A Study on the Influence of the Next Generation Colored Inorganic Geopolymer Material Paint on the Insulation Measurement of Concrete Building Shell

Abstract

:1. Introduction

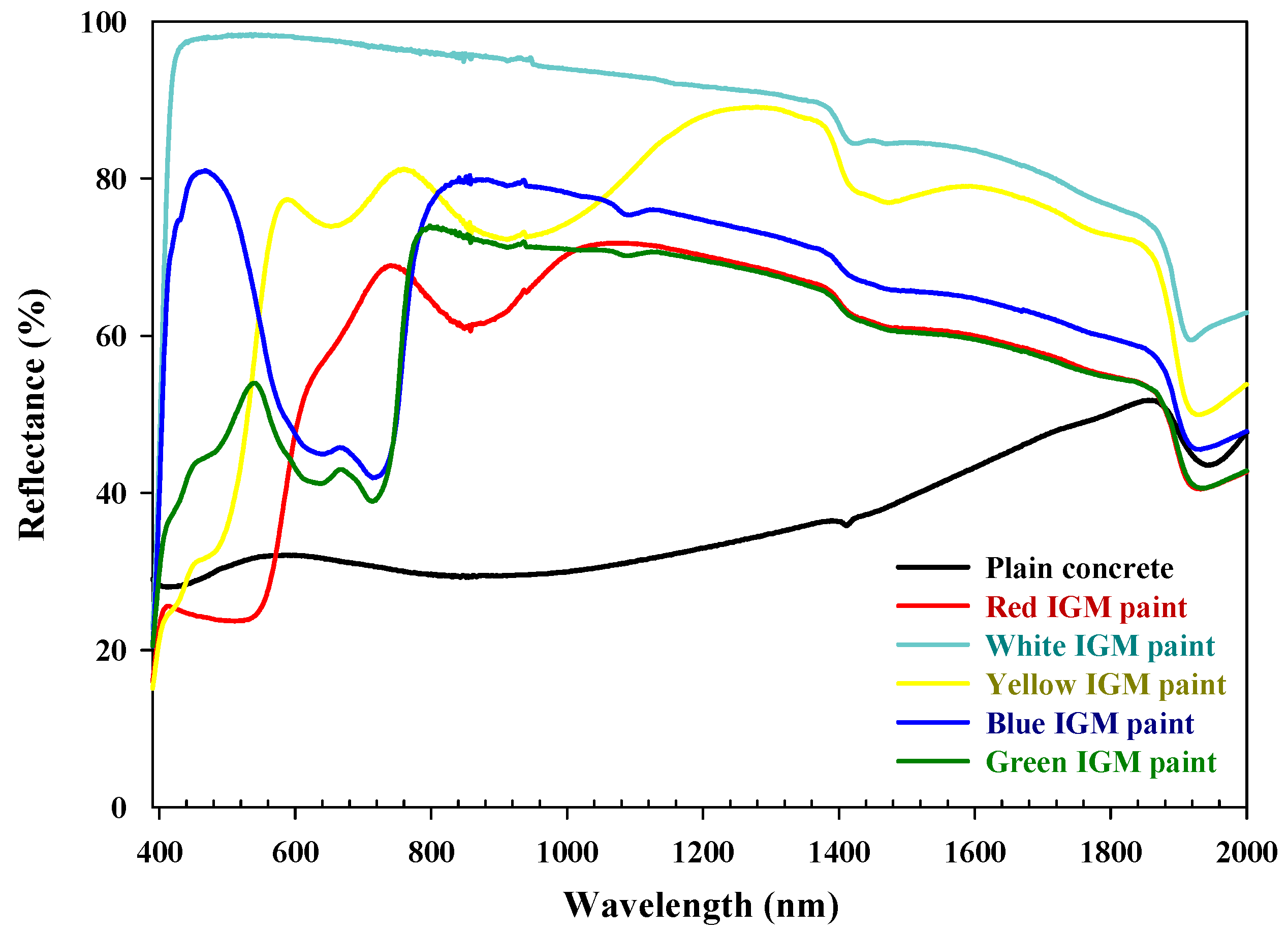

2. Experimental Measurement and Theory of Thermal Property

2.1. Light Reflectance Measurement

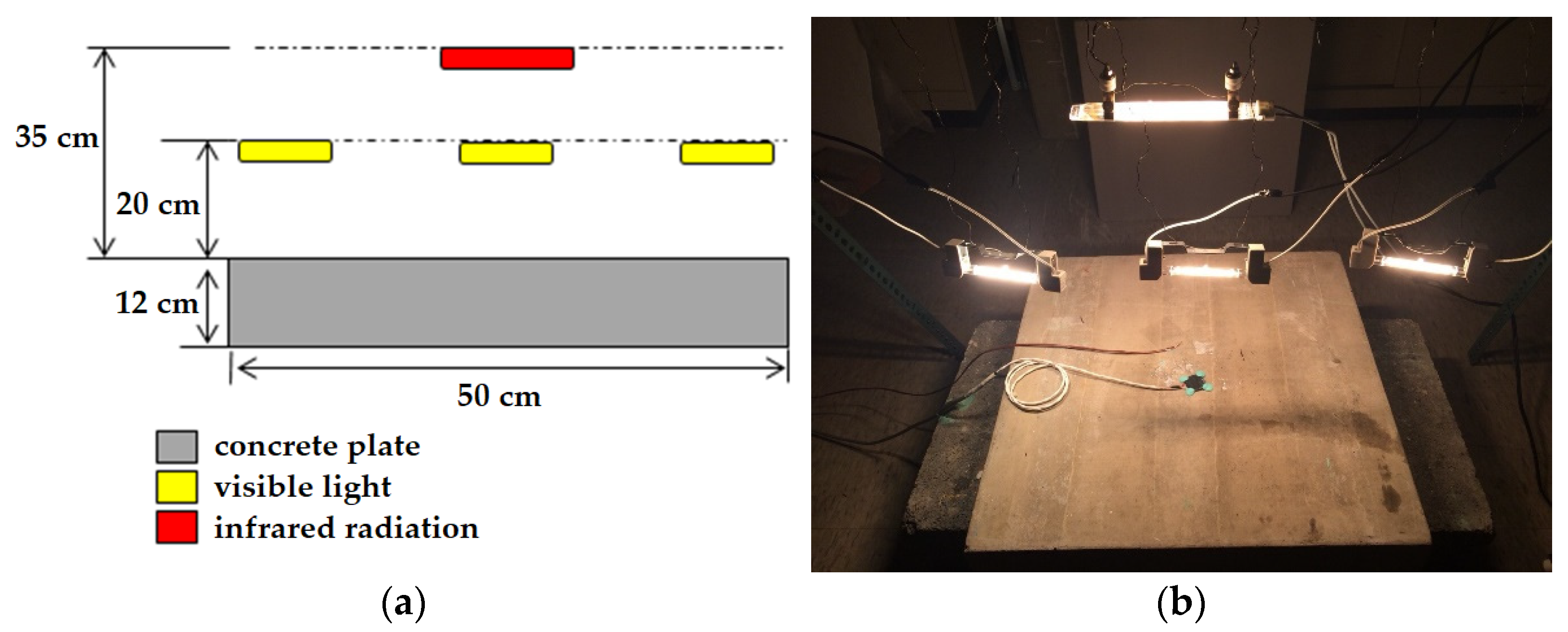

2.2. Laboratory Measurement of Heat Flux and Temperature

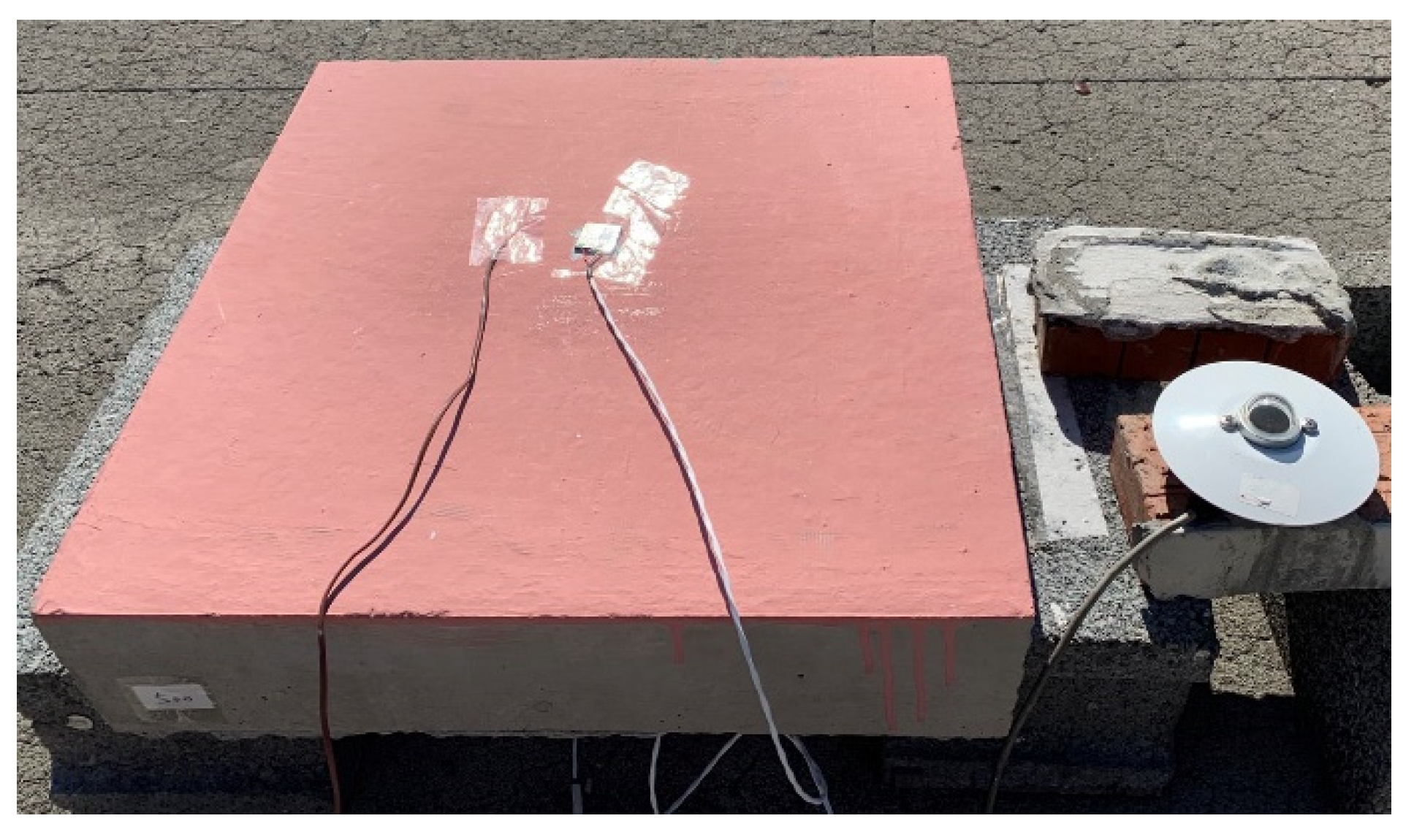

2.3. Outdoor Measurement of Heat Flux and Temperature

2.4. Heat Absorption, Conduction, and Storage

3. Light Reflectance Measurement Results

4. Laboratory Heat Flux and Surface Temperature Measurements

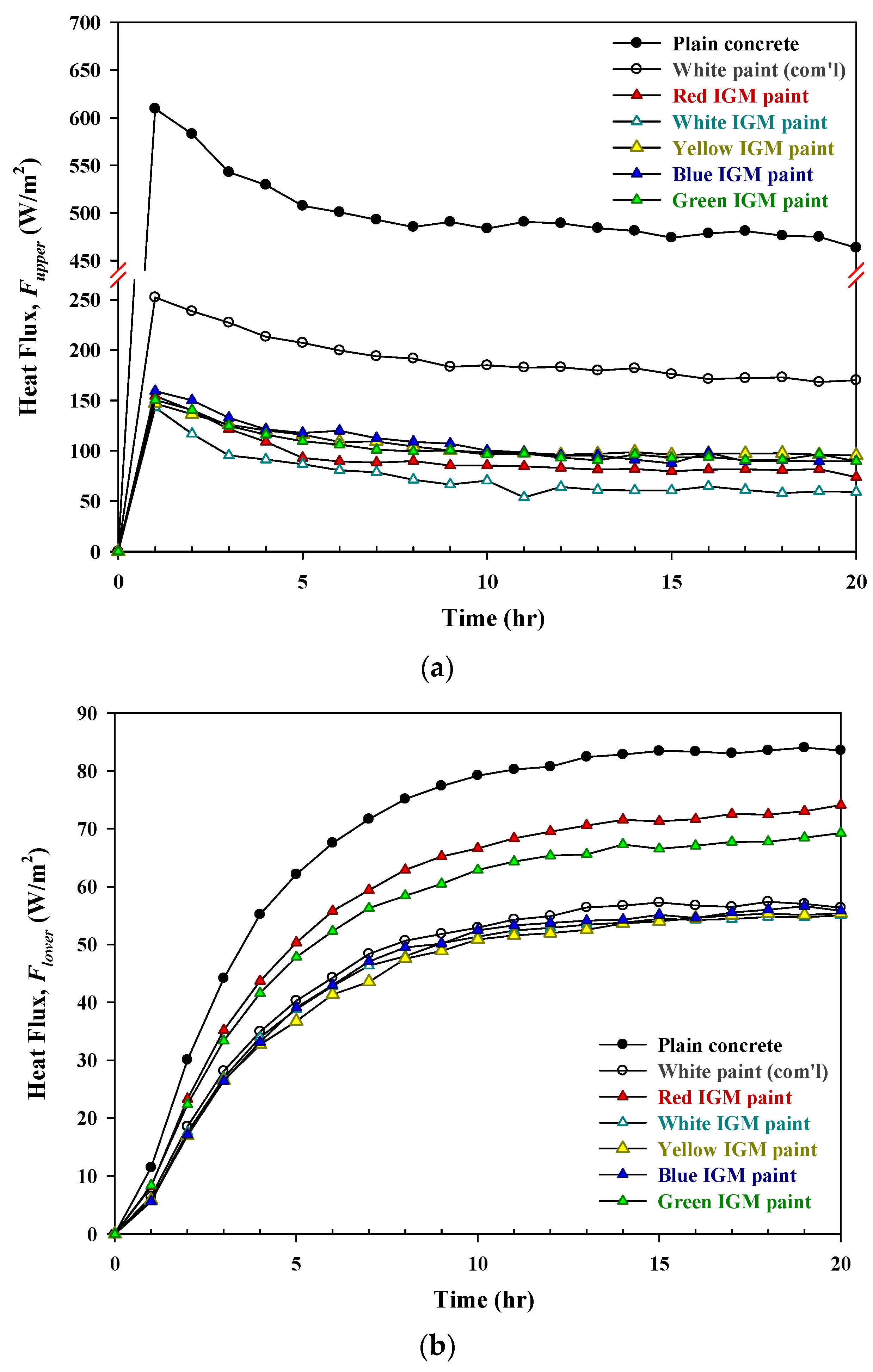

4.1. Laboratory Heat Flux Measurement Results

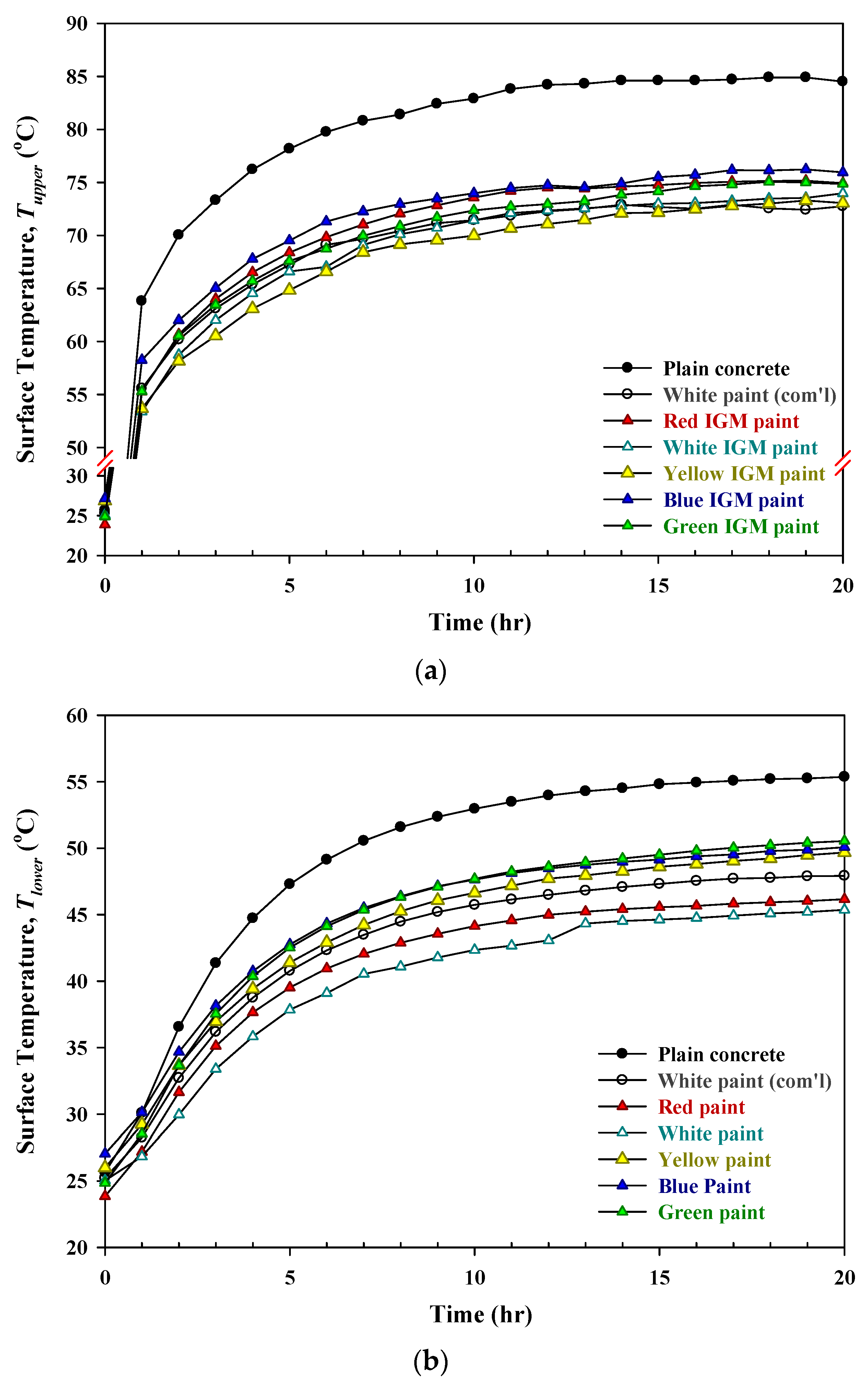

4.2. Laboratory Surface Temperature Measurement Results

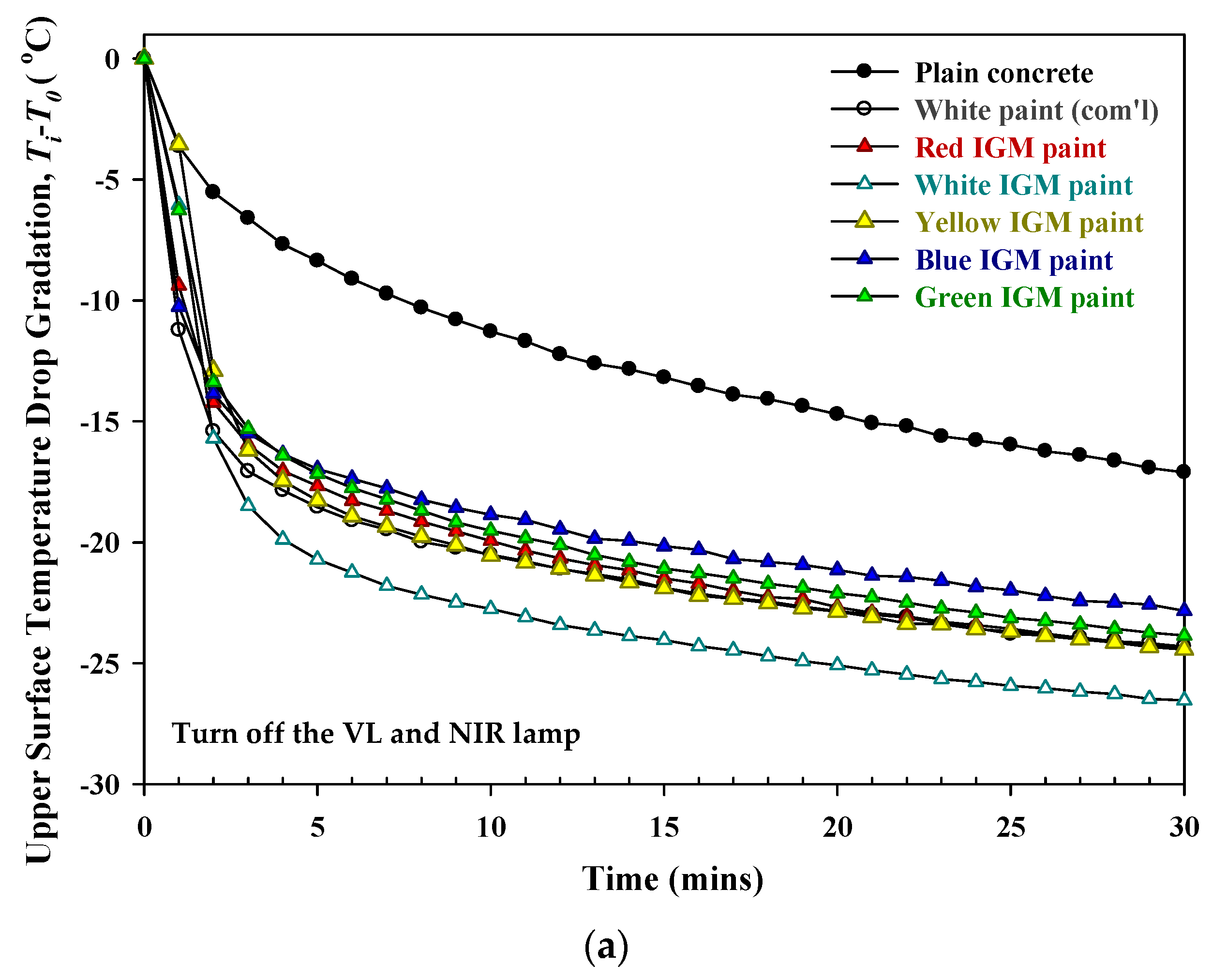

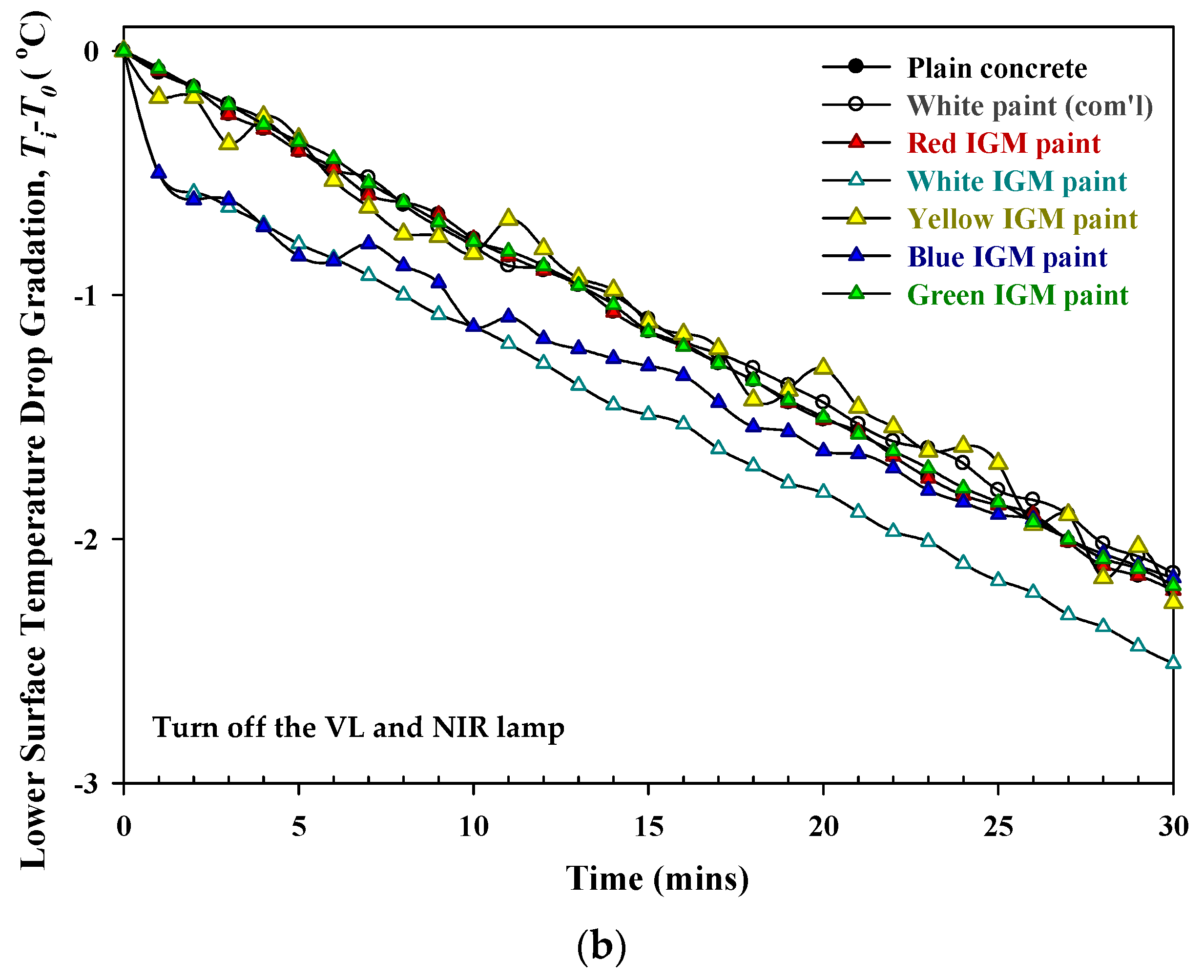

4.3. Laboratory Surface Temperature Measurement Results after Turn off the Light

4.4. Thermal Admittance Calculation and t-Test Analysis

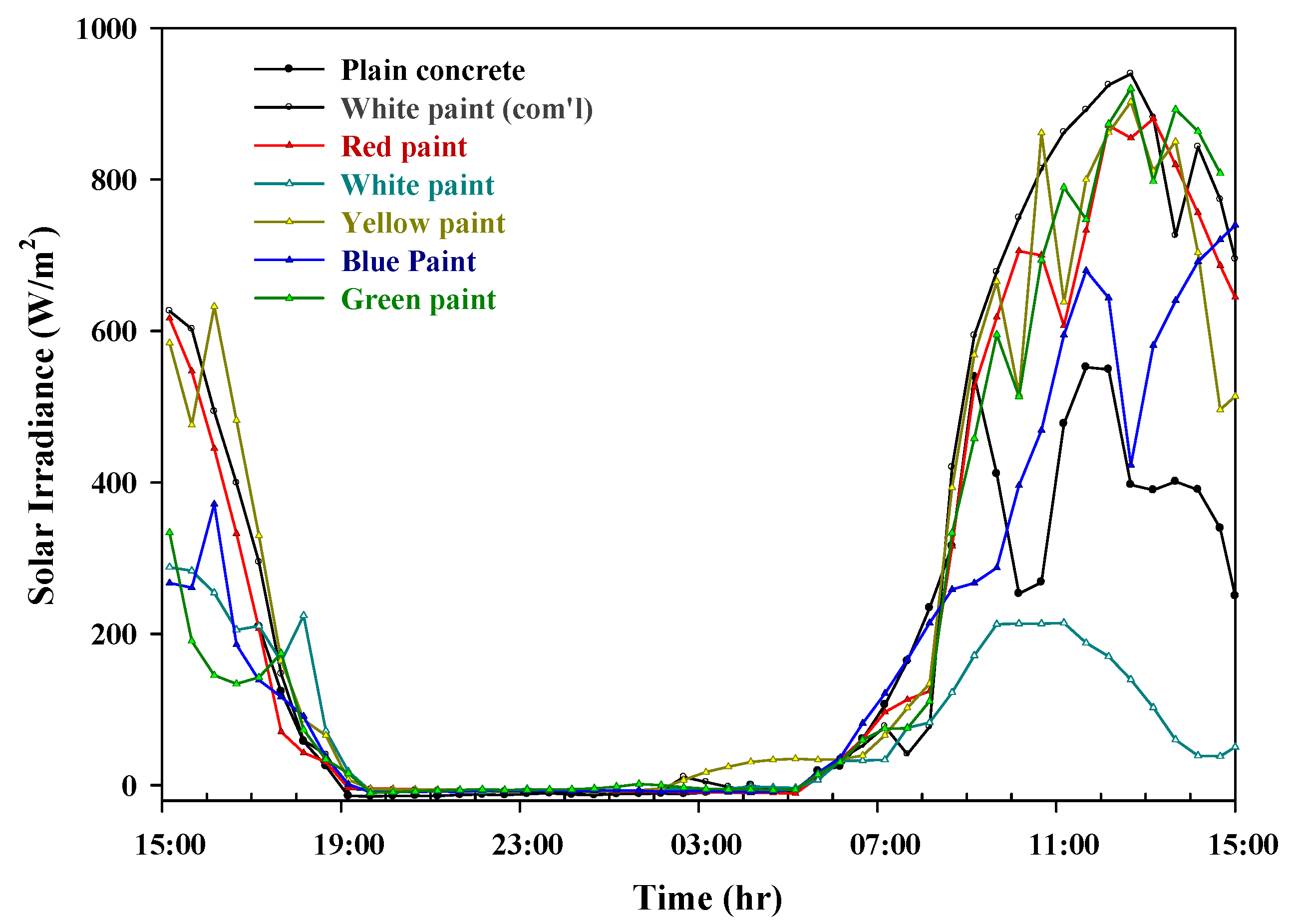

5. Outdoor Heat Flux and Surface Temperature Measurements

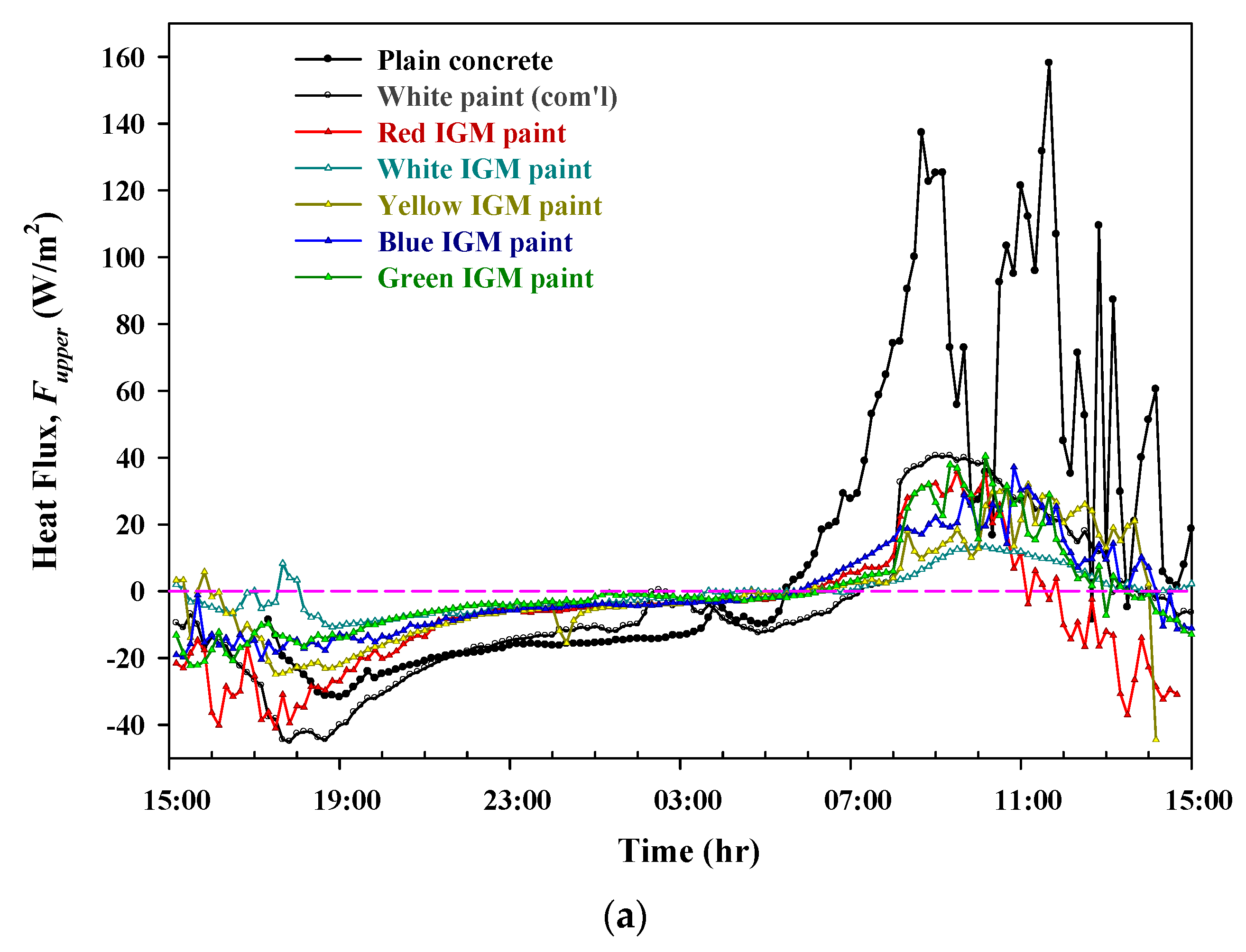

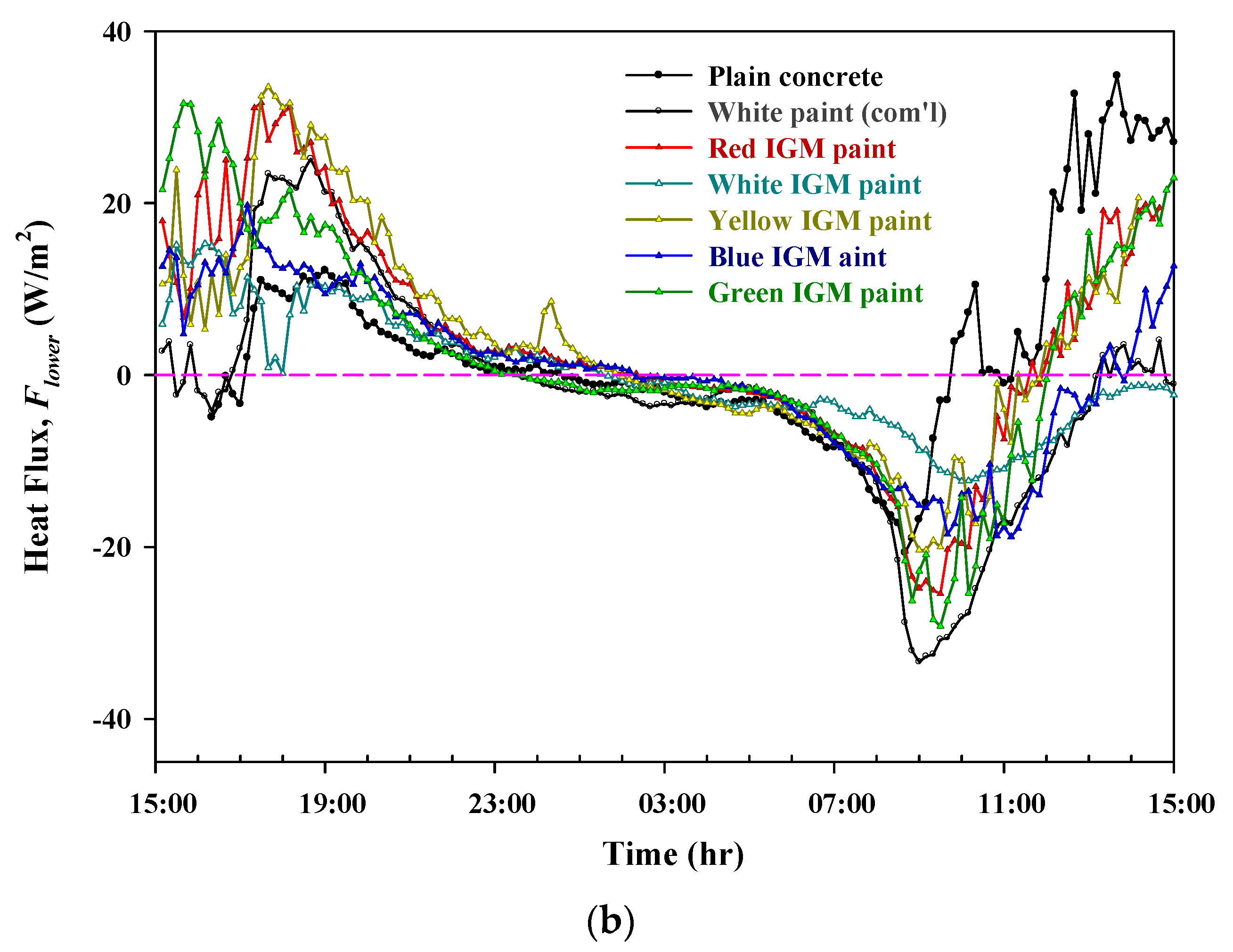

5.1. Outdoor Heat Flux Measurement Results

5.2. Outdoor Surface Temperature Measurement Results

6. Conclusions

- The average light reflectance values of various color paint materials were obtained by the light reflectance test. In the range of 390–2000 nm, the highest average light reflectance value of all the covering materials was the white IGM at 87.5%, and the light reflectance of the plain concrete was 36.4%.

- It is known from the thermal insulation results in the laboratory that the IGM paint had good thermal insulation properties. Under the influence of environmental factors, the measurement results were inevitably challenged. Nevertheless, the results of the experiment were still considered to be objective under the circumstances. That is, under the irradiance of simulated sunlight, the thermal insulation performance of the concrete specimens painted with the IGM paints were better than the plain concrete specimen.

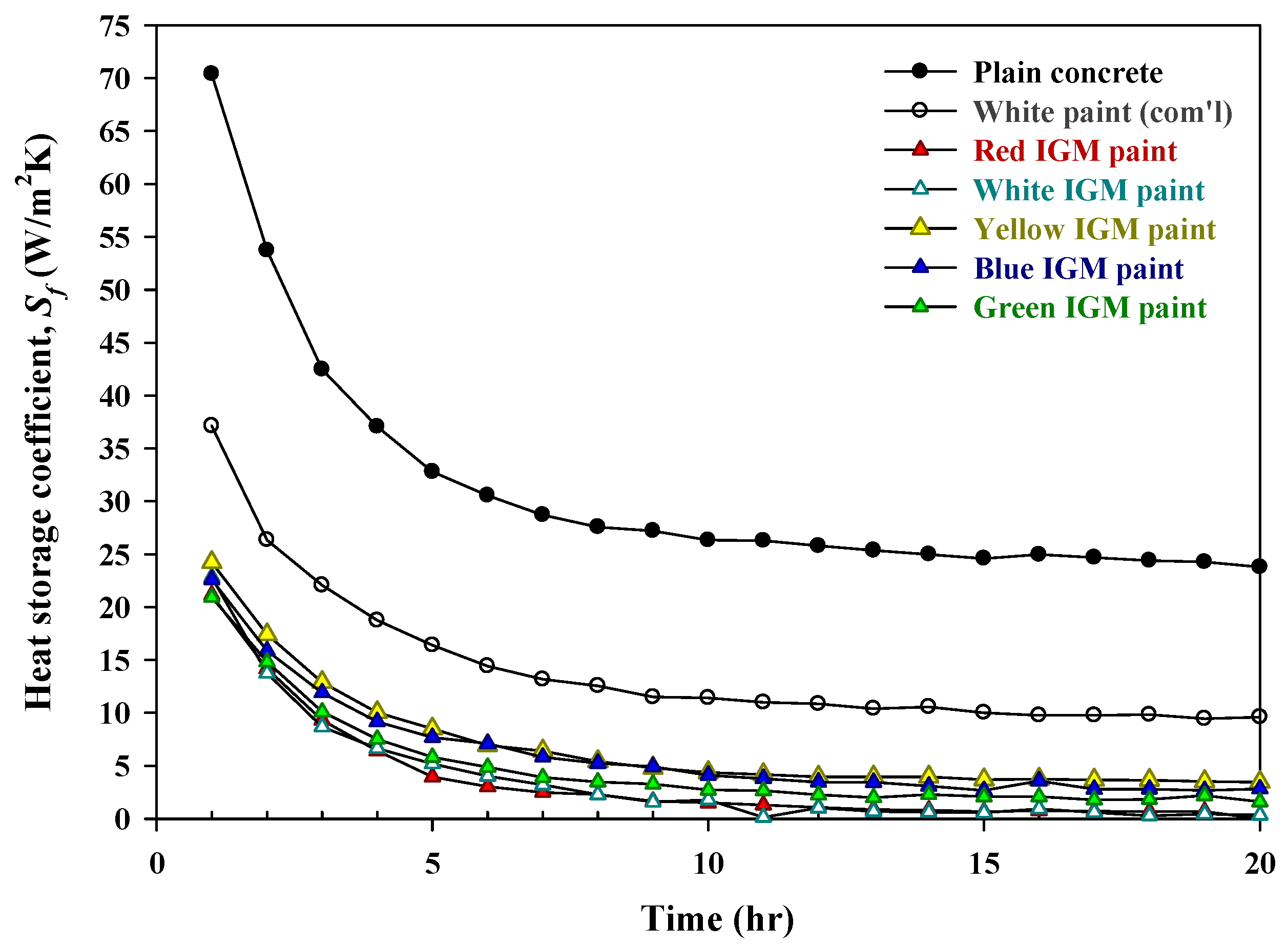

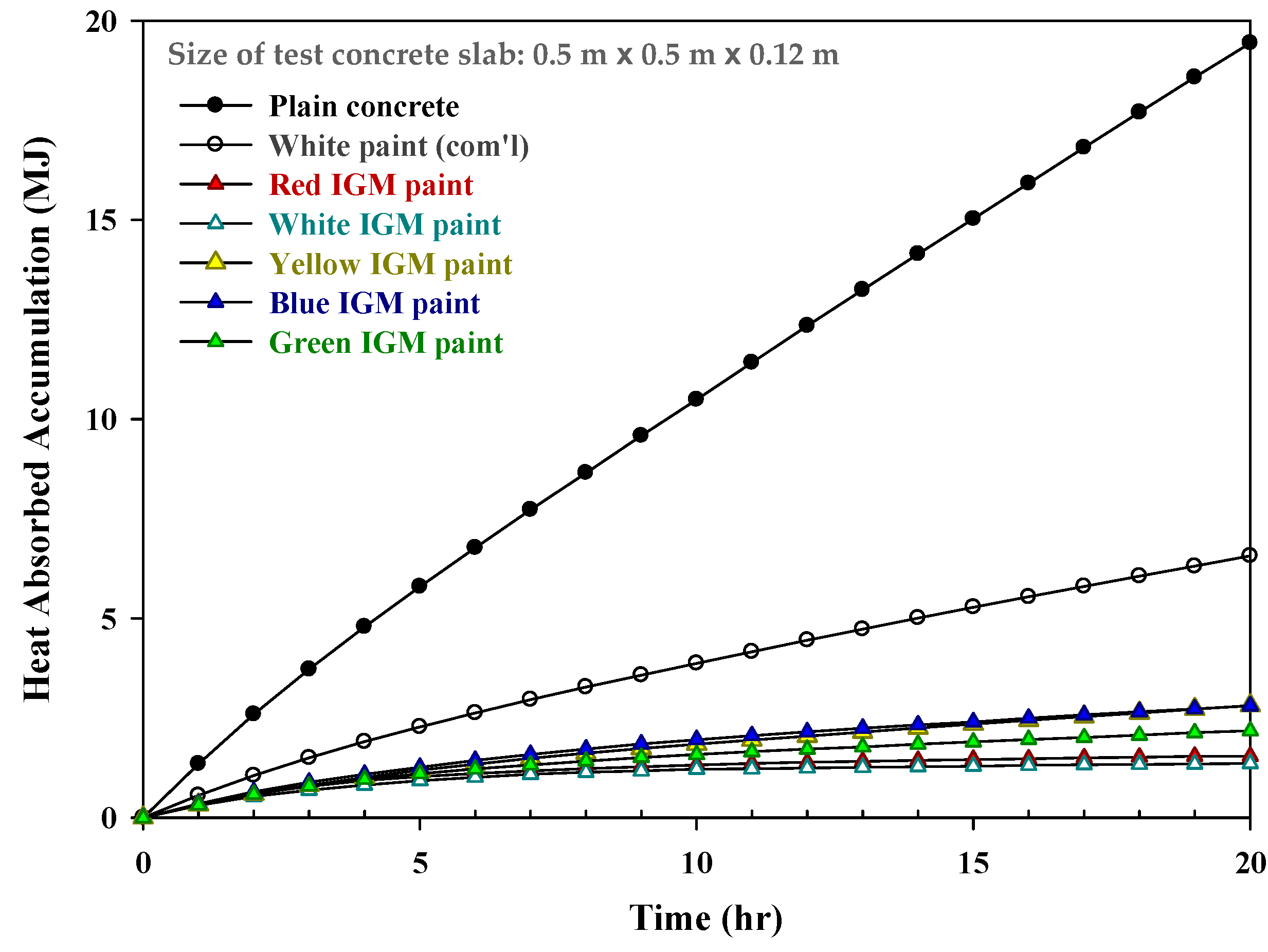

- Thermal admittance was described in place of the changes of the heat storage coefficient in this research. The results indicated that the IGM paints could reduce the quantity of heat absorption of the concrete slabs. The heat storage coefficient of red, white, yellow, blue, and green IGM-painted concrete slabs were 0.57, 0.53, 3.62, 2.95, and 1.91 W·m−2·K−1, respectively, which were lower than the plain concrete specimen (24.40 W·m−2·K−1). Based on the changes of the heat storage coefficient over time, it was confirmed that the heat absorption of specimens through the IGM paints and then into the concrete under the light was slowed, and it was lower than the commercial white paint specimen and the plain concrete specimen.

- The results of outdoor measurement showed that the IGM painted specimens had good thermal insulation ability, and these results were similar to the measurement results in the laboratory. The concrete specimens painted with IGM had better thermal insulation performance than the plain concrete specimen. Furthermore, the thermal insulation performance of the white IGM paint was also better than the commercial white paint.

- Through various physical properties and thermal insulation measurement results, it was clear that the next generation of colored IGM paints had high reflectivity, good thermal insulation, and low heat storage capacity. The next generation of colored IGM paint could be applied to various building shells and especially to concrete building shells in sustainable cities and communities. Its strong and practical characteristics could effectively reduce the indoor temperature and attain an energy-saving effect in subtropics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Crawford, B.; Krayenhoff, E.S.; Cordy, P. The urban energy balance of a lightweight low-rise neighborhood in Andacollo, Chile. Theor. Appl. Clim. 2016, 131, 55–68. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rapsomanikis, S.; Trepekli, A.; Loupa, G.; Polyzou, C. Vertical Energy and Momentum Fluxes in the Centre of Athens, Greece During a Heatwave Period (Thermopolis 2009 Campaign). Boundary-Layer Meteorol. 2015, 154, 497–512. [Google Scholar] [CrossRef]

- Akbari, H.; Bretz, S.; Kurn, D.M.; Hanford, J. Peak power and cooling energy savings of high-albedo roofs. Energy Build. 1997, 25, 117–126. [Google Scholar] [CrossRef]

- Zinzi, M.; Fasano, G. Properties and performance of advanced reflective paints to reduce the cooling loads in buildings and mitigate the heat island effect in urban areas. Int. J. Sustain. Energy 2009, 28, 123–139. [Google Scholar] [CrossRef]

- Bozonnet, E.; Doya, M.; Allard, F. Cool roofs impact on building thermal response: A French case study. Energy Build. 2011, 43, 3006–3012. [Google Scholar] [CrossRef]

- Guo, W.; Qiao, X.; Huang, Y.; Fang, M.; Han, X. Study on energy saving effect of heat-reflective insulation coating on envelopes in the hot summer and cold winter zone. Energy Build. 2012, 50, 196–203. [Google Scholar] [CrossRef]

- Garg, V.; Somal, S.; Arumugam, R.; Bhatia, A. Development for cool roof calculator for India. Energy Build. 2016, 114, 136–142. [Google Scholar] [CrossRef] [Green Version]

- Ferrari, C.; Libbra, A.; Cernuschi, F.M.; De Maria, L.; Marchionna, S.; Barozzi, M.; Siligardi, C.; Muscio, A. A composite cool colored tile for sloped roofs with high ‘equivalent’ solar reflectance. Energy Build. 2016, 114, 221–226. [Google Scholar] [CrossRef]

- Guo, X.; Wang, J.; Wu, Y.; Ao, Y.; Liu, X. Experimental study of the thermal performance of a new type of building reflective coating in hot summer and cold winter zone of China. Procedia Eng. 2017, 205, 603–608. [Google Scholar] [CrossRef]

- Qiu, T.; Wang, G.; Xu, Q.; Ni, G. Study on the thermal performance and design method of solar reflective–thermal insulation hybrid system for wall and roof in Shanghai. Sol. Energy 2018, 171, 851–862. [Google Scholar] [CrossRef]

- Cheng, V.; Ng, E.Y.Y.; Givoni, B. Effect of envelope colour and thermal mass on indoor temperatures in hot humid climate. Sol. Energy 2005, 78, 528–534. [Google Scholar] [CrossRef]

- Uemoto, K.L.; Sato, N.M.; John, V.M. Estimating thermal performance of cool colored paints. Energy Build. 2010, 42, 17–22. [Google Scholar] [CrossRef]

- Del Carpio, J.A.V.; Marinoski, D.L.; Trichês, G.; Lambert, R. Urban pavements used in Brazil: Characterization of solar reflectance and temperature verification in the field. Sol. Energy 2016, 134, 72–81. [Google Scholar] [CrossRef]

- Roman, K.K.; O’Brien, T.; Alvey, J.; Woo, O. Simulating the effects of cool roof and PCM (phase change materials) based roof to mitigate UHI (urban heat island) in prominent US cities. Energy 2016, 96, 103–117. [Google Scholar] [CrossRef]

- Synnefa, A.; Santamouris, M.; Livada, I. A study of the thermal performance of reflective coatings for the urban environment. Sol. Energy 2006, 80, 968–981. [Google Scholar] [CrossRef]

- Carnielo, E.; Fanchiotti, A.; Zinzi, M. Energy and Comfort Benefits of a Cool Roof Application in a Non-Residential Building Belonging to Roma Tre University. World Renew. Energy Congr. 2011, 57, 1970–1977. [Google Scholar]

- Shen, H.; Tan, H.; Tzempelikos, A. The effect of reflective coatings on building surface temperatures, indoor environment and energy consumption—An experimental study. Energy Build. 2011, 43, 573–580. [Google Scholar] [CrossRef]

- Santamouris, M.; Synnefa, A.; Karlessi, T. Using advanced cool materials in the urban built environment to mitigate heat islands and improve thermal comfort conditions. Sol. Energy 2011, 85, 3085–3102. [Google Scholar] [CrossRef]

- Parker, D.S.; Barkaszi, S.F. Roof solar reflectance and cooling energy use: Field research results from Florida. Energy Build. 1997, 25, 105–115. [Google Scholar] [CrossRef]

- Takebayashi, H.; Masakazu, M. Surface heat budget on green roof and high reflection roof for mitigation of urban heat island. Build. Environ. 2007, 42, 2971–2979. [Google Scholar] [CrossRef] [Green Version]

- Costanzo, V.; Evola, G.; Marletta, L. Energy savings in buildings or UHI mitigation? Comparison between green roofs and cool roofs. Energy Build. 2016, 114, 247–255. [Google Scholar] [CrossRef]

- Algarni, S.; Nutter, D. Influence of dust accumulation on building roof thermal performance and radiant heat gain in hot-dry climates. Energy Build. 2015, 104, 181–190. [Google Scholar] [CrossRef]

- Shariah, A.; Shalabi, B.; Rousan, A.; Tashtoush, B. Effects of absorptance of external surfaces on heating and cooling loads of residential buildings in Jordan. Energy Convers. Manag. 1998, 39, 273–284. [Google Scholar] [CrossRef]

- Ruivo, C.; Ferreira, P.; Vaz, D. On the error of calculation of heat gains through walls by methods using constant decrement factor and time lag values. Energy Build. 2013, 60, 252–261. [Google Scholar] [CrossRef]

- ASTM G173-03. Standard Tables for Reference Solar Spectral Irradiances: Direct Normal and Hemispherical on 37° Tilted Surface; American Society for Testing and Materials: West Conshohocken, PA, USA, 2020. [CrossRef]

- Pomianowski, M.; Heiselberg, P.; Jensen, R.L.; Cheng, R.; Zhang, Y. A new experimental method to determine specific heat capacity of inhomogeneous concrete material with incorporated microencapsulated-PCM. Cem. Concr. Res. 2014, 55, 22–34. [Google Scholar] [CrossRef]

- Shafigh, P.; Asadi, I.; Mahyuddin, N.B. Concrete as a thermal mass material for building applications—A review. J. Build. Eng. 2018, 19, 14–25. [Google Scholar] [CrossRef]

- Sarbu, I.; Sebarchievici, C. A Comprehensive Review of Thermal Energy Storage. Sustainability 2018, 10, 191. [Google Scholar] [CrossRef] [Green Version]

- Smith, E.R.; Daivis, P.J.; Todd, B.D. Measuring heat flux beyond Fourier’s law. J. Chem. Physics 2019, 150, 064103. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Childs, P.R.N.; Greenwood, J.R.; Long, C.A. Heat flux measurement techniques. Proc. Inst. Me Chanical Eng. Part C J. Mech. Eng. Sci. 1999, 213, 655–677. [Google Scholar] [CrossRef]

- Misra, K.; Shrotriya, A.K.; Singhvi, N.; Singh, R.; Chaudhary, D.R. Prediction of heat storage coefficient of two-phase systems with spherical inclusions. J. Phys. D Appl. Phys. 1994, 27, 1823. [Google Scholar] [CrossRef]

- Li, M.; Wu, Z.; Tan, J. Heat storage properties of the cement mortar incorporated with composite phase change material. Appl. Energy 2013, 103, 393–399. [Google Scholar] [CrossRef]

| Light | Wavelength | Average Light Reflectance (%) | |||||

|---|---|---|---|---|---|---|---|

| Plain Concrete | White | Yellow | Blue | Green | Red | ||

| VL | 390–700 nm | 30.7 | 94.0 | 53.9 | 59.6 | 43.7 | 36.6 |

| NIR | 700–2000 nm | 37.7 | 86.0 | 76.6 | 67.1 | 61.9 | 62.0 |

| SR | 390–2000 nm | 36.4 | 87.5 | 72.2 | 65.6 | 58.4 | 57.1 |

| Color | Upper Surface Heat Flux (W/m2) | Lower Surface Heat Flux (W/m2) |

|---|---|---|

| Plain Concrete (unpainted) | 463.40 | 83.50 |

| White Paint (com’l) | 170.10 | 56.35 |

| Red IGM Paint | 73.99 | 74.06 |

| White IGM Paint | 59.07 | 55.04 |

| Yellow IGM Paint | 95.40 | 55.40 |

| Blue IGM Paint | 89.88 | 55.83 |

| Green IGM Paint | 89.70 | 69.23 |

| Color | Temperature (°C) | ||

|---|---|---|---|

| Average Ambient | Upper Surface | Lower Surface | |

| Plain Concrete (unpainted) | 29.77 | 84.59 | 54.82 |

| White Paint (com’l) | 30.49 | 72.60 | 47.39 |

| Red IGM Paint | 28.57 | 74.83 | 45.65 |

| White IGM Paint | 31.18 | 73.10 | 44.66 |

| Yellow IGM Paint | 32.04 | 72.38 | 48.75 |

| Blue IGM Paint | 32.21 | 75.53 | 49.33 |

| Green IGM Paint | 30.14 | 74.28 | 49.70 |

| Color | Tmean (°C) | Tambient (°C) | (°C) | (W·m−2) | (J·kg−1·K−1) | (W·m−2·K−1·s0.5) | (W·m−2·K−1) |

|---|---|---|---|---|---|---|---|

| Plain Concrete (unpainted) | 69.94 | 29.74 | 40.203 | 391.34 | 126.96 | 9.73 | 24.40 |

| White Paint (com’l) | 60.19 | 30.66 | 29.533 | 114.18 | 50.43 | 3.87 | 9.69 |

| Red IGM Paint | 60.49 | 28.70 | 31.785 | 7.21 | 2.96 | 0.23 | 0.57 |

| White IGM Paint | 59.26 | 31.42 | 27.841 | 5.88 | 2.76 | 0.21 | 0.53 |

| Yellow IGM Paint | 61.09 | 32.28 | 28.806 | 41.66 | 18.86 | 1.45 | 3.62 |

| Blue IGM Paint | 62.88 | 32.50 | 30.382 | 35.73 | 15.34 | 1.18 | 2.95 |

| Green IGM Paint | 62.54 | 30.44 | 32.096 | 24.41 | 9.92 | 0.76 | 1.91 |

| Color | Upper Surface Heat Flux (W/m2) | Lower Surface Heat Flux (W/m2) |

|---|---|---|

| Plain Concrete (unpainted) | 158.10 | 34.80 |

| White Paint (com’l) | 40.58 | 25.16 |

| Red IGM Paint | 35.96 | 31.66 |

| White IGM Paint | 13.49 | 15.28 |

| Yellow IGM Paint | 32.00 | 33.53 |

| Blue IGM Paint | 37.17 | 19.72 |

| Green IGM Paint | 40.47 | 31.60 |

| Color | Ambient Temperature (°C) | Humidity (%) | Wind Speed (m/s) | Upper Surface Temperature (°C) | Lower Surface Temperature (°C) |

|---|---|---|---|---|---|

| Plain Concrete (unpainted) | 31.12 | 56.94 | 1.43 | 42.24 | 40.90 |

| White Paint (com’l) | 34.17 | 48.47 | 4.30 | 42.42 | 40.07 |

| Red IGM Paint | 35.80 | 43.84 | 2.38 | 45.97 | 41.91 |

| White IGM Paint | 33.02 | 57.47 | 2.46 | 35.41 | 35.23 |

| Yellow IGM Paint | 33.89 | 55.29 | 4.23 | 44.92 | 39.88 |

| Blue IGM Paint | 34.44 | 50.67 | 3.02 | 40.75 | 38.16 |

| Green IGM Paint | 33.70 | 56.50 | 3.23 | 42.37 | 38.75 |

| Color | Ambient Temperature (°C) | Humidity (%) | Wind Speed (m/s) | Upper Surface Temperature (°C) | Lower Surface Temperature (°C) |

|---|---|---|---|---|---|

| Plain Concrete (unpainted) | 26.49 | 81.72 | 1.16 | 31.64 | 33.98 |

| White Paint (com’l) | 30.06 | 68.90 | 2.67 | 29.47 | 30.46 |

| Red IGM Paint | 29.38 | 72.80 | 1.28 | 29.19 | 30.32 |

| White IGM Paint | 31.02 | 68.46 | 1.69 | 30.63 | 31.49 |

| Yellow IGM Paint | 29.45 | 82.07 | 3.50 | 30.36 | 31.17 |

| Blue IGM Paint | 29.32 | 78.75 | 1.50 | 29.82 | 30.86 |

| Green IGM Paint | 29.67 | 74.30 | 1.95 | 28.84 | 29.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.-F.; Xie, Y.-X.; Syu, J.-Y.; Huang, C.-H.; Tsai, H.-H.; Cheng, T.-W.; Chen, Y.-C.; Lee, W.-H. A Study on the Influence of the Next Generation Colored Inorganic Geopolymer Material Paint on the Insulation Measurement of Concrete Building Shell. Sustainability 2022, 14, 164. https://doi.org/10.3390/su14010164

Li Y-F, Xie Y-X, Syu J-Y, Huang C-H, Tsai H-H, Cheng T-W, Chen Y-C, Lee W-H. A Study on the Influence of the Next Generation Colored Inorganic Geopolymer Material Paint on the Insulation Measurement of Concrete Building Shell. Sustainability. 2022; 14(1):164. https://doi.org/10.3390/su14010164

Chicago/Turabian StyleLi, Yeou-Fong, Ya-Xuan Xie, Jin-Yuan Syu, Chih-Hong Huang, Hsin-Hua Tsai, Ta-Wui Cheng, Yen-Chun Chen, and Wei-Hao Lee. 2022. "A Study on the Influence of the Next Generation Colored Inorganic Geopolymer Material Paint on the Insulation Measurement of Concrete Building Shell" Sustainability 14, no. 1: 164. https://doi.org/10.3390/su14010164

APA StyleLi, Y.-F., Xie, Y.-X., Syu, J.-Y., Huang, C.-H., Tsai, H.-H., Cheng, T.-W., Chen, Y.-C., & Lee, W.-H. (2022). A Study on the Influence of the Next Generation Colored Inorganic Geopolymer Material Paint on the Insulation Measurement of Concrete Building Shell. Sustainability, 14(1), 164. https://doi.org/10.3390/su14010164