The Degree of Contribution of Digital Transformation Technology on Company Sustainability Areas

Abstract

1. Introduction

2. Research Background

2.1. Digital Transformation (DT)

2.2. Sustainability

3. Materials and Methods

3.1. Systematic Literature Review

3.2. Digital Enabling Technologies of DT for Company Sustainability

- (a)

- IoT (Internet of Things): these are the objects that combine information and communication without human interference. The concept of IoT service is the orchestration of a common service management network of separate systems, applications, and sensors [22].

- (b)

- Big Data and Analytics: represents information assets characterized by high volume, speed, and variety that require specific technology and analytical methods for their transformation into value; it is generally the term used for the data set that is so large or complex that traditional data processing applications are inadequate [20].

- (c)

- AI (Artificial Intelligence): artificial intelligence feeds the information used in chatbots (programmed response robots) along with machine learning techniques which allow to understand natural language and interact with users in personalized way [90].

- (d)

- Cloud Computing: multidirectional communication between production processes and products [86].

- (e)

- CPS (Cyber-Physical Systems): sophisticated ecosystem-based engineering that integrates virtual and physical environments [91].

- (f)

- 3D Printer (Additive Manufacturing): three-dimensional printing; changes the value proposition in business in manufacturing companies [60].

3.3. Analysis of Selected Articles in SLR

3.4. Degree of Contribution of DT-Enabling Technologies to Sustainability

4. Analysis and Results

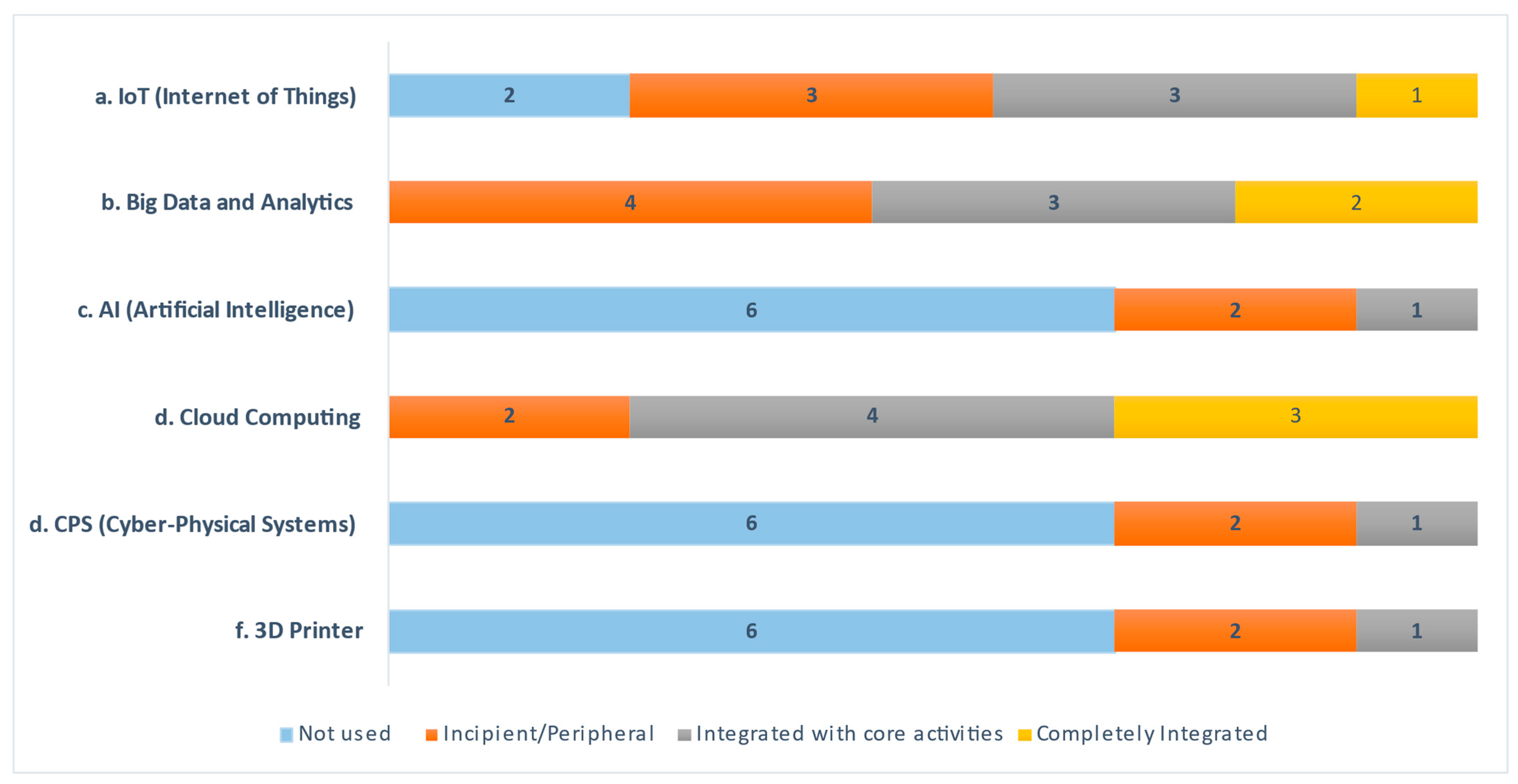

- In company 1, cloud computing, big data and analytics, and the IoT (Internet of Things) are important technologies for DT in sustainability.

- In company 2, beyond the technologies of cloud computing, big data and analytics, and the IoT (Internet of Things), CPS (cyber-physical systems) are also considered an important technology for DT in sustainability.

- In company 3, cloud computing is the most relevant in strategy for DT in sustainability, and big data and analytics, the IoT (Internet of Things), and AI (Artificial Intelligence) are relevant for DT in sustainability.

- The important technologies for the companies assessed in the subject of DT and sustainability are: IoT (Internet of Things), big data and analytics, and cloud computing.

- The technologies that are not relevant for these companies on the subject of DT and sustainability are: AI (Artificial Intelligence), CPS (Cyber-Physical Systems), and 3D printers.

- None of the six technologies in the consolidation reached the degree of “relevant”.

- IoT (Internet of Things) has a contribution grade between 7 and 8, with an “important” rating in the three companies surveyed;

- Big Data and Analytics has a contribution grade between 8 and 9, and the “important” rating was seen in the three companies surveyed;

- AI (Artificial Intelligence) has a contribution grade of 3 and a “not relevant” classification in company 1 and company 2, respectively; it has a contribution grade of 6 and an “important” classification in company 3;

- Cloud Computing has a contribution grade between 9 and 10, and a “relevant” rating was found in the three companies surveyed, being the only technology that scored a grade of 10 “relevant” in company 3;

- CPS (Cyber-Physical Systems) has contribution grade 3 and “not relevant” classification in company 1; it has contribution grade 6 and “important” classification in company 2; it has contribution grade 5 and “not relevant” classification in company 3;

- 3D Printer was rated as “not relevant” with a contribution grade of 3, 4, and 5 for company 1, company 2, and company 3, respectively.

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Author | Goal | Results | Comments |

|---|---|---|---|

| [7] Jones and Wynn | To analyze market-leading companies regarding the use of DT technologies to provide sustainability in their sectors. | The article concludes that the current sustainability objectives of technology companies are moved both by commercial reality and for altruistic reasons and that support and promotion of circular economy can offer the best opportunity for digital technologies to impact sustainable development significantly. | Concerning digital technologies to provide sustainability, cloud computing, AI, big data and analytics, intelligent sensors, adaptive robotics, and machine learning leverage the evolution of traditional factories to become efficient and sustainable smart factories. |

| [20] Wolfert et al. | To analyze the use of big data in factories and agricultural business transformation. | This analysis showed that the big data utilization started influencing the entire food supply chain, including raw materials, support to agricultural operations, and deciding on real-time and business processes redesign. | Big data’s improvements are helping farmers to improve their business profitability and effectiveness, making the agribusiness increasingly sustainable. |

| [21] Diez et al. | The aim of the article is to study digital transformation technologies and sustainability for the promotion of smart cities. | The study proposed a validation framework for smart-city projects to create an interoperability certificate, focusing on IoT technology. | Most smart cities have IoT devices as their main tool for data interoperability, through their sensors and for homogeneously storing data. Synchronism with some global Application Programming Interfaces (APIs) for stored data validation was verified. The authors concluded that due to the maturity reached by IoT technologies and their widespread presence, it is a fundamental aspect to develop urban environments. |

| [22] Hu, Chohan, and Liu | The study investigated the influence of factors in the intention of using IoT in public services by citizens. | The results of the studies show that the success of public services with IoT can be measured in the value perceived by citizens. The IoT technology was 59% positive. | This study contributed to the identification of actors related to public involvement with the IoT service, along with the description of the positive role of sustainable digital affinity with society. |

| [23] Putthiwat, Kamonchanok, and Pongsa | To research and develop digital transformation factors that can impact logistics service providers in Thailand, including the sustainability perspective. | Adopting perspectives from DT as part of a strategic transformation, companies can increase their competitive advantages and become sustainable. | DT in logistics and supply chain management represents changes in the value created by digital technologies. It means adapting strategies and processes and adaptation of facilitators, such as innovation and leadership to accomplish goals, as an increase in agility, higher productivity, and a more customer-centric approach and supply chain. Included technologies are web, cloud computing, sensors, analytics (big data), machine learning, blockchain technology, and IoT, which improve supply chain networks’ vertical and horizontal alignment. |

| [24] Hidayatno, Desttyanto, and Hulu | The research aimed to discover the systemic impact of the development and implementation of digital technologies for sustainable energy transition. | Proposal of a causal loop diagram, conceptual model, which would help better understand the variables that allow measuring the impact of Industry 4.0 technologies and quantitatively measure sustainable industrial energy in Indonesia. | Several surveys have attempted to quantitatively measure or predict the impact of Industry 4.0 technologies for sustainable industry energy. Authors summarized their research into two significant challenges, the first concerning renewable energies, which still contribute a 19.2% share of the Global Final Energy Consumption in 2016, and the second, energy efficiency. The study showed that the adoption of digital technologies of big data analytics, cloud computing, AR, AM, and others positively impacts energy efficiency. |

| [25] Brunetti et al. | The article through interviews analyzes the resistance to the implementation of digital transformation technologies in companies in the Tyrol Veneto region. | The authors for each challenge found proposed strategies that can help in the implementation of digital technologies. | Resistance is mainly related to digital culture or the implementation of new technologies, infrastructure, and technologies such as the Internet and stable networks for the application of IoT and AI associated with big data and analytics, among others. |

| [27] Feroz, Zo, and Chiravuri | Conduct a literature review for mapping DT in the scope of sustainability. | Digital technologies generate positive improvements for industry and society, as well as improvement of the environment. It is important to note that these technologies are not useful for achieving sustainability goals on their own without organizing the resources to use them. | Companies now rely on digital technologies such as AI, IoT, and big data and analytics to carry out sustainable business practices that involve reducing carbon emissions and minimizing other waste to the environment. Blockchain is considered a tool with enormous potential to achieve sustainability in business and industrial practices as it offers resources to extend the product life cycle, maximize the use of resources, and reduce carbon emissions, contributing to sustainability. |

| [30] Birkel et al. | The article proposes a framework of risks in the context of Industry 4.0 related to the Triple Bottom Line of sustainability. | This article discusses the framework based on the existing literature. Then, it proposes managerial and theoretical implications and suggests paths for future research. | The greatest concern regarding the use of technologies was AI due to its power in decision making and the possible loss of human control over them. Other risks highlighted: job loss because AI-powered technology is attributed to analyses carried out in big data, IoT, and others, making the workforce increasingly specialized. It can be seen as a sustainability risk. |

| [35] Akyazi et al. | To analyze the technologies in the European construction sector that is in the process of recovery. | It concluded that the European civil engineering sector needs to upgrade the skills of its workforce so that it can grow steadily and be a competitive industry, as it used to be in the past. | The development of smart digital technologies (AI, ML, big data and analytics, robotics, IoT, 3D printer, and others) facilitates a new phase of automation for this industry. Some of the innovations in construction are Building Information Modeling (BIM), sensor systems, smart materials, drones, etc. The results are reflected in the reduction of construction cost due to zero waste (sustainability). |

| [40] Waibel et al. | To analyze the social and environmental impact of digital transformation technologies. | This analysis showed that technology made maintenance easier, and from the environmental perspective, impacts tend to be reduced since technology promotes higher sustainability. | Authors state that big data, cloud, and IoT have been integrating systems that facilitate maintenance by people around the globe. In addition, those technologies improve data availability and predictability, contributing to sustainability and anticipating planning regarding the environment. |

| [41] Kenett, Zonnenshain, and Fortuna | To review data analytics and how it provides support to sustainable and advanced manufacturing. | Since Data Science is a multidisciplinary science, authors proposed a road map for analysis and techniques for sustainable advanced manufacturing. | Big data and analytics technology has great potential to deepen the understanding of phenomena that range from physical and biological to human and behavioral systems. Furthermore, with the union of mathematical algorithms, big data and analytics technology combined with IoT promotes sustainable manufacturing which means manufacturing processes with lower energy consumption and greater efficiency and real-time resource consumption monitoring. |

| [42] Luthra and Mangla | To demonstrate the challenges faced in implementing I4.0 (DT) technologies in the context of sustainability. | Using the AHP method, the authors identified four dimensions of changes that the introduction of digital technologies causes and challenges it brings. The focus of the study was the supply chains of Indian manufacturing companies. | IoT is a challenge because of the lack of global standards and data sharing protocols and poor Internet connectivity. Due to the low quality of the data, big data and analytics can cause huge security problems. These risks are also incurred in relation to the sustainability of the studied companies. |

| [43] Bressanelli et al. | To analyze if digital technology supports the circular economy paradigm. | Results from the proposed framework and applied case study show that digital transformation technologies can support the circular economy. | IoT technology transforms standalone products into intelligent and connected ones, and through it, companies can perform real-time monitoring of them. Big data and analytics can positively improve the management for the benefit of CE. CE paradigms promote sustainability. |

| [45] Dakhnovich, Moskvin, and Zeghzda | The article shows industrial safety challenges of Sustainable Industrial Control Systems (ICS) for Digital Transformation (DT). | It proposed an approach based on “garlic” routing principles to secure communications and provide a stable manufacturing process due to information failures, availability, and integrity between different segments. | The main challenge in providing security in digital manufacturing is keeping production sustainable by using IoT and other digital technologies. However, the authors raised the concern that not all companies can use big data systems with the IoT, placing the information directly in cloud computing, causing risks regarding information leakage. |

| [48] Savastano et al. | The goal was to verify the bibliographic database, providing a systematic literate review regarding Digital Transformation (DT). | Despite the concept and proposed technologies being new, authors concluded that they have accelerated industries and that there are also signs of growth in academic research. | Results show that the most widespread technologies in DT are: 3D printer, IoT, robotics, big data, cloud computing, and CAD tools. It shows that additive manufacturing uses most of these technologies, and it comes from smart factories. Additionally, sustainability is a motivator for adopting smart factories. |

| [50] Braccini and Margherita | To explore the industry organizational sustainability based on the TBL (Triple Bottom Line). | Results show that I4.0 technologies support the three sustainability dimensions (social, economic, and environmental). | The case study showed an increase in the balance sheet, a reduction in production lead time and energy consumption, and increased product quality and tracking of the production process. The technologies were CAD tools, 3D printer, IoT, big data and analytics, and robotics. |

| [51] Wang, Xu, and Ren | The article proposes the introduction of smart factory techniques for coal mining in China, called smart mining. | The article verifies that some problems still cannot be solved unless some technologies get better. However, the combined use of the new Industry 4.0 technologies already solves some of the problems encountered by miners in China. | The proposal was for coal mines to carry out the acquisition of information and fusion technology through IoT, automation, AI, big data and analytics, and cloud computing as a high-precision security platform. It verifies the mines are changing, allowing quick access in case of accidents, including through on-site sensors. The use of 3D printers aids in the geographic mapping of mines, and these analyses can evolve into unmanned mining through the use of robots and autonomous machines based on AI. |

| [53] Ávila-Gutiérrez et al. | The article proposes a framework for sustainability in line with the objectives of the 2020 Agenda for Sustainable Development. | The research presented a framework that supports the entire life cycle of systems and standardizes the circular economy (CE) as a paradigm of sustainability. | The Circular Economy (CE) is identified as a paradigm of sustainability and is characterized by its teleological, epistemological, ontological, axiological, and methodological aspects. The synergy of implementing sustainability through the CE paradigm in conjunction with Digital Transformation (DTY) allows for the use of a wide range of efficient techniques and tools. The article mentions technologies such as: IoT, CPS, robotics, AI, VR, AR, ML, and 3D printer. |

| [54] Pencarelli | Article aim is to analyze how tourism is changing with digital technology use. | The article found that Tourism 4.0 or smart tourism is being created by incorporating digital technologies and changing tourists’ experiences. | Smart tourism, as it is also called, aims at sustainable use and is based on technologies such as IoT, connectivity, AR, VR, and AI. A new tourist experience can be offered in pre-sale through Web 4.0, and all digital networking platforms and their experiences can capture tourists’ tastes and desires. Smart tourism is distinguished by scientific and technological innovations that are oriented toward people and sustainability. |

| [56] Kunkel and Matthess | The aim of the article is to study the risks of employability of digital technologies in the territory of Sub-Saharan Africa and the risks involved in the adoption of these technologies. | The analysis showed that policies express a wide range of vague expectations with more focus on the positive indirect impacts of the use of ICTs, the so-called green ICTs, for example, to increase efficiency and resource management, rather than the direct negative impacts of ICTs, such as electricity consumption. | There is a growth in energy use due to the creation of data centers and servers. On the other hand, with regard to resource efficiency, the study pointed out that it is possible that 3D printers have been increasing their efficiency in industry productions, with big data and analytics technology being identified as the main technology for the production of renewable energy. |

| [58] Ávila-Gutiérrez et al. | Proposed a circular business model (CE) based on Eco-Holonic Architecture to manage the complexity of integrating circular economy principles. | The study showed that the main enabling technologies for digital transformation in business are CPS to monitor and control it in real time, big data and analytics using AI for intelligent manufacturing creation, and use of robotics, VR, cloud computing, and LM, among others. | The objective of sustainability and CE is to naturalize technical systems from events that occur in the natural world. The main challenge for this approach is to bring the dynamics of natural operation (of natural ecosystems) to the industrial sector so that the rational use of natural resources occurs according to the rhythm of renewal, respect, and cooperation with nature. |

| [59] Ng and Ghobakhloo | The article reports the ways in which Industry 4.0 offers opportunities related to energy sustainability and how this happens. | The results indicate that there are sophisticated relationships of precedence between numerous energy sustainability functions of Industry 4.0. | It points out that intelligent automation, IoT, and CPPS can accelerate the deployment of sustainable energy in the manufacturing environment. In the energy transformation sector, the implementation of smart grids offers better energy management capabilities, and monitoring equipment and sensors offer the opportunity for production efficiency. AI supports energy sustainability through deep mining of existing data and decision making with big data and analytics technology. |

| [60] Godina et al. | The authors studied digital transformation technologies in the context of additive manufacturing which is a central element of the fourth industrial revolution. | The authors concluded that additive manufacturing technology or smart factories, when combined with other technology concepts from Industry 4.0, will revolutionize the production scenario. | They presented the benefits of IoT associated with the use of big data and analytics technology, allowing the monitoring and optimization of processes in real time. Smart factories are strongly supported by digital transformation technologies which are: AI, robotics, IoT, and big data and analytics. In this way, active manufacturing is not limited to the development of a new design, as it offers products with better performance, less waste, and adaptable production. |

| [61] Beier et al. | The objective is a literature review to verify the alignment of digital transformation technologies with sustainable development. | Industry 4.0 is not a single technology but a socio-technical concept in which technological, social, and organizational aspects interact. Effects of individual aspects do not necessarily allow conclusions to be drawn about the overall impacts on the overall sustainability system concept. | Big data and analytics have helped transform large amounts of raw data into useful information and technically support automations, making them increasingly sustainable. Through machine networks, Industry 4.0 increasingly allows for interconnectivity, with the use of RFID, cloud computing, and IoT. Systemic studies in a value chain located in a wide system become necessary to reliably estimate the real implications for the sustainability of the industrial concept. |

| [62] Bai et al. | In a case study, the authors verified whether Industry 4.0 technologies, such as AI, AR, autonomous robots, big data and analytics, blockchain, cloud computing, cyber security, IoT, nanotechnology, RFID, sensors, and simulation, could be classified as sustainable from the objectives of the SDGs and for different sectors. | The results show that despite being treated as a group of Industry 4.0 technologies, they are observed with greater granularity by each sector. Studies show that there are so-called trade-offs in some impacts, which does not allow for an exact measurement. | The authors argued that companies need to consider the contribution of digital technologies to sustainability. For example, nanotechnology is more sustainable in the automotive sector. IoT, big data and analytics, cloud computing, and AI are more used for sustainability in smart factories and agriculture. |

| [64] Furstenau et al. | To analyze whether scientific efforts are focused on solving existing problems to promote sustainable development. | The results show that scientific efforts are focused on driving the economic and environmental fields and highlight the lack of efforts related to social aspects. | The growing number of studies that relate Industry 4.0 and sustainability proves the strong relationship between the themes, characterizing sustainability as one of the pillars of intelligent manufacturing. To this end, this movement must be supported by big data and analytics, CPS, 3D printers, AI, VR, IoT, and robotics technologies to promote sustainability. |

| [67] Hrustek | Analyze the literature in the area of sustainability and agriculture led by Industry 4.0 digital technologies. | The analysis showed the high relevance of the subject in academic and national circles. Secondly, the concepts of sustainable agriculture and sustainability-oriented agriculture in the context of digital transformation were analyzed, and it was shown that transformed agriculture can successfully deal with today’s challenges. Finally, guidelines were defined for sustainable development driven by agriculture through the determinants of digital transformation. | By using 3D printer technology, it will be possible to ensure food security because it will be automatically controlled in every part of the supply chain through sensors. The benefits of applying digital technologies are definitely not in question, and big data and analytics, IoT, AI and ML systems, blockchain, and CPS are already applied. Global challenges such as climate change and global warming, drastic weather disasters, and unexpected disruptions are a growing problem in the economy. This gives one the reason to explore new and advanced possibilities of digital technologies. |

| [68] Fekete and Rhyner | Provide a conceptual overview of the impacts of DT on social vulnerability and human risk groups that should be reconsidered to include not only existing physical humans but also their digital extensions. | The study showed that sustainable development and the interdependencies between humans and technologies have been causing an increase in products and services, especially in information technology and electricity, which is aggravated in times of crisis and is already one of the main vulnerabilities of human societies. | DT concerning risk and security research includes developments in the fields connected to the Internet, mobile devices, AI, robotics, and IoT. The application of new digital products is already being widely used in disaster risk management in certain fields. |

| [70] Rossato and Castellani | Conduct a study on the longevity of some companies and the factors that have kept them so long lasting and their integration with DT technologies and Industry 4.0. | The study found that the longevity of companies comes first and foremost from their continuous and family management, and in recent years, the inclusion of digital technologies and sustainability has kept companies at a competitive advantage in the marketplace. | They considered new technologies called SMACIT (Social, Mobile, Analytics, Cloud Computing, and IoT) and other technologies such as AI, blockchain, robotics, and VR to form an operational backbone with the business resources that ensure the efficiency, scalability, reliability, quality, and predictability of core operations. A digital service platform and business capabilities facilitate the fast development and implementation of innovations. |

| [72] Sartal et al. | Conduct an SLR to analyze sustainable manufacturing through Industry 4.0 technologies. | It was analyzed that Industry 4.0 technologies promote, regarding ecology, the reduction of waste generation through recycling and the sustainable use of energy. From the economic point of view, the interconnection of processes directly or indirectly causes an increase in performance and efficiency indicators and responsiveness. | The review noted a sustainable manufacturing approach through Industry 4.0 frameworks comprising three major components: technology, process integration, and sustainability. Technologies included IoT, systems integration, cloud computing, simulation systems, 3D printer, virtualization, and robotics, all promoting system integration that in turn leads to sustainability. |

| [73] Soltovski et al. | To perform a systematic literature review for an analysis of the risk points of the implementation of Industry 4.0, aiming to find the benefits and directions for a better approach to the topic. | The risks found in the research were divided into economic, social, environmental, and technological categories. Within the points addressed, issues related to cyber security were the most commented upon; on the other hand, environmental issues were in the lower ranks, such as the increase in consumption of natural resources and the increase in electronic waste. | For the authors, from a business perspective, a great technological advance can be detrimental to the companies as well as to the whole society involved. The most commonly cited digital technologies in the study were: CPS which are digital systems that manage the physical and virtual world, IoT, big data analytics, cloud computing, cyber security, AR, simulation, ML, and 3D printer (additive manufacturing). |

| [74] Molina et al. | Bringing the vision of digital transformation to Spanish ports that aim to promote sustainability and environmental quality. | The research result shows that the Blue Ocean strategy is considered the most ideal for Spanish ports. | Smart ports, as they have been called, cover a multitude of aspects and variables, technologies such as automation, digitalization, IoT, interoperability, transparency, decentralization, and customer experience. |

| [75] Elavarasan et al. | To develop a guide to direct the post-pandemic COVID-19 scenario toward the sustainable path and achievement of the 17 UN goals (SDGs). | The result shows that SDG7 is the basic goal compared to the others in a scenario where there was no pandemic and that mapping sustainable energy to the world is the first goal that must be achieved. | The need for transformation is deeply rooted and aspects of transformation are discussed in various regards, such as smart grid, blockchain, the role of AI, ML, IoT, and others. |

| [80] Tsai and Lai | This study, which was based on production data from a paper company, aimed to propose a mathematical programming decision model that integrates green manufacturing technologies, activity-based costing (ABC), and the theory of constraint (TOC). | The evidence from this study should improve the paper industry’s competitiveness and provide insights into the value of an integrated mathematical programming model applied to decisions regarding products. | Authors noted that, with the characteristics of IoT and CPS, items such as sensors, machines, products, supply chain, and customers can be interconnected. They concluded that, in finding the most profitable product mix, companies are often limited by their short-term resources, which affects the company’s profit goal, and that digital technologies significantly improve the efficiency of business operations and its sustainability. |

| [83] Ivascu | To propose a hierarchical framework for sustainability assessment in manufacturing industries in Romania. | The research showed that among the most important benefits are: cost reduction, competitiveness, demand for partners, financial benefits, flexibility, reliable operation, and production interruptions. The barriers refer mainly to lack of financial resources, skills, supply chain sizing, and employee resistance. | The results of this research refer to the presentation of the relationship between circular economy and Industry 4.0, which includes the trend of companies toward automation and data exchange among technologies and manufacturing processes, which include CPS, the IoT, cloud computing, cognitive computing, AI, and other implications related to these fields. |

| [90] Talaviya et al. | It seeks to validate the use of AI in the agricultural environment and confirm that it is an emerging technology in the field of agriculture. | There is scope for AI exploration in areas that are still a challenge for agriculture. The challenge for the full introduction of AI is still the high cost of these platforms, making them still in the early stages of their use. | AI-based machines and equipment have taken the farming system to a different level. Recent automated system technologies such as the use of agricultural robots and drones have made a huge contribution to the agro-industry sector. As an example of sustainability, the authors presented the gaseous energy sprayer. |

References

- Tabrizi, B.; Lam, E.; Girard, K.; Irvin, V.V. Digital Transformation Is Not about Technology. Colin Anderson Productions. Available online: https://hbr.org/2019/03/digital-transformation-is-not-about-technology (accessed on 13 May 2021).

- Solis, B. The Six Stages of Digital Transformation Maturity. Custom Research by Altimeter Group on behalf of Cognizant, Altimeter. 2016. Available online: https://thedigitalminds.de/wp-content/uploads/2020/05/6-stages-of-DM-v4b.pdf (accessed on 16 November 2021).

- Biloslavo, R.; Bagnoli, C.; Massaro, M.; Cosentino, A. Business model transformation toward sustainability: The impact of legitimation. Manag. Decis. 2020, 58, 1643–1662. [Google Scholar] [CrossRef]

- Benites, L.L.K.; Polo, E.F. Sustainability as Business Strategic: The Corporate Governance and Application of the Triple Bottom Line in Masisa. Rev. Adm. UFSM Santa Maria 2013, 6, 827–841. [Google Scholar] [CrossRef][Green Version]

- Hsu, C.-C.; Tsaih, R.-H.; Yen, D.C. The Evolving Role of IT Departments in Digital Transformation. Sustainability 2018, 10, 3706. [Google Scholar] [CrossRef]

- Ribeiro, D.M.N.M.; Houneaux Junior, F.; Cunha, C.L.L.; Kaetsu, O.T.; Dionizio-Leite, P.F.; Machado Junior, C. Digital sustainability: How information and communication technologies (ICTs) support sustainable development goals (SDGs) assessment in municipalities. Digit. Policy Regul. Gov. 2021, 23, 229–247. [Google Scholar] [CrossRef]

- Jones, P.; Wynn, M. The Leading Digital Technology Companies and Their Approach to Sustainable Development. Sustainability 2021, 13, 6612. [Google Scholar] [CrossRef]

- Raut, R.D.; Mangla, S.K.; Narwane, V.S.; Gardas, B.B.; Priyadarshinee, P.; Narkhede, B.E. Linking big data analytics and operational sustainability practices for sustainable business management. J. Clean. Prod. 2019, 224, 10–24. [Google Scholar] [CrossRef]

- Lichtenthaler, U. Shared Value Innovation: Linking Competitiveness and Societal Goals in the Context of Digital Transformation. Int. J. Innov. Technol. Manag. 2017, 14, 1750018. [Google Scholar] [CrossRef]

- Lucato, W.C.; Vieira Júnior, M.; Vanalle, R.M.; Arantes Salles, J.A.A. Model to measure the degree of competitiveness for auto parts manufacturing companies. Int. J. Prod. Res. 2012, 50, 5508–5522. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Brozzi, R.; Forti, D.; Rauch, E.; Matt, D.T. The Advantages of Industry 4.0 Applications for Sustainability: Results from a Sample of Manufacturing Companies. Sustainability 2020, 12, 3647. [Google Scholar] [CrossRef]

- Madsen, D.Ø.; Berg, T. An Exploratory Bibliometric Analysis of the Birth and Emergence of Industry 5.0. Appl. Syst. Innov. 2021, 4, 87. [Google Scholar] [CrossRef]

- Matt, C.; Hess, T.; Benlian, A. Digital transformation strategies. Bus. Inf. Syst. Eng. 2015, 57, 339–343. [Google Scholar] [CrossRef]

- Kane, G.; Palmer, D.; Phillips, A. Achieving Digital Maturity. In Research Report Summer 2017; MIT Sloan Management Review & Deloittee University Press: New York, NY, USA, 2017; Available online: https://www.the-digital-insurer.com/wp-content/uploads/2017/11/1105-59180-MITSMR-Deloitte-Digital-Report-2017.pdf (accessed on 2 August 2021).

- Schallmo, D.; Williams, C. Digital Transformation of Business Models–Best Practice, Enablers and Roadmap. Int. J. Innov. Manag. 2017, 21, 740014. [Google Scholar] [CrossRef]

- Teichert, R. Digital Transformation Maturity: A Systematic Review of Literature. Acta Univ. Agric. Silvic. Mendel. Brun. 2019, 67, 1673–1687. [Google Scholar] [CrossRef]

- Kutnjak, A.; Pihir, I.; Fujan, T.M. Digital Transformation Case Studies across Industries–Literature Review. In Proceedings of the 2019 42nd International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), Opatija, Croatia, 20–24 May 2019. [Google Scholar] [CrossRef]

- Betchoo, N.K. Digital Transformation and its impact on Human Resource Management: A Case Analysis of two unrelated businesses in the Mauritian public service. In Proceedings of the IEEE International Conference on Emerging Technologies and Innovative Business Practices for the Transformation of Societies (EmergiTech), Balaclava, Mauritius, 3–6 August 2016; pp. 147–152. [Google Scholar] [CrossRef]

- Wolfert, S.; Ge, L.; Verdouwa, C.; Bogaardt, M.-J. Big Data in Smart Farming—A review. Agric. Syst. 2017, 153, 69–80. [Google Scholar] [CrossRef]

- Diez, L.; Choque, J.; Sánchez, L.; Muñoz, L. Fostering IoT Service Replicability in Interoperable Urban Ecosystems. IEEE Access 2020, 8, 228480–228495. [Google Scholar] [CrossRef]

- Hu, G.; Chohan, S.R.; Liu, J. Does IoT service orchestration in public services enrich the citizens’ perceived value of digital society? Asian J. Technol. Innov. 2020, 29, 1–27. [Google Scholar] [CrossRef]

- Putthiwat, S.; Kamonchanok, S.; Pongsa, P. Factors Influencing Digital Transformation of Logistics Service Providers: A Case Study in Thailand. J. Asian Financ. Econ. Bus. 2021, 8, 0241–0251. [Google Scholar] [CrossRef]

- Hidayatno, A.; Destyanto, A.R.; Hulu, C.A. Industry 4.0 Technology Implementation Impact to Industrial Sustainable Energy in Indonesia: A Model Conceptualization. Energy Procedia 2019, 156, 227–233. [Google Scholar] [CrossRef]

- Brunetti, F.; Matt, D.T.; Bonfant, A.; De Longhi, A.; Pedrini, G.; Orzes, G. Digital transformation challenges: Strategies emerging from a multi-stakeholder approach. TQM J. 2020, 32, 697–724. [Google Scholar] [CrossRef]

- Westerman, G.; Soule, D.L.; Eswaran, A. Building Digital-Ready Culture in Traditional Organizations. MIT Sloan Manag. Rev. 2019, 60, 59–68. [Google Scholar]

- Feroz, A.K.; Zo, H.; Chiravuri, A. Digital Transformation and Environmental Sustainability: A Review and Research Agenda. Sustainability 2021, 13, 1530. [Google Scholar] [CrossRef]

- Glavič, P.; Lukman, R. Review of sustainability terms and their definitions. J. Cleanner Prod. 2007, 15, 1875–1885. [Google Scholar] [CrossRef]

- Mcwilliams, A.; Parhankangas, A.; Coupet, J.; Welch, E.; Barnum, D.T. Strategic Decision Making for the Triple Bottom Line. Bus. Strategy Environ. 2016, 25, 193–204. [Google Scholar] [CrossRef]

- Birkel, H.S.; Veile, J.W.; Müller, J.M.; Hartmann, E.; Voigt, K.-I. Development of a Risk Framework for Industry 4.0 in the Context of Sustainability for Established Manufacturers. Sustainability 2019, 11, 384. [Google Scholar] [CrossRef]

- Guiltinan, J. Creative destruction and destructive creations: Environmental ethics and planned obsolescence. J. Bus. Ethics 2009, 89, 19–28. [Google Scholar] [CrossRef]

- Sarc, R.; Curtis, A.; Kandlbauer, L.; Khodier, K.; Lorber, K.E.; Pomberger, R. Digitalisation and intelligent robotics in value chain of circular economy-oriented waste management:A review. Waste Manag. 2019, 95, 476–492. [Google Scholar] [CrossRef]

- Ukko, J.; NasiriI, M.; Saunila, M.; Rantala, T. Sustainability strategy as a moderator in the relationship between digital business strategy and financial performance. J. Clean. Prod. 2019, 236, 117626. [Google Scholar] [CrossRef]

- Ordieres-Meré, J.; Remón, T.P.; Rubio, J. Digitalization: An Opportunity for Contributing to Sustainability from Knowledge Creation. Sustainability 2020, 12, 1460. [Google Scholar] [CrossRef]

- Akyazi, T.; Alvarez, I.; Alberdi, E.; Oyarbide-Zubillaga, A.; Goti, A.; Bayon., F. Skills Needs of the Civil Engineering Sector in the European Union Countries: Current Situation and Future Trends. Appl. Sci. 2020, 10, 7226. [Google Scholar] [CrossRef]

- Molla, A.; Abareshi, A. Green IT Adoption: A Motivational Perspective. In Proceedings of the 15th Pacific Asia Conference on Information Systems, PACIS 2011 Proceedings. 137; 2011. Available online: https://aisel.aisnet.org/pacis2011/137 (accessed on 1 September 2021).

- Nações Unidas do Brasil. Sobre o Nosso Trabalho Para Alcançar os Objetivos de Desenvolvimento Sustentável No Brasil. Available online: https://brasil.un.org/pt-br/sdgs (accessed on 1 May 2021).

- Munguia, N.; Esquer, J.; Guzman, H.; Herrera, J.; Gutierrez-Ruelas, J.; Velazquez, L. Energy Efficiency in Public Buildings: A Step toward the UN 2030 Agenda for Sustainable Development. Sustainability 2020, 12, 1212. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; Loures, E.D.E.R.; Ramos, L.F.P. Past, present and future of Industry 4.0: A systematic literature review and research agenda proposal. Int. J. Prod. Res. Taylor Fr. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Waibel, M.W.; Steenkamp, L.P.; Moloko, N.; Oosthuizen, G.A. Investigating the effects of Smart Production Systems on sustainability elements. Procedia Manuf. 2017, 8, 731–737. [Google Scholar] [CrossRef]

- Kenett, R.S.; Zonnenshain, A.; Fortuna, G. A road map for applied data sciences supporting sustainability in advanced manufacturing: The information quality dimensions. Procedia Manuf. 2018, 21, 141–148. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K. Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Saf. Environ. Prot. 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef]

- Franciosi, C.; Iung, P.; Miranda, S.; Riemma, S. Maintenance for Sustainability in the Industry 4.0 context: A Scoping Literature Review. IFAC-PapersOnLine 2018, 51, 903–908. [Google Scholar] [CrossRef]

- Dakhnovich, A.; Moskvin, D.; Zeghzda, D. An approach for providing industrial control system sustainability in the age of digital transformation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 497, 012006. [Google Scholar] [CrossRef]

- Belaud, J.-P.; Prioux, N.; Vialle, C.; Sablayrolles, C. Big data for agri-food 4.0: Application to sustainability management for by-products supply chain. Comput. Ind. 2019, 111, 41–50. [Google Scholar] [CrossRef]

- Müller, J.M. Business model innovation in small- and medium-sized enterprises-Strategies for industry 4.0 providers and users. J. Manuf. Technol. Manag. 2019, 30, 1127–1142. [Google Scholar] [CrossRef]

- Savastano, M.; Amendola, C.; Bellini, F.; D’Ascenzo, F. Contextual Impacts on Industrial Processes Brought by the Digital Transformation of Manufacturing: A Systematic Review. Sustainability 2019, 11, 891. [Google Scholar] [CrossRef]

- Türkeli, S.; Schophuizen, M. Decomposing the Complexity of Value: Integration of Digital Transformation of Education with Circular Economy Transition. Soc. Sci. 2019, 8, 243. [Google Scholar] [CrossRef]

- Braccini, A.M.; Margherita, E.G. Exploring Organizational Sustainability of Industry 4.0 under the Triple Bottom Line: The Case of a Manufacturing Company. Sustainability 2019, 11, 36. [Google Scholar] [CrossRef]

- Wang, G.; Xu, Y.; Ren, H. Intelligent and ecological coal mining as well as clean utilization technology in China: Review and prospects. Int. J. Min. Sci. Technol. 2019, 29, 161–169. [Google Scholar] [CrossRef]

- Johansson, N.; Roth, E.; Reim, W. Smart and Sustainable eMaintenance: Capabilities for Digitalization of Maintenance. Sustainability 2019, 11, 3553. [Google Scholar] [CrossRef]

- Ávila-Gutiérrez, M.J.; Martín-Gómez, A.; Aguayo-González, F.; Córdoba-Roldán, A. Standardization Framework for Sustainability from Circular Economy 4.0. Sustainability 2019, 11, 6490. [Google Scholar] [CrossRef]

- Pencarelli, T. The digital revolution in the travel and tourism industry. Inf. Technol. Tour. 2020, 22, 455–476. [Google Scholar] [CrossRef]

- Guo, H.; Nativi, S.; Liang, D.; Craglia, M.; Wang, L.; Schade, S.; Corban, C.; Hea, G.; Pesaresi, M.; Li, J.; et al. Big Earth Data science: An information framework for a sustainable planet. Int. J. Digit. Earth 2020, 13, 743–767. [Google Scholar] [CrossRef]

- Kunkel, S.; Matthess, M. Digital transformation and environmental sustainability in industry: Putting expectations in Asian and African policies into perspective. Environ. Sci. Policy 2020, 112, 318–329. [Google Scholar] [CrossRef]

- Lokuge, S.; Sedera, D.; Cooper, V.; Burstein, F. Digital Transformation: Environmental Friend or Foe? Panel Discussion at the Australasian Conference on Information Systems 2019. arXiv 2020, arXiv:2010.12034. [Google Scholar] [CrossRef]

- Ávila-Gutiérrez, M.J.; Martín-Gómez, A.; Aguayo-González, F.; Lama-Ruiz, J.R. Eco-Holonic 4.0 Circular Business Model to Conceptualize Sustainable Value Chain towards Digital Transition. Sustainability 2020, 12, 1889. [Google Scholar] [CrossRef]

- Ng, T.C.; Ghobakhloo, M. Energy sustainability and industry 4.0. IOP Conf. Ser. Earth Environ. Sci. 2020, 463, 012090. [Google Scholar] [CrossRef]

- Godina, R.; Ribeiro, I.; Matos, F.; Ferreira, B.T.; Carvalho, H.; Peças, P. Impact Assessment of Additive Manufacturing on Sustainable Business Models in Industry 4.0 Context. Sustainability 2020, 12, 7066. [Google Scholar] [CrossRef]

- Beier, G.; Ullrich, A.; Niehoff, S.; Reißig, M.; Habich, M. Industry 4.0: How it is defined from a sociotechnical perspective and how much sustainability it includes e A literature review. J. Clean. Prod. 2020, 259, 120856. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Farrukh, A.; Mathrani, S.; Taskin, N. Investigating the Theoretical Constructs of a Green Lean Six Sigma Approach towards Environmental Sustainability: A Systematic Literature Review and Future Directions. Sustainability 2020, 12, 8247. [Google Scholar] [CrossRef]

- Furstenau, L.B.; Sott, M.K.; Kipper, L.M.; Machado, E.L.; López-Robles, J.R.; Dohan, M.S.; Cobo, M.J.; Zahid, A.; Abbasi, Q.H.; Imran, M.A. Link Between Sustainability and Industry 4.0: Trends, Challenges and New Perspectives. IEEE Access 2020, 8, 140079–140096. [Google Scholar] [CrossRef]

- Andriushchenko, K.; Buriachenko, A.; Rozhko, O.; Lavruk, O.; Skok, P.; Yaroslava Leshchenko, Y.; Muzychka, Y.; Slavina, N.; Buchynska, O.; Kondarevych, V. Peculiarities of Sustainable Development of Enterprises in the Context of Digital Transformation. Entrep. Sustain. Issues 2020, 7, 2255–2270. [Google Scholar] [CrossRef]

- El Hilali, W.; El Manouar, A.; Idrissi, M.A.J. Reaching sustainability during a digital transformation: A PLS approach. Int. J. Innov. Sci. 2020, 12, 52–79. [Google Scholar] [CrossRef]

- Hrustek, L. Sustainability Driven by Agriculture through Digital Transformation. Sustainability 2020, 12, 8596. [Google Scholar] [CrossRef]

- Fekete, A.; Rhyner, J. Sustainable Digital Transformation of Disaster Risk—Integrating New Types of Digital Social Vulnerability and Interdependencies with Critical Infrastructure. Sustainability 2020, 12, 9324. [Google Scholar] [CrossRef]

- Chalmeta, R.; Santos-deLeón, N.J. Sustainable Supply Chain in the Era of Industry 4.0 and Big Data: A Systematic Analysis of Literature and Research. Sustainability 2020, 12, 4108. [Google Scholar] [CrossRef]

- Rossato, C.; Castellani, P. The contribution of digitalisation to business longevity from a competitiveness perspective. TQM J. 2020, 32, 617–645. [Google Scholar] [CrossRef]

- Lajoie-O’Malleya, A.; Bronsona, K.; Van der Burgb, S.; Klerkxc, L. The future(s) of digital agriculture and sustainable food systems: An analysis of high-level policy documents. Ecosyst. Serv. 2020, 45, 101183. [Google Scholar] [CrossRef]

- Sartal, A.; Bellas, R.; Mejıas, A.M.; García-Collado, A. The sustainable manufacturing concept, evolution and opportunities within Industry 4.0: A literature review. Adv. Mech. Eng. 2020, 12, 1–17. [Google Scholar] [CrossRef]

- Soltovski, R.; de Resende, L.M.M.; Pontes, J.; Yoshino, R.T.; da Silva, L.B.P. Um Estudo Quantitativo Sobre os Riscos da Indústria 4.0 no Contexto Industrial: Uma Revisão Sistemática da Literatura. RGD-Rev. Gestão E Desenvolv. 2020, 17, 165–191. [Google Scholar] [CrossRef]

- Molina, B.; Ortiz-Rey, M.; González-Cancelas, N.; Soler-Flores, F.; Camarero-Orive, A. Empleo de la Estrategia del Océano Azul Para Obtener Puertos 4.0. Ingeniería Y Compet. 2021, 23, 1–15. Available online: https://bibliotecadigital.univalle.edu.co/handle/10893/21379 (accessed on 29 October 2021).

- Elavarasan, R.M.; Pugazhendhi, R.; Jamal, T.; Dyduch, J.; Arif, M.T.; Kumar, N.M.; Shafiullah, G.M.; Chopra, S.S.; Nadarajah, M. Envisioning the UN Sustainable Development Goals (SDGs) through the lens of energy sustainability (SDG 7) in the post-COVID-19 world. Appl. Energy 2021, 292, 116665. [Google Scholar] [CrossRef]

- Denicolai, S.; Zucchella, A.; Magnani, G. Internationalization, digitalization, and sustainability: Are SMEs ready? A survey on synergies and substituting effects among growth paths. Technol. Forecast. Soc. Change 2021, 166, 120650. [Google Scholar] [CrossRef]

- Del Giudice, M.; Chierici, R.; Mazzucchelli, A.; Fiano, F. Supply chain management in the era of circular economy: The moderating effect of big data. Int. J. Logist. Manag. 2021, 32, 337–356. [Google Scholar] [CrossRef]

- Esses, D.; Csete, M.S.; Németh, B. Sustainability and Digital Transformation in the Visegrad Group of Central European Countries. Sustainability 2021, 13, 5833. [Google Scholar] [CrossRef]

- Kristoffersen, E.; Mikalef, P.; Blomsma, F.; Li, J. The effects of business analytics capability on circular economy implementation, resource orchestration capability, and firm performance. Int. J. Prod. Econ. 2021, 239, 108205. [Google Scholar] [CrossRef]

- Tsai, W.-H.; Lai, S.-Y. Green Production Planning and Control Model with ABC under Industry 4.0 for the Paper Industry. Sustainability 2018, 10, 2932. [Google Scholar] [CrossRef]

- Garcia-Muiña, F.E.; González-Sánchez, R.; Ferrari, A.M.; Volpi, L.; Pini, M.; Siligardi, C.; Settembre-Blundo, D. Identifying the Equilibrium Point between Sustainability Goals and Circular Economy Practices in an Industry 4.0 Manufacturing Context Using Eco-Design. Soc. Sci. 2019, 8, 241. [Google Scholar] [CrossRef]

- Çınar, Z.M.; Nuhu, A.A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine Learning in Predictive Maintenance towards Sustainable Smart Manufacturing in Industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Ivascu, L. Measuring the Implications of Sustainable Manufacturing in the Context of Industry 4.0. Processes 2020, 8, 585. [Google Scholar] [CrossRef]

- Sott, M.K.; Furstenau, L.B.; Kipper, L.M.; Giraldo, F.D.; López-Robles, J.R.L.; Cobo, M.J.; Zahid, A.; Abbasi, Q.H.; Imran, M.A. Precision Techniques and Agriculture 4.0 Technologies to Promote Sustainability in the Coffee Sector: State of the Art, Challenges and Future Trends. IEEE Access 2020, 8, 149854. [Google Scholar] [CrossRef]

- Blömeke, S.; Rickert, J.; Mennenga, M.; Thiede, S.; Spengler, T.S.; Herrmann, C. Recycling 4.0–Mapping smart manufacturing solutions to remanufacturing and recycling operations. Procedia CIRP 2020, 90, 600–605. [Google Scholar] [CrossRef]

- Felsberger, A.; Reiner, G. Sustainable Industry 4.0 in Production and Operations Management: A Systematic Literature Review. Sustainability 2020, 12, 7982. [Google Scholar] [CrossRef]

- Kondratieva, N. EU Agricultural Digitalization Decalogue. Istoriya 2021, 12, 73–84. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. Sustainable Supply Chains with Blockchain, IoT and RFID: A Simulation on Order Management. Sustainability 2021, 13, 6372. [Google Scholar] [CrossRef]

- Broadbent, S.; Cara, F. Seeking Control in a Precarious Environment: Sustainable Practices as an Adaptive Strategy to Living under Uncertainty. Sustainability 2018, 10, 1320. [Google Scholar] [CrossRef]

- Talaviya, T.; Shah, D.; Patel, N.; Yagnikc, H.; Shah, M. Implementation of artificial intelligence in agriculture for optimisation of irrigation and application of pesticides and herbicides. Artif. Intell. Agric. 2020, 4, 58–73. [Google Scholar] [CrossRef]

- Karnouskos, S.; Leitao, P.; Ribeiro, L.; Colombo, A.W. Industrial Agents as a Key Enabler for Realizing Industrial Cyber-Physical Systems: Multiagent Systems Entering Industry 4.0. IEEE Ind. Electron. Mag. 2020, 14, 18–32. [Google Scholar] [CrossRef]

- Klerkx, L.; Begemann, S. Supporting food systems transformation: The what, why, who, where and how of mission-oriented agricultural innovation systems. Agric. Syst. 2020, 84, 102901. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Jung, J.-S. The Effect of CSR Attributes on CSR Authenticity: Focusing on Mediating Effects of Digital Transformation. Sustainability 2021, 13, 7206. [Google Scholar] [CrossRef]

- Fathi, M.; Ghobakhloo, M. Enabling Mass Customization and Manufacturing Sustainability in Industry 4.0 Context: A Novel Heuristic Algorithm for in-Plant Material Supply Optimization. Sustainability 2020, 12, 6669. [Google Scholar] [CrossRef]

- Ballou, R.H. Logística Empresarial: Transportes, Administração de Materiais e Distribuição Física; Atlas: São Paulo, Brasil, 1993. [Google Scholar]

- Alvarenga, A.C.; Novaes., A.G.N. Logística Aplicada: Suprimento e Distribuição; Blucher: São Paulo, Brasil, 2000. [Google Scholar]

- Pacchini, A.P. O Grau de Prontidão das Empresas Industriais para implantação da Indústria 4.0: Um Estudo No Setor Automotivo Brasileiro. São Paulo: Universidade Nove de Julho. 2018. Available online: http://bibliotecatede.uninove.br/handle/tede/2220 (accessed on 2 August 2021).

- Marconi, M.A.; Lakatos, E.M. Técnicas de Pesquisa, Planejamento e Execução de Pesquisas, Amostragens e Técnicas de Pesquisa, Elaboração e Interpretação dos Dados, 7th ed.; Atlas: São Paulo, Brazil, 2015. [Google Scholar]

- de Oliveira Neto, G.C.; Correia, J.M.F.; Silva, P.C.; Sanches, A.G.O.; Lucato, W.C. Cleaner Production in the textile industry and its relationship to sustainable development goals. J. Clean. Prod. 2019, 228, 1514–1525. [Google Scholar] [CrossRef]

- Pigola, A.; Costa, R.P.; Carvalho, L.C.; Silva, L.F.; Kniess, C.T.; Macarri, E.A. Artificial Intelligence-Driven Digital Technologies to the Implementation of the Sustainable Development Goals: A Perspective from Brazil and Portugal. Sustainability 2021, 13, 13669. [Google Scholar] [CrossRef]

- Birkel, H.; Müller, J.M. Potentials of industry 4.0 for supply chain management within the triple bottom line of sustainability—A systematic literature review. J. Clean. Prod. 2021, 289, 125612. [Google Scholar] [CrossRef]

- Enyoghasi, C.; Badurdeen, F. Industry 4.0 for sustainable manufacturing: Opportunities at the product, process, and system levels. Resour. Conserv. Recycl. 2021, 166, 105362. [Google Scholar] [CrossRef]

- Nara, E.O.B.; da Costa, M.B.; Baierle, I.C.; Schaefer, J.L.; Benitez, G.B.; do Santos, L.M.A.L.; Benitez, L.B. Expected impact of industry 4.0 technologies on sustainable development: A study in the context of Brazil’s plastic industry. Sustain. Prod. Consum. 2021, 25, 102–122. [Google Scholar] [CrossRef]

| Explanation | |

|---|---|

| SER | Papers that do not have the constructs in the title, abstract, or keywords. |

| WF | Papers do have the constructs but without full text to be accessed. |

| NR | Papers do not have a relation to the topic, or they are comments, revisions, summaries, or proceedings. |

| LR | Exclude papers where the topic of sustainability appears but that are not related to digital transformation. |

| PR | Include papers where digital transformation is the main topic but is not related to sustainability. The constructs are used as support to cover other topics. There are the constructs but not as the focus. |

| CR | Include papers where the constructs are related to the topic and they are part of the focus. |

| # | Technology | Articles | Citations |

|---|---|---|---|

| 1 | Big Data and Analytics | [7,8,11,12,20,23,27,30,34,35,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79] | 50 |

| 2 | IoT (Internet of Things) | [7,11,12,20,21,22,23,25,27,30,34,35,40,41,42,43,44,45,46,47,48,50,51,52,53,54,56,57,58,59,60,61,62,64,65,67,68,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88] | 56 |

| 3 | AI (Artificial Intelligence) | [7,20,23,25,27,30,35,40,46,48,51,53,54,58,59,60,62,63,64,65,67,68,70,71,74,75,76,77,79,82,86,87,89,90,91,92,93] | 33 |

| 4 | Social Media | [27,57,61,68,70] | 5 |

| 5 | Cloud Computing | [7,12,20,23,27,30,42,48,50,51,54,58,59,62,63,64,65,67,70,71,72,73,83] | 23 |

| 6 | APIs | [21,65] | 2 |

| 7 | Blockchain | [23,58,60,62,70,74,75,85,86,87,88] | 11 |

| 8 | RFID | [83,88] | 2 |

| 9 | GPS | [35,54,61,85,88] | 5 |

| 10 | CPS (Cyber-Physical System) | [12,20,24,25,30,40,45,46,47,50,53,54,60,63,64,73,75,80,91] | 19 |

| 11 | AR (Augmented Reality) | [12,25,34,35,48,53,58,59,60,64,73,83,85] | 13 |

| 12 | 3D Printer (Additive Manufacturing) | [12,25,35,42,50,53,56,58,60,62,64,72,73,83,85,93] | 16 |

| 13 | Robotics | [7,20,35,42,50,53,58,70,72,83,92] | 11 |

| 14 | Smart Materials | [35,68,85] | 3 |

| 15 | VR (Virtual Reality) | [12,49,53,70,72] | 5 |

| 16 | WEB 4.0 | [49] | 1 |

| 17 | ML (Machine Learning) | [7,11,30,53,60,67,73,75,82,84] | 10 |

| 18 | Agility | [94] | 1 |

| 19 | 5G Mobile | [25] | 1 |

| TOTAL | 267 |

| Technology | Quantity Citations | % Citations | % Accumulated | Technology Classification | Digital Technology |

|---|---|---|---|---|---|

| 2 | 56 | 20% | 20% | A | IoT (Internet of Things) |

| 1 | 50 | 19% | 39% | A | Big Data and Analytics |

| 3 | 33 | 12% | 51% | A | AI (Artificial Intelligence) |

| 5 | 23 | 9% | 60% | A | Cloud Computing |

| 10 | 19 | 7% | 67% | A | CPS (Cyber-Physical Systems) |

| 12 | 17 | 6% | 73% | A | 3D Printer (Additive Manufacturing) |

| 13 | 13 | 5% | 78% | B | Robotics |

| 11 | 11 | 4% | 82% | B | AR (Augmented Reality) |

| 7 | 10 | 4% | 86% | B | Blockchain |

| 17 | 10 | 4% | 90% | B | ML (Machine Learning) |

| 4 | 6 | 2% | 92% | C | Social Media |

| 15 | 6 | 1% | 93% | C | VR (Virtual Reality) |

| 9 | 4 | 1% | 94% | C | GPS |

| 6 | 2 | 1% | 95% | C | APIs |

| 8 | 2 | 1% | 96% | C | RFID |

| 14 | 1 | 1% | 97% | C | Intelligent Material |

| 16 | 1 | 1% | 98% | C | WEB 4.0 |

| 18 | 1 | 1% | 99% | C | Agility |

| 19 | 1 | 1% | 100% | C | 5G Mobile |

| Element | Affirmation |

|---|---|

| Design—important role in designing products | New product design development for customers |

| Level | Classification |

|---|---|

| N0 | Absent |

| N1 | Low Incorporation |

| N2 | Medium Incorporation |

| N3 | Complete Incorporation |

| Dimension | Affirmation |

|---|---|

| a. IoT (Internet of Things) | (a.1) IoT is not used in any capacity at our company |

| (a.2) IoT is used only for capturing and storing data | |

| (a.3) IoT is used for capturing and storing data, and interacts with core business functionalities | |

| (a.4) IoT is used for capturing and storing data, interacts with core business functionalities, and is positively related to environmental issues | |

| b. Big Data and Analytics | (b.1) Big Data and Analytics is not used in any capacity at our company |

| (b.2) Big Data and Analytics is used in an incipient form, without generating value for the company | |

| (b.3) Big Data and Analytics provides predictive insights for results, drives real-time operational decisions and reinvents business processes | |

| (b.4) Big Data and Analytics provides predictive insights for results, drives real-time operational decisions and reinvents business processes, and is positively related to environmental issues | |

| c. AI (Artificial Intelligence) | (c.1) Artificial Intelligence is not used in any effective capacity at our company |

| (c.2) Artificial Intelligence is integrated in the business model at peripheral activities | |

| (c.3) Artificial Intelligence is integrated in the business model at both peripheral and core activities | |

| (c.4) Artificial Intelligence is integrated in the business model at both peripheral and core activities, and is positively related to environmental issues | |

| d. Cloud Computing | (d.1) Cloud computing is not used in any capacity at our company |

| (d.2) Cloud computing is integrated into the business model at peripheral activities | |

| (d.3) Cloud computing is integrated into the business model at both peripheral and core activities | |

| (d.4) Cloud computing is integrated into the business model at both peripheral and core activities and is positively related to environmental issues | |

| e. CPS (Cyber-Physical Systems) | (e.1) CPS are not used in any capacity at our company |

| (e.2) CPS are used in an embryonic or non-central aspect of the business model | |

| (e.3) CPS are integrated at the core of the business model | |

| (e.4) CPS are integrated at the core of the business model and is positively related to environmental issues | |

| f. 3D Printer (Design, Engineering, Operations of Construction, etc.) | (f.1) CPS are not used in any capacity at our company |

| (f.2) CPS are used in an embryonic or non-central aspect of the business model | |

| (f.3) CPS are integrated at the core of the business model | |

| (f.4) CPS are integrated at the core of the business model and is positively related to environmental issues |

| Level | Points | Classification | Description |

|---|---|---|---|

| N0 | 1 | Absent | There is no use of this technology. It is still being tested. |

| N1 | 2 | Low Incorporation | It is a known technology. Used in a few processes. |

| N2 | 3 | Medium Incorporation | Wide use of this technology. Important results. |

| N3 | 4 | Complete Incorporation | Completely used to support sustainability. Strategic perspective. |

| Degree of Contribution | Classification |

|---|---|

| 03–05 | Not relevant |

| 06–09 | Important |

| 10–12 | Relevant |

| Technology | Company | Degree | Classification |

|---|---|---|---|

| IoT (Internet of Things) | 01, 02 | 7 | Important |

| 03 | 8 | Important | |

| Big Data and Analytics | 01, 02 | 8 | Important |

| 03 | 9 | Important | |

| AI (Artificial Intelligence) | 01 | 3 | Not relevant |

| 02 | 4 | Not relevant | |

| 03 | 6 | Important | |

| Cloud Computing | 01, 02 | 9 | Important |

| 03 | 10 | Relevant | |

| CPS (Cyber-Physical Systems) | 01 | 3 | Not relevant |

| 02 | 6 | Important | |

| 03 | 5 | Not relevant | |

| 3D Printer | 01 | 3 | Not relevant |

| 02 | 4 | Not relevant | |

| 03 | 5 | Not relevant |

| Technology | Company 01 | Company 02 | Company 03 | Score | Classification |

|---|---|---|---|---|---|

| IoT (Internet of Things) | 7 | 7 | 8 | 7 | Important |

| Big Data and Analytics | 8 | 8 | 9 | 8 | Important |

| AI (Artificial Intelligence) | 3 | 4 | 6 | 4 | Not relevant |

| Cloud Computing | 9 | 9 | 10 | 9 | Important |

| CPS (Cyber-Physical Systems) | 3 | 6 | 5 | 5 | Not relevant |

| 3D Printer | 3 | 4 | 5 | 4 | Not relevant |

| Total Score | 5.50 | 6.33 | 7.17 |

| Technology | Company 1 | Classification | Company 2 | Classification | Company 3 | Classification |

|---|---|---|---|---|---|---|

| IoT (Internet of Things) | 7 | Important | 7 | Important | 8 | Important |

| Big Data and Analytics | 8 | Important | 8 | Important | 9 | Important |

| AI (Artificial Intelligence) | 3 | Not relevant | 3 | Not relevant | 6 | Important |

| Cloud Computing | 9 | Important | 10 | Relevant | 10 | Relevant |

| CPS (Cyber-Physical Systems) | 3 | Not relevant | 6 | Important | 5 | Not Relevant |

| 3D Printer | 3 | Not relevant | 4 | Not relevant | 5 | Not relevant |

| Technology | SDGs | Benefits |

|---|---|---|

| IoT (Internet of Things) | 3, 5, 7, 8, 9, 11, 12, 17 | Efficient processes, data sharing between robots, increased production capacity and innovation levels. |

| Cloud Computing | Process innovation and expansion. | |

| CPS (Cyber-Physical Systems) | Collaboration and resource consumption reduction. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, I.; Riccotta, R.; Montini, P.; Stefani, E.; de Souza Goes, R.; Gaspar, M.A.; Martins, F.S.; Fernandes, A.A.; Machado, C.; Loçano, R.; et al. The Degree of Contribution of Digital Transformation Technology on Company Sustainability Areas. Sustainability 2022, 14, 462. https://doi.org/10.3390/su14010462

Costa I, Riccotta R, Montini P, Stefani E, de Souza Goes R, Gaspar MA, Martins FS, Fernandes AA, Machado C, Loçano R, et al. The Degree of Contribution of Digital Transformation Technology on Company Sustainability Areas. Sustainability. 2022; 14(1):462. https://doi.org/10.3390/su14010462

Chicago/Turabian StyleCosta, Ivanir, Rosangela Riccotta, Paola Montini, Eduardo Stefani, Roberto de Souza Goes, Marcos Antonio Gaspar, Fellipe Silva Martins, Aguinaldo Aragon Fernandes, Celso Machado, Rodrigo Loçano, and et al. 2022. "The Degree of Contribution of Digital Transformation Technology on Company Sustainability Areas" Sustainability 14, no. 1: 462. https://doi.org/10.3390/su14010462

APA StyleCosta, I., Riccotta, R., Montini, P., Stefani, E., de Souza Goes, R., Gaspar, M. A., Martins, F. S., Fernandes, A. A., Machado, C., Loçano, R., & Larieira, C. L. C. (2022). The Degree of Contribution of Digital Transformation Technology on Company Sustainability Areas. Sustainability, 14(1), 462. https://doi.org/10.3390/su14010462