Comparative Study of Combustion, Performance and Emission Characteristics of Hydrotreated Vegetable Oil–Biobutanol Fuel Blends and Diesel Fuel on a CI Engine

Abstract

1. Introduction

2. Materials and Methods

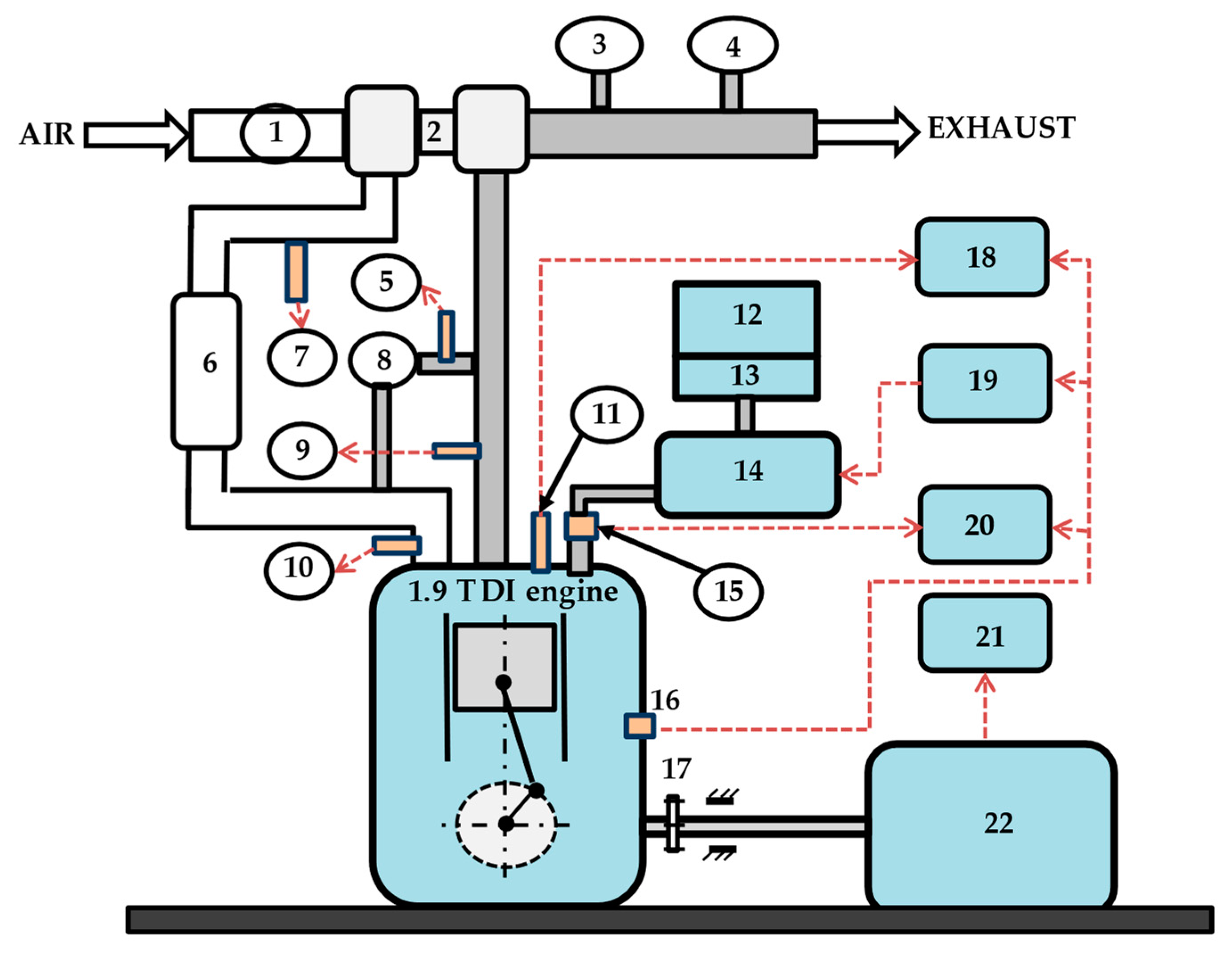

2.1. Testing Engine

2.2. Fuels and Testing Methods

3. Results and Discussion

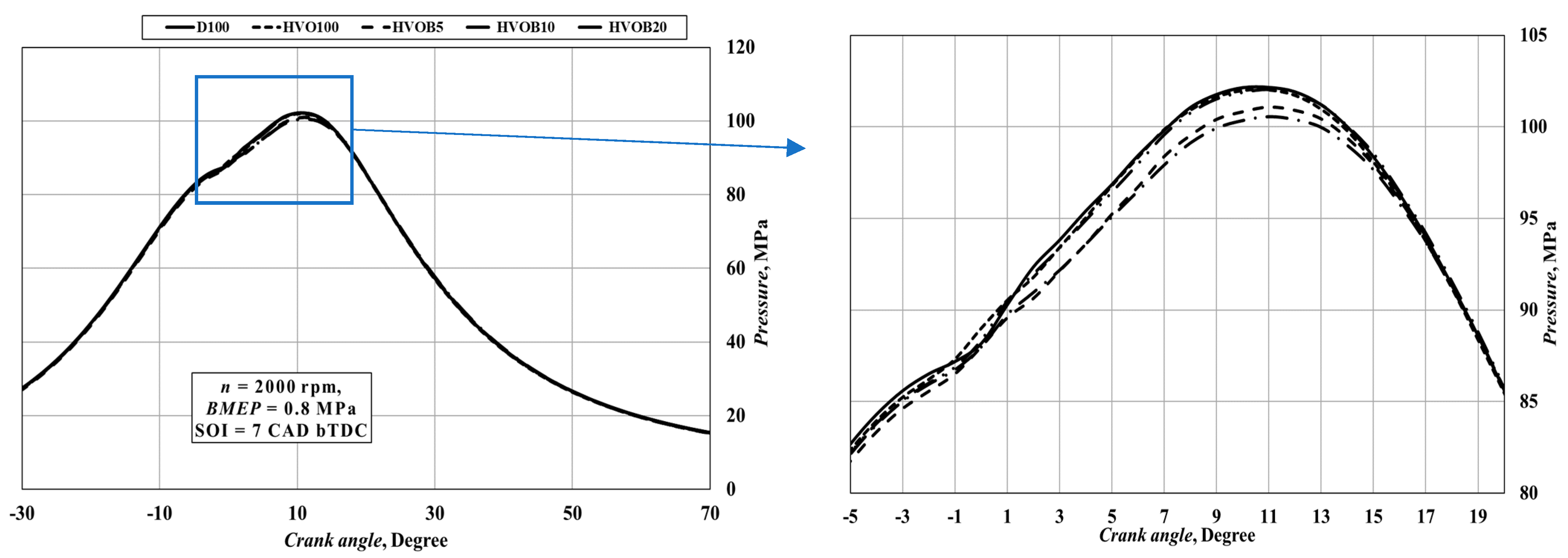

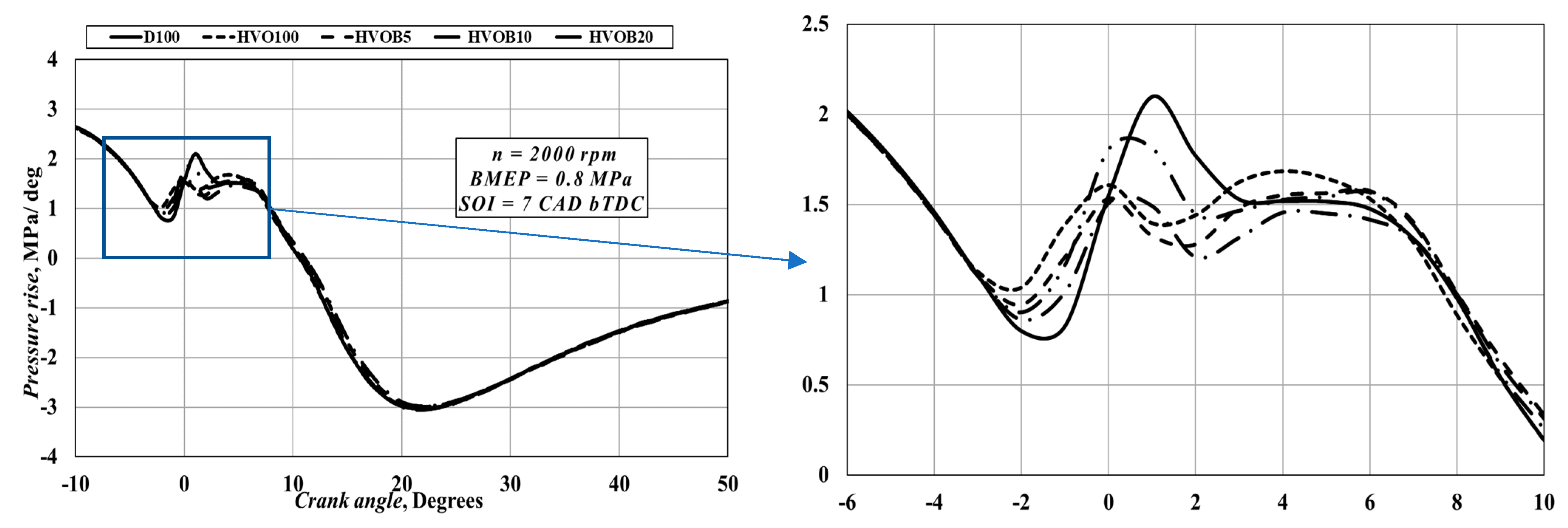

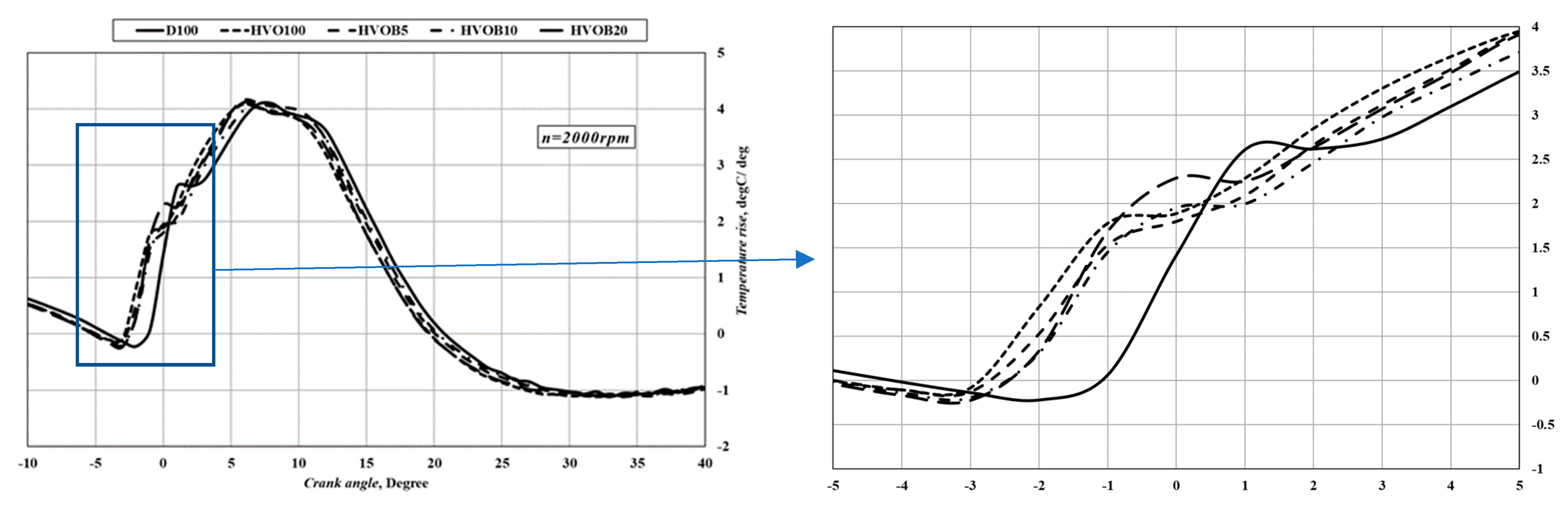

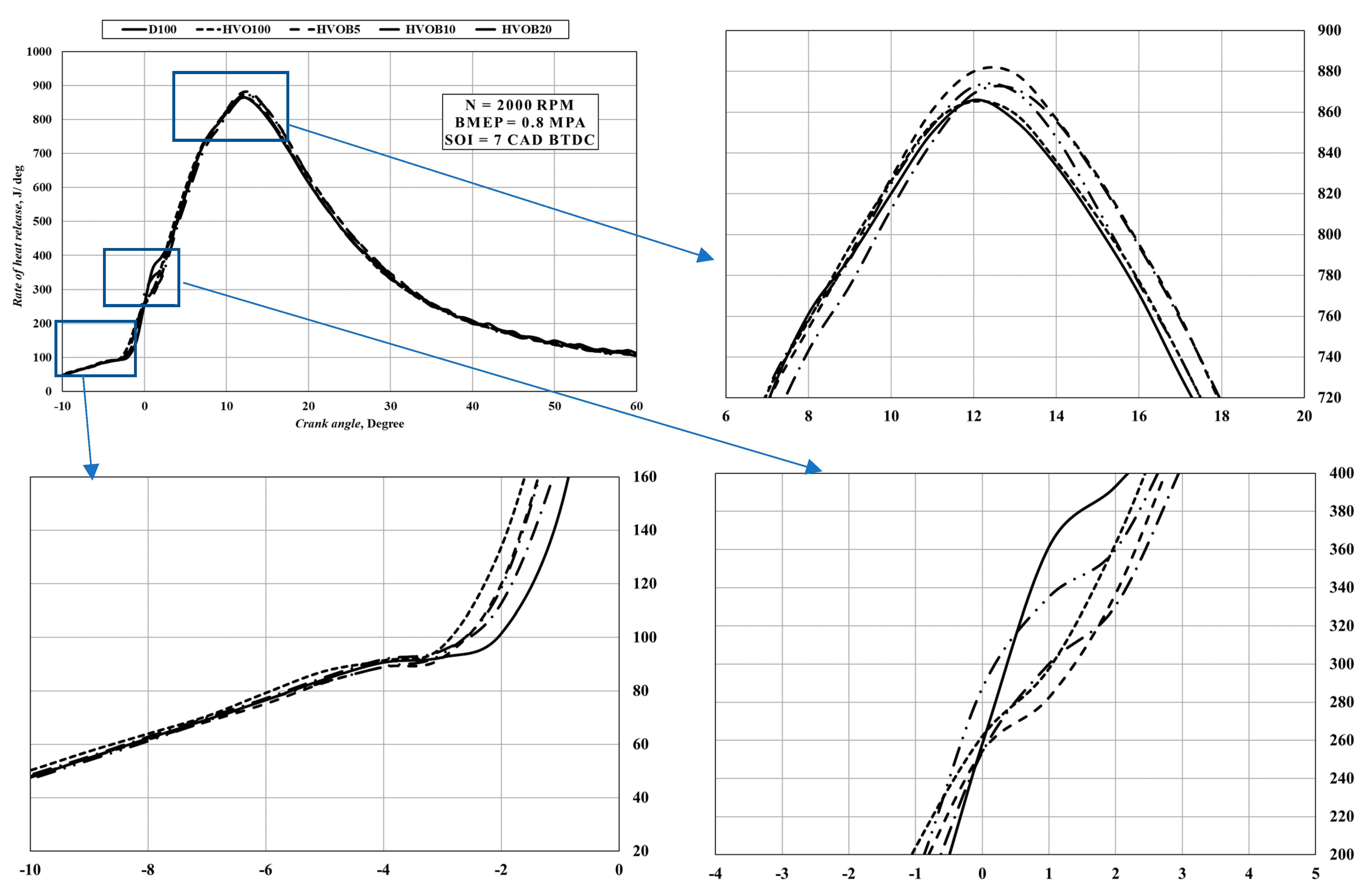

3.1. Combustion Parameters

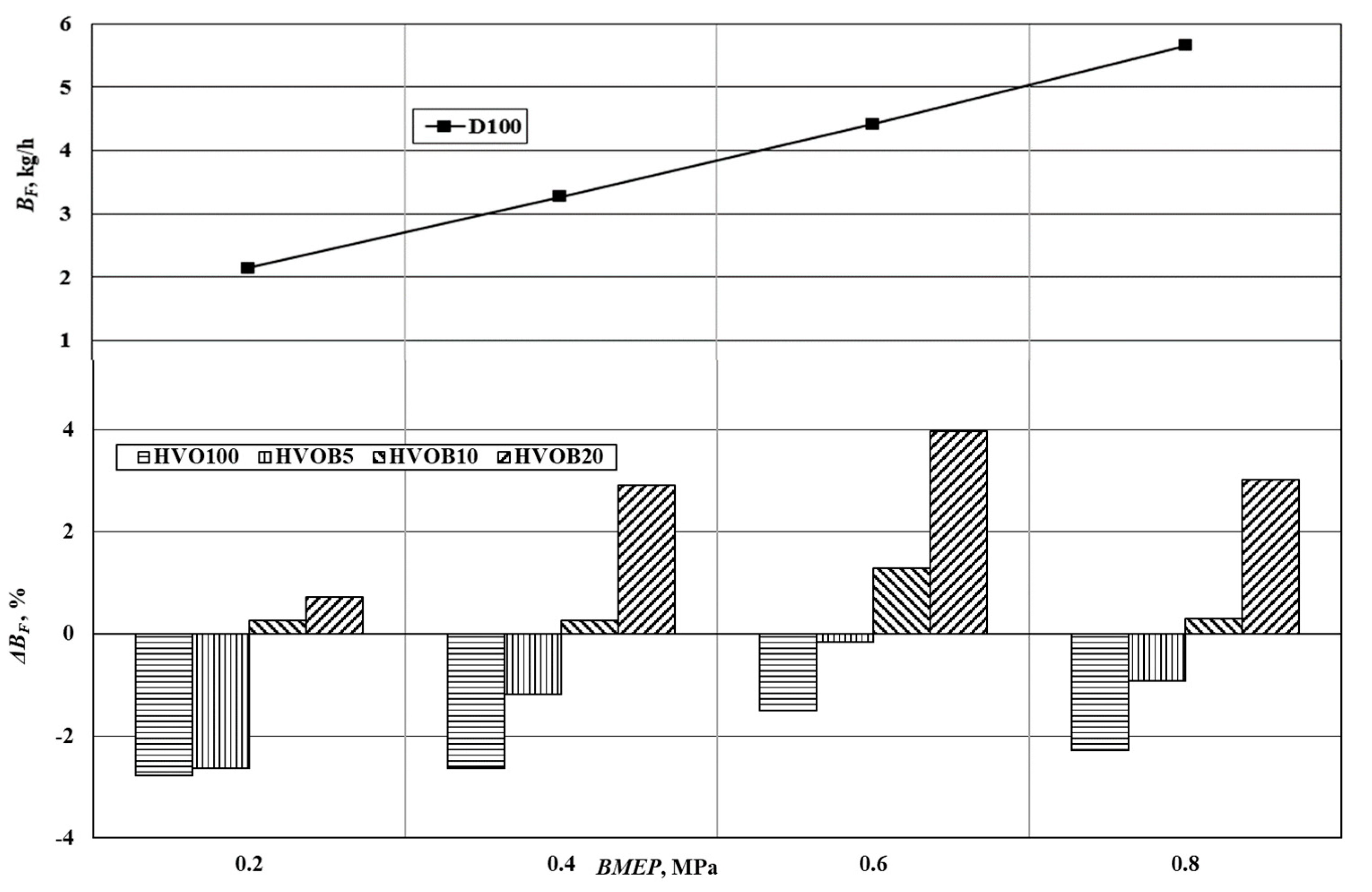

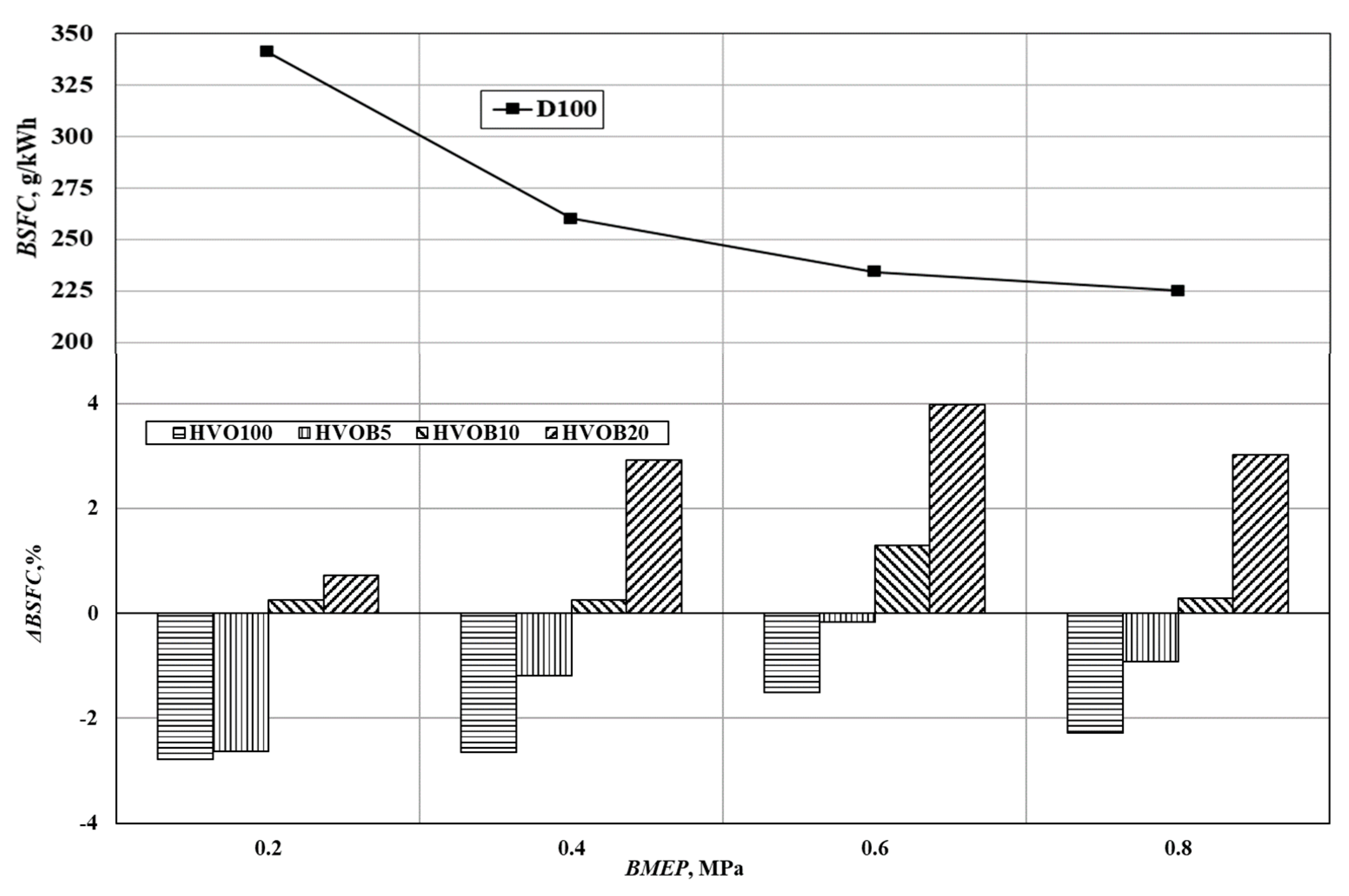

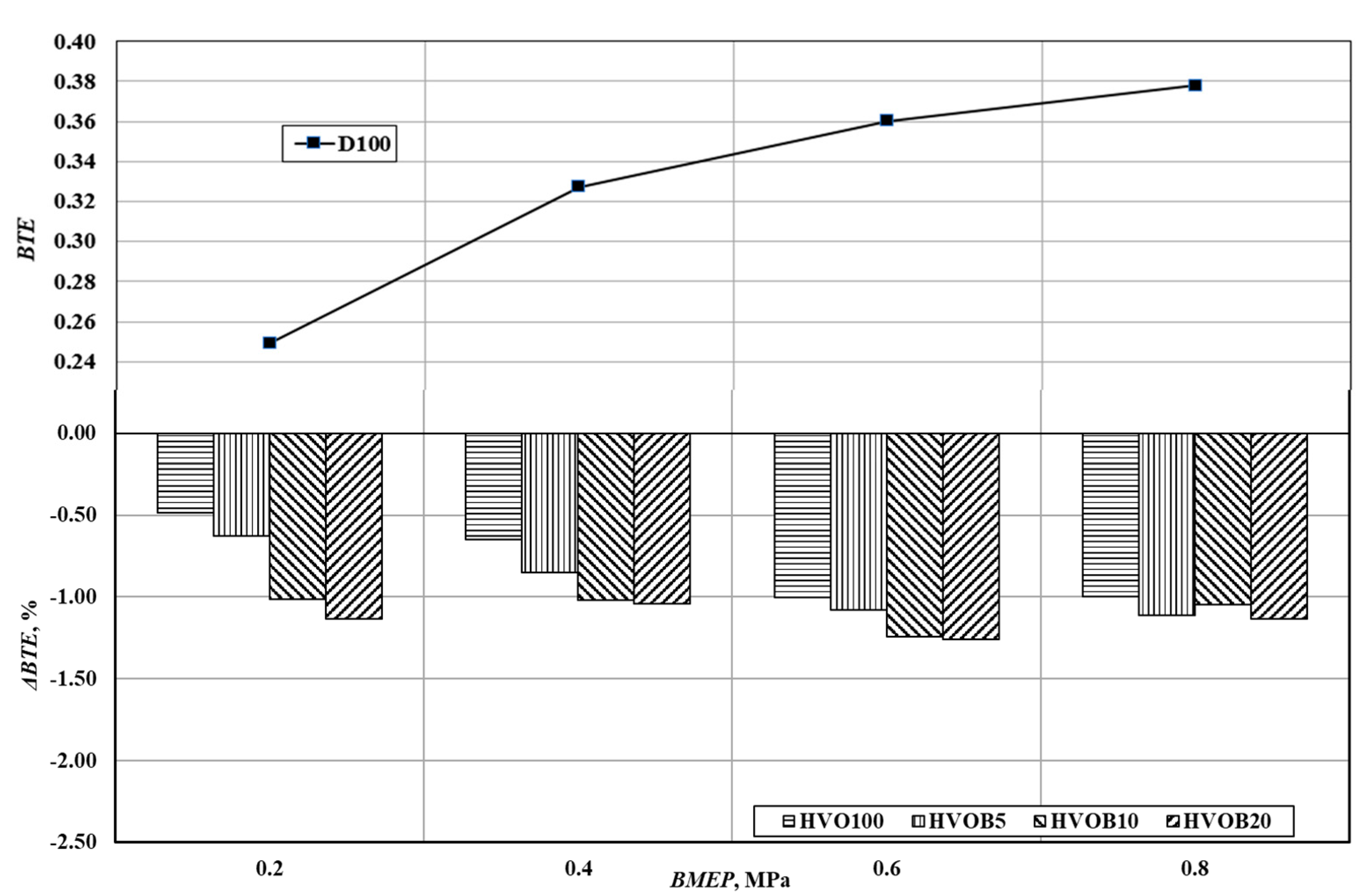

3.2. Performance Indicators

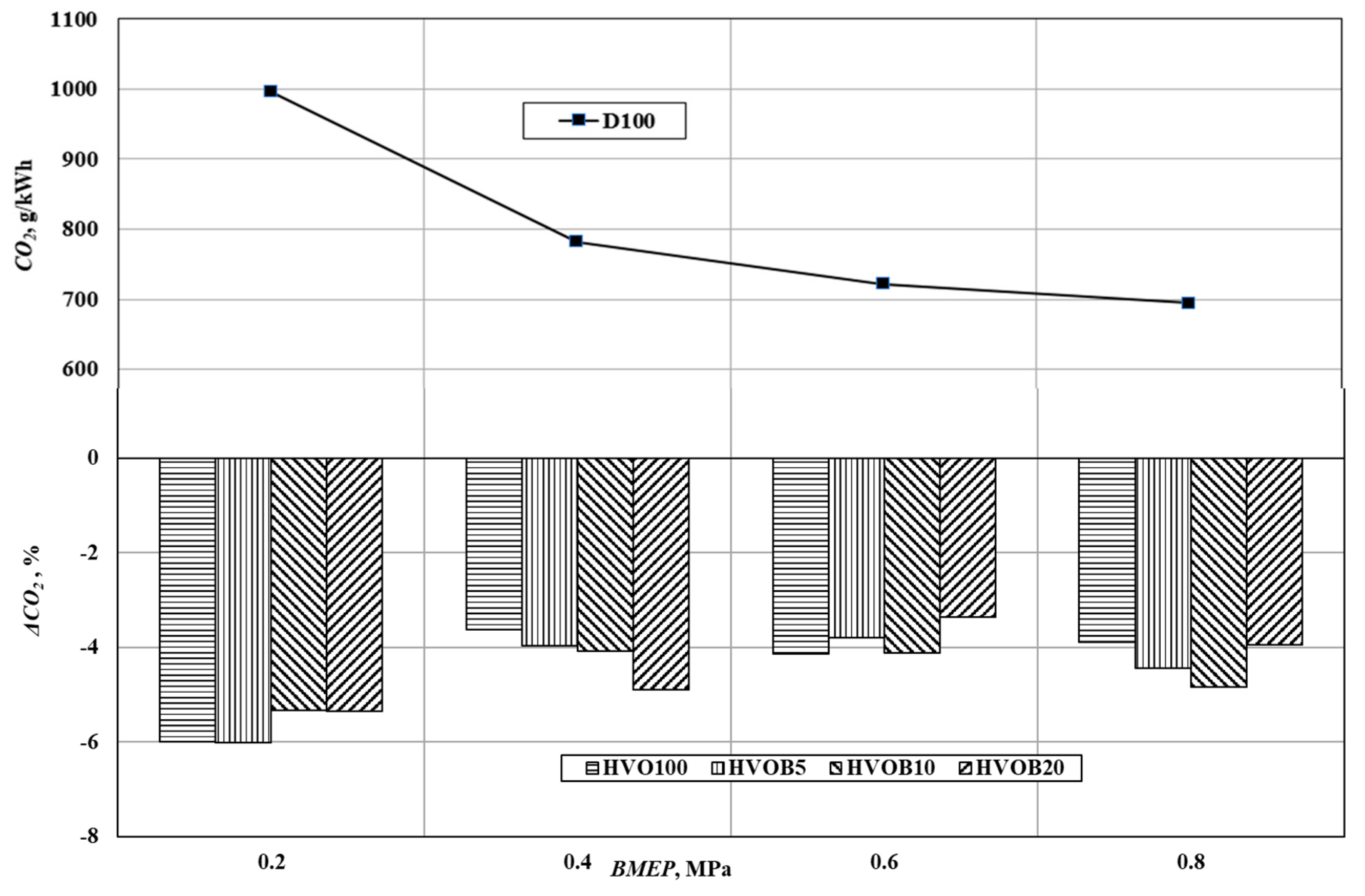

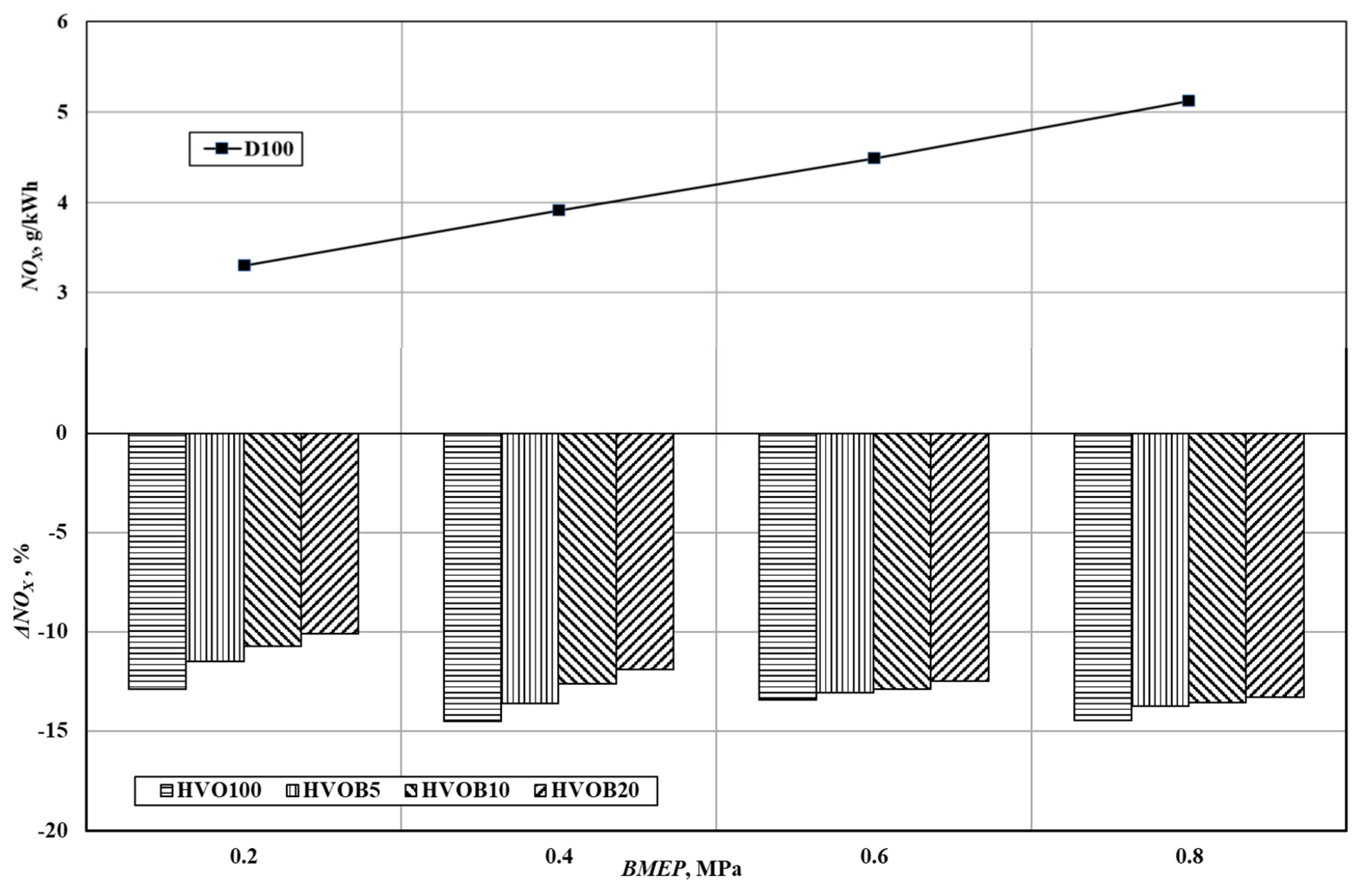

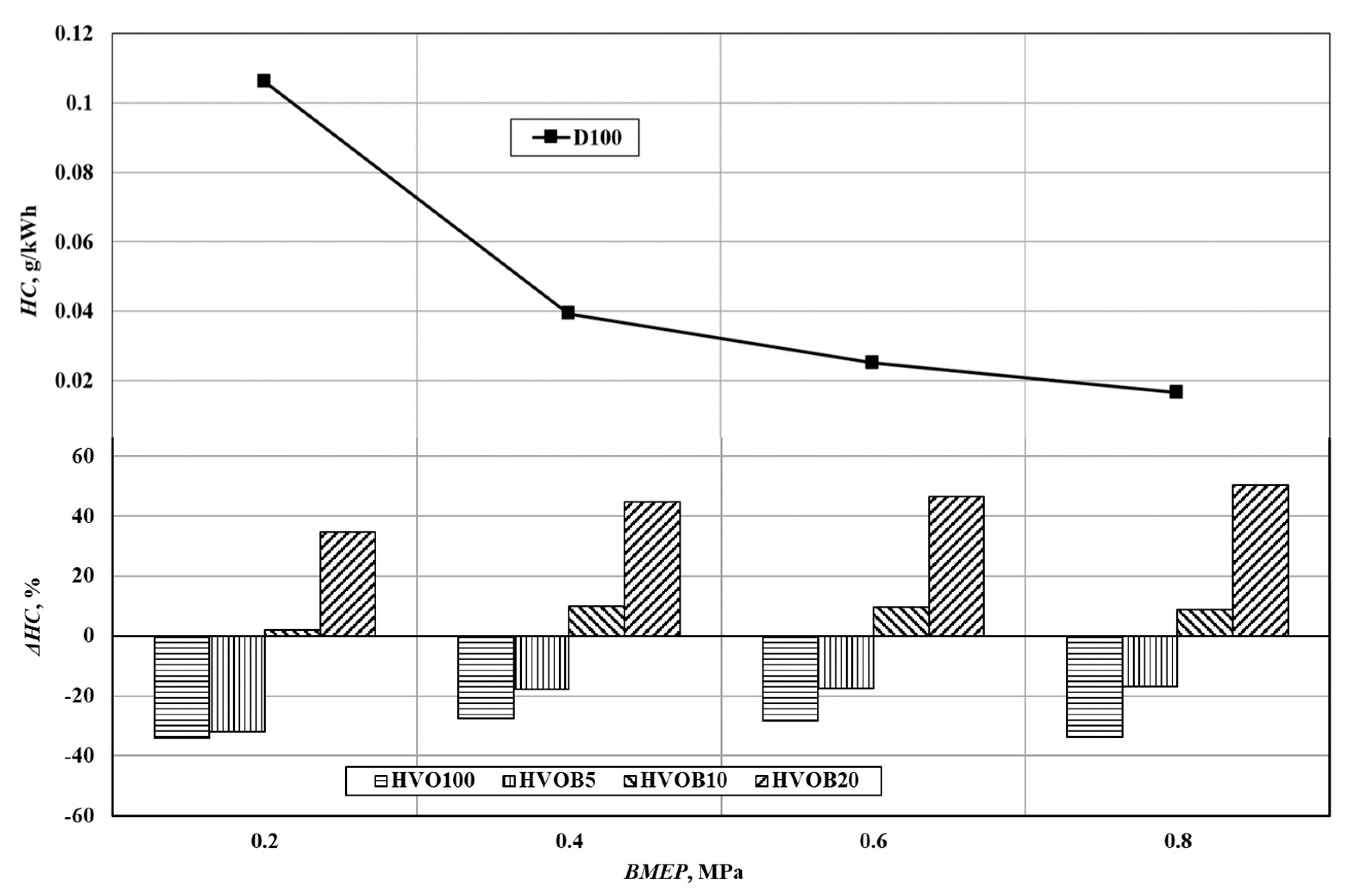

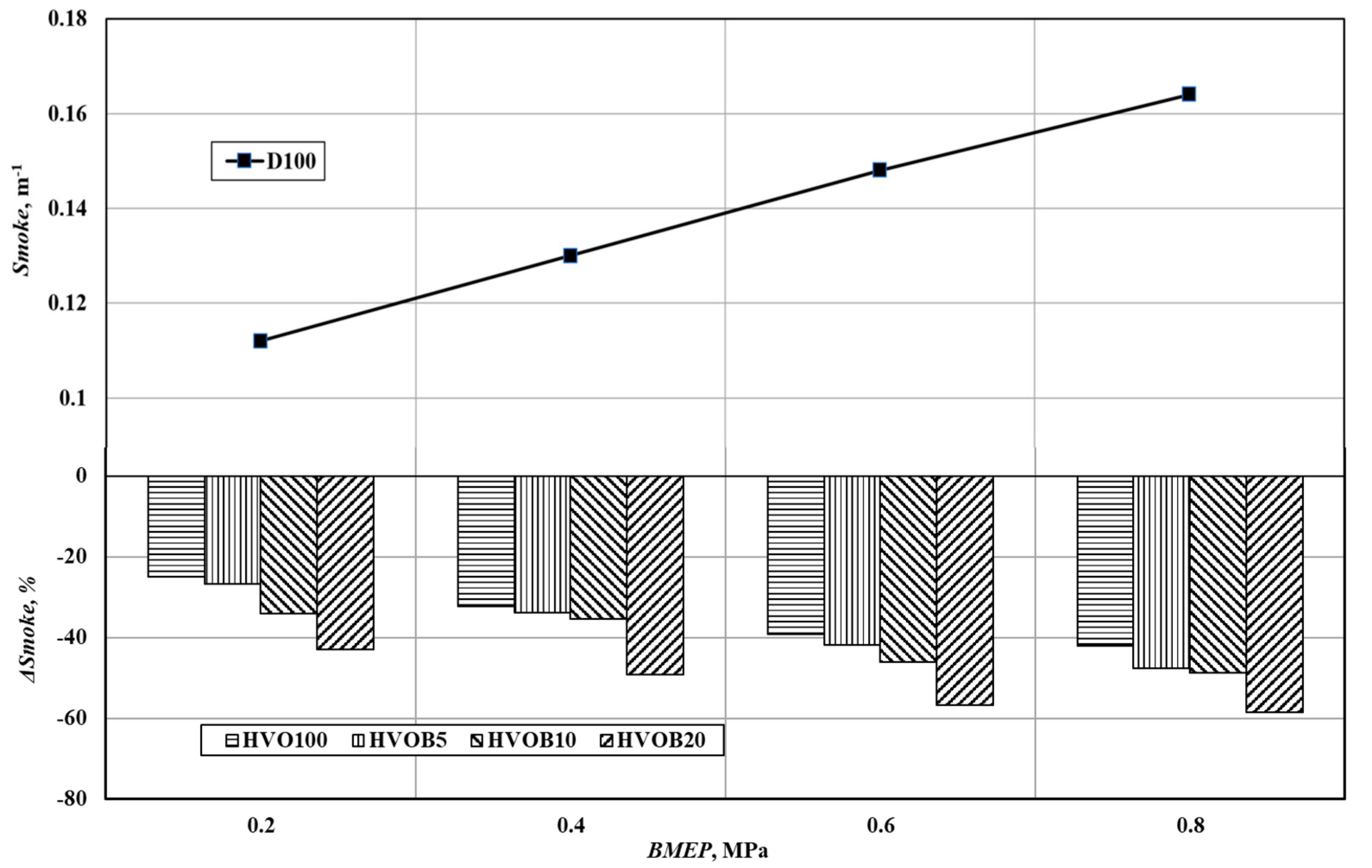

3.3. Emission Characteristics

4. Conclusions

- The blending of HVO and Butanol greatly complemented each other’s properties, and they had a great influence on increasing the performance and decreasing the emissions. Upon increasing the butanol concentration by 5% and 20% (from HVOB5 to HVOB10 and HVOB20), there appeared to be a 2- and 4-fold increase in the oxygen content. At the same time, with an increase in butanol content, the CN was found to decrease by ~3.5%, and the value was more than doubled to ~7.4% when the butanol content increased further to 20%.

- HVO, with its high CN, had the shortest ignition delay, but the combustion duration period was longer. With the rise in butanol percentage, the CN was reduced following the delay order, with diesel fuel ranking last, while the combustion duration period was extended due to butanol. BSFC, which is determined by the fuel LHV and the combustion process, is found to decrease with an increasing butanol concentration. The BSFC of D100 can be matched with HVOB5 and HVOB10.

- There is a comparatively small difference in BTE of all the fuels, with diesel being the highest. At lower loads, the fuel blends with HVO100 are ~0.5–1% lower than that of diesel, and at higher loads, the difference is found to be ~1–1.5%. The decrease in BTE is due to the longer combustion process caused by decreasing the calorific value of the fuel by increasing the concentration of butanol in the mixture with HVO fuel.

- Due to the low C/H ratio of HVO100, B100 and its blends, CO2 emissions are reduced by approximately ~4–6% at any given load. A stable reduction of ~10–15% in NOX emissions was observed at all loads for all the fuel mixtures with HVO100. Due to its high CN (which is ~50% higher than that of D100) and a lower combustion intensity during the premixing phase, HVO100 is found to have a consistent decrease in nitrogen emissions at all loads. With an increase in butanol content, the CN of the fuel blends was reduced, thereby increasing their NOX emissions. HVO100 was found to have the lowest emissions of HC, with an average reduction of ~31% at all loads compared to D100. With an increase in butanol, the HC emissions were found to increase due to prolonged combustion. Furthermore, with an increase in O2 content and a decrease in the C/H ratio with an increasing butanol concentration, the smoke levels were found to decrease at a minimum of ~30%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CNG | Compressed Natural Gas |

| LNG | Liquid Natural Gas |

| HVO | Hydro-treated Vegetable Oil |

| BTE | Brake Thermal Efficiency |

| BSFC | Brake Specific Fuel Consumption |

| ROHR | Rate of Heat Release |

| ECU | Electronic Control Unit |

| SOI | Start of Injection |

| bTDC | before Top Dead Centre |

| CO2 | Carbon Dioxide |

| CO | Carbon Monoxide |

| HC | Hydro Carbons |

| NOx | Nitrogen Oxides |

| PM | Particulate Matter |

References

- Di Blasio, G.; Agarwal, A.K.; Belgiorno, G.; Shukla, P.C. Introduction to Clean Fuels for Mobility. In Clean Fuels for Mobility; Energy, Environment, and Sustainability; Di Blasio, G., Agarwal, A.K., Belgiorno, G., Shukla, P.C., Eds.; Springer: Singapore, 2022; pp. 3–7. ISBN 9789811687471. [Google Scholar]

- Mizik, T. Sustainable Fuels in Private Transportation–Present and Future Potential. In Clean Fuels for Mobility; Energy, Environment, and Sustainability; Di Blasio, G., Agarwal, A.K., Belgiorno, G., Shukla, P.C., Eds.; Springer: Singapore, 2022; pp. 9–26. ISBN 9789811687471. [Google Scholar]

- Marczak, H.; Droździel, P. Analysis of Pollutants Emission into the Air at the Stage of an Electric Vehicle Operation. J. Ecol. Eng. 2021, 22, 182–188. [Google Scholar] [CrossRef]

- Wasilewski, J.; Szyszlak-Bargłowicz, J.; Zając, G.; Szczepanik, M. Assessment of Co2 Emission by Tractor Engine at Varied Control Settings of Fuel Unit. Agric. Eng. 2020, 24, 105–115. [Google Scholar] [CrossRef]

- ACEA—European Automobile Manufacturers’ Association. Fuel Types of New Cars: Battery Electric 7.5%, Hybrid 19.3%, Petrol 41.8% Market Share in Q2 2021; ACEA—European Automobile Manufacturers’ Association: Brussels, Belgium, 2021. [Google Scholar]

- Czech, P.; Madej, H. Application of Cepstrum and Spectrum Histograms of Vibration Engine Body for Setting up the Clearance Model of the Piston-Cylinder Assembly for RBF Neural Classifier. Eksploat. Niezawodn. Maint. Reliab. 2011, 52, 15–20. [Google Scholar]

- Figlus, T.; Liściak, S. Assessment of the Vibroactivity Level of SI Engines in Stationary and Non-Stationary Operating Conditions. J. Vibroeng. 2014, 16, 1349–1359. [Google Scholar]

- Pielecha, J.; Skobiej, K.; Kurtyka, K. Exhaust Emissions and Energy Consumption Analysis of Conventional, Hybrid, and Electric Vehicles in Real Driving Cycles. Energies 2020, 13, 6423. [Google Scholar] [CrossRef]

- Rybicka, I.; Stopka, O.; L’uptak, V.; Chovancova, M.; Droździel, P. Application of the methodology related to the emission standard to specific railway line in comparison with parallel road transport: A case study. In MATEC Web of Conferences; EDP Sciences: Ulis, France, 2018; Volume 244, p. 03002. [Google Scholar] [CrossRef]

- Kukuča, P.; Barta, D.; Labuda, R.; Gechev, T. Engine with Unconventional Crank Mechanism FIK 1. In MATEC Web of Conferences; EDP Sciences: Ulis, France, 2018; Volume 244, p. 03004. [Google Scholar] [CrossRef]

- Mieczkowski, G.; Szpica, D.; Borawski, A.; Diliunas, S.; Pilkaite, T.; Leisis, V. Application of Smart Materials in the Actuation System of a Gas Injector. Materials 2021, 14, 6984. [Google Scholar] [CrossRef]

- Krzysiak, Z.; Bartnik, G.; Samociuk, W.; Zarajczyk, J.; Plizga, K.; Rachwal, B.; Wierzbicki, S.; Krzywonos, L.; Brumercik, F. Analiza zagrożenia bezpieczeństwa przeciwwybuchowego na stacji paliw ciekłych. Przem. Chem. 2017, 96, 279–282. [Google Scholar] [CrossRef]

- Longwic, R.; Nieoczym, A.; Kordos, P. Evaluation of the Combustion Process in a Spark-Ignition Engine Based on the Unrepeatability of the Maximum Pressure. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 421, p. 042048. [Google Scholar] [CrossRef]

- Mamala, J.; Brol, S.; Graba, G. Hardware-in-the-Loop Type Simulator of Spark Ignition Engine Control Unit. In Proceedings of the 2013 International Symposium on Electrodynamic and Mechatronic Systems (SELM), Opole-Zawiercie, Poland, 15–18 May 2013; pp. 41–42. [Google Scholar]

- Szpica, D. Investigating Fuel Dosage Non-Repeatability of Low-Pressure Gas-Phase Injectors. Flow Meas. Instrum. 2018, 59, 147–156. [Google Scholar] [CrossRef]

- Aulin, D.; Klymenko, O.; Falendysh, A.; Kletska, O.; Dizo, J. Improvement of Diesel Injector Nozzle Test Techniques. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 985, p. 012031. [Google Scholar] [CrossRef]

- Eliasz, J.; Osipowicz, T.; Abramek, K.F.; Matuszak, Z.; Mozga, Ł. Fuel Pretreatment Systems in Modern CI Engines. Catalysts 2020, 10, 696. [Google Scholar] [CrossRef]

- Osipowicz, T.; Abramek, K.F.; Matuszak, Z.; Jaskiewicz, M.; Ludwinek, K.A.; Lagowski, P. The Concept of Annular Channels Application on the Spraying Nozzle Needle of Modern Fuel Injector in the Aspect of Combustion Process Improvement. In Proceedings of the 2018 XI International Science-Technical Conference Automotive Safety, Častá, Slovakia, 18–20 April 2018; pp. 1–7. [Google Scholar]

- Punov, P.; Gechev, T.; Mihalkov, S.; Podevin, P.; Barta, D. Experimental Study of Multiple Pilot Injection Strategy in an Automotive Direct Injection Diesel Engine. In MATEC Web of Conferences; EDP Sciences: Ulis, France, 2018; Volume 234, p. 03007. [Google Scholar] [CrossRef][Green Version]

- Wierzbicki, S.; Śmieja, M. Use of Biogas to Power Diesel Engines with Common Rail Fuel Systems. In MATEC Web of Conferences; EDP Sciences: Ulis, France, 2018; Volume 182, p. 01018. [Google Scholar] [CrossRef]

- Hurtová, I.; Sejkorová, M.; Verner, J. A Study of Diesel Particulate Filter Impact on Engine Oil Quality. In Proceedings of the Transport Means—Proceedings of the International Conference, Palanga, Litwa, 2–4 October 2019; Technologija: Kaunas, Lithuania, 2019; pp. 691–695. [Google Scholar]

- Gritsuk, I.; Volkov, V.; Gutarevych, Y.; Mateichyk, V.; Verbovskiy, V. Improving Engine Pre-Start and after-Start Heating by Using the Combined Heating System; SAE International: Warrendale, PA, USA, 27 September 2016; No. 2016-01-8071. [Google Scholar]

- Sejkorová, M.; Šarkan, B.; Verner, J. Efficiency Assessment of Fuel Borne Catalyst. In MATEC Web of Conferences; EDP Sciences: Ulis, France, 2017; Volume 134, p. 00051. [Google Scholar] [CrossRef]

- Fabiś, P.; Flekiewicz, M. Optimalisation of the SI Engine Timing Advance Fueled by LPG. Sci. J. Silesian Univ. Technol. Ser. Transp. 2021, 111, 33–41. [Google Scholar] [CrossRef]

- Šarkan, B.; Hudec, J.; Sejkorova, M.; Kuranc, A.; Kiktova, M. Calculation of the Production of Exhaust Emissions in the Laboratory Conditions. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2021; Volume 1736, p. 012022. [Google Scholar] [CrossRef]

- Ding, S.-L.; Song, E.-Z.; Yang, L.-P.; Litak, G.; Wang, Y.-Y.; Yao, C.; Ma, X.-Z. Analysis of Chaos in the Combustion Process of Premixed Natural Gas Engine. Appl. Therm. Eng. 2017, 121, 768–778. [Google Scholar] [CrossRef]

- Lebedevas, S.; Čepaitis, T. Parametric Analysis of the Combustion Cycle of a Diesel Engine for Operation on Natural Gas. Sustainability 2021, 13, 2773. [Google Scholar] [CrossRef]

- Bialy, M.; Wendeker, M.; Magryta, P.; Czyz, Z.; Sochaczewski, R. CFD Model of the Mixture Formation Process of the CNG Direct Injection Engine; SAE International: Warrendale, PA, USA, 13 October 2014; No. 2014-01–2575. [Google Scholar]

- Szpica, D.; Dziewiątkowski, M. Catalyst Conversion Rates Measurement on Engine Fueled with Compressed Natural Gas (CNG) Using Different Operating Temperatures. Mechanika 2021, 27, 492–497. [Google Scholar] [CrossRef]

- Khan, M.I.; Yasmin, T.; Shakoor, A. Technical Overview of Compressed Natural Gas (CNG) as a Transportation Fuel. Renew. Sustain. Energy Rev. 2015, 51, 785–797. [Google Scholar] [CrossRef]

- Jurkovič, M.; Kalina, T.; Skrúcaný, T.; Gorzelanczyk, P.; Ľupták, V. Environmental Impacts of Introducing LNG as Alternative Fuel for Urban Buses—Case Study in Slovakia. Promet-Traffic Transp. 2020, 32, 837–847. [Google Scholar] [CrossRef]

- Langshaw, L.; Ainalis, D.; Acha, S.; Shah, N.; Stettler, M.E.J. Environmental and Economic Analysis of Liquefied Natural Gas (LNG) for Heavy Goods Vehicles in the UK: A Well-to-Wheel and Total Cost of Ownership Evaluation. Energy Policy 2020, 137, 111161. [Google Scholar] [CrossRef]

- Jurkovič, M.; Kalina, T. Posúdenie pevnostných charakteristík LNG nádrží na plavidlách. Perner’s Contacts 2019, 14, 74–80. [Google Scholar]

- Duda, K.; Wierzbicki, S.; Mikulski, M.; Konieczny, Ł.; Łazarz, B.; Letuń-Łątka, M. Emissions from a medium-duty crdi engine fuelled with diesel-biodiesel blends. Transp. Probl. 2021, 16, 39–49. [Google Scholar] [CrossRef]

- Górski, K.; Sander, P.; Longwic, R. The Assessment of Ecological Parameters of Diesel Engine Supplied with Mixtures of Canola Oil with N-Hexane. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 421, p. 042025. [Google Scholar] [CrossRef]

- Hunicz, J.; Mikulski, M.; Shukla, P.C.; Gęca, M.S. Partially Premixed Combustion of Hydrotreated Vegetable Oil in a Diesel Engine: Sensitivity to Boost and Exhaust Gas Recirculation. Fuel 2022, 307, 121910. [Google Scholar] [CrossRef]

- Labaj, J.; Barta, D. Unsteady Flow Simulation and Combustion of Ethanol in Diesel Engines. Komunikácie 2006, 8, 27–37. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O.; Wasiak, A.; Świć, A.; Mieszkalski, L.; Wichłacz, J. Low Emissions Resulting from Combustion of Forest Biomass in a Small Scale Heating Device. Energies 2020, 13, 5495. [Google Scholar] [CrossRef]

- Zdziennicka, A.; Szymczyk, K.; Jańczuk, B.; Longwic, R.; Sander, P. Surface, Volumetric, and Wetting Properties of Oleic, Linoleic, and Linolenic Acids with Regards to Application of Canola Oil in Diesel Engines. Appl. Sci. 2019, 9, 3445. [Google Scholar] [CrossRef]

- Holjevac, N.; Cheli, F.; Gobbi, M. Multi-Objective Vehicle Optimization: Comparison of Combustion Engine, Hybrid and Electric Powertrains. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 234, 469–487. [Google Scholar] [CrossRef]

- Gil, L.; Pieniak, D.; Walczak, M.; Ignaciuk, P.; Sawa, J. Impact of acid number of fuels on the wear process of apparatus for fuel injection in diesel engines. Adv. Sci. Technol. Res. J. 2014, 8, 54–57. [Google Scholar] [CrossRef]

- Aatola, H.; Larmi, M.; Sarjovaara, T.; Mikkonen, S. Hydrotreated Vegetable Oil (HVO) as a Renewable Diesel Fuel: Trade-off between NOₓ, Particulate Emission, and Fuel Consumption of a Heavy Duty Engine. SAE Int. J. Engines 2009, 1, 1251–1262. [Google Scholar] [CrossRef]

- Gowdagiri, S.; Cesari, X.M.; Huang, M.; Oehlschlaeger, M.A. A Diesel Engine Study of Conventional and Alternative Diesel and Jet Fuels: Ignition and Emissions Characteristics. Fuel 2014, 136, 253–260. [Google Scholar] [CrossRef]

- AECC Position on Euro 7/VII. EURO 7/VII Emission Standards. For Cars, Vans, Buses and Trucks. Available online: https://www.aecc.eu/wp-content/uploads/2021/06/210628-AECC-position-on-Euro-7-final.pdf (accessed on 14 May 2022).

- Chen, H.; Su, X.; He, J.; Zhang, P.; Xu, H.; Zhou, C. Investigation on Combustion Characteristics of Cyclopentanol/Diesel Fuel Blends in an Optical Engine. Renew. Energy 2021, 167, 811–829. [Google Scholar] [CrossRef]

- Tunér, M. Combustion of Alternative Vehicle Fuels in Internal Combustion Engines; The Swedish Knowledge Centre of Renewable Transportation: Lund, Sweden, 2015; p. 40. [Google Scholar]

- Vojtisek-Lom, M.; Beránek, V.; Mikuška, P.; Křůmal, K.; Coufalík, P.; Sikorová, J.; Topinka, J. Blends of Butanol and Hydrotreated Vegetable Oils as Drop-in Replacement for Diesel Engines: Effects on Combustion and Emissions. Fuel 2017, 197, 407–421. [Google Scholar] [CrossRef]

- Pflaum, H.; Hofmann, P.; Geringer, B.; Weissel, W. Potential of Hydrogenated Vegetable Oil (HVO) in a Modern Diesel Engine; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Parravicini, M.; Barro, C.; Boulouchos, K. Experimental Characterization of GTL, HVO, and OME Based Alternative Fuels for Diesel Engines. Fuel 2021, 292, 120177. [Google Scholar] [CrossRef]

- Shepel, O.; Matijošius, J.; Rimkus, A.; Duda, K.; Mikulski, M. Research of Parameters of a Compression Ignition Engine Using Various Fuel Mixtures of Hydrotreated Vegetable Oil (HVO) and Fatty Acid Esters (FAE). Energies 2021, 14, 3077. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, C.D.; Dimaratos, A.M.; Rakopoulos, D.C. Exhaust Emissions with Ethanol or N-Butanol Diesel Fuel Blends during Transient Operation: A Review. Renew. Sustain. Energy Rev. 2013, 17, 170–190. [Google Scholar] [CrossRef]

- Zhang, Q.; Yao, M.; Zheng, Z.; Liu, H.; Xu, J. Experimental Study of N-Butanol Addition on Performance and Emissions with Diesel Low Temperature Combustion. Energy 2012, 47, 515–521. [Google Scholar] [CrossRef]

- Chen, H.; He, J.; Chen, Z.; Geng, L. A Comparative Study of Combustion and Emission Characteristics of Dual-Fuel Engine Fueled with Diesel/Methanol and Diesel–Polyoxymethylene Dimethyl Ether Blend/Methanol. Process Saf. Environ. Prot. 2021, 147, 714–722. [Google Scholar] [CrossRef]

- Han, J.; Bao, H.; Somers, L.M.T. Experimental Investigation of Reactivity Controlled Compression Ignition with N-Butanol/n-Heptane in a Heavy-Duty Diesel Engine. Appl. Energy 2021, 282, 116164. [Google Scholar] [CrossRef]

- Žvar Baškovič, U.; Vihar, R.; Rodman Oprešnik, S.; Seljak, T.; Katrašnik, T. RCCI Combustion with Renewable Fuel Mix—Tailoring Operating Parameters to Minimize Exhaust Emissions. Fuel 2022, 311, 122590. [Google Scholar] [CrossRef]

- Choudhary, P.; Rao, B.; Sharma, N. Butanol Fuel in Internal Combustion Engines. In Application of Clean Fuels in Combustion Engines; Energy, Environment, and Sustainability; Di Blasio, G., Agarwal, A.K., Belgiorno, G., Shukla, P.C., Eds.; Springer: Singapore, 2022; pp. 103–116. ISBN 9789811687518. [Google Scholar]

- Karagöz, M. Investigation of Performance and Emission Characteristics of an CI Engine Fuelled with Diesel—Waste Tire Oil—Butanol Blends. Fuel 2020, 282, 118872. [Google Scholar] [CrossRef]

- Kumar Sharma, P.; Sharma, D.; Lal Soni, S.; Jhalani, A.; Singh, D.; Sharma, S. Energy, Exergy, and Emission Analysis of a Hydroxyl Fueled Compression Ignition Engine under Dual Fuel Mode. Fuel 2020, 265, 116923. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Dimaratos, A.M.; Giakoumis, E.G.; Rakopoulos, D.C. Investigating the Emissions during Acceleration of a Turbocharged Diesel Engine Operating with Bio-Diesel or n-Butanol Diesel Fuel Blends. Energy 2010, 35, 5173–5184. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G.; Papagiannakis, R.G.; Kyritsis, D.C. Influence of Properties of Various Common Bio-Fuels on the Combustion and Emission Characteristics of High-Speed DI (Direct Injection) Diesel Engine: Vegetable Oil, Bio-Diesel, Ethanol, n-Butanol, Diethyl Ether. Energy 2014, 73, 354–366. [Google Scholar] [CrossRef]

- Miers, S.A.; Carlson, R.W.; McConnell, S.S.; Ng, H.K.; Wallner, T.; LeFeber, J. Video & Multimedia, Esper Images. Drive Cycle Analysis of Butanol/Diesel Blends in a Light-Duty Vehicle; SAE International: Warrendale, PA, USA, 2008. [Google Scholar]

- Karthick, C.; Nanthagopal, K. A comprehensive review on ecological approaches of waste to wealth strategies for production of sustainable biobutanol and its suitability in automotive applications. Energy Convers. Manag. 2021, 239, 114219. [Google Scholar] [CrossRef]

- Zöldy, M. Fuel Properties of Butanol—Hydrogenated Vegetable Oil Blends as a Diesel Extender Option for Internal Combustion Engines. Period. Polytech. Chem. Eng. 2020, 64, 205–212. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Fuel injection | Direct injection (single) |

| Fuel injection-pump design | Axial-piston distributor injection pump |

| Displacement (cm3) | 1896 |

| No. of cylinders | 4 |

| Compression ratio | 19.5 |

| Power (kW) | 66 (4000 rpm) |

| Torque (Nm) | 180 (2000–25,000 rpm) |

| Bore (mm) | 79.5 |

| Stroke (mm) | 95.5 |

| Nozzle type | Hole-type |

| Nozzle and holder assembly | Two-spring |

| Nozzle opening pressure (bar) | 200 |

| PROPERTIES | D100 | HVO100 | B100 |

|---|---|---|---|

| Density (kg/m3) | 835 | 779 | 809.8 |

| Mass Fraction (%): Carbon | 86.0 | 84.6 | 64.82 |

| Hydrogen | 13.9 | 15.4 | 13.6 |

| Oxygen | 0.1 | 0.00 | 21.59 |

| C/H | 6.19 | 5.49 | 4.77 |

| LHV, MJ/kg | 42.31 | 43.74 | 33.1 |

| Cetane number | 51.0 | 76.3 | 25.0 |

| PROPERTIES | D100 | HVO100 | HVOB5 | HVOB10 | HVOB20 |

|---|---|---|---|---|---|

| Density (kg/m3) | 835 | 779 | 780.6 | 782.19 | 785.35 |

| Mass Fraction (%): Carbon | 86.0 | 84.6 | 83.57 | 82.55 | 80.52 |

| Hydrogen | 13.9 | 15.4 | 15.31 | 15.21 | 15.03 |

| Oxygen | 0.1 | 0.00 | 1.12 | 2.24 | 4.45 |

| C/H | 6.19 | 5.49 | 5.46 | 5.43 | 5.36 |

| LHV, MJ/kg | 42.31 | 43.74 | 43.19 | 42.64 | 41.54 |

| Cetane number | 51.0 | 76.3 | 73.64 | 70.99 | 65.72 |

| Fuels | SOI, CAD BTDC | SOC, CAD BTDC | Delay, CAD | CD, CAD |

|---|---|---|---|---|

| D100 | 7.0 | 2.0 | 5.0 | 68.0 |

| HVO100 | 7.0 | 3.0 | 4.0 | 69.0 |

| HVOB5 | 7.0 | 2.6 | 4.4 | 69.4 |

| HVOB10 | 7.0 | 2.5 | 4.5 | 69.7 |

| HVOB20 | 7.0 | 2.4 | 4.6 | 70.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rayapureddy, S.M.; Matijošius, J.; Rimkus, A.; Caban, J.; Słowik, T. Comparative Study of Combustion, Performance and Emission Characteristics of Hydrotreated Vegetable Oil–Biobutanol Fuel Blends and Diesel Fuel on a CI Engine. Sustainability 2022, 14, 7324. https://doi.org/10.3390/su14127324

Rayapureddy SM, Matijošius J, Rimkus A, Caban J, Słowik T. Comparative Study of Combustion, Performance and Emission Characteristics of Hydrotreated Vegetable Oil–Biobutanol Fuel Blends and Diesel Fuel on a CI Engine. Sustainability. 2022; 14(12):7324. https://doi.org/10.3390/su14127324

Chicago/Turabian StyleRayapureddy, Sai Manoj, Jonas Matijošius, Alfredas Rimkus, Jacek Caban, and Tomasz Słowik. 2022. "Comparative Study of Combustion, Performance and Emission Characteristics of Hydrotreated Vegetable Oil–Biobutanol Fuel Blends and Diesel Fuel on a CI Engine" Sustainability 14, no. 12: 7324. https://doi.org/10.3390/su14127324

APA StyleRayapureddy, S. M., Matijošius, J., Rimkus, A., Caban, J., & Słowik, T. (2022). Comparative Study of Combustion, Performance and Emission Characteristics of Hydrotreated Vegetable Oil–Biobutanol Fuel Blends and Diesel Fuel on a CI Engine. Sustainability, 14(12), 7324. https://doi.org/10.3390/su14127324