Food Waste Diversion from Landfills: A Cost–Benefit Analysis of Existing Technological Solutions Based on Greenhouse Gas Emissions

Abstract

:1. Introduction

2. Materials and Methods

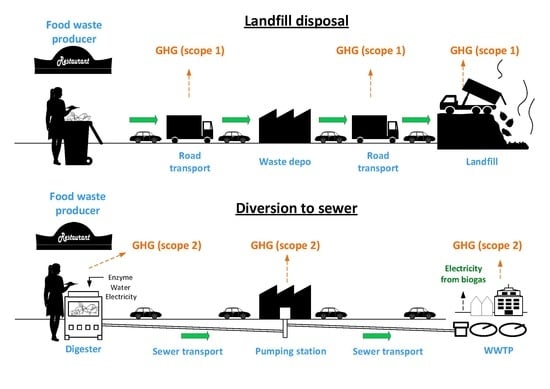

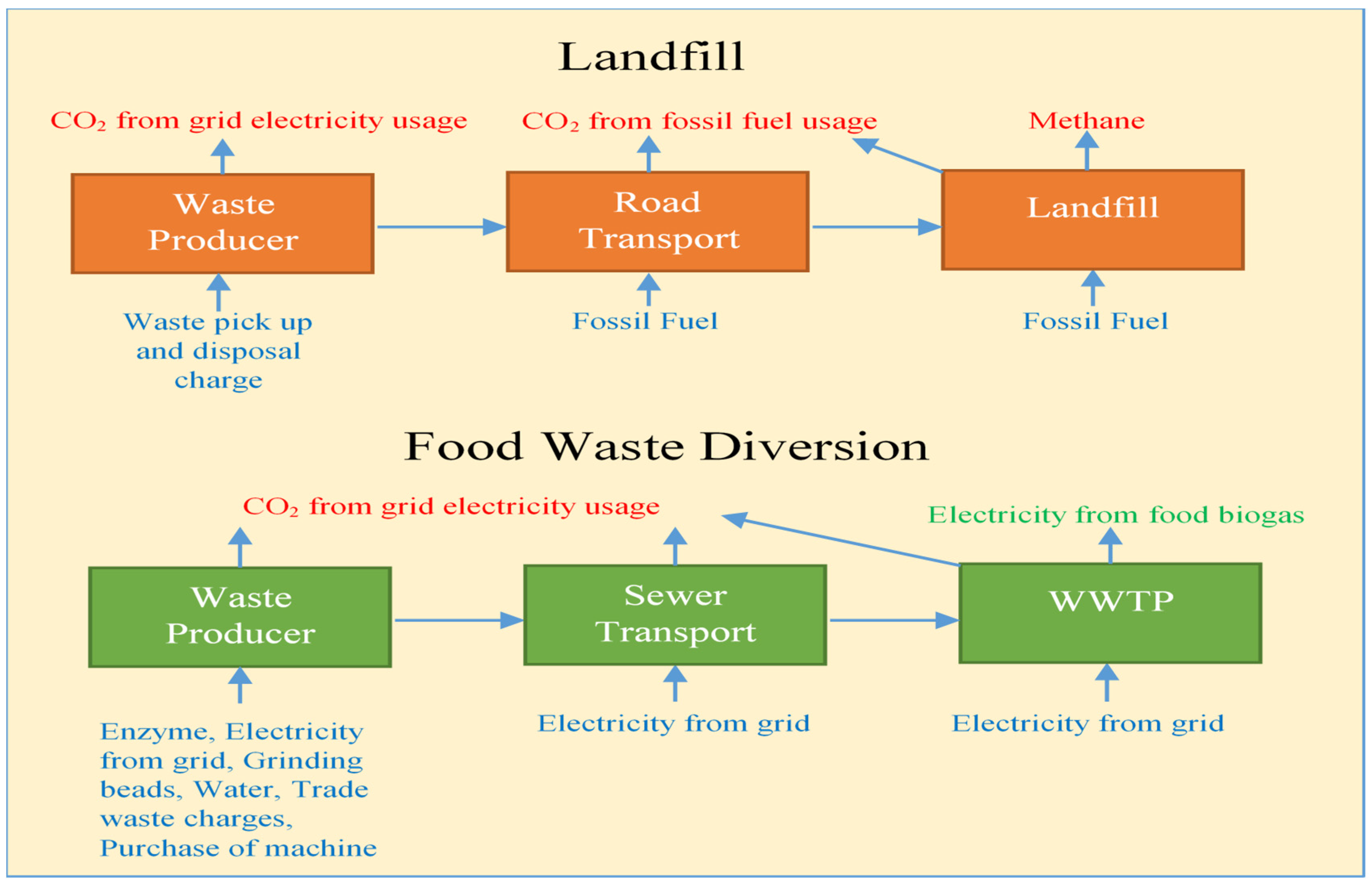

2.1. Scenario 1: Waste Pick Up and Landfill Disposal

2.2. Scenario 2: Waste Pick Up and Centralized Composting

2.3. Scenario 3: Dehydrator and Centralized Composting

2.4. Scenario 4: On-Site ADLO, Poor BOD Reduction Performance

2.5. Scenario 5: On-Site ADLO, BOD Reduction as Per Literature Case Study

2.6. Scenario 6: In-Sink Waste Disposal, No BOD Reduction

2.7. Assumptions and Calculation Parameter Setting

3. Results

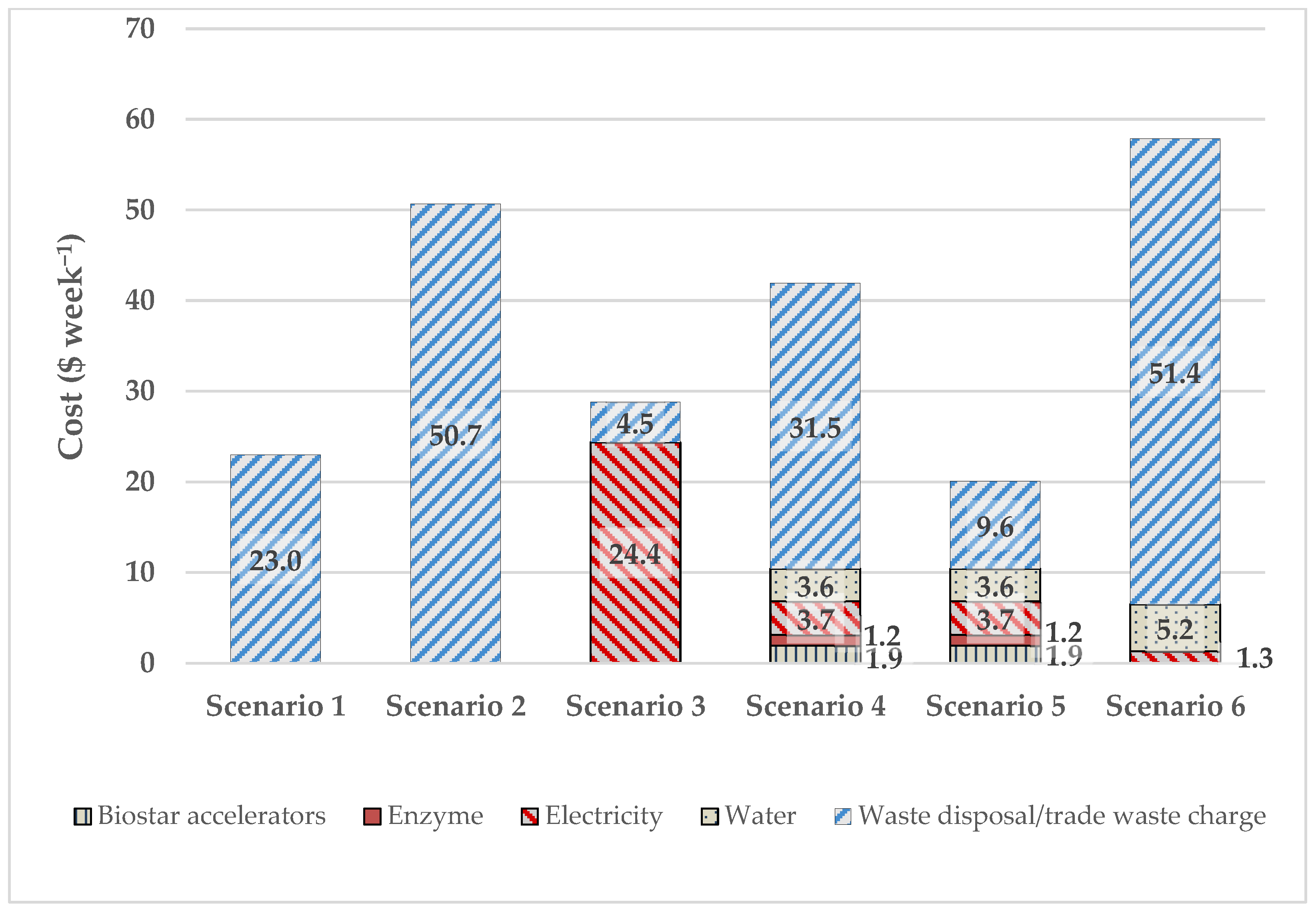

3.1. Techno-Economic Comparison of the Six Scenarios

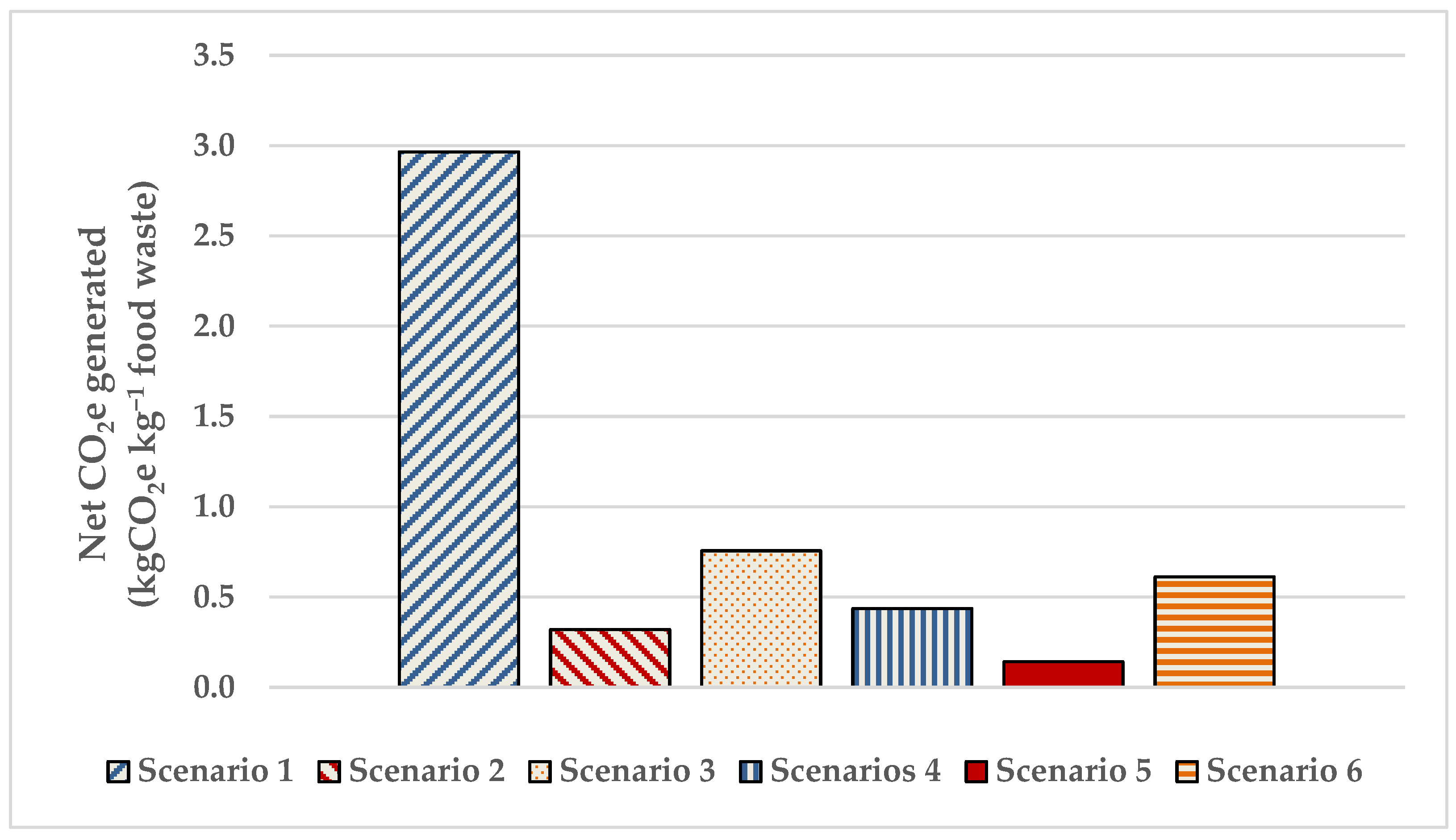

3.2. Environmental Benefit Assessment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Parameter | Setting/Value | Reference | Comments |

|---|---|---|---|

| BioStar accelerator medium (USD week−1) | 1.9 | [17] | Calculated from accelerator chip use (per kg of food waste) for ORCA machine in US case study. |

| Enzyme formulation (USD week−1) | 1.2. | [17] | Calculated from enzyme use (per kg of food waste) for ORCA machine in US case study. |

| Electricity cost (USD kWh−1) | 0.19 | [41] | Using average annual electricity bills of AUD 6000 for SMEs using 20,000 kWh (single rate) per annum in Victoria. Offers as of April 2018, GST inclusive. |

| EX-30 machine electricity usage (kWh day−1) | 3.2 | [30] | |

| EX-30 machine water usage (L day−1) | 278 | [30] | |

| EX-30 water usage (kL day−1) | 0.278 | [30] | |

| EX-30 water usage (kL week−1) | 1.67 | [30] | calculated assuming 6-day working week. |

| EX-30 weekly energy usage (kWh week−1) | 19.2 | [30] | calculated assuming 6-day working week. |

| EX-30 water usage (kL week−1) | 1.67 | [30] | calculated assuming 6-day working week. |

| Water usage charge (USD kL−1) | 2.16 | [22] | |

| Sewerage disposal charge (USD kL−1) | 1.37 | [22] | |

| Trade waste usage volume charge (USD kL−1) | 0.65 | [22] | |

| Trade waste usage BOD charge (USD kg−1 BOD) | 0.80 | [22] | |

| Trade waste usage Total Kjendhal N charge (USD kg−1 N) | 1.53 | [22] | |

| Trade waste usage SS charge (USD kg−1 SS) | 0.43 | [22] | |

| Trade waste usage Inorganic TDS charge (USD kg−1 TDS) | 0.02 | [22] | |

| Weight of food generated (kg week−1) | 180 | Assuming Ex-30 machine is operated at full capacity of 30 kg d−1 for 6 days a week. | |

| Density of food (g L−1) | 500 | [8] | |

| General food waste disposal costs (USD week−1) | 11.5 | [42] | For a 240 L bin. |

| Organics food waste disposal cost (USD week−1) | 29.8 | [43] | For a 240 L bin. |

| Volume of waste generated (L week−1) | 360 | Assuming food waste density of 500 g L−1. | |

| Moisture content of food waste (%) | 75% | [44] | |

| In-sink disposal water usage (kL week−1) | 2.4 | [31,45] | Using 4 L capita−1 day−1, assuming 3 meals capita−1 d−1, and 100 g food waste per meal and 1800 meals week−1. |

| Insinkerator energy usage (Watts) | 370.0 | [46] | |

| Insinkerator energy usage (KWh kg−1 food waste) | 0.037 | Assuming 3 h d−1 operation, 6 day week, 180 kg week−1 food waste. | |

| Centralized composting electricity consumption (kWh tonne−1 food waste) | 300 | [34] | |

| Dehydrator energy requirement (kWh kg−1 food waste) | 0.7 | [12] | |

| COD of food waste (g COD kg−1 food waste) | 350 | [18] |

| Parameter | Setting/Value | Reference | Comments |

|---|---|---|---|

| COD (g COD Kg−1 wet food waste) | 196 | [19] | Wet weight reduction of 44% in 1 day. Assumption that %COD reduction is the same as the %weight reduction. |

| BOD (g BOD kg−1 wet food waste) | 98 | Using BOD:COD ratio of two in undigested food in Kim et al. 2015. | |

| N (g N kg−1 wet food waste) | 4.1 | [47] | Assuming a COD:TotalN ratio of 48 for undigested food. |

| SS (g SS kg−1 food waste) | 154 | [18] | Assuming ~56% solubilization and a food waste, moisture content of 75%. |

| Inorganic TDS (g TDS kg−1 food waste) | 3.76 | [17] | Calculated from salinity of ORCA machine digestate, added water volume, and food load. |

| Parameter | Setting/Value | Reference | Comments |

|---|---|---|---|

| BOD (g BOD kg−1 wet food waste) | 8.3 | [17] | Calculated from ORCA digestate BOD, added water volume and food load. |

| N (g N kg−1 wet food waste) | 0.33 | Assuming similar N reduction and BOD reduction to BOD reduction. | |

| SS (g SS kg−1 food waste) | 93.2 | [17] | Calculated from ORCA digestate TSS, added water volume and food load. |

| Inorganic TDS (g TDS kg−1 food waste) | 3.76 | [17] | Calculated from salinity of ORCA machine digestate, added water volume, and food load. |

| Parameter | Setting/Value | Reference | Comments |

|---|---|---|---|

| COD of food waste (g COD kg−1 wet food waste) | 350 | [18] | |

| BOD (g BOD kg−1 wet food waste) | 175 | Using BOD:COD ratio of two in undigested food in Kim et al. 2015. | |

| N (g N kg−1 wet food waste) | 7 | [47] | Assuming a COD:Total N ratio of 48 for undigested food. |

| SS (g SS kg−1 food waste) | 250 | Assuming grinding reduces total solids to suspended solids. | |

| Estimated inorganic TDS, Scenarios 3 and 4 (g TDS kg−1 food waste) | 3.76 | [17] | Calculated from salinity of ORCA machine digestate, added water volume, and food load. |

| Water usage (L capita−1 day−1) | 4 | [31] | |

| Customer food waste production (kg meal−1 day−1) | 0.1 | [47] |

| Parameter | Setting/Value | Reference/Comments |

|---|---|---|

| Density of food waste (kg L−1) | 0.5 | [48] |

| Truck fuel consumption (L km−1) | 0.345 | [49] |

| Energy content of truck diesel fuel (MJ L−1) | 38.6 | [50] |

| Truck CO2 emissions (kgCO2e (km−1 tonnes−1 of food) | 0.2 | [33] |

| Distance to transfer station (km) | 15 | Estimate |

| Distance between transfer station and landfill (km) | 15 | Estimate |

| Moisture content of food (%) | 75% | [51] |

| Garbage truck maximum weight load (Tonnes) | 24 | [52] |

| CO2 equivalents from methane release (kgCO2e tonne−1 of food) | 2965 | [33] |

| Anaerobic digester recoverable energy (kWh tonne−1 of waste) | 400 | [52] |

| WWTP energy benchmark (kWh kg−1 COD removed) | 2.8 | [35] |

| COD of food waste (g COD Kg−1 of food waste) | 350 | [18] |

| Indirect CO2 equivalents from use of electricity in Victoria, Australia (kg CO2e kWh−1) | 1.08 | [53] |

| Scenario | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |||||||

| In | Out | In | Out | In | Out | In | Out | In | Out | In | Out | |

| On site and/or Road Energy Use and output (kWh kg−1 food waste) | 0.0046 (a) | 0 | 0.3 | 0 | 0.70 | 0 | 0.11 | 0 | 0.11 | 0 | 0.04 | 0 |

| Sewer+WWTP Energy use and output (kWh kg−1 food waste) | - | - | - | - | - | - | 0.55 (d) | 0.25 (c) | 0.05 (d) | 0.02 (c) | 0.98 (d) | 0.45 (c) |

| Water (L kg−1 food waste) | - | - | - | - | - | - | 9.3 | 9.3 | 9.3 | 9.3 | 13.3 | 13.3 |

| CO2 equivalents generated (b) (kgCO2e kg−1 food waste) | - | 3.0 | - | 0.32 | - | 0.76 | - | 0.70 | - | 0.17 | 1.1 | |

Appendix B. Sample Calculations

Appendix B.1. Cost Calculations

Appendix B.1.1. Scenario 1: Landfill Base Case)

Appendix B.1.1.1. Required Bin Volume (L week−1)

Appendix B.1.1.2. Disposal Cost (USD week−1)

Appendix B.1.2. Scenario 5: ADLO with Performance and per US Case Study

Total Cost (USD week−1)

- (1)

- BioStar accelerator Cost (USD week−1)

- (2)

- Enzyme Cost (USD week−1)

- (3)

- Electricity Cost (USD week−1)

- (4)

- Water Cost (USD week−1)

- (5)

- Trade Waste Costs

- Trade Waste Volume Cost (USD week−1)

- Trade Waste BOD Cost (USD week−1)

- Trade Waste N Cost (USD week−1)

- Trade waste SS Cost (USD week−1)

- Trade waste TDS cost (USD week−1)

Appendix B.2. Energy, Water and CO2 Equivalents Estimates

Appendix B.2.1. Scenario 1: Landfill Base Case

Appendix B.2.1.1. Energy Required (kWh kg−1 Food Waste)

Appendix B.2.1.2. CO2e Generated (kg CO2e kg−1 Food Waste)

Appendix B.2.2. Scenario 5: ADLO with Performance and per US Case Study

Net CO2e

- (1)

- Total CO2e generated (kgCO2e kg−1)

- CO2e generated from COD at WWTP (kgCO2e kg−1 food waste)= Energy required for treatment at WWTP on COD basis (kWh kg−1 food waste) × indirect (scope 2) CO2e from use of electricity (kg CO2e kWh−1)

- CO2e generated from electricity used by ADLO machine (kg CO2e kg−1 food waste)

- CO2e generated from electricity used to pump the digestate to the WWTP (kWh L−1)

- (2)

- CO2e Saving due to Electricity Generation from Food Waste Methane at WWTP (kg CO2e kg−1 Food Waste)

Appendix B.2.3. Scenario 6

Water Usage (L kg−1 Food Waste)

- (1)

- Water usage per meal (L meal−1)

- (2)

- Restaurant meal frequency (meals d−1)

References

- Australian Government Department of the Environment and Energy. National Food Waste Strategy: Halving Australia’s Food Waste by 2030. 2017. Available online: https://www.awe.gov.au/sites/default/files/documents/national-food-waste-strategy.pdf (accessed on 16 March 2022).

- European Government. European Union Regulation No 517/2014 of the European Parliament and of the Council of 16 April 2014 on Fluorinated Greenhouse Gases Annex IV. 2014. Available online: https://www.eea.europa.eu/policy-documents/regulation-eu-no-517-2014 (accessed on 16 March 2022).

- Nisbet, E.G.; Fisher, R.E.; Lowry, D.; France, J.L.; Allen, G.; Bakkaloglu, S.; Broderick, T.J.; Cain, M.; Coleman, M.; Fernandez, J.; et al. Methane Mitigation: Methods to Reduce Emissions, on the Path to the Paris Agreement. Rev. Geophys. 2020, 58, e2019RG000675. [Google Scholar] [CrossRef]

- Saunois, M.; Stavert, A.R.; Poulter, B.; Bousquet, P.; Canadell, J.G.; Jackson, R.B.; Raymond, P.A.; Dlugokencky, E.J.; Houweling, S.; Patra, P.K.; et al. The Global Methane Budget 2000–2017. Earth Syst. Sci. Data 2020, 12, 1561–1623. [Google Scholar] [CrossRef]

- United Nations Environment Programme and Climate and Clean Air Coalition. Global Methane Assessment: Benefits and Costs of Mitigating Methane Emissions; United Nations Environment Programme: Nairobi, Kenya, 2021; ISBN 978–92–807–3854–4. [Google Scholar]

- Iqbal, A.; Ekama, G.A.; Zan, F.; Liu, X.; Chui, H.-K.; Chen, G.-H. Potential for co-disposal and treatment of food waste with sewage: A plant-wide steady-state model evaluation. Water Res. 2020, 184, 116175. [Google Scholar] [CrossRef]

- Iacovidou, E.; Ohandja, D.-G.; Voulvoulis, N. Food waste co-digestion with sewage sludge e Realising its potential in the UK. J. Environ. Manag. 2012, 112, 267–274. [Google Scholar] [CrossRef] [PubMed]

- Victorian Government. Metropolitan Waste and Resource Recovery Plan 2016. 2016. Available online: https://www.mwrrg.vic.gov.au/assets/resource-files/Web-Metro-Implementation-Plan.pdf (accessed on 16 March 2022).

- Schultz, J. Fighting Food Waste. National Congress of State Legislature. 2017. Available online: https://www.ncsl.org/research/agriculture-and-rural-development/fighting-food-waste.aspx (accessed on 16 March 2022).

- European Environment Agency. Bio-Waste in Europe—Turning Challenges into Opportunities. EEA Report No 04/2020. 2020. Available online: https://www.eea.europa.eu/publications/bio-waste-in-europe (accessed on 16 March 2022).

- Mitchelmore, P. Degrave Street Recycling Facility MF-R1 Final Report. Melbourne Metropolitan Government. 2015. Available online: https://www.mwrrg.vic.gov.au/assets/resource-files/Degraves-Street-Recycling-MF-R1-Final-Report-Melbourne.pdf (accessed on 16 March 2022).

- Griffiths-Onnen, I.; Patten, Z.; Wong, J. On-Site Systems for Processing Food Waste: A Report to the Massachusetts Department of Environmental Protection. 2013. Available online: https://www.mass.gov/doc/report-on-site-systems-for-processing-food-waste-april-2013/download (accessed on 16 March 2022).

- American Institute of Architects (AIA). Zero Waste Design Guidelines: Design Strategies and Case Studies for a Zero Waste City. 2017. Available online: https://www.zerowastedesign.org/wp-content/uploads/2017/10/ZeroWasteDesignGuidelines2017_Web.pdf (accessed on 16 March 2022).

- EXBIO Waste Management Solutions UK. Available online: http://exbiouk.com/ (accessed on 16 March 2022).

- Innovative Clean Waste Technology—ORCA. 2020. Available online: https://www.feedtheorca.com/ (accessed on 16 March 2022).

- DeHaghin, M. Food Waste Liquefier Orca Green. Master’s Thesis, California State University, Northridge, CA, USA, 2013. Available online: https://scholarworks.csun.edu/bitstream/handle/10211.2/5166/DeHaghin-Maryam-thesis-2014.pdf?sequence=1 (accessed on 16 March 2022).

- Fey, C.; Chadderton, C.; Rodriguez, G.; Gilbert, D.; Urban, A.; Foran, C.M. Organic Waste Diversion Guidance for U.S. Army Installations. Final Technical Report. 2016. Available online: https://usace.contentdm.oclc.org/digital/api/collection/p266001coll1/id/3955/download (accessed on 16 March 2022).

- Graunke, R.E.; Wilkie, A.C. Examining the mechanisms of short-term solubilization of ground food waste for high-rate anaerobic digestion. Biodeterior. Biodegrad. 2014, 86, 327–333. [Google Scholar] [CrossRef]

- Kwon, S.H.; Lee, D.H. Evaluation of Korean food waste composting with fed-batch operations I: Using water extractable total organic carbon contents (TOCw). Process Biochem. 2004, 39, 1183–1194. [Google Scholar] [CrossRef]

- Xe Currency Converter. Available online: https://www.xe.com/currencytables/ (accessed on 16 March 2022).

- Coinnews Media Group Inflation Calculator. Available online: https://www.usinflationcalculator.com/ (accessed on 22 March 2022).

- City West Water. Trade Waste Charges Explained. Available online: https://www.citywestwater.com.au/business/trade_waste/trade_waste_charges_explained (accessed on 16 March 2022).

- Australian Government—Department of Agriculture Water and the Environment. National Waste Policy—Less Waste, More Resources. 2018. Available online: https://www.awe.gov.au/environment/protection/waste/how-we-manage-waste/national-waste-policy (accessed on 12 March 2022).

- City West Water. Trade Waste Acceptance Criteria. Available online: https://www.westernwater.com.au/assets/volumes/general-downloads/trade-wate-acceptance-criteria.pdf (accessed on 16 March 2022).

- The Mechanical Stomach: Iugis. Waste Management Review. 18 December 2019. Available online: https://wastemanagementreview.com.au/the-mechanical-stomach-iugis/ (accessed on 16 March 2022).

- Stokehouse Restaurant. Available online: https://stokehouse.com.au/melbourne/sustainability/ (accessed on 16 March 2022).

- Coles Group. Coles Sustainability Report 2019. 2019. Available online: https://www.colesgroup.com.au/FormBuilder/_Resource/_module/ir5sKeTxxEOndzdh00hWJw/file/Coles_Sustainability_Report_2019.pdf (accessed on 16 March 2022).

- Sustainability Allies: Veolia. Waste Management Review. 16 July 2019. Available online: https://wastemanagementreview.com.au/sustainability-allies/ (accessed on 16 March 2022).

- Turning Waste into Water in the City of Melbourne. Waste Management Review. 2018. Available online: https://wastemanagementreview.com.au/turning-waste-water-city-melbourne/ (accessed on 16 March 2022).

- ExBio Ex-Series Catalogue. Available online: http://exbiouk.com/catalogue/ (accessed on 16 March 2022).

- Stantec Consulting. Impact of Food Waste Disposal on WWTP. Final Report to the Town of Canmore. 2017. Available online: https://canmore.ca/documents/2270-2017-impact-of-food-waste-disposal-on-wwtp (accessed on 17 March 2022).

- Khanal, S.K. Anaerobic Biotechnology for Bioenergy Production: Principles and Applications; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2008; ISBN 978-0-813-82346-1. [Google Scholar]

- Moult, J.A.; Allan, S.R.; Hewitt, C.N.; Berners-Lee, M. Greenhouse gas emissions of food waste disposal options for UK retailers. Food Policy 2018, 77, 50–58. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.J.; Matsuto, T. Comparison of mass balance, energy consumption and cost of composting facilities for different types of organic waste. Waste Manag. 2011, 31, 416–422. [Google Scholar] [CrossRef] [PubMed]

- De Haas, D.; Appleby, G.; Charakos, G.; Dinesh, N.B. Benchmarking Energy Use for Wastewater Treatment Plants: A summary of the 2015–16 benchmarking study. Online J. Aust. Water Assoc. 2018, 3, 1–26. [Google Scholar] [CrossRef]

- Melbourne Water. Western Treatment Plant Sewage Treatment Process. 2021. Available online: https://fdocuments.net/document/benchmarking-energy-use-for-wastewater-treatment-the-wastewater-data-ow-and-concentration.html?page=1 (accessed on 17 March 2022).

- Melbourne Water. Our Path to Net Zero. 2021. Available online: https://www.melbournewater.com.au/water-data-and-education/environmental-issues/our-path-net-zero (accessed on 17 March 2022).

- Kim, Y.; Bothi, K.; Cha, D.; Chajes, M.; Aukam, R. Life Cycle Assessment of BioHiTech Digester for Food Waste Management, Department of Civil and Environmental Engineering University of Delaware Newark, Delaware 19716. Available online: https://renovareenv.com/wp-content/uploads/2020/11/LCA.pdf (accessed on 1 August 2018).

- Edwards, J.; Othman, M.; Crossin, E.; Burn, S. Life cycle assessment to compare the environmental impact of seven contemporary food waste management systems. Bioresour. Technol. 2018, 248, 156–173. [Google Scholar] [CrossRef] [PubMed]

- Jin, P.; Gu, Y.; Shi, X.; Yang, W. Non-negligible greenhouse gases from urban sewer system. Biotechnol. Biofuels 2019, 12, 100. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Analysis of Small Business Retail Energy Bills in Australia, Final Report. Alviss Consulting. June 2018. Available online: https://energyconsumersaustralia.com.au/wp-content/uploads/SME-Retail-Tariff-Tracker-Final-Report-June-2018.pdf (accessed on 17 March 2022).

- Waster Pty Ltd. 240 Litre General Waste Bin Service. Available online: https://waster.com.au/product/240-litre-general-waste-bin-service/ (accessed on 17 March 2022).

- Waster Pty Ltd. 120 Litre Organic Bin Service. Available online: https://waster.com.au/product/120-litre-organics-bin-service (accessed on 17 March 2022).

- Kumar, M.; Ou, Y.-L.; Lin, J.-G. Co-composting of green waste and food waste at low C/N ratio. Waste Manag. 2010, 30, 602–609. [Google Scholar] [CrossRef] [PubMed]

- McAdams, B.; von Massow, M.; Gallant, M.; Hayhoe, M.A. A cross industry evaluation of food waste in restaurants. J. Foodserv. Bus. Res. 2019, 22, 449–466. [Google Scholar] [CrossRef]

- Insinkerator Worldwide. Evolution 200 Disposer. Available online: https://www.insinkerator-worldwide.com/product/evolution-200-disposer (accessed on 17 March 2022).

- Kim, M.; Chowdhury, M.M.I.; Nakhla, G.; Keleman, M. Characterization of typical household food wastes from disposers: Fractionation of constituents and implications for resource recovery at wastewater treatment. Bioresour. Technol. 2015, 183, 61–69. [Google Scholar] [CrossRef] [PubMed]

- Waste Recycling Action Program (WRAP). Summary Report—Material Bulk Densities, Report Prepared by Resource Futures. 2009. Available online: http://docplayer.net/20954269-Material-bulk-densities.html (accessed on 17 March 2022).

- Transport and Environment. Truck-CO2-Emissions-2030. 2015. Available online: https://www.transportenvironment.org/discover/too-big-ignore-truck-co2-emissions-2030/ (accessed on 17 March 2022).

- Beer, T.; Grant, T.; Morgan, G.; Lapszewicz, J.; Anyon, P.; Edwards, J.; Nelson, P.; Watson, H.; Williams, D. Comparison of Transport Fuels, Final Report (EV45A/2/F3C) to the Australian Greenhouse Office on the Stage 2 study of Life-cycle Emissions Analysis of Alternative Fuels for Heavy Vehicles, Australia. 2001. Available online: http://www.fischer-tropsch.org/DOE/DOE_reports/ev45a_2_f3c/ev45a_2_f3c_toc.pdf (accessed on 17 March 2022).

- Banks, C.J.; Heaven, S.; Zhang, Y.; Baier, U. Food Waste Digestion: Anaerobic Digestion of Food Waste for a Circular Economy; Murphy, J.D., Ed.; IEA Bioenergy: Paris, France, 2018; ISBN 978-1-910154-57-1. [Google Scholar]

- City of Melbourne. Guidelines for Preparing a Waste Management Plan 2017. Available online: https://www.melbourne.vic.gov.au/sitecollectiondocuments/waste-management-plan-guidelines.pdf (accessed on 17 March 2022).

- Banks, C.; Chesshire, M.; Heaven, S.; Arnold, R.; Lewis, L. Biocycle anaerobic digester: Performance and benefits. In Proceedings of the Institution of Civil Engineers; Issue WR3; ICE Publishing: London, UK, 2011; pp. 141–150. [Google Scholar] [CrossRef]

| Parameter | Acceptance Criteria Limit | Scenario 4 | Scenario 5 (Orca Digestate [17]) |

|---|---|---|---|

| pH | 6–10 | 5.1 (a) | 4.2 |

| SS (mg L−1) | 10,000 | 97,000 | 67,000 |

| Nitrogen (mg L−1 TNK) | 500 | 3333 | 286 (b) |

| BOD (mg L−1) | 4000 | 70,000 | 6000 |

| Scenario | Approximate Equipment Cost (USD) | Simple Payback Period (yr) | |

|---|---|---|---|

| Base Case: Landfill (Scenario 1) | Base Case: Centralized Composting (Scenario 2) | ||

| 3: (dehyd.+compost) | 20,000 | np * | 18 |

| 4: (ADLO worst case) | 7500 | np | np |

| 5: (ADLO best case) | 7500 | 48 | 4 |

| 6: (in-sink disposal) | 1200 | np | np |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanciolo, P.; Rivera, E.; Navaratna, D.; Duke, M.C. Food Waste Diversion from Landfills: A Cost–Benefit Analysis of Existing Technological Solutions Based on Greenhouse Gas Emissions. Sustainability 2022, 14, 6753. https://doi.org/10.3390/su14116753

Sanciolo P, Rivera E, Navaratna D, Duke MC. Food Waste Diversion from Landfills: A Cost–Benefit Analysis of Existing Technological Solutions Based on Greenhouse Gas Emissions. Sustainability. 2022; 14(11):6753. https://doi.org/10.3390/su14116753

Chicago/Turabian StyleSanciolo, Peter, Eduardo Rivera, Dimuth Navaratna, and Mikel C. Duke. 2022. "Food Waste Diversion from Landfills: A Cost–Benefit Analysis of Existing Technological Solutions Based on Greenhouse Gas Emissions" Sustainability 14, no. 11: 6753. https://doi.org/10.3390/su14116753

APA StyleSanciolo, P., Rivera, E., Navaratna, D., & Duke, M. C. (2022). Food Waste Diversion from Landfills: A Cost–Benefit Analysis of Existing Technological Solutions Based on Greenhouse Gas Emissions. Sustainability, 14(11), 6753. https://doi.org/10.3390/su14116753