Optimizing the Power Generation of a Wind Farm in Low Wind Speed Regions

Abstract

1. Introduction

2. Literature Review

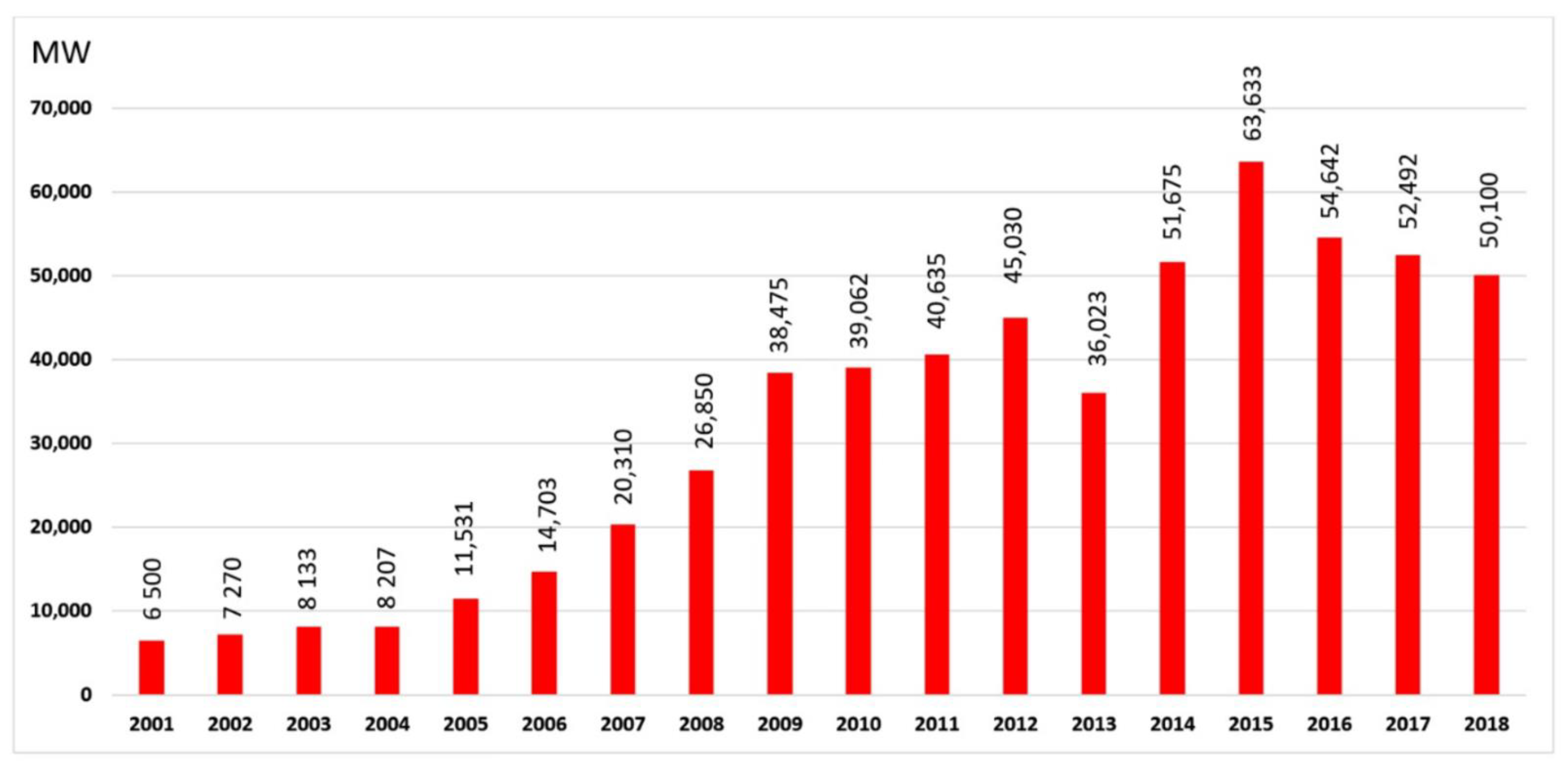

2.1. Global Wind Farm Power Generation

2.2. Wind Farm Status in GCC Countries

2.3. Potential Factors Affecting Wind Turbine Power Generation

2.4. State of Arts

2.5. Overview of the Sir Bani Yas Wind Farm

2.6. Sir Bani Yas’ Weather

3. Methodology

3.1. Research Approach

3.2. Proposed Strategies

3.3. Mathematical Model Set-Up

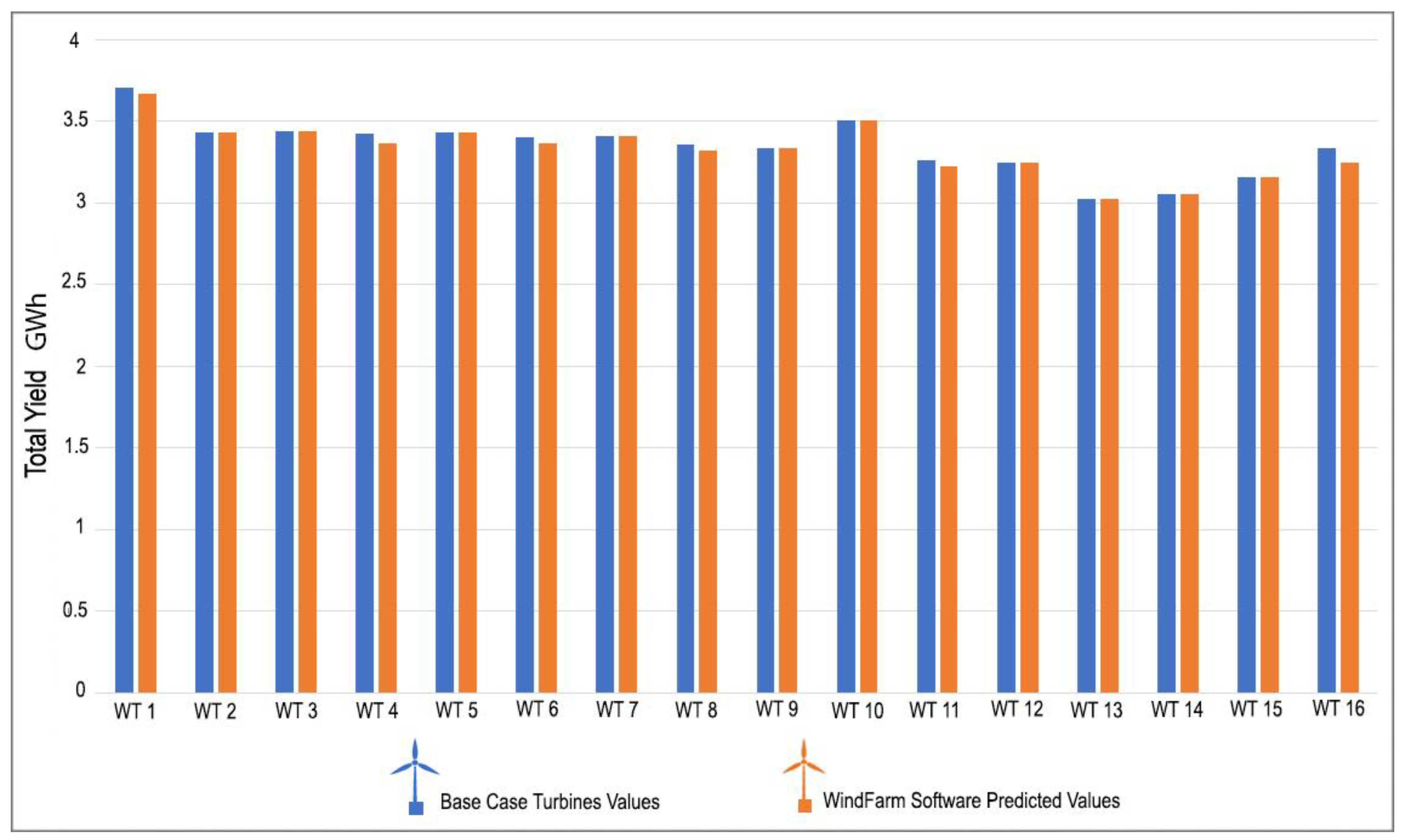

4. Results and Findings

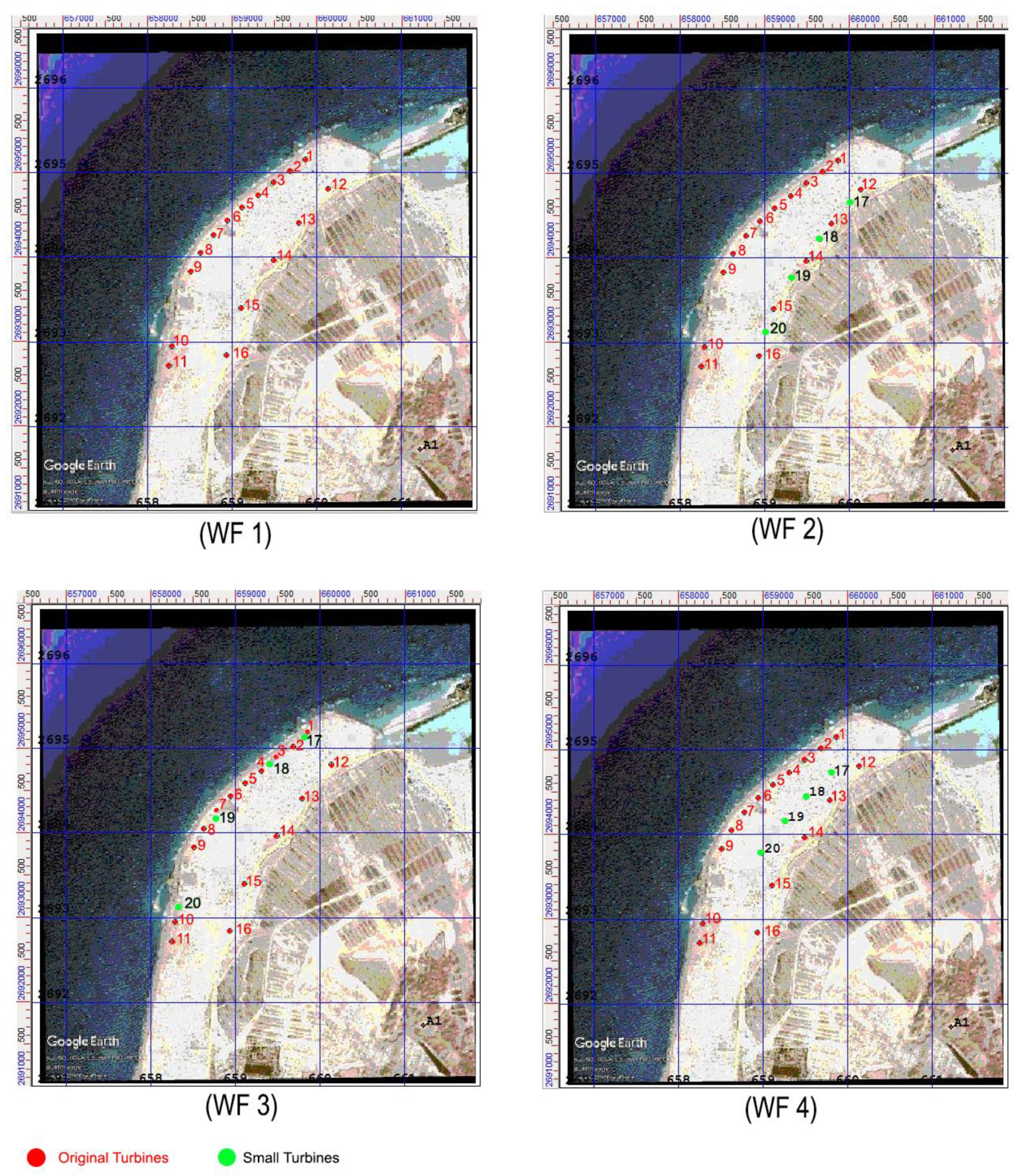

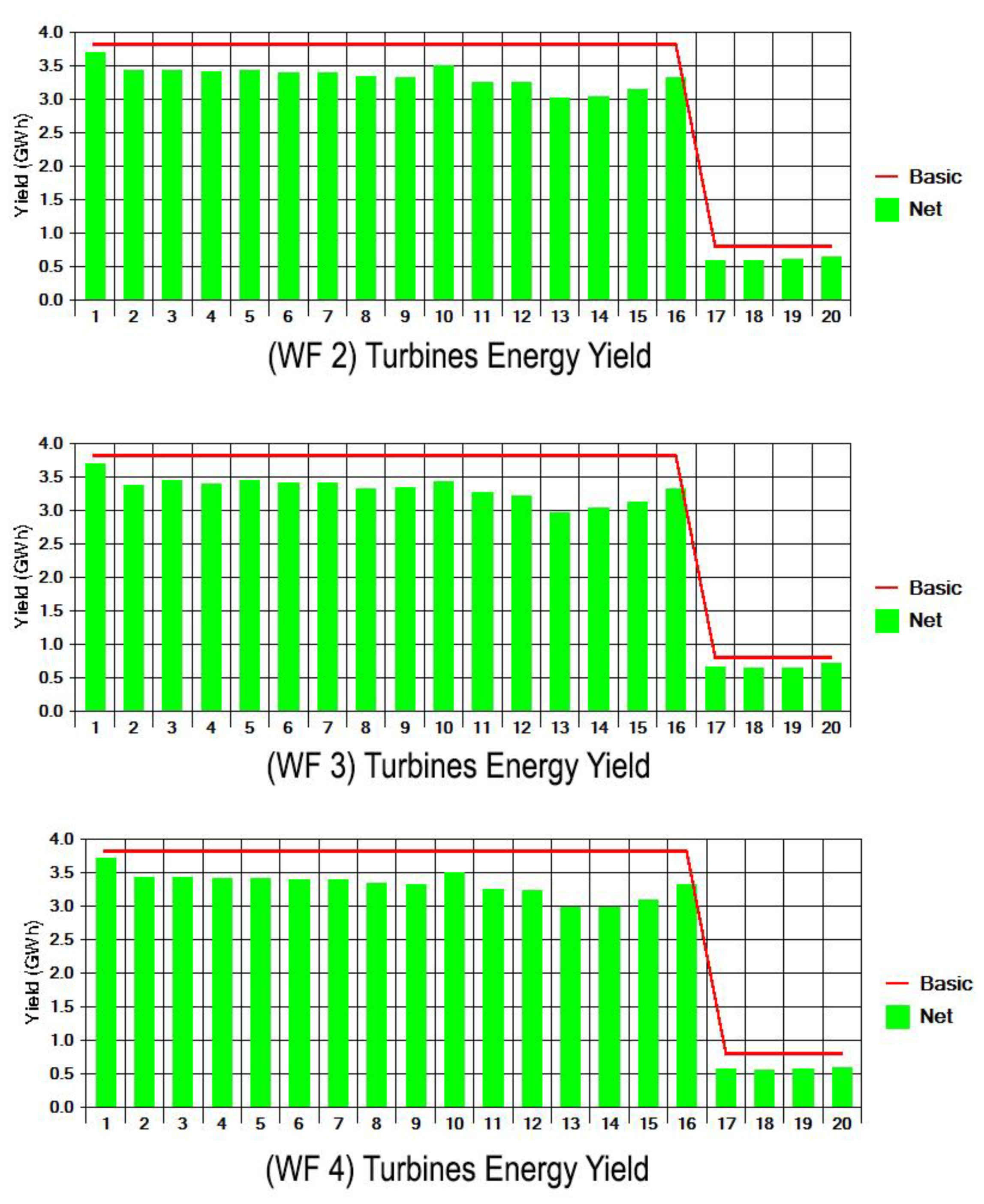

4.1. Strategy A: Inserting Smaller Turbines between the Original Turbines

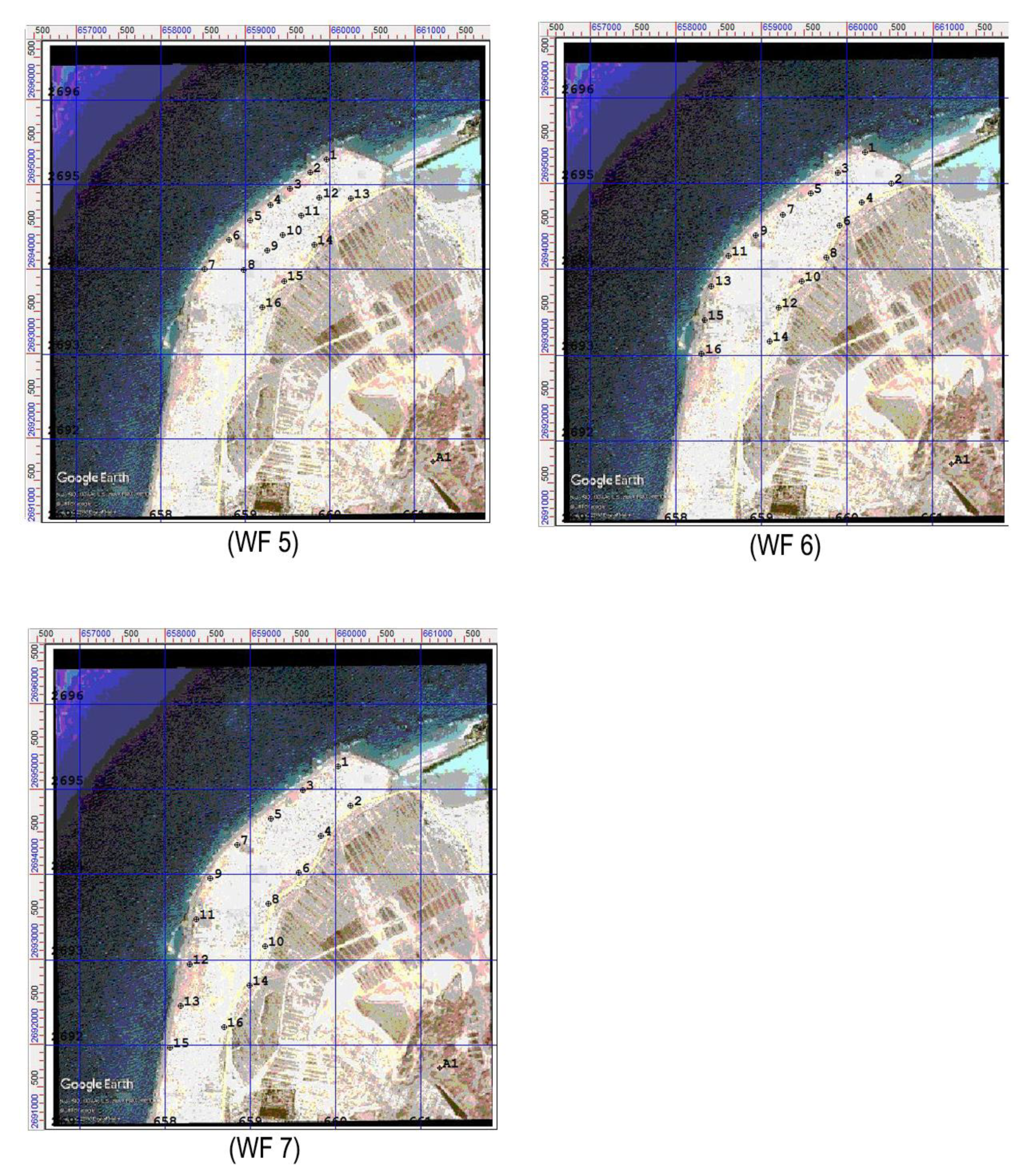

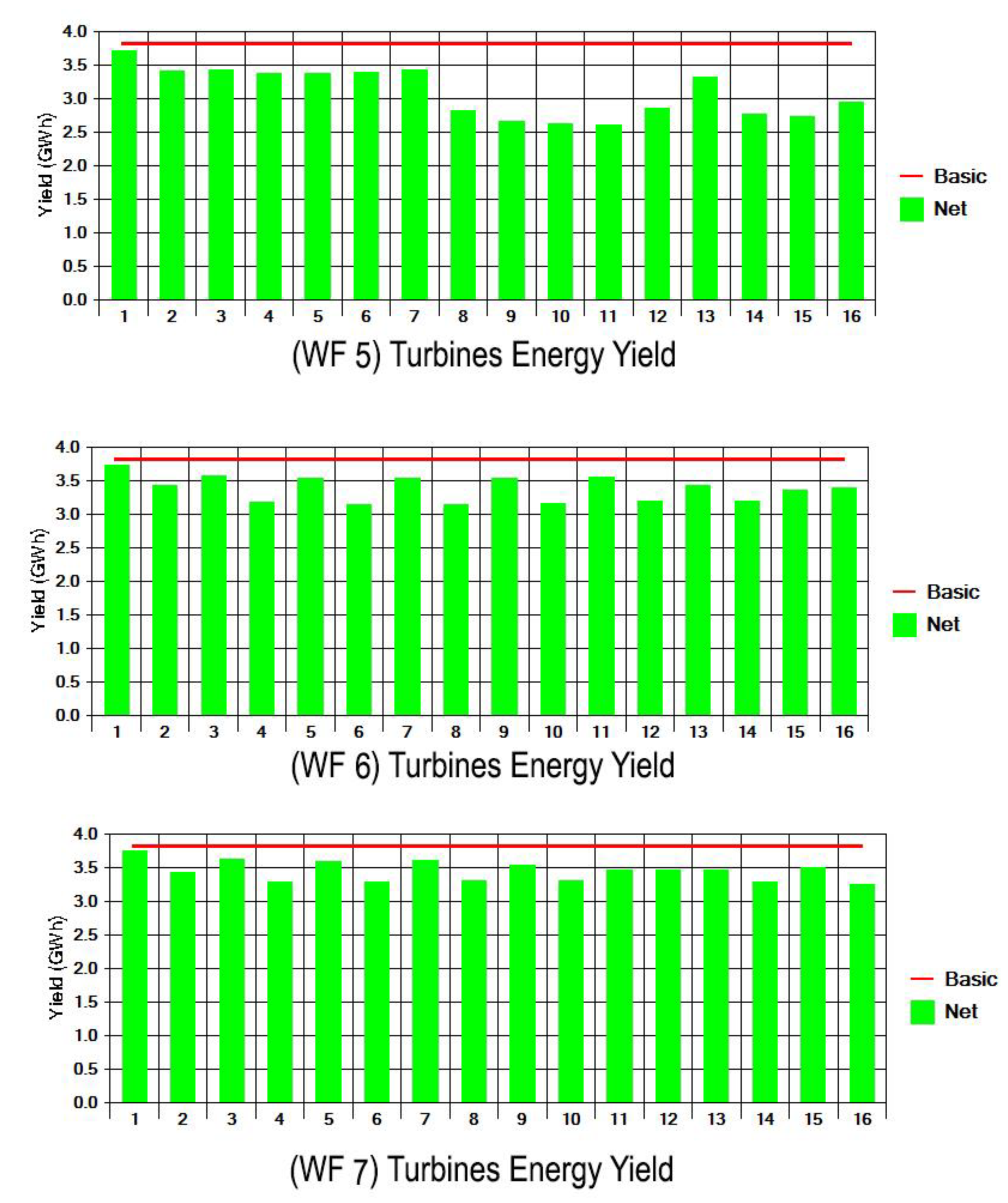

4.2. Strategy B: Changing the Spacing between the Turbines

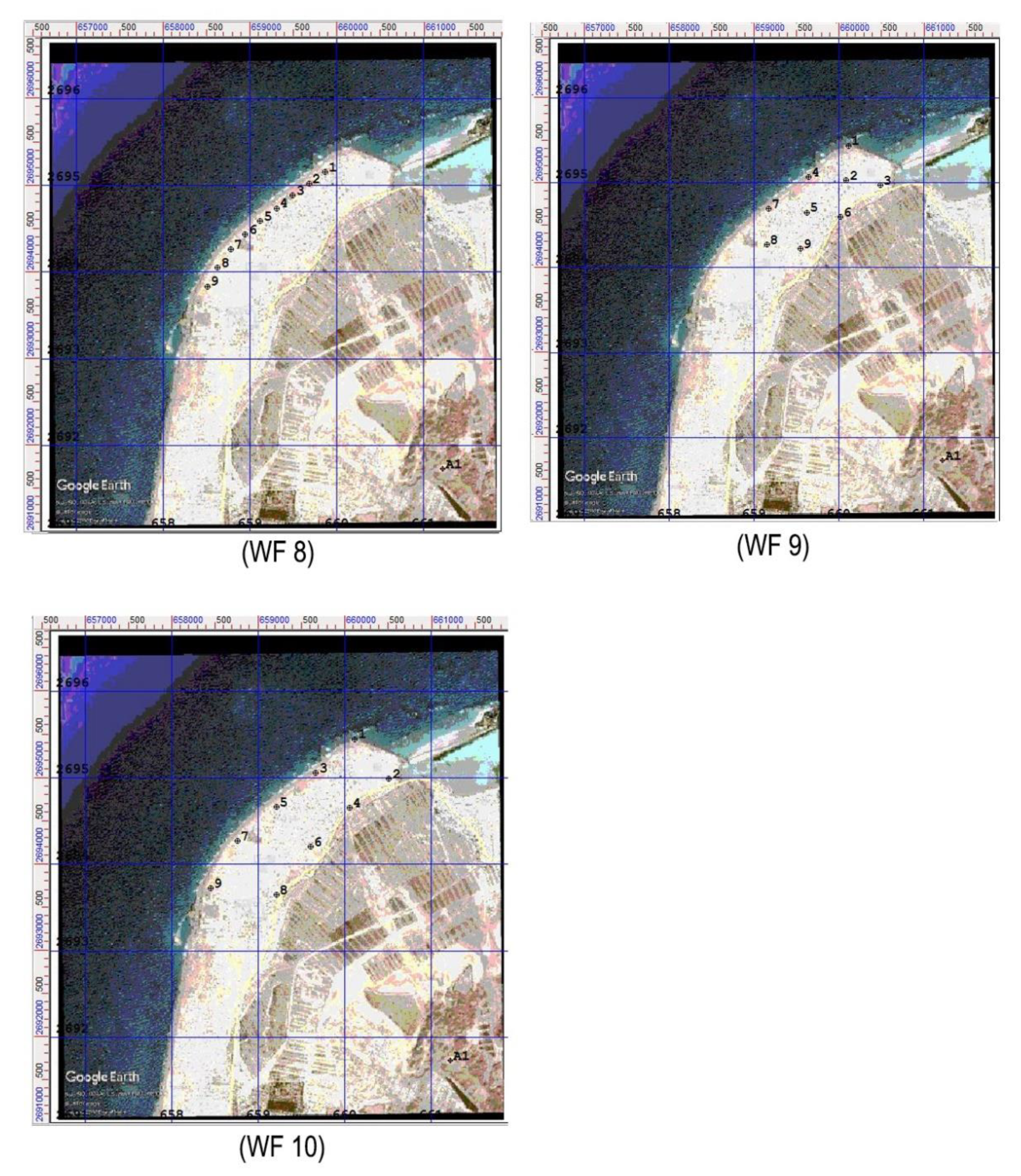

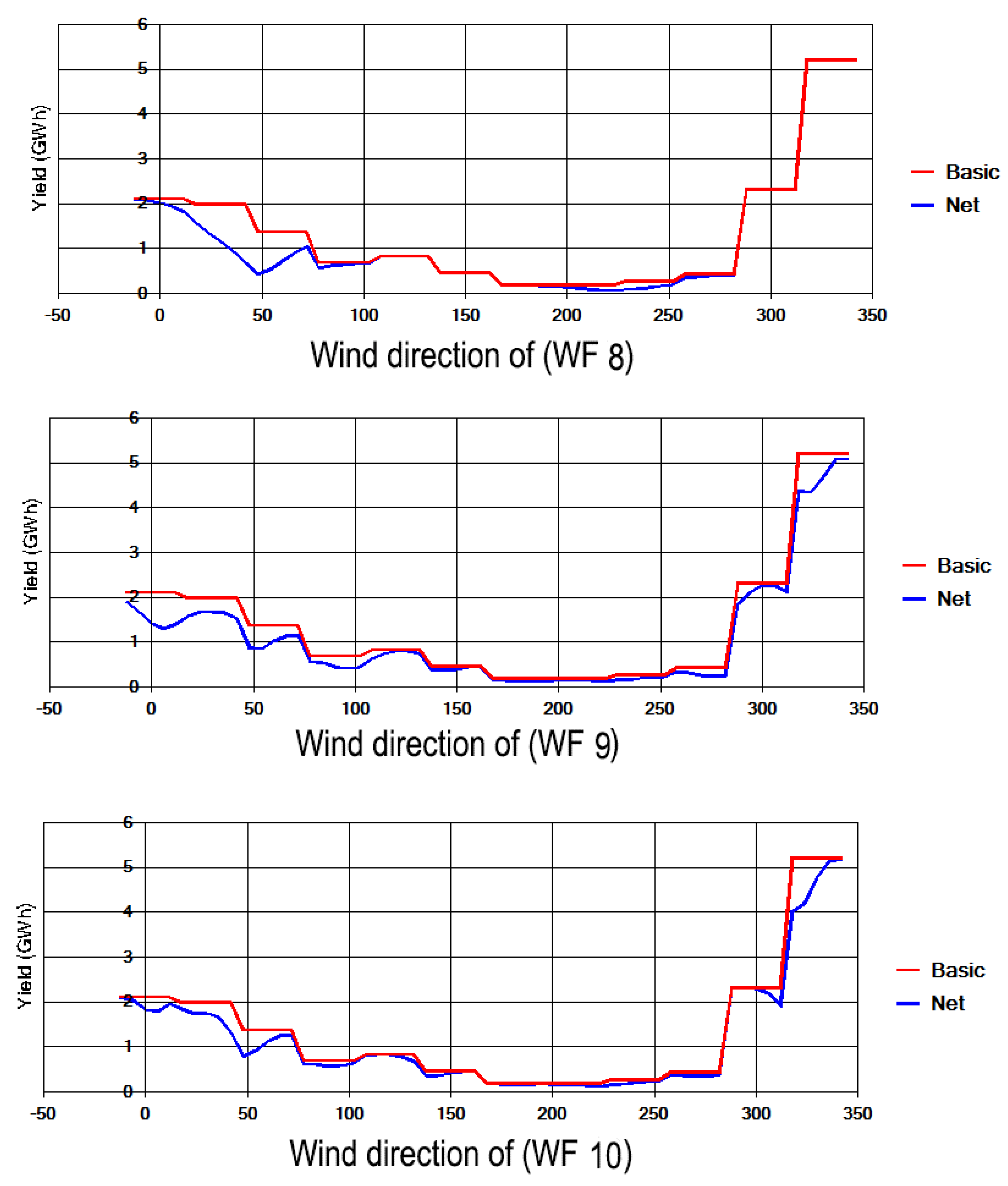

4.3. Strategy C: Substituting New Higher Efficiency Turbines in Place of the Existing Ones

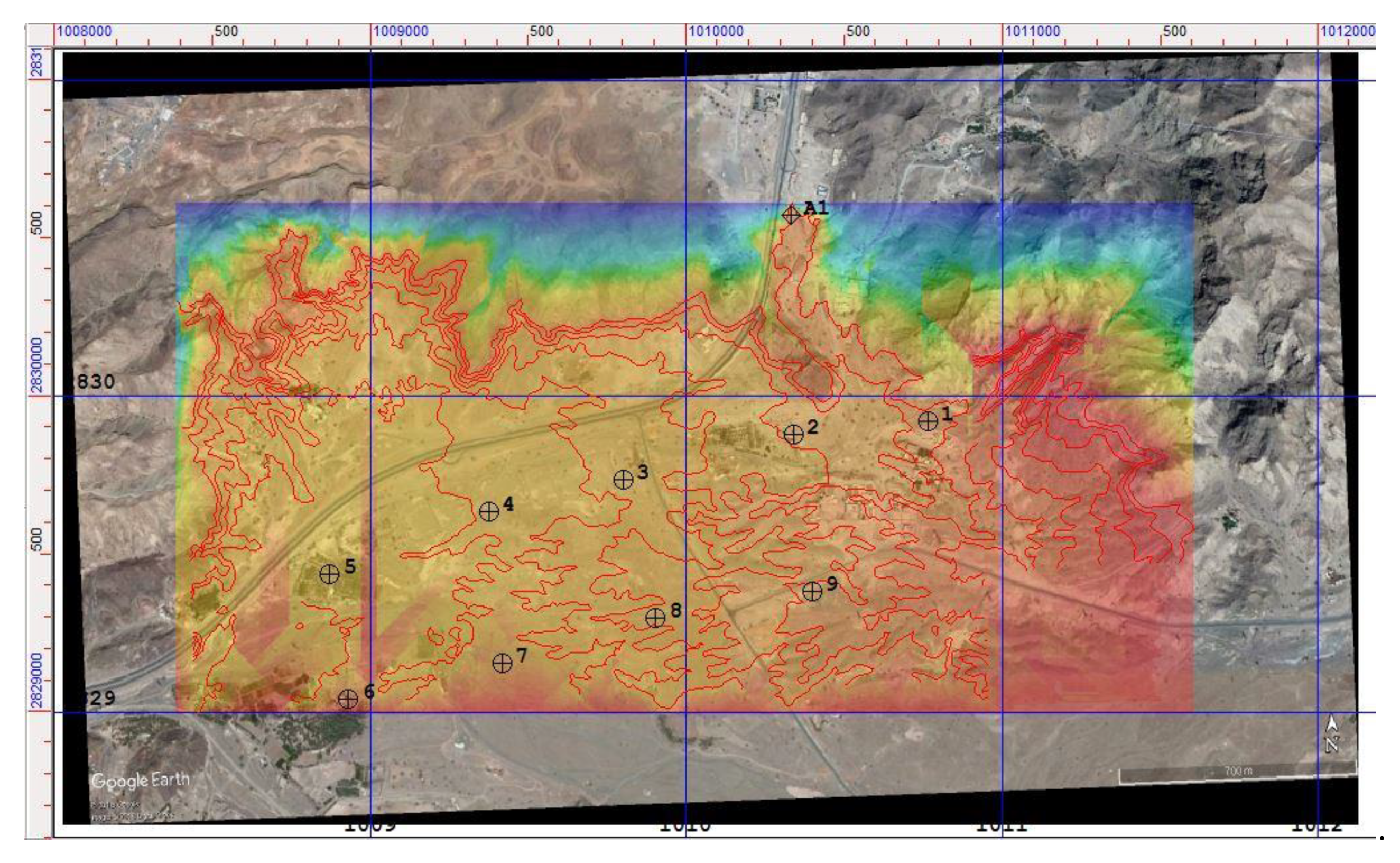

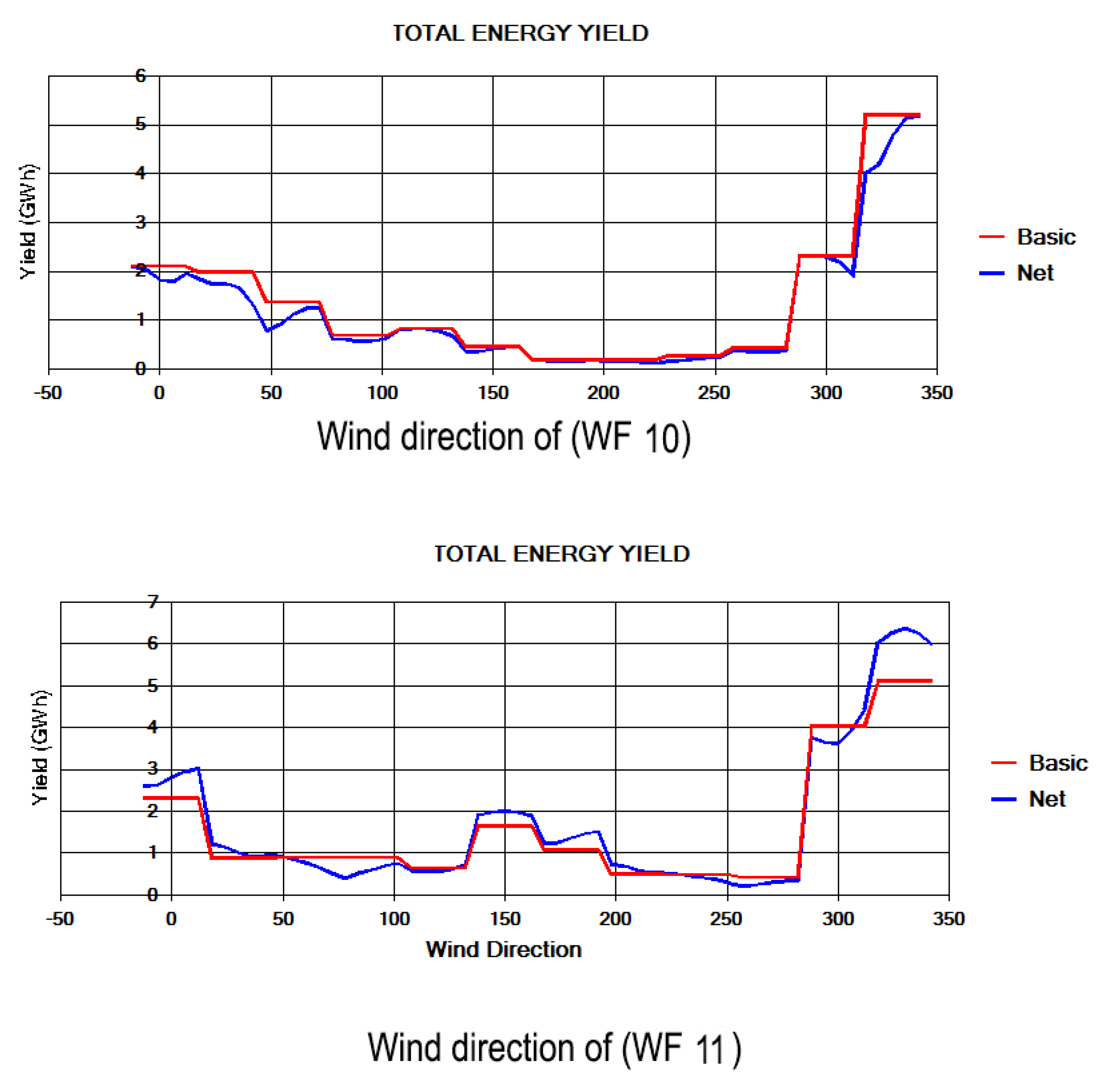

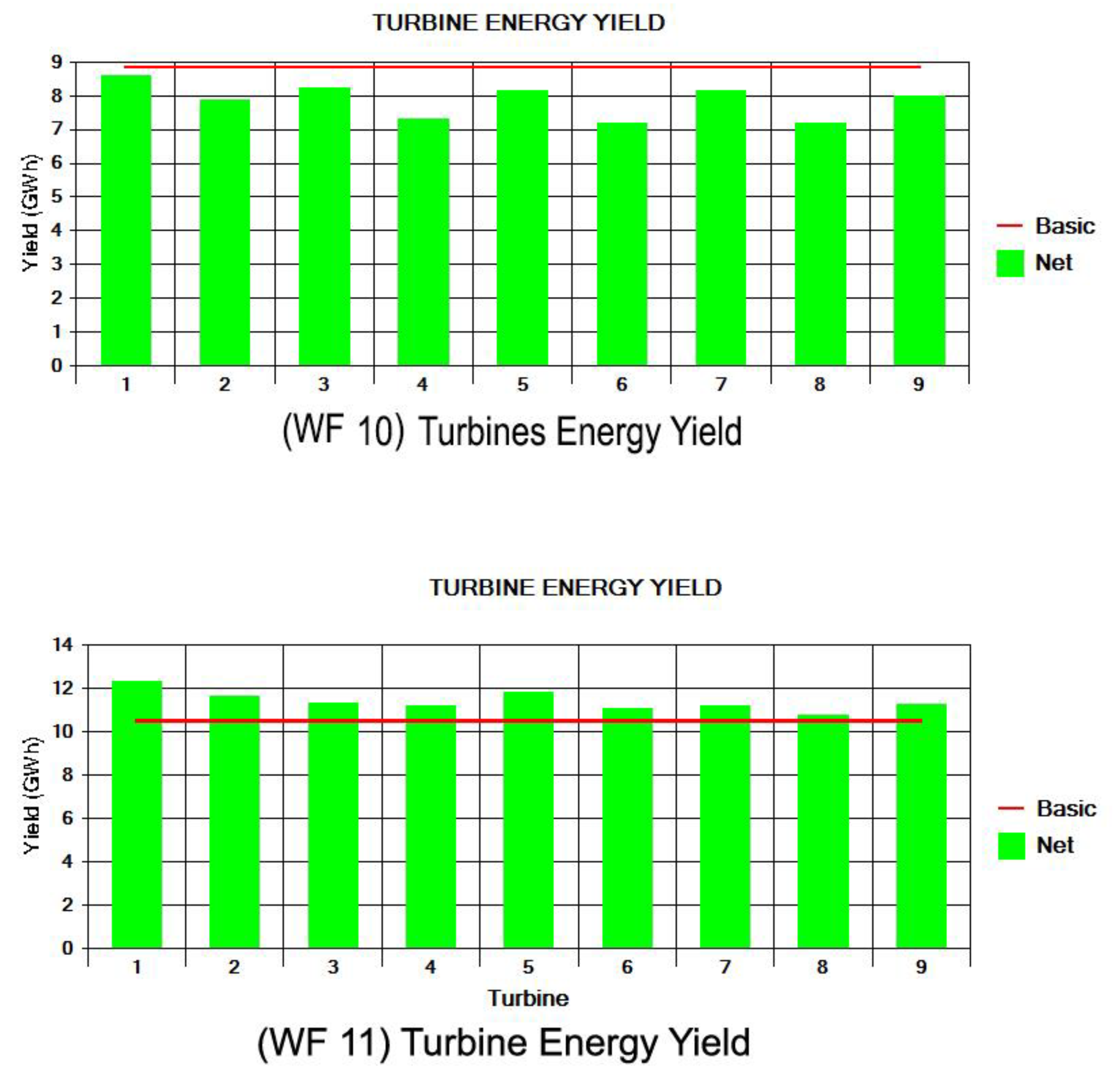

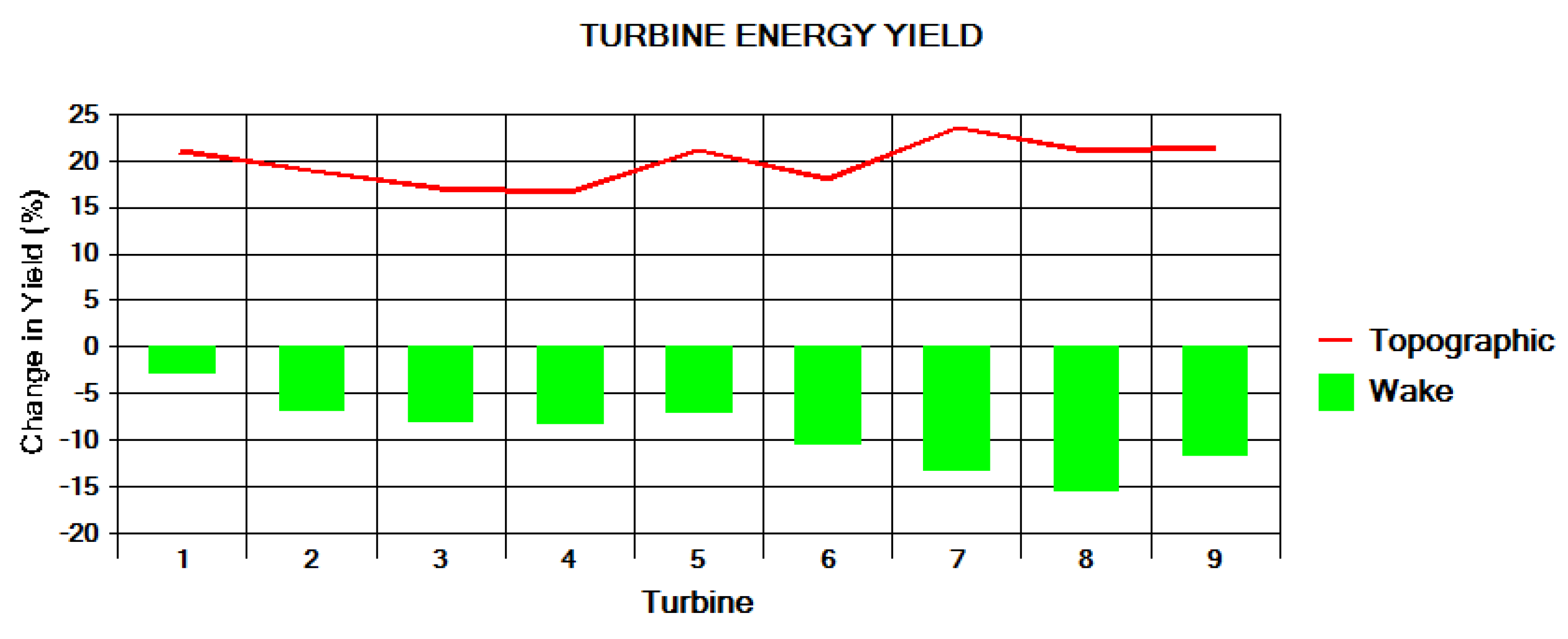

4.4. Strategy D: Moving the WF to Completely New Locations in Different Emirates within the UAE

5. Discussion

Overall Comparison

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AEP | Annual Energy Production |

| D | Rotor diameter |

| GCC | Gulf Cooperation Council |

| GWEC | Global Wind Energy Council |

| GWh | Gigawatt hours |

| HAWT | Horizontal Axis Wind Turbine |

| Hz | Hertz |

| MWh | m/s meter per second |

| WF | Wind farm |

| WWEA | World Wind Energy Association |

| WS | Wind speed |

| WT | Wind turbine |

| WL | Wake Loss |

| W/m2 | Watt per meter square |

| % | Percentage |

| kW | Kilowatt |

| km/h | Kilometer per hour |

| VAWT | Vertical Axis Wind Turbine |

References

- International Energy Agency. Global Energy Demand Rose by 2.3% in 2018, Its Fastest Pace in the Last Decade. 2019. Available online: https://www.iea.org/ (accessed on 16 June 2019).

- Al-mulali, U.; Che Sab, C.N.B. Energy consumption, CO2 emissions, and development in the UAE. Energy Sources Part B Econ. Plan. Policy 2018, 13, 231–236. [Google Scholar] [CrossRef]

- Kaygusuz, K. Wind Energy: Progress and Potential. Energy Sources 2004, 26, 95–105. [Google Scholar] [CrossRef]

- Turksoy, O.; Ayasun, S.; Hames, Y.; Sonmez, S. Gain-Phase Margins-Based Delay-Dependent Stability Analysis of Pitch Control System of Large Wind Turbines. Transactions of the Institute of Measurement and Control. 2019. Available online: https://journals.sagepub.com/doi/abs/10.1177/0142331219834605 (accessed on 30 March 2019).

- Manwell, J.F.; McGowan, J.G.; Rogers, A.L. Wind Energy Explained: Theory, Design and Application; Wiley: London, UK, 2010. [Google Scholar]

- Al-Amir, J.; Abu-Hijleh, B. Strategies and Policies from Promoting the Use of Renewable Energy Resource in the Uae. Renew. Sustain. Energy Rev. 2013, 26, 660–667. [Google Scholar] [CrossRef]

- Bachellerie, I.J. Enewable Energy in the GCC Countries—Resources, Potential, and Prospects; Gulf Research Center: Dubai, United Arab Emirates, 2010. [Google Scholar]

- WWEA. Wind Power Capacity Worldwide Reaches 597 GW, 50,1 GW Added in 2018. 2019. Available online: https://wwindea.org/blog/2019/02/25/wind-power-capacity-worldwide-reaches-600-gw-539-gw-added-in-2018/ (accessed on 17 June 2019).

- GWEC, Annual Installed Global Capacity 2001–2017. 2019. Available online: https://gwec.net/global-figures/graphs/ (accessed on 25 June 2018).

- Zhao, H.; Wu, Q. Modeling and Modern Control of Wind Power; John Wiley & Sons: London, UK, 2018. [Google Scholar]

- Chowdhury, S.; Zhang, J.; Castillo, L. Unrestricted wind farm layout optimization (UWFLO): Investigating key factors influencing the maximum power generation. power generation. Renew. Energy 2012, 38, 16–30. [Google Scholar] [CrossRef]

- Donovan, S. Wind Farm Optimization. In Proceedings of the 40th Annual Conference, Wellington, New Zealand, 2–3 December 2005. [Google Scholar]

- Yang, H.; Zhou, W.; Lou, C. Optimal Design and Techno-Economic Analysis of a Hybrid Solar-Wind Power Generation System. Appl. Energy 2009, 86, 163–169. [Google Scholar] [CrossRef]

- Chou, C.J.; Wu, Y.K.; Han, G.Y.; Lee, C.Y. In Comparative Evaluation of the Hvdc and Hvac Links Integrated in a Large Offshore Wind Farm—An Actual Case Study in Taiwan. IEEE Trans. Ind. Appl. 2011, 1, 1–8. [Google Scholar] [CrossRef]

- Al-Nassar, W.; Alhajraf, S.; Al-Enizi, A.; Al-Awadhi, L. Potential wind power generation in the State of Kuwait. Renew. Energy 2005, 30, 2149–2161. [Google Scholar] [CrossRef]

- Gharbia, Y.; Anany, M. ASME 2016 International Mechanical Engineering Congress and Exposition: Feasibility Study of Erecting a Wind Farm in Kuwait. In Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 11–17 November 2016. [Google Scholar]

- Jamil, M.; Ahmad, F.; Jeon, Y.J. Renewable energy technologies adopted by the UAE: Prospects and challenges—A comprehensive overview. Renew. Sustain. Energy Rev. 2016, 55, 1181–1194. [Google Scholar] [CrossRef]

- Yaseen, A.; Andreas, P. Parametric analysis for the implementation of wind power in United Arab Emirates. Renewable and Sustainable Energy Reviews. 2015, 52, 635–644. [Google Scholar]

- Shaahid, S.M.; Luai, M.A.; Rahman, M.K. Potential of Establishment of Wind Farms in Western Province of Saudi Arabia. Energy Procedia 2014, 52, 497–505. [Google Scholar] [CrossRef]

- MEED Editorial, Middle East Economic Digest. Special Reports Calendar. Power Oman 2014, 58, 13–21.

- Renwable Energy World, Wind Farm Design: Planning, Research and Commissioning. 2009. Available online: https://www.renewableenergyworld.com/articles/print/volume-12/issue-2/wind-power/wind-farm-design-planning-research-and-commissioning.html (accessed on 20 December 2018).

- Eroğlu, Y.; Seçkiner, S.U. Design of wind farm layout using ant colony algorithm. Renew. Energy 2012, 44, 53–62. [Google Scholar] [CrossRef]

- Jiang, J.N.; Tang, C.Y.; Ramakumar, R.G. Control and Operation of Grid-Connected Wind Farms: Major Issues, Contemporary Solutions, and Open Challenges; Springer: London, UK, 2016. [Google Scholar]

- Staffel, I.; Green, R. How does wind farm performance decline with ago? Renew. Energy 2014, 66, 775–786. [Google Scholar] [CrossRef]

- Mosetti, G.; Poloni, C.; Diviacco, B. Optimization of Wind Turbine Positioning in Large Windfarms by Means of a Genetic Algorithm. J. Wind Eng. Ind. Aerodyn. 1994, 51, 105–116. [Google Scholar] [CrossRef]

- Knudsen, T.; Bak, T.; Svenstrup, M. Survey of wind farm control, power and fatigue optmisation. Wind Energy 2015, 18, 1333–1352. [Google Scholar] [CrossRef]

- Wu, Y.-T.; Porté-Agel, F. Modeling Turbine Wakes and Power Losses Within a Wind Farm Using Les: An Application to the Horns Rev Offshore Wind Farm. Renew. Energy 2015, 75, 945–955. [Google Scholar] [CrossRef]

- Shakoor, R.; Hassan, M.Y.; Raheem, A.; Wu, Y.K. Wake Effect Modeling: A Review of Wind Farm Layout Optimization Using Jensen’s Model. Renew. Sustain. Energy 2016, 58, 1048–1059. [Google Scholar] [CrossRef]

- Vasel-Be-Hagh, A.; Archer, C.L. Wind Farm Hub Height Optimization. Appl. Energy 2017, 195, 905–921. [Google Scholar] [CrossRef]

- Feng, J.; Shen, W.Z. Solving the Wind Farm Layout Optimization Problem Using Random Search Algorithm. Renew. Energy 2015, 78, 182–192. [Google Scholar] [CrossRef]

- Gao, Y.X.; Lu, H. Optimization of Wind Turbine Layout Position in a Wind Farm Using a Newly-Developed Two-Dimensional Wake Model. Appl. Energy 2016, 174, 192–200. [Google Scholar] [CrossRef]

- Guirguis, D.; Romero, D.A.; Amon, C.H. Toward Efficient Optimization of Wind Farm Layouts: Utilizing Exact Gradient Information. Appl. Energy 2016, 179, 110–123. [Google Scholar] [CrossRef]

- Hou, P. Optimized Placement of Wind Turbines in Large-Scale Offshore Wind Farm Using Particle Swarm Optimization Algorithm. IEEE Trans. Sustain. Energy 2015, 6, 1271–1282. [Google Scholar] [CrossRef]

- Musselman, A.; Thomas, V.M.; Boland, N.; Nazzal, D. Optimizing wind farm siting to reduce power system impacts of wind variability. Wind Energy 2019. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/we.2328 (accessed on 30 March 2019).

- Sir Bani Yas Wind Farm Project, Clean Development Mechanism. 2018. Available online: https://cdm.unfccc.int/Projects/DB/DNV-CUK1183446238.91/MonitoringPlanRevisions/01/RevisedMonitoringPlan (accessed on 3 April 2019).

- Export Gov, United Arab Emirates—Renewable Energy. 2018. Available online: https://www.export.gov/article?id=United-Arab-Emirates-Renewable-Energy (accessed on 20 March 2018).

- Rehman, S.; Ahmad, A.; Al-Hadrami, L.M. Development and economic assessment of a grid connected 20 MW installed capacity wind farm. Renew. Sustain. Energy Rev. 2011, 15, 833–838. [Google Scholar] [CrossRef]

- Climate of Sir Bani Yas and Fujairah. 2019. Available online: https://www.meteoblue.com/ (accessed on 31 October 2019).

- Masdar, Masdar Clean Energy. 2019. Available online: https://masdar.ae/en/masdar-clean-energy (accessed on 20 March 2018).

- WindFarm Software. Summary of Capabilities. Available online: http://resoft.co.uk/English/index.htm (accessed on 24 February 2018).

- Mihăilă, J.M.; Bigan, C.; Panduru, V. Mathematical modelling of noise mapping at wind turbine farms. Appl. Sci. 2014, 16, 48–55. [Google Scholar]

- National Centre of Morphology, Climate of Sir Bani Yas. 2018. Available online: http://www.ncm.ae/en#!/Radar_Merge_Sat (accessed on 10 September 2018).

- Coakley, D.; Raftery, P.; Keane, M. A review of methods to match building energy. Renew. Sustain. Energy Rev. 2014, 37, 123–141. [Google Scholar] [CrossRef]

- Stephan, J. Calculation of Different Generator Systems for Wind Turbines; Shaker Verlag GmbH: Düren, Germany, 2013. [Google Scholar]

- Planningni, Planning Policy Statements and Supplementary Planning Guidance. Draft PPS 18: Renewable Energy. Annex 1 Wind Energy: Spacing of Turbines. 2018. Available online: https://www.planningni.gov.uk/index/policy/planning_statements_and_supplementary_planning_guidance/pps18/pps18_annex1/pps18_annex1_wind/pps18_annex1_technology/pps18_annex1_spacing.htm (accessed on 30 October 2018).

- Al Wasmi, N. Masdar Launches Wind Atlas to Promote Alternative Energy Source in Coastal UAE. 2015. Available online: https://www.thenational.ae/uae/environment/masdar-launches-wind-atlas-to-promote-alternative-energy-source-in-coastal-uae-1.119882 (accessed on 15 January 2018).

| No. | Aim | Findings | Citation |

|---|---|---|---|

| 1 | To investigate the mechanical/aerodynamic part, which includes the wind turbines, their power production, fatigue and wakes affecting neighboring wind turbines. | In dense wind farms, some wind turbines are placed in the wake of others, which drastically affects the average power per wind turbine by approximately 10%. | [26] |

| 2 | To propose modeling framework and validation to simulate turbine wakes and associated power losses in wind farms. | When the prevailing wind direction is parallel to the turbine rows, the velocity deficit and the power losses are greatest, and the turbulence intensity levels are highest and have a symmetrical pattern (dual-peak at hub height) on both sides of the turbine wakes. | [27] |

| 3 | To review the wake models in general and far wake models, in particular by using Jensen׳s model. | Jensen׳s far wake model is a good choice to solve the wind farm layout problem due to its simplicity and relatively high degree of accuracy. However, it was also found that there is a need of more optimization techniques to be applied to solve the layout problem. | [28] |

| 4 | To assess the effect of hub height optimization on the annual energy production (AEP) of a wind farm. The only optimization variable is the hub height of each wind turbine and all other characteristics of the wind farm, including base location, rotor diameter (D), and total number of wind turbines, remain unchanged. | Wind farms with multiple hub height turbines produce >2% more energy annually. | [29] |

| 5 | To use a random search algorithm based on continuous formulation to optimize the wind farm layout which starts from an initial feasible layout and then improves the layout iteratively in the feasible solution space. | It is found that up to 360 or more sectors for wind direction have to be used in order to obtain consistent and reliable optimization results. | [30] |

| 6 | To develop and validate a 2D analytical wind turbine wake model based on Jensen’s wake model using Gaussian function to optimize the wind turbine layout position by using different downwind distances of X = 2.5D, X = 5D, X = 7.5D and X = 10D. | By using the 2D Jensen–Gaussian wake model instead of Jensen’s wake model, the total power generation and wind farm efficiency decreased, which is in accordance with the literature on the power losses caused by the wake effect in large wind farms. | [31] |

| 7 | To optimize the wind farm layouts by utilizing the exact gradient information of the problem’s objective and constraints. | A single uniform staggered layout can result in good optimized solutions when used as a single starting point for the optimization. Wind farm designers may want run the optimization solver with different initial layouts to increase their confidence in the final solution. | [32] |

| 8 | To optimize the placement of wind turbines in a large-scale offshore wind farm using the particle swarm optimization algorithm. | It is found that the optimized sparse layout was the best considering LPC (levelized production cost) and annual energy yields. The optimized sparse layout represents a wind farm layout with different spaces between wind turbines in each row and column where the wake losses decreased the most compared to the other cases. | [33] |

| 9 | To optimize the wind farm siting to reduce system impacts of wind variability. | Both the average variability and max variability decreases as the average residential demand increases, because sites with lower wind output have a similar range across which the wind can vary. It is more economical to build a smaller amount of larger wind farms than small farms. | [34] |

| 10 | To investigate the effect of gain-phase, margins-based and delay-dependent stability analysis of the pitch control systems of large wind turbine with time delays. | Delay margins made only with regard to stability will cause oscillations that may cause instability in the system response. | [4] |

| Category/Code | (I) Base Case Turbines | (II) Small Turbines | (III) Higher Capacity Turbines |

|---|---|---|---|

| Model | V100-1.8 MW | V47-660 KW | V150-4.2 MW |

| Manufacturer | Vestas | Vestas | Vestas |

| Power Regulation | Pitch | Pitch | Pitch |

| Number of Blades | 3 | 3 | 3 |

| Swept Area (m2) | 7853.981 | 1734.945 | 17,671.459 |

| Hub Height (m) | 80 | 45 | 166 |

| Diameter (m) | 100 | 47 | 150 |

| RPM | 14.9 | 28.5 | 16.1 |

| Speed variation | Variable | Two Speed | Variable |

| Cut In Wind Speed (m/s) | 3 | 4 | 3 |

| Cut Out Wind Speed (m/s) | 20 | 25 | 22.5 |

| Rated Power (kW) | 1800 | 660 | 4200 |

| Rated Wind Speed (m/s) | 12 | 15 | 15 |

| Strategy | Scenarios | WT 1 (%) | WT 2 (%) | WT 3 (%) | WT 4 (%) | WT 5 (%) | WT 6 ((%) | WT 7 ((%) | WT 8 (%) | WT 9 (%) | WT 10 (%) | WT 11 (%) | WT 12 (%) | WT 13 (%) | WT 14 (%) | WT 15 (%) | WT 16 (%) | Small WT 1 | Small WT 2 | Small WT 3 | Small WT 4 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Base Case | (WF 1) | −2.78 | −10.02 | −9.75 | −10.11 | −9.98 | −10.7 | −10.55 | −11.89 | −12.41 | −8.02 | −14.43 | −14.87 | −20.59 | −19.91 | −17.18 | −12.48 | - | - | - | - |

| Strategy A: Inserting smaller turbines between the larger main original turbines | (WF 2) | −2.92 | −10.26 | −10.09 | −10.42 | −10.37 | −11.08 | −11.01 | −12.35 | −12.85 | −8.36 | −14.74 | −14.99 | −21.1 | −20.61 | −17.68 | −13.19 | −25.88 | −25.88 | −23.69 | −20.08 |

| (WF 3) | −2.94 | −11.58 | −9.78 | −11.19 | −9.91 | −10.71 | −10.71 | −13.17 | −12.32 | −10.24 | −14.21 | −15.72 | −22.16 | −20.47 | −18.09 | −13.13 | −16.51 | −19.14 | −19.54 | −9.68 | |

| (WF4) | −2.88 | −10.35 | −10.31 | −10.63 | −10.46 | −11.13 | −11.20 | −12.70 | −13.05 | −8.49 | −14.86 | −15.08 | −21.86 | −21.98 | −18.86 | −12.90 | −27.75 | −31.14 | −29.54 | −26.35 | |

| Strategy B: Changing the spacing between the turbines | (WF5) | −2.64 | −10.57 | −10.32 | −11.70 | −11.52 | −11.31 | −9.95 | −26.17 | −30.21 | −31.34 | −31.46 | −25.28 | −13.09 | −27.70 | −28.22 | −22.84 | - | - | - | - |

| (WF6) | −2.31 | −10.18 | −6.65 | −16.93 | −7.14 | −17.81 | −7.30 | −17.48 | −7.46 | −17.16 | −6.99 | −16.09 | −10.17 | −16.37 | −11.96 | −10.92 | - | - | - | - | |

| (WF7) | −1.72 | −10.29 | −4.91 | −14.01 | −5.96 | −13.95 | −5.67 | −13.65 | −7.28 | −13.65 | −9.20 | −9.38 | −9.45 | −13.91 | −8.45 | −14.63 | - | - | - | - | |

| Strategy C: Substituting new higher efficiency turbines in place of the existing ones | (WF8) | −2.08 | −12.7 | −13.82 | −11.23 | −12.51 | −13.57 | −12.84 | −14.48 | −14.1 | - | - | - | - | - | - | - | - | - | - | - |

| (WF9) | −3.08 | −15.47 | −14.29 | −8.64 | −21.87 | −24.77 | −9.59 | −19.66 | −27.24 | - | - | - | - | - | - | - | - | - | - | - | |

| (WF10) | −2.50 | −10.77 | −6.89 | −17.16 | −7.60 | −18.50 | −7.73 | −18.56 | −9.55 | -- | - | - | - | - | - | - | - | - | - | ||

| Strategy D: Relocating the base case (WF 11) to Al Fujairah | (WF 11) | −2.73 | −6.78 | −7.88 | −8.2 | −6.94 | −10.36 | −13.27 | −15.39 | −11.52 |

| Wind Turbine No. | Sir Bani Yas (Flat Terrain) | Al Fujairah | |||

|---|---|---|---|---|---|

| Vestas V100-1.8 MW | Vestas V150-4.2 MW | ||||

| Easting | Northing | Easting | Northing | Altitude | |

| 1 | 659,866 | 2,695,158 | 1,010,765 | 2,829,921 | 188 |

| 2 | 659,677 | 2,695,022 | 1,010,339 | 2,829,879 | 181 |

| 3 | 659,491 | 2,694,882 | 1,009,801 | 2,829,737 | 172 |

| 4 | 659,304 | 2,694,739 | 1,009,376 | 2,829,635 | 166 |

| 5 | 659,119 | 2,694,593 | 1,008,872 | 2,829,438 | 161 |

| 6 | 658,945 | 2,694,432 | 1,008,931 | 2,829,042 | 199 |

| 7 | 658,775 | 2,694,262 | 1,009,418 | 2,829,157 | 184 |

| 8 | 658,631 | 2,694,054 | 1,009,903 | 2,829,299 | 178 |

| 9 | 658,510 | 2,693,836 | 1,010,399 | 2,829,383 | 185 |

| 10 | 658,289 | 2,692,948 | - | - | - |

| 11 | 658,252 | 2,692,716 | - | - | - |

| 12 | 660,129 | 2,694,816 | - | - | - |

| 13 | 659,790 | 2,694,403 | - | - | - |

| 14 | 659,490 | 2,693,971 | - | - | - |

| 15 | 659,101 | 2,693,396 | - | - | - |

| 16 | 658,928 | 2,692,839 | - | - | - |

| Strategy | Scenarios | WT 1 (GWh) | WT 2 (GWh) | WT 3 (GWh) | WT 4 (GWh) | WT 5 (GWh) | WT 6 (GWh) | WT 7 (GWh) | WT 8 (GWh) | WT 9 (GWh) | WT 10 (GWh) | WT 11 (GWh) | WT 12 (GWh) | WT 13 (GWh) | WT 14 (GWh) | WT 15 (GWh) | WT 16 (GWh) | Small WT 1 | Small WT 2 | Small WT 3 | Small WT 4 | Total Power Generation (GWh) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Base Case | (WF1) | 3.7074 | 3.4314 | 3.4414 | 3.4277 | 3.4328 | 3.4054 | 3.4111 | 3.3597 | 3.3401 | 3.5073 | 3.2631 | 3.2464 | 3.0282 | 3.0542 | 3.1583 | 3.3373 | - | - | - | - | 53.5517 |

| Strategy A: Inserting smaller turbines between the larger main original turbines | (WF 2) | 3.7019 | 3.4221 | 3.4285 | 3.4161 | 3.4179 | 3.3909 | 3.3936 | 3.3425 | 3.3234 | 3.4947 | 3.2514 | 3.2418 | 3.0088 | 3.0273 | 3.1390 | 3.3105 | 0.5905 | 0.5905 | 0.6079 | 0.6367 | 55.7361 |

| (WF3) | 3.7013 | 3.3717 | 3.4404 | 3.3868 | 3.4356 | 3.4050 | 3.4051 | 3.3112 | 3.3436 | 3.4229 | 3.2715 | 3.2137 | 2.9683 | 3.0329 | 3.1236 | 3.3127 | 0.6652 | 0.6442 | 0.6410 | 0.7195 | 55.8161 | |

| (WF4) | 3.7036 | 3.4187 | 3.4201 | 3.4078 | 3.4145 | 3.3890 | 3.3864 | 3.3290 | 3.3156 | 3.4896 | 3.2465 | 3.2382 | 2.9798 | 2.9751 | 3.0940 | 3.3212 | 0.5756 | 0.5486 | 0.5614 | 0.5868 | 55.4013 | |

| Strategy B: Changing the spacing between the turbines | (WF5) | 3.7127 | 3.4102 | 3.4198 | 3.3670 | 3.3739 | 3.3822 | 3.4339 | 2.8155 | 2.6612 | 2.6183 | 2.6135 | 2.8491 | 3.3143 | 2.7569 | 2.7372 | 2.9423 | - | - | - | - | 49.4081 |

| (WF6) | 3.7251 | 3.4251 | 3.5599 | 3.1679 | 3.5409 | 3.1343 | 3.5350 | 3.1468 | 3.5288 | 3.1588 | 3.5468 | 3.1998 | 3.4255 | 3.1892 | 3.3574 | 3.3968 | - | - | - | - | 54.038 | |

| (WF7) | 3.7479 | 3.4207 | 3.6259 | 3.2792 | 3.5859 | 3.2814 | 3.5970 | 3.2927 | 3.5356 | 3.2928 | 3.4625 | 3.4555 | 3.4529 | 3.2830 | 3.4910 | 3.2552 | - | - | - | - | 55.0591 | |

| Strategy C: Substituting new higher efficiency turbines in place of the existing ones | (WF8) | 8.6461 | 7.7079 | 7.6097 | 7.8379 | 7.7254 | 7.6315 | 7.6962 | 7.5513 | 7.5849 | - | - | - | - | - | - | - | - | - | - | - | 69.991 |

| (WF9) | 8.558 | 7.4639 | 7.5679 | 8.0671 | 6.8985 | 6.6429 | 7.9825 | 7.0938 | 6.4240 | - | - | - | - | - | - | - | - | - | - | - | 66.6985 | |

| (WF10) | 8.6088 | 7.8790 | 8.2212 | 7.3142 | 8.1587 | 7.1964 | 8.1469 | 7.1906 | 7.9867 | - | - | - | - | - | - | - | - | - | - | - | 70.7024 | |

| Strategy D: Relocating the base case (WF 1) to Al Fujairah | Topographic effect | 21.03 | 18.94 | 17.06 | 16.62 | 21.13 | 18.06 | 23.55 | 21.06 | 21.39 | - | - | - | - | - | - | - | - | - | - | - | - |

| (WF 11) | 12.3112 | 11.5949 | 11.2765 | 11.196 | 11.7884 | 11.0676 | 11.2056 | 10.7106 | 11.2313 | - | - | - | - | - | - | - | - | - | - | - | 102.382 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taleb, H.M.; Abu Hijleh, B. Optimizing the Power Generation of a Wind Farm in Low Wind Speed Regions. Sustainability 2021, 13, 5110. https://doi.org/10.3390/su13095110

Taleb HM, Abu Hijleh B. Optimizing the Power Generation of a Wind Farm in Low Wind Speed Regions. Sustainability. 2021; 13(9):5110. https://doi.org/10.3390/su13095110

Chicago/Turabian StyleTaleb, Hanan M., and Bassam Abu Hijleh. 2021. "Optimizing the Power Generation of a Wind Farm in Low Wind Speed Regions" Sustainability 13, no. 9: 5110. https://doi.org/10.3390/su13095110

APA StyleTaleb, H. M., & Abu Hijleh, B. (2021). Optimizing the Power Generation of a Wind Farm in Low Wind Speed Regions. Sustainability, 13(9), 5110. https://doi.org/10.3390/su13095110