New Methodology to Characterize the Workability of Asphaltic Concrete Mixtures Based on Kinematic Compaction Energy

Abstract

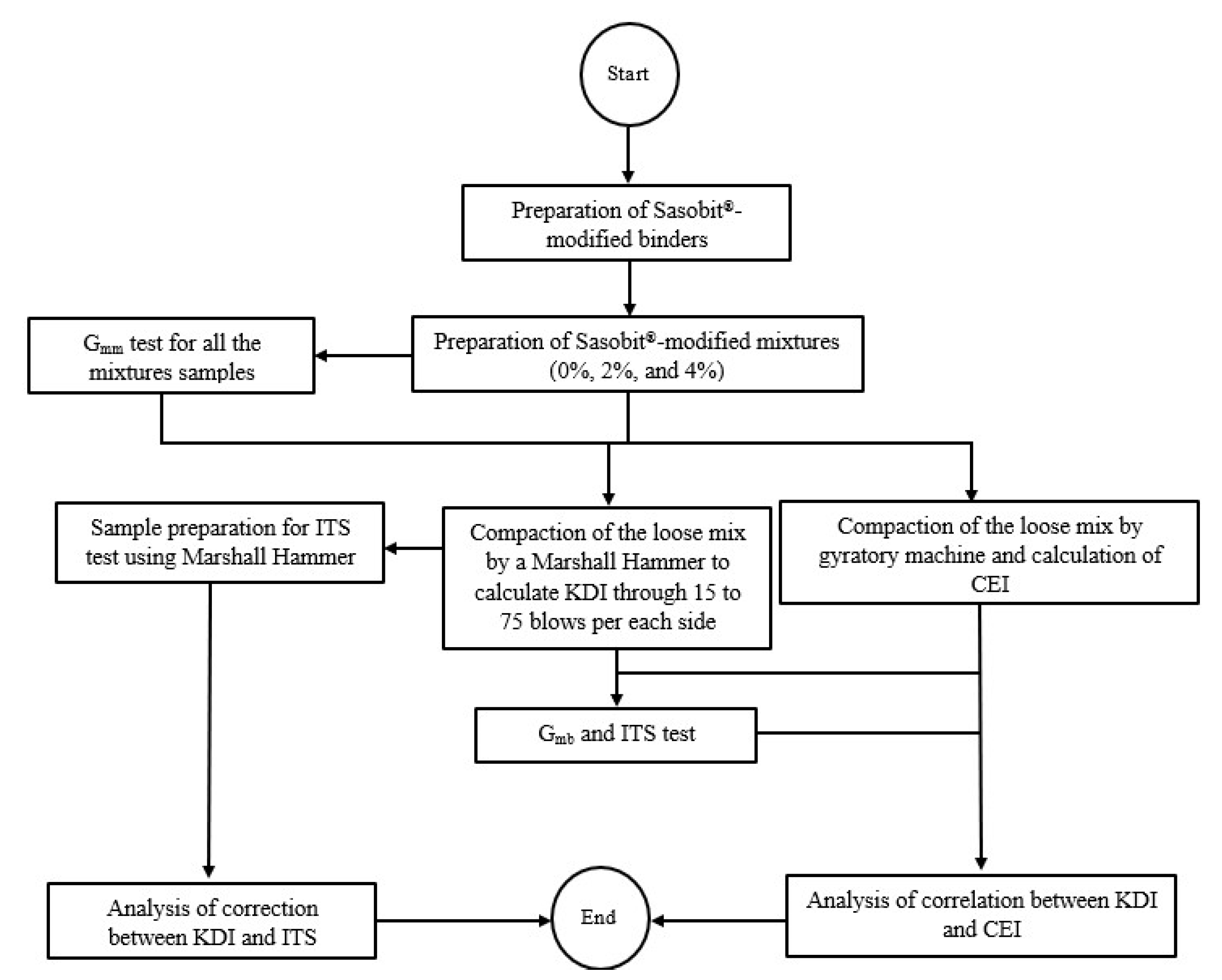

:1. Introduction

1.1. Equiviscous Temperature

1.2. Equi-Torque Temperature

1.3. Equi-Volumetric Principles

- (1)

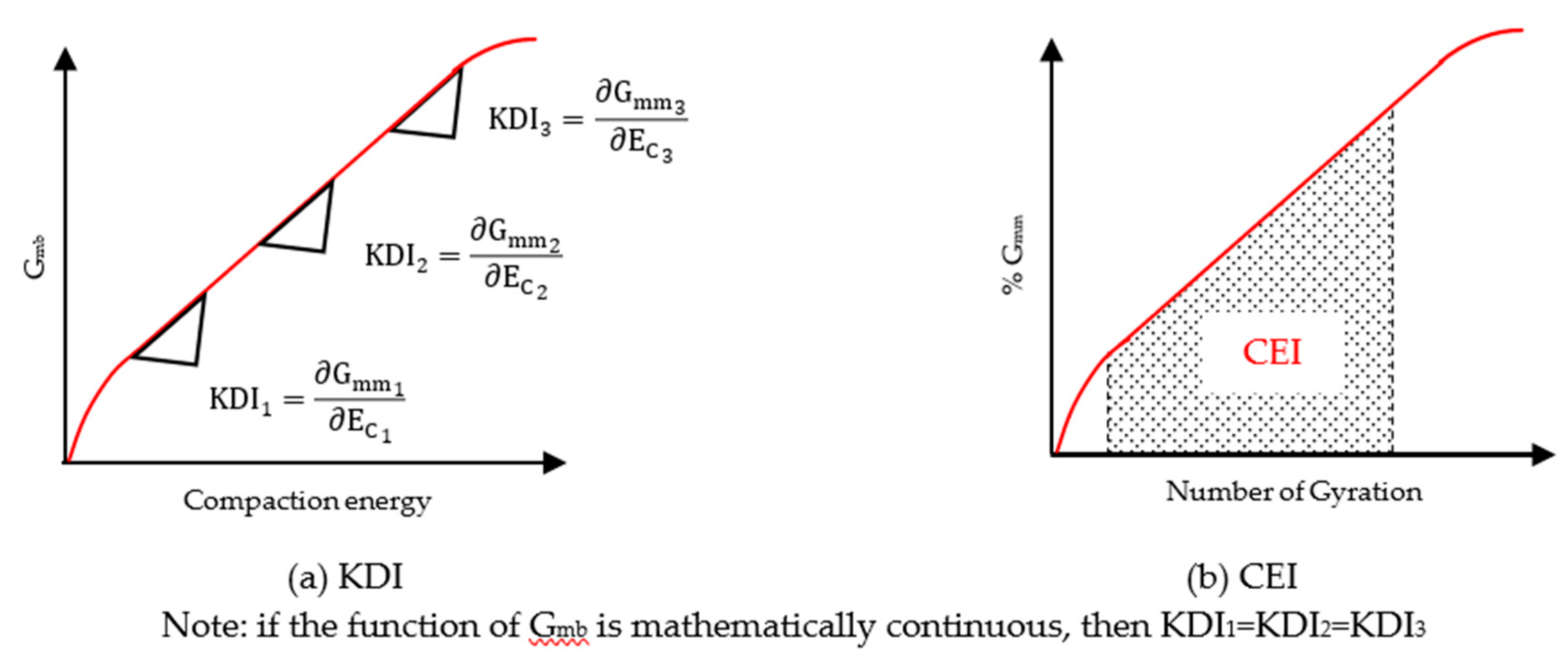

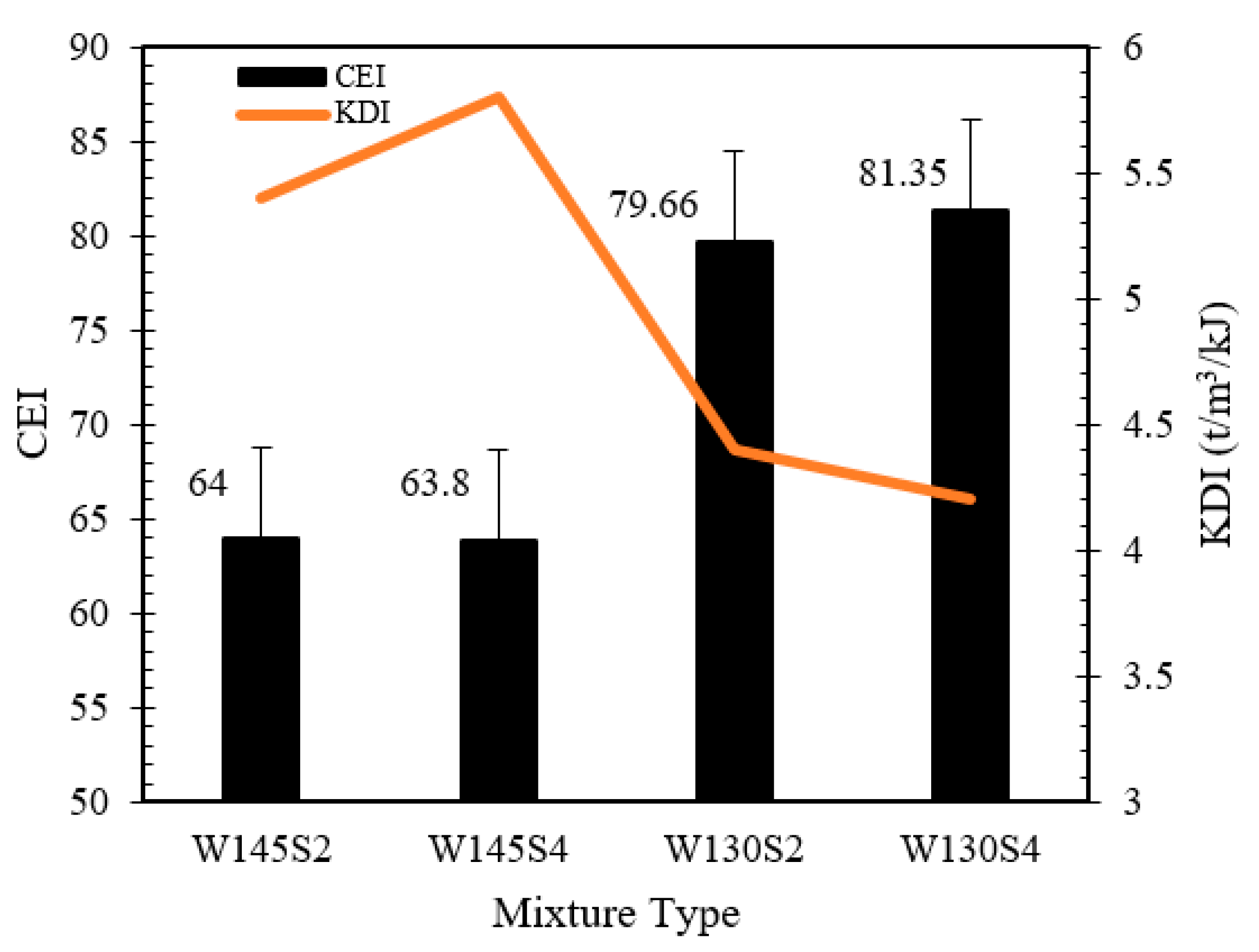

- The compaction energy index (CEI) is considered an indication of the work applied by a roller to reach the target compaction degree during the construction phase. The CEI can be employed as an indicator to measure the workability of the mixture.

- (2)

- The traffic densification index (TDI) represents the energy required to densify the mixture by traffic.

1.4. Aim

- To propose a new criterion to measure the workability of a mix based on kinematic energy and Newtonian mechanics via the Marshall method;

- To evaluate the effects of compaction-aid additives on the workability of mixtures using the new criterion via an electric or manual Marshal hammer (without using electricity);

- To compare the criterion to that of the workability indexes utilized in the literature;

- To correlate the proposed criteria to the mechanical properties of an asphalt mix.

2. Materials and Methods

2.1. Asphalt Binder

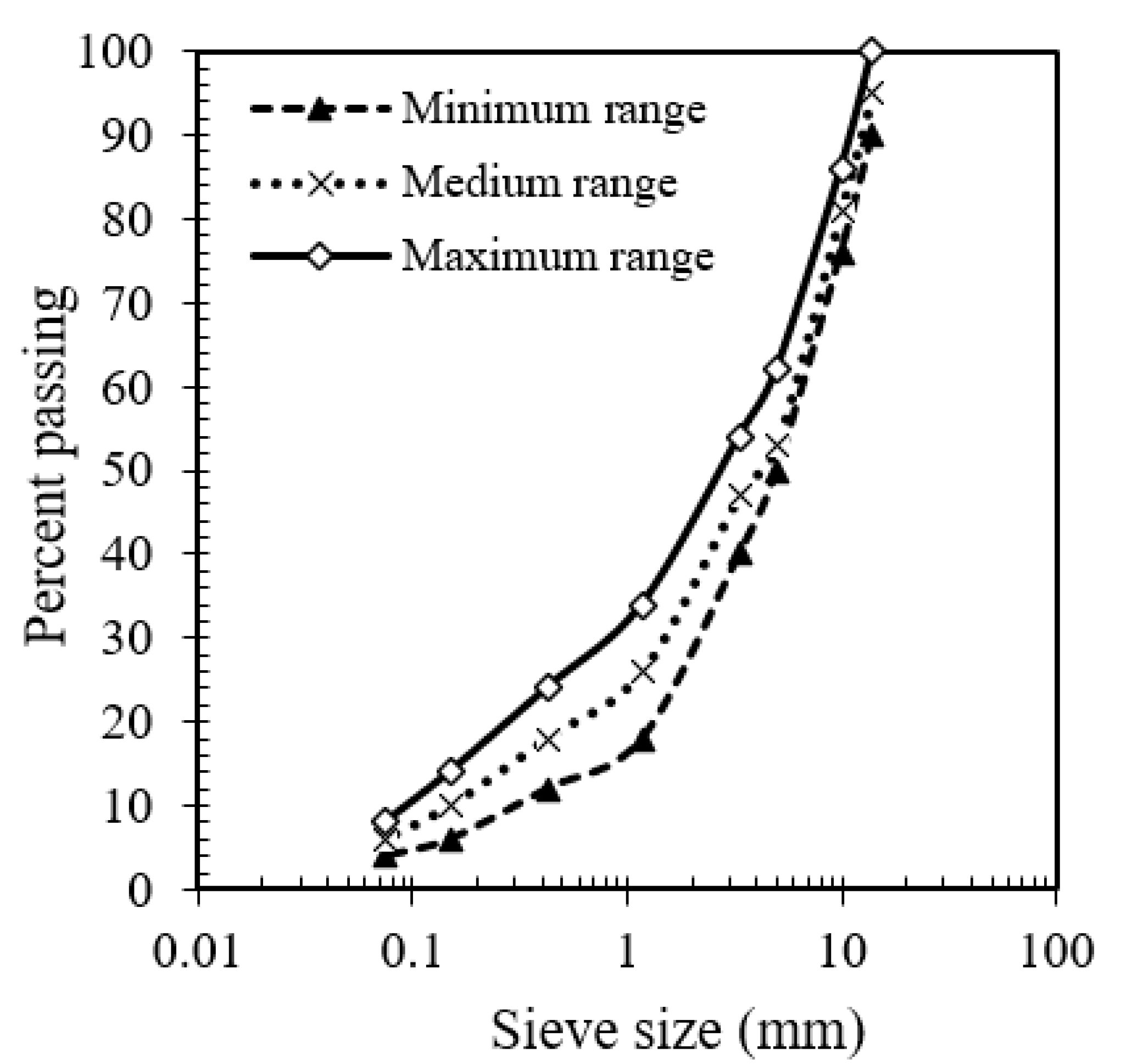

2.2. Aggregate Gradation

2.3. Compaction-Aid Additive

2.4. Sample Preparation and Mixture Test

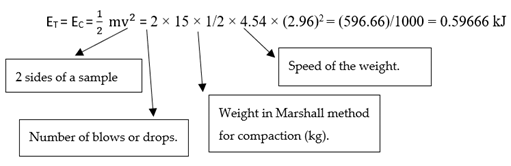

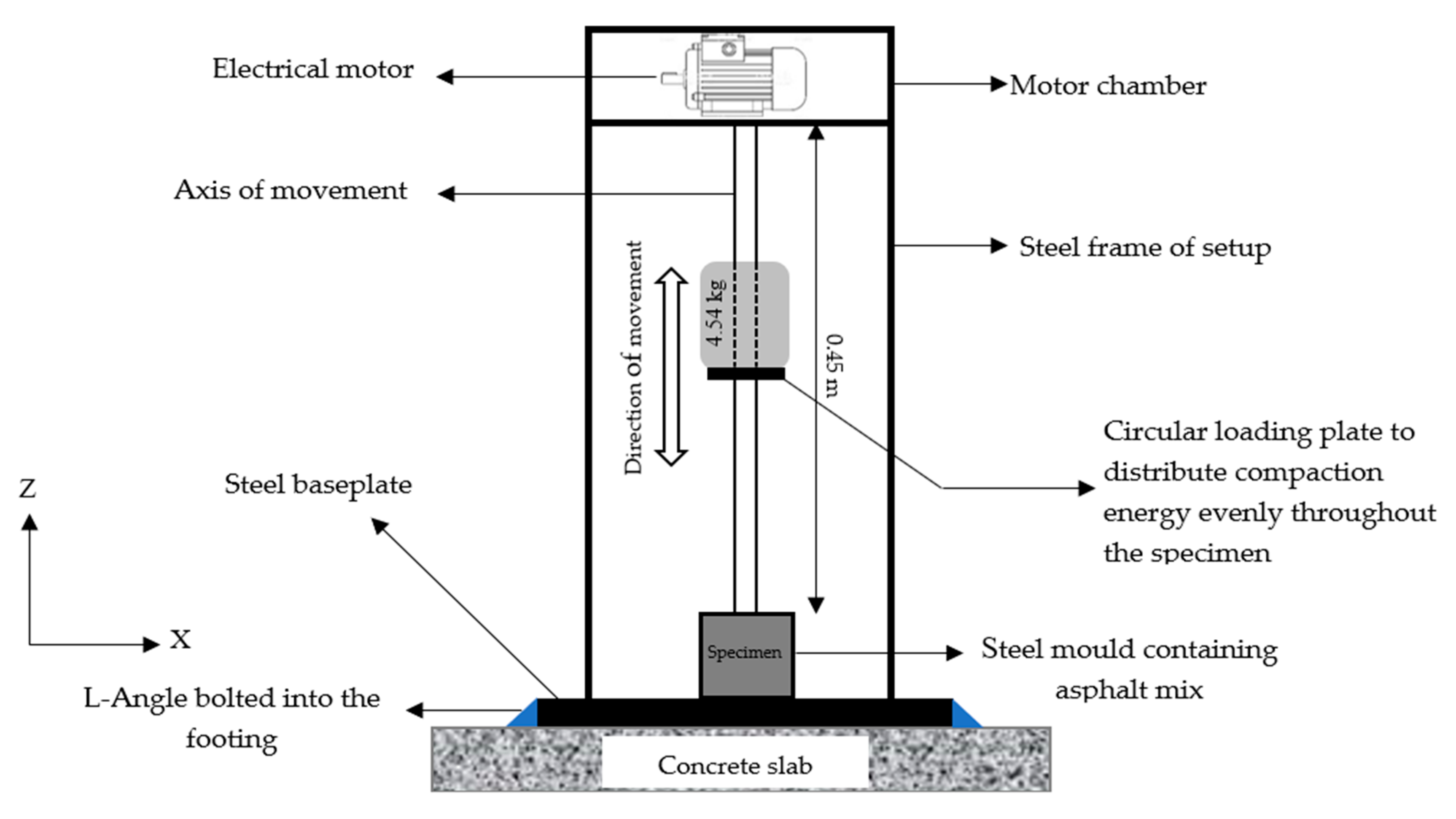

2.5. Proposed Workability Protocol Based on the Kinetic Compaction Energy

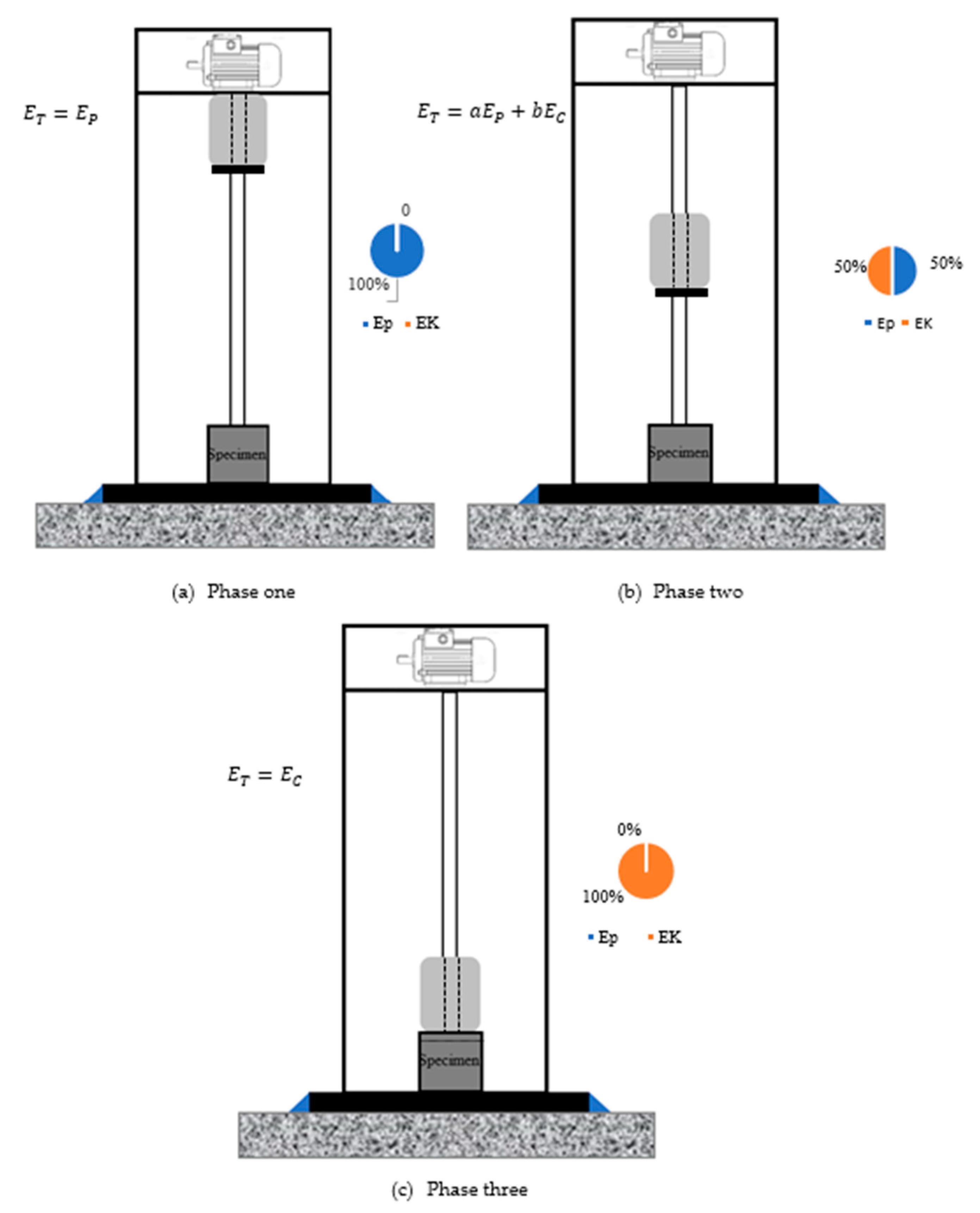

- ET: total mechanical energy; Ep: potential energy; EK: kinetic energy;

- m: mass; v: speed of mass; h: height;

- g: gravitational acceleration (9.80 m/s2).

2.5.1. Phase One

2.5.2. Phase Two

2.5.3. Phase Three

- EC: compaction energy (kJ); P: momentum (m2/s); i: number of initial compaction (0);

- j: number of final compactions per side (in this study: 75; two sides: 150); V0: initial speed of mass (m/s); VU: final speed of mass (m/s); m: weight (kg).

2.6. Hypotheses and Scope of Research

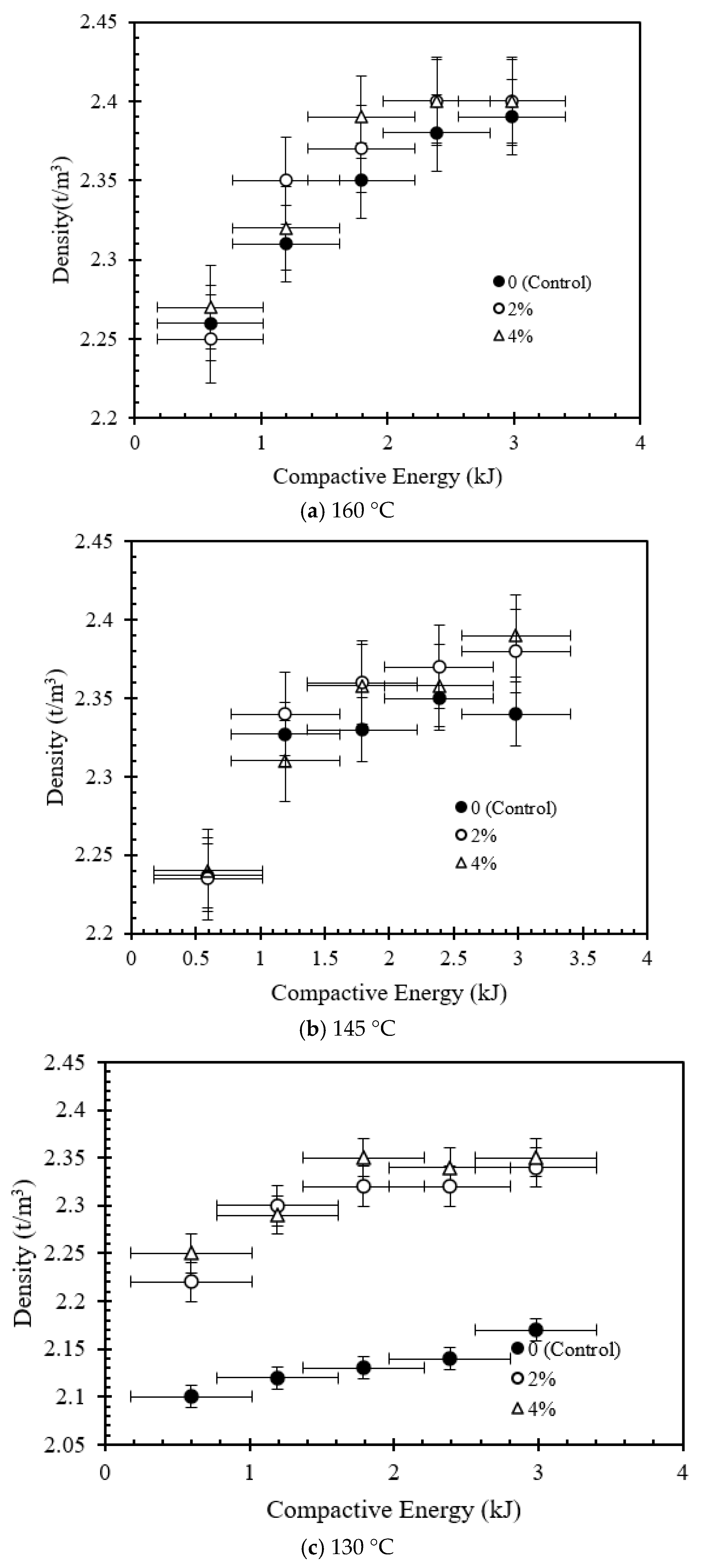

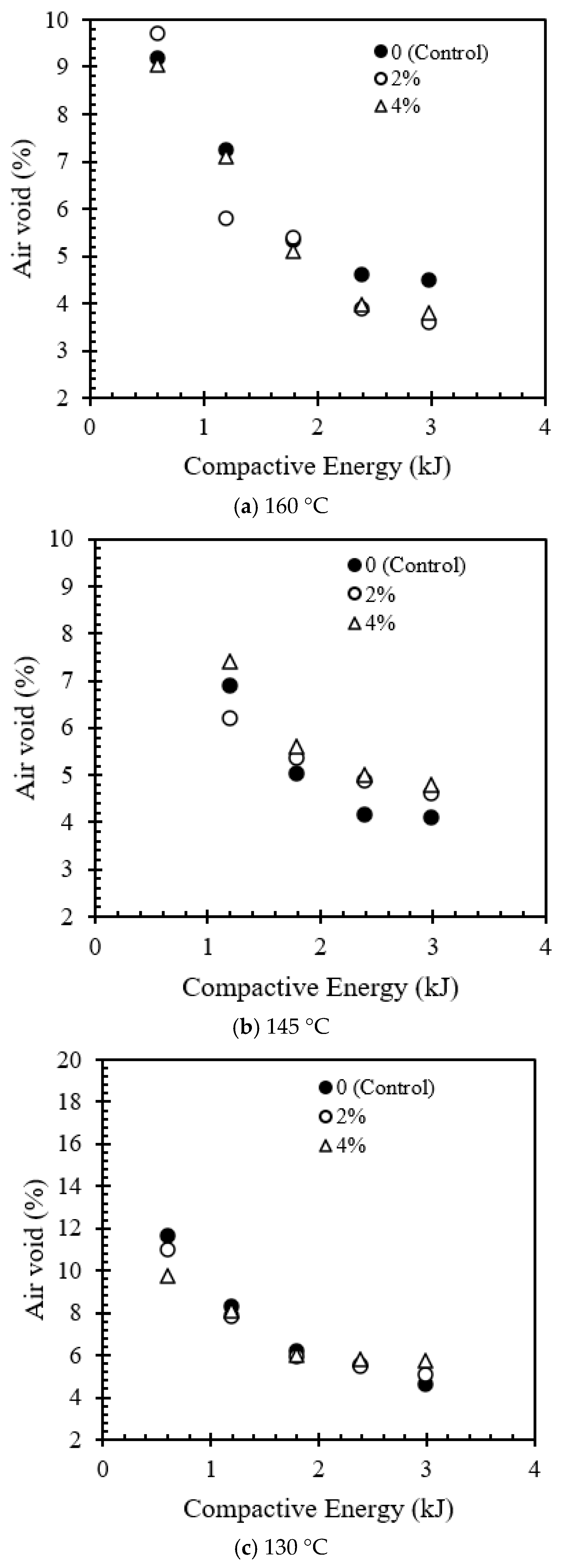

3. Results and Discussion

3.1. Correlation between KDI and Density

| R2 = 0.94 R2 = 0.80 R2 = 0.84 | 0 (Control) 2% Sasobit 4% Sasobit | T = 160 °C | (9) | |

| R2 = 0.63 R2 = 0.75 R2 = 0.63 | 0 (Control) 2% Sasobit 4% Sasobit | T = 145 °C | (10) | |

| R2 = 0.96 R2 = 0.76 R2 = 0.78 | 0 (Control) 2% Sasobit 4% Sasobit | T = 130 °C | (11) |

3.2. Comparison between KDI and CEI

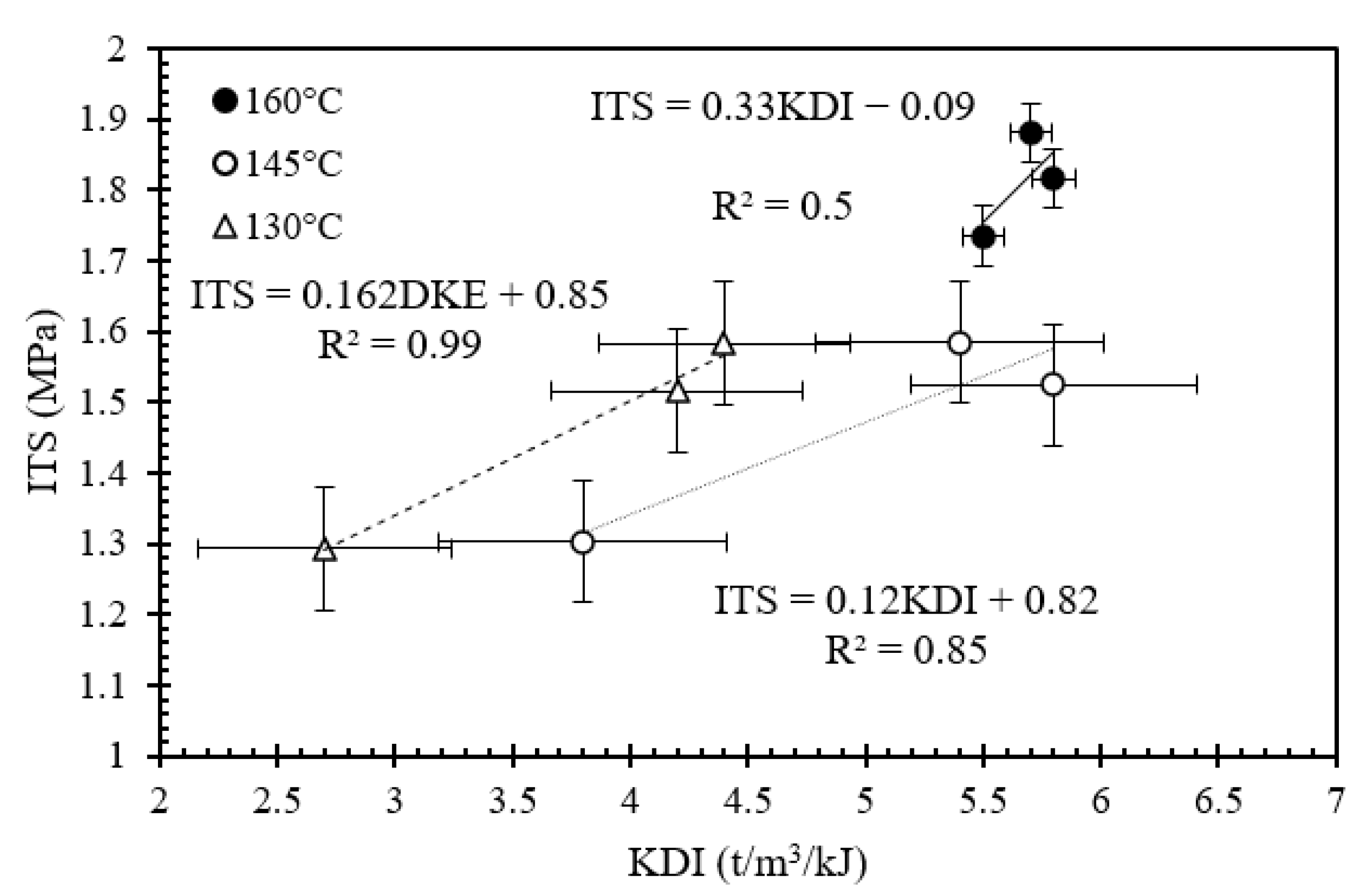

3.3. Effect of KDI on ITS

4. Conclusions

- A simple methodology was proposed to measure the workability of mixtures, incorporating various Sasobit® contents, using basic Newtonian mechanics or classic kinematic laws based on the energy conservation theory. The KDI, in accordance with the EVP-based indicator, was defined to characterize the effects of temperature and Sasobit® on the workability of asphalt mixtures. The indicator was applied to assess the densification of the mix per unit of compaction energy. The results of the analyses demonstrated that the KDI varies from 2.20 to 5.86 , depending on the Sasobit® content and mixing temperature.

- In addition, the results showed that there is a reverse relationship between the KDI and the CEI, i.e., CEI is equal to 16 times the KDI, in a rough estimation. This ratio may change for various binder types, aggregate types, and gradation. However, the ranking of the mixtures in terms of workability was identical, irrespective of the compaction method.

- The results demonstrated that the ITS increases proportionally as the KDI increases, due to the higher density and interlocking because of the temperature and the addition of Sasobit®.

- The KDI is an indicator that can link the engineering property of mixtures in terms of ITS and the compaction energy using the Marshall method. This parameter can be utilized as a supplementary indicator to compare the workability of mixtures in the construction phase of pavement without requiring a complex set-up and electricity in a laboratory, which is difficult for worksites located in a remote area, without access to equipment such as gyratory compactor, a computer, and data logger software.

Suggestions for Further Research

Author Contributions

Funding

Conflicts of Interest

References

- Mo, L.; Li, X.; Fang, X.; Huurman, M.; Wu, S. Laboratory investigation of compaction characteristics and performance of warm mix asphalt containing chemical additives. Constr. Build. Mater. 2012, 37, 239–247. [Google Scholar] [CrossRef]

- Li, X.; Wang, H.; Zhang, C.; Diab, A.; You, Z. Characteristics of a surfactant produced warm mix asphalt binder and workability of the mixture. J. Test. Eval. 2016, 44, 2219–2230. [Google Scholar] [CrossRef]

- Jamshidi, A.; Hamzah, M.O.; You, Z. Performance of warm mix asphalt containing Sasobit®: State-of-the-art. Constr. Build. Mater. 2013, 38, 530–553. [Google Scholar] [CrossRef]

- Yu, J.; Williams, R.C.; Buss, A.F. Laboratory evaluation of warm mix asphalt influence on theoretical maximum specific gravity. J. Test. Eval. 2012, 40, 669–676. [Google Scholar] [CrossRef]

- Hurley, G.C.; Prowell, B.D. Evaluation of Sasobit for Use in Warm Mix Asphalt; NCAT Report, 5(6); Auburn University: Auburn, AL, USA, 2005. [Google Scholar]

- Hurley, G.C.; Prowell, B.D. Evaluation of Evotherm for Use in Warm Mix Asphalt; NCAT Report, 2; Auburn University: Auburn, AL, USA, 2006. [Google Scholar]

- Hesami, E.; Birgisson, B.; Kringos, N. Effect of mixing sequence on the workability and performance of asphalt mixtures. Road Mater. Pavement Des. 2015, 16 (Suppl. S2), 197–213. [Google Scholar] [CrossRef]

- Asphalt Institute. Superpave Mix Design, 3rd ed.; Superpave Series No. 2 (SP-2); Asphalt Institute: Lexington, KY, USA, 2000. [Google Scholar]

- Yildirim, Y.; Ideker, J.; Hazlett, D. Evaluation of viscosity values for mixing and compaction temperatures. J. Mater. Civ. Eng. 2006, 18, 545–553. [Google Scholar] [CrossRef]

- Chen, F.; Jelagin, D.; Partl, M.N. Experimental and numerical analysis of asphalt flow in a slump test. Road Mater. Pavement Des. 2019, 20 (Suppl. 1), S446–S461. [Google Scholar] [CrossRef]

- Golchin, B. Effects of Rediset Additive on the Engineering Properties of Warm Asphalt Binders and Mixtures. Ph.D. Thesis, Univesiti Sains Malaysia, Penang, Malaysia, 2015. [Google Scholar]

- Jamshidi, A.; Golchin, B.; Hamzah, M.O.; Turner, P. Selection of type of warm mix asphalt additive based on the rheological properties of asphalt binders. J. Clean. Prod. 2015, 100, 89–106. [Google Scholar] [CrossRef]

- Bennert, T.; Reinke, G.; Mogawer, W.; Mooney, K. Assessment of workability and compactability of warm-mix asphalt. Transp. Res. Rec. 2010, 2180, 36–47. [Google Scholar] [CrossRef]

- Wang, C.; Hao, P.; Ruan, F.; Zhang, X.; Adhikari, S. Determination of the production temperature of warm mix asphalt by workability test. Constr. Build. Mater. 2013, 48, 1165–1170. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Austerman, A.J. Apparatus and Methods for Testing Asphalt Mix Workability. U.S. Patent Application No. 12/503,630, 21 January 2010. [Google Scholar]

- Gudimettla, J.M.; Cooley, L.A., Jr.; Brown, E.R. Workability of Hot Mix Asphalt, National Center for Asphalts Technology; NCAT Report 03-03; Auburn University: Auburn, AL, USA, 2003. [Google Scholar]

- Gudimettla, J.M.; Cooley, L.A., Jr.; Brown, E.R. Workability of hot-mix asphalt. Transp. Res. Rec. 2004, 1891, 229–237. [Google Scholar] [CrossRef] [Green Version]

- Marvillet, J.; Bougault, P. Workability of bituminous mixes—Development of a workability meter. In Proceedings of the Association of Asphalt Paving Technologists Proceedings, Denver, Colorado, 19–21 February 1979; Volume 48. [Google Scholar]

- Abdelgalil, S.M.K.; Abdul Rahman, M.; Arshad, A.K. Development of workability measuring device for asphalt mixture using electronic transducer and temperature regulator. J. Basic Appl. Sci. Res. 2011, 1, 721–726. [Google Scholar]

- Yu, H.; Leng, Z.; Dong, Z.; Tan, Z.; Guo, F.; Yan, J. Workability and mechanical property characterization of asphalt rubber mixtures modified with various warm mix asphalt additives. Constr. Build. Mater. 2018, 175, 392–401. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Tighe, S.L.; Zhao, G.; You, Z. Effects of preheating conditions on performance and workability of hot in-place recycled asphalt mixtures. Constr. Build. Mater. 2019, 226, 288–298. [Google Scholar] [CrossRef]

- Cabrera, J.G.; Dixon, J.R. Performance and Durability of Bituminous Material. In Proceedings of the Symposium, University of Leeds, Leeds, UK, 6–9 September 1994. [Google Scholar]

- Aburawi, B. Effects of Reduction in Construction Temperature on Workability of Warm Mix Asphalt Incorporating Rh-wma Additive. Ph.D. Thesis, Elmergib University, Al Khums, Lybia, 2018. [Google Scholar]

- European Standard BS EN 12697-10:2017; Bituminous Mixtures. Test Methods. Compactability. CEN-CENELEC Management Centre: Brussels, Belgium, 2017.

- Mahmoud, A.F.F.; Bahia, H. Using Gyratory Compactor to Measure Mechanical Stability of Asphalt Mixtures; Wisconsin Highway Research Program: Madison, WI, USA, 2004. [Google Scholar]

- JKR/SPJ/2008-S4; Standard Specifications for Road Works, Section 4, Flexible Pavements. Public Work Department (PWD): Kuala Lumpur, Malaysia, 2008.

- Button, J.W.; Estakhri, C.; Wimsat, A. A Synthesis of Warm-Mix Asphalt. USA; Texas Transportation Institute and Texas A&M University System: Bryan, TX, USA, 2007. [Google Scholar]

- ASTM D204; Standard Test Method for Theoretical Maximum Specific Gravity and Density of Asphalt Mixtures. ASTM: West Conshohocken, PA, USA, 2006.

- ASTM D2726; Standard Test Method for Bulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt Mixtures. ASTM: West Conshohocken, PA, USA, 2006.

- ASTM D6931-17; Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures. ASTM: West Conshohocken, PA, USA, 2006.

- Ji, J.; Xu, S. Study on the impact of Sasobit on asphalt's properties and micro-structure. In Pavements and Materials: Testing and Modeling in Multiple Length Scales; American Society of Civil Engineers: West Conshohocken, PA, USA, 2010; pp. 182–194. [Google Scholar]

- Hurley, G.C. Evaluation of New Technologies for Use in Warm Mix Asphalt. Master’s Thesis, University of Auburn, Auburn, AL, USA, 2006. [Google Scholar]

- Akisetty, C.K.; Lee, S.J.; Amirkhanian, S.N. High temperature properties of rubberized binders containing warm asphalt additives. Constr. Build. Mater. 2009, 23, 565–573. [Google Scholar] [CrossRef]

- Kristjonesdottir, O. Warm Mix Asphalt for Cold Weather Paving. Master’s Thesis, University of Washington, Washington, MD, USA, 2006. [Google Scholar]

- Diefenderfer, S.; McGhee, K.; Donaldson, B.M. Installation of Warm Mix Asphalt Projects in Virginia; Research Report No: FHWA/VTRC 07-R25; Transport Research Council: Knoxville, TN, USA, 2007. [Google Scholar]

| Rheological Property | Aging State | Unit | Value |

|---|---|---|---|

| Penetration@ 25 °C | unaged | (0.1 mm) | 88 |

| Softening point | °C | 46 | |

| Viscosity @ 135 °C | mPa s | 340 | |

| G*/sin δ @ 64 °C | kPa | 1.14 | |

| Viscosity @ 135 °C | Short-term aged | mPa s | 580 |

| G*/sin δ @ 64 °C | kPa | 2.68 | |

| G*sin δ @ 25 °C | Long-term aged | MPa | 2.68 |

| m-value @ −18 °C | - | 1.50 | |

| Stiffness @ −18 °C | MPa | 277 |

| Mixture Designation | Construction Technology | Sasobit (%) | Construction Temperature (°C) | Compaction Method | |

|---|---|---|---|---|---|

| Mixing | Compaction | ||||

| H160S0 | HMA | 0 | 160 | 150 | Marshall |

| H160S2 | 2 | ||||

| H160S4 | 4 | ||||

| W145S0 | WMA | 0 | 145 | 135 | |

| W145S2 | 2 | ||||

| W145S4 | 4 | ||||

| W130S0 | 0 | 130 | 120 | ||

| W130S2 | 2 | ||||

| W130S4 | 4 | ||||

| H160S0 | 0 | 160 | 150 | Gyratory | |

| W145S2 | 2 | 145 | 135 | ||

| W145S4 | 4 | ||||

| W130S2 | 2 | 130 | 120 | ||

| W130S4 | 4 | ||||

| Mixture | Ranking | |

|---|---|---|

| H160S2 | 1 | 5.85 |

| W145S4 | 2 | 5.80 |

| H160S4 | 3 | 5.70 |

| H160S0 | 4 | 5.50 |

| W145S2 | 5 | 5.40 |

| W130S2 | 6 | 4.40 |

| W130S4 | 7 | 4.20 |

| W145S0 | 8 | 3.80 |

| W130S0 | 9 | 2.20 |

| Mixture | CEI | KDI | ||

|---|---|---|---|---|

| Ranking | Values | Ranking | Values | |

| W145S4 | 1 | 64 | 1 | 5.80 |

| W145S2 | 2 | 63.80 | 2 | 5.40 |

| W130S2 | 3 | 79.66 | 3 | 4.40 |

| W130S4 | 4 | 81.35 | 4 | 4.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamshidi, A.; White, G.; Mohd Hasan, M.R. New Methodology to Characterize the Workability of Asphaltic Concrete Mixtures Based on Kinematic Compaction Energy. Sustainability 2022, 14, 6550. https://doi.org/10.3390/su14116550

Jamshidi A, White G, Mohd Hasan MR. New Methodology to Characterize the Workability of Asphaltic Concrete Mixtures Based on Kinematic Compaction Energy. Sustainability. 2022; 14(11):6550. https://doi.org/10.3390/su14116550

Chicago/Turabian StyleJamshidi, Ali, Greg White, and Mohd Rosli Mohd Hasan. 2022. "New Methodology to Characterize the Workability of Asphaltic Concrete Mixtures Based on Kinematic Compaction Energy" Sustainability 14, no. 11: 6550. https://doi.org/10.3390/su14116550

APA StyleJamshidi, A., White, G., & Mohd Hasan, M. R. (2022). New Methodology to Characterize the Workability of Asphaltic Concrete Mixtures Based on Kinematic Compaction Energy. Sustainability, 14(11), 6550. https://doi.org/10.3390/su14116550