Effect of Short-Term and UV Irradiation Aging on the Behaviour of SBS-Modified Bitumen

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

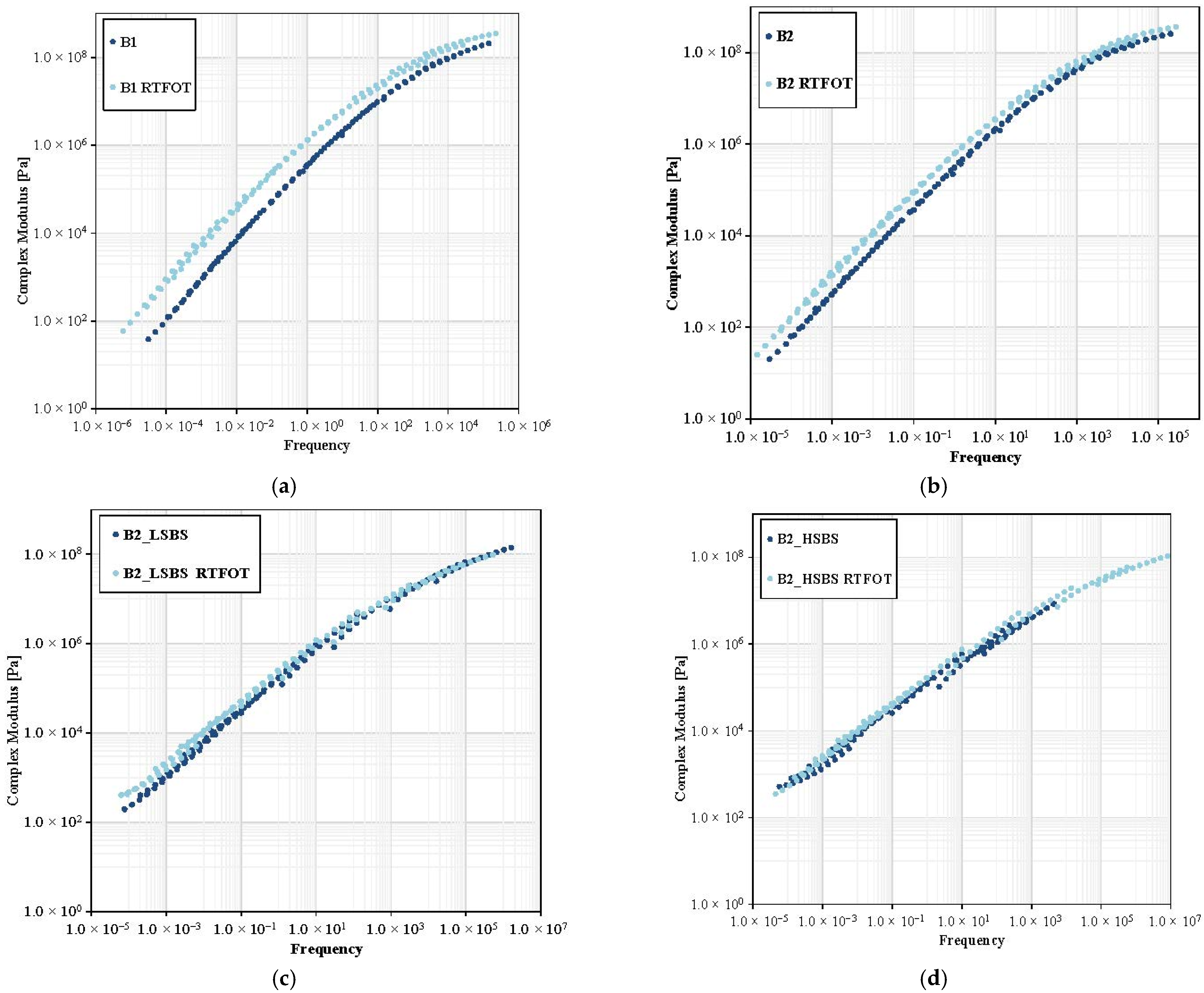

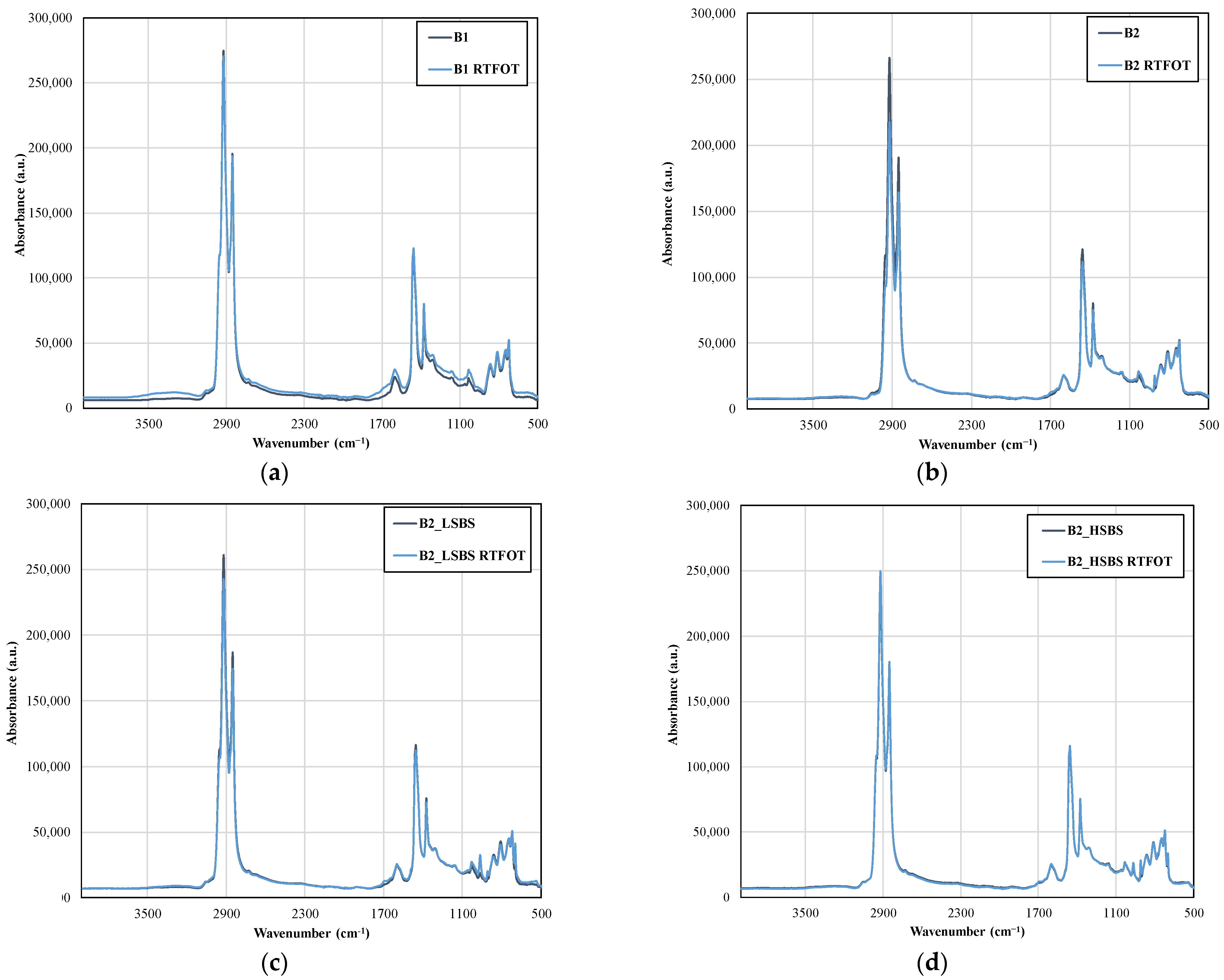

3.1. Short-Term Ageing

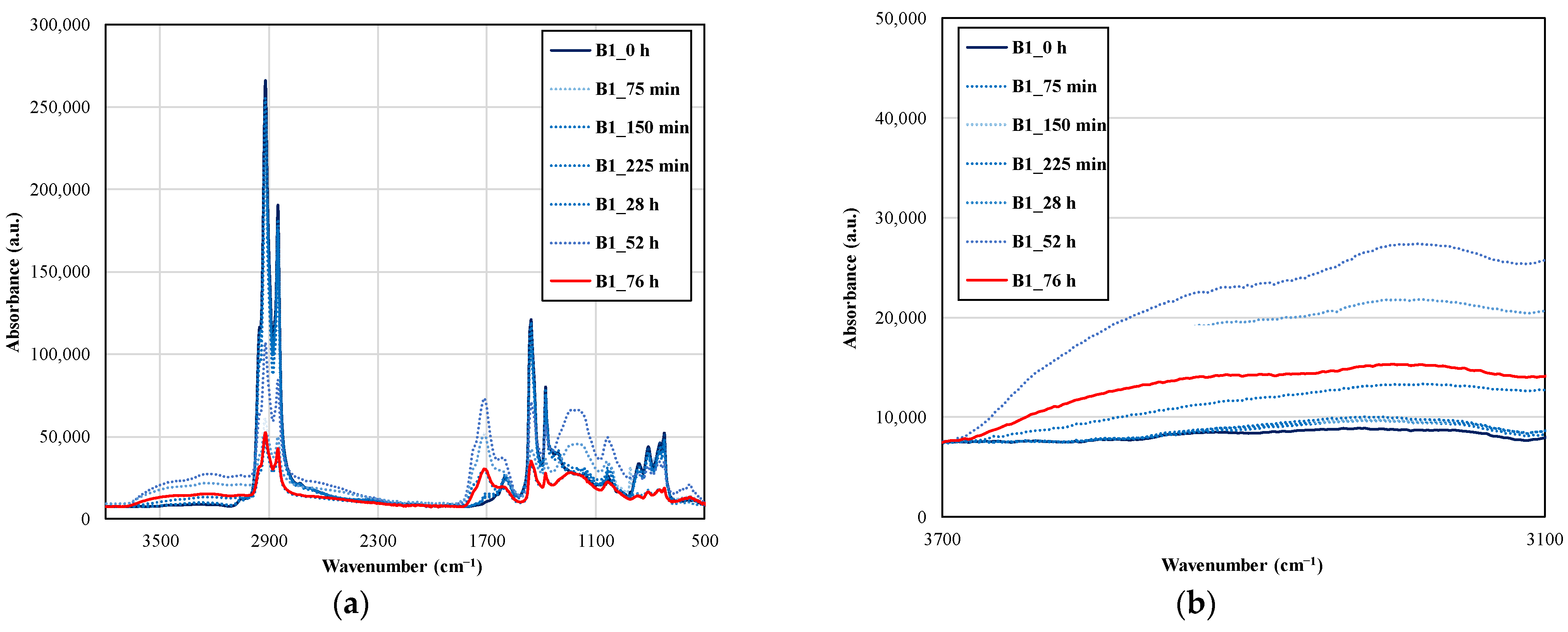

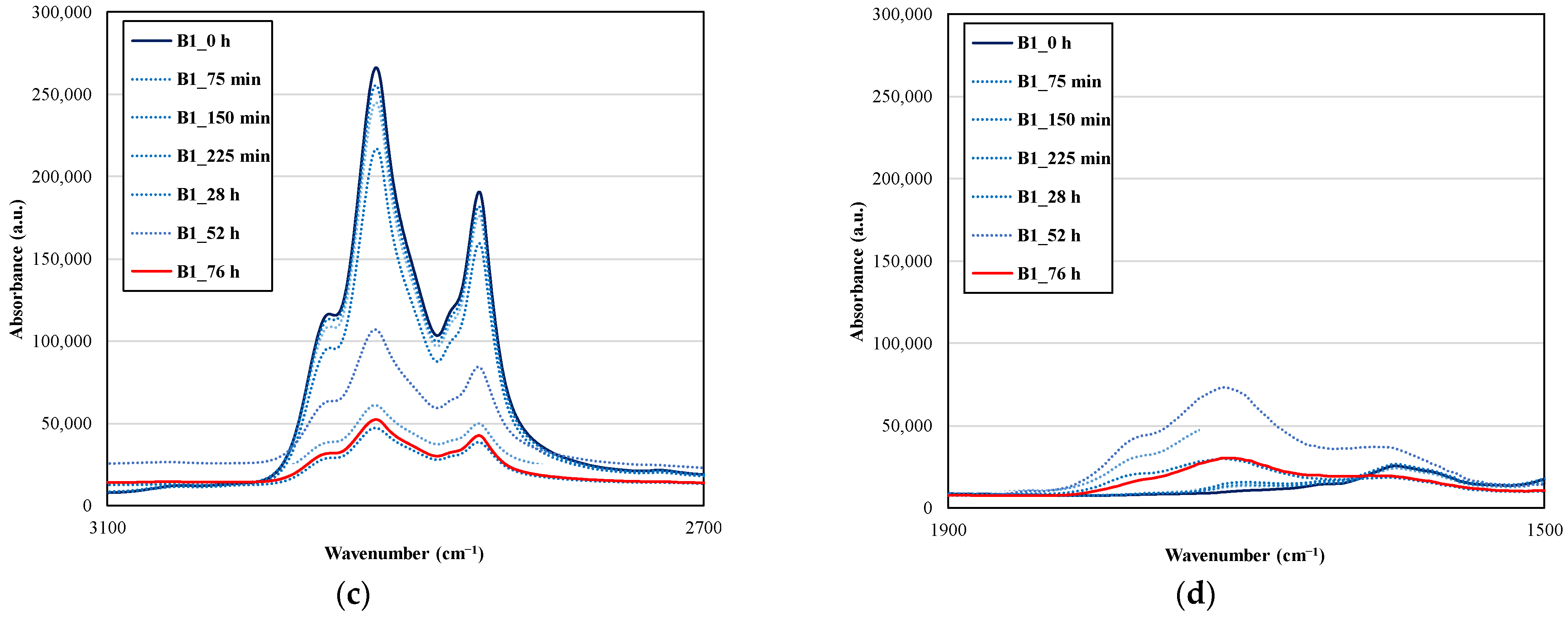

3.2. UV Irradiation Ageing

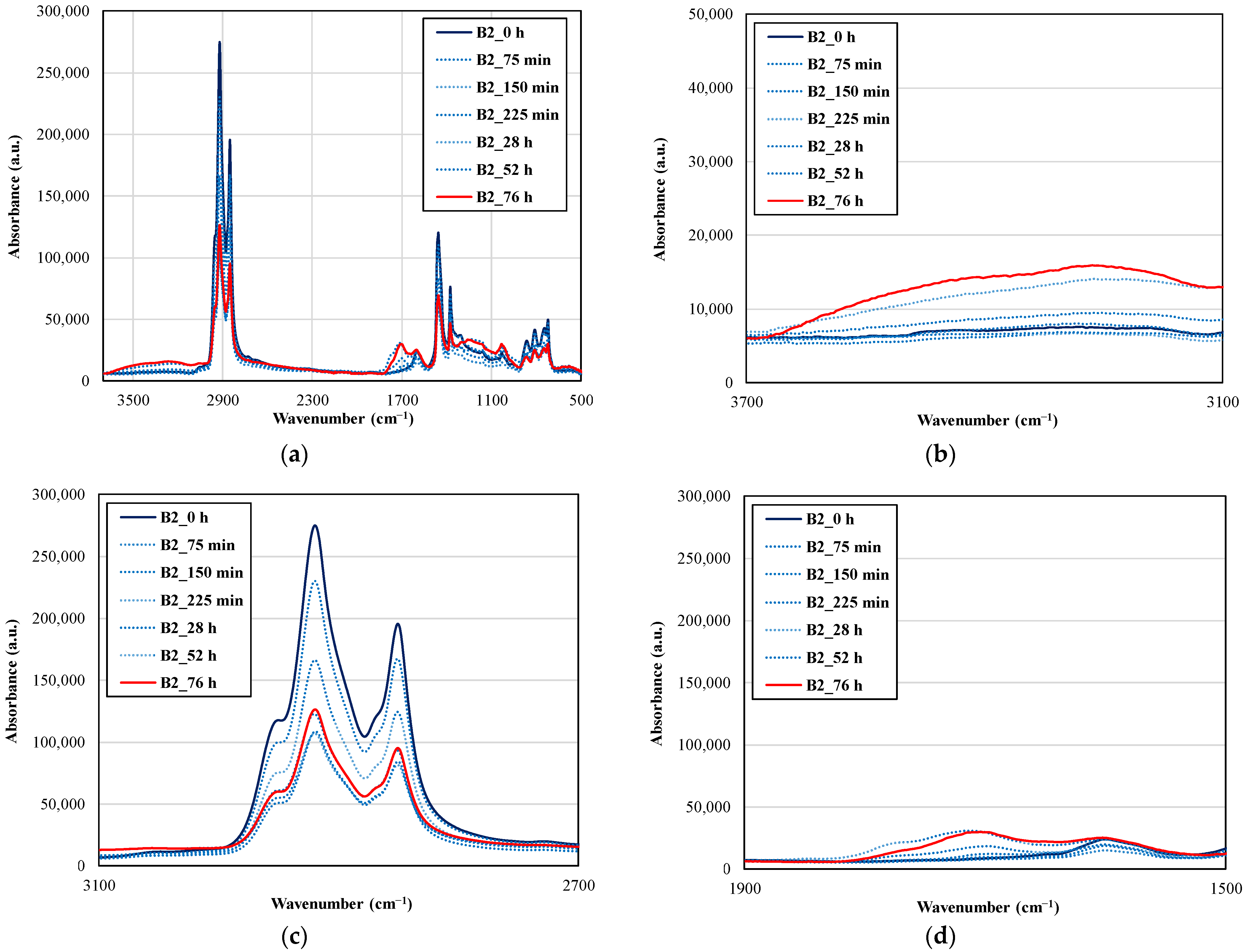

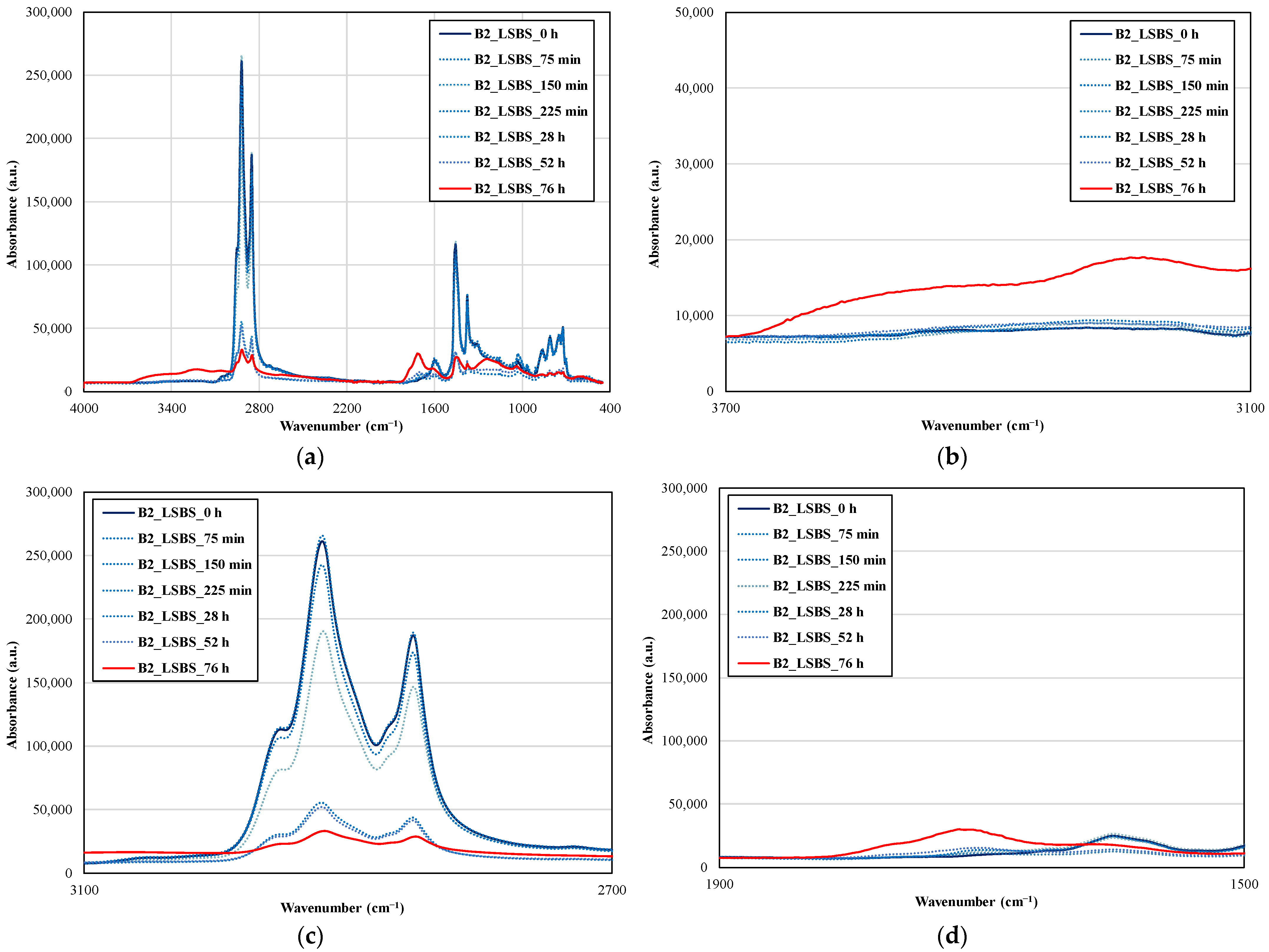

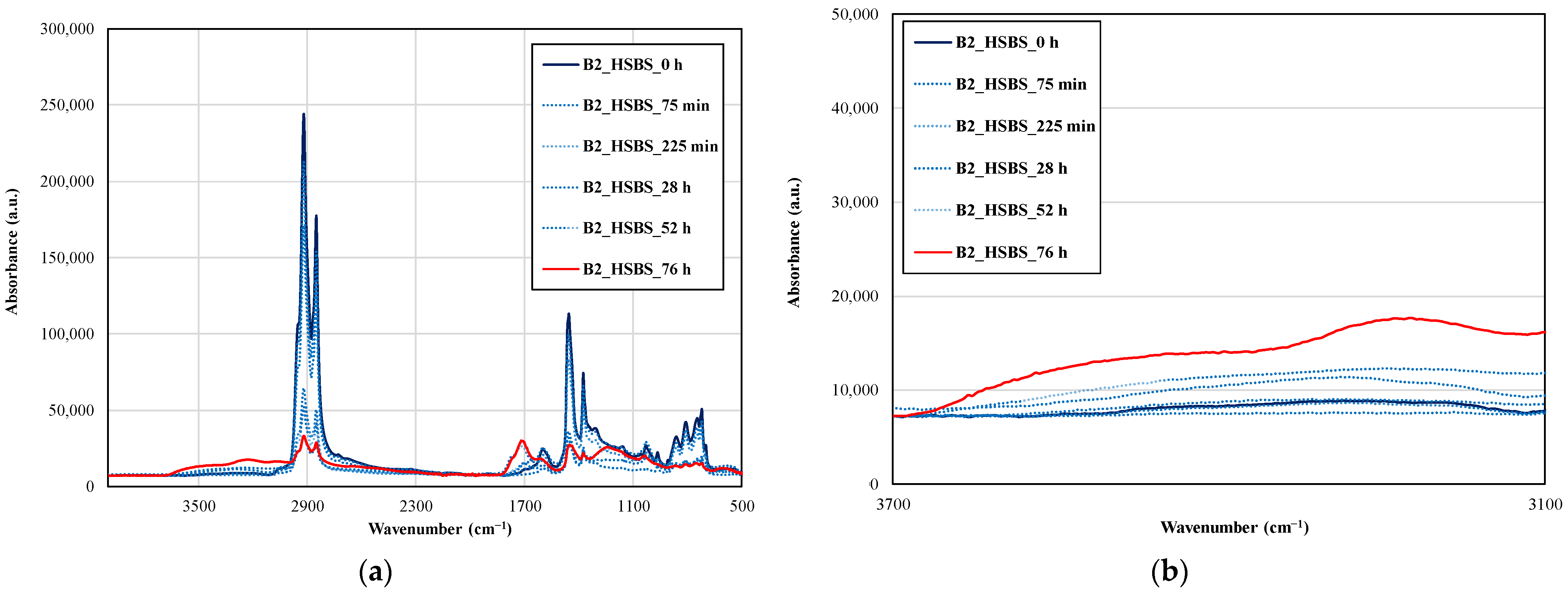

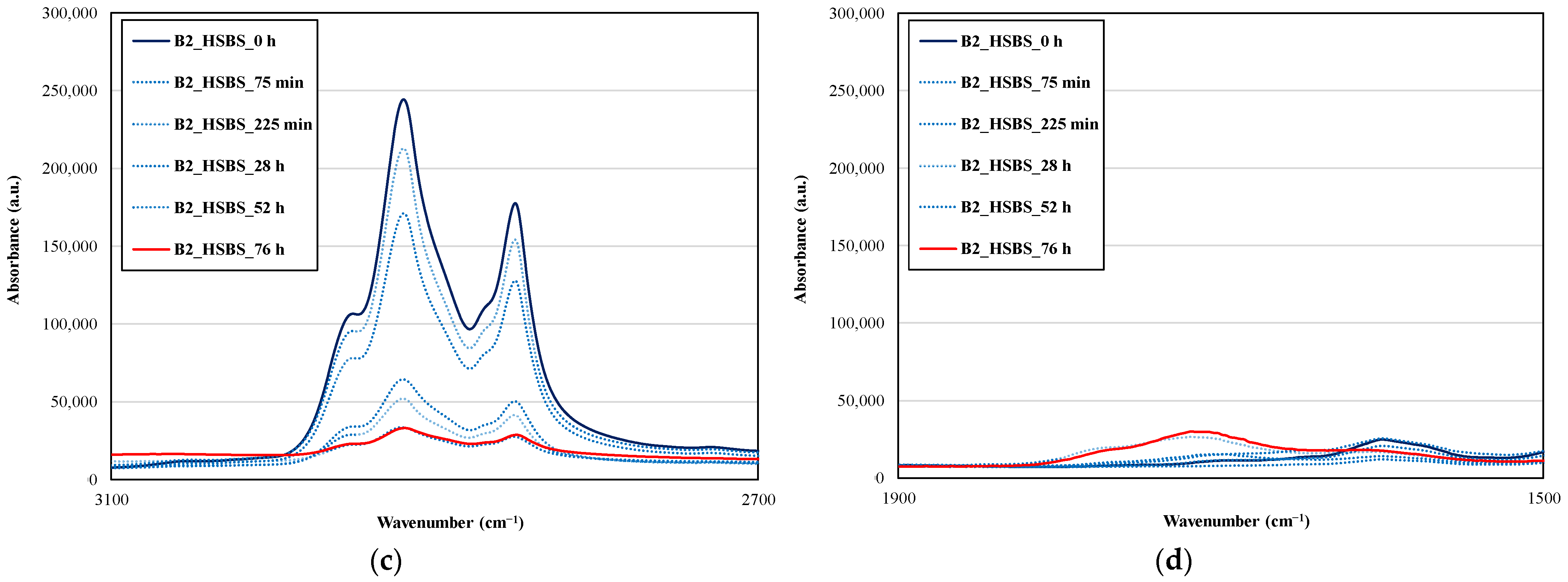

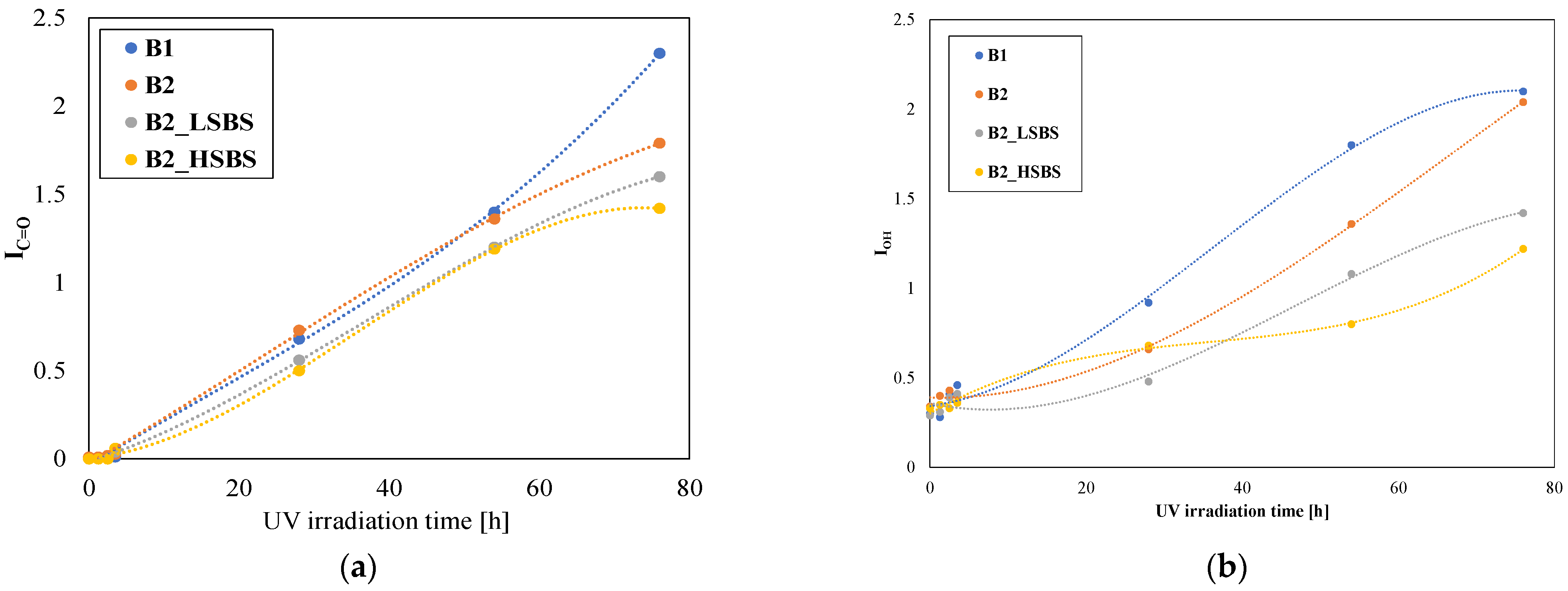

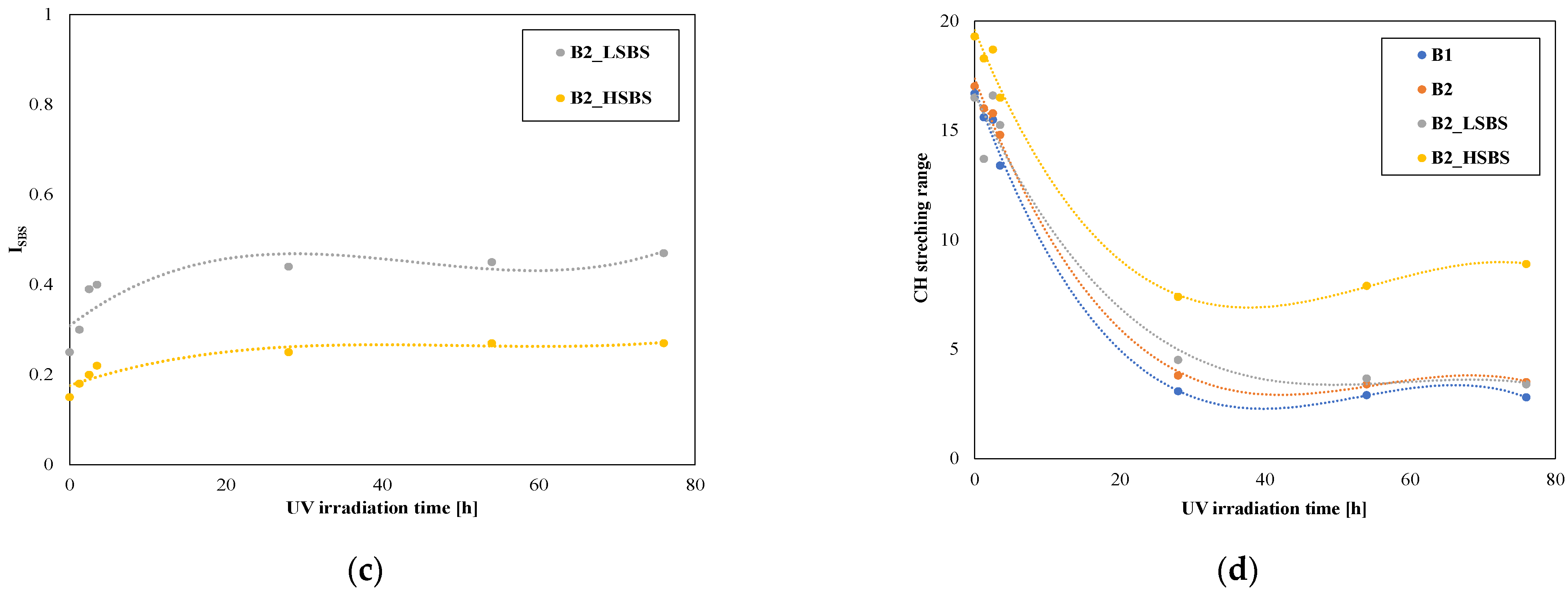

- (i)

- the gradual increases of broad peaks in the hydroxyl range, i.e., ca. 3600–3200 cm−1, as a function of UVB irradiation for all investigated bitumens, see Figure 3b, Figure 4b, Figure 5b and Figure 6b, can be related to the appearance of further free hydroxyl and/or carboxyl groups, which are typical degradation products upon UVB exposure.

- (ii)

- the gradual decreases of peaks at ca. 2925, 2850 and 2830 cm−1, which are attributed to asymmetric and symmetrical stretching vibration of C-H in methylene groups and to stretching vibration of aldehyde groups (see peaks assignments in Table 3), as a function of UVB irradiation time, can be related to the formations of crosslinked structures of chains containing unsaturation and/or butadiene units. These effects are noticeable for all investigated bitumens, i.e., B1, B2, B2_LSBS and B2_HSBS (see Figure 3c, Figure 4c, Figure 5c and Figure 6c).

- (iii)

- the gradual increases of peaks in the carbonyl range, mainly related on the building-up of new peak at ca. 1750 cm−1 and the increase in intensity of small peaks at ca. 1700 cm−1, can be related to the formation of esters and lactones, and the formation of further carboxyl contents, respectively (see Figure 3d, Figure 4d, Figure 5d and Figure 6d).

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ma, L.; Varveri, A.; Jing, R.; Erkens, S. Comprehensive review on the transport and reaction of oxygen and moisture towards coupled oxidative ageing and moisture damage of bitumen. Constr. Build. Mater. 2021, 283, 122632. [Google Scholar] [CrossRef]

- Hunter, R.N.; Self, A.; Read, J. The Shell Bitumen Handbook; Ice Publishing: London, UK, 2015. [Google Scholar]

- Theofilatos, A.; Yannis, G. A review of the effect of traffic and weather characteristics on road safety. Accid. Anal. Prev. 2014, 72, 244–256. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zhang, H.; Duan, H. Investigation of ultraviolet radiation aging gradient in asphalt binder. Constr. Build. Mater. 2020, 246, 118501. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, X.; Zhang, Z.; Zou, B.; Zhu, Z.; Lu, G.; Xu, W.; Yu, J.; Yu, H. Effect of Aging on Chemical and Rheological Properties of Bitumen. Polymers 2018, 10, 1345. [Google Scholar] [CrossRef] [Green Version]

- Mouillet, V.; Farcas, F.; Besson, S. Ageing by UV radiation of an elastomer modified bitumen. Fuel 2008, 87, 2408–2419. [Google Scholar] [CrossRef]

- Lamontagne, J.; Dumas, P.; Mouillet, V.; Kister, J. Comparison by Fourier Transform Infrared (FTIR) Spectroscopy of Different Ageing Techniques: Application to Road Bitumens. Fuel 2001, 80, 483–488. [Google Scholar] [CrossRef]

- Mouillet, V.; Farcas, F.; Chailleux, E.; Sauger, L. Evolution of bituminous mix behaviour submitted to UV rays in laboratory compared to field exposure. Mater. Struct. 2014, 47, 1287–1299. [Google Scholar] [CrossRef]

- McNally, T. Polymer Modified Bitumen; Woodhead Publishing: Cambridge, UK, 2011. [Google Scholar] [CrossRef]

- Celauro, C.; Bosurgi, G.; Sollazzo, G.; Ranieri, M. Laboratory and in-situ tests for estimating improvements in asphalt concrete with the addition of an LDPE and EVA polymeric compound. Constr. Build. Mater. 2019, 196, 714–726. [Google Scholar] [CrossRef]

- Polacco, G.; Stastna, J.; Vlachovicova, Z.; Biondi, D.; Zanzotto, L. Temporary networks in polymer-modified asphalts. Polym. Eng. Sci. 2004, 44, 2185–2193. [Google Scholar] [CrossRef]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef] [Green Version]

- Dong, F.; Zhao, W.; Zhang, Y.; Wei, J.; Fan, W.; Yu, Y.; Wang, Z. Influence of SBS and asphalt on SBS dispersion and the performance of modified asphalt. Constr. Build. Mater. 2014, 62, 1–7. [Google Scholar] [CrossRef]

- Singh, S.K.; Kumar, Y.; Ravindranath, S.S. Thermal degradation of SBS in bitumen during storage: Influence of temperature, SBS concentration, polymer type and base bitumen. Polym. Degrad. Stab. 2018, 147, 64–75. [Google Scholar] [CrossRef]

- Feng, Z.; Cai, F.; Yao, D.; Li, X. Aging properties of ultraviolet absorber/SBS modified bitumen based on FTIR analysis. Constr. Build. Mater. 2021, 273, 121713. [Google Scholar] [CrossRef]

- Polacco, G.; Filippi, S.; Merusi, F.; Stastna, G. A review of the fundamentals of polymer-modified asphalts: Asphalt/polymer interactions and principles of compatibility. Adv. Colloid Interface Sci. 2015, 224, 72–112. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Qin, X.; Liu, Z.; Yin, Y.; Zou, C.; Jiang, S. New preparation method of bitumen samples for UV aging behavior investigation. Constr. Build. Mater. 2019, 233, 117278. [Google Scholar] [CrossRef]

- Celauro, C.; Saroufim, E.; Mistretta, M.C.; La Mantia, F.P. Influence of Short-Term Aging on Mechanical Properties and Morphology of Polymer-Modified Bitumen with Recycled Plastics from Waste Materials. Polymers 2020, 12, 1985. [Google Scholar] [CrossRef]

- Feng, Z.-G.; Bian, H.-J.; Li, X.-J.; Yu, J.-Y. FTIR analysis of UV aging on bitumen and its fractions. Mater. Struct. 2015, 49, 1381–1389. [Google Scholar] [CrossRef]

- Hou, X.; Xiao, F.; Wang, J.; Amirkhanian, S. Identification of asphalt aging characterization by spectrophotometry technique. Fuel 2018, 226, 230–239. [Google Scholar] [CrossRef]

- Riccardi, C.; Falchetto, A.C.; Losa, M.; Wistuba, M.P. Rheological modeling of asphalt binder and asphalt mortar containing recycled asphalt material. Mater. Struct. 2016, 49, 4167–4183. [Google Scholar] [CrossRef]

- Autelitano, F.; Garilli, E.; Giuliani, F. Electronic nose for smart identification of roofing and paving grade asphalt. Transp. Res. Procedia 2019, 40, 4–11. [Google Scholar] [CrossRef]

- Autelitano, F.; Bianchi, F.; Giuliani, F. Airborne emissions of asphalt/wax blends for warm mix asphalt production. J. Clean. Prod. 2017, 164, 749–756. [Google Scholar] [CrossRef]

- Gaestel, C.; Smadja, R.; Lamminan, K. Contribution à la connaissance des propriétés des bitumes routiers. Rev. Gentile. Routes Aérodromes 1971, 466, 85–94. [Google Scholar]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Bai, X.; Qian, G.; Wei, H.; Gong, X.; Jin, J.; Li, Z. Impact of Ultraviolet Radiation on the Aging Properties of SBS-Modified Asphalt Binders. Polymers 2019, 11, 1111. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Allen, N.S.; Barcelona, A.; Edge, M.; Wilkinson, A.; Merchan, C.G.; Quiteria, V.R.S. Thermal and photooxidation of high styrene–butadiene copolymer (SBC). Polym. Degrad. Stab. 2004, 86, 11–23. [Google Scholar] [CrossRef]

- Zhang, W.; Li, Q.; Wang, J.; Meng, Y.; Zhou, Z. Aging Behavior of High-Viscosity Modified Asphalt Binder Based on Infrared Spectrum Test. Materials 2022, 15, 2778. [Google Scholar] [CrossRef]

| Characteristics | Standard | Unit | B1 | B2 | B2_LSBS | B2_HSBS |

|---|---|---|---|---|---|---|

| Penetration at 25 °C, pen | EN 1426 | 0.1 mm | 36 | 52.25 | 50.5 | 51 |

| Ring and ball softening point, TR&B | EN 1427 | °C | 54.5 | 52.6 | 77.6 | 88.5 |

| Penetration at 25 °C, pen (after short term ageing, according to EN 12607-1) | EN 1426 | 0.1 mm | - | 39.3 | 36 | 40 |

| Ring and ball softening point, TR&B (after RTOFT according to EN12607-1) | EN 1427 | °C | - | 56 | 84 | 91.25 |

| Viscosity at 100 °C | EN 13302 | Pa s | 5.25 | 2.20 | 11.46 | 19.83 |

| Viscosity at 135 °C | EN 13302 | Pa s | 0.55 | 0.29 | 1.70 | 2.14 |

| Viscosity at 150 °C | EN 13302 | Pa s | 0.27 | 0.15 | 1 | 1.25 |

| Viscosity at 180 °C | EN 13302 | Pa s | 0.09 | 0.1 | 0.40 | 0.58 |

| Bitumen | Saturates % | Aromatics % | Resins % | Asphaltenes % | Gaestel Index |

|---|---|---|---|---|---|

| B1 | 2.9 | 52.8 | 22.0 | 22.3 | 0.347 |

| B2 | 3.2 | 58.9 | 21.4 | 16.6 | 0.25 |

| Wavenumber (cm−1) | Peak Assignment |

|---|---|

| 2924, 2852 | Asymmetric and symmetrical stretching vibration of C-H in methylene |

| 2729 | Stretching vibration of aldehyde group |

| 1695 | C=O stretching vibration |

| 1671 | C=O stretching vibration of primary amide carbonyl |

| 1454 | Scissor vibration of methylene (—CH2—) |

| 1376 | Umbrella vibration of methyl (—CH3—) |

| 1021 | Stretching vibration of sulfoxide group (S=O) |

| 810, 860 | Stretching vibration of benzene ring |

| 743 | Bending vibration of aromatic branched chain |

| 723 | Synergistic vibration of methylene segment (CH2)n (n ≥ 4) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Celauro, C.; Teresi, R.; Dintcheva, N.T. Effect of Short-Term and UV Irradiation Aging on the Behaviour of SBS-Modified Bitumen. Sustainability 2022, 14, 6915. https://doi.org/10.3390/su14116915

Celauro C, Teresi R, Dintcheva NT. Effect of Short-Term and UV Irradiation Aging on the Behaviour of SBS-Modified Bitumen. Sustainability. 2022; 14(11):6915. https://doi.org/10.3390/su14116915

Chicago/Turabian StyleCelauro, Clara, Rosalia Teresi, and Nadka Tz. Dintcheva. 2022. "Effect of Short-Term and UV Irradiation Aging on the Behaviour of SBS-Modified Bitumen" Sustainability 14, no. 11: 6915. https://doi.org/10.3390/su14116915

APA StyleCelauro, C., Teresi, R., & Dintcheva, N. T. (2022). Effect of Short-Term and UV Irradiation Aging on the Behaviour of SBS-Modified Bitumen. Sustainability, 14(11), 6915. https://doi.org/10.3390/su14116915