Digitisation of Existing Water Facilities: A Framework for Realising the Value of Scan-to-BIM

Abstract

:1. Introduction

- (1)

- To demonstrate and evaluate various modelling scenarios concerning the different applications of back-built digital models for an existing water treatment plant (WTP);

- (2)

- To map out the cost–benefit elements of the scan-to-BIM process for relevant stakeholders;

- (3)

- To investigate the impact of various LOD and LOI levels on practical BIM application for the effective management of the WTP;

- (4)

- To recommend various modelling scenarios to the industry for better planning and execution of the scan-to-BIM processes;

- (5)

- To propose a framework for realising the value of scan-to-BIM for existing facilities.

2. Background

2.1. Applications of Building Information Modelling (BIM) in the Water Sector

- Establishing a more rigorous infrastructure investment decision-making process, with non-asset solutions, full-cycle costs, risks and existing alternatives being considered before a decision is made to construct infrastructure;

- Making the best use of existing infrastructure;

- Ensuring that infrastructure can sustain agreed customer service standards;

- Recognising asset management as a core business function to support service delivery.

2.2. Scan-to-BIM

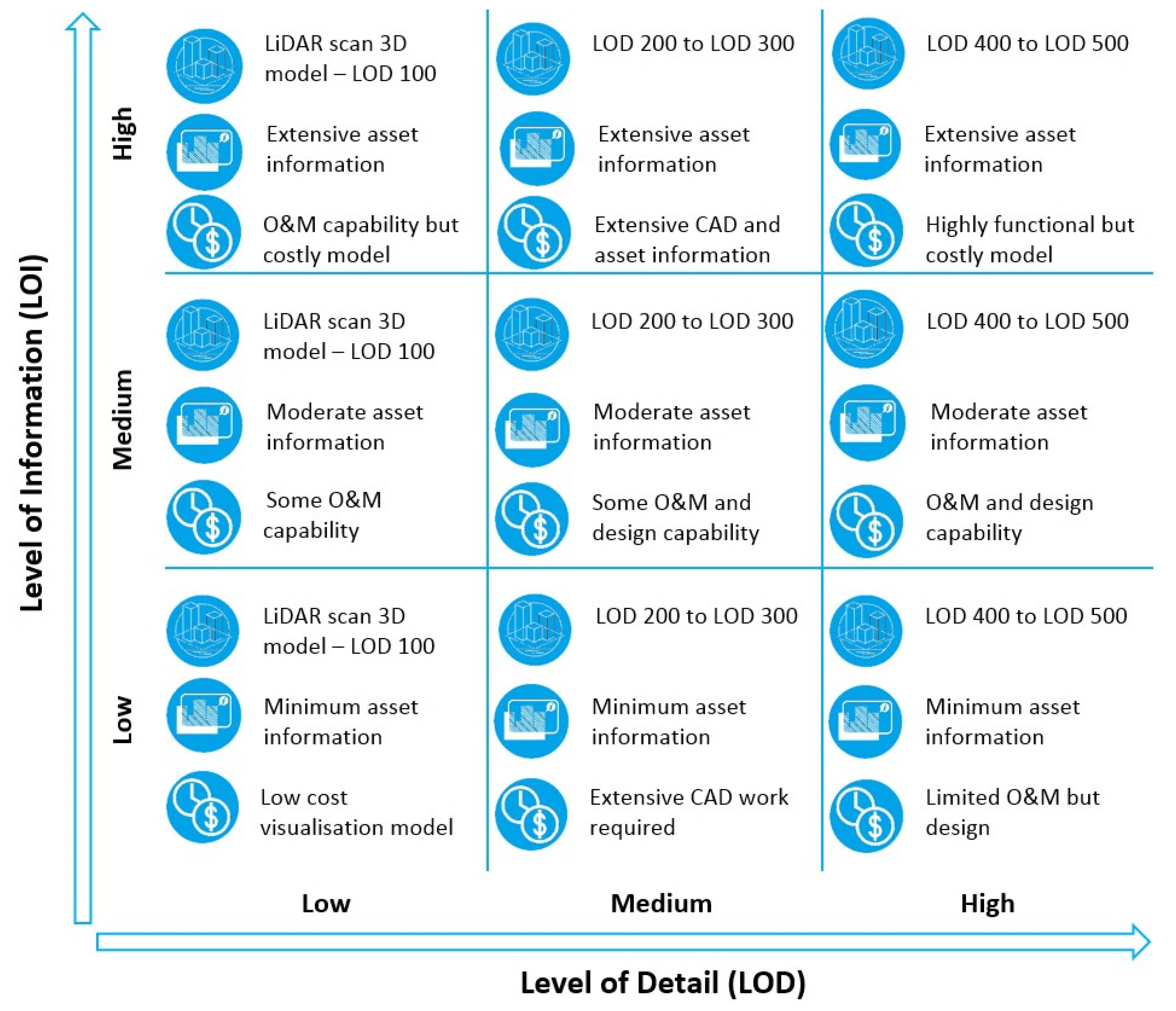

2.3. Level of Detail (LOD) and Level of Information (LOI)

3. Research Methods

4. Results and Discussion

4.1. Different BIM Integration Scenarios

- The asset information can be included; however, from an operational point of view, this model offers less functionality than the model options described below.

- The absence of data printouts, simulations and clash detections is a significant disadvantage of such a model.

- Basic LOI is provided, including only the critical asset information.

- Overall, the model is applicable for remote visualisation of the WTP to understand what assets are available and in what configuration.

- The point cloud data are included in the model.

- The model can create a P&ID or drawing’s library.

- Most asset information could be included. However, due to the software’s constructional approach, the benefits would primarily accrue during the design and construction phases of a project to deliver further benefits during the O&M phase.

- The model would be helpful for designers seeking to refurbish an existing WTP.

- For users without a design background, the unfriendly interface of the model makes it less appealing for general use by O&M professionals.

- The model can simulate plant processes, convert P&IDs to smart P&IDs and link them to the model, thereby updating the asset data at both ends.

- The model is beneficial from a WTP operational point of view, where most of the asset information can be uploaded to the model.

- The model can be constructed on top of the point cloud images, which have a precise layout of the case study area.

- Most asset information can be included, and simulation within the model is also possible.

- Due to the model’s complex interaction and the need for a constant exchange of data between Revit, point cloud data and Plant 3D, the interaction for the user is difficult and time-consuming.

4.2. Identified Costs of the Scan-to-BIM Integration

4.3. Identified Benefits of the Scan-to-BIM Integration

- BIM technical team;

- Facility personnel;

- Managers;

- Contractors;

- Clients;

- Owner/s;

- AEC professionals.

4.4. Fit-for-Purpose LOD-LOI Combination Scenarios

4.4.1. Functional Asset Management

4.4.2. Visualisation of As-Constructed Conditions

4.4.3. Back-Built Digital Twins

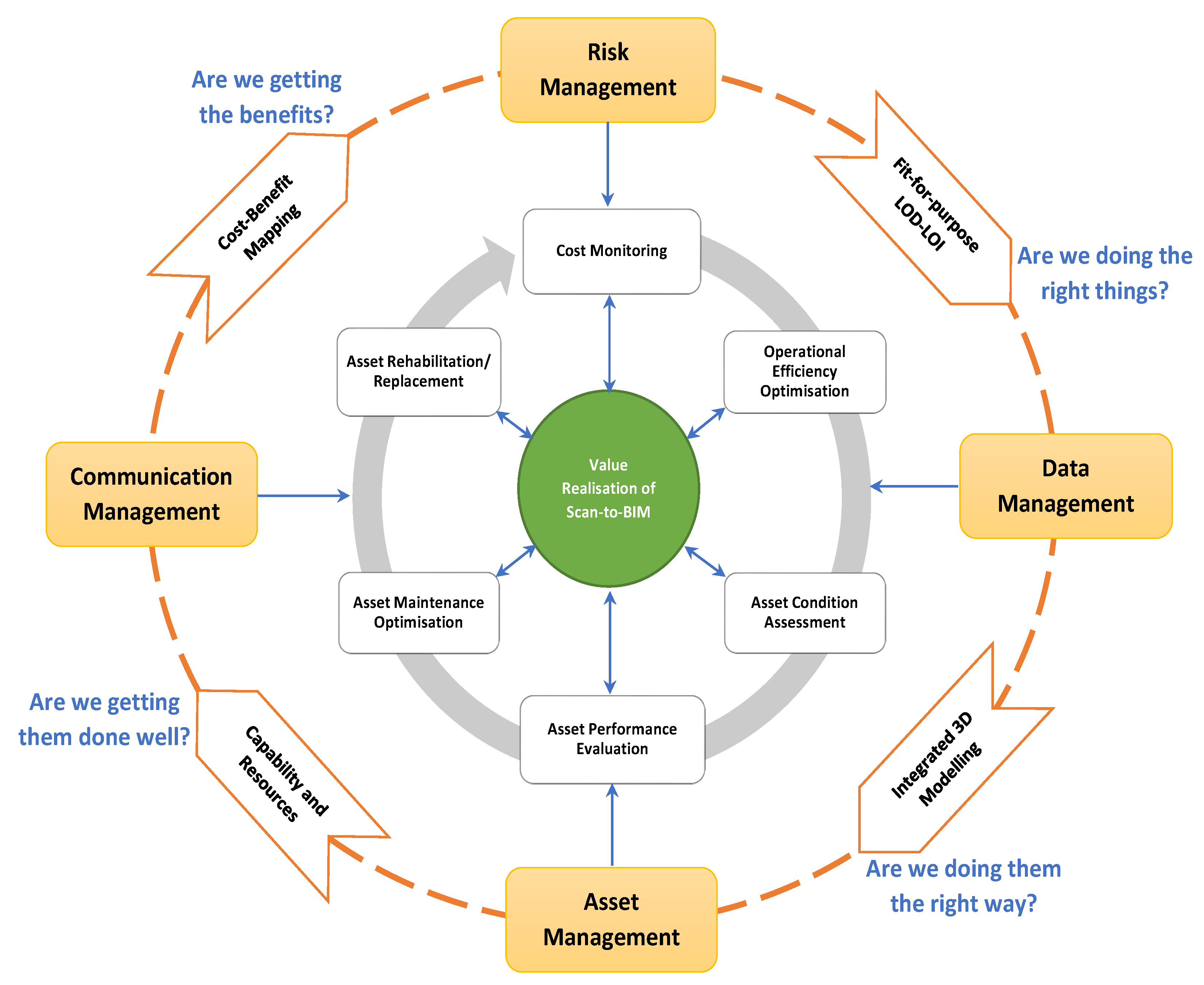

5. Scan-to-BIM LOD-LOI Combination Value Realisation Framework

- Monitoring of costs;

- Optimising operational efficiency;

- Assessing asset condition;

- Evaluating asset performance;

- Optimising asset maintenance;

- Replacing or upgrading assets.

5.1. Are We Doing the Right Things?

5.2. Are We Doing Them the Right Way?

5.3. Are We Getting Them Done Well?

5.4. Are We Getting the Benefits?

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Heaton, J.; Parlikad, A.K.; Schooling, J. A Building Information Modelling approach to the alignment of organisational objectives to Asset Information Requirements. Autom. Constr. 2019, 104, 14–26. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Roelvink, R.; Papadonikolaki, E.; Edwards, D.J.; Pärn, E. Integrating BIM into facility management. Int. J. Build. Pathol. Adapt. 2018, 36, 2–14. [Google Scholar] [CrossRef]

- Munir, M.; Kiviniemi, A.; Jones, S.W. Business value of integrated BIM-based asset management. Eng. Constr. Archit. Manag. 2019, 26, 1171–1191. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Zhang, C.; Guo, Y.; Osmani, M.; Demian, P. A Building Information Modelling (BIM) based Water Efficiency (BWe) Framework for Sustainable Building Design and Construction Management. Electronics 2019, 8, 599. [Google Scholar] [CrossRef] [Green Version]

- Construction Project Information Committee. Making Building Information Modelling Happen; CPIC Publications: London, UK, 2015. [Google Scholar]

- Mostafa, S.; Villamor, H.; Stewart, R.A.; Sturm, K.; Suprun, E.; Vohland, S. Costs and Benefits Data Mapping of BIM Laser Scan Integration: A Case Study in Australia. In Design and Construction of Smart Cities. JIC Smart Cities 2019. Sustainable Civil Infrastructures; El Dimeery, I., Baraka, M., Ahmed, S.M., Akhnoukh, A., Anwar, M.B., El Khafif, M., Hanna, N., Abdel Hamid, A.T., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Simpson, A.; Curthoys, A.; Vanderaa, P.; Lyndon, S.; McSweeney, B.; Baird, B.; Penn, C.; Jurgens, D.; Speranski, G.; Skawinski, J.; et al. Asset Information Requirements Guide: Information Required for the Operation and Maintenance of An Asset; Australasian BIM Advisory Board: Canberra, ACT, Australia, 2018. [Google Scholar]

- BIM4Water. Owner Operator Guidance Document; British Water: London, UK, 2017. [Google Scholar]

- Sanchez, A.; Hampson, K.; Vaux, S. Delivering Value with BIM: A Whole-Of-Life Approach; Routledge: London, UK, 2016. [Google Scholar] [CrossRef]

- Kamunda, A.; Renukappa, S.; Suresh, S.; Jallow, H. BIM in the water industry: Addressing challenges to improve the project delivery process. Eng. Constr. Archit. Manag. 2021, 28, 510–529. [Google Scholar] [CrossRef]

- Dodge Data & Analytics. Business Value of BIM for Water Projects. Available online: https://www.construction.com/toolkit/reports/business-value-bim-water-projects (accessed on 1 June 2021).

- Jiang, R.; Wu, C.; Lei, X.; Shemery, A.; Hampson, K.D.; Wu, P. Government efforts and roadmaps for building information modeling implementation: Lessons from Singapore, the UK and the US. Eng. Constr. Archit. Manag. 2022, 29, 782–818. [Google Scholar] [CrossRef]

- Department of State Development. Infrastructure and Planning. Digital Enablement for Queensland Infrastructure: Principles for BIM Implementation; Department of State Development: Brisbane, QLD, Australia, 2018. [Google Scholar]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Guo, J.; Kim, M.-K. An Application Oriented Scan-to-BIM Framework. Remote Sens. 2019, 11, 365. [Google Scholar] [CrossRef] [Green Version]

- Bosché, F.; Ahmed, M.; Turkan, Y.; Haas, C.T.; Haas, R. The value of integrating Scan-to-BIM and Scan-vs-BIM techniques for construction monitoring using laser scanning and BIM: The case of cylindrical MEP components. Autom. Constr. 2015, 49, 201–213. [Google Scholar] [CrossRef]

- Pepe, M.; Costantino, D.; Alfio, V.S.; Restuccia, A.G.; Papalino, N.M. Scan to BIM for the digital management and representation in 3D GIS environment of cultural heritage site. J. Cult. Herit. 2021, 50, 115–125. [Google Scholar] [CrossRef]

- Rocha, G.; Mateus, L.; Fernández, J.; Ferreira, V. A Scan-to-BIM Methodology Applied to Heritage Buildings. Heritage 2020, 3, 47–67. [Google Scholar] [CrossRef] [Green Version]

- Qldwater. Guidelines for Implementing Total Management Planning. Asset Management. Available online: https://www.qldwater.com.au/TMPs (accessed on 1 June 2021).

- Bradley, A.; Li, H.; Lark, R.; Dunn, S. BIM for infrastructure: An overall review and constructor perspective. Autom. Constr. 2016, 71, 139–152. [Google Scholar] [CrossRef]

- Suprun, E.; Stewart, R.A.; Mostafa, S.; Sahin, O.; Bertone, E. Integrating Lifecycle Thinking in Asset Management Through BIM: Opportunities for the Water Sector. In Proceedings of the The 10th International Conference on Engineering, Project, and Production Management. Lecture Notes in Mechanical Engineering, Berlin, Germany, 2–4 September 2019; Panuwatwanich, K., Ko, C.H., Eds.; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- Garber, R. BIM Design, Realising the Creative Potential of Building Information Modelling; John Wiley and Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Wong, J.K.W.; Ge, J.; He, S.X. Digitisation in facilities management: A literature review and future research directions. Autom. Constr. 2018, 92, 312–326. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Lin, C.-P.; Hu, H.-T.; Su, Y.-C. Developing final as-built BIM model management system for owners during project closeout: A case study. Adv. Eng. Inform. 2018, 36, 178–193. [Google Scholar] [CrossRef]

- Love, P.E.D.; Matthews, J.; Lockley, S. BIM for Built Asset Management. Built Environ. Proj. Asset Manag. 2015, 5. [Google Scholar] [CrossRef]

- Cheng, L.; Chen, S.; Liu, X.; Xu, H.; Wu, Y.; Li, M.; Chen, Y. Registration of Laser Scanning Point Clouds: A Review. Sensors 2018, 18, 1641. [Google Scholar] [CrossRef] [Green Version]

- Gao, T.; Akinci, B.; Ergan, S.; Garrett, J. An approach to combine progressively captured point clouds for BIM update. Adv. Eng. Inform. 2015, 29, 1001–1012. [Google Scholar] [CrossRef]

- Macher, H.; Landes, T.; Grussenmeyer, P. From Point Clouds to Building Information Models: 3D Semi-Automatic Reconstruction of Indoors of Existing Buildings. Appl. Sci. 2017, 7, 1030. [Google Scholar] [CrossRef] [Green Version]

- Godinho, M.; Machete, R.; Ponte, M.; Falcão, A.P.; Gonçalves, A.B.; Bento, R. BIM as a resource in heritage management: An application for the National Palace of Sintra, Portugal. J. Cult. Herit. 2020, 43, 153–162. [Google Scholar] [CrossRef]

- Wang, Q.; Sohn, H.; Cheng, J.C.P. Automatic As-Built BIM Creation of Precast Concrete Bridge Deck Panels Using Laser Scan Data. J. Comput. Civ. Eng. 2018, 32, 04018011. [Google Scholar] [CrossRef]

- Xiong, X.; Adan, A.; Akinci, B.; Huber, D. Automatic creation of semantically rich 3D building models from laser scanner data. Autom. Constr. 2013, 31, 325–337. [Google Scholar] [CrossRef] [Green Version]

- Building and Construction Authority. BIM Guide for Asset Information Delivery; Building and Construction Authority: Singapore, 2018. [Google Scholar]

- Farghaly, K.; Abanda, F.H.; Vidalakis, C.; Wood, G. Taxonomy for BIM and Asset Management Semantic Interoperability. J. Manag. Eng. 2018, 34, 04018012. [Google Scholar] [CrossRef] [Green Version]

- Munir, M.; Kiviniemi, A.; Jones, S.W.; Finnegan, S. The business value of BIM for asset owners: A cross-case analysis. J. Facil. Manag. 2020, 18, 469–486. [Google Scholar] [CrossRef]

- Pärn, E.A.; Edwards, D.J.; Sing, M.C.P. The building information modelling trajectory in facilities management: A review. Autom. Constr. 2017, 75, 45–55. [Google Scholar] [CrossRef] [Green Version]

- Love, P.E.D.; Matthews, J.; Simpson, I.; Hill, A.; Olatunji, O.A. A benefits realization management building information modeling framework for asset owners. Autom. Constr. 2014, 37, 1–10. [Google Scholar] [CrossRef]

- Suprun, E.; Sankhe, A.; Stewart, R.A.; Mostafa, S. BIM Adoption Case Study Report. Review of Benefits, Challenges, Strategies and Lessons Learnt for the Water Industry; Griffith University: Gold Coast, QLD, Australia, 2020. [Google Scholar]

- Alshorafa, R.; Ergen, E. Determining the level of development for BIM implementation in large-scale projects. Eng. Constr. Archit. Manag. 2021, 28, 397–423. [Google Scholar] [CrossRef]

- Boton, C.; Kubicki, S.; Halin, G. The Challenge of Level of Development in 4D/BIM Simulation Across AEC Project Lifecyle. A Case Study. Procedia Eng. 2015, 123, 59–67. [Google Scholar] [CrossRef] [Green Version]

- Dupuis, M.; April, A.; Lesage, P.; Forgues, D. Method to Enable LCA Analysis through Each Level of Development of a BIM Model. Procedia Eng. 2017, 196, 857–863. [Google Scholar] [CrossRef]

- National Building Specification. BIM Toolkit. Available online: https://toolkit.thenbs.com/ (accessed on 1 June 2021).

- Uusitalo, P.; Seppänen, O.; Lappalainen, E.; Peltokorpi, A.; Olivieri, H. Applying Level of Detail in a BIM-Based Project: An Overall Process for Lean Design Management. Buildings 2019, 9, 109. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Zhang, Z. BIM implementation in handover management for underground rail transit project: A case study approach. Tunn. Undergr. Space Technol. 2021, 108, 103684. [Google Scholar] [CrossRef]

- BIMForum. Level of Development Specification. Available online: https://bimforum.org/resources/Documents/LOD%20Spec%202020%20Part%20I%202020-12-31.pdf (accessed on 1 June 2021).

- Delavar, M.; Bitsuamlak, G.T.; Dickinson, J.K.; Costa, L.M.F. Automated BIM-based process for wind engineering design collaboration. Build. Simul. 2020, 13, 457–474. [Google Scholar] [CrossRef]

- Kent, D.; Smith, S. Case Study—Kawana STP Upgrade: Using BIM for Design, Construction and Operation. Available online: https://www.waternz.org.nz/Attachment?Action=Download&Attachment_id=3383 (accessed on 1 June 2021).

- BIM4Water. Case Study—Minworth Thermal Hydrolysis Plant. Available online: https://www.britishwater.co.uk/media/download.aspx?MediaId=1672 (accessed on 1 June 2021).

- Hamilton City Council. Case Study—Pukete Wastewater Treatment Plant. Available online: https://www.hamilton.govt.nz/our-services/water/wastewater/Pages/Pukete-Wastewater-Treatment-Plant.aspx (accessed on 1 June 2021).

- EchoWater. Case Study—EchoWater Project, Sacramento, California. Available online: https://www.water-technology.net/projects/echowater-project-sacramento-california/ (accessed on 1 June 2021).

- United Utilities. Case Study—Liverpool Wastewater Treatment Works. Available online: https://waterprojectsonline.com/wp-content/uploads/case_studies/2015/Liverpool-WwTW-2015.pdf (accessed on 1 June 2021).

- Johnson County. Case Study—Tomahawk Creek Wastewater Treatment Facility Expansion. Available online: https://www.jcwtomahawk.com/ (accessed on 1 June 2021).

- Huntsville Utilities. Case Study—Southeast Water Treatment Plant Construction. Available online: https://www.hsvutil.org/sewtp/ (accessed on 1 June 2021).

- Calgary. Case Study—Bonnybrook Wastewater Treatment Plant Upgrades and Expansion. Available online: https://www.calgary.ca/uep/water/construction-projects/construction-projects-and-upgrades/bonnybrook-wastewaste-treatment-plant-upgrade-and-expansions.html (accessed on 1 June 2021).

- FARO. SCENE WebShare Cloud Software. Available online: https://www.faro.com/en/Products/Software/WebShare (accessed on 1 November 2020).

- Autodesk. Revit. Multi-Disciplinary BIM Software. Available online: https://www.autodesk.com.au/products/revit/overview (accessed on 1 November 2020).

- Autodesk. AutoCAD Plant 3D. Available online: https://www.autodesk.com/products/autocad/included-toolsets/autocad-plant-3d (accessed on 1 November 2020).

- Ashworth, S.; Tucker, M.; Druhmann, C.K. Critical success factors for facility management employer’s information requirements (EIR) for BIM. Facilities 2019, 37, 103–118. [Google Scholar] [CrossRef]

- Cavka, H.B.; Staub-French, S.; Poirier, E.A. Developing owner information requirements for BIM-enabled project delivery and asset management. Autom. Constr. 2017, 83, 169–183. [Google Scholar] [CrossRef]

- Matarneh, S.T.; Danso-Amoako, M.; Al-Bizri, S.; Gaterell, M.; Matarneh, R.T. BIM for FM. Facilities 2020, 38, 378–394. [Google Scholar] [CrossRef]

- Munir, M.; Kiviniemi, A.; Jones, S.; Finnegan, S. BIM-based operational information requirements for asset owners. Archit. Eng. Des. Manag. 2020, 16, 100–114. [Google Scholar] [CrossRef]

- Thorp, J. The Information Paradox: Realizing the Business Benefits of Information Technology; McGraw-Hill Ryerson: Whitby, ON, Canada, 2003. [Google Scholar]

- Water Services Association of Australia. Asset Management Customer Value (AMCV); Water Services Association of Australia: Melbourne, VIC, Australia, 2017. [Google Scholar]

- Wei, T.; Chen, G.; Wang, J. Application of BIM Technology in Building Water Supply and Drainage Design. IOP Conf. Ser. Earth Environ. Sci. 2017, 100, 012117. [Google Scholar] [CrossRef] [Green Version]

- Mellado, F.; Wong, P.F.; Amano, K.; Johnson, C.; Lou, E.C.W. Digitisation of existing buildings to support building assessment schemes: Viability of automated sustainability-led design scan-to-BIM process. Archit. Eng. Des. Manag. 2020, 16, 84–99. [Google Scholar] [CrossRef]

| Project | Location | Case Study |

|---|---|---|

| Kawana Sewage Treatment Plant upgrade [46] | Sunshine Coast, Queensland, Australia | Using BIM for design, construction and operation |

| Minworth Thermal Hydrolysis Plant [47] | Minworth, West Midlands, UK | Using BIM for design, construction and operation |

| Smart asset management: Pukete Wastewater Treatment Plant [48] | Hamilton, New Zealand | Advancing the asset management practice |

| EchoWater project: Biological nutrient removal facility [49] | Elk Grove, California, USA | Pioneering BIM for life cycle operations |

| Liverpool Wastewater Treatment Works [50] | Liverpool, UK | Demonstrating the benefits of BIM on first try |

| Tomahawk Creek Wastewater Treatment Facility expansion [51] | Leawood, Kansas, USA | Improving coordination through visualisation and data sharing |

| Southeast Water Treatment Plant construction [52] | Huntsville, Alabama, USA | Transitioning to BIM |

| Bonnybrook Wastewater Treatment Plant upgrade and expansion [53] | Calgary, Canada | Expanding BIM use through design and operations |

| Capability | WebShare | Scan-to-BIM | ||

|---|---|---|---|---|

| Revit | Plant 3D | Plant 3D + Revit | ||

| Live interaction | √ | √ | √ | |

| All asset data and information | √ | √ | √ | √ |

| Manufacturer and supply data | √ | √ | √ | √ |

| AEC design | √ | √ | ||

| External link attachment | √ | √ | √ | √ |

| Pipe and plant creation | √ | √ | √ | √ |

| Simulation | √ | √ | √ | |

| ‘Smart’ P&ID | √ | √ | ||

| Clash detection | √ | √ | √ | |

| GIS data | √ | √ | √ | √ |

| Single mode assembly | √ | √ | ||

| Phone access | √ | √ | ||

| O&M manuals and other data | √ | √ | √ | √ |

| Reduction in construction costs and duration | √ | √ | √ | |

| Life cycle and maintenance data | √ | √ | √ | |

| QA/QC reports | √ | √ | √ | |

| Bill of materials | √ | √ | √ | |

| Level of detail | Low (LOD 100) | High (LOD 400) | High (LOD 400) | High (LOD 500) |

| Level of information | Low (LOI 100) | Medium (LOI 300) | Medium (LOI 300) | High (LOI 500) |

| Code | Software | Hardware | Labour | Training | Utility | Source |

|---|---|---|---|---|---|---|

| S | H | L | T | U | R | |

| 1 | Scan processor | PC—8G RAM | High | High | Internet CXN | Literature review |

| 2 | FARO Scene | PC—16G RAM | Medium | Medium | Online tutorials | |

| 3 | Autodesk Recap | PC—16G RAM above | Low | Low | 3D modelling | |

| 4 | Autodesk Revit | Web-browsing device | Site survey | |||

| 5 | Autodesk AutoCAD Plant 3D | Site interview | ||||

| 6 | Autodesk Navisworks | Laser-scan company |

| Element | Low | Medium | High |

|---|---|---|---|

| Labour | 0 to 20 h | 20 to 40 h | 40 to 80 h |

| Training | Online tutorials | Scale Low + manual consultations | Scale Medium + expert consultations (e.g., diagnostic blogs, company inquiry request, expert advice) |

| Activity | Code | Process/Function | Cost Element (Refer to Table 3) | Source (Refer to Table 3) | ||||

|---|---|---|---|---|---|---|---|---|

| Software | Hardware | Labour | Training | Utility | ||||

| Experimental BIM design | ||||||||

| LiDAR scan | C1 | Scan survey | AUD 3,500 (provided) | R6 | ||||

| Point cloud | C2 | Scanning processes | S2 | H1 | L2 | T1 | U1 | R1, R2, R3 |

| WebShare | C3 | Uploading processes | Scan package | R6 | ||||

| Laser-scanned integrated BIM | C5 | 3D modelling (Pipes, instruments, etc.) | S5 | H1 | L1 | T1 | U1 | R1, R2, R3 |

| C6 | Smart P&ID drafting | S5 | H1 | L3 | T1 | R1, R2, R3 | ||

| C7 | Asset input | S5 | H1 | L3 | T2 | U1 | R1, R2, R3 | |

| C8 | Validation | H4 | L3 | T3 | U1 | R4, R5 | ||

| C9 | Uploading processes, clash detection, revalidation, etc. | S6 | H1 | L3 | T2 | U1 | R1, R2, R3 | |

| O&M and potential upgrade | ||||||||

| Access | C10 | WebShare viewing | H4 | L3 | T3 | U1 | R1, R2 | |

| C11 | 3D view (Navisworks) | S6 | H2 | L2 | T2 | U1 | R1, R2 | |

| Input | C12 | WebShare data relay | H4 | L2 | T2 | U1 | R1, R2 | |

| C13 | Revit data update/relay | S4 | H3 | L1 | T1 | U1 | R1, R2 | |

| C14 | Plant 3D data update/relay | S5 | H3 | L1 | T1 | U1 | R1, R2 | |

| Output | C15 | WebShare print out | H4 | L3 | T2 | U1 | R1, R2 | |

| C16 | Revit data print out | S4 | H1 | L3 | T3 | R1, R2 | ||

| C17 | Plant 3D data print out | S5 | H1 | L3 | T3 | R1, R2 | ||

| Survey | C18 | WebShare measuring | H4 | L2 | T2 | U1 | R1, R2 | |

| Code | Benefit | References |

|---|---|---|

| B1 | Improved design solutions | [46,47,48,49,50,51,52,53] |

| B2 | Reduced errors and omissions in project documents | [46,47,48,49,50,51,52,53] |

| B3 | Enhanced ability to maintain quality | [46,47,49,50,51,52,53] |

| B4 | Reduced rework during construction | [46,47,48,49,50,51,52,53] |

| B5 | Better control and predictability | [46,49,50,51,52] |

| B6 | Reduced cycle time of workflows among multiple parties | [46,47,48,49,50,51,52,53] |

| B7 | Reduced construction cost | [46,49,50,51,53] |

| B8 | Improved safety and faster approval cycles | [46,47,48,49,50,51,52,53] |

| B9 | Better safety performance for all parties involved | [46,47,48,49,50,52,53] |

| B10 | Reduced project duration | [46,49,51,52,53] |

| B11 | Ability to work collaboratively with other project team members | [46,47,48,49,50,51,52,53] |

| B12 | Increased client satisfaction | [47,48,49,50,51,53] |

| B13 | Overall enhancement of the organisation’s reputation as an industry leader | [48,49,50,52,53] |

| B14 | Ability to offer new services | [46,49,50,51,52] |

| B15 | Marketing of new business to new clients | [49,50,52,53] |

| B16 | Ability to attract or retain talented staff | [47,48,49,50,51,52,53] |

| B17 | Maintenance of repeat business with past clients | [49,52,53] |

| B18 | Increased profits on projects using BIM | [49,50,51,52] |

| Code (Refer to Table 6) | BIM Lifecycle Phase | Element | Source (Refer to Table 3) | |||

|---|---|---|---|---|---|---|

| BIM Design | O&M | Upgrade Design | Upgrade Construction | |||

| B1 | √ | √ | Data/Asset | R1, R3, R4 | ||

| B2 | √ | √ | √ | Data/Asset | R1, R3, R4 | |

| B3 | √ | √ | Asset/Risk | R1, R3, R4 | ||

| B4 | √ | Communication/Risk | R1 | |||

| B5 | √ | √ | Communication/Risk | R1 | ||

| B6 | √ | √ | √ | √ | Data/Communication | R1 |

| B7 | √ | Asset/Risk | R1 | |||

| B8 | √ | √ | √ | √ | Communication/Risk | R1, R3, R4 |

| B9 | √ | √ | Communication/Risk | R1 | ||

| B10 | √ | Asset/Risk | R1 | |||

| B11 | √ | √ | √ | √ | Data/Communication | R1, R4 |

| B12 | √ | Communication/Risk | R1, R4 | |||

| B13 | √ | Data/Communication | R1, R4 | |||

| B14 | √ | Communication/Risk | R1, R4 | |||

| B15 | √ | Communication/Risk | R1 | |||

| B16 | √ | √ | √ | √ | Data/Asset | R1 |

| B17 | √ | Communication/Risk | R1, R4 | |||

| B18 | √ | Asset/Risk | R1 | |||

| Stakeholders | WebShare | Scan-to-BIM | BIM Lifecycle Phase | Potential Costs (Refer to Table 5) | Potential Benefits (Refer to Table 6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| BIM Design | O&M | Upgrade Design | Upgrade Construction | ||||||

| BIM technical team | BIM coordinator | √ | √ | √ | √ | √ | √ | C1–C14 | B1–B5, B8, B9 |

| Facility personnel | 3D BIM designers | √ | √ | √ | √ | √ | √ | C1–C14 | B1–B5, B8, B9 |

| Operators | √ | √ | √ | C10–C18 | B2–B9 | ||||

| Maintenance planners | √ | √ | √ | C10–C18 | B2–B9 | ||||

| Schedulers | √ | √ | √ | C10–C18 | B2–B9 | ||||

| Process engineers | √ | √ | √ | √ | C10–C18 | B2–B9 | |||

| Managers | Facility managers | √ | √ | √ | √ | C10, C11, C15–C17 | B2, B3, B5–B9, B11–B18 | ||

| Asset managers | √ | √ | √ | √ | √ | √ | C4–C18 | B2, B3, B5–B9, B11–B18 | |

| Project managers | √ | √ | √ | √ | √ | C10, C11, C15–C17 | B2, B3, B5–B9, B11–B18 | ||

| Contractors | Main contractors | √ | √ | √ | C10, C11, C15–C18 | B2–B9, B11–B18 | |||

| Sub-contractors | √ | √ | √ | C10, C11, C15–C18 | B2–B9, B11–B18 | ||||

| Suppliers | √ | √ | √ | C10, C11, C15–C18 | B2–B9, B11–B18 | ||||

| Clients | Local residents | √ | √ | C10 | B12, B14, B15 | ||||

| Local businesses | √ | √ | C10 | B12, B14, B15 | |||||

| Others | √ | √ | C10 | B12, B14, B15 | |||||

| Owner/s | Investor | √ | √ | √ | √ | √ | √ | C10, C11, C15–C17 | B1–B18 |

| Local government | √ | √ | √ | C10 | B1–B18 | ||||

| State government | √ | √ | √ | C10 | B1–B18 | ||||

| Federal government | √ | √ | √ | C10 | B1–B18 | ||||

| AEC professionals | Architects | √ | √ | √ | √ | C4–C18 | B1–B11, B16–B18 | ||

| Engineers | √ | √ | √ | √ | C4–C18 | B1–B11, B16–B18 | |||

| Construction personnel | √ | √ | √ | √ | C9–C18 | B1–B11, B16–B18 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suprun, E.; Mostafa, S.; Stewart, R.A.; Villamor, H.; Sturm, K.; Mijares, A. Digitisation of Existing Water Facilities: A Framework for Realising the Value of Scan-to-BIM. Sustainability 2022, 14, 6142. https://doi.org/10.3390/su14106142

Suprun E, Mostafa S, Stewart RA, Villamor H, Sturm K, Mijares A. Digitisation of Existing Water Facilities: A Framework for Realising the Value of Scan-to-BIM. Sustainability. 2022; 14(10):6142. https://doi.org/10.3390/su14106142

Chicago/Turabian StyleSuprun, Emiliya, Sherif Mostafa, Rodney A. Stewart, Harold Villamor, Katrin Sturm, and Alex Mijares. 2022. "Digitisation of Existing Water Facilities: A Framework for Realising the Value of Scan-to-BIM" Sustainability 14, no. 10: 6142. https://doi.org/10.3390/su14106142

APA StyleSuprun, E., Mostafa, S., Stewart, R. A., Villamor, H., Sturm, K., & Mijares, A. (2022). Digitisation of Existing Water Facilities: A Framework for Realising the Value of Scan-to-BIM. Sustainability, 14(10), 6142. https://doi.org/10.3390/su14106142