Systems Accounting for Carbon Emissions by Hydropower Plant

Abstract

:1. Introduction

2. Methodology

2.1. Framework of Life-Cycle Carbon Emissions Accounting for a Hydropower Plant

2.1.1. Direct Carbon Emissions Accounting

- (1)

- Fossil fuels combustion.

- (2)

- Reservoir surface release.

- (3)

- Carbon release from sediment.

2.1.2. Indirect Carbon Emissions Accounting

- (1)

- Categorize all inputs to form the inventory.

- (2)

- Choose an appropriate embodied carbon emission intensity database for all inputs.

- (3)

- Calculate the indirect carbon emissions of each input.

2.2. Indicator

3. Case Study

3.1. Case Description

3.2. The Carbon Emissions Accounting of the Case Plant

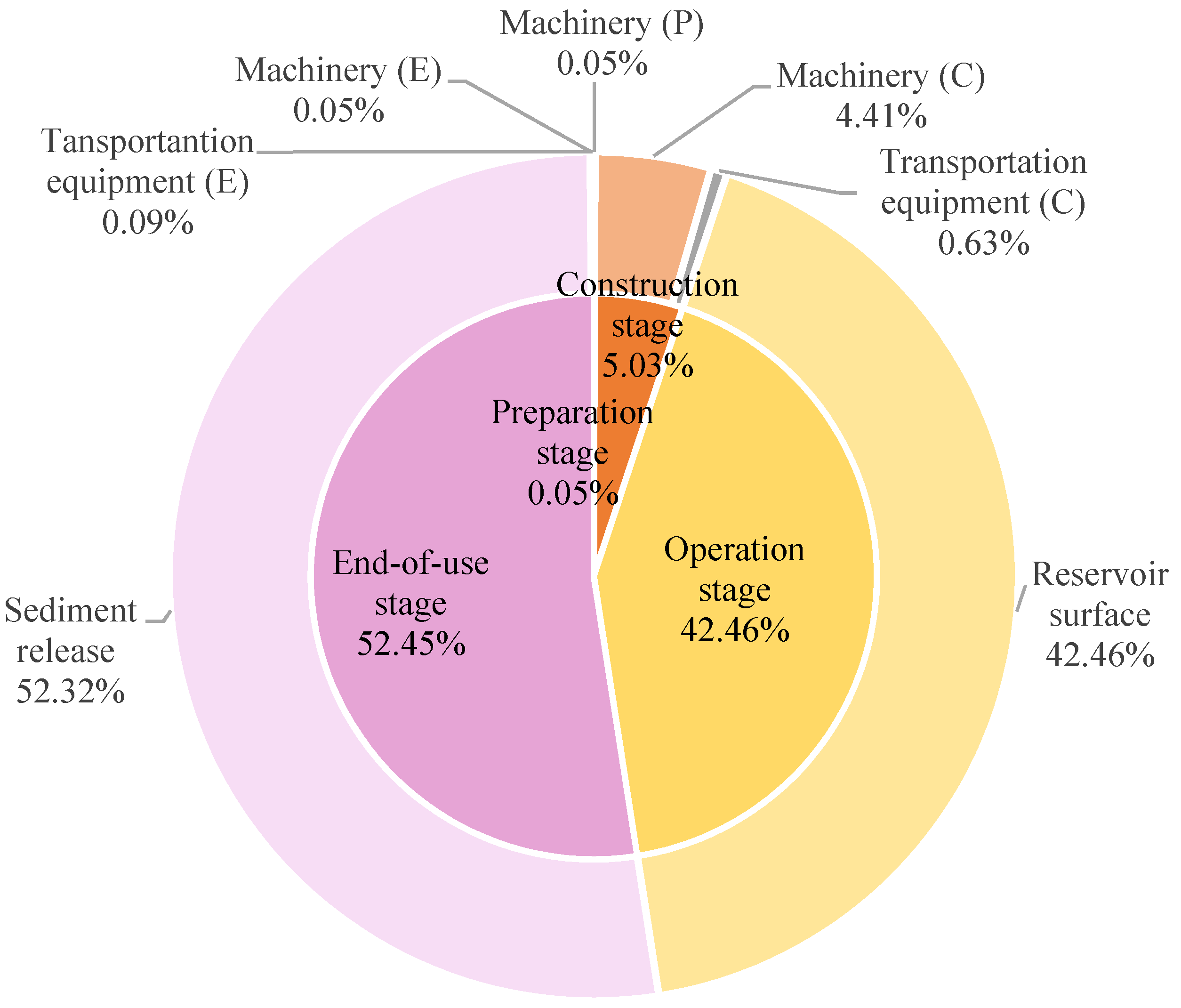

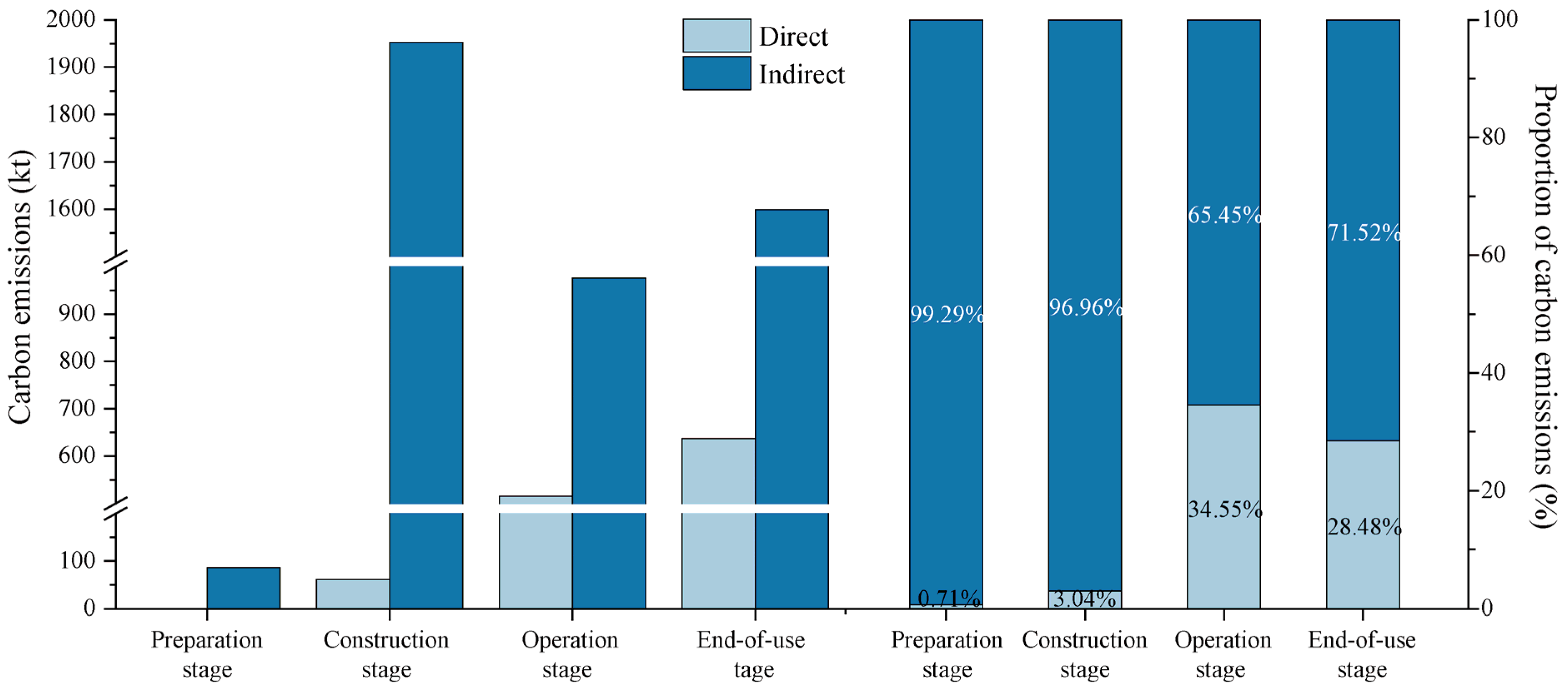

3.2.1. Direct Carbon Emissions

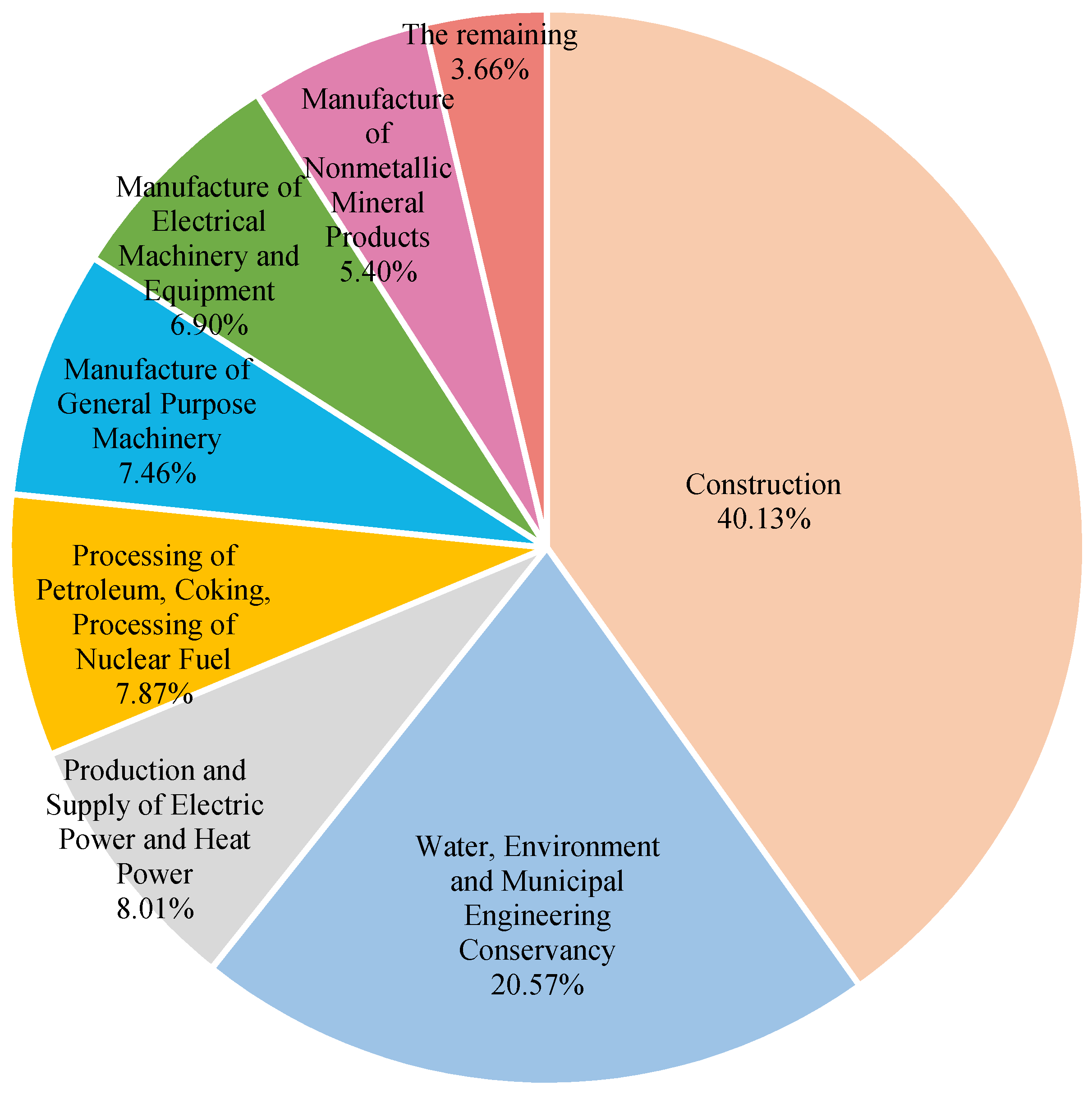

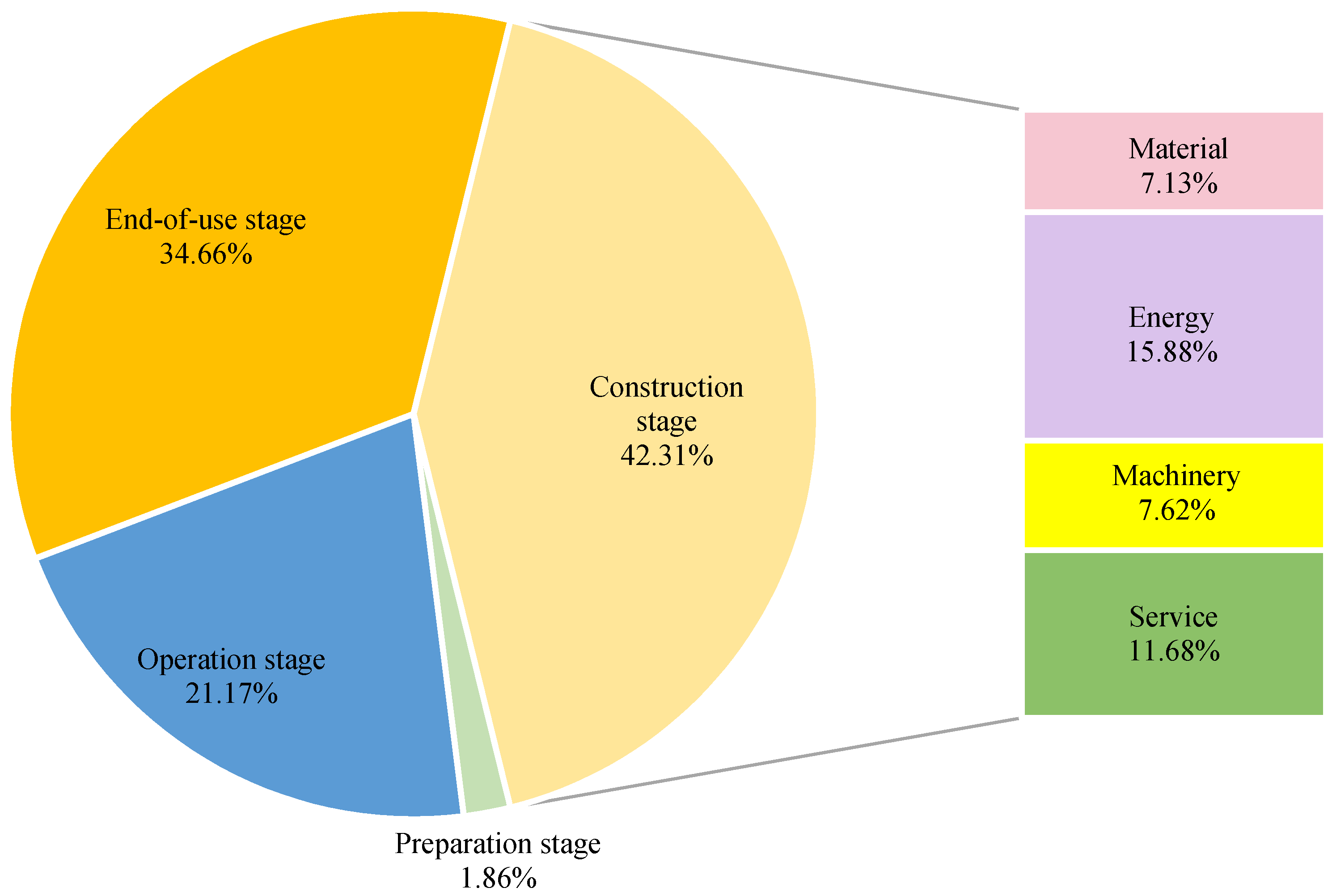

3.2.2. Indirect Carbon Emissions

3.2.3. The Life-Cycle Carbon Emissions

4. Discussion

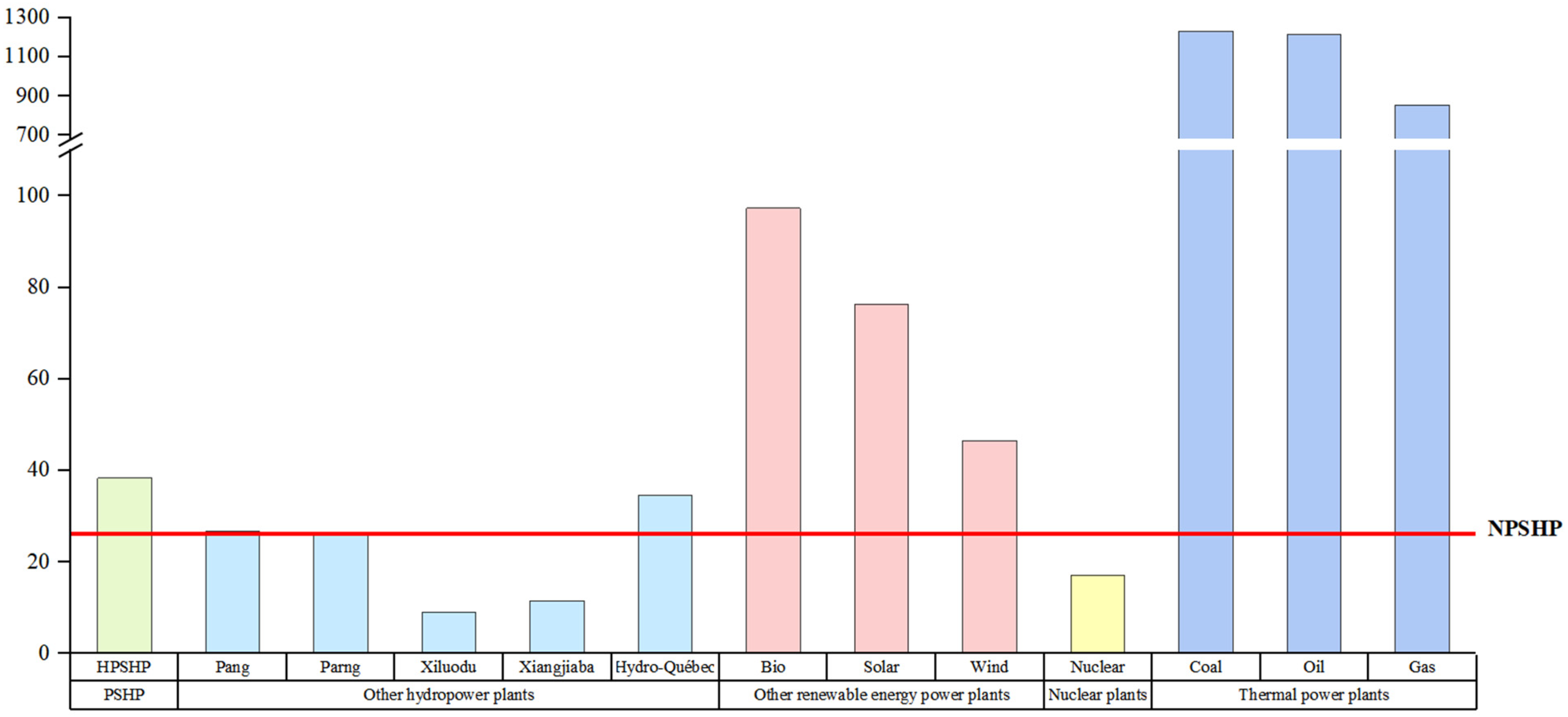

4.1. Comparison with Other Power Plants

4.2. Uncertainty and Outlook

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sovacool, B.K.; Schmid, P.; Stirling, A.; Walter, G.; MacKerron, G. Differences in carbon emissions reduction between countries pursuing renewable electricity versus nuclear power. Nat. Energy 2020, 5, 928–935. [Google Scholar] [CrossRef]

- Mirziyoyeva, Z.; Salahodjaev, R. Renewable energy and CO2 emissions intensity in the top carbon intense countries. Renew. Energy 2022, 192, 507–512. [Google Scholar] [CrossRef]

- IEA. Renewables 2021; IEA: Paris, France, 2021. [Google Scholar]

- dos Santos, M.A.; Rosa, L.P.; Sikar, B.; Sikar, E.; dos Santos, E.O. Gross greenhouse gas fluxes from hydro-power reservoir compared to thermo-power plants. Energy Policy 2006, 34, 481–488. [Google Scholar] [CrossRef]

- Wang, F.; Wang, B.; Liu, C.-Q.; Wang, Y.; Guan, J.; Liu, X.; Yu, Y. Carbon dioxide emission from surface water in cascade reservoirs–river system on the Maotiao River, southwest of China. Atmos. Environ. 2011, 45, 3827–3834. [Google Scholar] [CrossRef]

- Barros, N.; Cole, J.J.; Tranvik, L.J.; Prairie, Y.T.; Bastviken, D.; Huszar, V.L.M.; del Giorgio, P.; Roland, F. Carbon emission from hydroelectric reservoirs linked to reservoir age and latitude. Nat. Geosci. 2011, 4, 593–596. [Google Scholar] [CrossRef]

- Deemer, B.R.; Harrison, J.A.; Li, S.; Beaulieu, J.J.; DelSontro, T.; Barros, N.; Bezerra-Neto, J.F.; Powers, S.M.; dos Santos, M.A.; Vonk, J.A. Greenhouse Gas Emissions from Reservoir Water Surfaces: A New Global Synthesis. BioScience 2016, 66, 949–964. [Google Scholar] [CrossRef] [PubMed]

- Goldenfum, J.A. GHG Measurement Guidelines for Freshwater Reservoirs; The UNESCO/IHA Greenhouse Gas Emissions from Freshwater Reservoirs Research Project; International Hydropower Association: London, UK, 2018. [Google Scholar]

- Gallagher, J.; Styles, D.; McNabola, A.; Williams, A.P. Life cycle environmental balance and greenhouse gas mitigation potential of micro-hydropower energy recovery in the water industry. J. Clean. Prod. 2015, 99, 152–159. [Google Scholar] [CrossRef]

- Kadiyala, A.; Kommalapati, R.; Huque, Z. Evaluation of the Life Cycle Greenhouse Gas Emissions from Hydroelectricity Generation Systems. Sustainability 2016, 8, 539. [Google Scholar] [CrossRef] [Green Version]

- Levasseur, A.; Mercier-Blais, S.; Prairie, Y.T.; Tremblay, A.; Turpin, C. Improving the accuracy of electricity carbon footprint: Estimation of hydroelectric reservoir greenhouse gas emissions. Renew. Sustain. Energy Rev. 2021, 136, 110433. [Google Scholar] [CrossRef]

- Song, C.; Gardner, K.H.; Klein, S.J.W.; Souza, S.P.; Mo, W. Cradle-to-grave greenhouse gas emissions from dams in the United States of America. Renew. Sustain. Energy Rev. 2018, 90, 945–956. [Google Scholar] [CrossRef] [Green Version]

- Suwanit, W.; Gheewala, S.H. Life cycle assessment of mini-hydropower plants in Thailand. Int. J. Life Cycle Assess. 2011, 16, 849–858. [Google Scholar] [CrossRef]

- Bullard, C.W.; Penner, P.S.; Pilati, D.A. Net energy analysis: Handbook for combining process and input-output analysis. Resour. Energy 1978, 1, 267–313. [Google Scholar] [CrossRef]

- Crawford, R.H.; Bontinck, P.A.; Stephan, A.; Wiedmann, T.; Yu, M. Hybrid life cycle inventory methods—A review. J. Clean. Prod. 2018, 172, 1273–1288. [Google Scholar] [CrossRef]

- Wu, X.; Li, C.; Shao, L.; Meng, J.; Zhang, L.; Chen, G. Is solar power renewable and carbon-neutral: Evidence from a pilot solar tower plant in China under a systems view. Renew. Sustain. Energy Rev. 2021, 138, 110655. [Google Scholar] [CrossRef]

- Wu, X.; Shao, L.; Chen, G.; Han, M.; Chi, Y.; Yang, Q.; Alhodaly, M.; Wakeel, M. Unveiling land footprint of solar power: A pilot solar tower project in China. J. Environ. Manag. 2021, 280, 111741. [Google Scholar] [CrossRef]

- Li, Z.; Lu, L.; Lv, P.; Du, H.; Guo, J.; He, X.; Ma, J. Carbon footprints of pre-impoundment clearance on reservoir flooded area in China’s large hydro-projects: Implications for GHG emissions reduction in the hydropower industry. J. Clean. Prod. 2017, 168, 1413–1424. [Google Scholar] [CrossRef]

- Li, Z.; Du, H.; Xu, H.; Xiao, Y.; Lu, L.; Guo, J.; Prairie, Y.; Mercier-Blais, S. The carbon footprint of large- and mid-scale hydropower in China: Synthesis from five China’s largest hydro-project. J. Environ. Manag. 2019, 250, 109363. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Du, H.; Xiao, Y.; Guo, J. Carbon footprints of two large hydro-projects in China: Life-cycle assessment according to ISO/TS 14067. Renew. Energy 2017, 114, 534–546. [Google Scholar] [CrossRef]

- Liu, C.; Ahn Changbum, R.; An, X.; Lee, S. Life-Cycle Assessment of Concrete Dam Construction: Comparison of Environmental Impact of Rock-Filled and Conventional Concrete. J. Constr. Eng. Manag. 2013, 139, A4013009. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, L. Embodied carbon budget accounting system for calculating carbon footprint of large hydropower project. J. Clean. Prod. 2015, 96, 444–451. [Google Scholar] [CrossRef]

- DOE. DOE Global Energy Storage Database. 2022. Available online: https://sandia.gov/ess-ssl/gesdb/public/projects.html (accessed on 25 April 2022).

- Alqub, A.M. Design and Life Cycle Assessment of Pumped Hydro Energy Storage System for Nablus Western Wastewater Treatment Plant. Master’s Thesis, An-Najah National University, Nablus, Palestine, 2017. [Google Scholar]

- Immendoerfer, A.; Tietze, I.; Hottenroth, H.; Viere, T. Life-cycle impacts of pumped hydropower storage and battery storage. Int. J. Energy Environ. Eng. 2017, 8, 231–245. [Google Scholar] [CrossRef] [Green Version]

- Mahmud, M.A.P.; Huda, N.; Farjana, S.H.; Lang, C. Life-cycle impact assessment of renewable electricity generation systems in the United States. Renew. Energy 2020, 151, 1028–1045. [Google Scholar] [CrossRef]

- Wang, J.; Chen, X.; Liu, Z.; Frans, V.F.; Xu, Z.; Qiu, X.; Xu, F.; Li, Y. Assessing the water and carbon footprint of hydropower stations at a national scale. Sci. Total Environ. 2019, 676, 595–612. [Google Scholar] [CrossRef]

- Li, D.; Li, X.; Huang, W.; Chen, S.; Ma, G. Assessment on Whole Life Cycle of Pumped Storage System Based on LCA Theory. Water Power 2018, 44, 90–93. [Google Scholar]

- Shao, L.; Guan, D.; Zhang, N.; Shan, Y.; Chen, G.Q. Carbon emissions from fossil fuel consumption of Beijing in 2012. Environ. Res. Lett. 2016, 11, 114028. [Google Scholar] [CrossRef] [Green Version]

- Shao, L.; Guan, D.; Wu, Z.; Wang, P.; Chen, G.Q. Multi-scale input-output analysis of consumption-based water resources: Method and application. J. Clean. Prod. 2017, 164, 338–346. [Google Scholar] [CrossRef] [Green Version]

- Pacca, S. Impacts from decommissioning of hydroelectric dams: A life cycle perspective. Clim. Chang. 2007, 84, 281–294. [Google Scholar] [CrossRef]

- Murphy, D.J.; Hall, C.A.S. Year in review—EROI or energy return on (energy) invested. Ann. N. Y. Acad. Sci. 2010, 1185, 102–118. [Google Scholar] [CrossRef]

- Houghton, J.T.; Jenkins, G.J.; Ephraums, J.J. Climate change: The IPCC scientific assessment. Am. Sci. 1990, 80. Available online: https://www.osti.gov/biblio/6819363 (accessed on 25 April 2022).

- Lopes, T.d.N.; Coelho, L.H.G.; Mata-Lima, H.; de Jesus, T.A.; da Costa, A.C.R.; Pereira, J.M.d.A.; Benassi, R.F. The Influence of Pollution Sources on CH 4 and CO 2 Emissions in Urbanized Wetland Areas of a Tropical Reservoir, Southeast, Brazil. J. Environ. Eng. 2022, 148, 04021071. [Google Scholar] [CrossRef]

- IPCC. IPCC Guidelines for National Greenhouse Gas Inventories. Inst. Glob. Environ. Strateg. Jpn. 2006. Available online: https://www.osti.gov/etdeweb/biblio/20880391 (accessed on 25 April 2022).

- Shao, L.; Chen, G.Q.; Chen, Z.M.; Guo, S.; Han, M.Y.; Zhang, B.; Hayat, T.; Alsaedi, A.; Ahmad, B. Systems accounting for energy consumption and carbon emission by building. Commun. Nonlinear Sci. Numer. Simul. 2014, 19, 1859–1873. [Google Scholar] [CrossRef]

- EPA. Emission Factors for Greenhouse Gas Inventories; EPA: Washington, DC, USA, 2018.

- Hertwich, E.G.; Gibon, T.; Bouman, E.A.; Arvesen, A.; Suh, S.; Heath, G.A.; Bergesen, J.D.; Ramirez, A.; Vega, M.I.; Shi, L. Integrated life-cycle assessment of electricity-supply scenarios confirms global environmental benefit of low-carbon technologies. Proc. Natl. Acad. Sci. USA 2015, 112, 6277–6282. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Beaulieu, J.J.; Waldo, S.; Balz, D.A.; Barnett, W.; Hall, A.; Platz, M.C.; White, K.M. Methane and Carbon Dioxide Emissions From Reservoirs: Controls and Upscaling. J. Geophys. Res.-Biogeosci. 2020, 125, e2019JG005474. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.; Ma, J.-M.; Zheng, S.-L.; Nan, C.-Z.; Nie, L.-M. Different hydrodynamic conditions on the deposition of organic carbon in sediment of two reservoirs. Hydrobiologia 2016, 765, 15–26. [Google Scholar] [CrossRef]

- Zhan, H.; School of Economics and Management, China University of Geosciences, Beijing 100083, China; Pan, Y.; School of Economics and Management, China University of Geosciences, Beijing 100083, China; Shao, L.; School of Economics and Management, China University of Geosciences, Beijing 100083, China. Two-scale input–output modeling for embodied carbon emissions in Chinese economy, 2017. Personal communication, 2020. [Google Scholar]

- Gagnon, L.; van de Vate, J.F. Greenhouse gas emissions from hydropower: The state of research in 1996. Energy Policy 1997, 25, 7–13. [Google Scholar] [CrossRef]

- Varun; Prakash, R.; Bhat, I.K. Life cycle greenhouse gas emissions estimation for small hydropower schemes in India. Energy 2012, 44, 498–508. [Google Scholar] [CrossRef]

- Geller, M.T.B.; Bailão, J.L.; de Lima Tostes, M.E.; de Moura Meneses, A.A. Indirect GHG emissions in hydropower plants: A review focused on the uncertainty factors in LCA studies. Desenvolv. e Meio Ambiente 2020, 54. [Google Scholar] [CrossRef]

- Samour, A.; Baskaya, M.M.; Tursoy, T. The Impact of Financial Development and FDI on Renewable Energy in the UAE: A Path towards Sustainable Development. Sustainability 2022, 14, 1208. [Google Scholar] [CrossRef]

- National Energy Administration. Pumped Storage Medium and Long-Term Development Plan (2021–2035); National Energy Administration: Beijing, China, 2021.

| No. | Input | Sector Code | Sector Contents |

|---|---|---|---|

| Material | |||

| 1 | Cement | 13 | Manufacture of Nonmetallic Mineral Products |

| 2 | Cement mortar | 13 | Manufacture of Nonmetallic Mineral Products |

| 3 | Fly ash | 13 | Manufacture of Nonmetallic Mineral Products |

| 4 | Reinforced bar | 15 | Manufacture of Metal Products |

| 5 | Steel | 15 | Manufacture of Metal Products |

| 6 | Steel fabric | 15 | Manufacture of Metal Products |

| 7 | Timber | 9 | Processing of Timbers and Manufacture of Furniture |

| 8 | Explosive material | 12 | Chemical Industry |

| 9 | Anchor | 15 | Manufacture of Metal Products |

| 10 | Catalyst | 12 | Chemical Industry |

| 11 | Stranded wire | 15 | Manufacture of Metal Products |

| 12 | Gravel | 13 | Manufacture of Nonmetallic Mineral Products |

| 13 | Crushed stone | 13 | Manufacture of Nonmetallic Mineral Products |

| 14 | Rubble | 13 | Manufacture of Nonmetallic Mineral Products |

| Machinery | |||

| 15 | Turbine | 16 | Manufacture of General Purpose Machinery |

| 16 | Power generation | 19 | Manufacture of Electrical Machinery and Equipment |

| 17 | Main transformer | 19 | Manufacture of Electrical Machinery and Equipment |

| 18 | GIS high voltage switch | 19 | Manufacture of Electrical Machinery and Equipment |

| 19 | High speed pulping machine | 16 | Manufacture of General Purpose Machinery |

| 20 | Grouter | 16 | Manufacture of General Purpose Machinery |

| 21 | Concrete sprayer | 16 | Manufacture of General Purpose Machinery |

| 22 | Hoisting jack | 16 | Manufacture of General Purpose Machinery |

| 23 | Oil pump | 16 | Manufacture of General Purpose Machinery |

| 24 | Grouting automatic recorder | 21 | Manufacture of Measuring Instrument and Meter |

| 25 | Hydraulic excavator | 16 | Manufacture of General Purpose Machinery |

| 26 | Dump truck | 18 | Manufacture of Transport Equipment |

| 27 | Loader | 16 | Manufacture of General Purpose Machinery |

| 28 | Bulldozer | 16 | Manufacture of General Purpose Machinery |

| 29 | Down-the-hole drill | 16 | Manufacture of General Purpose Machinery |

| 30 | Hand drill | 16 | Manufacture of General Purpose Machinery |

| 31 | Blender | 16 | Manufacture of General Purpose Machinery |

| 32 | Vibrator | 16 | Manufacture of General Purpose Machinery |

| 33 | Air compressor | 16 | Manufacture of General Purpose Machinery |

| 34 | Belt filter press | 16 | Manufacture of General Purpose Machinery |

| 35 | Centrifugal dehydrator | 16 | Manufacture of General Purpose Machinery |

| 36 | Equipment maintenance | 16 | Manufacture of General Purpose Machinery |

| Energy | |||

| 37 | Gasoline | 11 | Processing of Petroleum, Coking, Processing of Nuclear Fuel |

| 38 | Diesel | 11 | Processing of Petroleum, Coking, Processing of Nuclear Fuel |

| 39 | Electricity | 24 | Production and Supply of Electric Power and Heat Power |

| Service | |||

| 40 | Building maintenance | 37 | Water, Environment and Municipal Engineering Conservancy |

| 41 | Manpower in construction | 27 | Construction |

| 42 | Manpower in operation | 37 | Water, Environment and Municipal Engineering Conservancy |

| 43 | Loan service | 32 | Finance |

| 44 | Emigrant relocation | 27 | Construction |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, Y.; Pan, Y.; Zhan, H.; Cheng, W.; Huang, L.; Wu, Z.; Shao, L. Systems Accounting for Carbon Emissions by Hydropower Plant. Sustainability 2022, 14, 6939. https://doi.org/10.3390/su14116939

Chu Y, Pan Y, Zhan H, Cheng W, Huang L, Wu Z, Shao L. Systems Accounting for Carbon Emissions by Hydropower Plant. Sustainability. 2022; 14(11):6939. https://doi.org/10.3390/su14116939

Chicago/Turabian StyleChu, Yuwen, Yunlong Pan, Hongyi Zhan, Wei Cheng, Lei Huang, Zi Wu, and Ling Shao. 2022. "Systems Accounting for Carbon Emissions by Hydropower Plant" Sustainability 14, no. 11: 6939. https://doi.org/10.3390/su14116939

APA StyleChu, Y., Pan, Y., Zhan, H., Cheng, W., Huang, L., Wu, Z., & Shao, L. (2022). Systems Accounting for Carbon Emissions by Hydropower Plant. Sustainability, 14(11), 6939. https://doi.org/10.3390/su14116939