Carbon Footprint Calculator Customized for Rice Products: Concept and Characterization of Rice Value Chains in Southeast Asia

Abstract

:1. Introduction

- Providing a user-friendly and easily accessible tool for CF calculation tailored for the rice value chain including a value-adjusted accounting of by-products,

- Assessing typical baseline of CFs for rice products in the regional context of Southeast Asia,

- Quantifying the contribution of (i) individual stages of the value chain as well as (ii) emissions of different Greenhouse Gases, namely, CH4, N2O and CO2, to the overall CF of the rice product, and

- Providing a comparative scenario assessment of technological options in rice value chains to show the range of CFs of rice products.

2. Methods

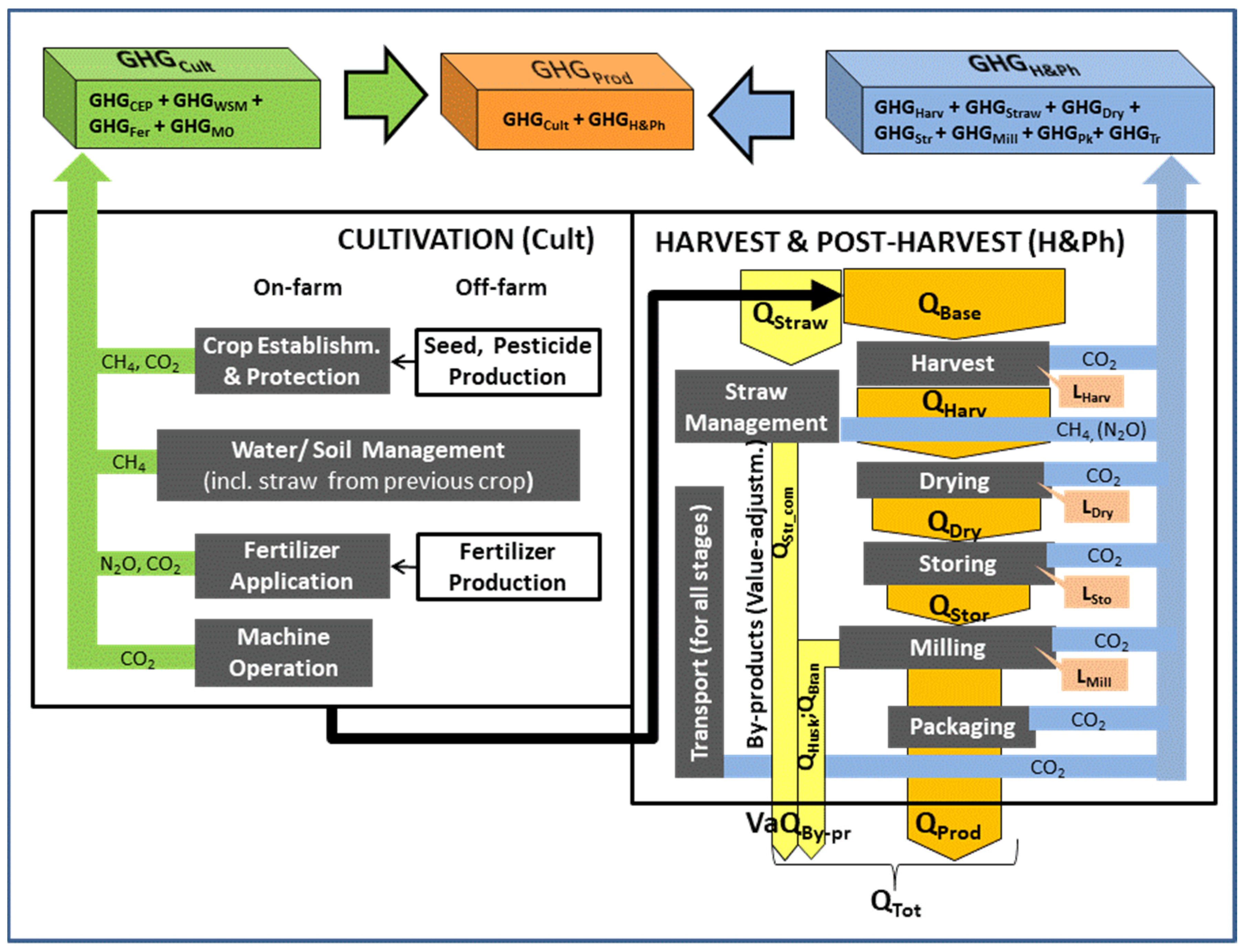

2.1. Principles of Carbon Footprint Calculation

2.2. System Boundaries

3. Results and Discussion

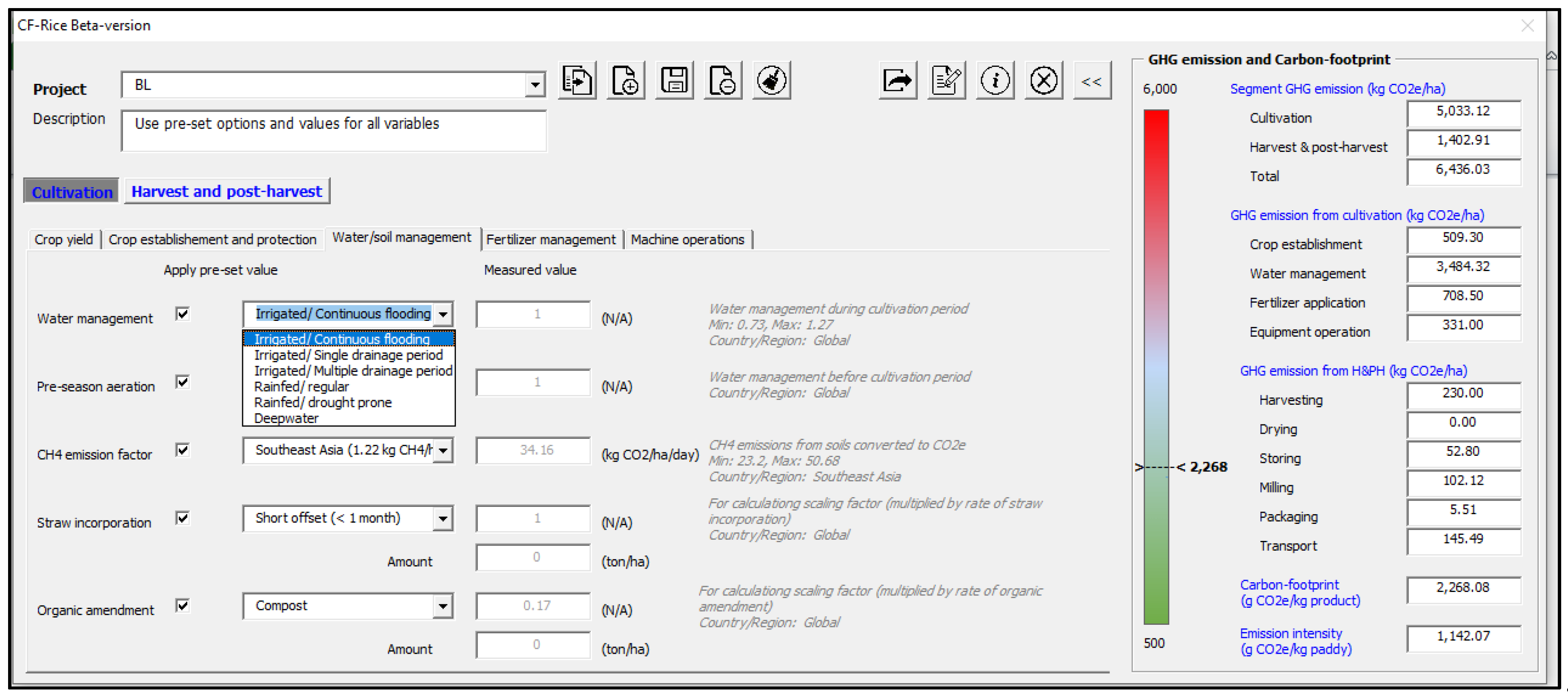

3.1. Application of CF-Rice in the Regional Context of Southeast Asia

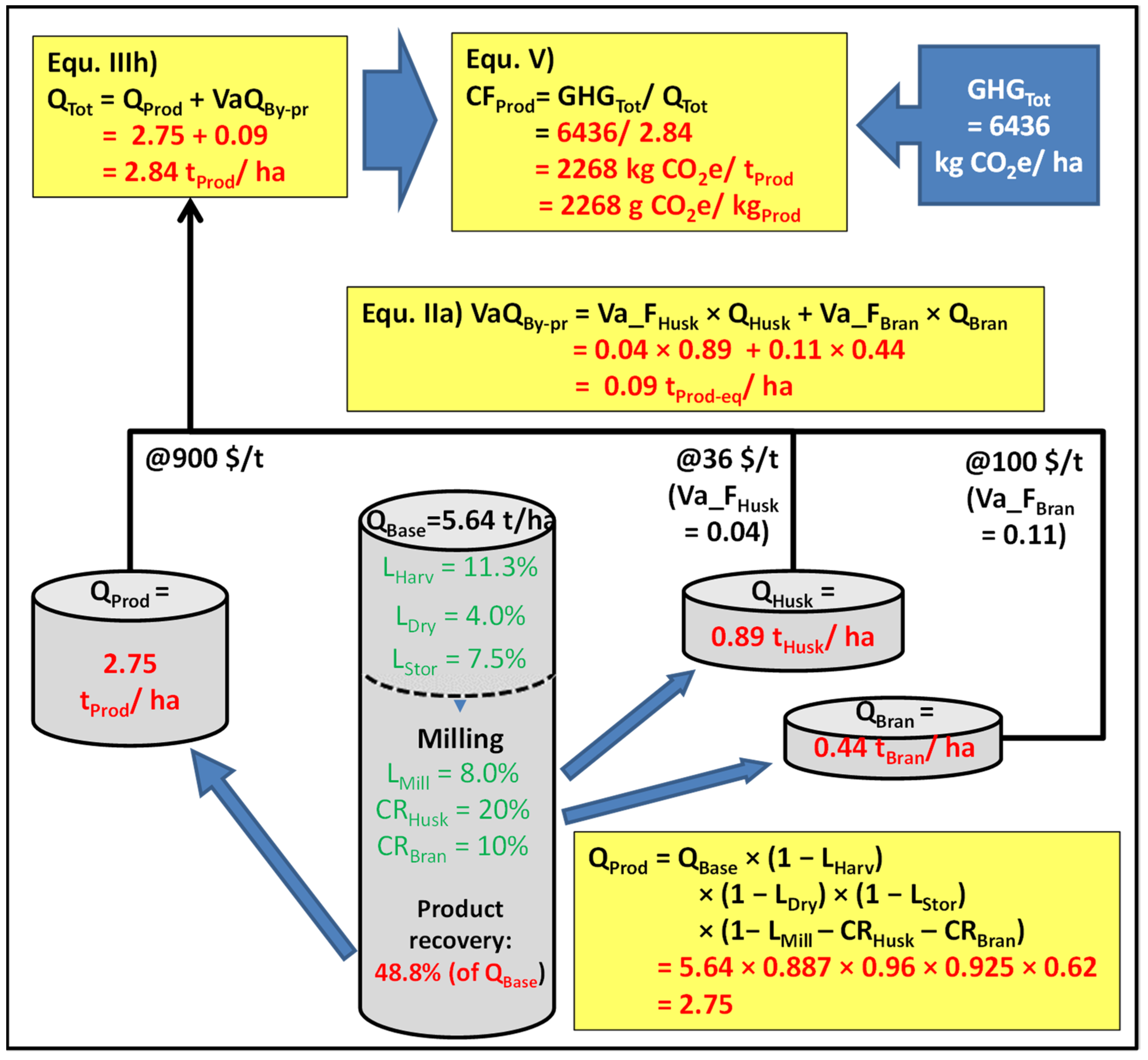

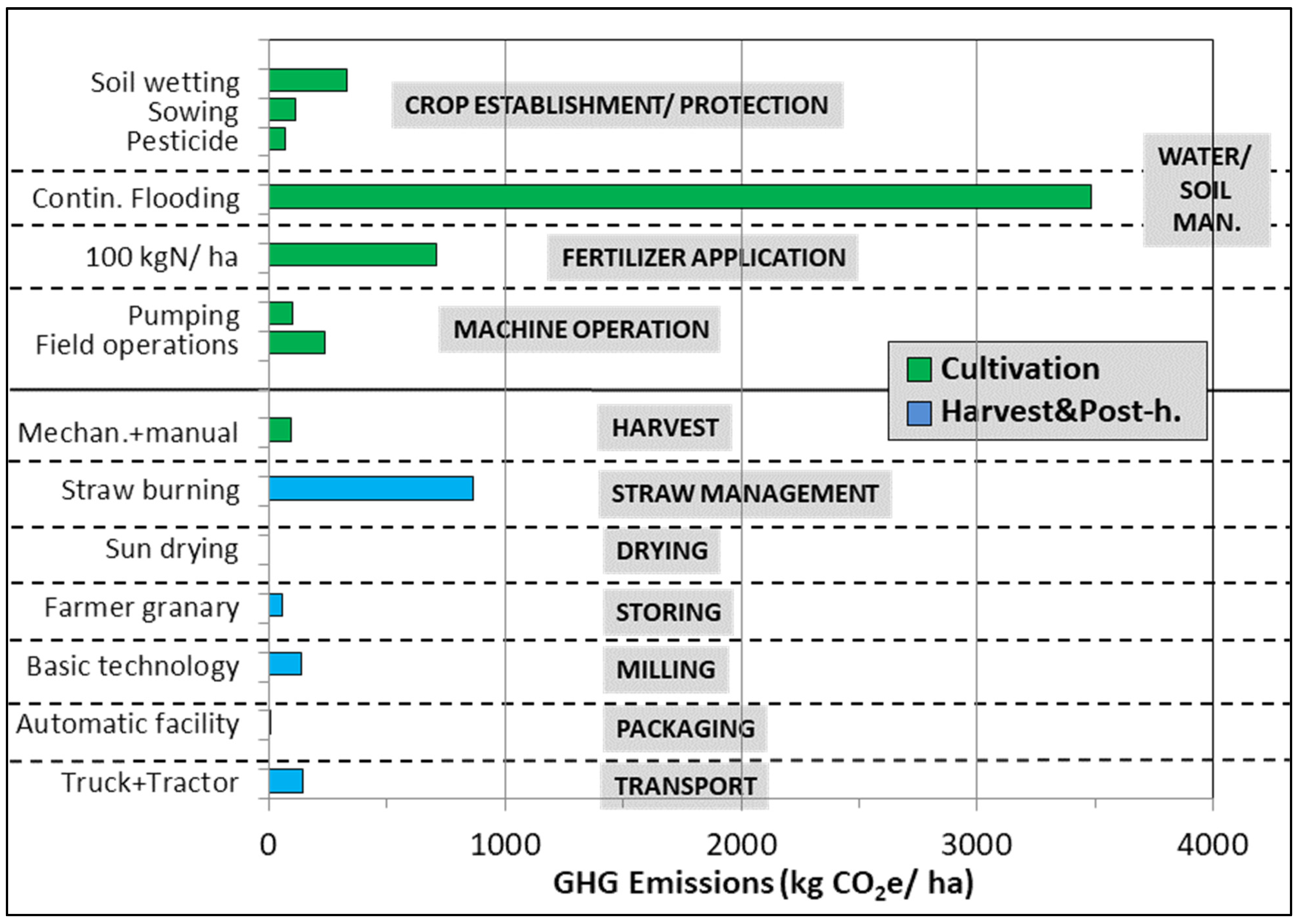

3.2. Hypothetical Baseline of the Rice Value Chain

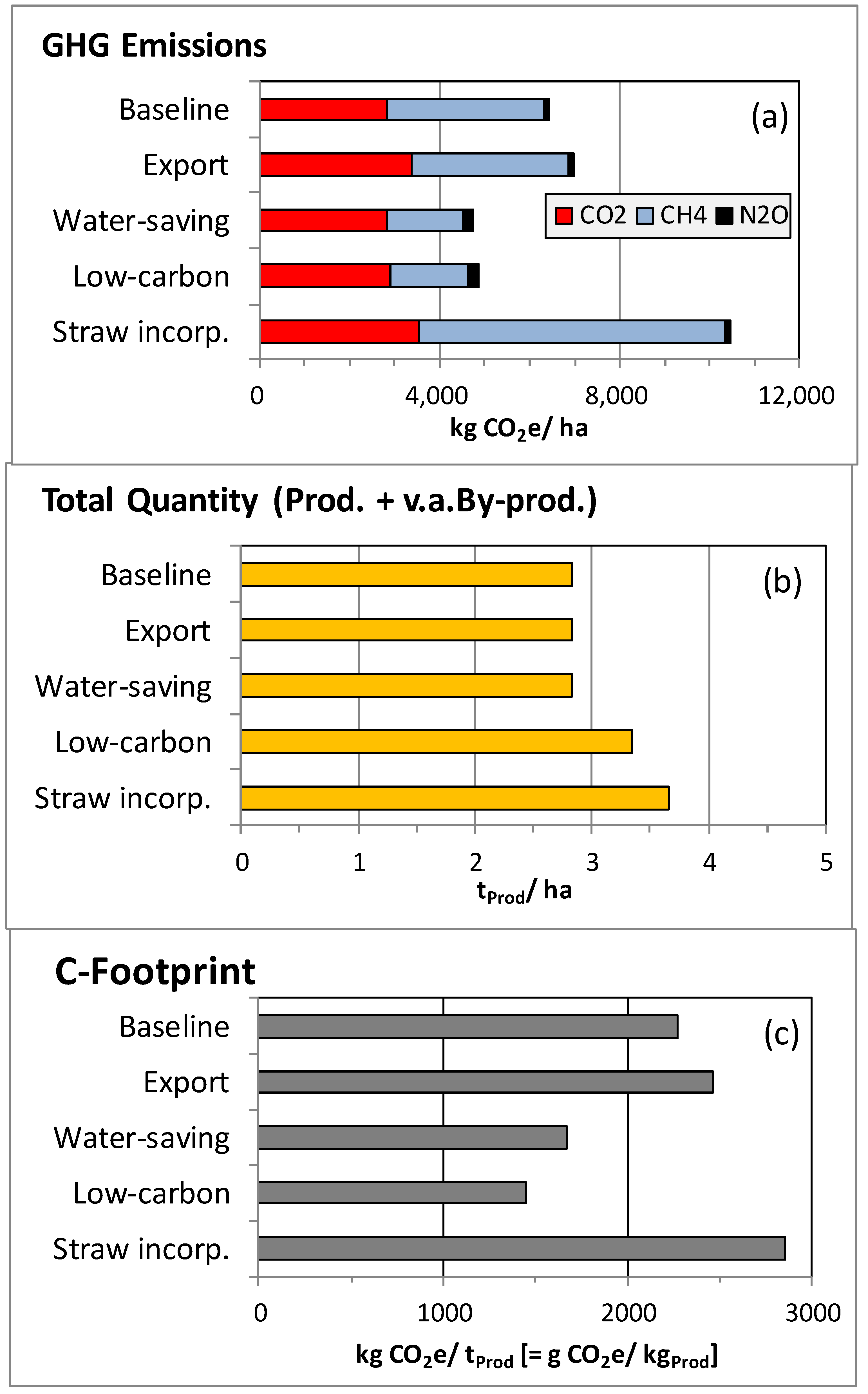

3.3. Scenario Assessment and Contributions by Different GHGs

3.4. Independent Validation through Other Calculation Tools

3.5. Literature Review of Carbon-Footprints Calculated for Rice Products

- More than half of the published studies considered GHG emissions along the full rice value chain (“from farm to shelf”) in line with the ISO definition. Many of these publications, however, show substantial differences as compared to the calculation procedure in our study, e.g., the use of distinctly high emission factors in studies leading to CFs from 3 to 6.4 kg CO2e/kgProd [37,38].

4. Conclusions

- In its current version, CF-Rice exclusively deals with the value chain of rice products which obviously limits the potential user group compared to those with specific interest in this commodity. At the same time, however, this focus on one of the most important cropping systems with high mitigation potential still targets a sizable number of potential users who will be encouraged by an easy selection of data inputs and free access to the tool.

- Given the focus on rice, we have systematically searched the literature and other open access sources to compile a comprehensive library of available CF data on the different technologies deployed in rice value chains. This technology library is embedded in the tool and encompasses empirical evidence on multiple processing options for harvest and postharvest actions that has recently been published and, thus, constitutes an update on the currently available database on rice.

- CF-Rice allows a detailed consideration of stage-specific recovery rates. In turn, the important role of yield losses for determining CFs can be assessed in much more detail.

- The CF-Rice database can be expanded by the user by adding adjusted GHG data and recovery rates from new literature sources or their own measurements. This capability broadens the versatility of using CF-Rice within any given geographical context as well as a being a tool for decision-making support, e.g., on identifying suitable investments to reduce CFs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Equation Cluster (I) Calculating the base quantity |

Assumptions:

(Ia) QBase = YHarv × (1 − MC)/(1 − 0.14)/PRRHarv Insert Equ. Ib = YHarv × (1 − MC)/(1 − 0.14)/(1-LHarv) (Ib) PRRHarv = 1 − LHarv In which, QBase = quantity of paddy in the field before harvesting (normalized to 14% moisture content), YHarv = yield of harvested (wet) paddy, PPRHarv; LHarv = Stage-specific product recovery rate and loss rate at harvest, MC = moisture content of harvested (wet) paddy |

| Equations Cluster (II) Selecting stage-specific recovery/loss rates and determining product and grain quantities |

Assumptions:

(IIa) QProd = QBase × PRRHarv × PRRDry × PRRStor × PRRMill insert Equ. IIb,c,d = QBase × (1 − LRHarv) × (1 − LDry) × (1 − LSto) × (1 − LMill − CRHusk − CRBran) (IIb) PRRDry = 1 − LDry (IIc) PRRStor = 1 − LSto (IId) PRRMill = 1 − LMill − CRHusk − CRBran In which, PRRDry; PRRStor; PRRMill = stage-specific product recovery rates for drying, storing and milling, LDry; LStor; LMill = stage-specific loss rates for drying, storing and milling, CRHusk; CRBran = commodity rate of husk and bran at milling, QProd = product quantity available in the market. |

| Equations Cluster (III) Calculating quantities of by-products followed by value-adjustment |

Assumptions:

(IIIa) VaQBy-pr = VaQStr_com + VaQHusk + VaQBran Insert Equ. IIIb, IIId, IIIf = QBase × CRStr_com × Va_FStr_com + QStor × (CRHusk × Va_FHusk+ CRBran × Va_FBran) (IIIb) VaQStr_com = QStr_com × Va_FStr_com Insert Equ. IIIc = QBase × CRStr_com × Va_FStr_com (IIIc) QStr_com = QBase × CRStr_com (IIId) VaQHusk = QHusk × Va_FHusk Insert Equ. IIIe = QStor × CRHusk × Va_FHusk (IIIe) QHusk = QSto × CRHusk (IIIf) VaQBran = QBran × Va_FBran Insert Equ. IIIg = QStor × CRBran × Va_FBran (IIIg) QBran = QSto × CRBran (IIIh) QTot = QProd + VaQBy-pr In which, VaQStr_com; VaQHusk; VaQBran; VaQBy-pr = value-adjusted quantities of straw (if traded as commodity), husk, bran and all by-products, QStraw_com; QHusk; QBran; QBy-pr = absolute quantities of straw (if traded as commodity), husk, bran and all by-products, Va_FStraw; Va_FHusk; Va_FBran = value adjustment factors of straw (if traded as commodity), husk, bran, CRStraw = commodity rate of straw (if traded as commodity), QTot = total quantity (products and value-adjusted by-products), QProd = product quantity. |

| Equations Cluster (IV) Calculating CO2-, CH4- and N2O- emissions for each stage |

Assumptions:

(IVa) GHGCEP = CO2CEP + CH4CEP (IVb) GHGWSM = CH4WSM (IVc) GHGFer = N2OFer + CO2Fer (IVd) GHGMO = CO2MO (IVe) GHGHarv = CO2Harv (IVf) GHGStraw = CO2Straw + CH4Straw (IVg) GHGDry = CO2Dry IVh) GHGSto = CO2Sto (IVi) GHGMill = CO2Mill (IVj) GHGPk = CO2Pk (IVk) GHGTr = CO2Tr In which, GHGCEP; GHGWSM; GHGFer; … GHGTr = stage-specific GHG emissions, CO2CEP; CO2Fer; CO2MO; … CO2Tr = stage-specific CO2- emissions, CH4CEP; CH4WSM; CH4Straw = stage-specific CH4 emissions, N2OFer = stage-specific N2O- emissions (only fertilizer application). |

| Equations Cluster (V) Aggregating GHG emissions for CO2, CH4 and N2O as well as for stages |

Assumptions:

+ CO2Tr (Vb) CH4Tot = CH4CEP + CH4WSM + CH4Straw (Vc) N2OTot = N2OFer (Vd) GHGTot = CO2Tot + CH4Tot + N2OTot (Ve) GHGTot = GHGCEP + GHGWSM + GHGFer + GHGMO + GHGHarv + GHGStraw + GHGDry + GHGSto + GHGMill + GHGPk + GHGTr In which, CO2Tot; CH4Tot; N2OTot = total emissions of CO2, CH4 and N2O, respectively, GHGTot = total GHG emissions. |

| Equations Cluster (VI) Calculating CF |

Assumptions:

(VI) CFProd = GHGTot/QTot Insert Equ. IIIf = GHGTot/(QProd + vQBy-pr) In which, CFProd = CF of product. |

References

- Porter, J.; Howden, M.; Smith, P. Considering agriculture in IPCC assessments. Nat. Clim. Chang. 2017, 7, 680–683. [Google Scholar] [CrossRef] [Green Version]

- Poore, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef] [Green Version]

- Hjorth, T.; Huseinovic, E.; Hallström, E.; Strid, A.; Johansson, I.; Lindahl, B.; Sonesson, U.; Winkvist, A. Changes in dietary carbon footprint over ten years relative to individual characteristics and food intake in the Västerbotten Intervention Programme. Sci. Rep. 2020, 10, 20. [Google Scholar] [CrossRef]

- Clark, M.A.; Domingo, N.G.G.; Colgan, K.; Thakrar, S.K.; Tilman, D.; Lynch, J.; Azevedo, I.L.; Hill, J.D. Global food system emissions could preclude achieving the 1.5° and 2 °C climate change targets. Science 2020, 370, 705–708. [Google Scholar] [CrossRef] [PubMed]

- Wassmann, R. Environmental Footprints of Modernization Trends in Rice Production Systems of Southeast Asia; Oxford Research Encyclopedia of Environmental Science; Oxford University Press: Oxford, UK, 2019. [Google Scholar] [CrossRef]

- Seck, P.A.; Diagne, A.; Mohanty, S.; Wopereis, M.C.S. Crops that feed the world 7: Rice. Food Secur. 2012, 4, 7–24. [Google Scholar] [CrossRef]

- Smith, P.; Clark, H.; Dong, H.; Elsiddig, E.A.; Haberl, H.; Harper, R.; House, J.; Jafari, M.; Masera, O.; Mbow, C.; et al. Agriculture, Forestry and Other Land Use (AFOLU). In Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Farahani, E., Kadner, S., Seyboth, K., Adler, A., Baum, I., Brunner, S., Eickemeier, P., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Roe, S.; Streck, C.; Beach, R.; Busch, J.; Chapman, M.; Daioglou , V.; Deppermann, A.; Doelman, J.; Emmet-Booth, J. Contribution of the land sector to a 1.5 °C world. Nat. Clim. Chang. 2021, 9, 817–828. [Google Scholar] [CrossRef]

- IPCC (Intergovernmental Panel on Climate Change). 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Institute for Global Environmental Studies (IGES): Hayama, Japan, 2006. [Google Scholar]

- IPCC (Intergovernmental Panel on Climate Change). Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Calvo Buendia, E., Tanabe, K., Kranjc, A., Baasansuren, J., Fukuda, M., Ngarize, S., Osako, A., Pyrozhenko, Y., Shermanau, P., Federici, S., Eds.; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- SRP—Sustainable Rice Platform. Sustainable Rice Platform Performance Indicators for Sustainable Rice Cultivation (Version 2.1). Bangkok. 2019. Available online: https://www.sustainablerice.org/wp-content/uploads/2021/10/203-SRP-Performance-Indicators-Version-2.1.pdf (accessed on 19 December 2021).

- Van Hung, N.; Migo, M.V.; Quilloy, R.; Chivenge, P.; Gummert, M. Life cycle assessment applied in rice production and residue management. In Sustainable Rice Straw Management; Gummert, M., van Hung, N., Chivenge, P., Douthwaite, B., Eds.; Springer Nature: Berlin/Heidelberg, Germany, 2020; pp. 161–174. [Google Scholar] [CrossRef] [Green Version]

- Janz, B.; Weller, S.; Kraus, D.; Racela, H.S.; Wassmann, R.; Butterbach-Bahl, K.; Kiese, R. Greenhouse gas footprint of diversifying rice cropping systems: Impacts of water regime and organic amendments. Agric. Ecosyst. Environ. 2019, 270-271, 41–54. [Google Scholar] [CrossRef]

- Van Hung, N.; Sander, B.O.; Quilty, J.; Balingbing, C.; Castalone, A.G.; Romasanta, R.; Alberto, M.C.R.; Sandro, J.M.; Jamieson, C.; Gummert, M. An assessment of irrigated rice production energy efficiency and environmental footprint with in-field and off-field rice straw management practices. Sci. Rep. 2019, 9, 16887. [Google Scholar] [CrossRef]

- Mainuddin, M.; Kirby, M. Spatial and temporal trends of water productivity in the lower Mekong River Basin. Agric. Water Management. 2009, 96, 1567–1578. [Google Scholar] [CrossRef]

- Gummert, M.; Hung, N.V.; Cabardo, C.; Quilloy, R.; Aung, Y.L.; Thant, A.M.; Kyaw, M.A.; Labios, R.; Htwe, N.M.; Singleton, G.R. Assessment of post-harvest losses and carbon footprint in intensive lowland rice production in Myanmar. Sci. Rep. 2020, 10, 19797. [Google Scholar] [CrossRef]

- Romasanta, R.R.; Sander, B.O.; Gaihre, Y.K.; Alberto, M.C.; Gummert, M.; Quilty, J.; Castalone, A.G.; Balingbing, C.; Sandro, J.; Correa, T., Jr.; et al. How does rice straw burning compare with other straw management practices in terms of on-field CH4 and N2O emissions? A comparative field experiment. Agric. Ecosyst. Environ. 2017, 239, 143–153. [Google Scholar] [CrossRef]

- RCB—Rice Knowledge Bank. Available online: http://www.knowledgebank.irri.org/step-by-step-production/postharvest (accessed on 19 December 2021).

- Grolleaud, M. Post-harvest losses: Discoverying the full story. In Overview of the Phenomenon of Losses during the Post-Harvest System; FAO, Agro Industries and Post-Harvest Management Service (AGSI): Rome, Italy, 2002; Available online: https://www.fao.org/3/ac301e/ac301e04.htm (accessed on 20 December 2021).

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.O.; Wernet, G. Overview and Methodology. Data Quality Guideline for the Ecoinvent Database Version 3; Ecoinvent Report 1(V3); The Ecoinvent Centre: St. Gallen, Switzerland, 2013; Available online: https://lca-net.com/files/Overview_and_methodology.pdf (accessed on 19 December 2021).

- Van Nguyen, H.; Nguyen, C.D.; van Tran, T.; Hau, H.D.; Nguyen, N.T.; Gummert, M. Energy efficiency, greenhouse gas emissions, and cost of rice straw collection in the Mekong river delta of Vietnam. Field Crop. Res. 2016, 198, 16–22. [Google Scholar] [CrossRef] [Green Version]

- Van Hung, N.; Tuan, T.V.; Meas, P.; Tado, C.J.M.; Kyaw, M.A.; Gummert, M. Best practices for paddy drying: Case studies in Vietnam, Cambodia, Philippines, and Myanmar. Plant Prod. Sci. 2018, 22, 107–118. [Google Scholar] [CrossRef]

- Mutert, E.; Fairhurst, T.H. Developments in rice production in Southeast Asia. Better Crops Int. 2002, 15, 12–17. [Google Scholar]

- IRRI International Rice Research Institute 2019. Regional Strategy for Southeast Asia. Available online: http://books.irri.org/SEA-Regional-Strategy-2020-2025-full.pdf (accessed on 19 December 2021).

- Kritee, K.; Nair, D.; Zavala-Araiza, D.; Proville, J.; Rudek, J.; Adhya, T.K.; Loecke, T.D.; Esteves, T.; Balireddygari, S.; Dava, O.; et al. High nitrous oxide fluxes from rice indicate the need to manage water for both long- and short-term climate impacts. Proc. Natl. Acad. Sci. USA 2018, 115, 9720–9725. [Google Scholar] [CrossRef] [Green Version]

- Wassmann, R.; Sander, B.O.; Yadav, S.; Bouman, B.; Singleton, G.; Stuart, A.; Hellin, J.; Johnson, D.; Hughes, J.; Butterbach-Bahl, K.; et al. New records of very high nitrous oxide fluxes from rice cannot be generalized for water management and climate impacts. Proc. Natl. Acad. Sci. USA 2019, 116, 1464–1465. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, Y.; Carrijo, D.; Huang, S.; Chen, J.; Balaine, N.; Zhang, W.; van Groenigen, K.J.; Linquist, B. Water management to mitigate the global warming potential of rice systems: A global meta-analysis. Field Crop. Res. 2019, 234, 47–54. [Google Scholar] [CrossRef]

- Carrijo, D.R.; Lundy, M.E.; Linquist, B.A. Rice yields and water use under alternate wetting and drying irrigation: A meta-analysis. Field Crop. Res. 2017, 203, 173–180. [Google Scholar] [CrossRef]

- Tirol-Padre, A.; Minamikawa, K.; Tokida, T.; Wassmann, R.; Yagi, K. Site-specific feasibility of alternate wetting and drying as a greenhouse gas mitigation option in irrigated rice fields in Southeast Asia: A synthesis. Soil Sci. Plant Nutr. 2017, 64, 2–13. [Google Scholar] [CrossRef]

- Buresh, R.J.; Castillo, R.L.; Torre, J.C.D.; Laureles, E.V.; Samson, M.I.; Sinohin, P.J.; Guerra, M. Site-specific nutrient management for rice in the Philippines: Calculation of field-specific fertilizer requirements by Rice Crop Manager. Field Crop. Res. 2019, 239, 56–70. [Google Scholar] [CrossRef]

- Hillier, J.; Walter, C.; Malin, D.; Garcia-Suarez, T.; Mila-I-Canals, L.; Smith, P. A farm-focused calculator for emissions from crop and livestock production. Environ. Model. Softw. 2011, 26, 1070–1078. [Google Scholar] [CrossRef]

- Grewer, U.; Bockel, L.; Galford, G.; Gurwick, N.; Nash, J.; Pirolli, G.; Wollenberg, E. A Methodology for Greenhouse Gas Emission and Carbon Sequestration Assessments in Agriculture: Supplemental Materials for Info Note Series Analyzing Low Emissions Agricultural Practices in USAID Development Projects. CCAFS Working Paper no. 187; Copenhagen, Denmark, 2016; Available online: https://cgspace.cgiar.org/bitstream/handle/10568/77767/Working%20Paper%20187%20Methodology%20for%20GHG%20emissions%20Nov%202016.pdf (accessed on 19 December 2021).

- Tseng, M.-C.; Roel, A.; Deambrosi, E.; Terra, J.; Zorrilla, G.; Riccetto, S.; Pittelkow, C.M. Towards actionable research frameworks for sustainable intensification in high-yielding rice systems. Sci. Rep. 2020, 10, 9975. [Google Scholar] [CrossRef]

- Wang, X.-L.; Wang, W.; Guan, Y.-S.; Xian, Y.-R.; Huang, Z.-X.; Feng, H.-Y.; Chen, Y. A joint use of emergy evaluation, carbon footprint and economic analysis for sustainability assessment of grain system in China during 2000–2015. J. Integr. Agric. 2018, 17, 2822–2835. [Google Scholar] [CrossRef]

- Arunrat, N.; Wang, C.; Pumijumnong, N. Alternative cropping systems for greenhouse gases mitigation in rice field: A case study in Phichit province of Thailand. J. Clean. Prod. 2016, 133, 657–671. [Google Scholar] [CrossRef]

- Carlsson-Kanyama, A. Climate change and dietary choices—How can emissions of greenhouse gases from food consumption be reduced? Food Policy 1998, 23, 277–293. [Google Scholar] [CrossRef]

- Mungkung, R.; Pengthamkeerati, P.; Chaichana, R.; Watcharothai, S.; Kitpakornsanti, K.; Tapananont, S. Life Cycle Assessment of Thai organic Hom Mali rice to evaluate the climate change, water use and biodiversity impacts. J. Clean. Prod. 2019, 211, 687–694. [Google Scholar] [CrossRef]

- Thanawong, K. Eco-efficiency of paddy rice production in Northeastern Thailand: A comparison of rain-fed and irrigated cropping systems. J. Clean. Prod. 2014, 73, 204–217. [Google Scholar] [CrossRef]

- Clune, S.; Crossin, E.; Verghese, K. Systematic review of greenhouse gas emissions for different fresh food categories. J. Clean. Prod. 2017, 140, 766–783. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.D.; Xu, C.C.; Ji, L.; Feng, J.F.; Li, F.B.; Zhou, X.Y.; Fang, F.P. Effects of multi-cropping system on temporal and spatial distribution of carbon and nitrogen footprint of major crops in China. Glob. Ecol. Conserv. 2019, 22, e00895. [Google Scholar] [CrossRef]

- Haq, M.E. Carbon Footprint of Selected Cereal and Legume Crops Cultivated in the Old Brahmaputra Floodplain Soil. Master’s Thesis, Bangladesh Agricultural University, Mymensingh, Bangladesh, 2014. Available online: https://www.researchgate.net/publication/306277898_CARBON_FOOTPRINT_OF_SELECTED_CEREAL_AND_LEGUME_CROPS_CULTIVATED_IN_THE_OLD_BRAHMAPUTRA_FLOODPLAIN_SOIL (accessed on 19 December 2021). [CrossRef]

- Jimmy, A.N.; Khan, N.A.; Hossain, M.N.; Sujauddin, M. Evaluation of the environmental impacts of rice paddy production using life cycle assessment: Case study in Bangladesh. Model. Earth Syst. Environ. 2017, 3. [Google Scholar] [CrossRef]

- Kägi, T.; Wettstein, D.; Dinkel, F. Comparing rice products: Confidence intervals as a solution to avoid wrong conclusions in communicating carbon footprints. Proc. LCA Food 2010, 1, 229–233. [Google Scholar]

- Kim, S.; Kim, T.; Smith, T.; Suh, K. Environmental Implications of Eco-Labeling for Rice Farming Systems. Sustainability 2018, 10, 1050. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.; Hu, Y.; Cui, S.; Kang, J.; Xu, L. Carbon footprints of food production in China (1979–2009). J. Clean. Prod. 2015, 90, 97–103. [Google Scholar] [CrossRef]

- Phong, L.T.; de Boer, M.; Udo, K.M.J. Life cycle assessment of food production in integrated agriculture–aquaculture systems of the Mekong Delta. Livest. Sci. 2011, 139, 80–90. [Google Scholar] [CrossRef]

- Saarinen, M.; Kurppa, S.; Virtanen, Y.; Usva, K.; Mäkelä, J.; Nissinen, A. Life cycle assessment approach to the impact of home-made, ready-to-eat and school lunches on climate and eutrophication. J. Clean. Prod. 2012, 28, 177–186. [Google Scholar] [CrossRef]

- Xia, L.; Ti, C.; Li, B.; Xia, Y.; Yan, X. Greenhouse gas emissions and reactive nitrogen releases during the life-cycles of staple food production in China and their mitigation potential. Sci. Total Environ. 2016, 556, 116–125. [Google Scholar] [CrossRef]

- Xu, X.; Lan, Y. Spatial and temporal patterns of carbon footprints of grain crops in China. J. Clean. Prod. 2017, 146, 218–227. [Google Scholar] [CrossRef]

- Xu, Z.; Xu, W.; Peng, Z.; Yang, Q.; Zhang, Z. Effects of different functional units on carbon footprint values of different carbohydrate-rich foods in China. J. Clean. Prod. 2018, 198, 907–916. [Google Scholar] [CrossRef]

- Zhang, D.; Shen, J.; Zhang, F.; Li, Y.; Zhang, W. Carbon footprint of grain production in China. Sci. Rep. 2017, 7, 4126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, G.; Wang, X.; Zhang, L.; Xiong, K.; Zheng, C.; Lu, F.; Zhao, H.; Zheng, H.; Ouyang, Z. Carbon and water footprints of major cereal crops production in China. J. Clean. Prod. 2018, 194, 613–623. [Google Scholar] [CrossRef]

- FAOSTAT. Data for 2019. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 21 November 2021).

- Carlson, K.M.; Gerber, J.; Mueller, N.D.; Herrero, M.; MacDonald, G.; Brauman, K.A.; Havlik, P.; O’Connell, C.S.; Johnson, J.; Saatchi, S.; et al. Greenhouse gas emissions intensity of global croplands. Nat. Clim. Chang. 2017, 7, 63–68. [Google Scholar] [CrossRef]

- Tilman, D.; Clark, M. Global diets link environmental sustainability and human health. Nature 2014, 515, 518–522. [Google Scholar] [CrossRef] [PubMed]

| Stage (Acronym) | GHG Emission Source Incl. Citation | GHG Calculation and Input Parameters B= Baseline Technology; A1…A5 = Alternative Technologies) | |||||

|---|---|---|---|---|---|---|---|

| Crop establishment and protection (CEP) | CH4 from water-logged soil [13]; CH4 from seed production; CO2 from pesticide production [14] | GHGCEP = GHGWet + GHGSeed + GHGPest = EFWet + EFSeed × @Seed_Rate + EFPest | |||||

| EFawet: B = Conventional | EFSeed: B = Conventional; A1 = Hybrids; @Seed_Rate (kg/ha) | EFPest B = Recomm.; A1 = High intensity rate; A2 = No pesticides | |||||

| Water/soil manage- ment (WSM) | CH4 from soil flooding [11] based on daily emission factor, cultivation period, water management, pre-season management and organic amendments | GHGWSM = EFCH4 × @Cult_Per × ScFW × ScFP × (1 + @ROAStraw × CFOAStraw + @ROAAdd_Org × CFOAAdd_Org)0.59 | |||||

| EFCH4 B = Southeast Asia; A1 = … South Asia … A5 = South America; @Cult_Per (d) SFW: B = Contin. Flooding; A1 = Intermitt. Drainage; A2 = Multiple drainage SFP: B = Short aeration; A1 = Long aer.; A2 = Extra-long aer. A3 = Water logged | CFOAStraw: B = Straw: Short offset A1 = Straw: Long offset A2 = Straw: Incorpor. as compost @ ROAStraw (t/ha) CFOAAdd_Org: B = No additional OA A1 = Farm yard man. A2 = Green manure @ROAAdd_Org. (t/ha) | ||||||

| Fertilizer applications (Fer) | N2O from on-site application [10]; CO2 from fertilizer production [14] | GHGFert = GHGN2O + GHGCO2_F = (EFN-N2O + EFCO2-N) × @N_Rate | |||||

| EFN-N2O B = Continuous Flooding; A1 = Intermittent drainage | EFCO2-N B= Conventional Fertilizer Production @N_Rate (kg N/ha) | ||||||

| Machine operations (MO) | CO2 from electricity for pumping [15]; CO2 from fuel for vehicles [16] | GHGMO = EFMO EFMO: B = Conventional (pumping and field operations) | |||||

| Harvest (H) | CO2 from fuel; food losses [14,16] | GHGHarv = EFHarv EFHarv: B = Conventional; A1 = Combine harvesting | |||||

| Straw management (SM) | CH4 from straw burning [17]; minor N2O emissions are neglected | GHGStraw = EFStraw × @Straw_Rate EFStraw: B = Burning; A1 = Here not considered; A2 = Used as commodity; @Straw_Rate (only for burning) | |||||

| Drying (D) | CO2 from electricity [16]; food losses [16,18]) | GHGDry = CoFDry × QHarv CoFDry: B = Sun drying; A1 = Solar bubble dryer; A2 = Flatbed dryer; A3 = Recirculating dryer | |||||

| Storage (S) | CO2 from electricity food losses [16,18]) | GHGSto = CoFSto × QDry CoFSto: B = Farmer granary A1= Hermetic storage A2= Back stacking A3= Bulk stacking | |||||

| Milling (M) | CO2 from electricity [16]) food losses and by-products [19] | GHGMill = CoFMill × QSto CoFMill: B = Basic technology; A1 = Integrated techn./white rice; A2= Integrated techn./brown rice | |||||

| Packaging (Pk) | CO2 from electricity [20] | GHGPk = CoFPk × QProd CoFPk: B = Automatic facility | |||||

| Transport (Tr) | CO2 from fuel [20] | GHGTr = GHGTruck + GHGTract + GHGShip + GHGBoat = (CoFTract × DistTract + CoaTruck × DistTruck + CoFBoat+ × DistBoat + CoFShip × DistShip) × QProd | |||||

| CoFTruck: B = Conventional truck @ DistTruck (km) CoFTract: B = Conventional tractor/trailer @ DistTract (km) | CoFBoat: B = Conventional boat @ DistBoat (km) CoFShip: B = Conventional ship @ DistShip (km) | ||||||

| Stage of Value Chain | Scenarios | ||||

|---|---|---|---|---|---|

| B | E | W | L | S | |

| Water management | |||||

| Continuous flooding | X | X | X | ||

| Multiple drainage | X | X | |||

| Pre-season management | - | - | - | - | |

| Short aeration | X | X | X | ||

| Long aeration | X | X | |||

| Organic amendm. | - | - | - | - | |

| Straw (2.1 t/ha) | X | ||||

| Fertilizer application (kg N/ha) | |||||

| EFN-N2O/contin. flood. | 100 | 100 | 90 | ||

| EFN-N2O/mult. drain. | 100 | 80 | |||

| Harvest | |||||

| Conventional | X | X | X | X | |

| Combine harvester | X | ||||

| Straw management | |||||

| Straw burning | X | X | X | X | |

| Here not considered | X | ||||

| Drying | |||||

| Sun drying | X | X | X | X | |

| Solar bubble dryer | X | ||||

| Storing | |||||

| Farmer granary | X | X | X | X | |

| Hermetic storage | X | ||||

| Milling | |||||

| Basic technology/white | X | X | X | X | |

| Integrated techn./white | X | ||||

| Transport | |||||

| Truck (km) | 100 | 100 | 100 | 100 | 100 |

| Tractor/Trailor (km) | 50 | 50 | 50 | 50 | 50 |

| Ship (km) | 9000 | ||||

| Stage | Setting | Calculation by Different Tools (kg CO2e/ha) | Remarks | |||

|---|---|---|---|---|---|---|

| CF- Rice | CFT 1 | EX- ACT 2 | EX-ACT_VC 3 | |||

| Soil/water manage- ment | Conti- nuous Flood. | 3484 | 3422 | 3484 | - | Possible rounding error in the CFT results due to recalculation from data output as percentage |

| Multiple Drainage | 1916 | 1728 | 1916 | - | CF-Rice and EX-ACT use SFW = 0.55 [10], whereas CFT appears to use SFw = 0.52 [9] | |

| Fertilizer application (under continuous flooding) | 100 kg N | 569 (CO2) 140 (N2O) | 725 (CO2 + N2O) | 642 (CO2) 443 (N2O) | - | CF-Rice and CFT are based on the specific IPCC value given for flooded rice (EFN-N2O = 0.3% of applied N) [10], whereas EX-ACT appears to assume the uniform value for upland crops (EFN-N2O = 1% of applied N) [9] |

| Straw management | Burning | 867 | 467 | - | - | CF-Rice is based on specific GHG measurements for rice straw burning under typically moist conditions whereas CFT uses a global GHG average for straw burning of various crops |

| Milling | Basic technology | 102 | - | - | (A) 118 (B) 82 (C) 80 | (A) including by-products; (B) including value-adjusted by-products; (C) exclusing by-poducts |

| Source | CF (kgCO2e/kgProd) | Remarks | Geographic Scope | |

|---|---|---|---|---|

| Rice Production | Rice Consumpt. | |||

| [39] | Mean: 2.66; Median: 2.55; Stdev: 1.29; Min: 0.66; Max: 5.69 | Meta-analysis used as reference for data outputs of CF-Rice (Figure A2) | Global | |

| [40] | 0.74 to 0.83 | Comparison of crops | China | |

| [41] | 0.86 to 1.28 | Comparison of cereal and legume crops | Bangladesh | |

| [42] | 3.15 | High irrigation costs | Bangladesh | |

| [43] | 2.6 to 3.1 | USA | Switzerland | |

| [44] | 1.87 to 2.98 | Focus on eco-friendly rice | Korea | |

| [45] | 1.6 to 2 | Comparison of crops | China | |

| [46] | 0.94 | Rice—aquaculture rotation | Vietnam/Mekong Delta | |

| [47] | 2.67 | Comparison of diets | Finland | |

| [48] | 1.84 to 2.49 | Mitigation assessment | China | |

| [49] | 1.06 | Comparison of crops | China | |

| [50] | 2.9 | Focus on carbohydrate-rich foods | China | China |

| [51] | 1.60 | Comparison of crops | China | |

| [52] | 1.4 | Comparison of crops | China | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wassmann, R.; Van-Hung, N.; Yen, B.T.; Gummert, M.; Nelson, K.M.; Gheewala, S.H.; Sander, B.O. Carbon Footprint Calculator Customized for Rice Products: Concept and Characterization of Rice Value Chains in Southeast Asia. Sustainability 2022, 14, 315. https://doi.org/10.3390/su14010315

Wassmann R, Van-Hung N, Yen BT, Gummert M, Nelson KM, Gheewala SH, Sander BO. Carbon Footprint Calculator Customized for Rice Products: Concept and Characterization of Rice Value Chains in Southeast Asia. Sustainability. 2022; 14(1):315. https://doi.org/10.3390/su14010315

Chicago/Turabian StyleWassmann, Reiner, Nguyen Van-Hung, Bui Tan Yen, Martin Gummert, Katherine M. Nelson, Shabbir H. Gheewala, and Bjoern Ole Sander. 2022. "Carbon Footprint Calculator Customized for Rice Products: Concept and Characterization of Rice Value Chains in Southeast Asia" Sustainability 14, no. 1: 315. https://doi.org/10.3390/su14010315

APA StyleWassmann, R., Van-Hung, N., Yen, B. T., Gummert, M., Nelson, K. M., Gheewala, S. H., & Sander, B. O. (2022). Carbon Footprint Calculator Customized for Rice Products: Concept and Characterization of Rice Value Chains in Southeast Asia. Sustainability, 14(1), 315. https://doi.org/10.3390/su14010315