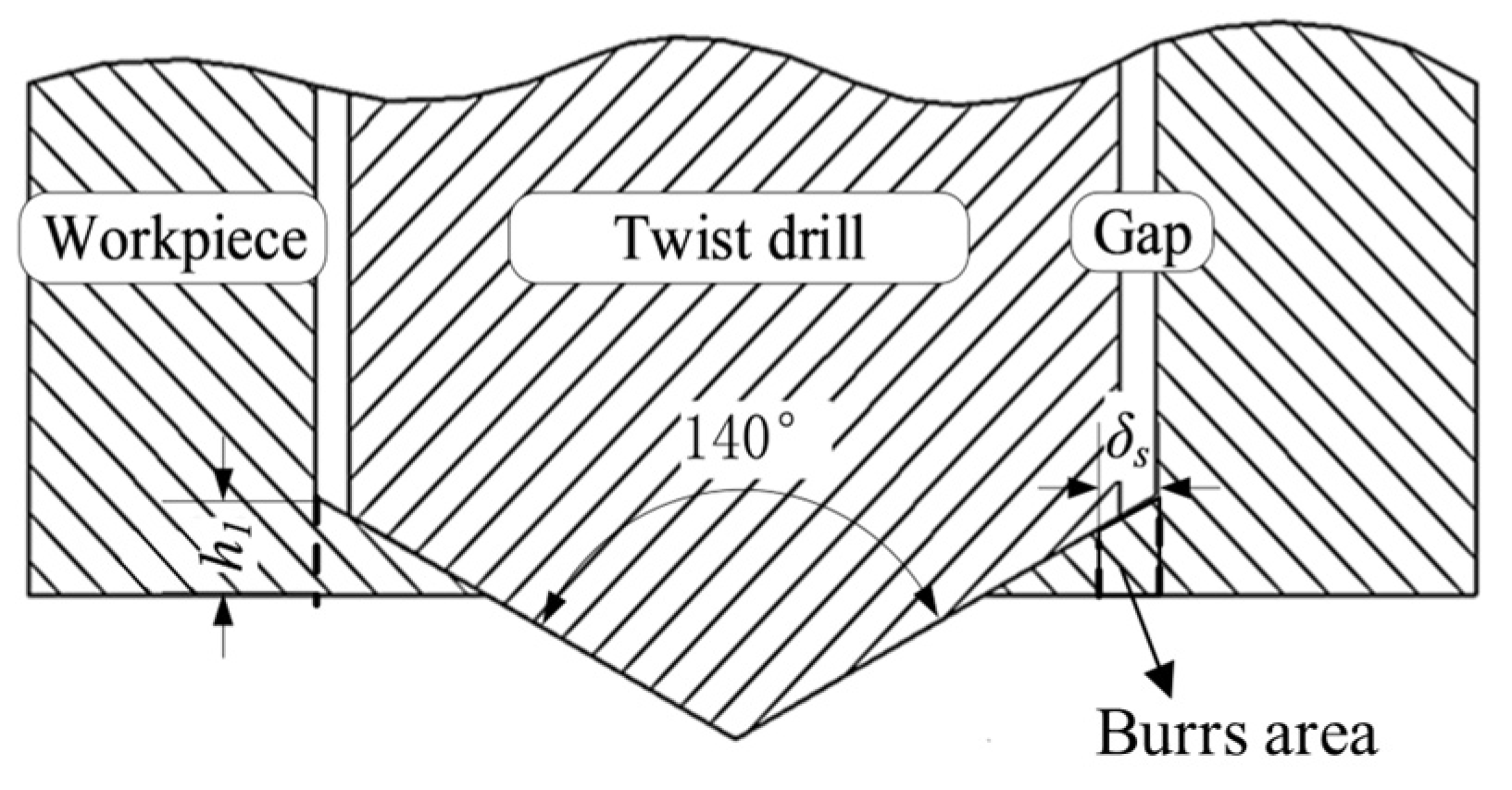

| Parameter | Index |

|---|---|

| System processor | 32-bit MPU Flash EEPROM RAM |

| Communication interface | Ethernet 100BASE-T RS232 115.2K |

| Mode of motion | Point-to-point positioning control Location tracking JOG 2D line/arc interpolation with feed multiplier 1–4 axis linear interpolation Electronic gear control with multiple driving shafts Synchronism of gate bridge Electronic cam Contour control S-curve acceleration and deceleration |

| Memory function | 450 lines × 40 characters 126 variables 800 elements in 6 arrays |

| Range of motion | Position: 32 bits Speed: 32 bits Acceleration: 32 bits |

| Universal digital I/O | 8 inputs/4 outputs |

| High-speed set latch | 4-way latch input for X, Y, Z, W axis |

| Private input | Master encoder input: A, A−, B, B−, I, I−; +/−12 V Positive and negative limit input Back to zero input High-speed position latch input Emergency stop input |

| Private output | Instruction pulse and direction output for stepper motor Servo enable output Signal transfer output |

| Minimum servo updating rate | 1–2 axis: 125 us 3–4 axis: 250 us |

| Maximum encoder feedback rate | 12 MHZ |

| Maximum step forward motor command rate | 3 MHZ |

| Power source specification | 19–33VDC, ≥0.5 A |

| Work environment | Working temperature: 0–70 °C Humidity: 20–95% RH |

| Parameter | Index | |

|---|---|---|

| Analog input | Number of channels | 2–4 |

| AD precision: | 24 bits or double 24 bits (double core) | |

| Maximum sampling frequency | 51.2 KHz for each channel | |

| Frequency indication and resolution error | <0.01% | |

| Spectrum amplitude error | <1% | |

| Dynamic range of 24 bits channel | 120 dB (typical value), 110 dB (guaranteed value) | |

| Dual-core channel range | 160 dB | |

| Input range of 24 bits channel | 10 V, 1 V, 0.1 V | |

| Dual-core channel input range | 10 V for one gear only (range: 160 dB) | |

| Input noise of 24 bits channel | <0.05 m Vrms @ ±10 V range (typical value 0.03 m Vrms) | |

| Dual-core channel input noise | <0.005 m Vrms @ ±10 V range (typical value 0.003 m Vrms) | |

| Anti-aliasing filter | 256 times oversampling + digital filter + analog anti-aliasing filter, the total attenuation steepness is over −300 dB/oct | |

| Total harmonic distortion | −70 dB | |

| Interchannel crosstalk | −100 dB | |

| Input impedance | >1MΩ | |

| Input mode | Voltage DC, voltage AC, IEPE(ICP) | |

| External conditioning unit | Charge, strain | |

| Rpm input Tacho | Number of channels | 0–1 |

| Internal sampling rate | 25 MHz, supporting torsional vibration measurement | |

| Rotary speed range | 3–3,000,000 rpm | |

| Input voltage range | −5 to +5 VDC | |

| Interface | LEMO three-core connector, can supply power of +5 V to photoelectric sensor | |

| Digital input/ output system | Mode | RS232 |

| Number of channels | 0–1 | |

| Cascade connection | Number of cascade acquisition instruments | Standard: 1–8 sets; customize: 9–32 or more |

| Cascade synchronization between instruments | Synchronous cable RJ45 twisted pair cable, maximum 100 m; built-in GPS module, external antenna | |

| Parameter | Index |

|---|---|

| Rated output | 1.0 mV/V ± 0.1% |

| Zero balance | ±1% of rated output |

| Creep after 30 min | ±0.5% of rated output |

| Nonlinearity | ±0.5% of rated output |

| Hysteresis | ±0.5% of rated output |

| Repeatability | ±2.0% of rated output |

| Temp. effect on output | ≤0.02% of applied output/°C |

| Temp. effect on zero | ≤0.02% of applied output/°C |

| Safe temp. range | −10 °C to +70 °C |

| Temp. compensated | −10 °C to +40 °C |

| Safe overload | 150% |

| Input impedance | 387 ohm ± 20 ohm |

| Output impedance | 350 ohm ± 5 ohm |

| Rated excitation | 10 V DC/AC |

| Maximum excitation | 15 V DC/AC |

References

- Bi, S.; Liang, J. Robotic drilling system for titanium structures. Int. J. Adv. Manuf. Tech. 2011, 54, 767–774. [Google Scholar] [CrossRef]

- Cen, L.; Melkote, S.N.; Castle, J.; Appelman, H. A wireless force-sensing and model-based approach for enhancement of machining accuracy in robotic milling. IEEE/ASME Trans. Mechatron. 2016, 21, 2227–2235. [Google Scholar] [CrossRef]

- Zeng, Y.; Tian, W.; Liao, W. Positional error similarity analysis for error compensation of industrial robots. Robot C. Int. Manuf. 2016, 42, 113–120. [Google Scholar] [CrossRef]

- Bu, Y.; Liao, W.; Tian, W.; Zhang, J.; Zhang, L. Stiffness analysis and optimization in robotic drilling application. Precis. Eng. 2017, 49, 388–400. [Google Scholar] [CrossRef]

- Huang, J.; Xiong, Y.; Huang, J.; Wang, G. Finite element analysis of burr formation in micro-machining. Appl. Mech. Mater. 2014, 487, 225–229. [Google Scholar] [CrossRef]

- Huang, J.; Zhu, Y.; Li, Q.; Wang, G. Active control methods of cutting burr in precision and ultra-precision machining. Appl. Mech. Mater. 2014, 494–495, 620–623. [Google Scholar] [CrossRef]

- Zai, P.; Tong, J.; Liu, Z.; Zhang, Z.; Song, C.; Zhao, B. Analytical model of exit burr height and experimental investigation on ultrasonic-assisted high-speed drilling micro-holes. J. Manuf. Proc. 2021, 68, 807–817. [Google Scholar] [CrossRef]

- Zheng, X. Key Technology and Fundamental Research of Micro-Drilling and Micro-Milling. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2013. [Google Scholar]

- Mondal, M.S.; Mandal, M.C. FPA based optimization of drilling burr using regression analysis and ANN model. Measurement 2020, 152, 107327. [Google Scholar] [CrossRef]

- Jia, Z.; Zhang, C.; Wang, F.; Fu, R.; Chen, C. An investigation of the effects of step drill geometry on drilling induced delamination and burr of Ti/CFRP stacks. Compos. Struct. 2020, 235, 111786. [Google Scholar] [CrossRef]

- Kwon, B.; Mai, N.D.D.; Cheon, E.S.; Ko, S.L. Development of a step drill for minimization of delamination and uncut in drilling carbon fiber reinforced plastics (CFRP). Int. J. Adv. Manuf. Tech. 2020, 106, 1291–1301. [Google Scholar] [CrossRef]

- Hassan, A.A.; Soo, S.L.; Aspinwall, D.K.; Arnold, D.; Dowson, D. An analytical model to predict interlayer burr size following drilling of CFRP-metallic stack assemblies. Cirp. Ann. Manuf. Technol. 2020, 69, 109–112. [Google Scholar] [CrossRef]

- Hu, L.; Zheng, K.; Dong, S. Burr characteristics of robotic rotary ultrasonic drilling aluminum alloy stacked components. J. Beijing Univ. Aeronaut. Astronaut. 2020, 46, 407–413. [Google Scholar]

- Li, S.; Zhang, D.; Liu, C.; Tang, H. Exit burr height mechanistic modeling and experimental validation for low-frequency vibration-assisted drilling of aluminum 7075-T6 alloy. J. Manuf. Proc. 2020, 56, 350–361. [Google Scholar] [CrossRef]

- Yang, F.; Xing, Y.; Li, X. A comprehensive error compensation strategy for machining process with general fixture layouts. Int. J. Adv. Manuf. Tech. 2020, 107, 2707–2717. [Google Scholar] [CrossRef]

- Chen, B.; Chen, X.; Li, B.; He, Z.; Cao, H.; Cai, G. Reliability estimation for cutting tool based on logistic regression model. J. Mech. Eng. 2011, 47, 158–164. [Google Scholar] [CrossRef]

- Gebraeel, N.; Lawley, M. A neural network degradation model for computing and updating residual life distributions. IEEE Trans. Autom. Sci. Eng. 2008, 5, 154–163. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, B.; Liu, Q. Analysis and comparison of various cutting force models in the milling process simulation. J. Vib. Eng. 2015, 28, 82–90. [Google Scholar]

- Chang, D.; Pang, J.; Pan, J. Dynamics modeling of deep hole processing based on boring and trepanning association. Sci. Technol. Eng. 2014, 14, 216–219. [Google Scholar]

- Zheng, X.; Dong, D.; Huang, L.; An, Q.; Wang, X.; Chen, M. Research on fixture hole drilling quality of printed circuit board. Int. J. Precis. Eng. Man. 2013, 14, 525–534. [Google Scholar] [CrossRef]

- Xavier, R.; Francois, C.J.; Ewa, K.S.J.; Marek, B. Burr height monitoring while drilling CFRP/ titanium/aluminium stacks. Mech. Ind. 2017, 18, 114–125. [Google Scholar]

- An, Q.; Tao, Z.; Xu, X.; Mansori, M.E.; Chen, M. A data-driven model for milling tool remaining useful life prediction with convolutional and stacked LSTM network. Measurement 2020, 154, 107461. [Google Scholar] [CrossRef]

- Xu, X.; Tao, Z.; Ming, W.; An, Q.; Chen, M. Intelligent monitoring and diagnostics using a novel integrated model based on deep learning and multi-sensor feature fusion. Measurement 2020, 165, 108086. [Google Scholar] [CrossRef]

- Dahl, G.E.; Yu, D.; Deng, L.; Acero, A. Context-dependent pre-trained deep neural networks for large-vocabulary speech recognition. IEEE Trans. Audio Speech Lang. Processing 2011, 20, 30–42. [Google Scholar] [CrossRef] [Green Version]

- Montavon, G.; Samek, W.; Müller, K. Methods for interpreting and understanding deep neural networks. Digit. Signal Proc. 2018, 73, 1–15. [Google Scholar] [CrossRef]

- Abd-Elwahed, M.S. Drilling process of GFRP composites: Modeling and optimization using hybrid ANN. Sustainability 2022, 14, 6599. [Google Scholar] [CrossRef]

- Gaitonde, V.N.; Karnik, S.R. Minimizing burr size in drilling using artificial neural network (ANN)-particle swarm optimization (PSO) approach. J. Intell. Manuf. 2012, 23, 1783–1793. [Google Scholar] [CrossRef]

- Gan, M.; Wang, C.; Zhu, C.A. Construction of hierarchical diagnosis network based on deep learning and its application in the fault pattern recognition of rolling element bearings. Mech. Syst. Signal Pr. 2016, 72–73, 92–104. [Google Scholar] [CrossRef]

- Wang, J.; Ye, L.; Gao, R.; Li, C.; Zhang, L. Digital Twin for rotating machinery fault diagnosis in smart manufacturing. Int. J. Prod. Res. 2019, 57, 3920–3934. [Google Scholar] [CrossRef]

- Yu, J.; Song, Y.; Tang, D.; Dai, J. A Digital Twin approach based on nonparametric Bayesian network for complex system health monitoring. J. Manuf. Syst. 2020, 2020, 293–304. [Google Scholar] [CrossRef]

- Booyse, W.; Wilke, D.N.; Heyns, S. Deep digital twins for detection, diagnostics and prognostics. Mech. Syst. Signal Pr. 2020, 140, 106612. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Ye, Y.; Zhang, C.; Wei, Y. A hybrid predictive maintenance approach for CNC machine tool driven by Digital Twin. Robot C. Int. Manuf. 2020, 65, 101974. [Google Scholar] [CrossRef]

- Wang, C.; Erkorkmaz, K.; Mcphee, J.; Engin, S. In-process digital twin estimation for high-performance machine tools with coupled multibody dynamics. Cirp. Ann.-Manuf. Technol. 2020, 69, 321–324. [Google Scholar] [CrossRef]

- Hu, F.; Yang, Y.; Liu, S.; Zheng, X.; Lv, X.; Bao, J. Digital twin high-fidelity modeling method for spinning forming of aerospace thin-walled parts. CIMS 2022, 28, 1282–1292. [Google Scholar]

- Liu, J.; Zhao, P.; Zhou, H.; Liu, X.; Feng, F. Digital twin-driven machining process evaluation method. CIMS 2019, 25, 1600–1610. [Google Scholar]

- Liu, S.; Bao, J.; Lu, Y.; Li, J.; Lu, S.; Sun, X. Digital twin modeling method based on biomimicry for machining aerospace components. J. Manuf. Syst. 2021, 58, 180–195. [Google Scholar] [CrossRef]

- Han, G.; Pan, G.; Wu, W.; Xu, L. Research on the burr forming characteristics of ultrasonic assisted micro-milling process. J. B Inst Technol. 2018, 38, 888–892. [Google Scholar]

- Zaeh, M.; Roesch, O. Improvement of the machining accuracy of milling robots. Prod. Eng. 2014, 8, 737–744. [Google Scholar] [CrossRef]

- Huang, J.; Huang, J.; Yang, C.; Wang, G. Development research on micro-machining burr. Mach. Des. Manuf. 2014, 7, 256–258. [Google Scholar]

- Wu, D.; Huang, S.; Gao, Y.; Dong, Y.; Ma, X. Predictive model for the interlayer burr height during drilling of stacked aluminum plates. J. Tsinghua Univ. Sci. Technol. 2017, 57, 591–596, 603. [Google Scholar]

- Hu, Y.; Song, Y.; Li, Y.; Yao, Z. An analytical model to predict interfacial burr height for metal stack drilling. Proc. Inst. Mech. Eng. Part B 2019, 233, 99–108. [Google Scholar] [CrossRef]

- Sachnik, P.; Hoque, S.E.; Volk, W. Burr-free cutting edges by notch-shear cutting. J. Mater. Proc. Tech. 2017, 249, 229–245. [Google Scholar] [CrossRef]

- Régnier, T.; Fromentin, G.; Marcon, B.; Outeiro, J.; D’Acunto, A.; Crolet, A.; Grunder, T. Fundamental study of exit burr formation mechanisms during orthogonal cutting of AlSi aluminium alloy. J. Mater. Proc. Tech. 2018, 257, 112–122. [Google Scholar] [CrossRef] [Green Version]

- Zhou, W.; Liao, W.; Tian, W. Theory and experiment of industrial robot accuracy compensation method based on spatial interpolation. J. Eng. Mech. 2013, 49, 42–44. [Google Scholar] [CrossRef]

- Gao, X.; Ma, D.; Han, H.; Gao, H. Fault prediction of complex industrial process based on DAE and TCN. Chin. J. Sci. Instrum. 2021, 42, 140–151. [Google Scholar]

- Shi, H.; Liu, X.; Xiao, Q. Improved temporal convolutional networks for sequential recommendation. J. Chin. Comput. Syst. 2021, 42, 1382–1388. [Google Scholar]

- Tsironi, E.; Barros, P.; Weber, C.; Wermter, S. An analysis of convolutional long short-term memory recurrent neural networks for gesture recognition. Neurocomputing 2017, 268, 76–86. [Google Scholar] [CrossRef]

| Level | Burr Height Ratio (Burr Height/Material Thickness) | Rating Instructions |

|---|---|---|

| Level 1 | <5% | This rating may be deemed not to require deburring operations. |

| Level 2 | 5–7% | This rating is considered a qualified hole for deburring operations. |

| Level 3 | >7% | Deburring should be carried out, and the hole qualification should be evaluated. |

| Main Components | Relevant Parameters |

|---|---|

| Rotary servomotor of power head spindle | Rated power: 1.8 kw; torque: 6 Nm |

| Feed servomotor of power head spindle | Rated power: 0.4 kw; torque: 1.27 Nm |

| Data acquisition card DMC-B140-M (Table A1) | Displacement: 32 bit Velocity: maximum output pulse 32 MHz Acceleration: maximum 1,073,740,800 pulse/s2 |

| Acceleration sensor INV3062T (Table A2) | AD precision: 24 bits; dynamic range: 120 dB |

| Four-axis force sensor NOS C906 (Table A3) | Rated load: 1 KN/1 KN/2 KN/200 Nm; sensitivity: 1% |

| Serial Number | Feed (mm) | Spindle Speed (r/min) | Burr Height (mm) | Workpiece Thickness (mm) | Real Burr Classification | Drilling Mechanism Classification | Error Label |

|---|---|---|---|---|---|---|---|

| 1 | 0.16 | 1600 | 0.71 | 6 | Level 3 | Level 3 | Null |

| 2 | 0.18 | 1600 | 0.43 | 6 | Level 2 | Level 2 | Null |

| 3 | 0.20 | 1800 | 0.59 | 6 | Level 3 | Level 3 | Null |

| 4 | 0.22 | 1800 | 0.77 | 6 | Level 3 | Level 3 | Null |

| 5 | 0.16 | 2000 | 0.31 | 6 | Level 2 | Level 3 | Up grading |

| 6 | 0.18 | 2000 | 0.23 | 6 | Level 1 | Level 2 | Up grading |

| 7 | 0.20 | 2200 | 0.42 | 6 | Level 2 | Level 2 | Null |

| 8 | 0.22 | 2200 | 0.33 | 6 | Level 2 | Level 1 | Down grading |

| 9 | 0.16 | 2400 | 0.29 | 6 | Level 1 | Level 1 | Null |

| 10 | 0.18 | 2400 | 0.38 | 6 | Level 2 | Level 2 | Null |

| Layer Name | Specific Description |

|---|---|

| Convolutional Layer 1 | Using convolution expansion; convolution block d = 1; activation function Relu; dropout coefficient 0.5 |

| Convolutional Layer 2 | Using convolution expansion; convolution block d = 2; the convolution sequence is convolved for each time period; activation function Relu; dropout coefficient 0.5 |

| Convolutional Layer 3 | Using convolution expansion; convolution block d = 4; the convolution sequence is convolved for each time period; activation function Relu; dropout coefficient 0.5 |

| Convolutional Layer 4 | Using convolution expansion; convolution block d = 8; the convolution sequence is convolved for each time period; activation function Relu; dropout coefficient 0.5 |

| Convolutional Layer 5 | Using convolution expansion; convolution block d = 16; the convolution sequence is convolved for each time period; activation function Relu; dropout coefficient 0.5 |

| Fully Connected Layer 1 | Node number 256; activation function Relu |

| Fully Connected Layer 2 | Node number 128; activation function Relu |

| Fully Connected Layer 3 | Node number 3; activation function Relu |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, S.; Zheng, X.; Wu, M.; Yang, Q. A Novel Sustainable Processing Mode for Burr Classified Prediction of Weak Rigid Drilling Process Using a Fusion Modeling Method. Sustainability 2022, 14, 7429. https://doi.org/10.3390/su14127429

Ding S, Zheng X, Wu M, Yang Q. A Novel Sustainable Processing Mode for Burr Classified Prediction of Weak Rigid Drilling Process Using a Fusion Modeling Method. Sustainability. 2022; 14(12):7429. https://doi.org/10.3390/su14127429

Chicago/Turabian StyleDing, Siyi, Xiaohu Zheng, Mingyu Wu, and Qirui Yang. 2022. "A Novel Sustainable Processing Mode for Burr Classified Prediction of Weak Rigid Drilling Process Using a Fusion Modeling Method" Sustainability 14, no. 12: 7429. https://doi.org/10.3390/su14127429

APA StyleDing, S., Zheng, X., Wu, M., & Yang, Q. (2022). A Novel Sustainable Processing Mode for Burr Classified Prediction of Weak Rigid Drilling Process Using a Fusion Modeling Method. Sustainability, 14(12), 7429. https://doi.org/10.3390/su14127429