1. Introduction

Supply chain sustainability is the management of environmental, social and economic impacts of products and services throughout their lifecycle, and the promotion of good governance practices [

1]. Managing supply chain sustainability effectively is required for the promotion of good governance practices [

2] and for the proper management of the environmental, social, and economic impacts of products and services throughout their life cycle [

3]. Furthermore, the purpose of supply chain sustainability is to create, protect and develop long-term environmental, social and economic values for all stakeholders involved in the delivery of products and services to the market [

4].

In particular, with the rapid increase in population and demand worldwide and the decrease in natural resources, the problem of meeting the food needs has become one of the most important issues for the global community [

5]. This problem increases the importance of planning the future of the food sectors, and it is extremely important to focus on sustainable food and food supply chains in order to meet the nutritional needs of the growing population safely and to leave a liveable world to future generations [

6].

The food supply chain needs to be handled as a whole system due to the abundance of data related to the activity, starting with the supply of quality and safe raw materials [

7], the processes of the food, intermediate and finished product logistics and reaching the consumer [

2]. Food supply chain management aims to protect food safety and quality, and is the coordination of business processes in order to ensure the sustainability of product and information flow throughout the chain [

7].

Sustainability in food supply chains has always been a difficult issue [

6]. Supply chains have been adversely affected around the world, especially in uncertain times such as the COVID-19 pandemic, with emerging restrictions and business interruptions, and the sustainability of supply chains is facing disruption [

8]. In particular, the food supply chain faces difficulties from the first to the last stage [

9]. The restrictions brought by the COVID-19 pandemic make it difficult for farmers to access the inputs that constitute the first stage of the food supply chain and affect the production capacity, and also logistical problems arise in the food supply chain [

10]. In addition, there are many problems such as the uncertainties in the current situation caused by the COVID-19 pandemic, difficulty in accessing raw materials in food supply chains [

8], loss of cooperation between suppliers, communication problems experienced in the processes i.e., [

10]. This uncertain time threatens the sustainable food supply chain [

11]. Hence, it is critical to achieve sustainable food supply chains [

12]. Furthermore, increasing the resilience of food supply chains, especially in times of uncertainty, depends on its sustainability [

11] and the resilience and sustainability are related terms with each other for food supply chain [

10].

The main goal of this study is to find answers to the questions: what factors should be considered in order to ensure sustainability in food supply chains and which of these factors have been the most affected in uncertain times such as the COVID-19 pandemic? In order words, this study aims to determine the factors that contribute to sustainable food supply chains and ensure that the necessary measures are taken for the sustainability of food supply chains in the future, while also increase their resilience to disruptions in uncertain times such as the COVID-19 pandemic. For this purpose, the research question of the study is given below:

Research Question 1 (RQ1). How are the relationships between sustainability factors in the context of food supply chains to assess the impact of COVID-19?

To find an answer to this research question, first of all, sustainability factors based on stages of sustainable food supply chains are determined by considering a literature review and, secondly, the relationships between sustainability factors based on stages of sustainable food supply chains are analysed by using Interpretive Structural Modelling (ISM). One of the main contributions of this study to the literature is the determination and analyses of the factors that need to be provided for the sustainability of food supply chains in times of uncertainty, in terms of the various stages of the food supply chain. Moreover, as a uniqueness of the study, the study aims to assess the impact of COVID-19 on sustainable food supply chains by determining sustainability factors based on stages of sustainable food supply chains and showing the relationships between sustainability factors.

The paper reviews the literature on sustainable food supply chains and factors of sustainable food supply chains in

Section 2.

Section 3 covers methodology and

Section 4 includes the implementation of the methodology in this study.

Section 5 consists of a discussion of results and the implications of the study. Lastly,

Section 6 concludes this study by assessing limitations and scope for future works.

2. Literature Review: Sustainability Factors Based on Stages of Sustainable Food Supply Chains

Food supply chains are very vulnerable and complex supply chains by nature [

10]. For this reason, the sustainability of the food supply chain in the face of disruptions such as the COVID-19 pandemic is under threat [

11]. Sustainability of food supply chains depend on ensuring sustainability at every stage, which are production, processing, distribution, retail and consumer of the supply chain [

12]. After considering the literature, these are the factors that make food supply chains sustainable. However, as shown in

Table 1, at which stage of the food supply chain these factors are important and should be considered is an issue that needs to be studied [

13]. In line with this research gap, in this study, the 10 main sustainability factors required for the five main stages of food supply chains were determined based on the literature.

According to literature, traceability provides sustainability in the production stage of food supply chains [

9]. The traceability of the production process, which is the first stage of the food supply chain, ensures that the production supply chain starts error-free from the first stage [

14]. Moreover, traceability in food supply chains helps to prevent losses in the production process and supports increased sustainability in food supply chain [

15]. Especially in uncertain times such as the COVID-19 pandemic, tracing production process provides to increase responsiveness of food supply chains from the beginning section of the supply chain [

11,

16]. Furthermore, food safety and security are an important sustainability factors based on stages of sustainable food supply chains [

14]. Especially in the production stage of food supply chains, there can be food fraud and losses because of the lack of safety and security issues [

16]. Therefore, it is critical to adopt new measures to trace the production stage in food supply chains, particularly in uncertain times [

17].

Table 1.

Summary of the studies on the sustainability factors of food supply chains.

Table 1.

Summary of the studies on the sustainability factors of food supply chains.

| Factors | Authors |

|---|

| Traceability | [9,14,15] |

| Food safety and security | [14,16] |

| Know-how transfer | [5,14,17,18,19,20] |

| Information sharing | [19,20] |

| Logistics Networking | [13,21,22,23,24] |

| Risk mitigation | [24,25] |

| Responsiveness | [25,26,27,28] |

| Employee Commitment | [29,30] |

| Innovation | [31,32,33] |

| Managerial Approaches | [34,35] |

After the production stage of food supply chains, the processing stage is another critical stage for sustainable food supply chains [

18]. The majority of losses in food supply chains come from the processing stage [

14]. In the processing stage, lack of knowledge in processes, traditional methods of operations [

5] and, most importantly, the lack of know-how threaten the sustainability of food supply chains [

18]. Therefore, know-how transfer provides the learning of information on how to do the job in the production process and the use of technology in the food supply chain production stage [

19]. In order to stay resilient to disruptions and to be able to be responsive and sustainable, issues such as worker regulation and adoption of new technologies within the scope of know-how transfer come to the fore [

20]. In addition, information sharing prevents lack of misunderstandings about operations and conflicts between suppliers in processing process of food supply chains [

19]. Especially in times of disruption, since food supply chains have multiple stakeholders and many suppliers in the processing process, a lack of information sharing causes many problems in the aim to be resilient to disruptions [

20].

Since food supply chains covers vulnerable products, the distribution stage is critical for sustainable food supply chains [

13,

14,

15,

16,

17,

18,

19,

20,

21]. Dependant on food type, distribution routes, networks or vehicle conditions may change [

22]. Moreover, one of the most critical things is providing network optimization in distribution process of food supply chains to be sustainable [

23]. Effective network optimization can provide several environmental and economic advantages to companies such as providing low emissions and low transportation and distribution cost and reflection of low carbon emissions also enables social sustainability to be achieved. Thus, it is crucial in order to achieve sustainability dimensions simultaneously in order to gain competitive advantages. Especially in uncertain times such as the COVID-19 pandemic, food supply chains have been faced with disruptions in terms of logistics [

24]. For this reason, providing an effective logistics networking in food supply chains ensures that food supply chains are resilient to disruptions and sustainable based on economic, environmental and social dimension [

22]. Furthermore, as mentioned previously, food is a product worth considering and there are many risks, especially in times of disruption. Therefore, risk mitigation strategies are crucial for the businesses [

25].

In uncertain times, such as during the COVID-19 pandemic, the most important thing is to be able to react to the difficulties encountered [

25]. Responsiveness enables rapid adaptation to new conditions in the face of sudden changes that may occur [

26]. Being able to meet responsiveness, especially at the retail stage, is extremely important for the sustainability of food supply chains [

27]. In the retail stage, it is significant able to react quickly to changing conditions and adapting to new conditions affects the sustainability of food supply chains [

25,

28]. In addition, although it is crucial to every stage of sustainable food supply, employee commitment in the retail stage contributed to being more sustainable and resilient against sudden disruptions [

29]. The commitment of the employees in the process ensures that the sustainability of the food supply chain is increased in the retail stage, which is the previous stage from the consumer, and the wastes and problems that will arise in the retail stage are prevented [

30].

Furthermore, ensuring sustainability at the consumer stage, which is the last stage of the food supply chain, is a key element [

31]. Moreover, innovation is the power source that is critical for solving economic, social, environmental and political problems, increasing growth and prosperity and resolving crises [

32]. Being able to adopt innovative approaches at the consumer stage, especially in uncertain times such during the COVID-19 pandemic, ensures that consumers are more involved in the process and the sustainability of the food supply chain [

32]. Similarly, innovation-oriented approaches change consumer perception and create more flexible, responsive and sustainable food supply chains in the face of sudden disruptions [

33]. Lastly, in addition to all the aforementioned factors, managerial approaches, especially at the consumer stage, affects the sustainability and resiliency of food supply chains [

34]. The support and efforts of the management increase the sustainability of the food supply chain on the consumer side and make it resilient against sudden disruptions [

35].

Different factors have been discussed in the literature for different stages of the supply chain, but the impact of COVID-19 in the sustainable food supply chain is a very important issue for every stage and needs to be evaluated in a holistic way. Ten different sustainability factors as indicated in

Table 1 have an impact on sustainability in terms of economic, environmental and environmental aspects. Indicated factors affect sustainability in terms of three main dimension and all of these factors affect each other and are crucial to creating more sustainable supply chains. In order to increase the resilience of the supply chain against the disruptions encountered in times of uncertainty, this paper aims to determine the factors affecting the sustainability of food supply chains, and to ensure that the necessary measures are taken for the sustainability of the food supply chains.

3. Methodology

This study focuses on investigating relationships between factors in order to ensure sustainability in food supply chains and determining factors that most affected in uncertain times. Based on the literature, 10 different key factors of sustainability in the food supply chain are proposed. Using ISM methodology, the relationships between sustainability factors in the food supply chain are investigated. ISM methodology is discussed in the next section.

Interpretive Structural Modelling

The ISM method is useful for understanding the relationships between factors and analysing them [

36]. This method provides the determination of the factors affecting and affected by the system by analysing the relationships between the components [

37]. This method is beneficial in revealing direct and indirect factors in the system rather than individual effects and in order to decrease complexity of the system [

38]. Diagraph is important in order to present clear relationships between factors [

39]. After determining factors in the system, the first stage is beginning with the developing structural self-interaction matrix [

40]. In the second stage, self-interaction matrix is converting into reachability matrix with the carried-out transitivity controlling process [

41]. The final stage includes classifications of the factors [

42] and developing of the structural model. Stage of this model is summarized below [

43].

Stage 1—Developing Structural Self-Interaction Matrix: Structural self-interaction matrix is developed considering pairwise comparisons of experts. It is the stage of creating a structural Self-Interaction Matrix using ideas from experts. In this stage, a decision-making team evaluate the contextual relationships between factors, these experts establish contextual relationships with the different symbols used in SSIM. Contextual relationships were created by contacting the experts in person to collect the necessary data to create this matrix. Expert opinions are collected through a standard questionnaire. Individual answers are compiled and contextual relations are shared with experts to ensure consensus. The relations are indicated in the matrix by using V, A, X, O symbols based on their relationships between them. Thus, each expert evaluated the relationship of the proposed factors with each other by using the symbols V, A, X, O symbols. The meaning of this symbols is explained below.

V: for the relation from factor i to factor j

A: for the relation from factor j to factor i

X: for both direction relations

O: no relation between the factors

Stage 2—Transforming to Reachability Matrix: This step covers developing initial and final reachability matrix. Transforming the initial reachability matrix from structural self-interaction matrix are conducted in this stage. After carrying out the transitivity controlling process, a final reachability matrix is developed.

Stage 3—Presenting Level partitions: At this stage, an accessibility set and antecedent sets are developed for the factors. Using the final accessibility matrix, an intersection set is created for all factors to determine the level of factors. This process is repeated to find all factor levels.

Stage 4—Constituting Conical matrix: Conical matrix is developed in order to cluster factors depending on their dependency power.

Stage 5—Developing Digraph: To identify the relations between factors, digraph visual representation is developed.

4. Implementation of the Study

This study focuses on the ISM approach in order to analyse a relationship of sustainability factors in food supply chains during COVID-19.

Table 2 indicated the sustainability factors in the food supply chain.

This methodology begins with the development of pair-wise comparisons by gathering expert opinions. A decision-making team consists of industry and academic expert to evaluate the contextual relationships between sustainability factors in the food supply chain. Ten industry experts are competent in their field, working at different stages of the supply chain and have more than 5 years of experience. Besides, five experts are chosen from academia who has different qualification and papers related to food supply chain management. Details are indicated in

Table 3.

Table 4 shows a Self-Interaction Matrix constructed using expert opinions. To evaluate the contextual relationships between sustainability factors, a decision-making team composed of experts which was shown in

Table 3 is organized. For the obtaining of the data required to create the contextual relationship between the sustainability factors in the food supply chain, the experts are contacted in person and the opinion of experts is collected by standardized questionnaire. These individual responses are compiled and shared with the experts again the final version of matrix in order to provide consensus of opinions for the contextual relationships between the sustainability factors in the food supply chain.

This Structured Self Interaction Matrix is converting into binary format considering using symbol meanings.

Table 5 indicates the initial reachability matrix.

Table 6 presents the final reachability matrix through transitivity processes and it shows driving and dependence power. Transitivity is shown as a notation 1*.

Dependence power and driving power of sustainability factors are presented in the

Table 7.

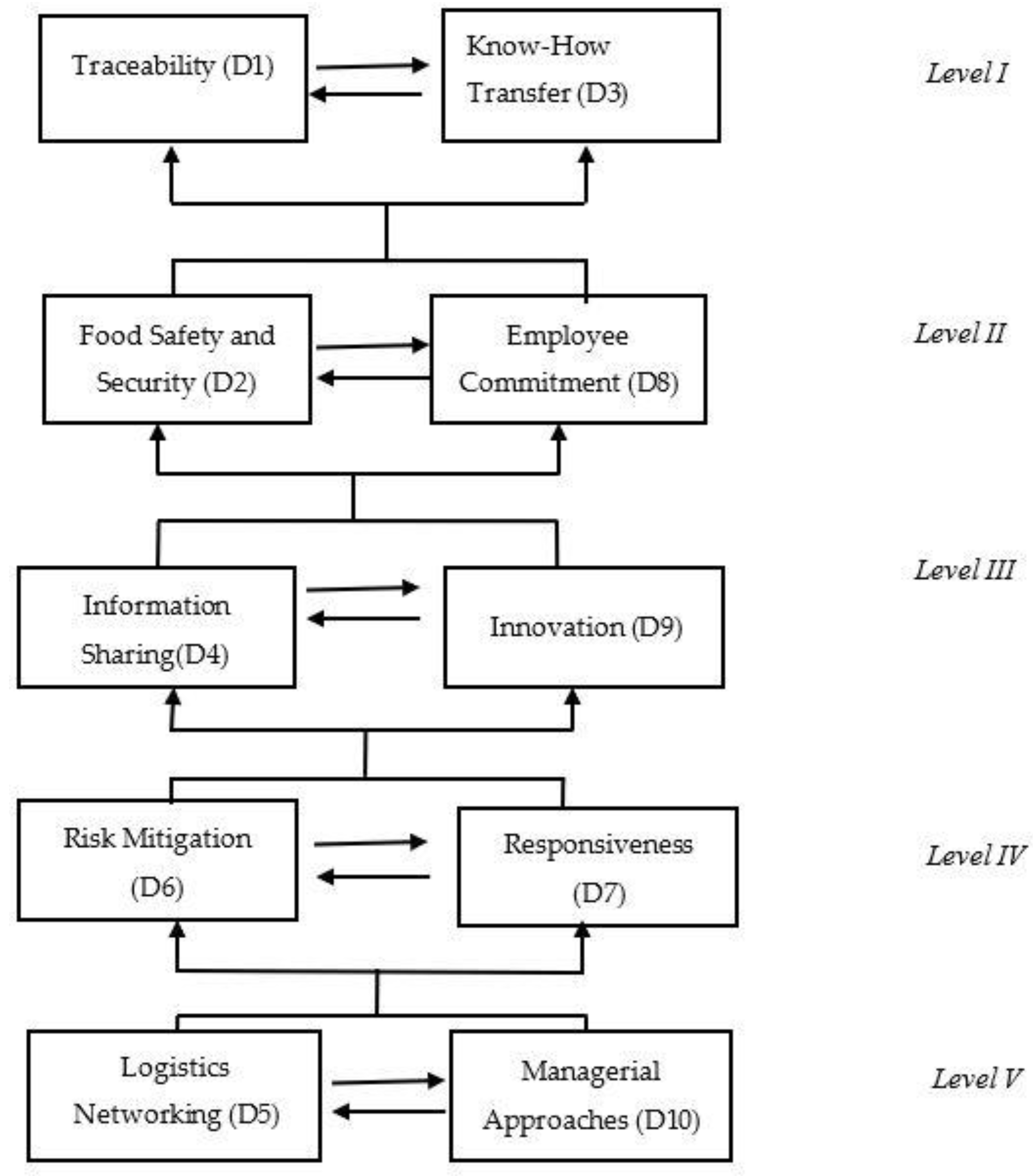

Ten sustainability factors are placed in five levels after five iterations.

Table 8 summarized the iteration process.

As presented in

Table 8, iteration I of the level partition matrix, the matching sustainability factors are Traceability and Know-How Transfer that located at the top level of the ISM diagram. The matching factors are in iteration 2, Food Safety and Security and Employee Commitment that located at the second level of the ISM diagram. In iteration 3, the matching factors are Information Sharing and Innovation. The matching factors in the iteration 4 are Risk Mitigation and Responsiveness that presented at level four in the ISM diagram. In the last iteration, in the iteration 5, the matching factors are Logistics Networking and Managerial Approaches that shown at the lowest level in the ISM diagram.

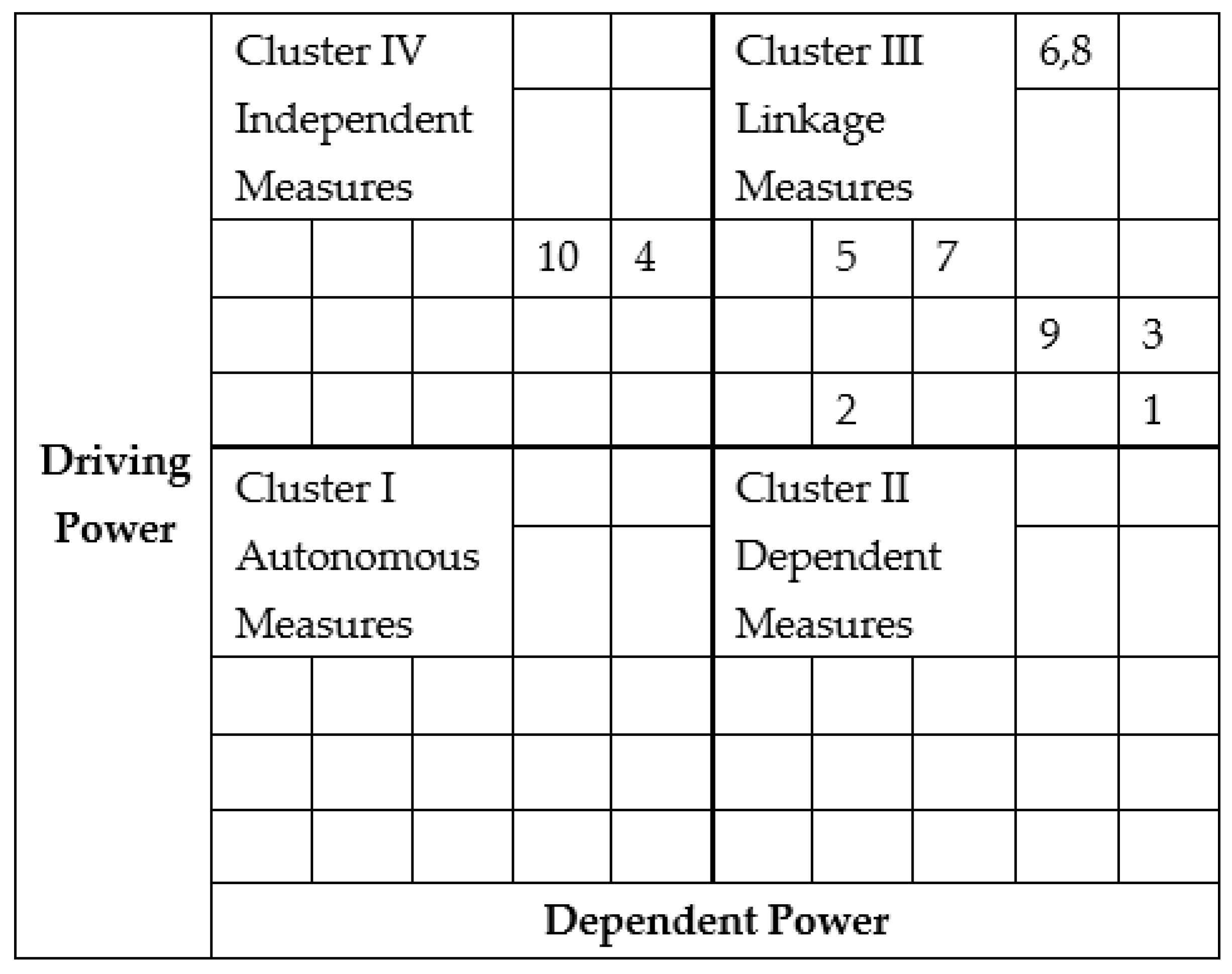

MICMAC analysis presented in the

Figure 1. It can be concluded that information sharing and managerial approaches are classified as driving factor; food safety and security, know-how transfer, logistics networking, risk mitigation, employee commitment, innovation traceability and responsiveness are categorized as a linkage factor.

MICMAC analysis that is cross-impact matrix multiplication to provide classification is based on the indirect relationships method to define measures of factors. MICMAC analysis is used to classify the factors and validate the interpretive structural model factors in the study. According to the MICMAC analysis, each factor is plotted as a point in the four quadrants in the coordinate system. Autonomous factors have a weak effect compared to other factors but due to strong key factors, maximum attention is required. In order to comprehend system, independent factors that has high driving power but low dependency are crucial since most factors depend on these cluster. These factors have a great influence on other factors in the system. Information Sharing and Managerial Approaches are independent factors in this system. Thus, as a deduced from the

Figure 1, Information Sharing and Managerial Approaches are strong key factors and play an important role in achieving sustainability. Besides, linkage factors that have both strong driving power and dependency power, thus any change in the system can directly affect these factors. Other sustainability factors suggested in

Table 2: Traceability, Food Safety and Security, Know-How Transfer, Logistics Networking, Risk Mitigation, Responsiveness, Employee Commitment, Innovation are linkage factors that are unstable and most influence others. Sustainability in the food supply chain is mainly focuses on the creating, protecting and developing long-term environmental, social and economic values for all stakeholders in the supply chain. Due to the dynamic, complex and holistic nature of sustainability, these proposed factors have been achieved interrelated and interrelated.

Figure 2 showed ISM diagraph for sustainability factors in the food supply chain.

According to

Figure 2, logistics networking and managerial approaches which located at the lower level in the ISM diagraph are fundamental factors for the ensure sustainability in the food supply chain. Especially, during the COVID-19 pandemic, logistics networking has become vital for firms since they need to manage their activities effectively in order to deal with disruptions in the supply chain. Besides, managerial approaches also need to encourage the improving sustainability in the food supply chain, it is crucial to adopt approaches that will provide flexibility to adapt to constantly changing conditions, especially during the pandemic. Another important factor are risk mitigation and responsiveness which are interrelated with each other in order to decrease risk in the supply chain, responsiveness and information sharing is required for ensure sustainability. By increasing information sharing with the stakeholders, food safety and security can be achieved. Employee commitment can be stimulated by innovations and effective information sharing. In addition, adopting innovative ideas in the supply chain using digital technologies and know-how transfer in the supply chain by increasing collaboration between stakeholders, food safety and security have caused to be increased traceability in the supply chain.

5. Discussion and Implications

As mentioned before, sustainability is one of the core issues for food supply chains to provide continuity for the processes with minimum losses [

44]. Since food supply chains consist of vulnerable products and processes, food supply chains cannot stay agile, resilient and sustainable [

45]. For this purpose, in this study, sustainability factors based on stages of sustainable food supply chains are determined to understand that which factors should be taken into consideration to be sustainable in uncertain times such as the COVID-19 pandemic.

According to results of the study, Information Sharing and Managerial Approaches are handled as driving factor similar with [

46]; Food Safety and Security is determined as one of the linkage factors in contrast with [

47]. Moreover, Know-How Transfer is another linkage factor similar with [

48] and also Logistics Networking, Risk Mitigation, Employee Commitment, Innovation are categorized as a linkage factor [

49]. Furthermore, Traceability and Responsiveness determined as linkage factor in this study with the similar with [

50].

As a managerial implication, for the production stages of the food supply chains, food safety and security are essential factor in food supply chains especially in food production stages. If food safety cannot be ensured at the initial stage of supply chains, which is production, disruptions will occur in all processes of the supply chain and sustainability will suffer. Therefore, employees in the selection of manufacturers must be qualified personnel and have knowledge of production processes. At the same time, the producers or suppliers to be partnered with should be passed through certain processes and their knowledge levels should be increased. In terms of food safety, it is necessary to work with producers who produce in accordance with legal regulations.

Traceability is determined as a linkage factor in food supply chains especially in production stages. The supplier must establish a documented traceability system for each product that meets its requirements. New technologies should be used to ensure traceability in the production process of food supply chains. With the help of technologies such as Blockchain, RFID, barcode system, a traceable system can be obtained from the first stage of production.

For processing stage, since information sharing is one of the driving factors of sustainability in food supply chains, managers should give importance to information sharing between partners in food supply chains. In particular, data supporting process improvements or management decisions is realized through information sharing and collaboration with supply chain stakeholders in processing stages of the food supply chains. Therefore, new technological advances such as Blockchain, Industry 4.0 i.e., can be beneficial to provide effective information sharing in processing stages of food supply chains. By the way, it will be beneficial to reduce food loss and waste in processing stages of the food supply chains.

In processing stage of food supply chains, know-how transfer is another essential factor to have sustainable food supply chains. In this case, new policies should be adopted between stakeholders of food supply chains to provide collaboration between operations. Moreover, university-industry collaborations can be organized to provide know-how transfer in food supply chains.

Especially in the processing stages, since food is a vulnerable product, it is not resistant to disruptions. The effective network structure enables companies to carry out their operations with high efficiency and low costs. For this reason, network optimization methods should be adopted. Network optimization helps to create the desired network structure by quickly identifying the inefficiencies in the supply chain infrastructure from end to end. By converting network optimization models to digital models, comparisons can be made between scenarios. Traditional supply chain risk managements are insufficient to reduce the risks in the supply chain in the globalizing world. The most important step in the face of the situations encountered in the supply chain is to determine the risk and to make a strategy decision accordingly. For this reason, in order to reduce the risk in the supply chains, it is necessary to provide flexibility, information sharing and cooperation at the processing stage.

For the retailer stage, responsiveness level varies depending on retailer knowledge level and discipline in the process. For this reason, trainings and seminars should be organized in order to have qualified employees at retailer level and to ensure excellence in operations. Retailers should be constantly included in the process and duty awareness should be increased. Moreover, ensuring employee commitment at the retailer stage of food supply chains can be achieved with high employee motivation. Training, information and motivation activities to be organized by the management for the employees will increase the commitment of the employees to the process. At the same time, adopting a reliability strategy among retailers will increase the competitive advantage.

For consumer stages, to have sustainability standards in food supply chains, another important factor is managerial approaches. Especially at the consumer stage, management’s approaches make it easier for the feedback from the consumer to be effective and to ensure sustainability throughout the food supply chain. Management should adopt a customer-oriented, demand-sensitive system approach that maximizes customer satisfaction in order to ensure sustainability in the food supply chain.

Especially in the face of sudden disruptions in food supply chains, being able to involve the consumer in the process and increasing their loyalty increases the resilience of the supply chains. In addition, the idea of “winning together” comes to the fore in the global supply chain, and this process requires being a whole at all stages of the supply chain. For this reason, innovation-oriented approaches should be adopted at the consumer stage. Being able to make changes in the process in the face of sudden situations, being flexible, and being able to offer innovations by thinking consumer-oriented, provides an increase in innovation at the consumer stage of food supply chains.

6. Conclusions

Food supply chains are more complex and vulnerable since the world is changing and globalized. Increasing population and demand numbers affect sustainability in the food supply chain. Pandemics that cause sudden disruptions in supply chains, especially COVID-19, affect even more due to the vulnerable structure of the food supply chain.

Moreover, the most important way to ensure sustainability in food supply chains is to know and understand the sustainability factors of food supply chains based on food supply chain stages. In line with this purpose, one of the main contributions of this study to the literature is to be able to define the sustainability factors in the five stages of the food supply chain, which are production, processing, distribution, retail and consumer stages. The other critical contribution is to find logical relationships between these determined sustainability factors of food supply chains based on food supply chain stages. Therefore, Interpretive Structural Modelling method is implemented in this study. As a result, while Information Sharing and Managerial Approaches are classified as driving factor; Food Safety and Security, Know-How Transfer, Logistics Networking, Risk Mitigation, Employee Commitment, Innovation, Traceability and Responsiveness are categorized as a linkage factor.

As a limitation of the study, in digitalization age, these determined factors can be modified over time. For future research, the study can be conducted in another supply chains instead of food supply chains. Moreover, the implementation of the study can be organized in developed countries. Furthermore, the impact of digitalization, using new technologies in food supply chains, can be studied.