The Influence of the Digital Supply Chain on Operational Performance: A Study of the Food and Beverage Industry in Indonesia

Abstract

1. Introduction

2. Literature Review

2.1. Digital Supply Chain

- Big data: By providing an integrated platform for tracking performance and customer engagement through real-time data analysis and critical decision-making scenarios, big data contributes to improved visibility. As a result, the likelihood of supply chain disturbances and delays is decreased [21].

- Cloud computing: Cloud technology allows the storage and processing of large volumes of data in real time, with information available to all supply chain participants [22,23]. In comparison to traditional information technology solutions, cloud technologies enable rapid acquisition and deployment without requiring a company to significantly extend or change its existing infrastructure [24], thus allowing the company to change as necessary.

- IoT: The real-time data generated by IoT enable the tracking of supply chain activities from product design to end user, providing reliable and timely data to assist businesses in adapting to market changes [27].

- Robotics: Autonomous robots are expected to continue to evolve in this field in the future, enabling individuals to move to more strategic, less risky, and higher-value jobs [28]. Robotics offers manufacturers greater versatility than other types of automation [29]. Robotics also answers a question of those working in the supply chain: how will the company improve efficiency and save money? [30]. In doing so, the 21st century has witnessed many companies investing much of their revenue in adopting technology in the supply chain and a massive number are considering the investment of their money in robotics and automation [31].

2.2. Operational Performance

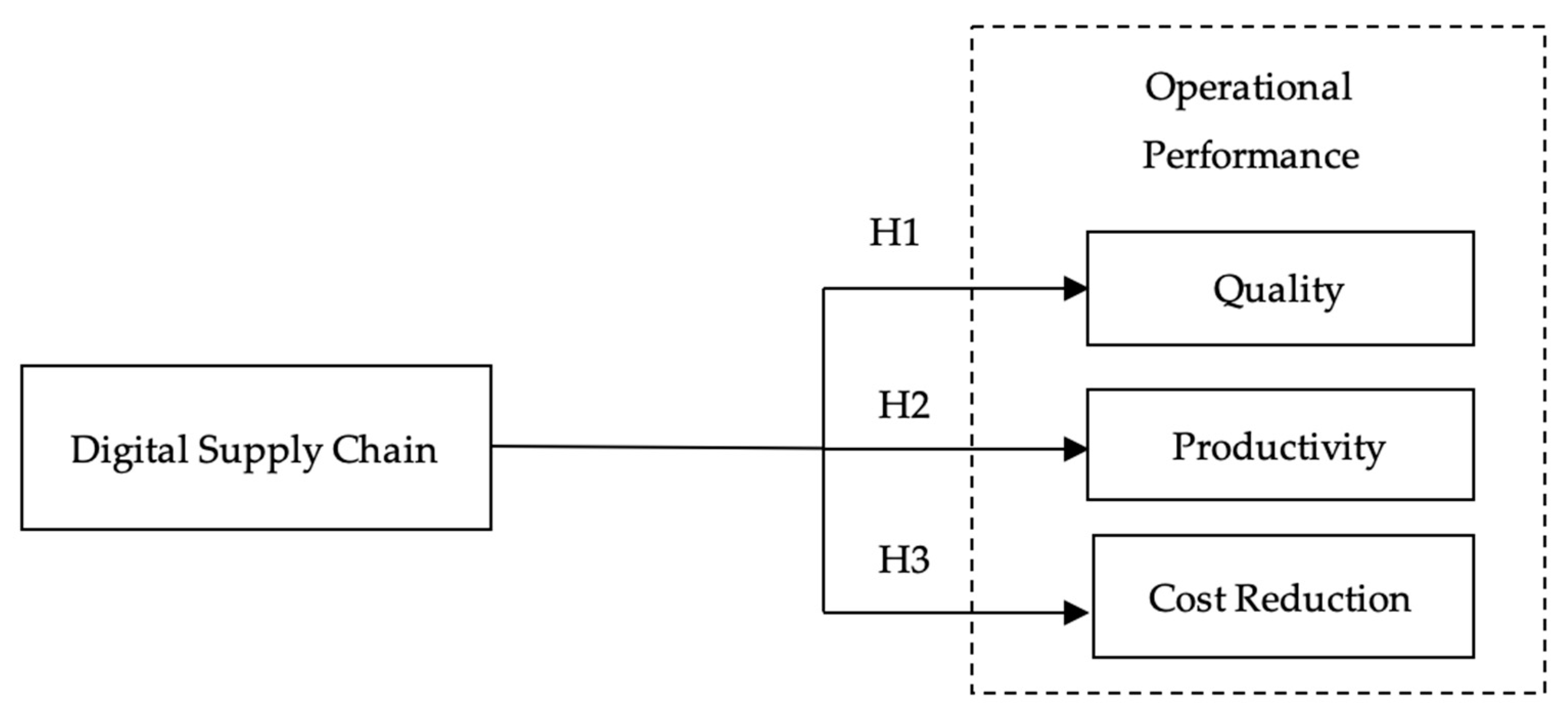

3. Conceptual Framework and Hypotheses

3.1. Conceptual Framework

3.2. Hypotheses

3.2.1. The Digital Supply Chain and Quality Performance

3.2.2. The Digital Supply Chain and Productivity Performance

3.2.3. The Digital Supply Chain and Cost Reduction Performance

4. Research Methodology

4.1. Survey and Data Collection

4.2. Analysis Technique

4.3. Measurements

5. Research Results

5.1. Demographic Profile

5.2. Data Analysis

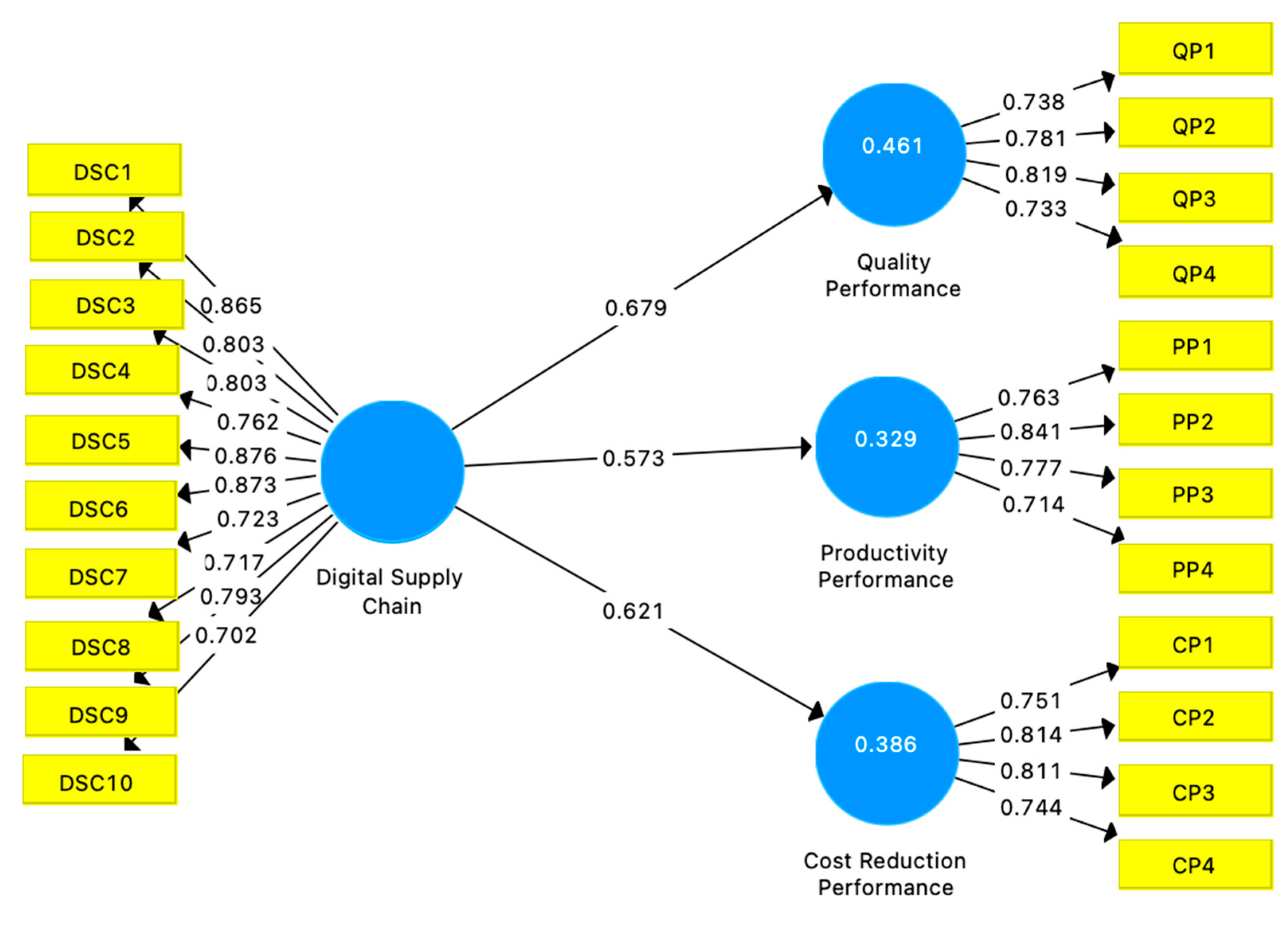

5.2.1. Assessment of the Measurement Model

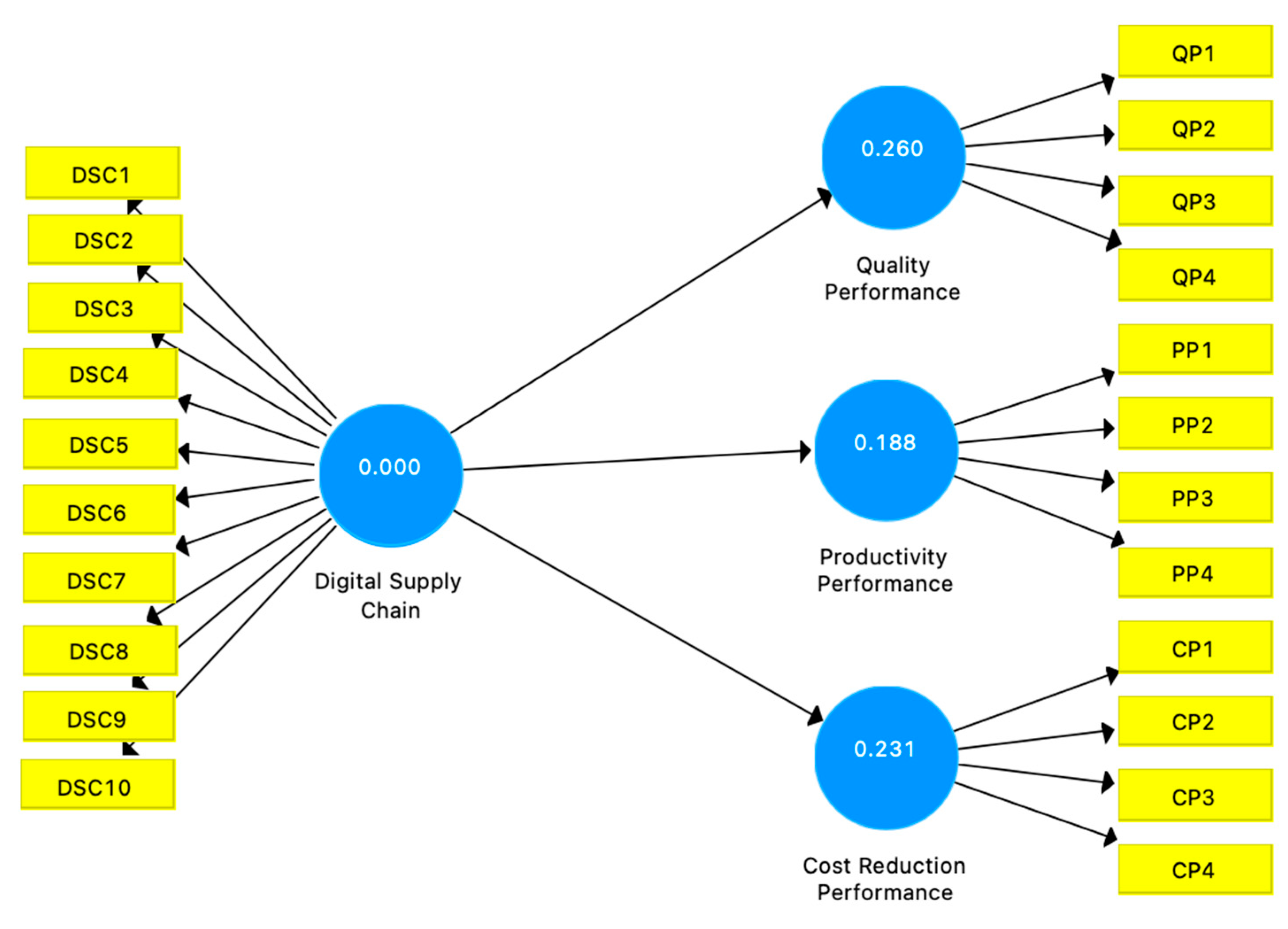

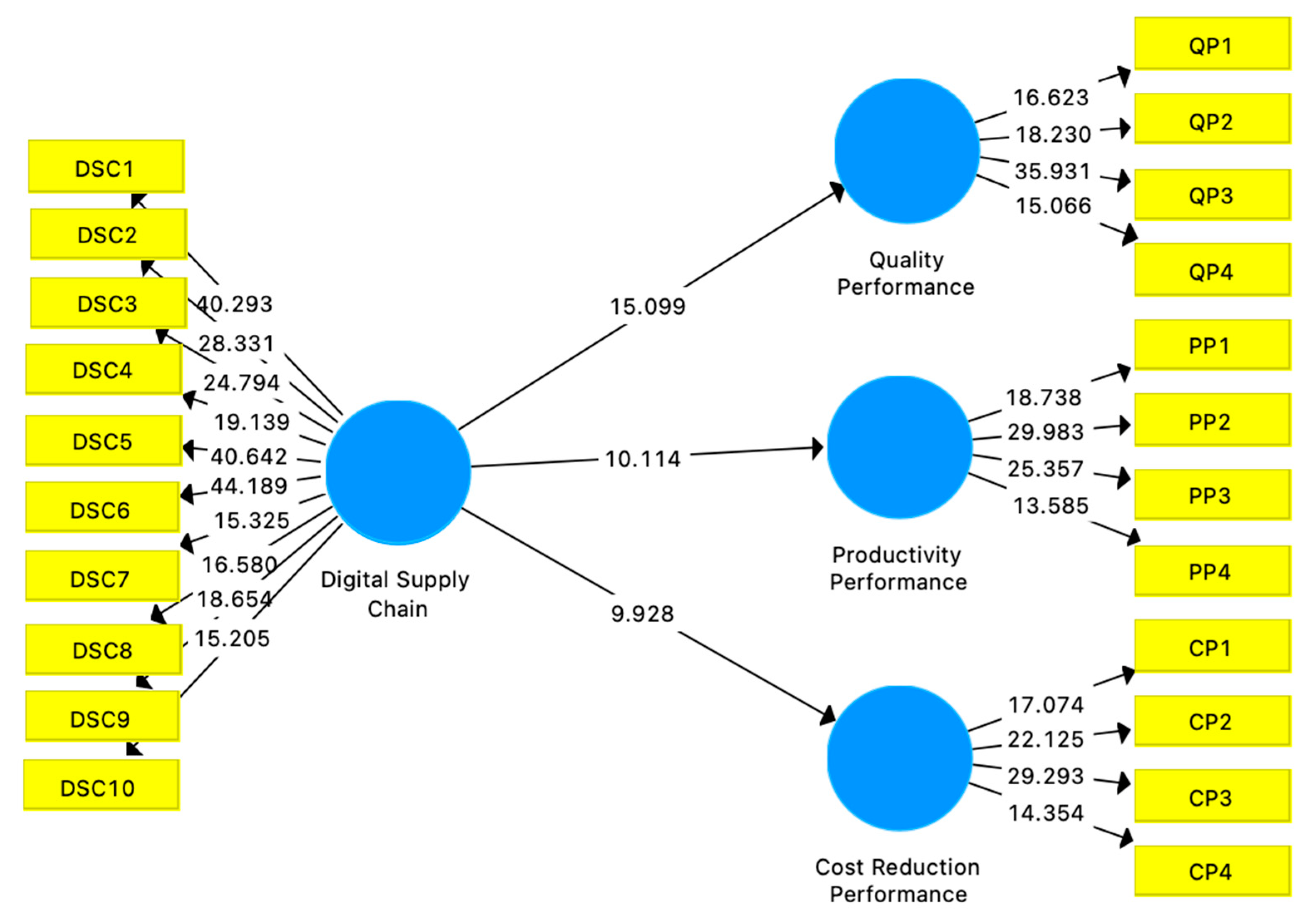

5.2.2. Assessment of the Structural Model

6. Discussion

7. Conclusions

8. Managerial Implications

9. Limitations and Recommendations for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. The Measurements

| Main Variables | Items | Statement | References |

| Digital Supply Chain | DSC_1 | Big data is used to improve our data quality. | Raman et al. [65]; Schoenherr et al. [92]; Cegielski et al. [93]; Ben-Daya et al. [94]; Merlino and Sproģe [30]. |

| DSC_2 | Our company is able to monitor customer interaction through real time data analysis. | ||

| DSC_3 | Our company is able to achieve information exchange with cloud computing. | ||

| DSC_4 | Cloud technologies enhance process capability and local storage. | ||

| DSC_5 | Blockchain improves traceability of products in the supply chain. | ||

| DSC_6 | Exchange of information with customers and suppliers is easier through the application of blockchain. | ||

| DSC_7 | IoT provides a link between customers and the company. | ||

| DSC_8 | IoT provides the linkage for all devices to the internet associated with production processes. | ||

| DSC_9 | Robotics is used to improve production capacity. | ||

| DSC_10 | Our company uses or plans to use robotics on a regular basis in the future. | ||

| Quality performance | QP_1 | Our company is able to produce consistent quality products with a low rate of defects. | Maani and Sluti [41]; Safizadeh et al. [95]; Tracey et al. [44]; Koufteros et al. [96]. |

| QP_2 | Our company operates regular customer satisfaction surveys to monitor our product quality. | ||

| QP_3 | Our company is able to maintain a low number of customer complaints concerning product quality. | ||

| QP_4 | Our company is able to supply products based on conformance quality (national and international standards). | ||

| Productivity performance | PP_1 | Our labor and machine productivity is performing better than in its intended function. | Ward and Duray [42]; Wong et al. [43]. |

| PP_2 | Our company is able to optimize our production defect/waste to acceptable levels. | ||

| PP_3 | Our company is able to provide short delivery times acceptable to our customers. | ||

| PP_4 | Our company is able to increase capacity utilization in our production when demand requires it. | ||

| Cost reduction performance | CP_1 | Our company is able to manufacture products at competitive prices while maintaining a profitable operational performance. | Davis and Schul [97]; Maani and Sluti [41]; Tracey et al. [44]. |

| CP_2 | Our company is able to produce products from a low inventory of raw materials thereby minimizing production costs. | ||

| CP_3 | Overall, our logistics costs (including distribution, transportation, and handling costs) can be reduced year on year through our supply chain management. | ||

| CP_4 | The reductions in cost achieved are considerably better value than expected. |

Appendix B. Calculation of the Mean, Standard Deviation, Excess Kurtosis, and Skewness

| Mean | Standard Deviation | Excess Kurtosis | Skewness | |

| DSC_1 | 3.943 | 0.889 | −0.303 | −0.503 |

| DSC_2 | 4.115 | 0.873 | 0.16 | −0.791 |

| DSC_3 | 4.077 | 0.861 | −0.07 | −0.648 |

| DSC_4 | 4.177 | 0.765 | 0.496 | −0.701 |

| DSC_5 | 3.962 | 0.89 | 0.096 | −0.621 |

| DSC_6 | 3.962 | 0.874 | −0.195 | −0.531 |

| DSC_7 | 4.244 | 0.734 | −0.15 | −0.639 |

| DSC_8 | 4.191 | 0.74 | 0.901 | −0.752 |

| DSC_9 | 4.115 | 0.816 | 1.764 | −1.013 |

| DSC_10 | 4.033 | 0.899 | 0.694 | −0.863 |

| QP_1 | 4.167 | 0.761 | 0.991 | −0.817 |

| QP_2 | 4.349 | 0.69 | 0.112 | −0.765 |

| QP_3 | 4.239 | 0.726 | 0.965 | −0.78 |

| QP_4 | 4.411 | 0.687 | −0.127 | −0.837 |

| PP_1 | 4.206 | 0.765 | −0.239 | −0.628 |

| PP_2 | 4.287 | 0.766 | 1.108 | −0.992 |

| PP_3 | 4.306 | 0.665 | −0.274 | −0.539 |

| PP_4 | 4.321 | 0.73 | −0.258 | −0.731 |

| CP_1 | 4.182 | 0.78 | 0.979 | −0.88 |

| CP_2 | 4.201 | 0.731 | 1.071 | −0.778 |

| CP_3 | 4.167 | 0.822 | 0.524 | −0.841 |

| CP_4 | 4.278 | 0.764 | −0.043 | −0.778 |

References

- Bughin, J.; Chui, M.; Manyika, J. An Executive’s Guide to the Internet of Things. Available online: https://www.mckinsey.com/business-functions/mckinsey-digital/our-insights/an-executives-guide-to-the-internet-of-things (accessed on 1 February 2021).

- Attaran, M. Digital technology enablers and their implications for supply chain management. Supply Chain Forum Int. J. 2020, 21, 158–172. [Google Scholar] [CrossRef]

- Igarashi, M.; de Boer, L.; Fet, A.M. What is required for greener supplier selection? A literature review and conceptual model development. J. Purch. Supply Manag. 2013, 19, 247–263. [Google Scholar] [CrossRef]

- Inemek, A.; Tuna, O. Global supplier selection strategies and implications for supplier performance: Turkish suppliers’ perception. Int. J. Logist. Res. Appl. 2009, 12, 381–406. [Google Scholar] [CrossRef]

- Johnsen, T.E. Supply network delegation and intervention strategies during supplier involvement in new product development. Int. J. Oper. Prod. Manag. 2011, 31, 686–708. [Google Scholar] [CrossRef]

- Kannan, V.R.; Tan, K.C. Supplier alliances: Differences in attitudes to supplier and quality management of adopters and non-adopters. Supply Chain Manag. Int. J. 2004, 9, 279–286. [Google Scholar] [CrossRef]

- Oosterhuis, M.; van der Vaart, T.; Molleman, E. The value of upstream recognition of goals in supply chains. Supply Chain Manag. Int. J. 2012, 17, 582–595. [Google Scholar] [CrossRef]

- Finne, M.; Holmström, J. A manufacturer moving upstream: Triadic collaboration for service delivery. Supply Chain Manag. Int. J. 2013, 18, 21–33. [Google Scholar] [CrossRef]

- Li, T.; Zhang, H. Information sharing in a supply chain with a make-to-stock manufacturer. Omega 2015, 50, 115–125. [Google Scholar] [CrossRef]

- Carvalho, H.; Azevedo, S.G.; Machado, V.C. Supply chain management resilience: A theory building approach. Int. J. Supply Chain Oper. Resil. 2014, 1. [Google Scholar] [CrossRef]

- Choi, S.-B.; Min, H.; Joo, H.-Y.; Choi, H.-B. Assessing the impact of green supply chain practices on firm performance in the Korean manufacturing industry. Int. J. Logist. Res. Appl. 2016, 20, 129–145. [Google Scholar] [CrossRef]

- Kumar, V.; Holt, D.; Ghobadian, A.; Garza-Reyes, J.A. Developing green supply chain management taxonomy-based decision support system. Int. J. Prod. Res. 2014, 53, 6372–6389. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int. J. Prod. Res. 2019, 58, 1319–1337. [Google Scholar] [CrossRef]

- Agrawal, P.; Narain, R. Digital supply chain management: An overview. IOP Conf. Ser. Mater. Sci. Eng. 2018, 455, 012074. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital supply chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Embassy of Indonesia Washington DC, Facts & Figures. Available online: https://www.embassyofindonesia.org/basic-facts/ (accessed on 10 February 2021).

- BPS-Statistics. BPS Indikator Ekonomi November 2020. Available online: https://www.bps.go.id/publication/2021/01/29/6c1dad079e0ecd16e8bcfa8e/indikator-ekonomi-november-2020.html (accessed on 10 February 2021).

- Kemenperin, Indonesia’s Fourth Industrial Revolution Making Indonesia 4.0. Available online: http://www.kemenperin.go.id/ (accessed on 1 February 2021).

- OxfordBusinessGroup. Sustained growth makes Indonesia’s food and beverages industry a priority for spending. Available online: https://oxfordbusinessgroup.com/analysis/growth-driver-sustained-growth-makes-food-and-beverages-industry-priority-spending-and-investment (accessed on 8 February 2021).

- Farahani, P.; Meier, C.; Wilke, J. Digital supply chain management agenda for the automotive supplier industry. Shap. Digit. Enterp. 2017. [Google Scholar] [CrossRef]

- Blanchard, D. Internet of Things. Available online: https://www.industryweek.com/ (accessed on 12 February 2020).

- Vazquez-Martinez, G.A.; Gonzalez-Compean, J.L.; Sosa-Sosa, V.J.; Morales-Sandoval, M.; Perez, J.C. CloudChain: A novel distribution model for digital products based on supply chain principles. Int. J. Inf. Manag. 2018, 39, 90–103. [Google Scholar] [CrossRef]

- Xu, G.; Li, M.; Chen, C.-H.; Wei, Y. Cloud asset-enabled integrated IoT platform for lean prefabricated construction. Autom. Constr. 2018, 93, 123–134. [Google Scholar] [CrossRef]

- Aymerich, F.M.; Fenu, G.; Surcis, S. An approach to a cloud computing network. In Proceedings of the 2008 First International Conference on the Applications of Digital Information and Web Technologies (ICADIWT), Ostrava, Czech Republic, 4–6 August 2008. [Google Scholar]

- Hofmann, E.; Strewe, U.M.; Bosia, N. Supply Chain Finance and Blockchain Technology. The Case of Reverse Securitisation; Springer: New York, NY, USA, 2018; Volume VIII. [Google Scholar]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2018, 57, 829–846. [Google Scholar] [CrossRef]

- Mishra, D.; Angappa Gunasekaran, D.N.D.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Dubey, R.; Wamba, S. Vision, applications and future challenges of internet of things. Ind. Manag. Data Syst. 2016, 116, 1331–1355. [Google Scholar] [CrossRef]

- Fitzgerald, J.; Quasney, E. Using Manufacturing-Autonomous-Robots-Supply-Chain-Innovation; Deloitte Consulting: London, UK, 2020. [Google Scholar]

- Dhillon, B.S. Robot reliability. In Robot Reliability and Safety; Springer: New York, NY, USA, 1991. [Google Scholar]

- Merlino, M.; Sproģe, I. The augmented supply chain. Procedia Eng. 2017, 178, 308–318. [Google Scholar] [CrossRef]

- Chao, L. Robots gain traction with supply chain managers. Available online: https://www.wsj.com/articles/robots-gain-traction-with-supply-chain-managers-1459936836 (accessed on 8 February 2021).

- Bartezzaghi, E.; Turco, F. The impact of just-in-time on production system performance: An analytical framework. Int. J. Oper. Prod. Manag. 1989, 9, 40–62. [Google Scholar] [CrossRef]

- Lu, D.; Ding, Y.; Asian, S.; Paul, S.K. From supply chain integration to operational performance: The moderating effect of market uncertainty. Glob. J. Flex. Syst. Manag. 2017, 19, 3–20. [Google Scholar] [CrossRef]

- Franco-Santos, M.; Kennerley, M.; Micheli, P.; Martinez, V.; Mason, S.; Marr, B.; Gray, D.; Neely, A. Towards a definition of a business performance measurement system. Int. J. Oper. Prod. Manag. 2007, 27, 784–801. [Google Scholar] [CrossRef]

- Ebrahimi, S.M. Examining the Impact of Supply Chain Integration on Organization Structure and Operational Performance in Oil and Gas Supply Chains: A Contingency Approach. Available online: http://etheses.whiterose.ac.uk/10170/1/Seyed%20PhD%20online%20submission.pdf (accessed on 8 February 2021).

- Devaraj, S.; Krajewski, L.; Wei, J.C. Impact of eBusiness technologies on operational performance: The role of production information integration in the supply chain. J. Oper. Manag. 2007, 25, 1199–1216. [Google Scholar] [CrossRef]

- Behrouzi, F.; Wong, K.Y.; Behrouzi, F. A study on lean supply chain performance measures of SMEs in the automotive industry. In Proceedings of the 2011 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 6–9 December 2011. [Google Scholar]

- Yu, W.; Chavez, R.; Feng, M.; Wiengarten, F. Integrated green supply chain management and operational performance. Supply Chain Manag. Int. J. 2014, 19, 683–696. [Google Scholar] [CrossRef]

- Neely, A. Business Performance Measurement: Unifying Theory and Integrating Practice; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Ageron, B.; Bentahar, O.; Gunasekaran, A. Digital supply chain: Challenges and future directions. Supply Chain Forum Int. J. 2020, 21, 133–138. [Google Scholar] [CrossRef]

- Maani, K.E.; Sluti, D.G. A conformance-performance model: Linking quality strategies to business unit–s performance. In Manufacturing Strategy; Ettlie, J.E., Burstein, M.C., Fiegenbaum, A., Eds.; Springer: Dordrecht, The Netherlands, 1990. [Google Scholar]

- Ward, P.T.; Duray, R. Manufacturing strategy in context: Environment, competitive strategy and manufacturing strategy. J. Oper. Manag. 2000, 18, 123–138. [Google Scholar] [CrossRef]

- Wong, C.Y.; Boon-itt, S.; Wong, C.W.Y. The contingency effects of environmental uncertainty on the relationship between supply chain integration and operational performance. J. Oper. Manag. 2011, 29, 604–615. [Google Scholar] [CrossRef]

- Tracey, M.; Vonderembse, M.A.; Lim, J.-S. Manufacturing technology and strategy formulation: Keys to enhancing competitiveness and improving performance. J. Oper. Manag. 1999, 17, 411–428. [Google Scholar] [CrossRef]

- Abdallah, A.B.; Obeidat, B.Y.; Aqqad, N.O. The impact of supply chain management practices on supply chain performance in jordan: The moderating effect of competitive intensity. Int. Bus. Res. 2014, 7. [Google Scholar] [CrossRef]

- Dehning, B.; Richardson, V.J.; Zmud, R.W. The financial performance effects of IT-based supply chain management systems in manufacturing firms. J. Oper. Manag. 2007, 25, 806–824. [Google Scholar] [CrossRef]

- Fynes, B.; Voss, C.; de Búrca, S. The impact of supply chain relationship quality on quality performance. Int. J. Prod. Econ. 2005, 96, 339–354. [Google Scholar] [CrossRef]

- Boon-itt, S. Achieving Product Quality Performance: The Roles of Supply Chain Integration and Information Technology. Int. J. Innov. Manag. Technol. 2011, 2, 373–376. [Google Scholar]

- Matt, C.; Hess, T.; Benlian, A. Digital Transformation Strategies. Bus. Inf. Syst. Eng. 2015, 57, 339–343. [Google Scholar] [CrossRef]

- Akter, S.; Fosso Wamba, S.; Gunasekaran, A.; Dubey, R.; Childe, S.J. How to improve firm performance using big data analytics capability and business strategy alignment? Int. J. Prod. Econ. 2016, 182, 113–131. [Google Scholar] [CrossRef]

- Weichhart, G.; Molina, A.; Chen, D.; Whitman, L.E.; Vernadat, F. Challenges and current developments for Sensing, Smart and Sustainable Enterprise Systems. Comput. Ind. 2016, 79, 34–46. [Google Scholar] [CrossRef]

- Fawcett, S.E.; Wallin, C.; Allred, C.; Fawcett, A.M.; Magnan, G.M. Information technology as an enabler of supply chain collaboration: A dynamic-capabilities perspective. J. Supply Chain Manag. 2011, 47, 38–59. [Google Scholar] [CrossRef]

- Kwon, O.; Lee, N.; Shin, B. Data quality management, data usage experience and acquisition intention of big data analytics. Int. J. Inf. Manag. 2014, 34, 387–394. [Google Scholar] [CrossRef]

- Sharma, M.; Joshi, S. Digital supplier selection reinforcing supply chain quality management systems to enhance firm’s performance. TQM J. 2020. ahead-of-print. [Google Scholar] [CrossRef]

- Agus, A. Supply Chain Management, Product Quality and Business Performance. In Proceedings of the International Conference on Sociality and Economics Development, Kuala Lumpur, 4–5 June 2011; Volume 10. [Google Scholar]

- Wang, M.; Altaf, M.S.; Al-Hussein, M.; Ma, Y. Framework for an IoT-based shop floor material management system for panelized homebuilding. Int. J. Constr. Manag. 2018, 20, 130–145. [Google Scholar] [CrossRef]

- Ittmann, H.W. The impact of big data and business analytics on supply chain management. J. Transp. Supply Chain Manag. 2015, 9. [Google Scholar] [CrossRef]

- Ellis, S.; Santagate, J.; Morris, H.D. Iot-enabled analytic applications revolutionize supply chain planning and execution. In IDC Analyze the Future White Paper; 2015; Volume 259697, pp. 1–13. Available online: https://www.savi.com/wp-content/uploads/IDC-IoT-enabled-analytics-applications_final.pdf (accessed on 30 April 2021).

- Kim, J.-S.; Shin, N. The impact of blockchain technology application on supply chain partnership and performance. Sustainability 2019, 11, 6181. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In In Proceedings of the International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Foidl, H.; Felderer, M. Research challenges of industry 4.0 for quality management. Available online: https://link.springer.com/chapter/10.1007/978-3-319-32799-0_10 (accessed on 8 February 2021).

- Gunasekaran, A.; Ngai, E.W.T. Information systems in supply chain integration and management. Eur. J. Oper. Res. 2004, 159, 269–295. [Google Scholar] [CrossRef]

- Zhu, K.; Kraemer, K.L. E-commerce metrics for net-enhanced organizations: Assessing the value of e-commerce to firm performance in the manufacturing sector. Inf. Syst. Res. 2002, 13, 275–295. [Google Scholar] [CrossRef]

- Yu, W.; Chavez, R.; Jacobs, M.A.; Feng, M. Data-driven supply chain capabilities and performance: A resource-based view. Transp. Res. Part E: Logist. Transp. Rev. 2018, 114, 371–385. [Google Scholar] [CrossRef]

- Raman, S.; Patwa, N.; Niranjan, I.; Ranjan, U.; Moorthy, K.; Mehta, A. Impact of big data on supply chain management. Int. J. Logist. Res. Appl. 2018, 21, 579–596. [Google Scholar] [CrossRef]

- Nair, P.R. Tackling supply chain through cloud computing: Management: Opportunities, challenges and successful deployments. In ICT and Critical Infrastructure: Proceedings of the 48th Annual Convention of Computer Society of India, Visakhapatnam, India, 13–15 December 2013; Volume II, pp. 761–767. [Google Scholar]

- Mahyuni, L.P.; Adrian, R.; Darma, G.S.; Krisnawijaya, N.N.K.; Dewi, I.G.A.A.P.; Permana, G.P.L.; Foroudi, P. Mapping the potentials of blockchain in improving supply chain performance. Cogent Bus. Manag. 2020, 7. [Google Scholar] [CrossRef]

- Creswell, J.W.; Poth, C.N. Qualitative Inquiry & Research Design; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Malhotra, M.K.; Grover, V. An assessment of survey research in POM: From constructs to theory. J. Oper. Manag. 1998, 16, 407–425. [Google Scholar] [CrossRef]

- Kelley, K.; Clark, B.; Brown, V.; Sitzia, J. Good practice in the conduct and reporting of survey research. Int. J. Qual. Health Care 2003, 15, 261–266. [Google Scholar] [CrossRef]

- Jones, T.L.; Baxter, M.A.; Khanduja, V. A quick guide to survey research. Ann R Coll Surg Engl 2013, 95, 5–7. [Google Scholar] [CrossRef]

- Sekaran, U.; Bougie, R. Research Methods for Business: A Skill-Building Approach; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Chang, D.; Lee, S.M. The impact of critical success factors of JIT implementation on organizational performance. Prod. Plan. Control 1996, 7, 329–338. [Google Scholar] [CrossRef]

- Jeyaraman, K.; Teo, K.L. A conceptual framework for critical success factors of lean six sigma. Int. J. Lean Six Sigma 2010, 1, 191–215. [Google Scholar] [CrossRef]

- Hair Jr, J.F.; Sarstedt, M.; Hopkins, L.; Kuppelwieser, V.G. Partial least squares structural equation modeling (PLS-SEM). An emerging tool in business research. Eur. Bus. Rev. 2014, 26, 106–121. [Google Scholar] [CrossRef]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Hair, J.; Joseph, F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- Chin, W.W. The partial least squares approach to structural equation modeling. In Modern Methods for Business Research; Marcoulides, G.A., Ed.; Lawrence Erlbaum Associates: Mahwah, NJ, USA, 1998; pp. 295–336. [Google Scholar]

- Chin, W.W. How to Write Up and Report PLS Analyses. In Handbook of Partial Least Squares; Esposito Vinzi, V., Chin, W., Henseler, J., Wang, H., Eds.; Springer Handbooks of Computational Statistics; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Benitez, J.; Henseler, J.; Castillo, A.; Schuberth, F. How to perform and report an impactful analysis using partial least squares: Guidelines for confirmatory and explanatory IS research. Inf. Manag. 2020, 57. [Google Scholar] [CrossRef]

- Raithel, S.; Sarstedt, M.; Scharf, S.; Schwaiger, M. On the value relevance of customer satisfaction. Multiple drivers and multiple markets. J. Acad. Mark. Sci. 2012, 40, 509–525. [Google Scholar] [CrossRef]

- Li, D.; Wang, X. Dynamic supply chain decisions based on networked sensor data: An application in the chilled food retail chain. Int. J. Prod. Res. 2015, 55, 5127–5141. [Google Scholar] [CrossRef]

- Raguseo, E. Big data technologies: An empirical investigation on their adoption, benefits and risks for companies. Int. J. Inf. Manag. 2018, 38, 187–195. [Google Scholar] [CrossRef]

- Brandyberry, A.; Rai, A.; White, G.P. Intermediate performance impacts of advanced manufacturing technology systems: An empirical investigation. Decis. Sci. 1999, 30, 993–1020. [Google Scholar] [CrossRef]

- Pilat, D.; Criscuolo, C. The future of productivity what contribution can digital transformation make? Policy Q. 2018, 14, 14–16. [Google Scholar] [CrossRef]

- Özemre, M.; Kabadurmus, O. A big data analytics based methodology for strategic decision making. J. Enterp. Inf. Manag. 2020, 33, 1467–1490. [Google Scholar] [CrossRef]

- Maulina, E.; Natakusumah, K. Determinants of supply chain operational performance. Uncertain Supply Chain Manag. 2020, 8, 117–130. [Google Scholar] [CrossRef]

- Rai, A.; Patnayakuni, R.; Seth, N. Firm performance impacts of digitally-enabled supply chain integration capabilities. Mis Quartely 2006, 30, 225–246. [Google Scholar] [CrossRef]

- Oh, J.; Jeong, B. Tactical supply planning in smart manufacturing supply chain. Robot. Comput. Integr. Manuf. 2019, 55, 217–233. [Google Scholar] [CrossRef]

- Haddud, A.; Khare, A. Digitalizing supply chains potential benefits and impact on lean operations. Int. J. Lean Six Sigma 2020, 11, 731–765. [Google Scholar] [CrossRef]

- Brinch, M.; Stentoft, J. Digital Supply Chains: Still More “Wannabe” than Practice. Available online: https://findresearcher.sdu.dk:8443/ws/portalfiles/portal/124535660/Do_17_2_DDSCP_digital_supply_chains.pdf (accessed on 8 February 2021).

- Schoenherr, T.; Speier-Pero, C. Data science, predictive analytics, and big data in supply chain management: Current state and future potential. J. Bus. Logist. 2015, 36, 120–132. [Google Scholar] [CrossRef]

- Cegielski, C.G.; Allison Jones-Farmer, L.; Wu, Y.; Hazen, B.T. Adoption of cloud computing technologies in supply chains. Int. J. Logist. Manag. 2012, 23, 184–211. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of things and supply chain management: A literature review. Int. J. Prod. Res. 2017, 57, 4719–4742. [Google Scholar] [CrossRef]

- Safizadeh, M.H.; Ritzman, L.P.; Sharma, D.; Wood, C. An empirical analysis of the product-process matrix. Manag. Sci. 1996, 42, 1576–1591. [Google Scholar] [CrossRef]

- Koufteros, X.A.; Vonderembse, M.A.; Doll, W.J. Examining the competitive capabilities of manufacturing firms. Struct. Equ. Modeling Multidiscip. J. 2002, 9, 256–282. [Google Scholar] [CrossRef]

- Davis, P.S.; Schul, P.L. Addressing the contingent effects of business unit strategic orientation on relationships between organizational context and business unit performance. J. Bus. Res. 1993, 27, 183–200. [Google Scholar] [CrossRef]

| N = 209 | Frequency | Percentage (%) | |

|---|---|---|---|

| Age of the company | 0–10 | 59 | 28.2 |

| >10–20 | 65 | 31.1 | |

| Over 20 | 85 | 40.7 | |

| Number of employees | 0–20 person | 4 | 1.9 |

| 20–99 person | 59 | 28.2 | |

| >=100 person | 146 | 69.9 | |

| Legal entity status | Limited company (PT) | 199 | 95.2 |

| Limited partnership (CV) | 4 | 1.9 | |

| Private/Individual company | 6 | 2.9 | |

| Educational background | High school and Diploma | 27 | 12.9 |

| Undergraduate degree | 130 | 62.2 | |

| Master’s degree | 50 | 23.9 | |

| Doctoral degree | 2 | 1 | |

| Years of experience in the company | 5 to 10 years | 170 | 81.3 |

| 11 to 20 years | 29 | 13.9 | |

| Over 20 years | 10 | 4.8 | |

| Role in the organization | Supervisor | 69 | 33 |

| Department head | 11 | 5.3 | |

| Assistant manager | 8 | 3.8 | |

| Manager | 91 | 43.5 | |

| Vice director | 5 | 2.4 | |

| Director | 25 | 12 | |

| Main Variables | Items | Loadings | Cronbach’s Alpha | CR | AVE |

|---|---|---|---|---|---|

| Digital Supply Chain (DSC) | DSC_1 | 0.865 | 0.934 | 0.944 | 0.630 |

| DSC_2 | 0.803 | ||||

| DSC_3 | 0.803 | ||||

| DSC_4 | 0.762 | ||||

| DSC_5 | 0.876 | ||||

| DSC_6 | 0.873 | ||||

| DSC_7 | 0.723 | ||||

| DSC_8 | 0.717 | ||||

| DSC_9 | 0.793 | ||||

| DSC_10 | 0.702 | ||||

| Quality Performance (QP) | QP_1 | 0.738 | 0.769 | 0.852 | 0.591 |

| QP_2 | 0.781 | ||||

| QP_3 | 0.819 | ||||

| QP_4 | 0.733 | ||||

| Productivity Performance (PP) | PP_1 | 0.763 | 0.777 | 0.857 | 0.601 |

| PP_2 | 0.841 | ||||

| PP_3 | 0.777 | ||||

| PP_4 | 0.714 | ||||

| Cost Reduction Performance (CP) | CP_1 | 0.751 | 0.786 | 0.862 | 0.609 |

| CP_2 | 0.814 | ||||

| CP_3 | 0.811 | ||||

| CP_4 | 0.744 |

| CP | DSC | PP | QP | |

|---|---|---|---|---|

| CP | 0.781 | |||

| DSC | 0.621 | 0.794 | ||

| PP | 0.511 | 0.573 | 0.775 | |

| QP | 0.553 | 0.679 | 0.564 | 0.769 |

| Main Variables | DSC | QP | PP | CP |

|---|---|---|---|---|

| DSC_1 | 0.865 | 0.576 | 0.480 | 0.540 |

| DSC_2 | 0.803 | 0.527 | 0.440 | 0.521 |

| DSC_3 | 0.803 | 0.505 | 0.447 | 0.502 |

| DSC_4 | 0.762 | 0.548 | 0.468 | 0.436 |

| DSC_5 | 0.876 | 0.603 | 0.462 | 0.521 |

| DSC_6 | 0.873 | 0.559 | 0.480 | 0.527 |

| DSC_7 | 0.723 | 0.477 | 0.448 | 0.431 |

| DSC_8 | 0.717 | 0.551 | 0.386 | 0.458 |

| DSC_9 | 0.793 | 0.480 | 0.449 | 0.508 |

| DSC_10 | 0.702 | 0.554 | 0.484 | 0.475 |

| QP_1 | 0.469 | 0.738 | 0.424 | 0.437 |

| QP_2 | 0.495 | 0.781 | 0.427 | 0.361 |

| QP_3 | 0.610 | 0.819 | 0.389 | 0.462 |

| QP_4 | 0.498 | 0.733 | 0.508 | 0.437 |

| PP_1 | 0.401 | 0.446 | 0.763 | 0.355 |

| PP_2 | 0.494 | 0.473 | 0.841 | 0.453 |

| PP_3 | 0.466 | 0.466 | 0.777 | 0.430 |

| PP_4 | 0.408 | 0.357 | 0.714 | 0.332 |

| CP_1 | 0.482 | 0.402 | 0.401 | 0.751 |

| CP_2 | 0.514 | 0.443 | 0.481 | 0.814 |

| CP_3 | 0.500 | 0.454 | 0.335 | 0.811 |

| CP_4 | 0.440 | 0.427 | 0.376 | 0.744 |

| Variable | R2 |

|---|---|

| Quality Performance | 0.461 |

| Productivity Performance | 0.329 |

| Cost Reduction Performance | 0.386 |

| Hypothesis | Relationship | T-Value | P-Value | Decision |

|---|---|---|---|---|

| Hypothesis 1 | DSC → QP | 15.099 | 0.000 | Supported |

| Hypothesis 2 | DSC → PP | 10.114 | 0.000 | Supported |

| Hypothesis 3 | DSC → CP | 9.928 | 0.000 | Supported |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saryatmo, M.A.; Sukhotu, V. The Influence of the Digital Supply Chain on Operational Performance: A Study of the Food and Beverage Industry in Indonesia. Sustainability 2021, 13, 5109. https://doi.org/10.3390/su13095109

Saryatmo MA, Sukhotu V. The Influence of the Digital Supply Chain on Operational Performance: A Study of the Food and Beverage Industry in Indonesia. Sustainability. 2021; 13(9):5109. https://doi.org/10.3390/su13095109

Chicago/Turabian StyleSaryatmo, Mohammad Agung, and Vatcharapol Sukhotu. 2021. "The Influence of the Digital Supply Chain on Operational Performance: A Study of the Food and Beverage Industry in Indonesia" Sustainability 13, no. 9: 5109. https://doi.org/10.3390/su13095109

APA StyleSaryatmo, M. A., & Sukhotu, V. (2021). The Influence of the Digital Supply Chain on Operational Performance: A Study of the Food and Beverage Industry in Indonesia. Sustainability, 13(9), 5109. https://doi.org/10.3390/su13095109