Turbulent Kinetic Energy Distribution around Experimental Permeable Spur Dike

Abstract

:1. Introduction

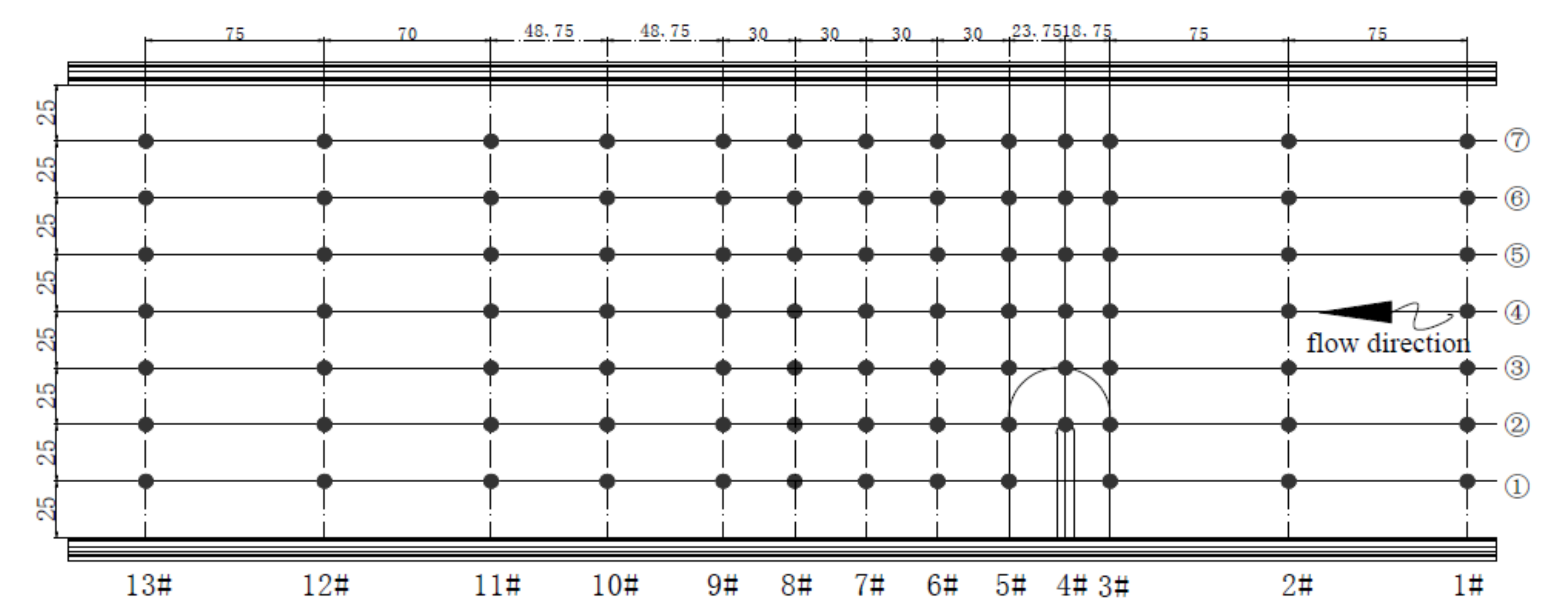

2. Physical Model

3. Calculation Method of Turbulent Kinetic Energy

4. Flow Turbulence Kinetic Energy Distribution

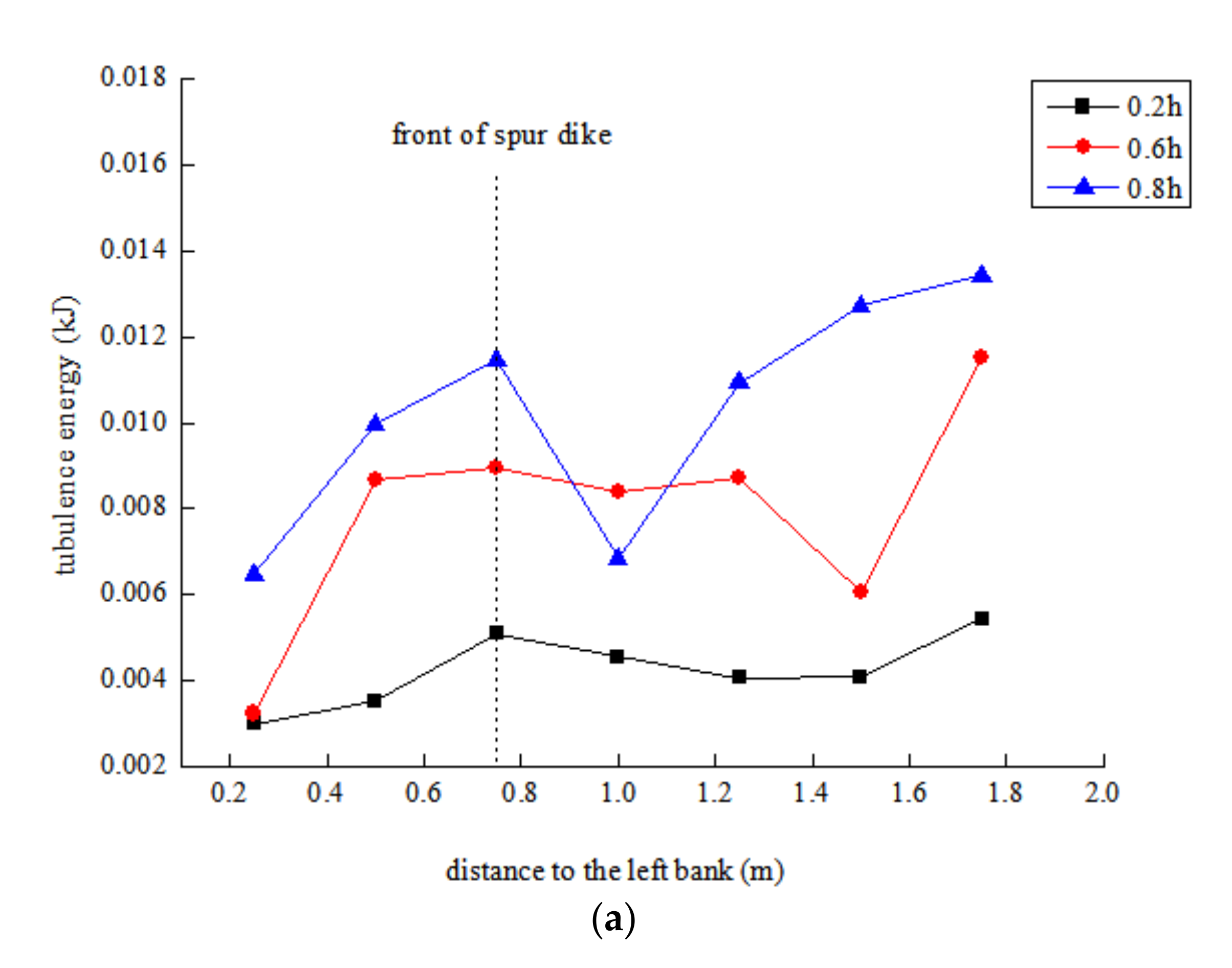

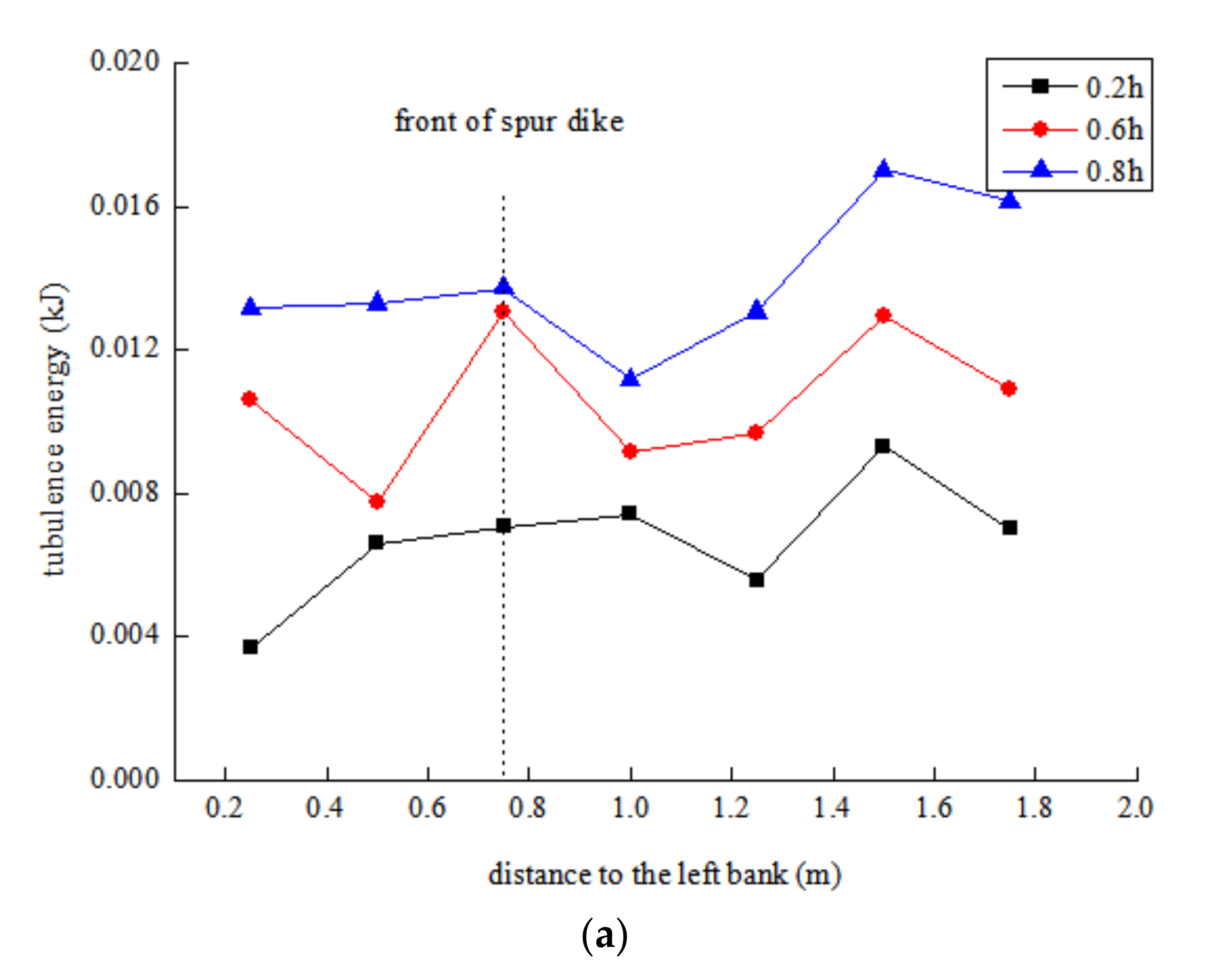

4.1. Effect of Submergence Degree on Kinetic Energy of Flow Turbulence

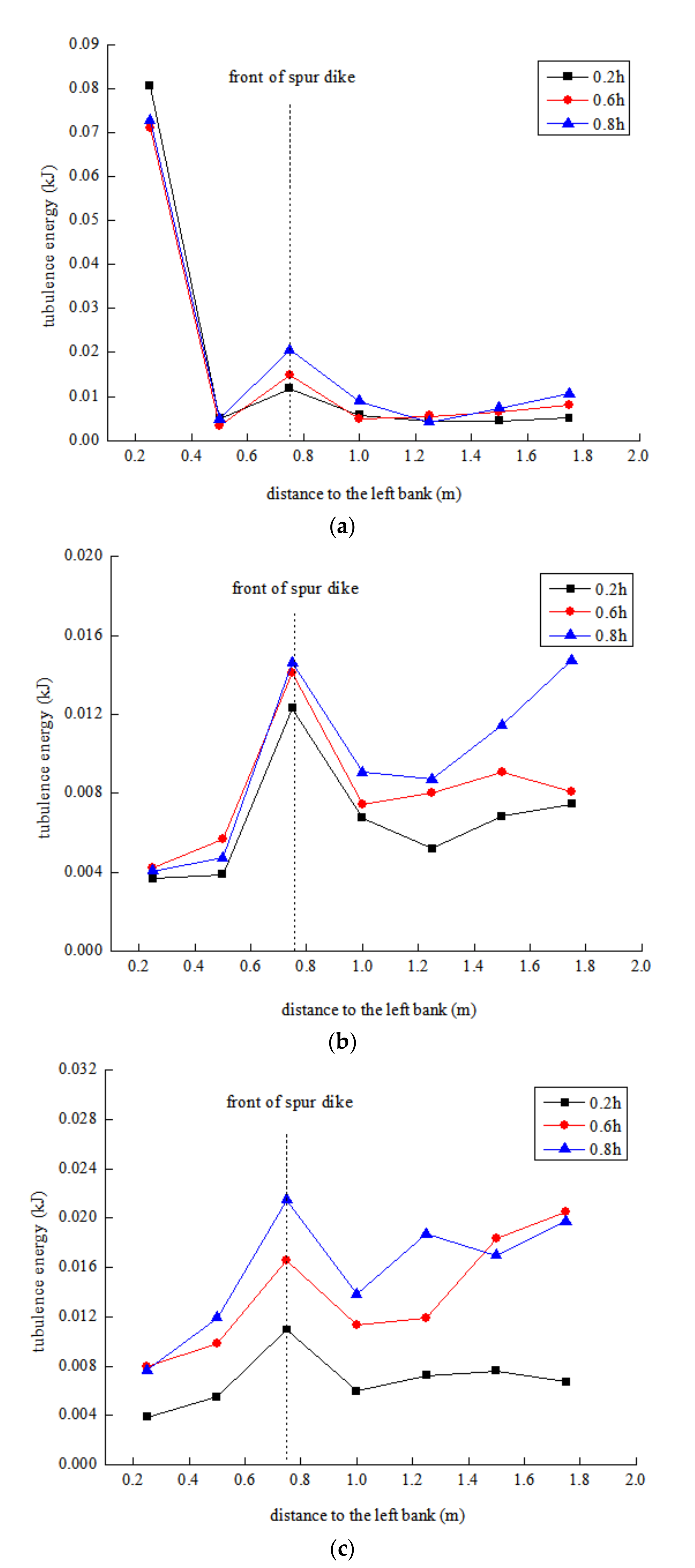

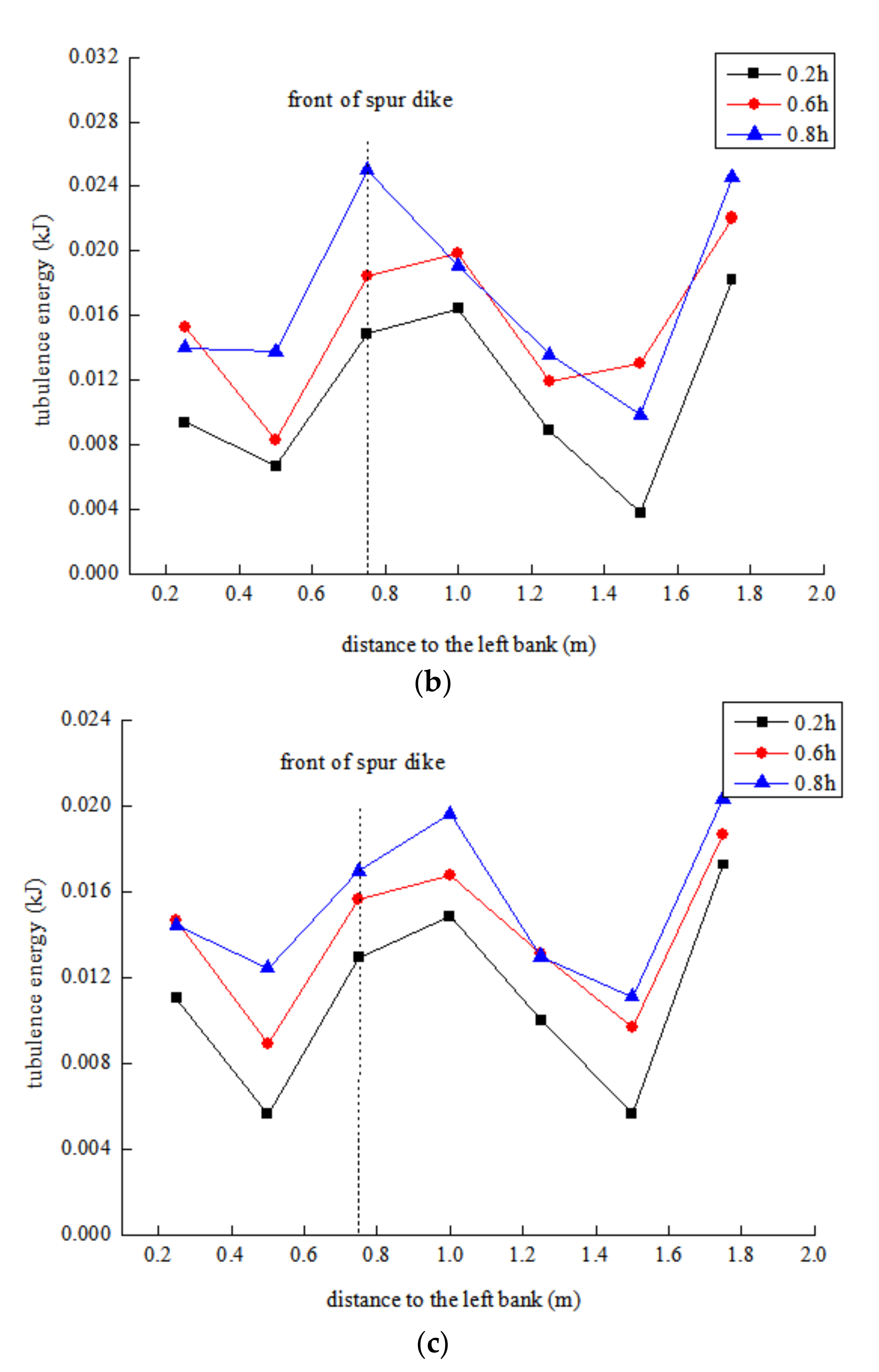

4.2. Effect of Porosity on Kinetic Energy of Flow Turbulence

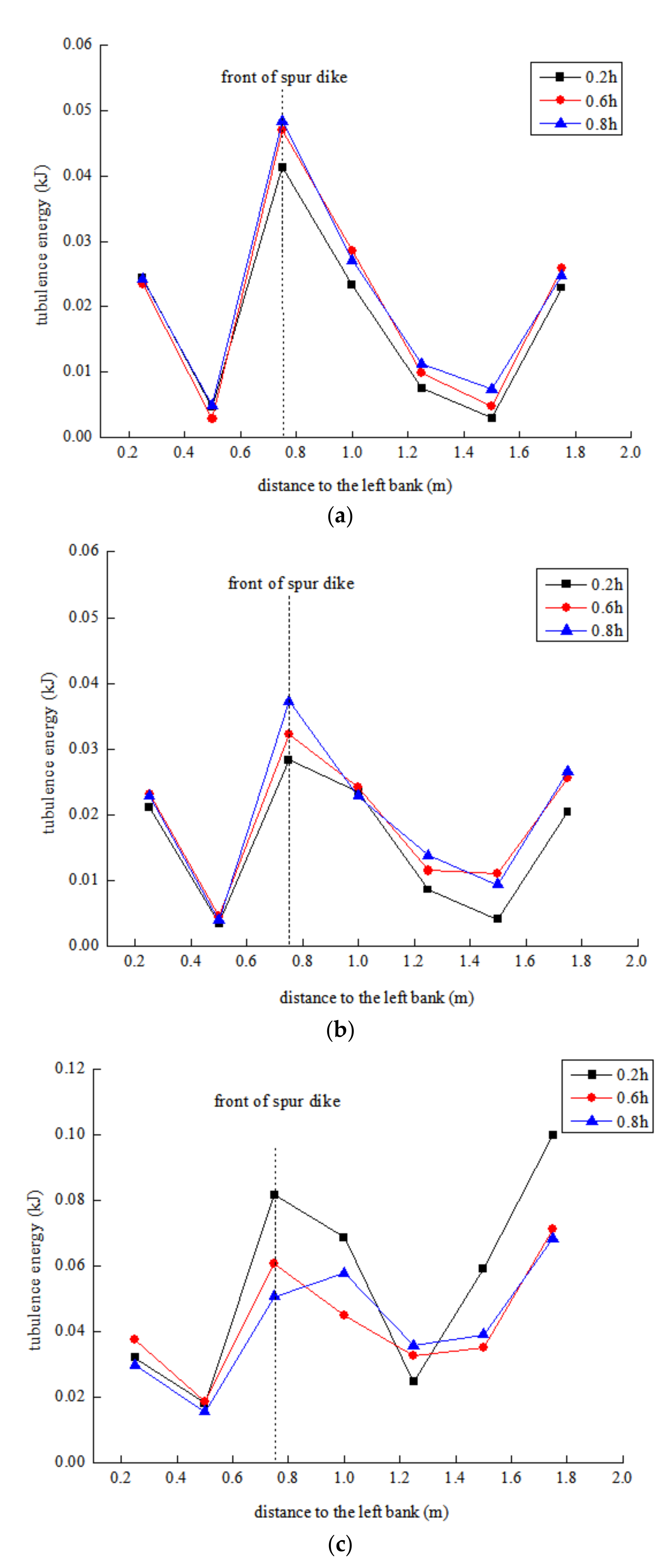

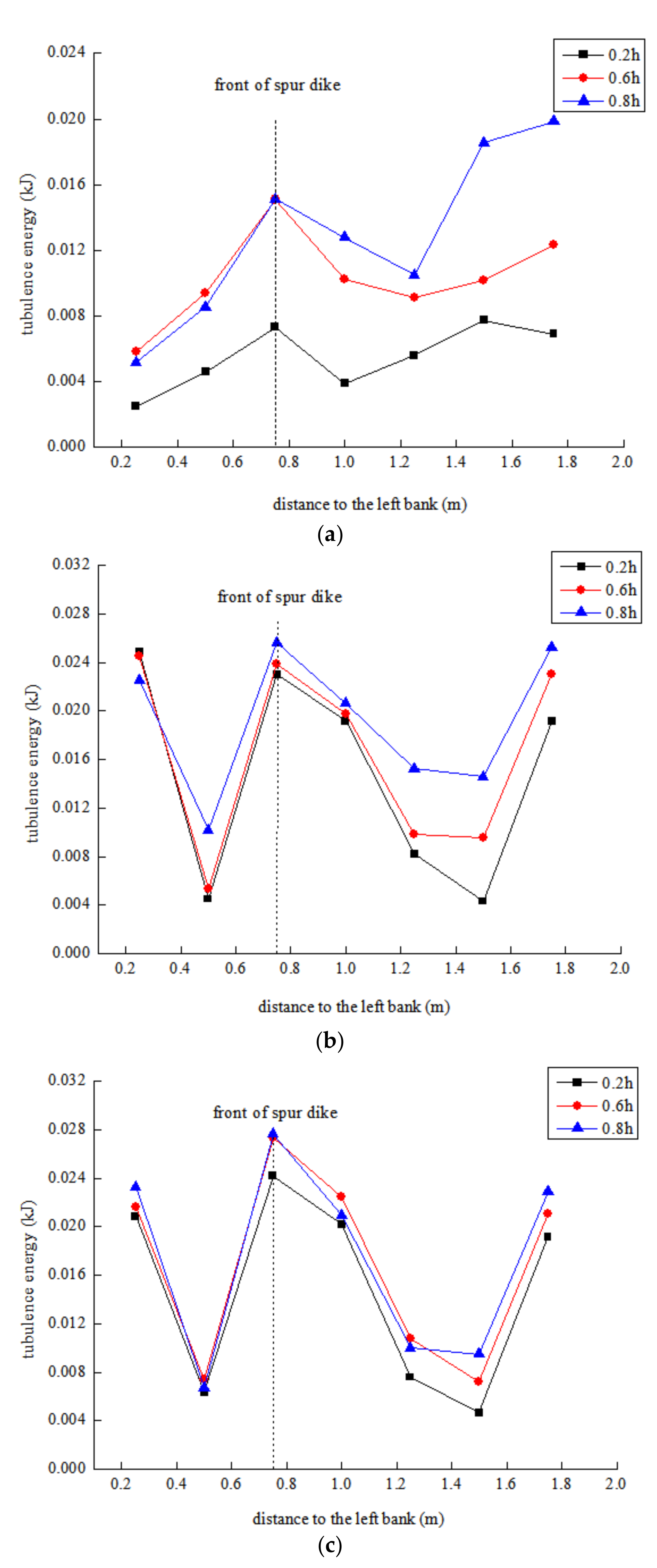

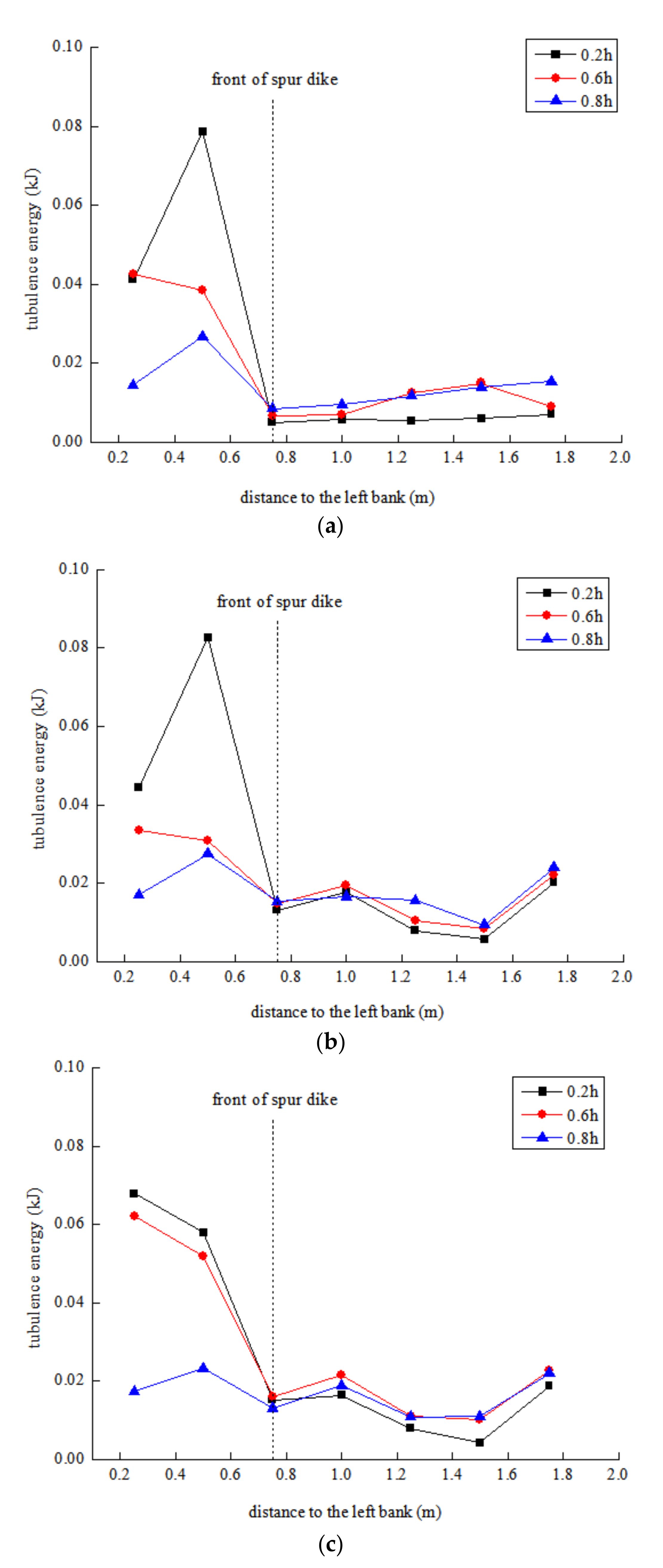

4.3. Effect of Pore Size on Kinetic Energy of Flow Turbulence

5. Conclusions

- Near the front of the spur dike, the turbulent kinetic energy is the smallest at 0.2h, followed by 0.6h, and it is the largest at 0.8h. The turbulent kinetic energy increases with the increase of the submerged degree, increases with the increase of porosity, and shows a trend of first increase and then decrease with the increase of pore size;

- Near the dike axis, the turbulent kinetic energy is the smallest at 0.2h, followed by 0.6h, and it is the largest at 0.8h. The turbulent kinetic energy decreases with the increase of the submerged degree, firstly decreases and then increases with the increase of the porosity, and increases with the increase of the pore size. The position of the maximum turbulent kinetic energy moves from the dike root to the front end of the dike head with the increase of the submergence degree and porosity, and from the front end of the dike head to the dike root with the increase of pore size;

- The turbulent kinetic energy behind the spur dike has the maximum value in the entire experimental observation range, and the turbulent kinetic energy is the largest at 0.2h, followed by 0.6h, and it is the smallest at 0.8h. This change gradually decreases as it moves away from the dike body.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- She, J.; Xia, Y.; Xu, H.; Du, D.; Hao, S. Experimental study on local scouring of submerged spur dike head under bottom protection condition. Adv. Water Sci. 2016, 27, 579–585. [Google Scholar]

- Cai, Z.; Xia, Y.; Xu, H.; Yan, J. Study on hydrodynamic characteristics of new submerged groin in deepwater channel regulation. Hydro-Sci. Eng. 2018, 3, 16–23. [Google Scholar]

- Kong, L.; Xu, B.; Lu, J.; Jia, X. Experimental study on initiation of fine sediment under wave action. China Ocean Eng. 2020, 38, 73–80. [Google Scholar]

- Ren, Z.; Li, Y.; Shi, K.; Zhou, Q. Experiment of scour prevention and sedimentation promotion effect for hydraulic flashboard permeable spur dike in different water permeability rates. J. Water Resour. Water Eng. 2016, 27, 172–174. [Google Scholar]

- Xu, B.; Yu, T.; Wang, P.; Yang, X.; Zhang, X. Experimental studies on flow profile of permeable spur dikes in upper reaches of Yangtze River. Hydro-Sci. Eng. 2019, 5, 62–68. [Google Scholar]

- Wei, M.; Chiew, Y.M.; Emadzadeh, A. Flow Patterns and Turbulent Kinetic Energy Budget of Undular Jumps in a Narrow Flume. J. Hydraul. Eng. 2020, 146, 04020060. [Google Scholar] [CrossRef]

- Zhong, L.; Liao, S.; Zhang, J.; Liu, J. Turbulence characteristics of open channel flow with dense roughness bed. J. Sediment. Res. 2020, 45, 8–14. [Google Scholar]

- Wang, W.; Liao, W.; Qi, L. Experiment of turbulent characteristics of flow in wind-and-narrow channels. Adv. Water Sci. 2020, 31, 394–403. [Google Scholar]

- Pang, W.; Dai, Z.; Ma, B.; Wang, J.; Li, S. Linkage between turbulent kinetic energy, waves and suspended sediment concentrations in the nearshore zone. Mar. Geol. 2020, 425, 106190. [Google Scholar] [CrossRef]

- Puzdrowska, M.; Heese, T. Turbulent Kinetic Energy in Bolt Fishway. AgriEngineering 2019, 1, 20. [Google Scholar] [CrossRef] [Green Version]

- Gao, G.; Wang, P.; Yang, C.; Liu, H. Distribution of Pulsation Kinetic Energy of Flow Around Spur Dike. Port Waterw. Eng. 2017, 11, 75–79. [Google Scholar]

- Kumar, A.; Ojha, C.S.P. Effect of Different Compositions in Unsubmerged L-head Groynes to Mean and Turbulent Flow Characteristics. KSCE J. Civ. Eng. 2019, 23, 4327–4338. [Google Scholar] [CrossRef]

- Penna, N.; Coscarella, F.; D’lppoloto, A.; Gaudio, R. Bed roughness effects on the turbulence characteristics of flows through emergent rigid vegetation. Water 2020, 12, 2401. [Google Scholar] [CrossRef]

| Run Title | Porosity (%) | Water Depth (cm) | Flow Rate (L/s) |

|---|---|---|---|

| TR1 | 6.8 | 11 | 65 |

| TR2 | 6.8 | 14 | 95 |

| TR3 | 6.8 | 17 | 135 |

| TR4 | 14.1 | 11 | 65 |

| TR5 | 14.1 | 14 | 95 |

| TR6 | 14.1 | 17 | 135 |

| TR7 | 22.5 | 11 | 65 |

| TR8 | 22.5 | 14 | 95 |

| TR9 | 22.5 | 17 | 135 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, T.; Yun, B.; Wang, P.; Han, L. Turbulent Kinetic Energy Distribution around Experimental Permeable Spur Dike. Sustainability 2022, 14, 6250. https://doi.org/10.3390/su14106250

Yu T, Yun B, Wang P, Han L. Turbulent Kinetic Energy Distribution around Experimental Permeable Spur Dike. Sustainability. 2022; 14(10):6250. https://doi.org/10.3390/su14106250

Chicago/Turabian StyleYu, Tao, Baoge Yun, Pingyi Wang, and Linfeng Han. 2022. "Turbulent Kinetic Energy Distribution around Experimental Permeable Spur Dike" Sustainability 14, no. 10: 6250. https://doi.org/10.3390/su14106250

APA StyleYu, T., Yun, B., Wang, P., & Han, L. (2022). Turbulent Kinetic Energy Distribution around Experimental Permeable Spur Dike. Sustainability, 14(10), 6250. https://doi.org/10.3390/su14106250