Abstract

This study aims to evaluate the environmental impacts of off-site construction using ultra-high-performance concrete (UHPC) and different curing methods. Life cycle assessment (LCA) is implemented to evaluate the environmental impacts of the proposed UHPC and the traditional concrete (TC) under different curing conditions from cradle to gate. Unlike the previous studies that considered the function unit of concrete as 1 m3, this study investigates the concrete elements with the same load capacity. Comparison is made between off-site water bath heating curing (HC) ultra-high-performance concrete (UHPC), on-site UHPC, off-site HC traditional concrete (TC), on-site TC, and off-site CO2 curing TC. The LCA results show that UHPC is generally better than TC in terms of environmental impacts. Using off-site CO2 curing further improves its environmental benefits. The off-site HC UHPC shows higher productivity and higher environmental impacts compared to the on-site construction method. However, when the design load capacity of the concrete increases, the difference between off-site construction using 50 °C HC UHPC and on-site curing (20 °C HC UHPC) decreases.

1. Introduction

The construction industry takes up over 40% of global energy consumption, 38% of global greenhouse gas emissions, 12% of global potable water use, and 40% of solid waste generation in developed countries. In order to meet the goals of the Paris Agreement on Climate Change to achieve decarbonization (i.e., net-zero carbon) in buildings and the construction sector by 2050, sustainable construction becomes a concern. However, the greatest challenge in developing sustainable construction is the cost. In this regard, how to make a balance between cost and environmental impact attracts a lot of attention in the research community.

Off-site construction might become the answer to the challenge question. Off-site construction was first adopted in the construction industry in the mid-1960s [1] and has radically changed the way we make a building by transferring on-site construction work to factories [2]. Due to many advantages such as high efficiency, low environmental impact and better quality [3], it has been widely adopted in recent years. The housing and Development Committee in Shanghai settled the aim that all building units finished after 2019 should have an assembly rate greater than 60% [4]. If its advantages can be further enhanced, it will be better. Though many researchers have made efforts to improve the off-site construction method, there is some room for further improvement.

In most existing studies, the concrete used for off-site construction is the traditional concrete as the on-site construction method [5,6], which imposes certain constraints on the potential of the off-site construction method. In fact, the off-site method is free to use different curing methods and different mix designs [7], which can significantly influence the concrete strength. Secondly, comparisons were made among the concrete elements produced with the same volume or amount [8] in most previous studies, which gives an unfair evaluation because the concrete elements have different strengths [9]. Therefore, this article investigates the concrete elements with the same load capacity.

This study aims to find a better off-site construction method by comparing the environmental impacts of off-site construction using ultra-high-performance concrete (UHPC) with using traditional concrete (TC). UHPC is a kind of cement-based material, which generally consists of cement, sand, aggregate, silica fume, and superplasticizer [10]. The hydration of reactive particles such as silica fume and fly ash also forms C-S-H or C-A-H gel which can provide rigid connection between particles [11], this can significantly influence the strength development of concrete, the compressive strength can reach 150–250 MPa [12]. Thus, curing conditions become a crucial issue for UHPC. Either the water bath heat curing (HC) method or the carbon dioxide (CO2) curing method is used to ensure the quality of the concrete. HC is a general approach that can be applied to both UHPC and TC. From 0–50 °C, the early strength of concrete increases as the curing temperature increases [13]. However, the 28-day strength of TC will reduce with temperature increasing [14]. Another curing method only used in TC systems is CO2 curing. As shown in Equations (1) and (2), the main component in cement (tricalcium silicate (C3S), dicalcium silicate (C2S)) can react with carbon dioxide and water and finally form calcium carbonate and calcium silicate hydrate (C-S-H) gel [15,16]. The formation of C-S-H and CaCO3 can improve the compressive strength of concrete and thus reduce the cement amount in concrete; meanwhile, it can reduce the usage of cement clinker amount and absorb CO2 to further reduce the environmental impacts of concrete. Column components were selected as the research project, which can carry and transfer loads.

Life cycle assessment (LCA) is implemented to evaluate the environmental impacts of the proposed UHPC and the traditional concrete (TC) under different curing conditions from cradle to gate. According to ISO 14040, there are four phases for LCA, which are: (1) Goal and Scope phase; (2) Inventory Analysis phase; (3) Impact Assessment phase; (4) Interpretation phase. This method was firstly used in the building sector in the 1990s [17]. Kamali et al. [5] compared the environmental impact of material production and construction phase and found that for off-site construction, material always had a higher impact, hence this study mainly focused on optimizing the material phase rather than adjusting the construction process. Dong et al. [3] showed that the environmental impact of off-site construction buildings had a lower impact compared to the conventional method. Manjunatha et al. [18] found cement and aggregates were the top two contributors to concrete pollution. In order to reduce the environmental impact of concrete, many researchers suggested using green cement or high strength concrete (UHPC). As for aggregates, Knoeri et al. [19] analyzed the life cycle effects of twelve types of recycled aggregate concrete (RAC) and found out using recycled concrete can reduce the environmental impact by about 30% compared with TC. These studies all indicated that there is great potential for reducing concrete environmental impact.

The goal of this research is to determine whether the efficiency or environmental impact of the off-site construction method can be improved, the results will be obtained by comparing the environmental impacts of UHPC and TC produced under different curing conditions. Some suggestions will be given to the construction company and government based on these LCA studies.

2. Methodology

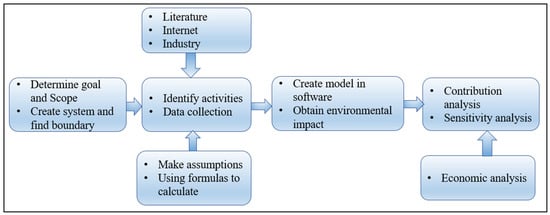

This study is focusing on investigating the potential of off-site construction methods if they are free to use different curing methods. To get the quantitative results, LCA studies of eight different types of columns were conducted, Figure 1 shows the framework of this project. Firstly, the goal and scope need to be determined. After the research products and system boundaries have been set, some data will be collected from published literature or websites to finish the model. Impact assessment of different systems will be calculated based on that model and then the contribution and uncertainty analysis will be carried out, which would be helpful to understand the crucial processes in different methods. By improving these key steps in off-site construction, the environmental impacts and efficiency of production can be further improved.

Figure 1.

The framework of this paper.

2.1. Goal and Scope

2.1.1. Functional Unit

In order to compare the impacts of concrete columns with different strengths, the load capacity of 8400 KN was defined as the functional unit. All the columns in this study were designed with the same load capacity of 8400 KN, which is the load capacity of a 500 × 500 mm column produced by C30 concrete [9]. The height of the column is assumed to be 3 m, which is the average floor height of a building, and the material needed for different methods was calculated based on that assumption. The water bath curing cabinet was preheated to the required curing temperature. The concretes were poured into molds for 2 h, and then they were stored in the water bath for another 24 h. UHPC column will be cured at 10 °C, room temperature 20 °C, 50 °C and 80 °C; TC column will be cured at room temperature at 20 °C, 40 °C, and 60 °C. TC column is also produced under CO2 curing conditions, CO2 was injected during the mixing process of concrete.

2.1.2. System Boundary and Flow Chart

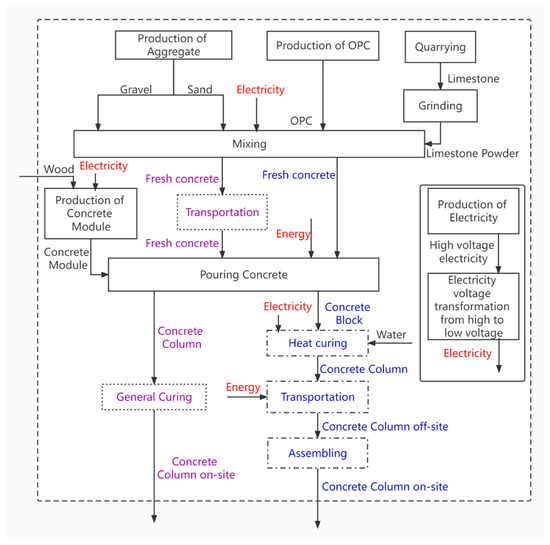

This is a partial LCA study, which only considers the impacts of the production of columns, i.e., a cradle to site research. Figure 2 illustrates the flow chart for the production of traditional concrete (TC). The flow chart shows the unit process, input, and output considered in this study. The products such as aggregate, sand, and Ordinary Portland Cement (OPC), are intermediate flows in the LCA study. The intermediate flow highlighted in red is low voltage electricity, and it is generated by the production of electricity and transformation from high voltage electricity to low voltage. Because low electricity is a resource required in many processes, to simplify the flow chart, the author used separate product electricity to represent low voltage electricity in the flow chart.

Figure 2.

Flow chart for on-site and off-site TC.

The processes and flows highlighted in purple (Figure 2) represent the production process for the on-site construction method. While the processes and flows highlighted in blue (Figure 2) are the processes for the off-site construction method. CEM II 42.5 N based on limestone filler was used to produce TC. The differences are mainly in the curing methods and the time of transportation. For the on-site construction method, the mixed concrete will be transported to the construction site and pouring concrete elements on-site. For the off-site method, this process is finished in the factory, and after concrete elements are cured and meet the requirements, the elements will be transported to the construction site. Other processes and flows in black are the common processes needed for both on-site and off-site methods.

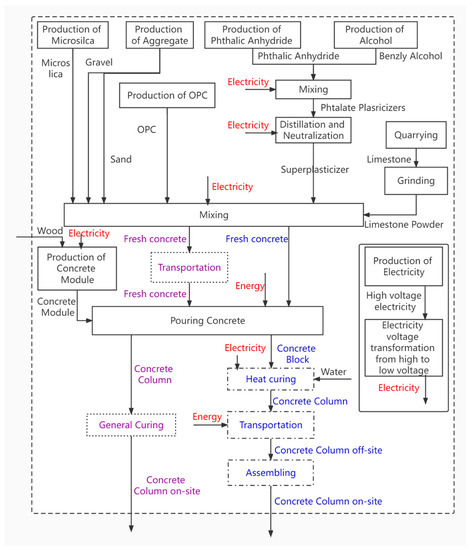

Figure 3 shows the flow chart for the production of UHPC: words in purple represent flow and material need for on-site construction; words in blue represent flow and material need for off-site construction. CEM I 42.5 N was used for the production of UHPC. The difference between TC and UHPC is that the material needed for UHPC is more complex than TC (silica fume and plasticizer are required in the production of UHPC), whereas silica fume is treated as waste in the production of electricity. As for the curing method, HC will be applied to both TC and UHPC, while CO2 curing will only be applied to TC.

Figure 3.

Flow chart for on-site and off-site UHPC.

2.2. Life Cycle Inventory

2.2.1. Data Collection

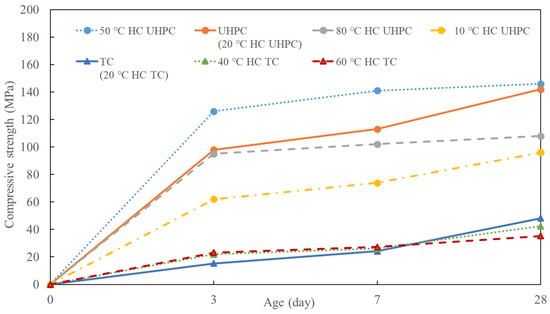

The mix design and strength of heat curing TC are obtained from Topçu and Toprak [14], which is cured at 20 °C, 40 °C, and 60 °C. The data for concrete produced by the CO2 curing method is collected from Monkman and MacDonald [15]. According to the America Concrete Institute (ACI) Committee 301, a minimum curing period corresponds to concrete attaining 70% of the specified compressive strength [20]. Thus, this study also obtained the LCA results designed on the 70% compressive strength of UHPC and TC. The compressive strength development method was determined by Kim et al. [21], and the compressive strength development for different curing conditions used in this study is shown in Figure 4.

Figure 4.

Strength development of UHPC and TC from [14,15].

From Figure 4, the maximum strength for UHPC is 146 MPa cured at 50 °C, and the maximum strength for TC is 48.2 MPa cured at 20 °C. For both UHPC and TC the degree of hydration of concrete will reduce with the increase in temperature. For the UHPC cured at 80 °C, the early strength is lower than that of 50 °C. tTis is because the hydration degree of cement at 80 °C is lower than that of 50 °C, but the hydration speed at three days still increases with the increment of temperature. Based on these data, the mass and volume of concrete under different curing conditions can be calculated. However, the energy needs in different processes need to be further determined. The calculation process can be seen in Table 1.

Table 1.

Calculation of concrete volume for different curing conditions.

The data used in this study are obtained from previous studies and the cement used in these articles is CEM I, which allows one to replace up to 5% of cement clinker. This study used limestone powder as the supplementary cementite material to ensure the accuracy of this study. The major component of limestone is CaCO3, which is also the production of CO2 curing. The study of Aqel [22] showed that the physical and chemical properties of concrete with limestone will not be influenced by heat curing. Only the strength of concrete will be slightly increased at 16 h and 28 days which means the environmental impacts obtained in this study might be slightly conservative.

Besides the chemical and physical stability, it is also necessary to keep the design of the binder reasonable, the factor binder intensity (Bi) is used to check the feasibility of the binder. Bi value is calculated by Equation (3).

where b is the total amount of binder material (kg/m3) and p is the 28-day compressive strength. When the compressive strength is over 60 MPa, the minimum Bi value should be greater than 5 kg/m3/MPa; while for the compressive strength less than 60 MPa, the Bi value is range from 10 to 20 kg/m3/MPa [23].

The energy needed for heat curing is calculated by heat capacity. The heat capacity (C) for concrete and water is 4.2 KJ/kg∙K and 1 KJ/kg∙K, respectively, and the power factor € for a heating machine is assumed to be 0.7, where the power factor defined as input energy divided by output energy [24]. The energy needed for heat curing can be calculated in Equation (4).

where m is the mass of the concrete column and is the temperature difference between room temperature (20 °C).

The concrete module is assumed to be made of plywood, and the thickness of plywood is assumed to be 20 mm for the bottom and 10 mm for the side. The plywood volume was calculated based on the maximum concrete volume in this study, the module of concrete was assumed to be damaged after using 100 times.

Besides the energy needed for heat curing, electricity consumption is another factor that needs to be determined. To solve that, the author collected data from the Sichuan Lingtong industry: the power of a mixing machine for concrete is 15 kw and its productivity is 6–8 m3/h. Based on the volume needed for different columns, the electricity for the mixing process can be calculated.

The plasticizer is one of the essential components for UHPC, and the production process of plasticizer is obtained from Technobell company. The production is complex and difficult to be modeled in software. Therefore, the complex production process is simplified into two phases: the reaction of phthalate plasticizer and the distillation and neutralization. The energy needed for these phases is also calculated by heat capacity. Different from Equation (4), the energy needed for reaction is based on the mole’s number. Mole mass for benzyl alcohol and phthalic anhydride are 108.14 g/mol and 148.11 g/mol, the heat capacity of them is 215.94 J/mol∙K and 161.8 J/mol∙K. The minimum reaction temperature of the first phase is 230 °C and the temperature for the second phase is 100 °C. We replaced mass with mole mass in Equation (4), hence the energy needed for the production of plasticizer can be obtained. Because the amount of plasticizer used only takes 1% of the total mass of cement and the annual production of a plasticizer factory is over 120 thousand tons, the consumption of construction of plasticizer factories and machines for plasticizers can be negligible for this study. This is an approximated approach to estimate the ting energy needs for the unit process.

2.2.2. Allocation

Allocation in life cycle inventory is the main question that needs to be determined. To simplify the LCA model, the production for most materials is defined as a mono-functional production process, which only has a single functional flow in their production systems. Thus, all of the components used in this production system need to be produced from raw materials.

2.3. Life Cycle Impact Assessment Method

This study uses HC and CO2 curing to replace general curing on different construction methods. Heat curing is applied to both UHPC and TC while CO2 curing is only applied to TC concrete. These columns are designed with a load capacity of 8400 KN and material needs for the column are calculated based on 28-day strength, which is the general case for most construction projects. For the on-site construction method, both UHPC and TC are produced under general curing conditions, which means concrete columns are cured under 20 °C and have 95% relative humidity. According to profit maximization theory, when the precast factory is located and adjusted to the concrete batching plant, thus the transportation distance of prefabrication and on-site construction is the same. In LCA study, the impact results are analyzed by IMPACT 2002+ (endpoint), which includes four impact categories—climate change, ecosystem, human health, and resources.

Impact assessment is a quantitative process to describe the effects of environmental impacts, which was conducted based on IMPACT 2002+ methodology. IMPACT 2002+ is a method developed at EPFL (Lausanne), and it can combine 14 midpoint categories into four damage categories [25]. Both midpoints and endpoints show the final result, but the midpoint method is an intermediate point between LCI results and the damage categories (endpoint); some midpoints might have several links to the final damage categories, which could lead the result difficult to be understood. Thus, this study will analyze the results in these four damage categories (endpoint level) and analyze the impact of the process at the mid-point level.

The four impact categories in IMPACT 2002+ (endpoint) are Human Health, Ecosystem Quality, Climate Change, and Resources. Because these factors are describing damage categories in different areas, the unit of damage will be different. In order to compare the categories in different areas, Table 2 gives the normalization factors for the four damage categories.

Table 2.

Normalization factors for the four categories [24].

By using normalization factors, the final results for LCA environmental impact can be analyzed. As can be seen in Table 2, the unit for different impact categories is different; in order to simplify the explanation, we used point to replace DALY, PDF·m2, Kg CO2, and MJ. Then all unit is point/person/year, which is not a cumulative fact. In this study, this is not an essential task for reducing one specific impact, hence the weighting factor used in this study is equal to 1.

3. Results and Discussion

3.1. Impact Assessment

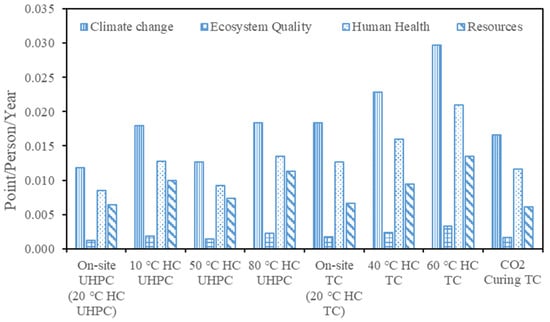

Using these data obtained above, we created this model in software, using normalization factor in Table 2 and weighting factor equal to 1 to calculate different environmental impacts, which are shown in Figure 5.

Figure 5.

LCA results for on-site and off-site construction methods.

The impacts of on-site construction and off-site 20 °C curing are nearly the same, but the difference between them is the transportation process. For the on-site construction process, vehicles for on-site construction are agitating trucks, while vehicles for off-site construction are conventional trucks. However, because only a small amount of concrete is considered in this study, the difference between these two methods is negligible. In order to simplify the explanation, on-site construction is used to represent these two methods.

The results showed that the on-site UHPC system has the lowest environmental impacts on four categories among eight groups (Figure 5). The system with the highest environmental impact is off-site 60 °C HC TC. Climate change is the most important impact that needs to be considered, whose environmental burden can reach 0.0297 point/person/year in 60 °C HC TC. For the off-site heat curing (HC) method for both UHPC and TC, the impact value obtained for HC are higher than the on-site method. For TC curing at all temperatures, the 28-day strength was lower than that of on-site curing. The water bath heat curing not only consumes additional energy but also reduces strength and requires more materials—all of these reasons lead to a higher environmental impact of HC TC. As for UHPC, the reason was similar, only UHPC curing at 50 °C has a slightly higher strength; therefore, it has a similar impact to on-site UHPC, which is the second-lowest impact among these eight systems. This condition could be regarded as a potential method to be modified for industry application. Comparing these four impact categories, climate change is the major impact category contributor to the total impacts in all systems, the influence of human health and resources is the second and third important impact category, while the ecosystem quality is the lowest contribution to the total impacts.

As for CO2 curing TC, the impact on climate change is 0.01657, which reduced 10% impact compared with on-site TC. For other impact categories, the reduction rate is about 8%, which means that CO2 curing is a useful method to reduce the impact of concrete. It has to be mentioned that CO2 in this production system is produced as an industrial product, and the environmental impact of this method can be further reduced with the application of carbon capture.

The results illustrated that using UHPC to replace TC is a potential method to optimize the design and further reduce the total environmental impacts of the off-site method. The total impact for on-site UHPC is only 70% of the cumulated impacts of on-site TC. UHPC has a much higher compressive strength than TC, even if it requires additional admixtures such as silica fume and superplasticizer, but the influence of saving material is more significant than the influence of adding high environmental impact materials.

As for using CO2 curing, it would be a general approach to replace general curing; CO2 curing has reduced the environmental impact by 10% compared with general off-site TC. This result is consistent with the previous results obtained by Huang et al. [26]. In this study, silica fume and CO2 curing reduce 6.7% of cement without compressive strength loss [15]. However, this method may not be suitable for concrete containing a high amount of steel bars—the CO2 will reduce the pH value of concrete and accelerate chloride penetration, which led to the corrosion of steel [26].

As for heat curing (HC), the impacts for both HC UHPC and HC TC columns are higher than the on-site construction method. This is because the designed 28-day strength of TC decreases with the increase in temperature (Figure 4), thus more material is needed to achieve the same loading capacity. The heat curing consumes additional energy and increases the environmental impacts for TC. As for UHPC used in this study, the maximum strength is obtained at 50 °C, while the 28-day compressive strength only increased by 4 MPa compared with the room curing (Figure 4) [13], which will not lead to a significant difference in material consumption, but extra energy for heat curing is consumed. However, the main purpose of heat curing is to improve the early strength, reduce the curing period and thus improve the productivity of factories. In that way, the environmental impacts of concrete based on early compressive strength are also conducted.

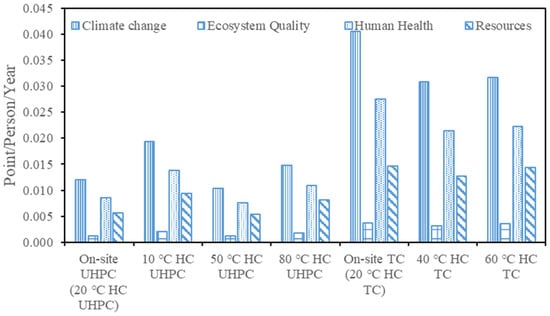

According to the ACI committee 301, curing should not be removed until it reaches 70% design strength, the design load will change to 5880 KN (70% of 28-day load capacity) if only consider the process before curing. We assumed all columns need to finish curing within 3 days, hence all the columns will be designed based on the three-day compressive strength obtained from Figure 4. The amount of material used for the three-day strength design is shown in Table 3, it can reflect some special conditions for projects (finish construction in a short time) or the method to improve productivity for factories. The result of this phenomenon is illustrated in Figure 6.

Table 3.

Calculation of concrete volume based on three-day compressive strength.

Figure 6.

LCA results for heat curing method based on three-day strength.

The off-site 50 °C HC UHPC system has the lowest impact among these seven systems, which can be treated as the most suitable off-site construction condition if only considering the early strength of the total impacts. Its impact on Climate Change, Ecosystem Quality, Human Health, and Resources is 0.0103, 0.00118, 0.0076, and 0.0245, respectively. The on-site TC (20 °C HC TC) system has the heaviest environmental burden; in addition, its impact on climate change is about 4 times higher than that of 50 °C HC UHPC. All UHPC columns have lower impacts compared with TC columns. This proves that UHPC can further reduce the environmental impacts of the off-site construction method. For TC columns, heat curing at all temperatures can reduce the environmental impacts; this seems to be a common method that can be applied to TC if only considering early strength. In summary, heat curing can not only improve the early strength but also reduce the environmental impacts if only considering the early strength of concrete columns. Thus, this study shows that heat curing would be an appealing method for concrete factories to improve productivity or the projects that need to be finished in a short time.

3.2. Contribution Analysis

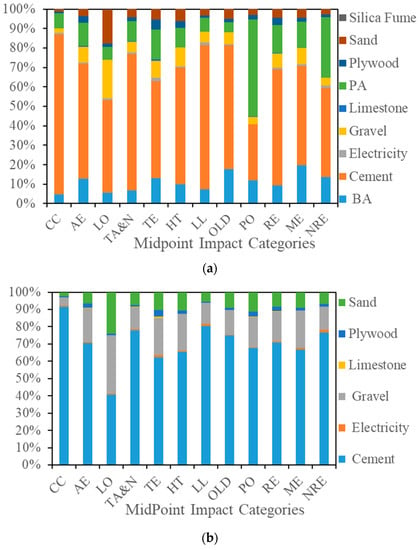

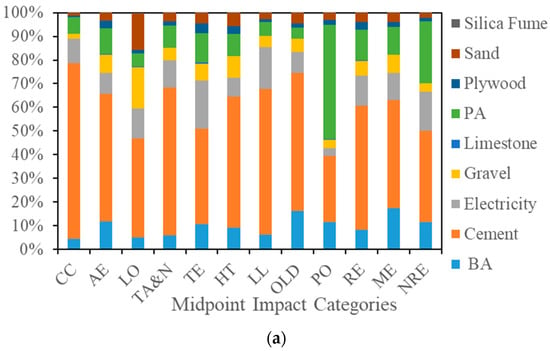

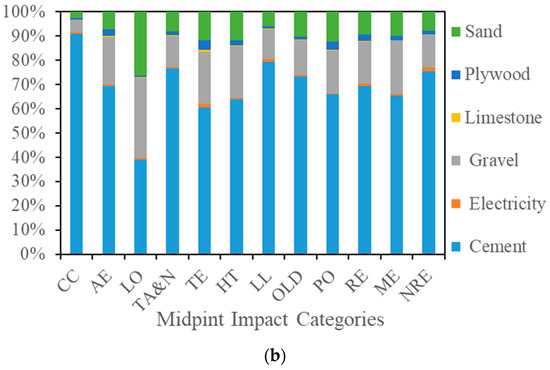

The contribution, uncertainty, and sensitivity analysis have been conducted based on the 28-day design strength. Figure 7 reports the contribution analysis results for general off-site construction TC and UHPC.

Figure 7.

Contribution analysis for (a) UHPC and (b) TC (CC: Climate Change; AE: Aquatic Ecotoxicity; LO: Land Occupation; TA&N: Terrestrial Acidification and Nutrification; TE: Terrestrial Ecotoxicity; HT: Human Toxicity; LL: Lonising Ladiation; OLD: Ozone Layer Depletion; PO: Photochemical Oxidation; RE: Respiratory Effects; ME: Mineral Extraction; NRE: Non-renewable Energy; PA: Phthalic Anhydride; BA: Benzyl Alcohol).

As illustrated in Figure 7, the cement has the heaviest environmental impacts among all the midpoint impact categories, except for photochemical oxidation in the UHPC group and land occupation in the TC group. This indicates that cement is the main contributor, which is also confirmed by Sidodikromo et al. [27]. When considering the total impact, cement has the hugest influence on climate change, it takes up 92.1% of climate change for general off-site TC and 82.9% for general off-site UHPC. As for the photochemical oxidation category for the UHPC group, the main contributor is benzyl alcohol and phthalic anhydride, which takes over 60% of the total impact. Benzyl alcohol and phthalic anhydride used in this study come from petroleum, while the production of petroleum has a huge influence on photochemical oxidation; thus, the impact of benzyl alcohol and phthalic anhydride has dominated this category. Thus, using green admixture will also be a crucial problem need to be determined in the future. The environmental problem related to sand and aggregate is the land occupation—aggregate (both sand and gravel) contributes 32.82% in UHPC and 57.72% in TC, which is much higher than other categories. This phenomenon indicates that reducing the environmental impact of aggregate can further reduce the impact of concrete, especially for traditional concrete.

Figure 8 shows the results of contribution analysis for off-site construction methods (HC UHPC and CO2 TC systems). Compared to the difference between Figure 7 and Figure 8, the impact of heat curing in UHPC mainly increases the impact of electricity, what has to be mentioned here is the reduction in cement percentage is due to the increase of total impact, but not the decrease of cement impact. For CO2 curing TC, the reason for cement percentage reduction is attributed to the decrease in the total amount of cement, which means that the total impact decreases. This phenomenon indicates that CO2 curing can reduce the environmental impact of concrete.

Figure 8.

Contribution analysis for off-site (a) 50 °C HC UHPC and (b) CO2 curing TC.

The contribution of the curing process in 50 °C HC UHPC is around 5% to climate change. Interestingly, a similar result is obtained in the CO2 curing TC system. Compared with impacts of material, the impacts of different curing methods seem to have less influence on total impacts.

After determining these crucial production processes in off-site construction, the following part will focus on some potential methods to develop these processes and finally can further improve off-site methods.

The first key process that needs to be mentioned is the production of cement, which is the most important part of all systems. Compared to Figure 7 and Figure 8, the contribution of cement can be reduced by using different curing methods. Using CO2 curing can partially replace cement clinker which can be helpful to reduce the total environmental impact. Compared to the cement used in TC and UHPC, CEM II allows for the replacing of 35% of clinker [28], while CEM I only allows for the replacing of 5% of clinker. If the percentage can be further increased without decreasing strength, the final impacts might be further reduced.

Therefore, the first potential method to reduce the environmental impacts of concrete is replacing cement clinker with other low-carbon supplementary cementitious materials (SCMs) such as slag, fly ash, and calcined clays. Besides this, cement is produced by heating limestone and clay mixture at 1450 °C, this process will generate considerable greenhouse gas and consume resources. Therefore, if some renewable energy resources can be used in factories, the total impacts of cement and concrete production can also be reduced. Thus, for further investigations, there are two possible approaches—one is to use CEM II or other low-carbon cement to replace CEM I, and the other approach is to find renewable energy resources that can be used in factories. Geopolymer concrete could be also the solution as the minimum environmental impact of geopolymer concrete is only 20% of OPC-based concrete [29,30].

The second process mentioned earlier is the production of plasticizers. The contribution of plasticizers to resources reaches 44.9% in general off-site UHPC, which is doubtful compared with the results obtained from Fehling and Schmidt [31] in that it is slightly higher than expected. Their study indicated that the impact of plasticizers is one of the main impacts on concrete production, but the results showed that the production of plasticizers has more influence on ecosystem quality. The feedstocks used to produce plasticizers are general from petroleum. The production process of them will generate some chemical components such as SOx and NOx; the emission gases will deposit on land or water and change their pH value and finally cause damage to the ecosystem [32]. However, this result could be acceptable since the mix design for UHPC used in this study has 29 kg of plasticizer, while the concrete mass is only 2552 kg, the plasticizer amount is slightly higher compared with other studies. According to BS EN 934-2 [33], the amount of plasticizer added into concrete is designed based on the slump value (the amount of plasticizer would be acceptable when the concrete can meet slump requirements). In order to reduce the impacts of plasticizers, further work should consider the green production of plasticizers, e.g., some renewable raw materials to replace petroleum-based plasticizer materials.

The third process that can be improved is the production of aggregates. Natural aggregates (NA) used in this study are directly from mining, which consumes natural resources and has a huge environmental impact. Using recycled aggregate (RA) from construction and demolition waste (CDW) is not only an effective method to reduce the environmental impact of concrete but also an approach to dealing with CDW. The higher porosity and water absorption of RA will lead to a lower compressive strength compared with NA [34]. The incorporation of RA in the concrete could slightly reduce the compressive strength of concrete compared with the reference concrete [35], which is due to the higher porosity of RA generated by the presence of adherent cement paste [36]. The use of RA in the concrete could be a potential method to reduce the environmental impacts compared with that of NAC.

3.3. Uncertainty and Sensitivity Analysis

Uncertainty analysis is used to determine the influence of variables. The power factor (e) of heat machines is assumed to be 0.7 in this study, which is the general power factor of power supplies. However, for power supplies with active power factor correction, the power factor can even reach 0.99 [24]. Thus, the e value is adjusted to 0.8 and then it is compared to the results obtained with an e value equal to 0.7.

The results of the uncertainty analysis are shown in Table 4. They indicated that improving the power factor can slightly reduce the total impact of columns, which is especially useful for concrete columns cured at high temperatures. This result should be combined with the results obtained from contribution analysis, whereas the contribution of curing is just around 10%. Thus, in order to determine the influence of the power factor on curing, the number in Table 4 should be multiplied by 10. Improving the value of the power factor by 0.1 would lead to a 40% increase in curing efficiency. This would a suitable method to improve the efficiency of heat curing but not a useful method to reduce the total environmental impacts.

Table 4.

Difference between e = 0.7 and e = 0.8 in %.

The ecosystem quality is the most sensitive impact category for UHPC, while resources become the considerable impact category affected by e value for TC. This inconsistency is caused by additional cement, silica fume, and plasticizer are required in the mix design of UHPC, which makes the impacts of resources take a larger part of the total impacts for UHPC. Thus, when the electricity consumption changes, the influence of resources will become smaller. Therefore, for the heat curing off-site construction method, it is a possible approach to find a suitable method to improve the power factor of curing machines, this method will increase the total cost of industries but reduce the environmental impacts. Further work in this field would be of great help in balancing the cost of factories and environmental impacts.

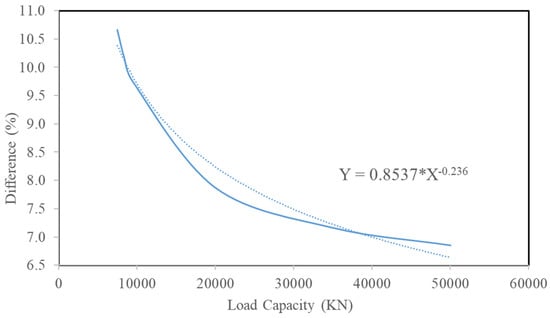

Sensitivity analysis is a tool for studying the robustness and the sensitivity to uncertainties. The UHPC columns produced by off-site HC at 50 °C and on-site have lower environmental impacts compared to other conditions. Thus, sensitivity analysis of load capacity will base on these two conditions. LCA studies of columns with load capacities of 7500 KN, 9500 KN, 20,000 KN, 35,000 KN, and 50,000 KN are carried out, then the difference between off-site heat curing and on-site method are compared (Figure 9).

Figure 9.

Difference between 50 °C HC and general off-site UHPC as a function of the load capacity.

From Figure 9, it can be found out the difference between HC and on-site construction method decrease rapidly when the load capacity is less than 20,000 KN, while the difference between them decreased at a slower speed and the sloping was generally to be flat when the load capacity is greater than 20,000 KN. This trend can be explained by the strength of UHPC reaching its peak at 50 °C [13]. Higher compressive strength will lead to a smaller cross-section area and less material consumption; therefore, the impacts of column material will decrease with the increase of compressive strength. Meanwhile, the concrete elements cured at 50 °C require additional energy consumption and increase the total impacts. Thus, the impact of saving material is more efficient than that of the impact of energy consumption.

By analyzing the trendy line, the curve can fit it well. The difference between HC and general curing will not eliminate until the load goes infinite (the difference will keep decreasing with the load increasing). This way, for the elements that need to have high load capacity, off-site HC seems to be a useful method. For factories producing concrete elements on a large scale, many columns are produced and cured together, which can be treated as a very huge concrete element that can carry a heavy load. Therefore, the off-site heat curing method will have a similar environmental impact as the general off-site construction method but with higher productivity and higher early strength.

3.4. Economic Analysis

As a limitation of LCA is the isolated approach to environmental issues [37], it does not link the impact with other areas such as labor cost and the effect on the surrounding client and traffic. To overcome the shortcoming of LCA studies, the economic impact of the off-site construction method is carried out.

The construction period is an important factor that cannot be reflected in LCA studies; off-site construction methods can have a shorter construction period compared to traditional construction methods. Flood Precast Company stated that they can finish the column construction within 15 min by using the off-site construction method, while the time required for on-site concrete is about 75 min [36]. It can help the company save GBP 375 per column. As for complex structures such as stairs, the saving time even reaches 87%. It is an attractive point for construction companies since they can both save time and reduce costs by using off-site construction methods. A shorter construction time will come up the fewer loan interests. Since the loan prime rate in China is 4.25% for a one-year loan, assuming a project with a loan of CNY 1 million and an estimated construction of 10 months is needed using the traditional construction method. Using offsite construction can save 80% of construction time, which can help a company save CNY 28,333.

This project is only focusing on the production of a single column; therefore, the effect of transportation is insignificant, but it will be different for large-scale production of concrete. As shown in Figure 1 and Figure 2, fresh concrete will be transported on-site, while concrete elements are transported in the off-site method. For the same amount of material, the environmental impacts obtained in LCA are similar. The concrete elements can be transported in larger trucks which require fewer vehicles. Tam [38] claimed 1.68 vehicles can be saved per day for a residential project, which will be helpful to the city congestion. For the projects in cosmopolitan cities such as London, the average hours lost in congestion per driver reached 149 h in 2019, and the cost of congestion per driver even reached GBP 1162 [38]. For the government, off-site construction methods will make a huge contribution to relieving the traffic pressure on cities. For the construction company, off-site construction methods can also help them save the transportation cost.

Considering the labor cost, Tam [38] demonstrated that off-site construction can save over 40% labor compared with the traditional construction method. Meanwhile, the Office for National Statistics stated that the average weekly income for the construction industry increases to 635.7 Pounds per week in December 2018, which is the second only after the finance and business services sector. Nevertheless, labor productivity measured by output per hour has fallen by 4.8% compared with the previous year [39]. This is absolutely bad news for construction companies, who must spend more money on labor but with less outcome. Moreover, the Construction Leadership Council showed that four skilled workers will leave construction industries, while only one worker will be trained [40]. Off-site construction can use a machine to replace labor and reduce the pressure on labor, which is a dream method for government to deal with the trend in labor decrease.

3.5. Limitation Discussion

For this study, there exist some limitations that need to be improved. The first limitation is lacking data support—collected data in this study were obtained from the published articles and missing data, through the internet by different methods. Besides this, most production processes in this study are defined as mono-function systems, which have a signal product, which is different from the realistic production. However, after applying allocation factors to the system, the environmental impacts will decrease and the results in this study can be considered as a conservative result.

Another limitation is all columns in this study are assumed to be failed in compression but not buckling. Thus, the slenderness of columns will not be taken into consideration. However, for the columns have small cross-section areas, they are more easily to fail in buckling rather than compression. Besides this, the connections between structural components are a problem, which become the weakest part of structures. In order to improve the resistance to seismic, denser rebar or energy consumption methods may be applied. This also needs to be considered when doing an LCA study for the whole structure.

4. Conclusions

The influence of off-site construction by using ultra-high-performance concrete or traditional concrete with different curing methods was investigated through life cycle assessment. Some conclusions can be drawn as follows:

- (1)

- An on-site UHPC system has a lower environmental impact than the on-site TC system under the same load capacity, which can reduce about 29.4% of the total environmental impacts of TC. The water bath heat curing will increase the environmental burden both for UHPC and TC. For large-scale production, the UHPC curing at 50 °C has a similar environmental impact to on-site construction, which indicates that this system could be a potential way to replace the on-site TC.

- (2)

- When considering the early strength, heat curing can reduce the total impacts of the off-site construction method. The heat curing can not only improve the early strength but also reduce the environmental impacts if only considering the early strength of concrete columns. Heat curing would be an appealing method for concrete factories to improve productivity or the projects that need to be finished in a short time.

- (3)

- CO2 curing is a useful method to reduce the environmental impacts of off-site construction methods, it can reduce 9.3% of the total impact of traditional concrete and reduce 11.1% impact on climate change.

- (4)

- The unit process that has the highest environmental impact is the production of cement, which takes up an 80.2% impact of the climate change in traditional concrete. The environmental impact of cement can be reduced by replacing clinker with supplementary cementitious materials. Plasticizers are the second biggest contributor to UHPC and occupy over 20% of the impacts on Ecosystem Quality and Human Health. Aggregates (both fine and coarse) are relative to the land occupation problem.

Based on these findings, off-site construction methods should be adopted to replace traditional construction methods. The concrete company can have higher productivity through off-site heat curing without increasing environmental impact. Construction companies can use off-site UHPC to replace on-site construction to reduce the construction period, and it is a meaningful method to reduce the cost of transportation and labor. Government should encourage construction companies to use high-performance concrete rather than traditional concrete to reduce environmental impacts. In addition, the off-site construction methods can help the government deal with increasing pressure on labor and traffic.

Author Contributions

C.J.: writing—original draft preparation, conceptualization, methodology, investigation. Y.W.: data curation, visualization. Z.Z.: writing—review and editing, funding acquisition. C.C.: writing—review and editing, validation. L.Y.: validation. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Fundamental Research Funds for the Central Universities, funding numbers: 22120220084 and 22120220205 (Tongji University).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to acknowledge Tongji University for the financial support from young scholar research funding. The authors would like to thank Myers Rupert for his help during the preparation of this paper.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Taylor, S. Offsite Production in the UK Construction Industry, a Brief Overview; Health and Safety Executive: London, UK, 2009. Available online: https://www.Buildoffsite.com/content/uploads/2015/04/HSE-off-site_production_june09.pdf (accessed on 5 June 2022).

- Zhu, H.; Hong, J.; Shen, G.Q.; Mao, C.; Zhang, H.; Li, Z. The exploration of the life-cycle energy saving potential for using prefabrication in residential buildings in China. Energy Build. 2018, 166, 561–570. [Google Scholar] [CrossRef]

- Dong, Y.H.; Jaillon, L.; Chu, P.; Poon, C.S. Comparing carbon emissions of precast and cast-in-situ construction methods—A case study of high-rise private building. Constr. Build. Mater. 2015, 99, 39–53. [Google Scholar] [CrossRef]

- Gao, Y.; Tian, X.L. Prefabrication policies and the performance of construction industry in China. J. Clean. Prod. 2020, 253, 120042. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K.; Sadiq, R. Conventional versus modular construction methods: A comparative cradle-to-gate LCA for residential buildings. Energy Build. 2019, 204, 109479. [Google Scholar] [CrossRef]

- Sandanayake, M.; Luo, W.; Zhang, G. Direct and indirect impact assessment in off-site construction—A case study in China. Sustain. Cities Soc. 2019, 48, 101520. [Google Scholar] [CrossRef]

- Nguyen, M.H.; Nakarai, K.; Torrent, R. Service life prediction of steam-cured concrete utilizing in-situ air permeability measurements. Cem. Concr. Compos. 2020, 114, 103747. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Ruan, S.; Wong, T.N.; Tan, M.J.; Yeong, K.L.O.; Qian, S. Comparative economic, environmental and productivity assessment of a concrete bathroom unit fabricated through 3D printing and a precast approach. J. Clean. Prod. 2020, 261, 121245. [Google Scholar] [CrossRef]

- Xiao, J.; Huang, X.; Shen, L. Seismic behavior of semi-precast column with recycled aggregate concrete. Constr. Build. Mater. 2012, 35, 988–1001. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Hussein, H.H.; Chen, G. Flexural strengthening of reinforced concrete beams or slabs using ultra-high performance concrete (UHPC): A state of the art review. Eng. Struct. 2020, 205, 110035. [Google Scholar] [CrossRef]

- Columbu, S.; Usai, M.; Rispoli, C.; Fancello, D. Lime and Cement Plasters from 20th Century Buildings: Raw Materials and Relations between Mineralogical–Petrographic Characteristics and Chemical–Physical Compatibility with the Limestone Substrate. Minerals 2022, 12, 226. [Google Scholar] [CrossRef]

- Kang, S.H.; Lee, J.H.; Hong, S.G.; Moon, J. Microstructural investigation of heat-treated ultra-high performance concrete for optimum production. Materials 2017, 10, 1106. [Google Scholar] [CrossRef] [Green Version]

- Fladr, J.; Broukalova, I. Influence of curing temperature on the mechanical properties of high-performance concrete. IOP Conf. Ser. Mater. Sci. Eng. 2019, 583, 012011. [Google Scholar] [CrossRef] [Green Version]

- Topçu, I.B.; Toprak, M.U. Fine aggregate and curing temperature effect on concrete maturity. Cem. Concr. Res. 2005, 35, 758–762. [Google Scholar] [CrossRef]

- Monkman, S.; MacDonald, M. On carbon dioxide utilization as a means to improve the sustainability of ready-mixed concrete. J. Clean. Prod. 2017, 167, 365–375. [Google Scholar] [CrossRef]

- Liang, C.; Pan, B.; Ma, Z.; He, Z.; Duan, Z. Utilization of CO2 curing to enhance the properties of recycled aggregate and prepared concrete: A review. Cem. Concr. Compos. 2020, 105, 103446. [Google Scholar] [CrossRef]

- Fava, J. Will the next 10 years be as productive in advancing life cycle approaches as the last 15 years? Int. J. Life Cycle Assess. 2006, 11, 6–8. [Google Scholar] [CrossRef]

- Manjunatha, M.; Preethi, S.; Mounika, H.G.; Niveditha, K.N. Life cycle assessment (LCA) of concrete prepared with sustainable cement-based materials. Mater. Today Proc. 2021, 47, 3637–3644. [Google Scholar] [CrossRef]

- Knoeri, C.; Sanyé-Mengual, E.; Althaus, H. Comparative LCA of recycled and conventional concrete for structural applications. Int. J. Life Cycle Assess. 2013, 18, 909–918. [Google Scholar] [CrossRef] [Green Version]

- ISO 14040; Environmental Management-Life Cycle Assessment-Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Kim, J.-K.; Moon, Y.-H.; Eo, S.-H. Compressive strength development of concrete with different curing time and temperature. Cem. Concr. Res. 1998, 28, 1761–1773. [Google Scholar] [CrossRef]

- Aqel, M.A. Steam Cured Self-Consolidating Concrete and the Effects of Limestone Filler. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2016. [Google Scholar]

- Damineli, B.L.; Kemeid, F.M.; Aguiar, P.S.; John, V.M. Measuring the eco-efficiency of cement use. Cem. Concr. Compos. 2010, 32, 555–562. [Google Scholar] [CrossRef]

- Suzuki, Y.; Teshima, T.; Sugawara, I.; Takeuchi, A. Experimental Studies on Active and Passive PlFC Circuits. In Proceedings of the Power and Energy Systems in Converging Markets, Melbourne, Australia, 23 October 1997. [Google Scholar]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.J.; Bauer, C.; Doka, G.; Dones, R.; Hischier, R.; Hellweg, S.; Humbert, S.; Margni, M.; et al. Swiss Centre for Life Cycle Inventories A joint initiative of the ETH domain and Swiss Federal Offices Implementation of Life Cycle Impact Assessment Methods. 2004. Available online: www.ecoinvent.ch (accessed on 5 June 2022).

- Huang, H.; Wang, T.; Kolosz, B.; Andresen, J.; Garcia, S.; Fang, M.; Maroto-Valer, M.M. Life-cycle assessment of emerging CO2 mineral carbonation-cured concrete blocks: Comparative analysis of CO2 reduction potential and optimization of environmental impacts. J. Clean. Prod. 2019, 241, 118359. [Google Scholar] [CrossRef]

- Sidodikromo, E.P.; Chen, Z.; Habib, M. Review of The Cement-Based Composite Ultra-High-Performance Concrete (UHPC). Open Civ. Eng. J. 2019, 13, 147–162. [Google Scholar] [CrossRef] [Green Version]

- BS EN 197-1; Cement–Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardisation: London, UK, 2011.

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Abdel-Gawwad, H.A.; Abo-El-Enein, S.A. A novel method to produce dry geopolymer cement powder. HBRC J. 2016, 12, 13–24. [Google Scholar] [CrossRef] [Green Version]

- Fehling, E.; Schmidt, M.; Stürwald, S. Ultra High Performance Concrete:(UHPC). In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; Volume 10. [Google Scholar]

- Jamarani, R.; Erythropel, H.C.; Nicell, J.A.; Leask, R.L.; Marić, M. How green is your plasticizer? Polymers 2018, 10, 834. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- BS EN 934-2; Admixtures For Concrete, Mortar and Grout-Part 2: Concrete Admixtures; Definitions, Requirements, Conformity, Marking and Labelling. European Committee for Standardisation: London, UK, 2009.

- Iizuka, A.; Nakagawa, M.; Kumagai, K.; Yamasaki, A.; Yanagisawa, Y. Chemical extraction and mechanical crushing method for fine aggregate recycling from waste concrete. J. Chem. Eng. Jpn. 2010, 43, 906–912. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Buyle, M.; Braet, J.; Audenaert, A. Life cycle assessment in the construction sector: A review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar] [CrossRef]

- Tam, C.M. Impact on Structure of Labour Market Resulting From Large-scale Implementation of Prefabrication. Adv. Build. Technol. 2002, 1, 399–403. [Google Scholar]

- Wojcikowski, C. Index of Labour Costs Per Hour; Office For National Statistics: London, UK, 2019.

- The Farmer Review of the UK Construction Labour Model Modernise or Die Time to Decide the industry’s Future. 2016. Available online: www.cast-consultancy.com (accessed on 5 June 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).