Evaluation of Reinforced Adobe Techniques for Sustainable Reconstruction in Andean Seismic Zones

Abstract

1. Introduction

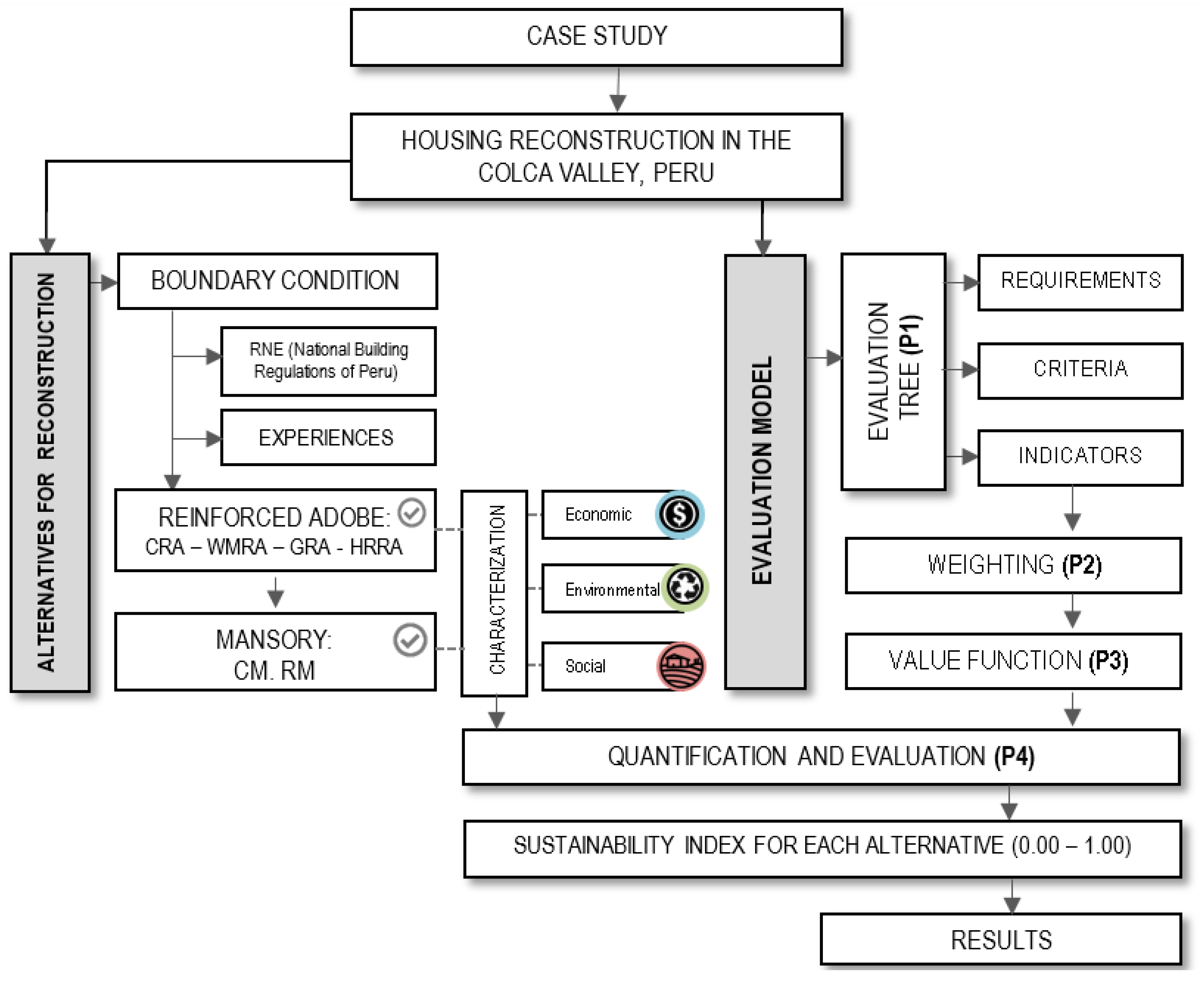

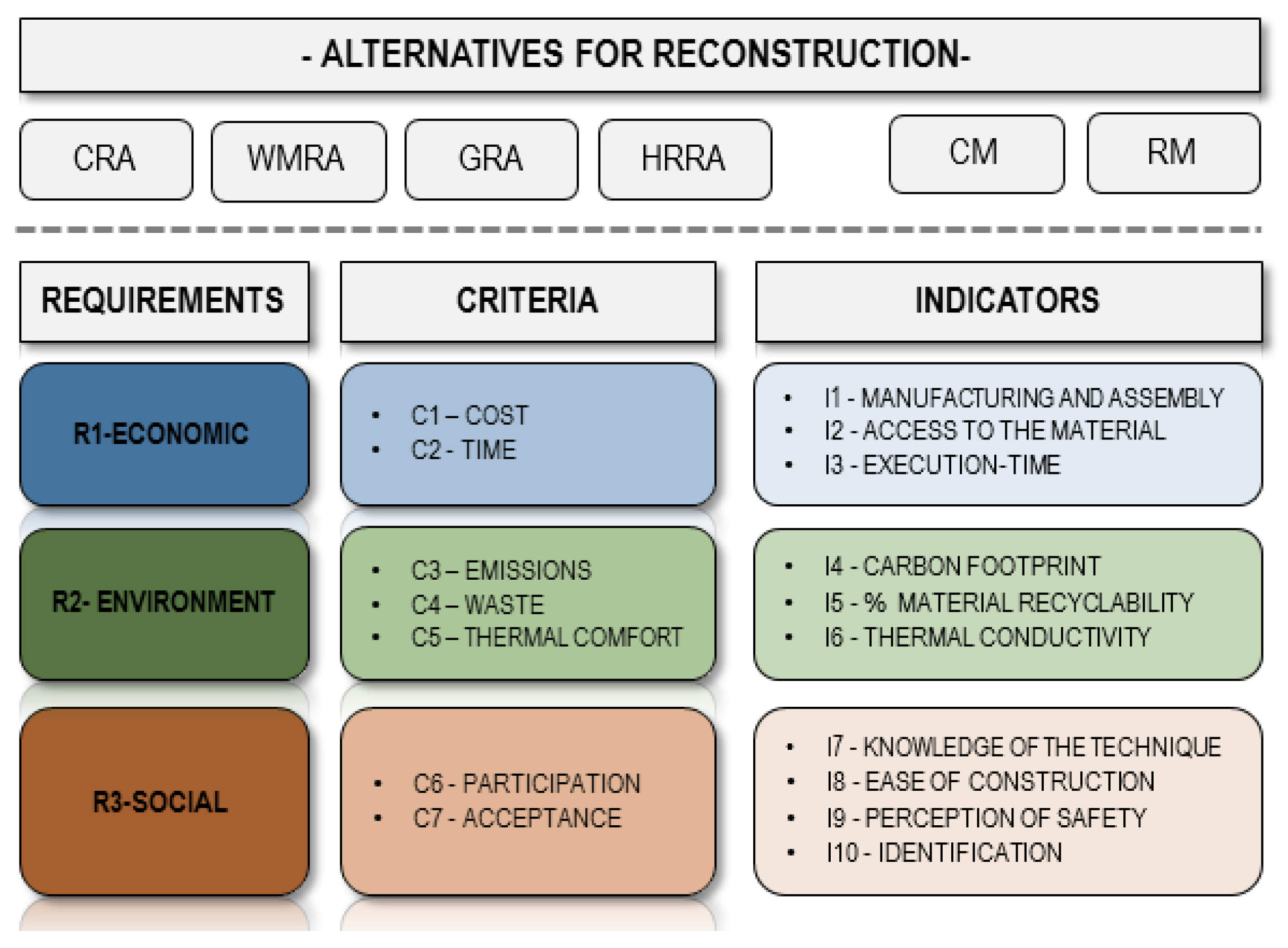

2. Methodology

3. Case Study

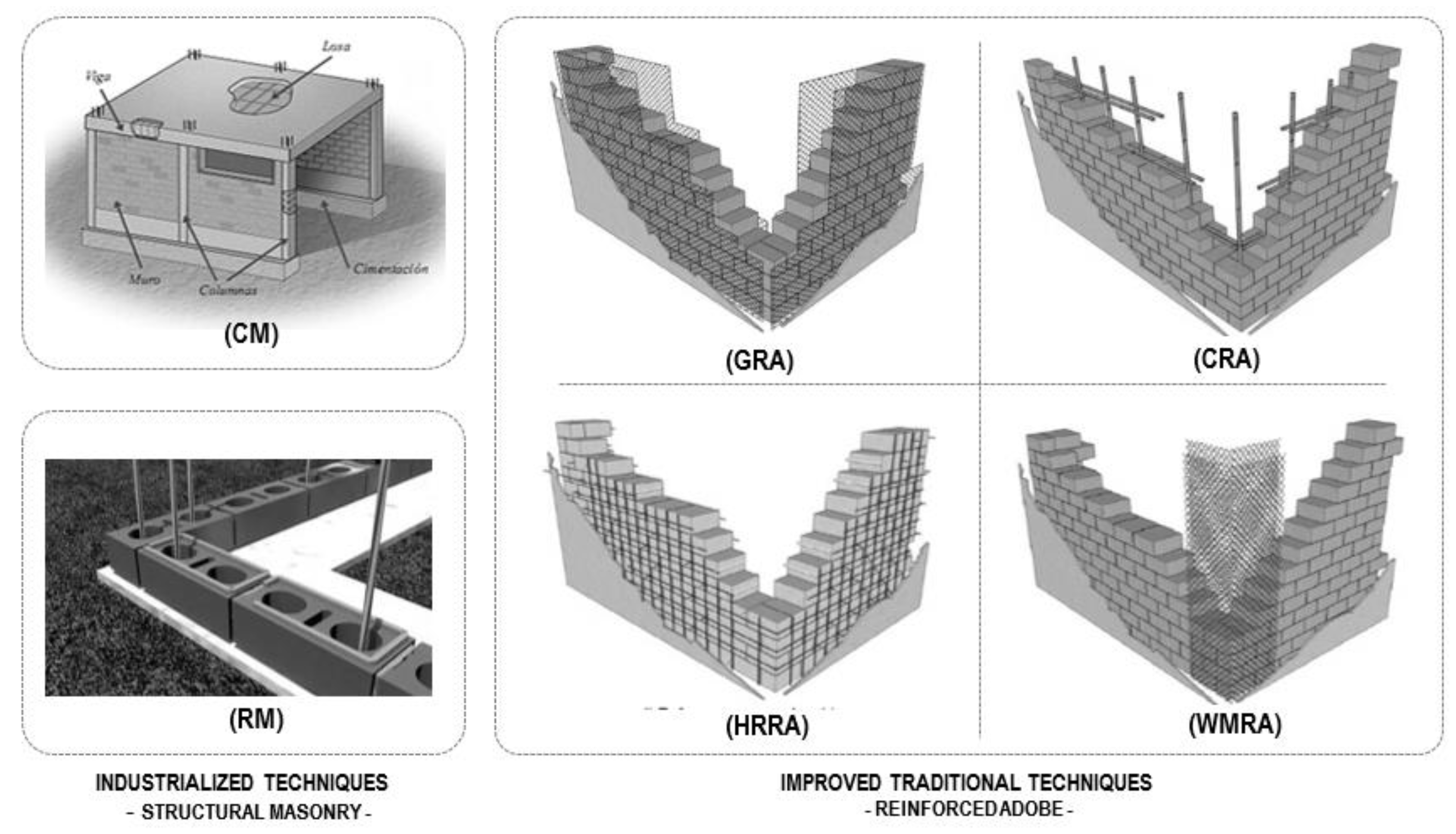

3.1. Alternatives for Reconstruction

3.2. Boundary Conditions

- -

- Cane reinforced adobe (CRA) is a building system that uses open cane as horizontal reinforcement and whole cane as vertical reinforcement in courses of mud mortar. The vertical canes must be anchored to the foundation and the base beam [30].

- -

- Wire mesh reinforced adobe (WMRA) is based on the placement of electro-welded mesh on the surface of the walls, simulating confinement beams and columns in adobe walls, to provide greater rigidity and avoid the separation of these by seismic action [32].

- -

- Geogrid reinforced adobe (GRA) uses a polypropylene mesh that is responsible for confining the adobe blocks that are joined together by pieces of rope that go through the wall and are placed in the mortar joints [30].

- -

- Halyard rope reinforced adobe (HRRA) is a system of synthetic ropes that wrap the walls vertically and horizontally, forming a mesh that confines the walls of the house and prevents them from collapsing [30].

| Material | Technique | Acronyms | Year Introduced | Boundary Conditions | Refs. | ||

|---|---|---|---|---|---|---|---|

| RNE Code | Experience | ||||||

| Earthen Construction | Simple Adobe | SA | 750 AC | - | Yes | ||

| Adobe reinforced with: | Canes | CRA | 1978 | E-080 | Yes | [33,34] | |

| Wire mesh | WMRA | 1997 | E-080 | Yes | [33] | ||

| Geogrid | GRA | 2007 | E-080 | Yes | [33,34] | ||

| Halyard ropes | HRRA | 2015 | E-080 | Yes | [33] | ||

| Tire-straps | TSRA | 2011 | - | - | [35] | ||

| Steel profiles | SPRA | 2005 | - | - | [36] | ||

| Reinforced concrete | RARC | 2011 | - | - | [37] | ||

| Prefabricated Quincha | PQ | 1984 | - | Yes | [34,38] | ||

| Masonry | Confined masonry | CM | 1982 | E-070 | Yes | [39] | |

| Reinforced masonry | RM | 1986 | E-070 | Yes | [40] | ||

- −

- Confined masonry (CM) uses reinforced concrete columns and beams around its perimeter; the concrete is poured after the setting of walls, which are generally made of fired clay bricks [31].

- −

3.3. Characterization of Techniques

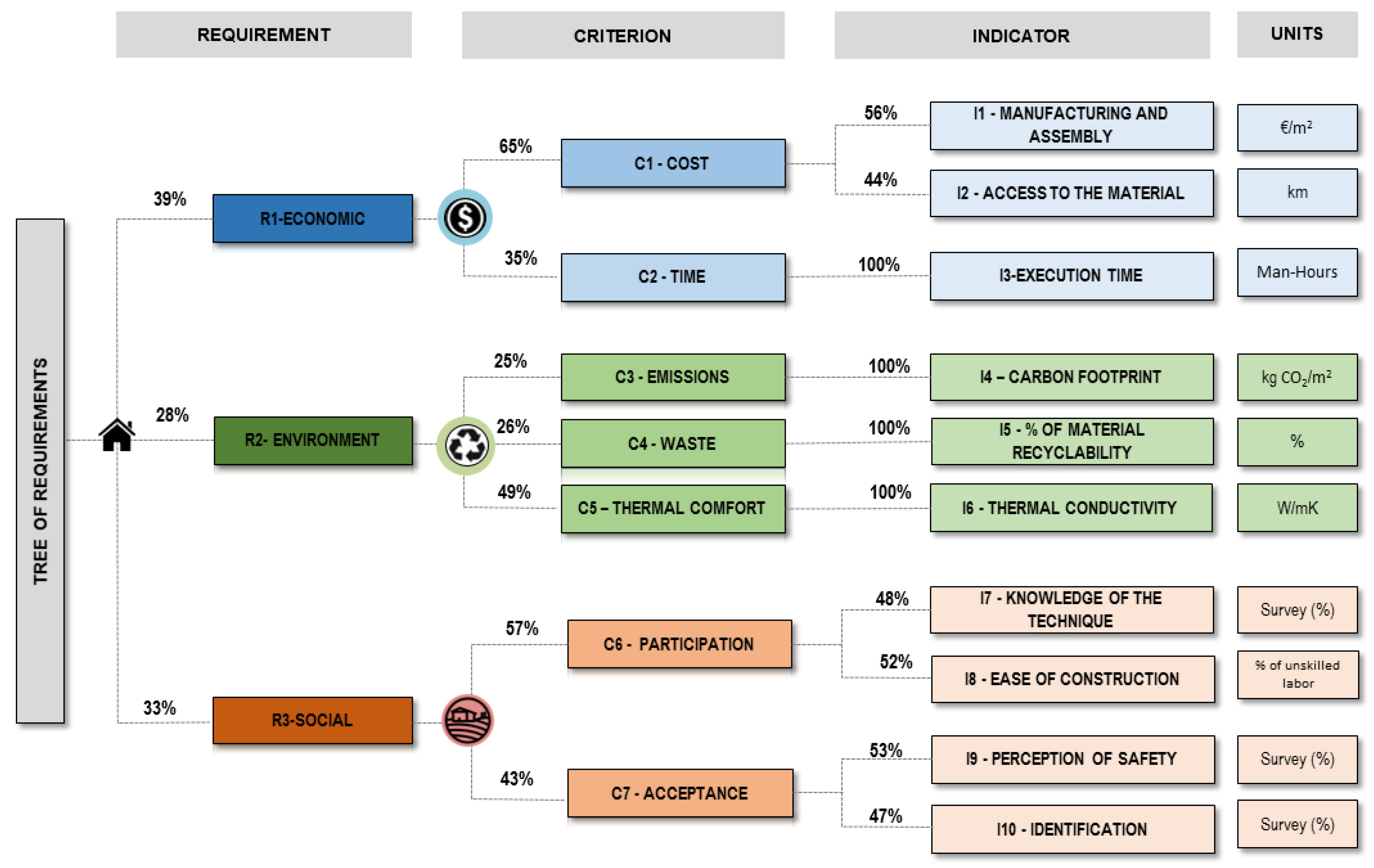

3.3.1. Economic Indicators—R1

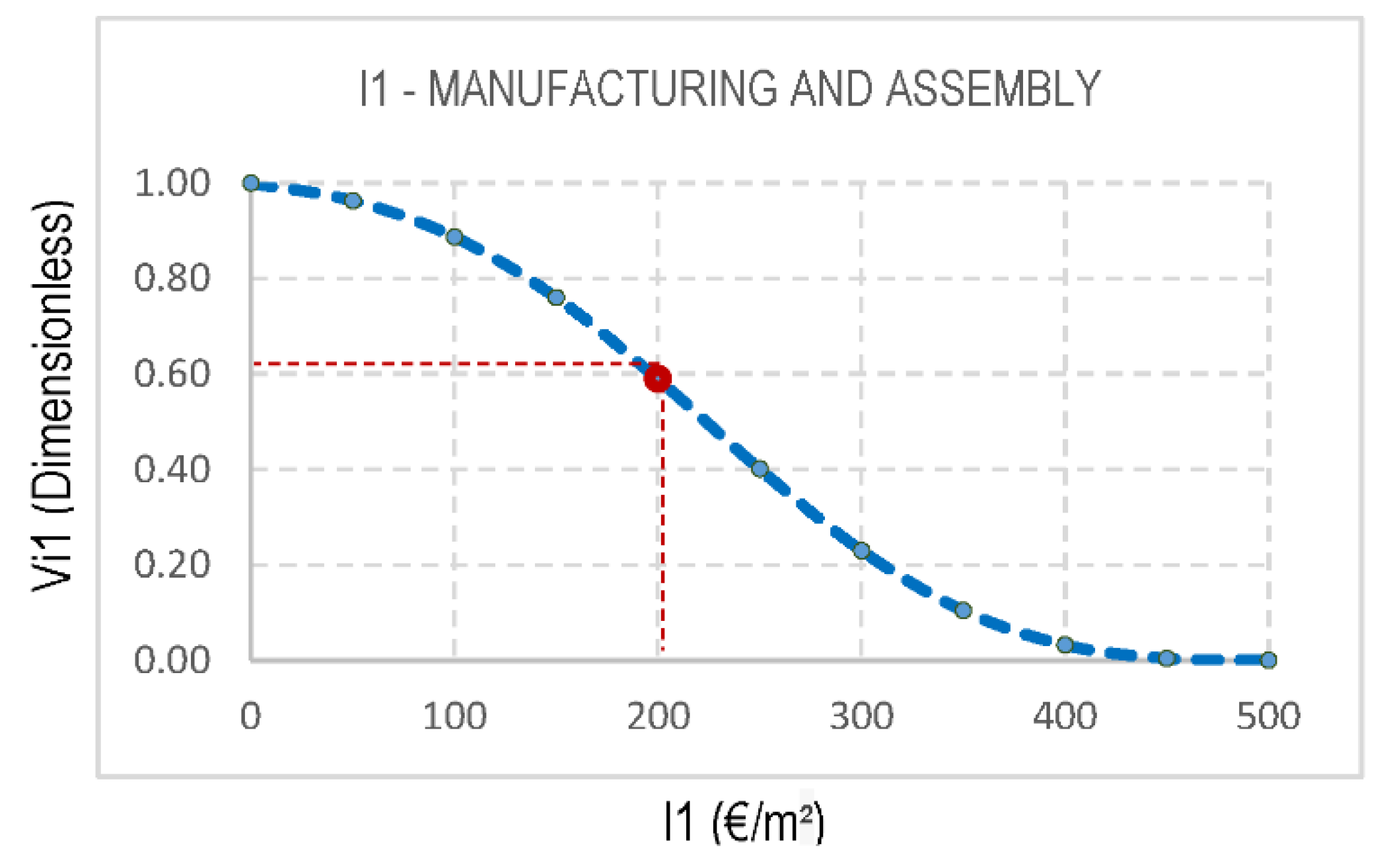

- Manufacturing and assembly—€/m2 (I1): we analyzed popular housing modules already executed in Peru, formulated by institutions with experience in reconstruction issues such as PUCP ( Pontifical Catholic University of Peru), COPASA (Cooperation for the Sustainable Development Process of Arequipa), GIZ (German Agency for Technical Cooperation), SDC (The Swiss Agency for Development and Cooperation-SDC), JICA (Japan International Cooperation Agency) and PNVR (National Rural Housing Program), among others. In order to have more comparable data, we took as a criterion the cost per m2 of useful area, since adobe walls have a thickness of 0.40 m and masonry thickness is 0.15 m. The cost includes basic finishes such as wall plastering and wood carpentry, which as a whole are not significant in proportion to the structural elements. The cost options in the reinforced adobe houses range from €197.5/m2, if using halyard ropes, to € 225.4/m2, if using wire mesh reinforcement. We observed similar values in the case of cane reinforcement, with a value of € 212.5/m2, and the geogrid reinforcement, with a value of € 215.3/m2; however, if cane reinforcement were more accessible, the value would drop considerably. In the case of confined masonry, the value is € 370.5/m2, practically double the value of reinforced adobe. Reinforced masonry has a value of € 307.9/m2; its cost is lower than that of confined masonry, because it does not require reinforced concrete elements such as columns and confinement beams (Table 3).

- Access to the material (I2): for each construction technique we calculated the distance in km from the town of Ichupampa, the one most affected by the 2016 earthquake, to the closest material distribution point. The geogrid, the wire mesh and the concrete blocks for reinforced masonry are the most difficult materials to obtain because they must be brought from the city of Arequipa (200 km distance). The canes are brought from the lower valleys (50 km) and the halyard ropes are sold in most hardware stores in the populated centers of the Colca Valley. Brick and concrete can be purchased in Chivay, capital of the province (15 km), but they have costs above the national average for being brought from the city of Arequipa (Table 3).

- Execution time (I3): the time required in man-hours (MH) to execute 10 m2 of wall was established as the unit cost analysis for each construction technique. Of the reinforced adobe techniques, the WMRA requires 10.9 MH because it needs a concrete complement in the corners; the HRRA requires 9.2 MH because it needs more manual work in the placement of the ropes and knots; the CRA requires 8.7 MH and the GRA requires 8.4 MH, which are comparatively shorter times because the placement of the canes and geogrid is faster and more practical. The confined masonry technique, CM, requires 22.6 MH due to the placement of formworks for the confinement of columns and beams; the reinforced masonry technique, RM, needs 15.1 MH, less time than in the CM, because it does not require confinement elements in the reinforced concrete (beams and columns) (Table 3).

3.3.2. Environmental Indicators—R2

- Carbon footprint (I4): the unit of measure kg CO2/m2, equivalent to kg of CO2 for the construction of 1 m2 of wall, was used for each of the six techniques. Confined masonry has a value of 301 kg CO2/m2 because it requires industrialized materials such as fired clay brick and concrete (cement plus aggregate), both with a high CO2 emission, especially from clinker, the main component of cement. Reinforced masonry reaches a value of 455 kg CO2/m2 by using steel rods that require a high CO2 value for production. Adobe reinforced with canes consists of natural materials; thus, the CO2 emitted during its production is considered as null, with only the emission from the adobe production considered (74 kg CO2/m2). Wire mesh (electro-welded) is manufactured from low-alloy steel and presents a considerably high energy consumption in its production process (96 kg CO2/m2). The biaxial geogrid is made with high molecular weight and high tenacity polypropylene that provides high passive load resistance (79 kg CO2/m2). Finally, the halyard rope has nylon as its main component, which is a synthetic polymer that belongs to the group of polyamides; being a petroleum derivative, it has an impact on the environment (82 kg CO2/m2) (Table 4).

- Thermal conductivity (I5): the Colca Valley is over 3000 m high, requiring construction materials to withstand the intense cold in this area, especially between June and August, with temperatures reaching −4 °C [47]. The economic conditions of this area prevent the use of heating or additional insulating materials, so the adoption of a suitable enclosure material is in many cases the only protection against the effects of the weather. The unit of measure of thermal conductivity, W/mK, is used for the main materials of each construction technique [48]. In this regard, the four reinforced adobe techniques reached a similar value of 0.46 W/mK, which is basically attributed to the adobe units because the contribution of the reinforcement elements is considered thermally negligible. Confined masonry has a value of 1.04 W/mK, and reinforced masonry has a value of 0.91 W/mK (Table 4).

- Recyclability of material (I6): once the life cycle of a building is completed, it is important to establish the proportion (%) of material that can be recycled or reincorporated into a production cycle. The higher the recycling percentage is, the lower the impact on the environment, due, among other factors, to the lower amount of energy required to produce new construction materials from extraction and processing of raw materials. In the case of adobe, according to the study carried out by E. Vargas (2020) [49], 80% recycling capacity is reached due to the physical properties of the earth of being easily reintroduced into the production cycles and, in this sense, generating low residue levels. In the case of confined masonry, the percentage is 23%, because brick requires more complex processes for recycling. Reinforced masonry reaches 44%; simple grinding can produce light aggregate (Table 4).

3.3.3. Social Indicators—R3

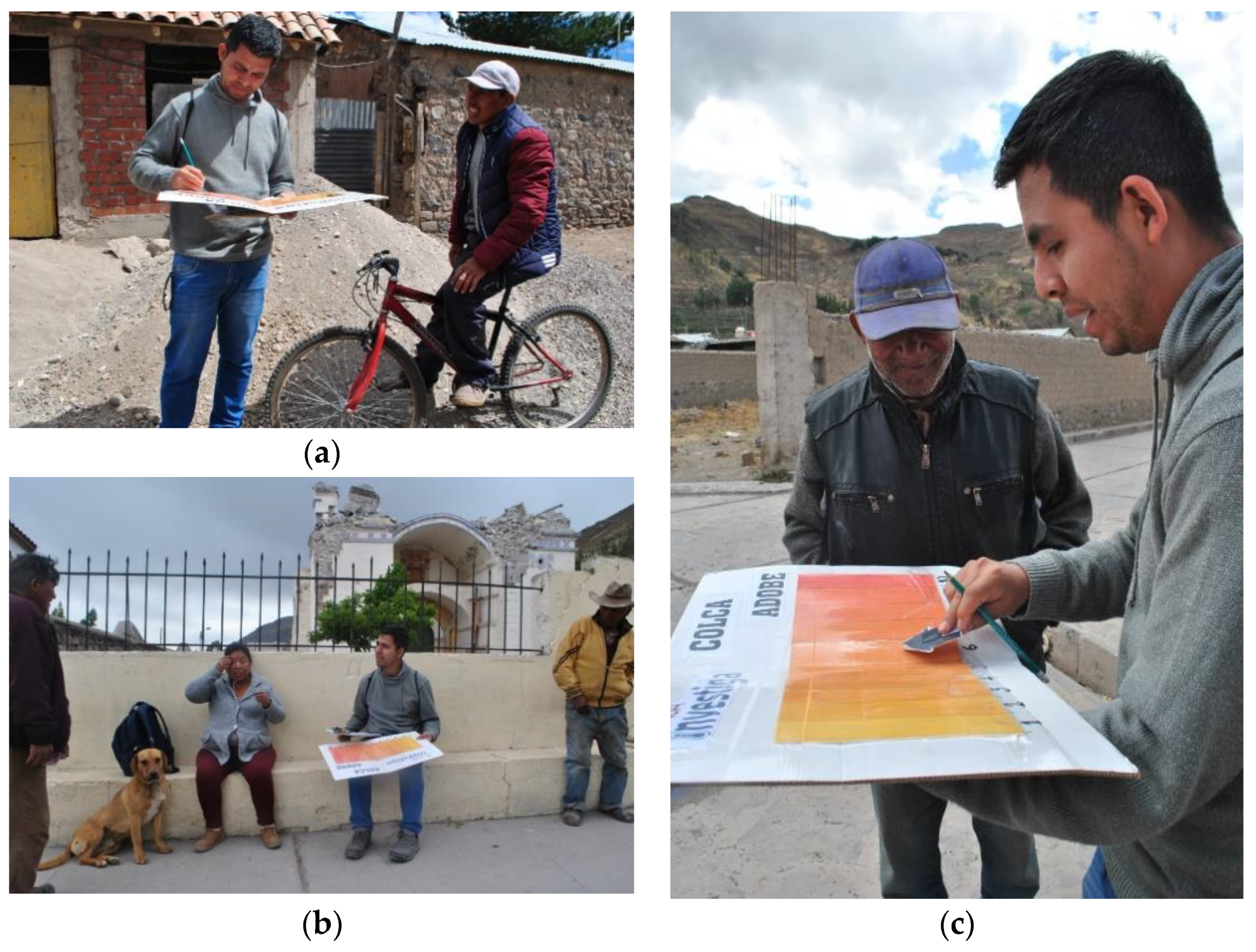

- Knowledge of the technique (I7): 100% of those surveyed stated that they knew the confined masonry technique because it is one of the most widely used and widespread techniques, while in terms of reinforced masonry only 26% of those surveyed knew about it. Of the adobe reinforcement techniques, the best known was the wire mesh technique with 33% of respondents knowing of it (several housing modules were built after the 2001 earthquake), followed by reinforcement with canes with 29% and geogrid with 24%. The halyard ropes technique had only 6% recognition, as it is the most recent to be introduced and still has very little diffusion. Additionally, 80% of the population stated that they had participated in the construction of at least one adobe house, but they stated that this tradition is being lost because the new generation has greater resources and gives preference to masonry construction (Table 5).

- Ease of construction (I8): this factor measures the level of complexity in the construction process of each reinforcement technique and the feasibility of it being replicated by the inhabitants, in self-building processes, with minimal training and the use of simple tools. For measuring between the cost of unskilled labor and the cost of total labor, we used a ratio; data were obtained from the housing modules already analyzed in Table 5. Under this analysis, the reinforcement with halyard ropes requires 50.46%, reinforcement with canes 49.30%, reinforcement with wire mesh 42.41%, and with geogrid 41.42%. In confined masonry this value reaches 31.25%, and for reinforced masonry 15.30%. The more complex the technique, the higher the ratio of specialized labor, which logically also implies a higher economic cost (Table 5).

- Perception of safety (I9): a chromatic scale was used with a ranking range from 1 to 10 (with 1 being very bad and 10 very good) for measuring this variable and for a better understanding of the method by the surveyed population. The confined masonry reached, according to the perception of safety that the respondents showed, a value of 8.40, and the reinforced masonry reached value of 7.50. In the case of reinforced adobe, the technique with wire mesh reached a value of 6.50; cane, 6.30; geogrid, 6.90; halyard ropes, 5.90. This shows greater confidence in masonry techniques compared to reinforced adobe constructions, which is explained by the growing fear generated by the collapse of adobe housing after the 2016 earthquake. However, it must be remembered that these houses did not have the proper structural reinforcement (Table 5).

- Identification (I10): this indicator measures the level of identification of the population with each construction technique and how they believe it contributes wealth and heritage value to their district. A total of 90% of those surveyed consider that their town has an important heritage value, and 88% attribute it to the traditional buildings (housing and churches). Under these criteria, on a ranking scale from 1 to 10 (1 being very bad and 10 very good), confined masonry reaches a value of 3.3, reinforced masonry reaches a value of 3.0, and adobe constructions in general reach a value of 8.0. The adult population shows greater attachment to traditional buildings, while young people feel identify more with industrialized techniques such as masonry (Table 5).

4. Evaluation Model

4.1. Development of the Tree of Requirements (P1)

4.2. Weighting and Assignment of Relative Weights (P2)

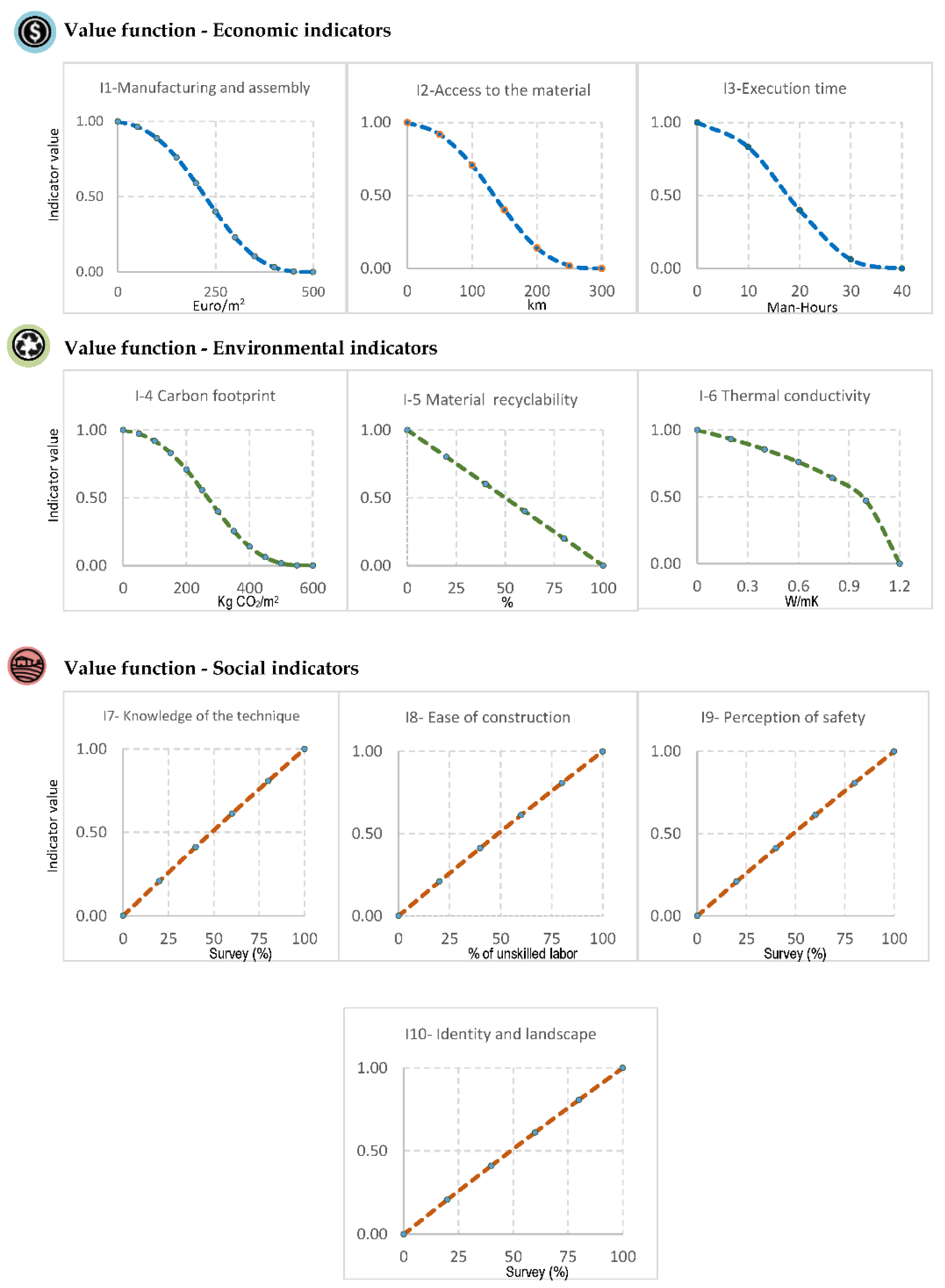

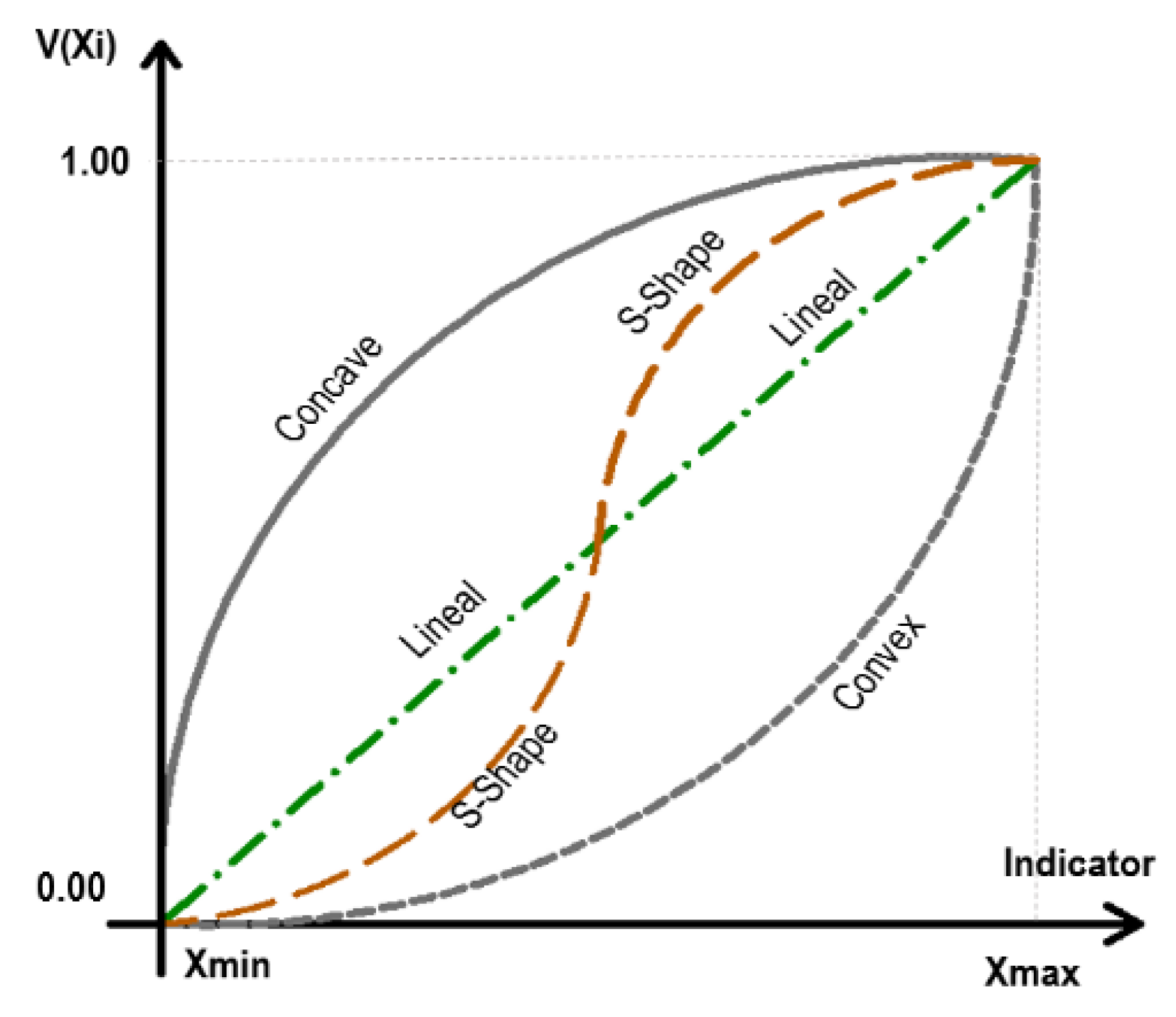

4.3. Assignment of Function Value (P3)

4.4. Quantification and Evaluation (P4)

- −

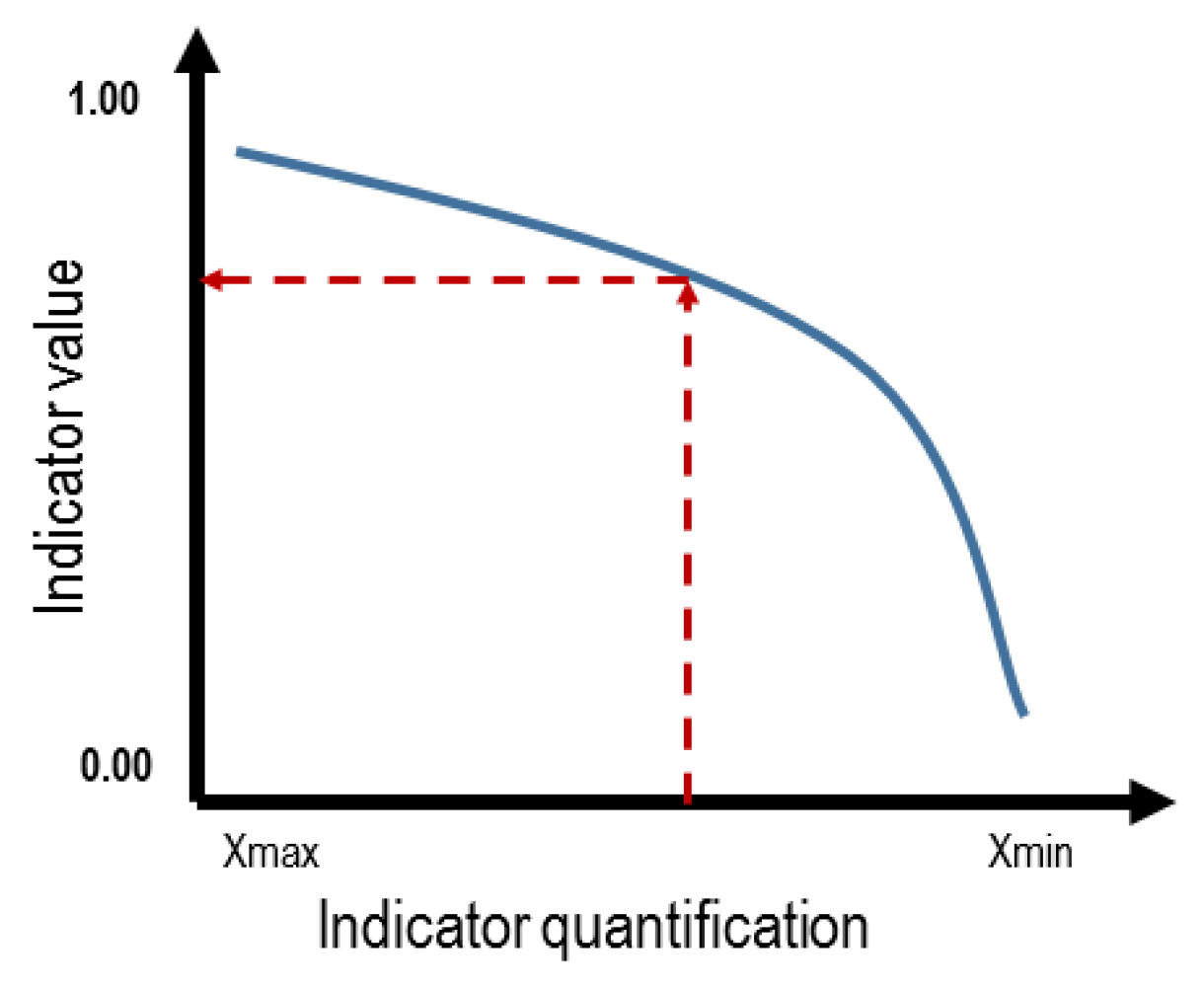

- Value of the indicators is obtained from the value function and the quantification of the indicator for each alternative. The quantification of the alternative is the abscissa of the point of the value function, whose ordinate is the value of the indicator for the alternative studied. It is shown in the example in Figure 12.

- −

- Value of the criteria is obtained from the value of the indicators belonging to the same criterion multiplied by their respective weights (Equation (4)).

- −

- Value of the requirements is the sum of the values of the criteria belonging to that same requirement multiplied by their weights (Equation (5)).

- −

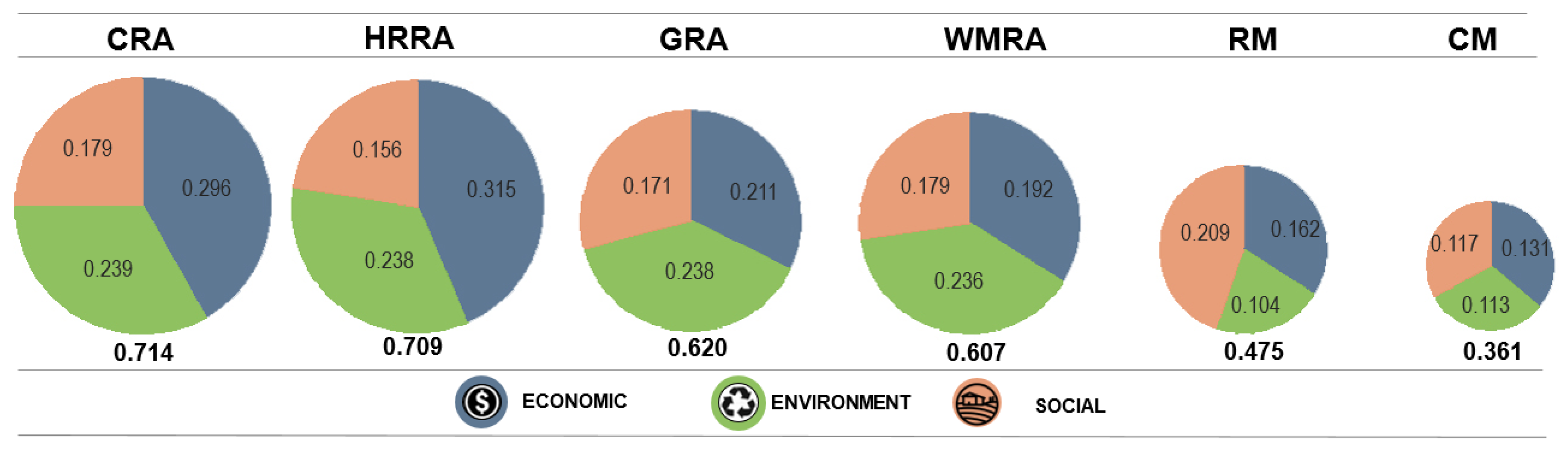

- Value Index is determined by adding the value of the requirements multiplied by their weights (Equation (6)).

5. Analysis of Results

6. Conclusions

- −

- The MIVES methodology demonstrated its effectiveness in the development of multi-criteria decision processes for the case study. The new decision-making tool could be applied in other contexts of the Andean rural area, adapting the requirements tree structure and updating the weighting of the criteria involved.

- −

- From the evaluation carried out, the reinforced adobe technique achieved the highest score due to its affordable cost, low environmental impact and ease of construction. The leader in this category was reinforcement with canes (CRA), with a value of 0.714, followed closely by reinforcement with halyard ropes (HRRA), with an index of 0.709. In third place was reinforcement with geogrid (GRA), which reached a value of 0.620, followed closely by reinforcement with wire mesh (WMRA), with an index of 0.607. Masonry techniques have a lower value for having higher construction costs, higher CO2 emissions in their production and low thermal performance against the cold; however, they are widely accepted by the local population, who see in them as a safer and more modern alternative. The confined masonry (CM) achieves an index of 0.475, followed by the reinforced masonry, with a value of 0.361.

- −

- These research results show that reinforced adobe techniques are a viable and competitive option with respect to masonry because they meet the same safety characteristics but at almost half the price, with the additional advantages of using traditional materials and construction methods, producing less environmental impact, using a reduced amount of embodied energy, producing fewer emissions associated with transportation, and having better thermal performance in cold climates.

- −

- Industrialized techniques such as confined and reinforced masonry would be a viable option in towns close to distribution centers, preferably less than 50 km away, which ensures that the equity value of their environment is not endangered and where qualified labor is available.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- EM-DAT. The International Disaster Database. CRED/UCLouvain 2020. 2020. Available online: https://public.emdat.be/data (accessed on 22 May 2020).

- Masi, A.; Santarsiero, G.; Chiauzzi, L.; Gallipoli, M.R.; Piscitelli, S.; Vignola, L.; Bellanova, J.; Calamita, G.; Perrone, A.; Lizza, C.; et al. Different damage observed in the villages of Pescara del Tronto and Vezzano after the M6.0 august 24, 2016 central Italy earthquake and site effects analysis. Ann. Geophys. 2016, 59, 1–12. [Google Scholar] [CrossRef]

- Khadka, B. Mud masonry houses in Nepal: A detailed study based on entire reconstruction scenario in 31 earthquake-affected districts. Structures 2020, 25, 816–838. [Google Scholar] [CrossRef]

- Pribadi, K.S.; Pradoto, R.G.; Hanafi, E.A.; Rasmawan, I.M.A.B. Lombok earthquake, one year later: Housing sector recovery. In Proceedings of the 4th International Conference on Earthquake Engineering and Disaster Mitigation (ICEEDM 2019), West Sumatra, Indonesia, 25–27 September 2019; Volume 156, pp. 1–10. [Google Scholar] [CrossRef]

- Torres Gilles, C.; Jorquera Silva, N. Técnicas de refuerzo sísmico para la recuperación estructural del patrimonio arquitectónico chileno construido en adobe (“Seismic reinforcement techniques for the structural recovery of Chilean architectural heritage built in adobe”). Inf. Constr. 2018, 70, 252. [Google Scholar] [CrossRef]

- Bragança, L.; Mateus, R.; Koukkari, H. Building Sustainability Assessment. Sustainability 2010, 2, 2010–2023. [Google Scholar] [CrossRef]

- Yidnekachew, D.; Zhang, H. Decision-making model for the evaluation of industrialized housing systems in Ethiopia. Eng. Constr. Archit. Manag. 2020, 27, 296–320. [Google Scholar] [CrossRef]

- Tarque, N.; Salsavilca, J.; Yacila, J.; Camata, G. Multi-criteria analysis of five reinforcement options for Peruvian confined masonry walls. Earthq. Struct. 2019, 17, 205–219. [Google Scholar] [CrossRef]

- Haroun, H.A.A.F.; Bakr, A.F.; Hasan, A.E.S. Multi-criteria decision making for adaptive reuse of heritage buildings: Aziza Fahmy Palace, Alexandria, Egypt. Alex. Eng. J. 2019, 58, 467–478. [Google Scholar] [CrossRef]

- Khoshnava, S.M.; Rostami, R.; Valipour, A.; Ismail, M.; Rahmat, A.R. Rank of green building material criteria based on the three pillars of sustainability using the hybrid multi criteria decision making method. J. Clean. Prod. 2018, 173, 82–99. [Google Scholar] [CrossRef]

- Hosseini, S.M.A.; De, A.; Pons, O. Multi-criteria decision-making method for assessing the sustainability of post-disaster temporary housing units technologies: A case study in Bam, 2003. J. Constr. Eng. Manag. 2017, 142, 04016036. [Google Scholar] [CrossRef]

- De Azevedo, R.C.; De Oliveira Lacerda, R.T.; Ensslin, L.; Jungles, A.E.; Ensslin, S.R. Performance measurement to aid decision making in the budgeting process for apartment-building construction: Case study using MCDA-C. J. Constr. Eng. Manag. 2013, 139, 225–235. [Google Scholar] [CrossRef]

- Ugwu, O.O.; Haupt, T.C. Key performance indicators and assessment methods for infrastructure sustainability—A South African construction industry perspective. Build. Environ. 2007, 42, 665–680. [Google Scholar] [CrossRef]

- National Institute of Statistics and Informatics of Peru. Censos Nacionales 2017: XII de Población, VII de Vivienda y III de Comunidades Indígenas. (2017 National Censuses: XII of Population, VII of Housing and III of Indigenous Communities. Lima, Peru, 2017). Available online: https://www.inei.gob.pe/media/MenuRecursivo/publicaciones_digitales/Est/Lib1544/ (accessed on 24 May 2019).

- Instituto Nacional de Estadistica e Informatica del Perú (National Institute of Statistics and Informatics of Peru), “Reporte de Pobreza en el Perú 2019 (Poverty Report in Peru 2019). 2020. Available online: https://www.inei.gob.pe/media/MenuRecursivo/noticias/np_65_2020.pdf (accessed on 15 April 2020).

- Tello, P.; BAstidas, D.; Pisconte, J. Gestión Pública, Programa de formación: Desarrollo de capacidades para el fortalecimiento de las organizaciones políticas (“Public Management,” Training Program: Capacity Building for Strengthening Political Organizations); Asociación Civil Transparencia: Lima, Perú, 2009; p. 140. [Google Scholar]

- Ministerio de Vivienda Construcción y Saneamiento del Peru. Politica Nacional de Vivienda y Urbanismo—Documento para Discusión; Ministerio de Vivienda Construcción y Saneamiento del Peru: Lima, Peru, 2017.

- Department of Civil and Environmental Engineering—UPC. 2020. Available online: https://deca.upc.edu/es/proyectos/mives (accessed on 5 June 2020).

- Pons, O.; De La Fuente, A. Integrated sustainability assessment method applied to structural concrete columns. Constr. Build. Mater. 2013, 49, 882–893. [Google Scholar] [CrossRef]

- De La Fuente, A.; Casanovas-Rubio, M.D.M.; Pons, O.; Armengou, J. Sustainability of Column-Supported RC Slabs: Fiber Reinforcement as an Alternative. J. Constr. Eng. Manag. 2019, 145, 04019042. [Google Scholar] [CrossRef]

- Zubizarreta, M.; Cuadrado, J.; Orbe, A.; García, H. Modeling the environmental sustainability of timber structures: A case study. Environ. Impact Assess. Rev. 2019, 78, 106286. [Google Scholar] [CrossRef]

- Pons, O.; Aguado, A. Integrated value model for sustainable assessment applied to technologies used to build schools in Catalonia, Spain. Build. Environ. 2012, 53, 49–58. [Google Scholar] [CrossRef]

- Josa, I.; Pons, O.; de la Fuente, A.; Aguado, A. Multi-criteria decision-making model to assess the sustainability of girders and trusses: Case study for roofs of sports halls. J. Clean. Prod. 2020, 249, 119312. [Google Scholar] [CrossRef]

- De La Fuente, A.; Pons, O.; Josa, A.; Aguado, A. Multi-criteria decision making in the sustainability assessment of sewerage pipe systems. J. Clean. Prod. 2016, 112, 4762–4770. [Google Scholar] [CrossRef]

- Hosseini, S.M.A.; Yazdani, R.; de la Fuente, A. Multi-objective interior design optimization method based on sustainability concepts for post-disaster temporary housing units. Build. Environ. 2020, 173, 106742. [Google Scholar] [CrossRef]

- Sánchez-Garrido, A.J.; Yepes, V. Multi-criteria assessment of alternative sustainable structures for a self-promoted, single-family home. J. Clean. Prod. 2020, 258, 120556. [Google Scholar] [CrossRef]

- Tavera, H.; Guzman, J.; Velarde, L.; Cuya, A. Sismo de Ichupampa del 14 de Agosto del 2016 (Ichupampa Earthquake of August 14, 2016); Centro Nacional de Monitoreo Sísmico (National Centre for Seismic Monitoring): Lima, Peru, 2016; Available online: https://n9.cl/zj36 (accessed on 24 April 2021).

- Paul, V.K.; Seth, V. Benchmarking and objective selection of technologies for housing in india using quality function deployment. J. Constr. Dev. Ctries. 2017, 22, 63–78. [Google Scholar] [CrossRef]

- Servicio Nacional de Capacitación para la Industria de la Construcción—SENCICO (National Training Service for the Construction Industry). Reglamento Nacional de Edificaciones del Peru (National Building Regulations of Peru), Peru. 2020. Available online: http://page.sencico.gob.pe/publicaciones.php?id=230 (accessed on 24 April 2021).

- SENCICO. Norma E.080: Diseño y Construcción Con Tierra Reforzada (Standard E.080—Design and Construction with Reinforced Earth); Ministerio de Vivienda, Construcción y Saneamiento de Perú: Lima, Peru, 2017.

- San Bartolome, A.; Quiun, D. Diseño de mallas electrosoldadas para el reforzamiento sísmico de viviendas de adobe típicas del Perú (Design of Electrowelded Meshes for the Seismic Reinforcement of Typical Adobe Houses in Peru). Rev. Fac. Ing. Univ. Cent. Venez. 2015, 30, 71–80. Available online: http://ve.scielo.org/pdf/rfiucv/v30n1/art08.pdf (accessed on 24 April 2021).

- SENCICO (Perú). Norma E. 070—Albañilería (Standard E. 070—Masonry); Ministerio de Vivienda, Construcción y Saneamiento de Perú: Lima, Peru, 2020.

- Blondet, M.; Vargas, J.; Tarque, N.; Iwaki, C. Construcción sismorresistente en tierra: La gran experiencia contemporánea de la Pontificia Universidad Católica del Perú (Earthquake-resistant construction on land: The great contemporary experience of the Pontificia Universidad Católica del Perú). Inf. Constr. 2011, 63, 41–50. [Google Scholar] [CrossRef]

- Kruse, C.; Peña, M. Reconstruyendo Hogares: Modelos de Vivienda Rural del proceso de Reconstrucción de la Zona Afectada por el Sismo del 2007 en el Perú (Rebuilding Homes: Rural Housing Models of the Reconstruction Process of the Area Affected by the 2007 Earthquake in Peru); Proyecto COVIPRED: Lima, Peru, 2011; Available online: http://bvpad.indeci.gob.pe/doc/pdf/esp/doc1946/doc1946.htm (accessed on 24 April 2021).

- Quispe, J.; Rondón, S. Propuesta integral de reforzamiento para edificaciones de adobe. In Comprehensive Reinforcement Proposal for Adobe Buildings. Application to the Case of an Adobe School Building; Pontificia Universidad Catolica del Peru: Lima, Peru, 2012; Available online: http://hdl.handle.net/20.500.12404/1492 (accessed on 24 April 2021).

- Orta, B.; Adell, J.M.; Bustamante, R.; García, A.; Vega, S. The integral masonry system with adobe block tested in Lima for earthquake resistance. Inf. Constr. 2009, 61, 59–65. [Google Scholar] [CrossRef][Green Version]

- San Bartolomé, Á.; Quiun, D. Investigaciones experimentales y propuesta de diseño sísmico para la mampostería de adobe confinado (Experimental Investigations and Seismic Design proposal for Confined Adobe Masonry). Rev. Int. Rev. Int. Ing. Estruct. 2011, 16, 139–150. Available online: http://repositorio.espe.edu.ec/handle/21000/4546 (accessed on 24 April 2021).

- Díaz Gutiérrez, A. Sistema constructivo «Quincha Prefabricada» (Constructive system «Prefabricated Quincha»). Inf. Constr. 1984, 36, 25–34. [Google Scholar] [CrossRef]

- Bartolomé, A.S.; Quiun, D. Diseño sísmico de edificaciones de albañilería confinada (Seismic Design of Confined Masonry Buildings). Rev. Cienc. 2010, 13, 161–186. Available online: http://repositorio.espe.edu.ec/handle/21000/3030 (accessed on 24 April 2021).

- Bartolome, A.S. Comentarios a la Norma Técnica de Edificación e. 070 Albañilería (Comments on the Technical Building Standard e. 070 “Masonry”); National Training Service for the Construction Industry: Lima, Perú, 2008; Available online: http://blog.pucp.edu.pe/blog/wp-content/uploads/sites/82/2008/01/C00-Introduccion.pdf (accessed on 24 April 2021).

- Fisher, A. Comparacion de Propuestas Tecnicas de Viviendas Sismoresistentes (Comparison of Technical Proposals for Earthquake Resistant Houses); COSUDE: Lima, Perú, 2010. [Google Scholar]

- Rodriguez, A.; Walker, M. Módulo básico de adobe reforzado con Geomalla (Basic adobe module reinforced with Geogrid); Proyectos Especiales Sur DARS—PUCP: Lima, Perú, 2009. [Google Scholar]

- Ministerio de Vivienda Construccion y Saneamiento del Peru (Ministry of Housing Construction and Sanitation of Peru). Valores unitarios oficiales de edificación, vigentes para el Ejercicio Fiscal 2020 (Official Building Unit Values, in Force for Fiscal Year 2020). 2020. Available online: https://diariooficial.elperuano.pe/normas (accessed on 24 April 2021).

- Haider, J.; Chuquimia, E.; Huerta, J. Retos de la Adopción de tecnología Sismo-Resistente para Viviendas de Adobe en la Sierra Peruana (Challenges in the adoption of earthquake-resistant technology for adobe houses in the Peruvian highlands). In SismoAdobe2005: Arquitectura, Construcción y Conservación de Edificaciones de Tierra en Areas Sísmicas; Pontificia Universidad Católica del Perú: Lima, Peru, 2005; Volume 1–14. [Google Scholar]

- Ramos, J. Costos y Presupuestos en Edificaciones (Costs and Budgets in Buildings); Editorial Macro: Lima, Perú, 2015. [Google Scholar]

- Construction Price Generator. Peru. CYPE Ingenieros, S.A. 2020. Available online: https://n9.cl/rvg5 (accessed on 18 November 2020).

- SENAMHI: National Meteorology and Hydrology Service of Peru. Datos Meteorológicos—Peru (Meteorological Data—Peru). 2021. Available online: https://www.senamhi.gob.pe/?p=descarga-datos-hidrometeorologicos (accessed on 24 April 2021).

- Serrano, S.; Rincón, L.; González, B.; Navarro, A.; Bosch, M.; Cabeza, L.F. Rammed earth walls in Mediterranean climate: Material characterization and thermal behaviour. Int. J. Low Carbon Technol. 2017, 12, 281–288. [Google Scholar] [CrossRef]

- Esther, V. El reciclaje de Residuos por Demolición de Edificaciones Menores en el Desarrollo Sostenible (The Recycling of Waste by Demolition of Minor Buildings in Sustainable Development); Universidad Nacional Federico Villareal: Lima, Peru, 2020. [Google Scholar]

- Guigou, C. La Tierra como Material de Construcción (Earth as a Building Material); Colegio Oficial de arquitectos de Canarias: Tenerife, Spain, 2002. [Google Scholar]

- Domínguez Alonso, M. Propiedades térmicas de los adobes (‘Thermal properties of adobes’). In IX Encuentro Internacional de Trabajo Navapalos (IX Navapalos International Labor Meeting); Publications Centre Ministry of Development: Madrid, Spain, 1998. [Google Scholar]

- Ashby, M. Materials and the Environment: Eco-Informed Material Choice, 2nd ed.; Elsevier: Waltham, MA, USA, 2013. [Google Scholar]

- Bestraten, S.; Hormías, E.; Altemir, A. Construcción con tierra en el siglo XXI (Earth construction in the 21st century). Inf. Constr. 2011, 63. [Google Scholar] [CrossRef]

- Institute of Statistics and Informatics of Peru. Perú: Estimaciones y Proyecciones de Población por Departamento, Provincia y Distrito, 2018—2020 (Peru: Population Estimates and Projections by Department, Province, and District, 2018–2020); Boletin 26: Lima, Perú, 2020; Available online: https://www.inei.gob.pe/media/MenuRecursivo/publicaciones_digitales/Est/Lib1715/libro.pdf (accessed on 24 April 2021).

- Fachelli, S. Metodologia de la Investigacion Social Cuantitativa (Methodology of Quantitative Social Research). Rev. Educ. Derecho 2018. Available online: http://ddd.uab.cat/record/129382 (accessed on 24 April 2021).

- Zegarra, J. Costos y Presupuestos en Edificacion (Building Costs and Budgets); Peruvian Chamber of Construction: Lima, Peru, 2014. [Google Scholar]

- Bibiana, A.; Aguado, A.; Manga, R.; Josa, A. A value function for assessing sustainability: Application to industrial buildings. Sustainability 2010, 3, 35–50. [Google Scholar] [CrossRef]

- Viñolas Prat, B.; Cortés, F.; Marques, A.; Josa Garcia-Tornel, A.; de Cea, A. MIVES: Modelo integrado de valor para evaluaciones de sostenibilidad (MIVES: Integrated value model for sustainability assessments). In II Congrés Internacional de Mesura i Modelització de La Sostenibilitat, Terrassa, Spain, 5–6 November 2009; Centro Internacional de Métodos Numéricos en Ingeniería: Barrcelona, Spain, 2009; pp. 1–24. Available online: http://hdl.handle.net/2117/9704 (accessed on 24 April 2021).

- Department of Civil and Environmental Engineering-Polytechnic University of Catalonia. Manual Mives—Modelo Integrado de Valor para Evaluaciones Sostenibles (Manual Mives—Integrated Value Model for Sustainable Assessments); Department of Civil and Environmental Engineering-Polytechnic University of Catalonia: Barcelona, Spain, 2009. [Google Scholar]

| Year | Country | Author | Research | Criteria | Ref. | |||

|---|---|---|---|---|---|---|---|---|

| Economy | Environment | Social | Others | |||||

| 2020 | Ethiopia | Daget, Y. | Industrialized housing systems | X | X | [7] | ||

| 2019 | Peru | Tarque, N | Selecting reinforcement for masonry walls | X | X | [8] | ||

| 2019 | Egypt | Haroun, H. | Reuse of heritage buildings | X | X | X | X | [9] |

| 2016 | Malaysia | Khoshnava, S. | Classification of sustainable materials | X | X | X | [10] | |

| 2016 | Iran | Hosseini A. | Technologies for post-disaster temporary housing | X | X | [11] | ||

| 2013 | Brazil | De Azevedo, R. | Construction of apartment buildings | X | X | X | [12] | |

| 2007 | South Africa | Ugwu, O. | Sustainability in the construction industry | X | X | X | X | [13] |

| Technique | Manufacturing and Assembly | Access to the Material | Execution Time | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Authors | Useful Area (m2) | €/m2 * | Supplier | km | Man Hours, MH (10 m2 of Wall) | ||||

| Adobe Reinforced with: | Wire mesh—WMRA | CARITAS | 33.0 | 225.4 € | [34] | Arequipa | 200 | 10.9 ** | [41] |

| Canes—CRA | CARITAS, JICA | 34.0 | 212.5 € | [34,41] | Pedregal | 50 | 8.7 | [41] | |

| Geogrid—GRA | GIZ-COSUDE, CARE 1-PUCP | 34.1 | 215.3 € | [34] | Arequipa | 200 | 8.4 | [42] | |

| Halyard Ropes—HRRA | GIZ-COSUDE, CARE-PUCP | 34.0 | 197.5 € | [34] | Ichupampa | 5 | 9.2 ** | [41] | |

| Confined masonry—CM | MVCS 2 | 34.0 | 370.5 € | [43,44] | Chivay | 15 | 22.6 | [45] | |

| Reinforced masonry—RM | MVCS | 25.0 | 307.9 € | [43] | Arequipa | 200 | 15.1 | [46] | |

| Technique | Waste | Thermal Comfort | Emissions | ||||||

|---|---|---|---|---|---|---|---|---|---|

| % of Material Recyclability | Thermal Conductivity (W/mK) | Carbon Footprint | kg CO2/m2 of Wall | Partial | |||||

| Adobe Reinforced With: | Wire mesh—WMRA * | 80% | [49] | 0.46 | [50,51] | Low alloy steel ** | 22 | [52] | 96 |

| Adobe wall | 74 | [53] | |||||||

| Canes—CRA * | 80% | [49] | 0.46 | [50,51] | Reeds ** | 0 | [52] | 74 | |

| Adobe wall | 74 | [53] | |||||||

| Geogrid—GRA * | 80% | [49] | 0.46 | [50,51] | Polypropylene ** | 5 | [52] | 79 | |

| Adobe wall | 74 | [53] | |||||||

| Halyard ropes—HRRA * | 80% | [49] | 0.46 | [50,51] | Nylon ** | 8 | [52] | 82 | |

| Adobe wall | 74 | [53] | |||||||

| Confined masonry—CM | 23% | [49] | 1.04 | [53] | Solid brick | 301 | [53] | 301 | |

| Reinforced masonry—RM | 44% | [49] | 0.91 | [53] | Precast concrete + 2% steel | 455 | [52] | 455 | |

| 455 | [52] | ||||||||

| Technique | Participation | Acceptance | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Knowledge of the Technique | Ease of Construction (% of Unqualified Labor Force) | Perception of Safety (1 to 10) | Identification (1 to 10) | ||||||

| Adobe reinforced with: | Wire mesh—WMRA | 33% | * | 42.41% | [34] | 6.50 | * | 8.00 | * |

| Canes—CRA | 29% | * | 49.30% | [34,41] | 6.30 | * | 8.00 | * | |

| Geogrid—GRA | 24% | * | 41.42% | [34] | 6.90 | * | 8.00 | * | |

| Ropes—HRRA | 6% | * | 50.46% | [34] | 5.90 | * | 8.00 | * | |

| Confined masonry—CM | 100% | * | 31.25% | [44,56] | 8.40 | * | 3.30 | * | |

| Reinforced masonry—RM | 26% | * | 15.30% | [56] | 7.50 | * | 3.00 | * | |

| Field | Expert | Speciality | Years of Experience |

|---|---|---|---|

| Building systems | BS1 | Post-disaster earthquake-resistant housing: adobe and masonry | 30 |

| BS2 | Structural safety of reinforced and unreinforced masonry | 15 | |

| BS3 | Earthquake-resistance for social and sustainable housing | 30 | |

| BS4 | Unconventional building materials | 25 | |

| Rural housing | RH1 | Participatory technology transfer for the Andean region. | 25 |

| RH2 | Design and construction with participatory methods. | 20 | |

| RH3 | Technology transfers for low-cost housing | 18 | |

| RH4 | Construction with earth and other natural materials | 20 | |

| Heritage | H1 | Consultant in the development of heritage building regulations | 30 |

| H2 | Consultant for the UNESCO Heritage Committee | 20 |

| Increasing Function | |||

|---|---|---|---|

| Function | C | K | P |

| Lineal | |||

| Convex | |||

| Concave | |||

| S-shaped | 0.2/0.8 | ||

| Indicator | Units | Function | C | K | P | |||

|---|---|---|---|---|---|---|---|---|

| I1 | Manufacturing and assembly | Euro/m2 | S-Decr | 500 | 0 | 250 | 0.5 | 3 |

| I2 | Access to the material | km | S-Decr | 300 | 0 | 150 | 0.5 | 3 |

| I3 | Execution time | Man-Hours | S-Decr | 40 | 0 | 20 | 0.5 | 3 |

| I4 | Carbon footprint | kg CO2/m2 | S-Decr | 600 | 0 | 300 | 0.5 | 3 |

| I5 | % of material recyclability | % | Linear | 0 | 100 | 90 | 0.01 | 1 |

| I6 | Thermal conductivity | W/mK | Convex | 1.2 | 0 | 1.08 | 0.5 | 0.5 |

| I7 | Knowledge of the technique | Survey (%) | Linear | 0 | 100 | 10 | 0.01 | 1 |

| I8 | Ease of construction | % of unskilled labor | Linear | 0 | 100 | 10 | 0.01 | 1 |

| I9 | Perception of safety | Survey (%) | Linear | 0 | 10 | 1 | 0.01 | 1 |

| I10 | Identification | Survey (%) | Linear | 0 | 10 | 1 | 0.01 | 1 |

| Global Ranking of Techniques | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Requirement | Economic  | Environment  | Social  | Index | ||||||||

| Criterion | Cost | Time | Emissions | Waste | Thermal Comfort | Participation | Acceptance | |||||

| Indicator | Manufacturing and Assembly | Access to the Material | Execution-Time | Carbon Footprint | % Material Recyclability | Thermal Conductivity | Knowledge of the Technique | Ease of Construction | Perception of Safety | Identification | ||

| Adobe reinforced with: | Canes—CRA | 0.076 | 0.101 | 0.119 | 0.067 | 0.058 | 0.114 | 0.026 | 0.051 | 0.048 | 0.054 | 0.714 |

| Halyard ropes—HRRA | 0.086 | 0.112 | 0.117 | 0.066 | 0.058 | 0.114 | 0.006 | 0.051 | 0.045 | 0.054 | 0.709 | |

| Geogrid—GRA | 0.076 | 0.015 | 0.120 | 0.066 | 0.058 | 0.114 | 0.023 | 0.041 | 0.053 | 0.054 | 0.620 | |

| Wire mesh—WMRA | 0.068 | 0.015 | 0.109 | 0.064 | 0.058 | 0.114 | 0.032 | 0.043 | 0.050 | 0.054 | 0.607 | |

| Confined Masonry—CM | 0.010 | 0.112 | 0.040 | 0.028 | 0.017 | 0.059 | 0.090 | 0.032 | 0.064 | 0.023 | 0.475 | |

| Reinforced Masonry—RM | 0.030 | 0.015 | 0.086 | 0.004 | 0.032 | 0.077 | 0.024 | 0.015 | 0.057 | 0.021 | 0.361 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cárdenas-Gómez, J.C.; Bosch Gonzales, M.; Damiani Lazo, C.A. Evaluation of Reinforced Adobe Techniques for Sustainable Reconstruction in Andean Seismic Zones. Sustainability 2021, 13, 4955. https://doi.org/10.3390/su13094955

Cárdenas-Gómez JC, Bosch Gonzales M, Damiani Lazo CA. Evaluation of Reinforced Adobe Techniques for Sustainable Reconstruction in Andean Seismic Zones. Sustainability. 2021; 13(9):4955. https://doi.org/10.3390/su13094955

Chicago/Turabian StyleCárdenas-Gómez, José Carlos, Montserrat Bosch Gonzales, and Carlos Arturo Damiani Lazo. 2021. "Evaluation of Reinforced Adobe Techniques for Sustainable Reconstruction in Andean Seismic Zones" Sustainability 13, no. 9: 4955. https://doi.org/10.3390/su13094955

APA StyleCárdenas-Gómez, J. C., Bosch Gonzales, M., & Damiani Lazo, C. A. (2021). Evaluation of Reinforced Adobe Techniques for Sustainable Reconstruction in Andean Seismic Zones. Sustainability, 13(9), 4955. https://doi.org/10.3390/su13094955