Assessment of Strength and Durability Properties of Self-Compacting Concrete Comprising Alccofine

Abstract

:1. Introduction

2. Experimental Investigation

2.1. Materials

2.2. Mix Proportions

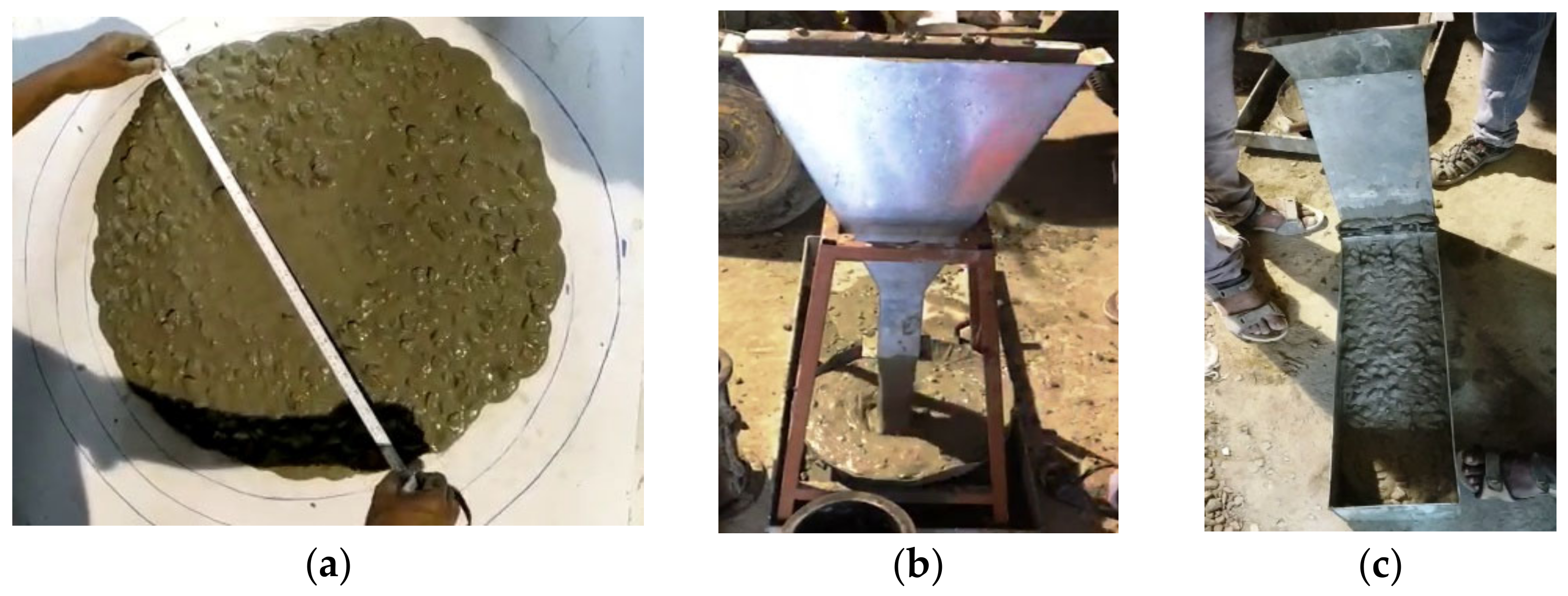

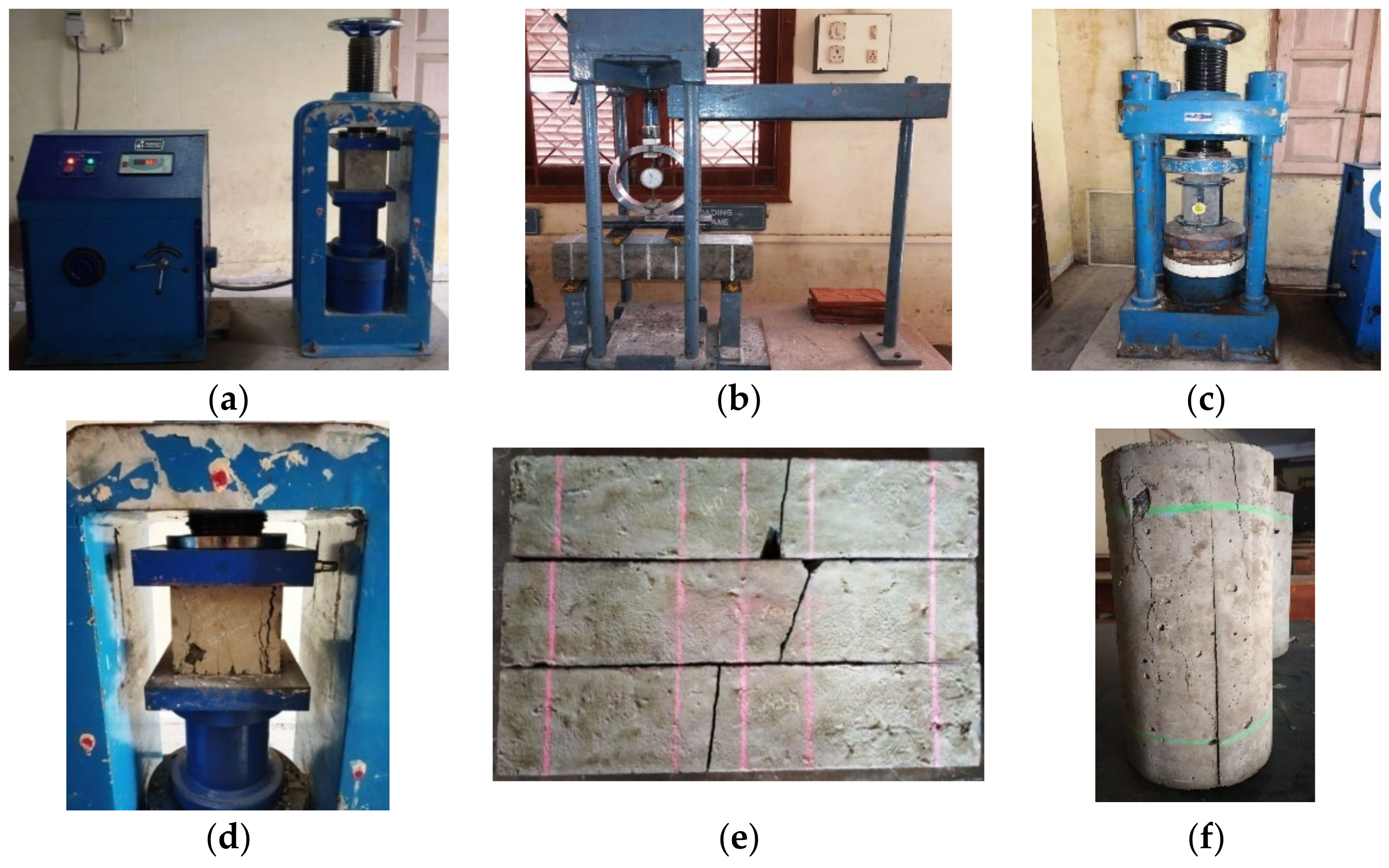

2.3. Testing of Fresh and Mechanical Properties of SCC

2.4. Testing of Durability Properties of SCC

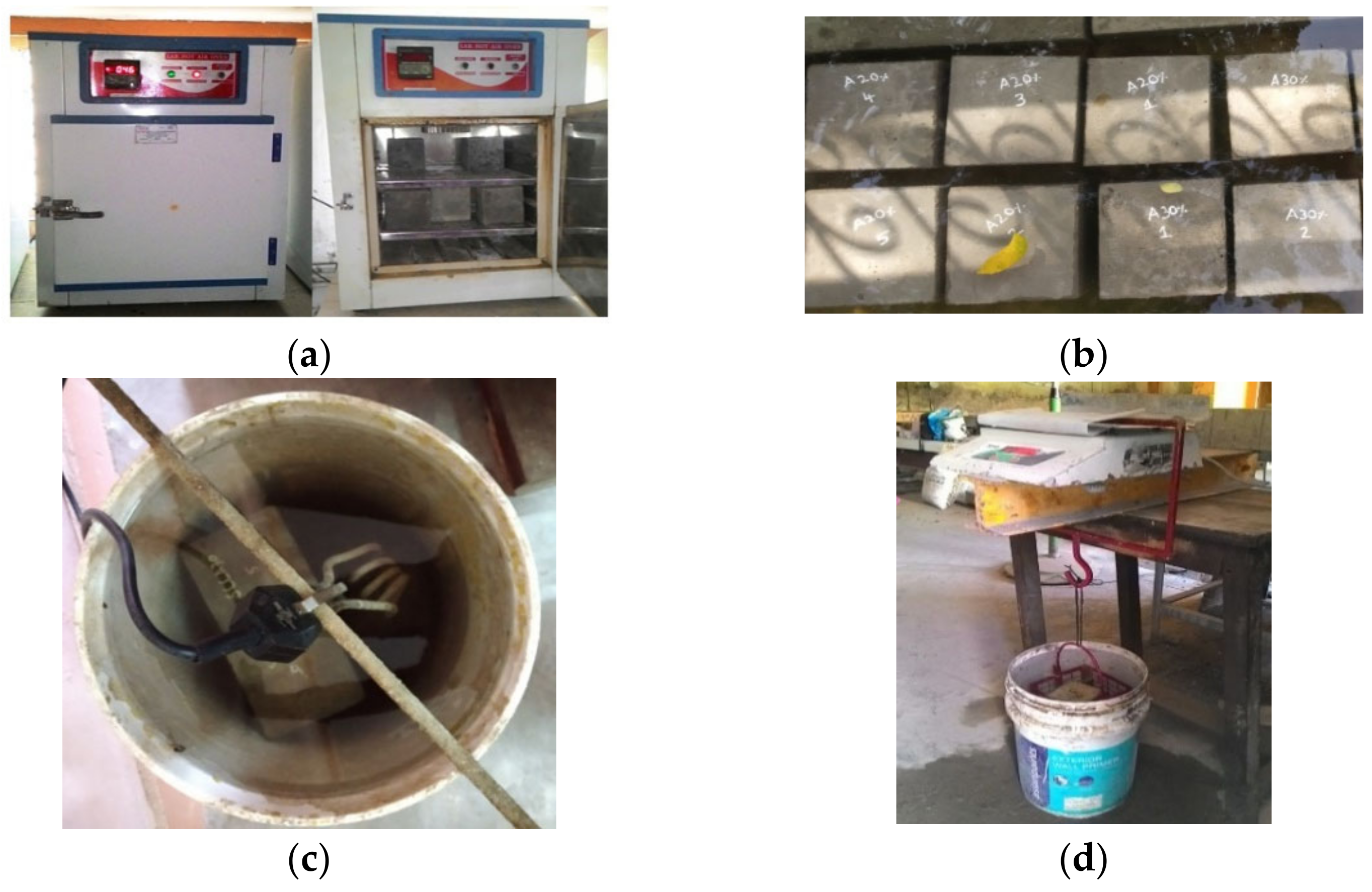

2.4.1. Determination of Density, Absorption, and Voids in Hardened Concrete

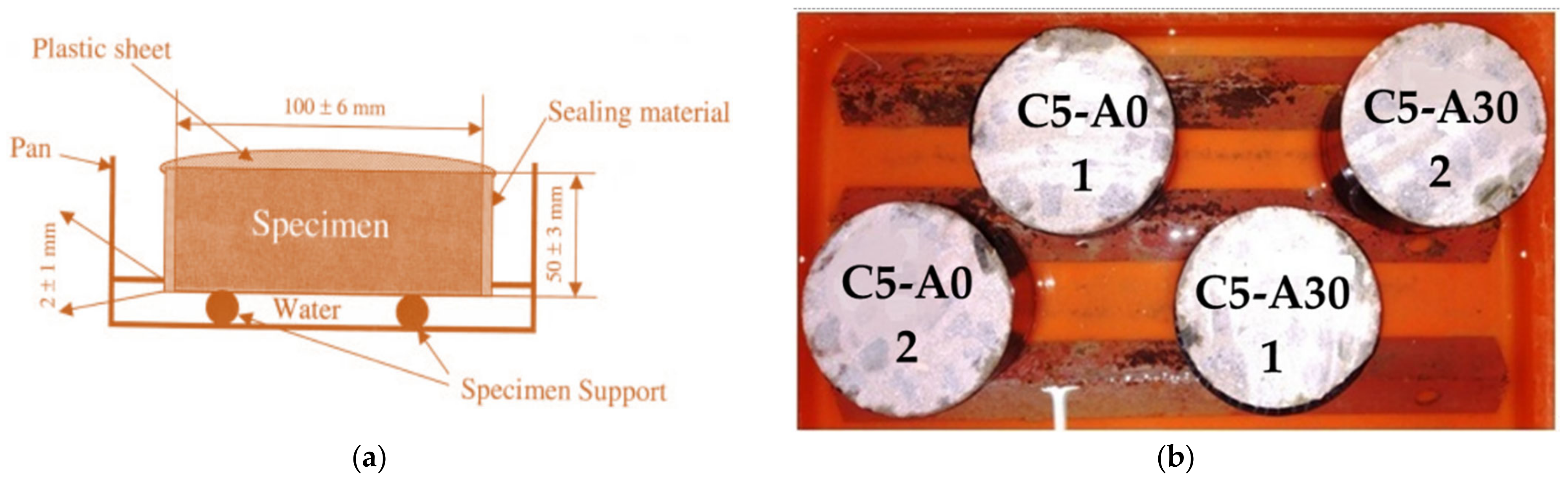

2.4.2. Determination of Sorptivity

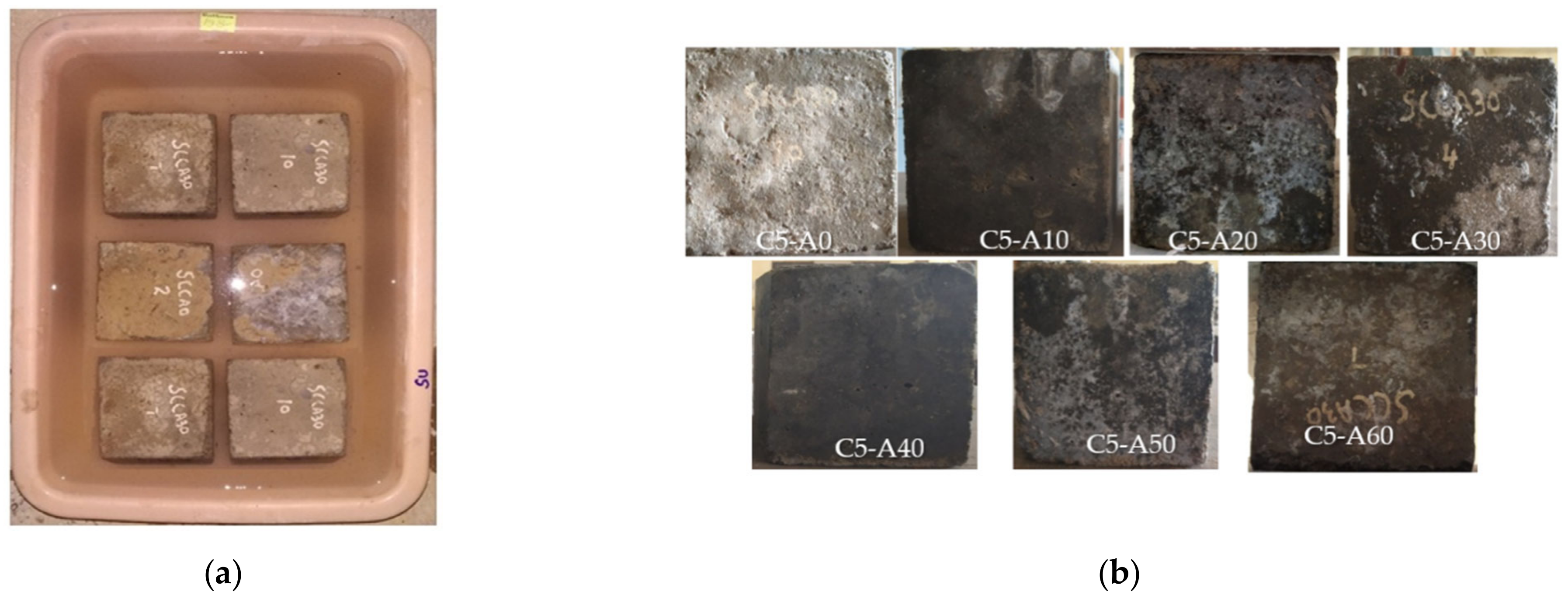

2.4.3. Sulphate Resistance

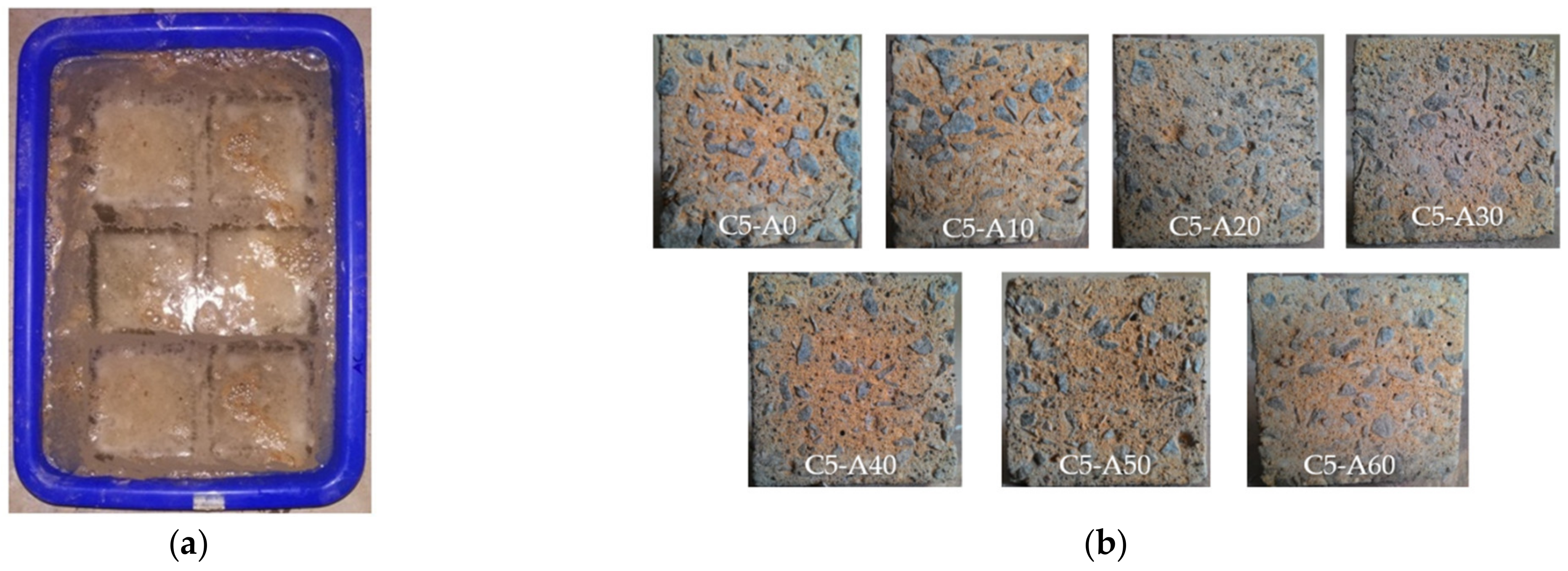

2.4.4. Acid Resistance

3. Results and Discussion

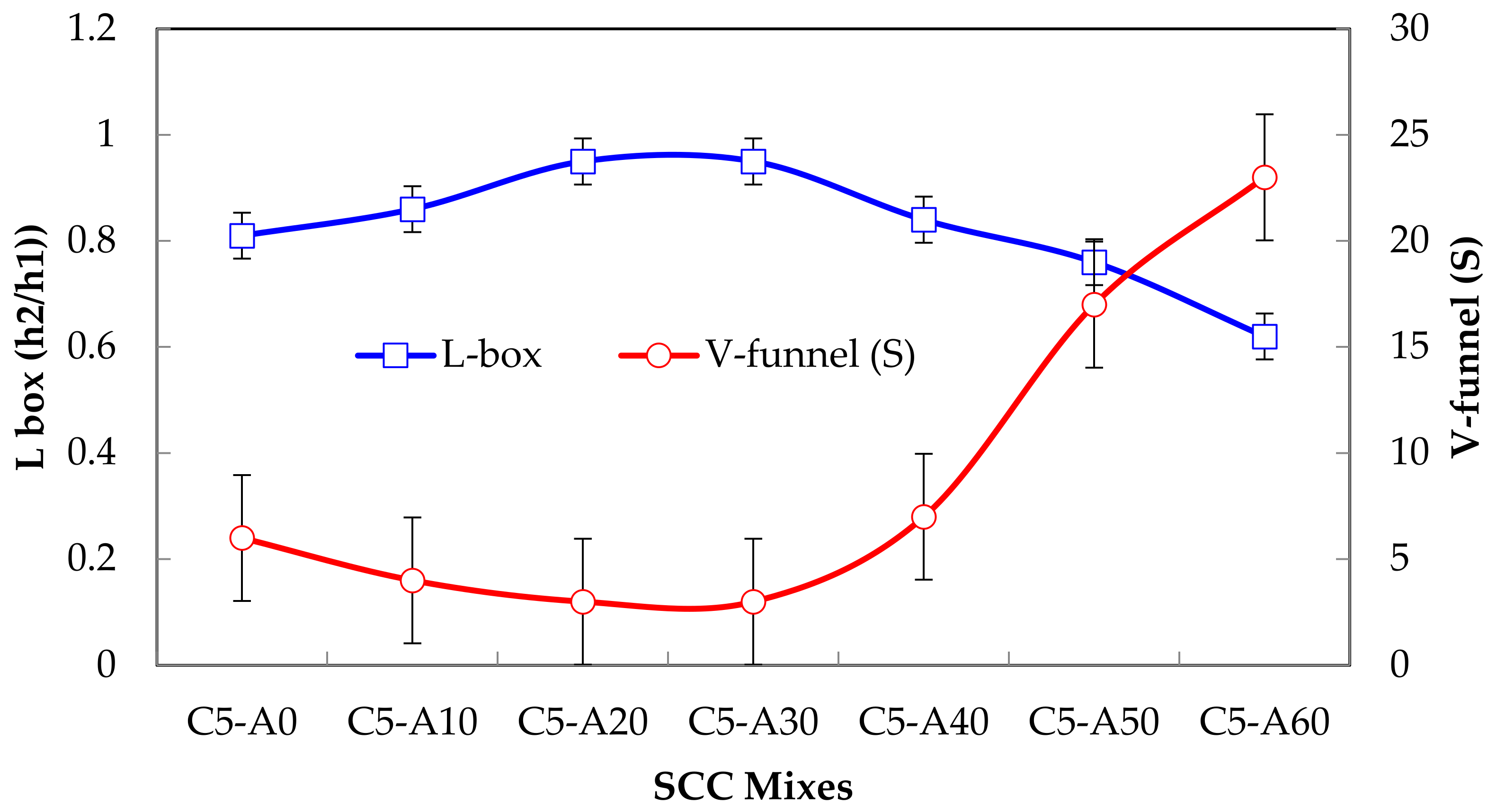

3.1. Properties of Fresh Concrete

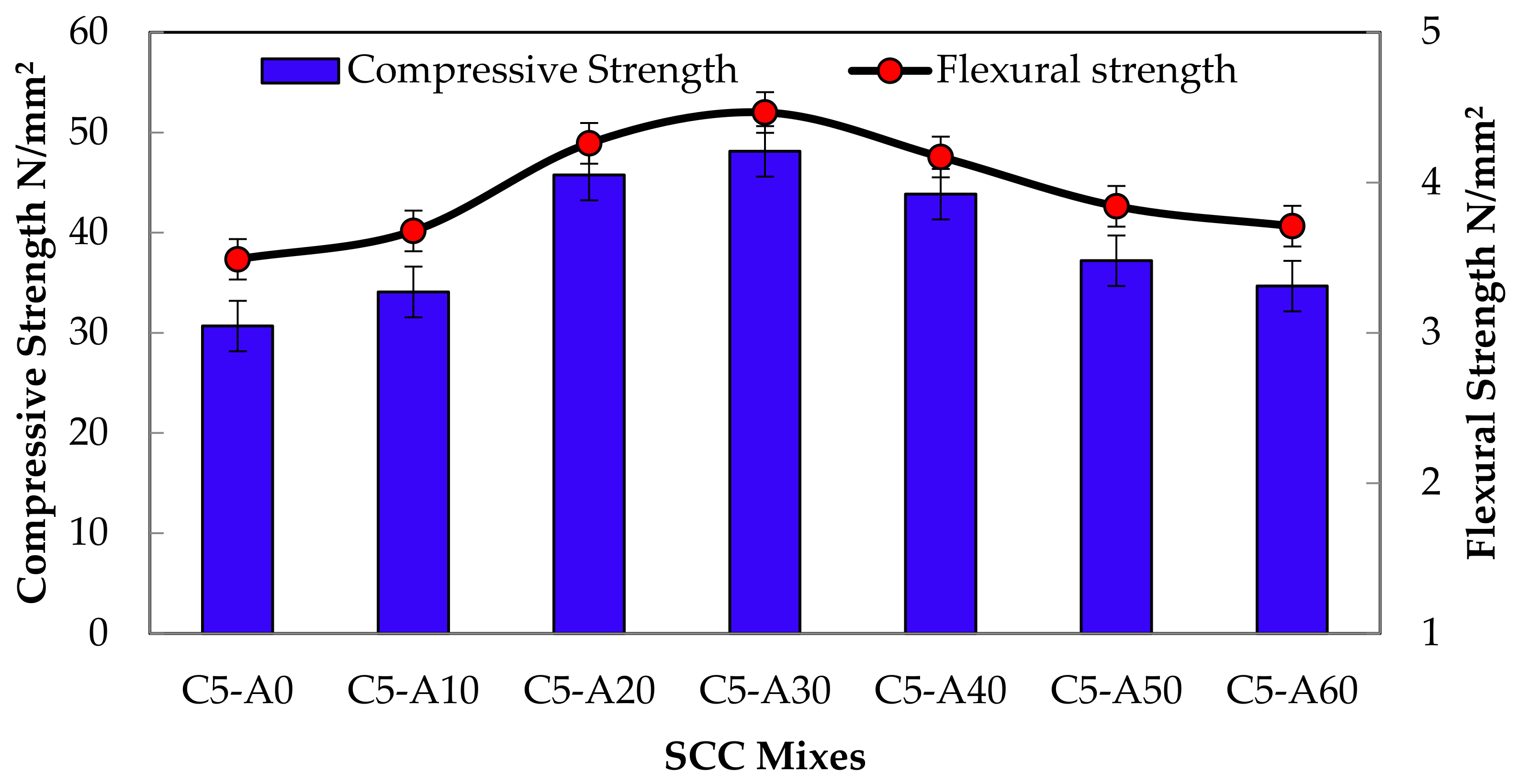

3.2. Properties of Hardened Concrete

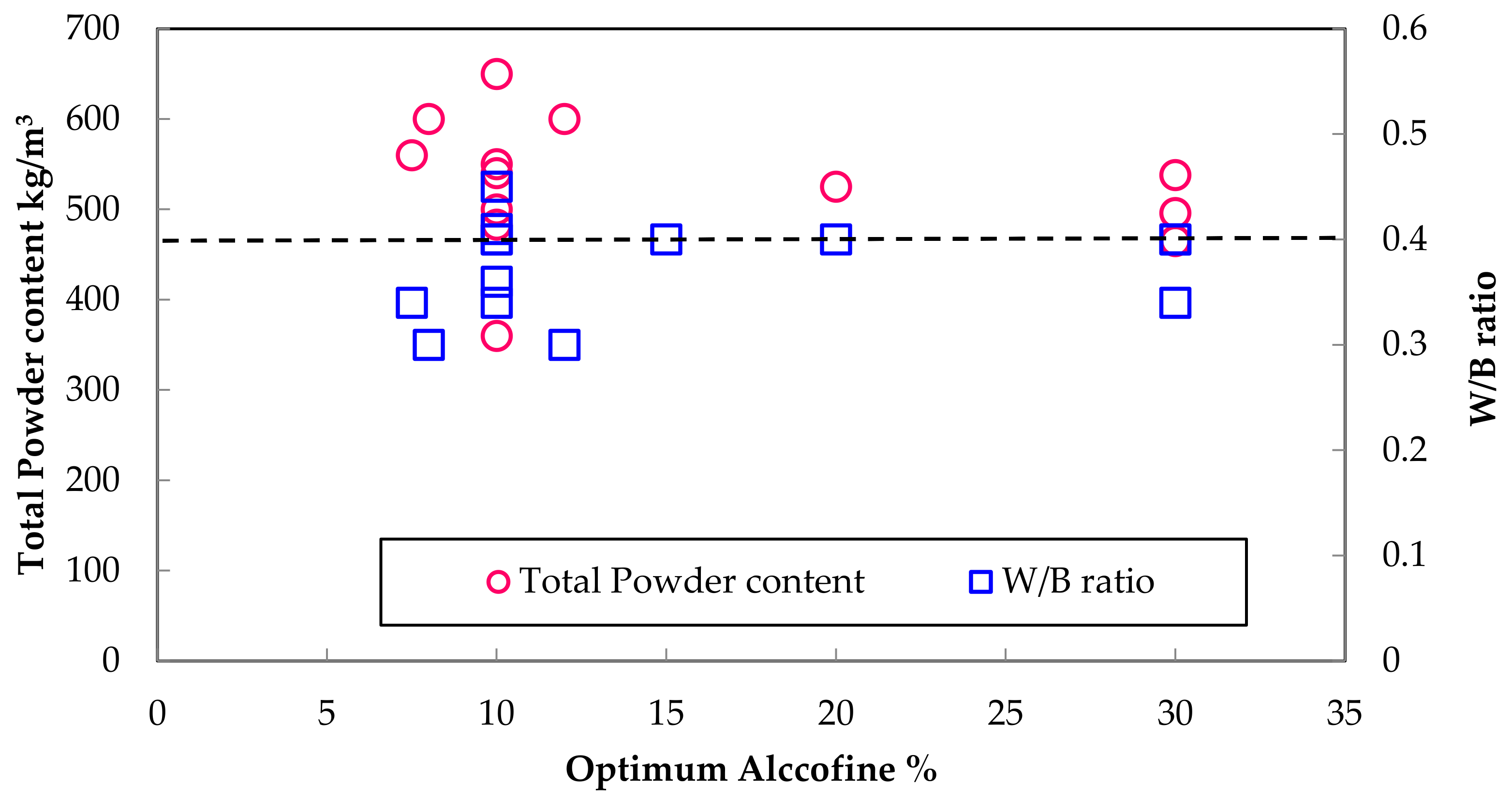

3.3. Comparison of Utilization Percentage of Alccofine with Existing Research

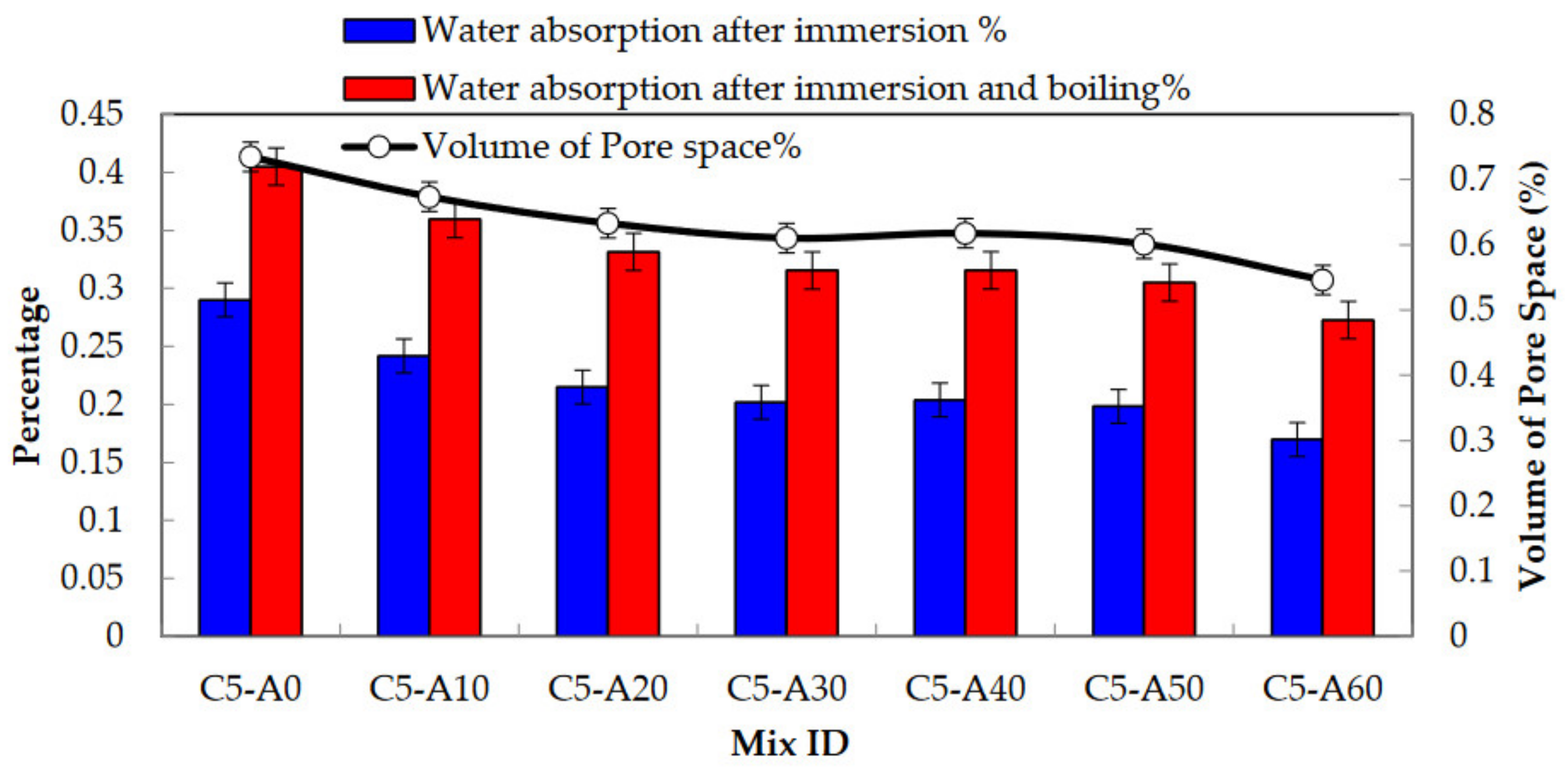

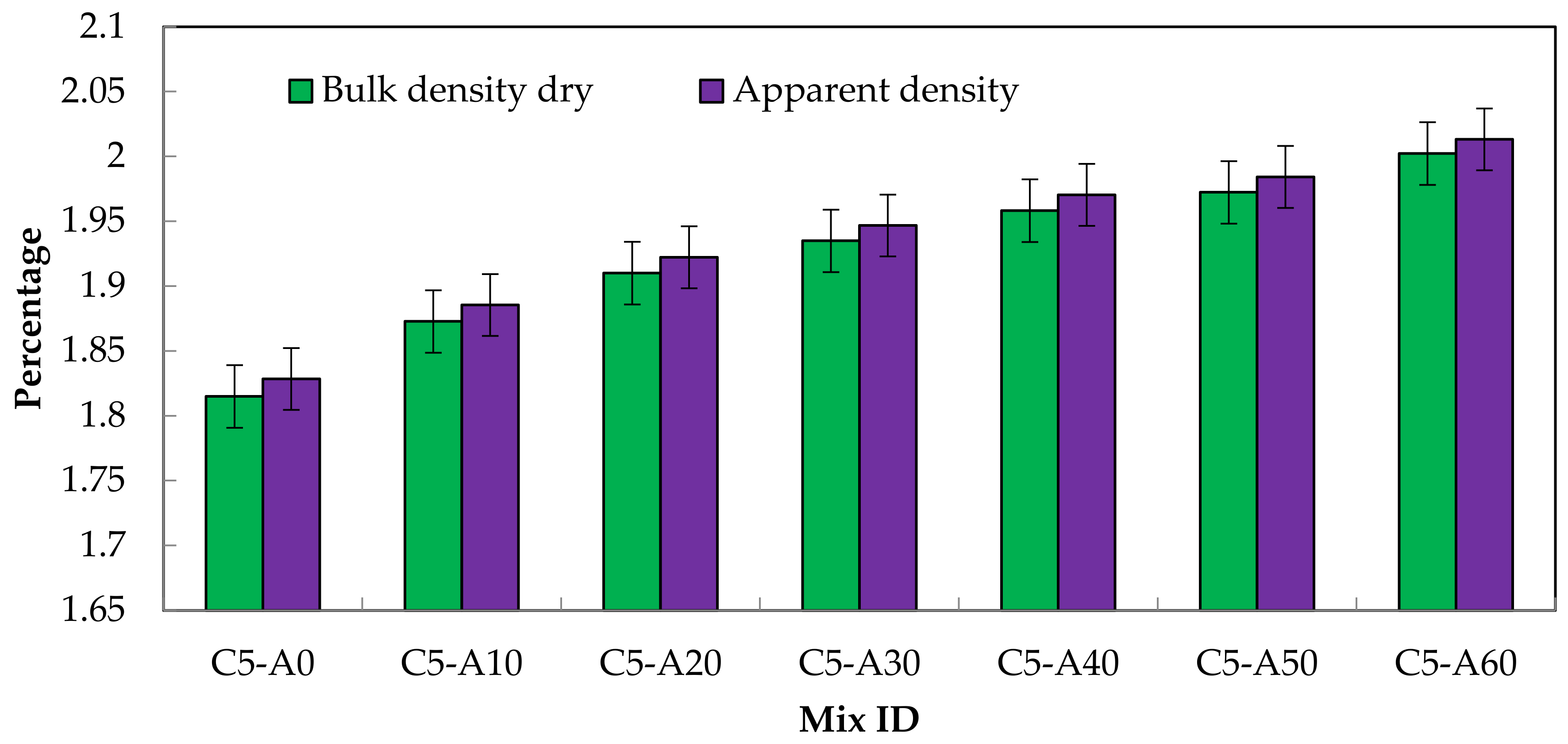

3.4. Density, Absorption, and Voids in Hardened Concrete

3.5. Sorptivity Test

3.6. Sulphate Resistance Test

3.7. Acid Resistance Test

4. Conclusions

- The fresh properties of alccofine-based SCC mixes are increased from 10 to 30% due to the enhanced lubrication effect for the selected W/B ratio and SP dosage. However, it has considerably decreased from 40 to 60% due to the superior surface area produced by slag addition and increased water demand;

- The mechanical properties are gradually increased for the mixes C5-A10 to C5-A30 and decreased further. The increase in strength is due to the increased total specific surface area, denser particle packing, and high pozzolanic reactivity that resulted in an enhanced hydration process. The occurrence of a higher amount of calcium, silica, and alumina in alccofine is one reason for the enhancement of the compressive strength;

- The improved flexural strength and Young’s modulus of concrete are due to its pozzolanic reaction, which improved the bond between binder material and aggregate and resulted in improved strength at the Interfacial Transition Zone;

- The water absorption percentage, voids, and sorptivity of the mixes C5-A0 to C5-A60 are decreased gradually. The increase in the replacement percentage of alccofine in the SCC mix considerably reduced water absorption capacity, voids, and sorptivity due to the presence of rich fineness, which leads to fewer pores and higher density in the concrete;

- The percentage of strength loss for the mixes C5-A0 to C5-A30 is gradually reduced for sulphate and acid resistance tests, respectively. Furthermore, it is increased for C5-A40 to C5-A60. Overall, the mix C5-A30 showed better resistance against chemicals in the durability examination. This enhanced resistance is due to lower permeability, better formation of C-S-H gel by improved hydration, and a reduction in the size of capillary pores.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mohan, A.; Mini, K.M. Strength Studies of SCC Incorporating Silica Fume and Ultra Fine GGBS. Mater. Today Proc. 2018, 5, 23752–23758. [Google Scholar] [CrossRef]

- Kathirvel, P.; Murali, G.; Vatin, N.I.; Abid, S.R. Experimental Study on Self Compacting Fibrous Concrete Comprising Magnesium Sulphate Solution Treated Recycled Aggregates. Materials 2022, 15, 340. [Google Scholar] [CrossRef] [PubMed]

- Uysal, M.; Sumer, M. Performance of self-compacting concrete containing different mineral admixtures. Constr. Build. Mater. 2011, 25, 4112–4120. [Google Scholar] [CrossRef]

- Yazici, H. The effect of silica fume and high-volume Class C fly ash on mechanical properties, chloride penetration and freeze-thaw resistance of self-compacting concrete. Constr. Build. Mater. 2008, 22, 456–462. [Google Scholar] [CrossRef]

- Okamura, H.; Ouchi, M. Self-Compacting Concrete. J. Adv. Concr. Technol. 2003, 1, 5–15. [Google Scholar] [CrossRef]

- Dinakar, P.; Babu, K.G.; Santhanam, M. Cement & Concrete Composites Durability properties of high volume fly ash self compacting concretes. Cem. Concr. Compos. 2008, 30, 880–886. [Google Scholar] [CrossRef]

- Ramanathan, P.; Baskar, I.; Muthupriya, P.; Venkatasubramani, R. Performance of self-compacting concrete containing different mineral admixtures. KSCE J. Civ. Eng. 2013, 17, 465–472. [Google Scholar] [CrossRef]

- ISO 1920-13:2018; Testing of Concrete-Part 13 Properties of Fresh Self Compacting Concrete. ISO: Geneva, Switzerland, 2018.

- Khatib, J.M. Performance of self-compacting concrete containing fly ash. Constr. Build. Mater. 2008, 22, 1963–1971. [Google Scholar] [CrossRef]

- Boukendakdji, O.; Kenai, S.; Kadri, E.H.; Rouis, F. Effect of slag on the rheology of fresh self-compacted concrete. Constr. Build. Mater. 2009, 23, 2593–2598. [Google Scholar] [CrossRef]

- Madandoust, R.; Mousavi, S.Y. Fresh and hardened properties of self-compacting concrete containing metakaolin. Constr. Build. Mater. 2012, 35, 752–760. [Google Scholar] [CrossRef]

- Balamuralikrishnan, R.; Saravanan, J. Effect of Alccofine and GGBS Addition on the Durability of Concrete. Civ. Eng. J. 2019, 5, 1273–1288. [Google Scholar] [CrossRef]

- Patel, Y.; Patel, P.J.; Jignesh; Patel, H.S. Study on Durability of High Performance Concrete with Alccofine and Fly ash. Int. J. Adv. Eng. Res. Stud. 2013, 2, 154–157. [Google Scholar]

- Challagalli, R.; Hiremath, G.S. Comparative Study on Durability Properties of Self-Compacting Concrete Produced Using Different Pozzolanas. Imp. J. Interdiscip. Res. 2017, 3, 31–34. [Google Scholar]

- Domone, P.L. Self-compacting concrete: An analysis of 11 years of case studies. Cem. Concr. Compos. 2006, 28, 197–208. [Google Scholar] [CrossRef]

- Prithiviraj, C.; Saravanan, J. Characteristics of Self-Compacting Concrete with Different Size of Coarse Aggregates and Alccofine. Trends Sci. 2022, 19, 3042. [Google Scholar] [CrossRef]

- Prithiviraj, C.; Saravanan, J. Flexural Performance of Alccofine-based Self-Compacting Concrete Reinforced with Steel and GFRP Bars. Int. Trans. J. Eng. Manag. Appl. Sci. Technol. 2021, 12, 1–12. [Google Scholar] [CrossRef]

- Prithiviraj, C.; Saravanan, J. Influence of W/B Ratio and Chemical Admixture on Fresh and Hardened Properties of Self Compacting Concrete using Alccofine. J. Xidian Univ. 2020, 14, 4906–4915. [Google Scholar] [CrossRef]

- Vivek, S.S.; Dhinakaran, G. Durability characteristics of binary blend high strength SCC. Constr. Build. Mater. 2017, 146, 1–8. [Google Scholar] [CrossRef]

- BIS IS 12269:2013; Ordinary Portland Cement, 53 Grade Specification. Bureau of Indian Standards (BIS): New Delhi, India, 2013; pp. 1–14.

- BIS IS 383-2016; Specification for Coarse and Fine Aggregates from Natural Sources for Concrete. Bureau of Indian Standards (BIS): New Delhi, India, 2016.

- BIS IS 9103-1999; Concrete Admixtures-Specification. Bureau of Indian Standards (BIS): New Delhi, India, 1999.

- BIS IS 516-2018; Methods of Tests for Strength of Concrete. Bureau of Indian Standards (BIS): New Delhi, India, 2018.

- ASTM C 642-97; Density, Absorption, and Voids in Hardened Concrete 1. ASTM International: West Conshohocken, PA, USA, 2005; pp. 1–3.

- ASTM C1585-13; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM C1012-04; Standard Test Method for Length Change of Hydraulic-Cement Mortars Exposed to a Sulfate Solution. ASTM International: West Conshohocken, PA, USA, 2004.

- ASTMC1898-20; Standard Test Method for Determining the Chemical Resistance of Concrete Products to Acid Attack. ASTM International: West Conshohocken, PA, USA, 2000.

- Nagataki, S.; Fujiwara, H. Self-Compacting Property of Highly Flowable Concrete. Online J. 1995, 154, 301–314. [Google Scholar] [CrossRef]

- Khayat, K.H. Optimization and performance of air-entrained, self-consolidating concrete. ACI Mater. J. 2000, 97, 526–535. [Google Scholar]

- Felekoǧlu, B.; Türkel, S.; Baradan, B. Effect of water/cement ratio on the fresh and hardened properties of self-compacting concrete. Build. Environ. 2007, 42, 1795–1802. [Google Scholar] [CrossRef]

- Narender Reddy, A.; Meena, T. A Study on Compressive Behavior of Ternary Blended Concrete Incorporating Alccofine. Mater. Today Proc. 2018, 5, 11356–11363. [Google Scholar] [CrossRef]

- Kavyateja, B.V.; Jawahar, G. Sashidhar Effectiveness of alccofine and fly ash on mechanical properties of ternary blended self compacting concrete. Mater. Today Proc. 2020, 33, 73–79. [Google Scholar] [CrossRef]

- Bradu, A.; Cazacu, N.; Florea, N.; Mihai, P. Modulus of Elasticity of Self Compacting Concrete with Diferents Levels of Limestone Powder. Bul. Inst. Politeh. Din Iasi 2016, 66, 43–52. [Google Scholar]

- Sagar, B.; Sivakumar, M.V.N. An Experimental and Analytical Study on Alccofine Based High Strength Concrete. Int. J. Eng. 2020, 33, 530–538. [Google Scholar] [CrossRef]

- Kohistani, A.S.; Singh, K. An Experimental Investigation by Utilizing Plastic Waste and Alccofine in Self-Compacting Concrete. Indian J. Sci. Technol. 2018, 11, 1–14. [Google Scholar] [CrossRef]

- Khatana, R.S.; Aggarwal, P.; Aggarwal, Y. Effect of Alccofine on Fresh and Hardened Properties of Self Compacting concrete. In Proceedings of the National Conference on Technological Innovations for Sustainable Infrastructure, Calicut, India, 13–14 March 2015; pp. 34–38. [Google Scholar]

- Abraham, R.; Neelakantan; Babu, R. Self-compacting Concrete with Alccofine and Glass Fiber. Int. J. Eng. Adv. Technol. 2019, 9, 188–191. [Google Scholar] [CrossRef]

- Kavitha, S.; Kala, T.F. Evaluation of Strength Behavior of Self-Compacting Concrete using Alccofine and GGBS as Partial Replacement of Cement. Indian J. Sci. Technol. 2016, 9, 1–5. [Google Scholar] [CrossRef]

- Pawar, M.S.; Saoji, A.C. Effect of Alccofine on Self Compacting Concrete. Int. J. Eng. Sci. 2013, 2, 5–9. [Google Scholar]

- Baby, B.; Anto, J. Study of Properties of Self Compacting Concrete with Micro Steel Fibers and Alccofine. Int. Res. J. Adv. Eng. Sci. 2017, 2, 83–87. [Google Scholar]

- Baby, B.; Anto, J.; Johny, B.; Sreenath, S. Rheology, Strength and Durability Characteristics of Alccofine Blended Fibre Reinforced Self Consolidating Concrete. Int. J. Eng. Technol. 2018, 7, 209. [Google Scholar] [CrossRef]

- Nadeem, P.; Arbaaz, P.; Azhar, F.; Javeed, Z.; Wasif, A. An Experimental Study on SSC using Mixture of Alccofine and GGBS as Partial Replacement of Cement. Int. J. Sci. Res. Dev. 2017, 5, 944–948. [Google Scholar]

- RajaL, A.; Hameed, M.S. Mechanical and Rheological Properties of Fiber Reinforced Self Compacting Concrete with Alccofine. Int. J. Curr. Eng. Sci. Res. 2017, 4, 72–77. [Google Scholar]

- Aarthi, K.; Arunachalam, K. Durability studies on fibre reinforced self compacting concrete with sustainable wastes. Int. J. Sci. Technol. Eng. 2018, 174, 247–255. [Google Scholar] [CrossRef]

- Bansal, T.; Pal, S.; Maitra, J. Effect of Alccofine and Metakaolin on the Performance of SCC. In Proceedings of the 1st International Conference on New Frontiers in Engineering, Science & Technology, New Delhi, India, 8–12 January 2018. [Google Scholar]

- Mehetre, A.S. Use of Alccofine and Steel Fibre in Self Compacting Concrete. Int. J. Adv. Res. Innov. Ideas Educ. 2020, 6, 433–440. [Google Scholar]

- Vivek, K.C.; Palanisamy, M.; Debnath, S.; Munagala, M. Performance Evaluation of Durability and Flexural behaviour of Self Compacting Concrete blended with Alccofine. IOP Conf. Ser Mater. Sci. Eng. 2021, 1126, 012083. [Google Scholar] [CrossRef]

- Zhu, W. Permeation properties of self-compaction concrete. In Self-Compacting Concrete: Materials, Properties and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 117–130. ISBN 9780128173695. [Google Scholar]

- Nehdi, M.; Pardhan, M.; Koshowski, S. Durability of self-consolidating concrete incorporating high-volume replacement composite cements. Cem. Concr. Res. 2004, 34, 2103–2112. [Google Scholar] [CrossRef]

- Jones, M.R.; Dhir, R.K.; Magee, B.J. Concrete containing ternary blended binders: Resistance to chloride ingress and carbonation. Cem. Concr. Res. 1997, 27, 825–831. [Google Scholar] [CrossRef]

- Brooks, J.J.; Neville, A.M. Concrete Technology, 2nd ed.; Pearson Education Limited: London, UK, 2010; Volume 13. [Google Scholar]

- Dias, W.P.S. Reduction of concrete sorptivity with age through carbonation. Cem. Concr. Res. 2000, 30, 1255–1261. [Google Scholar] [CrossRef]

- Zhang, S.P.; Zong, L. Evaluation of relationship between water absorption and durability of concrete materials. Adv. Mater. Sci. Eng. 2014, 2014, 650373. [Google Scholar] [CrossRef] [Green Version]

- Gummerson, R.J.; Hall, C.; Hoff, W.D. Water movement in porous building materials-II. Hydraulic suction and sorptivity of brick and other masonry materials. Build. Environ. 1980, 15, 101–108. [Google Scholar] [CrossRef]

- Hall, C.; Hall, C. Water sorptivity of mortars and concretes: A review. Mag. Concr. Res. 1989, 41, 51–61. [Google Scholar] [CrossRef]

- Ramezanianpour, A.M.; Hooton, R.D. Sulfate resistance of Portland-limestone cements in combination with supplementary cementitious materials. Mater. Struct. 2013, 46, 1061–1073. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Al-Attar, T.S.; Taha, A.A. Performance of high-volume fly ash self-compacting concrete exposed to external sulfate attack. In Proceedings of the 6th International Conference on Durability of Concrete Structures, ICDCS, Leeds, UK, 18–20 July 2018. [Google Scholar]

- Bassuoni, M.T.; Nehdi, M.; Amin, M. Self-compacting concrete: Using limestone to resist sulfuric acid. Proc. Inst. Civ. Eng. Constr. Mater. 2007, 160, 113–123. [Google Scholar] [CrossRef]

- Kannan, V.; Ganesan, K. Chloride and chemical resistance of self compacting concrete containing rice husk ash and metakaolin. Constr. Build. Mater. 2014, 51, 225–234. [Google Scholar] [CrossRef]

- Siad, H.; Mesbah, H.A.; Khelafi, H.; Kamali-Bernard, S.; Mouli, M. Effect of mineral admixture on resistance to sulphuric and hydrochloric acid attacks in selfcompacting concrete. Can. J. Civ. Eng. 2010, 37, 441–449. [Google Scholar] [CrossRef]

| Chemical Composition (%) | ||

|---|---|---|

| Component | Cement | Alccofine 1203 |

| CaO | 66.67 | 32.20 |

| SiO2 | 18.91 | 35.30 |

| Fe2O3 | 4.94 | 1.20 |

| Al2O3 | 4.51 | 21.40 |

| SO3 | 2.5 | 0.13 |

| MgO | 0.87 | 6.20 |

| K2O | 0.43 | - |

| Na2O | 0.12 | - |

| Description | Mix ID | ||||||

|---|---|---|---|---|---|---|---|

| C5-A0 | C5-A10 | C5-A20 | C5-A30 | C5-A40 | C5-A50 | C5-A60 | |

| Cement | 465 | 418.5 | 372 | 325.5 | 279 | 232.5 | 186 |

| Alccofine | 0 | 46.5 | 93 | 139.5 | 186 | 232.5 | 279 |

| Fine aggregate | 915 | 915 | 915 | 915 | 915 | 915 | 915 |

| Coarse aggregate | 836 | 836 | 836 | 836 | 836 | 836 | 836 |

| Water | 186 | 186 | 186 | 186 | 186 | 186 | 186 |

| Superplasticizer | 4.65 | 4.65 | 4.65 | 4.65 | 4.65 | 4.65 | 4.65 |

| Description | Mix ID | ||||||

|---|---|---|---|---|---|---|---|

| C5-A0 | C5-A10 | C5-A20 | C5-A30 | C5-A40 | C5-A50 | C5-A60 | |

| Slump (mm) | 562 | 650 | 687 | 690 | 645 | 580 | 525 |

| T50 cm (s) | 6 | 5 | 4 | 4 | 5 | 6 | 8 |

| V-Funnel (s) | 6 | 4 | 3 | 3 | 7 | 17 | 23 |

| L-Box (h2/h1) | 0.81 | 0.86 | 0.95 | 0.95 | 0.84 | 0.76 | 0.62 |

| Description | Mix ID | ||||||

|---|---|---|---|---|---|---|---|

| C5-A0 | C5-A10 | C5-A20 | C5-A30 | C5-A40 | C5-A50 | C5-A60 | |

| Compressive Strength N/mm2 | 30.69 | 34.09 | 45.77 | 48.13 | 43.84 | 37.21 | 34.68 |

| Flexural Strength N/mm2 | 3.49 | 3.67 | 4.26 | 4.46 | 4.17 | 3.84 | 3.71 |

| E-for Concrete ×103 N/mm2 | 26.77 | 28.21 | 32.82 | 33.79 | 32.1 | 29.53 | 28.54 |

| Reference | Total Powder Content (kg/m3) | W/B Ratio | Combination | Slump Flow | Compressive Strength (N/mm2) | Utilization Range of Alccofine % | Optimum Alccofine % | ||

|---|---|---|---|---|---|---|---|---|---|

| Binary | Ternary | 7 Days | 28 Days | ||||||

| [35] | 483 | 0.45 | C + AF | - | 580 to 720 | 24.6 to 31.7 | 28.55 to 35.25 | 10 | 10 |

| [32] | 500 | 0.36 | - | C + AF+ FA | - | 20 to 24 | 32 to 34 | 5–15 | 10 |

| [36] | 550 | 0.41 | - | C + AF+ FA | 540 to 690 | 20 to 30 | 31 to 41 | 2.5–10 | 10 |

| [1] | 540 | 0.34 | C + AF | - | 700 to 720 | 46.22 to 48.89 | 57.33 to 62.67 | 5–15 | 10 |

| [37] | 650 | 0.4 | C + AF | - | 665 to 692 | 34.66 to 36.44 | 57.77 to 60.44 | 5–15 | 10 |

| [38] | - | - | - | C + AF + GGBS | 670 to 720 | 25.2 to 29.6 | 38.2 to 42.9 | 5–20 | 10 |

| [18] | 465 | 0.4 | C + AF | - | 521 to 712 | 16.3 to 37.14 | 26.34 to 58.11 | 10–60 | 30 |

| [16] | 465 | 0.4 | C + AF | - | 525 to 690 | 25.86 to 32.11 | 34.09 to 48.13 | 10–60 | 30 |

| [13] | 600 | 0.3 | - | C + AF+ FA | - | 44.06 | 54.89 | 4–14 | 8 |

| [39] | - | - | C + AF | - | 700–710 | 17.66 to 28.66 | 27 to 34 | 5–15 | 10 |

| [40,41] | 360 | 0.4 | C + AF+ FA | 630–680 | 26.5 to 36.8 | 41.9 to 46.4 | 5–15 | 10 | |

| [42] | 560 | 0.34 | - | C + AF + GGBS | - | 28.19 to 30.69 | 41.85 to 46.79 | 2.5–10 | 7.5 |

| [43,44] | 496 | 0.34 | C + AF | - | 657–670 | - | - | 10–40 | 30 |

| [45] | 600 | 0.3 | - | C + AF+ FA | 720–760 | - | 71.3 to 80.2 | 3–15 | 12 |

| [46] | - | 0.4 | - | C + AF+ FA | 550–612 | - | 20.05 to 30.88 | 10–25 | 15 |

| [47] | 525 | 0.4 | C + AF | - | 640–670 | 15.49 to 20.79 | 43.21 to 51.16 | 10–50 | 20 |

| Description | Mix ID | ||||||

|---|---|---|---|---|---|---|---|

| C5-A0 | C5-A10 | C5-A20 | C5-A30 | C5-A40 | C5-A50 | C5-A60 | |

| After 48 h immersion | 0.290 | 0.242 | 0.215 | 0.202 | 0.204 | 0.198 | 0.170 |

| After boiling | 0.405 | 0.360 | 0.331 | 0.315 | 0.315 | 0.305 | 0.273 |

| Bulk density dry, Mg/m3 | 1.815 | 1.873 | 1.910 | 1.935 | 1.958 | 1.972 | 2.002 |

| Apparent density Mg/m3 | 1.828 | 1.885 | 1.922 | 1.947 | 1.970 | 1.984 | 2.013 |

| Volume of permeable pore space % | 0.735 | 0.674 | 0.633 | 0.610 | 0.618 | 0.601 | 0.546 |

| Description | Mix ID | ||||||

|---|---|---|---|---|---|---|---|

| C5-A0 | C5-A10 | C5-A20 | C5-A30 | C5-A40 | C5-A50 | C5-A60 | |

| Initial rate of absorption (mm/s1/2) | 0.016 | 0.009 | 0.009 | 0.008 | 0.006 | 0.006 | 0.004 |

| Correlation coefficient R2 | 0.99 | 0.99 | 0.98 | 0.98 | 0.98 | 0.98 | 0.99 |

| Description | Mix ID | ||||||

|---|---|---|---|---|---|---|---|

| C5-A0 | C5-A10 | C5-A20 | C5-A30 | C5-A40 | C5-A50 | C5-A60 | |

| MgSO4 Solution at 28 days | 28.60 | 32.87 | 44.85 | 47.51 | 42.96 | 36.17 | 33.02 |

| MgSO4 Solution at 56 days | 25.75 | 29.84 | 40.48 | 42.93 | 38.42 | 32.47 | 29.76 |

| Description | Mix ID | ||||||

|---|---|---|---|---|---|---|---|

| C5-A0 | C5-A10 | C5-A20 | C5-A30 | C5-A40 | C5-A50 | C5-A60 | |

| HCl Solution at 28 days | 25.46 | 28.94 | 41.58 | 43.78 | 39.12 | 31.48 | 29.18 |

| HCl Solution at 56 days | 21.59 | 25.94 | 35.58 | 37.74 | 34.12 | 28.08 | 25.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prithiviraj, C.; Saravanan, J.; Ramesh Kumar, D.; Murali, G.; Vatin, N.I.; Swaminathan, P. Assessment of Strength and Durability Properties of Self-Compacting Concrete Comprising Alccofine. Sustainability 2022, 14, 5895. https://doi.org/10.3390/su14105895

Prithiviraj C, Saravanan J, Ramesh Kumar D, Murali G, Vatin NI, Swaminathan P. Assessment of Strength and Durability Properties of Self-Compacting Concrete Comprising Alccofine. Sustainability. 2022; 14(10):5895. https://doi.org/10.3390/su14105895

Chicago/Turabian StylePrithiviraj, Chidambaram, Jagadeesan Saravanan, Deivasigamani Ramesh Kumar, Gunasekaran Murali, Nikolai Ivanovich Vatin, and Packirisamy Swaminathan. 2022. "Assessment of Strength and Durability Properties of Self-Compacting Concrete Comprising Alccofine" Sustainability 14, no. 10: 5895. https://doi.org/10.3390/su14105895

APA StylePrithiviraj, C., Saravanan, J., Ramesh Kumar, D., Murali, G., Vatin, N. I., & Swaminathan, P. (2022). Assessment of Strength and Durability Properties of Self-Compacting Concrete Comprising Alccofine. Sustainability, 14(10), 5895. https://doi.org/10.3390/su14105895