Industrial Buildings with Zero Energy Consumption: Cathedral Warehouse for Sherry Wines

Abstract

:1. Introduction

2. Materials and Methods

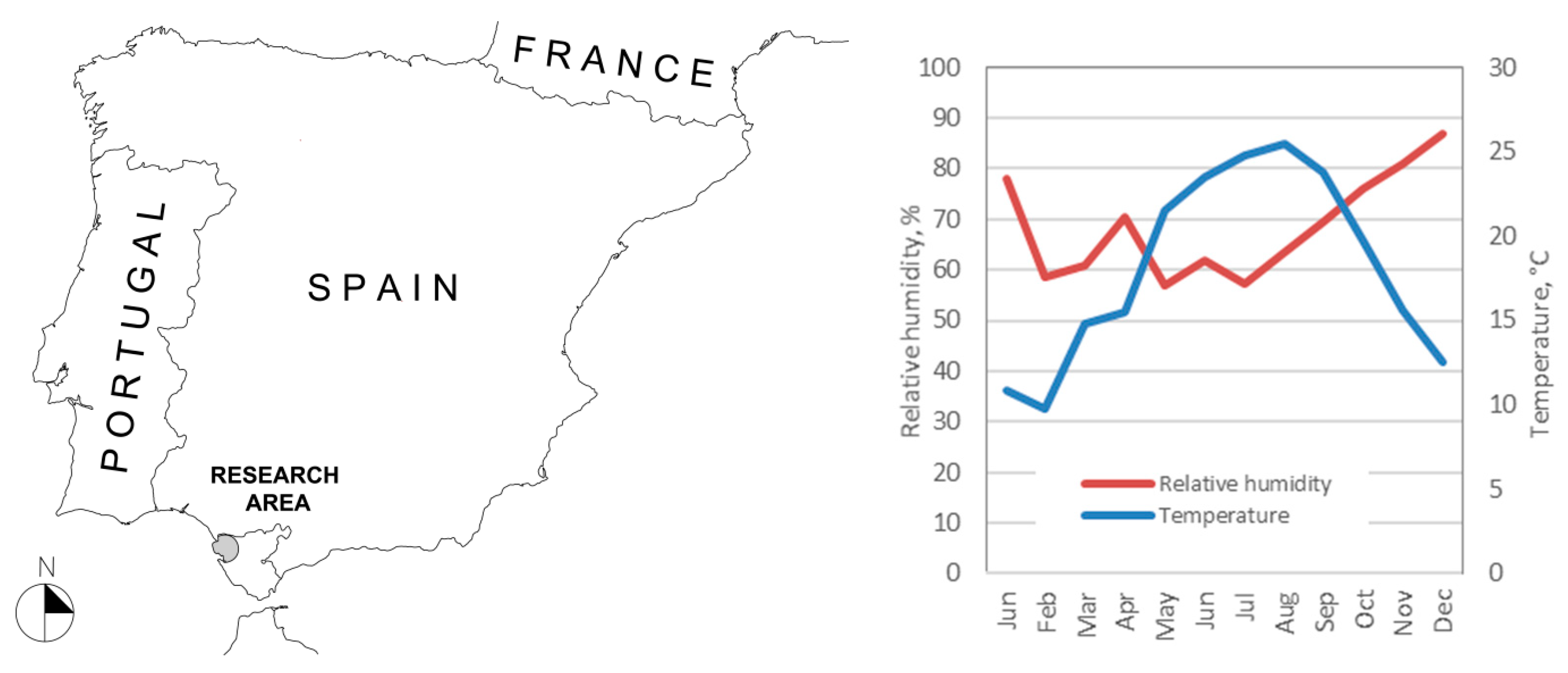

2.1. Area of Study

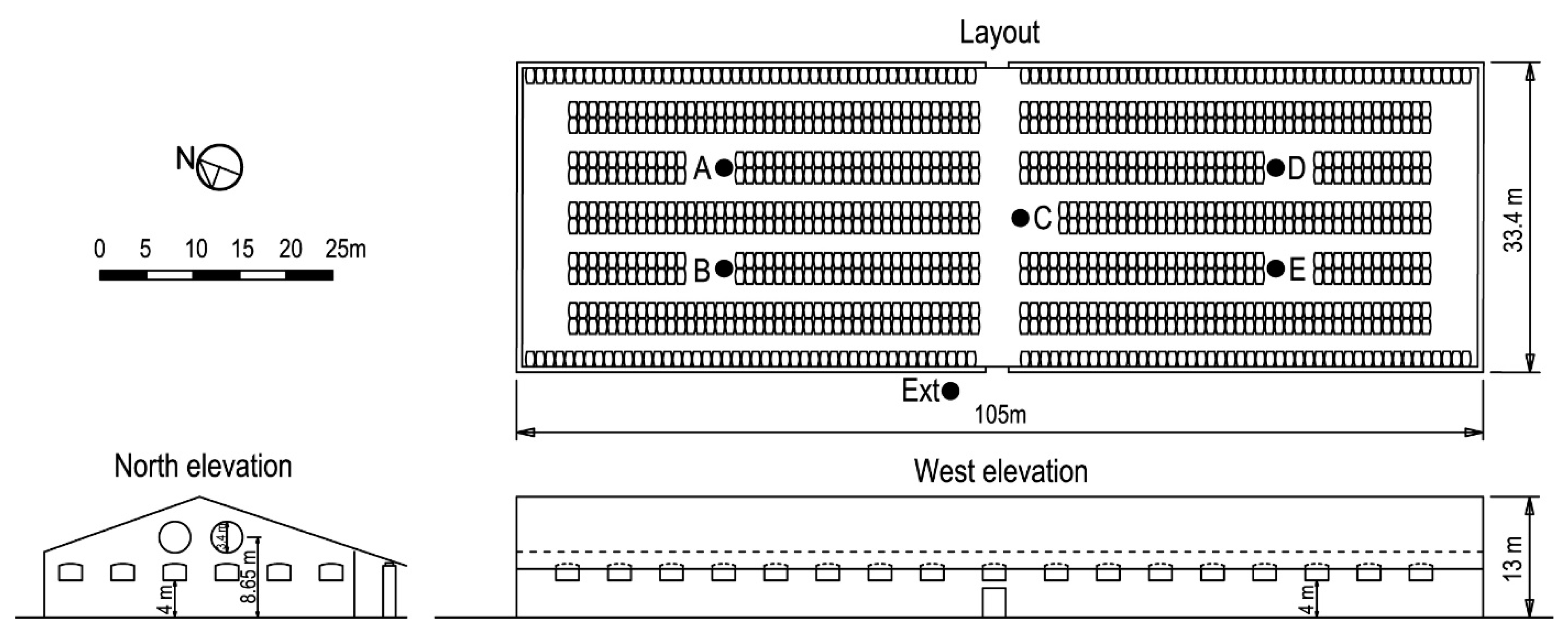

2.2. Analyzed Building

- It has a pitched roof with two slopes that meet at a central ridge. The orientation of the building and the design of the roof with two slopes allow the indoor heating of the building during the summer months to be lower, as the heat interchange is mainly done through one of the slopes. The materials that form the roof are ceramic roofing tiles (exterior material), mortar of lime and sand mortar, thick compact cooked clay bricks (5 cm), and a mixture of wood slats. The entire roof relies on large wood joists. the thermal characteristics of the roof are shown in Table 1.

- The structure is made of several courses of pillars (60 cm2) that hold the roof and of load-bearing 80 cm thick walls that work as a closing. The pillars are made of stone and brick and support large wooden beams where the joists are supported. The very large span, in addition to its structural function, allows for ventilation and the height of the ceiling. The walls are made with mortar (lime, sand, and water), stone masonry, and mortar (lime, sand, and water). Exterior walls help maintain indoor environmental humidity due to the materials they have been built with. Sandstone has high hygroscopic properties that allow the wall to absorb water from the terrain [16]. The indoor and outdoor finishing is hygroscopic and allows the transpiration of the building. The white lime exterior finishing (reflecting) reduces the effect of sun beams.

- Voids in façade: The accesses to the building, made of large wood doors, are placed in the central part of the longitudinal façades. The window openings (1.6 m × 2.5 m) are located four meters from the ground and distributed throughout the perimeter of the building. The openings do not have windows [25], but they have an iron bar frame and are usually covered with thick esparto blinds, allowing ventilation in addition to preventing direct entry of sunlight and subsequent indoor heating of the building. The window voids located at great height favor natural ventilation and transpiration inside the building. Additionally, there are two large round openings in the upper northwest part of the building, close to the roof, that have the function of favoring ventilation.

- The pavement is formed by long concrete flooring as distributors, and the rest of the floor is built with a mix of sand, lime, and some iron (Figure 3). Their use has traditionally been justified as a means to conserve humidity and as a passive refrigerator in the lower area, where the product is stored [16]. When the outdoor temperature is high, the sand floor is watered to reduce the temperature by evaporative cooling.

2.3. Monitoring

2.4. Analysis of the Data

3. Results

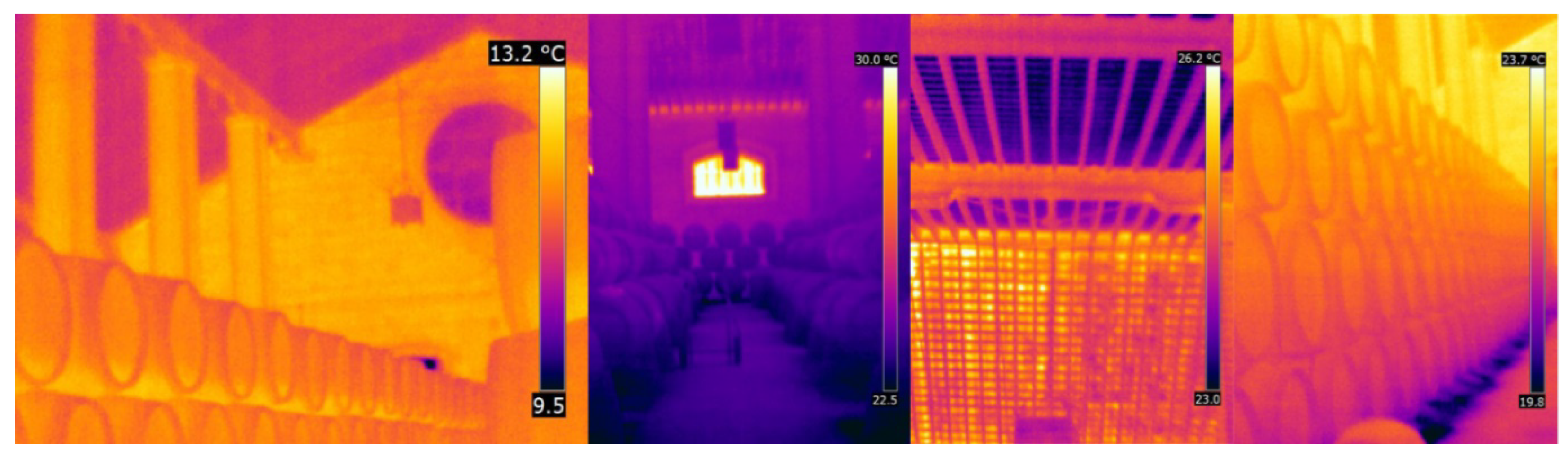

3.1. Preliminary Analysis through Thermographic Inspection

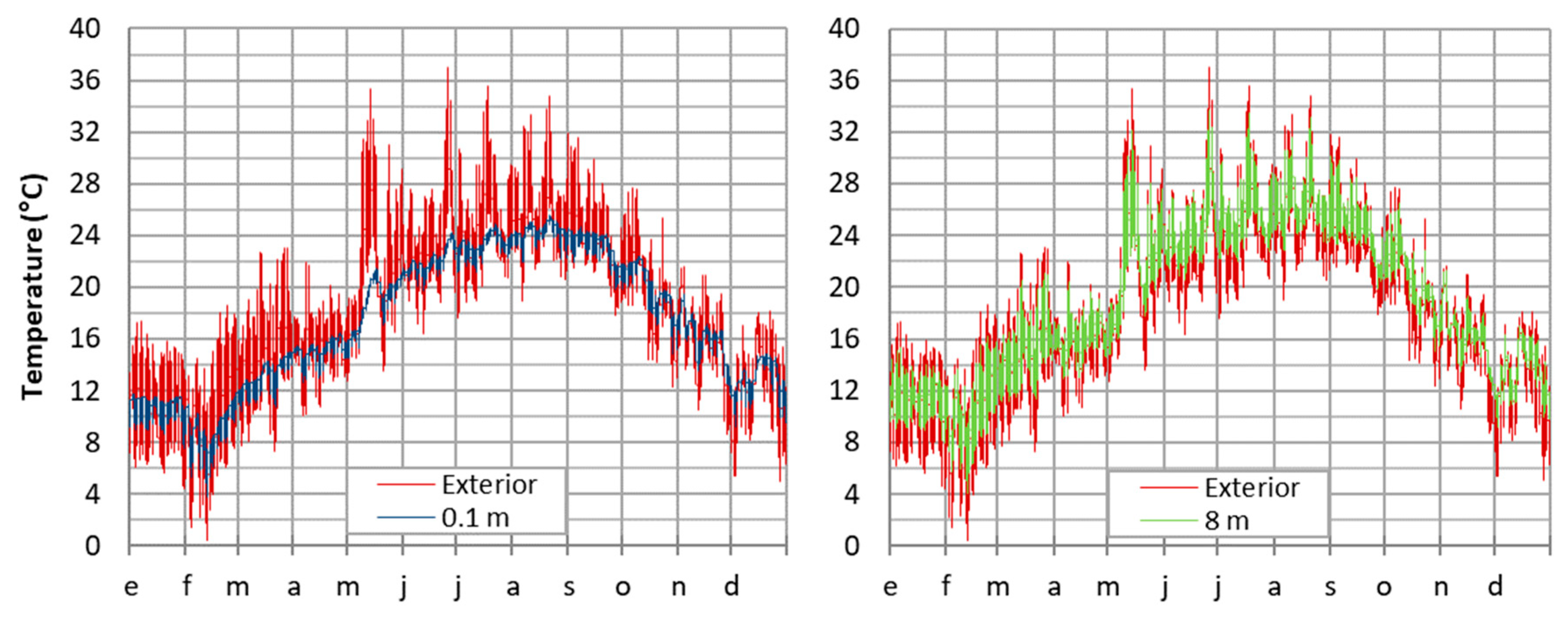

3.2. Analysis of The Data of Permanent Monitoring

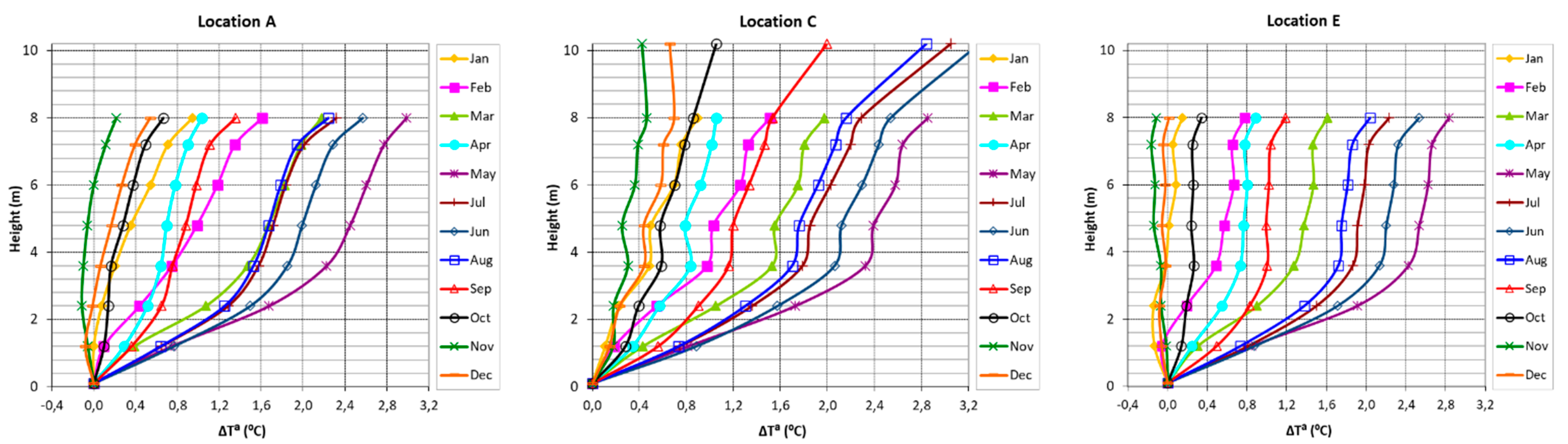

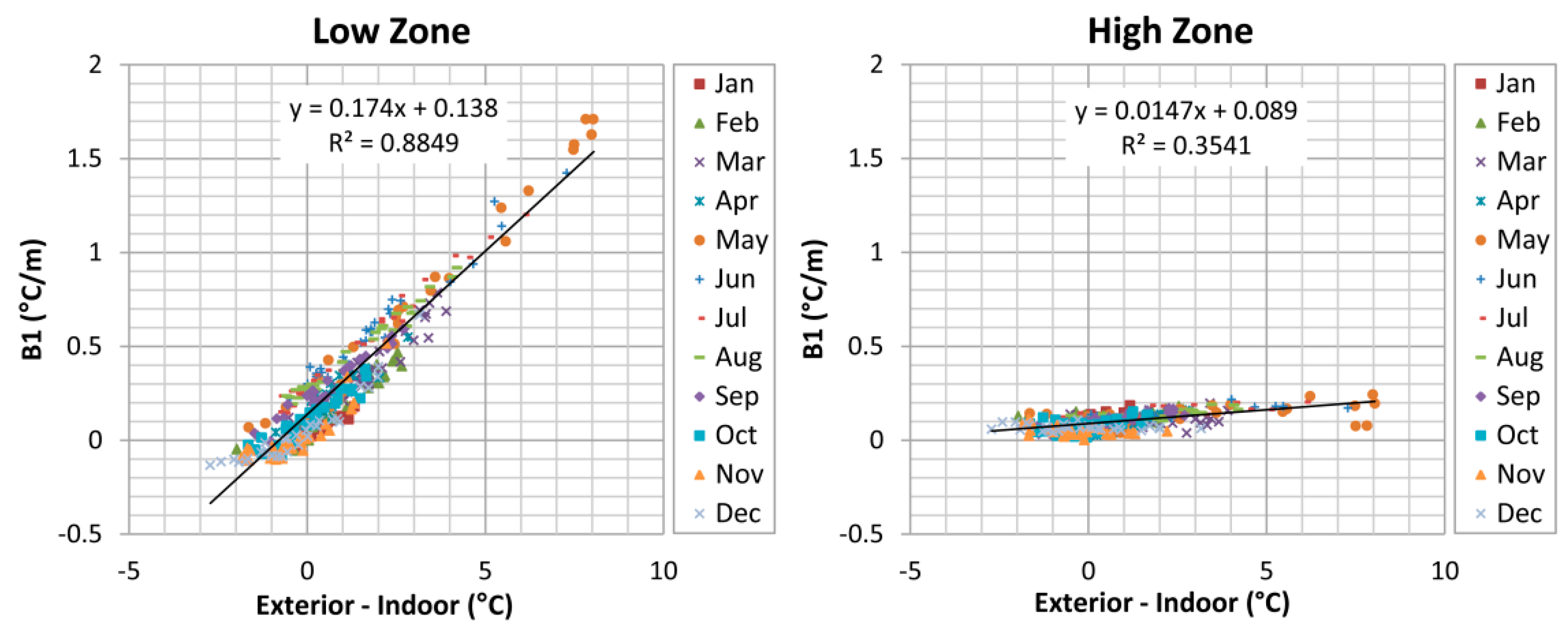

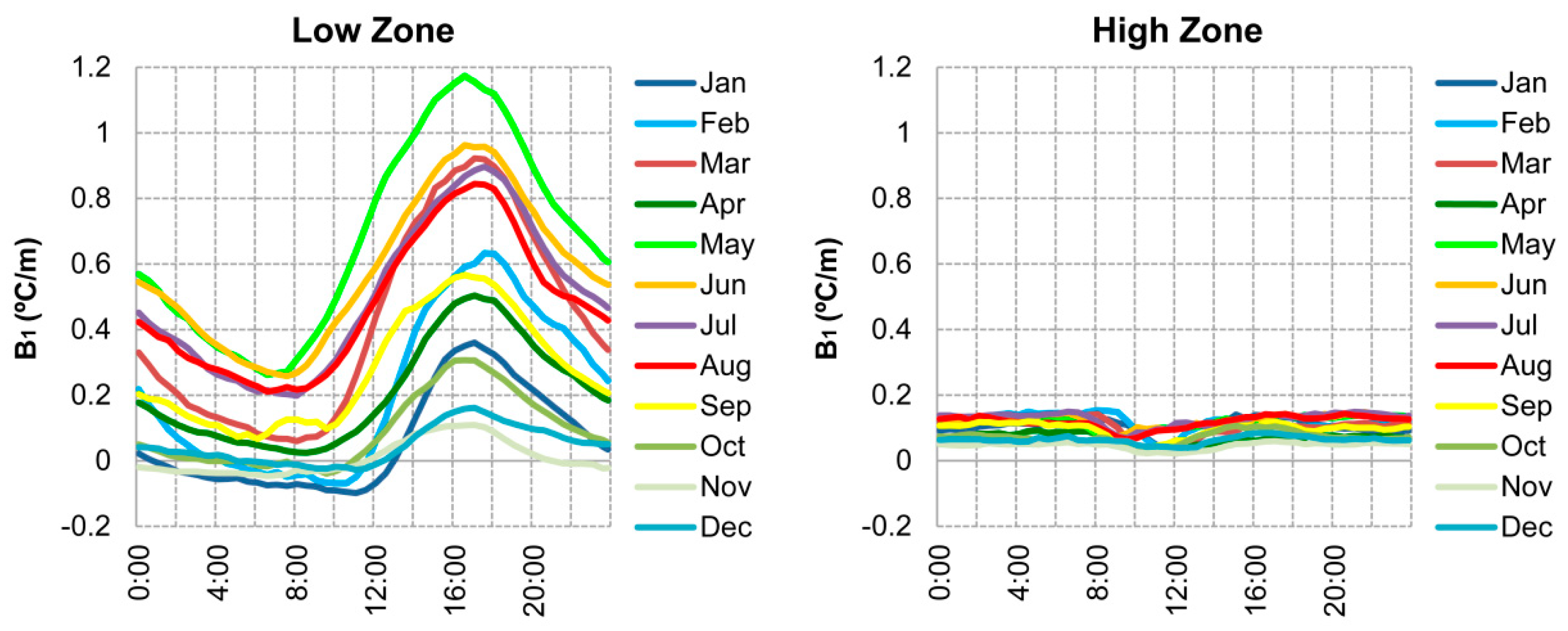

3.3. Statistical Analysis of the Vertical Stratification of the Temperature

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rodriguez-Ubinas, E.; Montero, C.; Porteros, M.; Vega, S.; Navarro, I.; Castillo-Cagigal, M.; Matallanas, E.; Gutiérrez, A. Passive design strategies and performance of Net Energy Plus Houses. Energy Build. 2014, 83, 10–22. [Google Scholar] [CrossRef] [Green Version]

- EIA. International Energy Outlook 2011; Tech. Rep. DOE/EIA-0484; Administration, E.I., Ed.; Center for Strategic and International Studies: Washington, DC, USA, 2011. [Google Scholar]

- Akbari, H.; Sezgen, O. Analysis of energy use in building services of the industrial sector in California: Two case studies. Energy Build. 1992, 19, 133–141. [Google Scholar] [CrossRef] [Green Version]

- Filippín, C.; Flores Larsen, S.; Beascochea, A.; Lesino, G. Response of conventional and energy-saving buildings to design and human dependent factors. Sol. Energy 2005, 78, 455–470. [Google Scholar] [CrossRef]

- Lam, J.C.; Yang, L.; Liu, J. Development of passive design zones in China using bioclimatic approach. Energy Convers. Manag. 2006, 47, 746–762. [Google Scholar] [CrossRef]

- Eshraghi, J.; Narjabadifam, N.; Mirkhani, N.; Sadoughi Khosroshahi, S.; Ashjaee, M. A comprehensive feasibility study of applying solar energy to design a zero energy building for a typical home in Tehran. Energy Build. 2014, 72, 329–339. [Google Scholar] [CrossRef]

- Badescu, V.; Laaser, N.; Crutescu, R.; Crutescu, M.; Dobrovicescu, A.; Tsatsaronis, G. Modeling, validation and time-dependent simulation of the first large passive building in Romania. Renew. Energy 2011, 36, 142–157. [Google Scholar] [CrossRef]

- Feist, W.; Schnieders, J.; Dorer, V.; Haas, A. Re-inventing air heating: Convenient and comfortable within the frame of the Passive House concept. Energy Build. 2005, 37, 1186–1203. [Google Scholar] [CrossRef]

- Wyon, D.; Kok, R.; Lewis, M.I.; Meese, G.B. Effects of moderate cold and heat-stress on factory-workers in Southern-Africa. 1. Introduction to a series of full-scale simulation studies. South Afr. J. Sci. 1982, 78, 184–189. [Google Scholar]

- Wyon, D.; Kok, R.; Lewis, M.I.; Meese, G.B. Effects of moderate cold and heat-stress on factory-workers in Southern-Africa. 2: Skill and performance in the cold. South Afr. J. Sci. 1982, 78, 190–197. [Google Scholar]

- Kok, R.; Lewis, M.I.; Meese, G.B.; Wyon, D. Effects of moderate cold and heat-stress on factory-workers in Southern-Africa. 3. skill and performance in the heat. South Afr. J. Sci. 1982, 78, 306–314. [Google Scholar]

- Lewis, M.I.; Meese, G.B.; Kok, R.; Wentzel, J.D.; Wyon, D. Effects of moderate cold and heat-stress on factory-workers in Southern-Africa. 4. skin temperature oral temperature heart rate and comfort vote. South Afr. J. Sci. 1983, 79, 28–37. [Google Scholar]

- Meese, G.B.; Kok, R.; Lewis, M.I. Effects of moderate cold and heat-stress on factory-workers in Southern-Africa. 5. comparison between naive and skilled workers. South Afr. J. Sci. 1984, 80, 517–526. [Google Scholar]

- Kok, R.; Lewis, M.I.; Meese, G.B. Effects of moderate cold and heat-stress on factory-workers in Southern-Africa. 6. performance and physiological reactions to increased humidity. South Afr. J. Sci. 1988, 84, 50–63. [Google Scholar]

- Kumar, S.; Mathur, A.; Singh, M.K.; Rana, K.B. Adaptive thermal comfort study of workers in a mini-industrial unit during summer and winter season in a tropical country, India. Build. Environ. 2021, 197, 107874. [Google Scholar] [CrossRef]

- Ambrosy, l.G.d.B. Las Bodegas Del Vino de Jerez; Agrarias, I.N.d.I., Ed.; Mº Agricultura, Pesca y Alimentación: Madrid, Spain, 1984. [Google Scholar]

- Ángeles Pozo-Bayón, M.; Victoria Moreno-Arribes, M. Chapter 2-Sherry Wines. In Advances in Food and Nutrition Research; Ronald, S.J., Ed.; Academic Press: Cambridge, MA, USA, 2011; pp. 17–40. [Google Scholar]

- Jackson, R.S. 9-Specific and Distinctive Wine Styles. In Wine Science, 3rd ed.; Jackson, R.S., Ed.; Academic Press: San Diego, CA, USA, 2008; pp. 520–576. [Google Scholar]

- Mazarrón, F.R.; Cid-Falceto, J.; Cañas, I. Ground Thermal Inertia for Energy Efficient Building Design: A Case Study on Food Industry. Energies 2012, 5, 227–242. [Google Scholar] [CrossRef]

- Mazarrón, F.R.; Cañas, I. Seasonal analysis of the thermal behaviour of traditional underground wine cellars in Spain. Renew. Energy 2009, 34, 2484–2492. [Google Scholar] [CrossRef]

- Mazarrón, F.R.; Cid-Falceto, J.; Cañas, I. An assessment of using ground thermal inertia as passive thermal technique in the wine industry around the world. Appl. Therm. Eng. 2012, 33–34, 54–61. [Google Scholar] [CrossRef]

- Armstrong, M.; Chihata, B.; MacDonald, R. Cold Weather Destratification Energy Savings of a Warehousing Facility. In Ashrae Transactions 2009, Proceedings of the ASHRAE 2009 Annual Meeting: Louisville, KY, USA, 20–24 June 2009; Volume 115, pp. 513–518.

- Mazarrón, F.R.; López-Ocón, E.; Garcimartín, M.A.; Cañas, I. Assessment of basement constructions in the winery industry. Tunn. Undergr. Space Technol. 2013, 35, 200–206. [Google Scholar] [CrossRef]

- Porras-Amores, C.; Mazarrón, F.; Cañas, I. Study of the Vertical Distribution of Air Temperature in Warehouses. Energies 2014, 7, 1193–1206. [Google Scholar] [CrossRef] [Green Version]

- Richard Glass, C.; Walters, K.F.; Gaskell, P.H.; Lee, Y.C. Recent advances in computational fluid dynamics relevant to the modelling of pesticide flow on leaf surfaces. Pest Manag. Sci. 2010, 66, 2–9. [Google Scholar] [CrossRef] [PubMed]

| Material | Thickness (m) | Density (kg/m3) | Conductivity (W/m·K) |

|---|---|---|---|

| Walls | U-Value: 0.886 W/m2K | ||

| Mortar (lime, sand, and water) | 0.025 | 2100 | 1.3 |

| Stone masonry | 0.600 | 2050 | 0.55 |

| Mortar (lime, sand, and water) | 0.025 | 2100 | 1.3 |

| Roof | U-Value: 3.125 W/m2K | ||

| Ceramic tiles | 0.0400 | 2000 | 1.00 |

| Nonventilated air chamber | 0.100 | 1.293 | 0.50 |

| Mortar (lime, sand, and water) | 0.025 | 2100 | 1.3 |

| Compact cooked clay bricks | 0.050 | 2300 | 0.82 |

| Low Area | High Area | |||||||

|---|---|---|---|---|---|---|---|---|

| Model Summary | Unstand. Coefficient | Model Summary | Unstand. Coefficient | |||||

| Month | R2 | Err | β1 | Err | R2 | Err | β1 | Err |

| Jan | 0.74 | 0.06 | 0.06 | 0.02 | 0.95 | 0.04 | 0.11 | 0.02 |

| Feb | 0.88 | 0.10 | 0.22 | 0.04 | 0.93 | 0.05 | 0.13 | 0.02 |

| Mar | 0.98 | 0.10 | 0.42 | 0.04 | 0.94 | 0.05 | 0.11 | 0.02 |

| Apr | 0.92 | 0.06 | 0.21 | 0.02 | 0.97 | 0.02 | 0.07 | 0.01 |

| May | 0.95 | 0.18 | 0.68 | 0.07 | 0.93 | 0.05 | 0.13 | 0.02 |

| Jun | 0.95 | 0.19 | 0.58 | 0.07 | 0.95 | 0.05 | 0.13 | 0.02 |

| Jul | 0.95 | 0.16 | 0.50 | 0.06 | 0.95 | 0.05 | 0.14 | 0.02 |

| Aug | 0.95 | 0.15 | 0.47 | 0.06 | 0.94 | 0.05 | 0.13 | 0.02 |

| Sep | 0.86 | 0.12 | 0.28 | 0.04 | 0.94 | 0.04 | 0.10 | 0.02 |

| Oct | 0.77 | 0.05 | 0.09 | 0.02 | 0.94 | 0.03 | 0.08 | 0.01 |

| Nov | 0.77 | 0.05 | 0.01 | 0.02 | 0.89 | 0.02 | 0.05 | 0.01 |

| Dec | 0.80 | 0.07 | 0.05 | 0.03 | 0.94 | 0.03 | 0.07 | 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navia-Osorio, E.G.; Mazarrón, F.R.; Porras-Amores, C.; Cañas, I. Industrial Buildings with Zero Energy Consumption: Cathedral Warehouse for Sherry Wines. Sustainability 2022, 14, 563. https://doi.org/10.3390/su14010563

Navia-Osorio EG, Mazarrón FR, Porras-Amores C, Cañas I. Industrial Buildings with Zero Energy Consumption: Cathedral Warehouse for Sherry Wines. Sustainability. 2022; 14(1):563. https://doi.org/10.3390/su14010563

Chicago/Turabian StyleNavia-Osorio, Eduardo Galán, Fernando R. Mazarrón, César Porras-Amores, and Ignacio Cañas. 2022. "Industrial Buildings with Zero Energy Consumption: Cathedral Warehouse for Sherry Wines" Sustainability 14, no. 1: 563. https://doi.org/10.3390/su14010563

APA StyleNavia-Osorio, E. G., Mazarrón, F. R., Porras-Amores, C., & Cañas, I. (2022). Industrial Buildings with Zero Energy Consumption: Cathedral Warehouse for Sherry Wines. Sustainability, 14(1), 563. https://doi.org/10.3390/su14010563