Study on Compressibility and Settlement of a Landfill with Aged Municipal Solid Waste: A Case Study in Taizhou

Abstract

1. Introduction

2. Materials and Methods

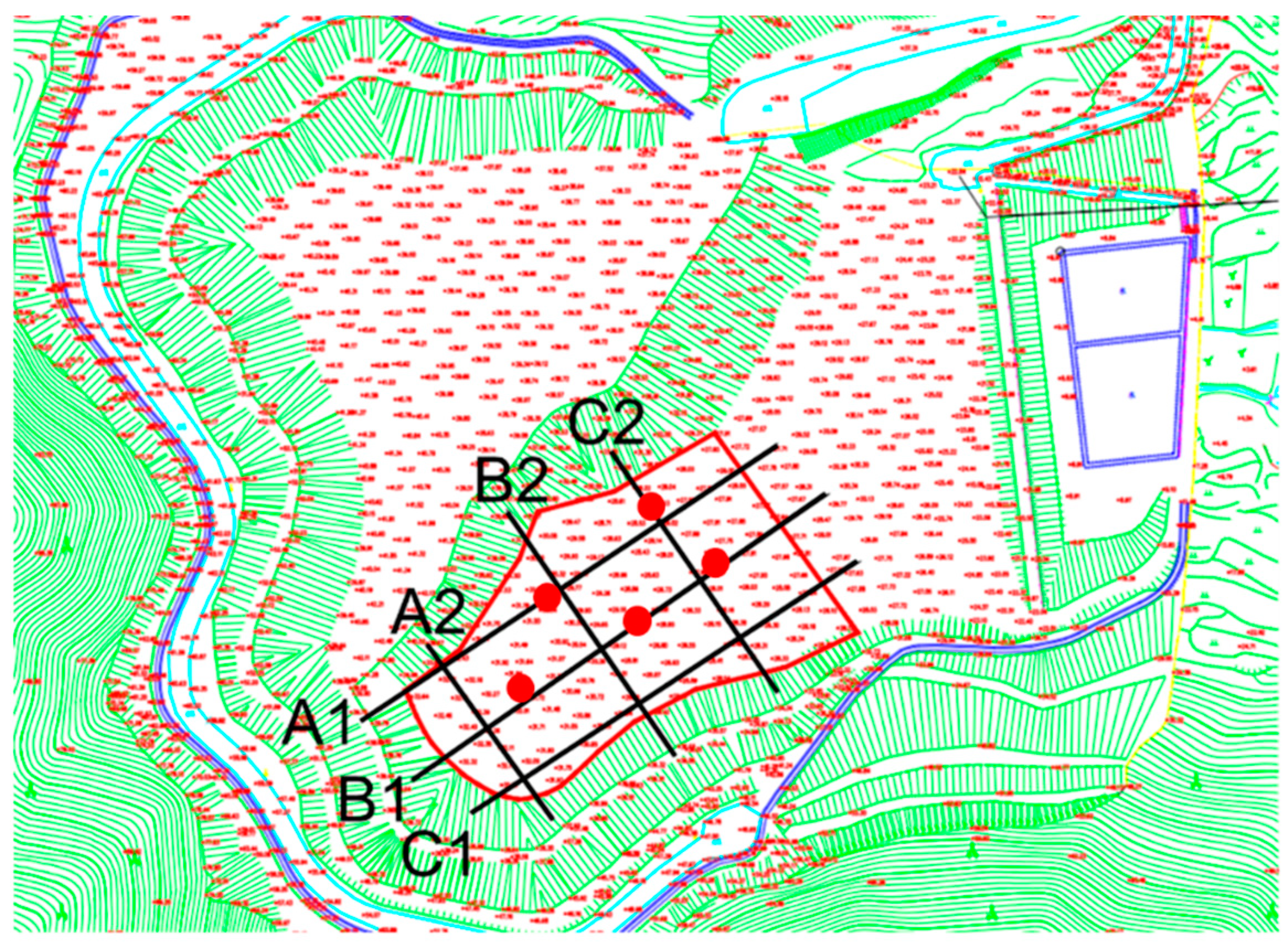

2.1. Site Description

2.2. Experimental Materials

2.3. Experimental Methods

2.3.1. Testing Apparatus

2.3.2. Experimental Procedure

2.4. Settlement Calculation Method of MSW

3. Results and Discussion

3.1. Moisture Content Distribution

3.2. Volumetric Weight

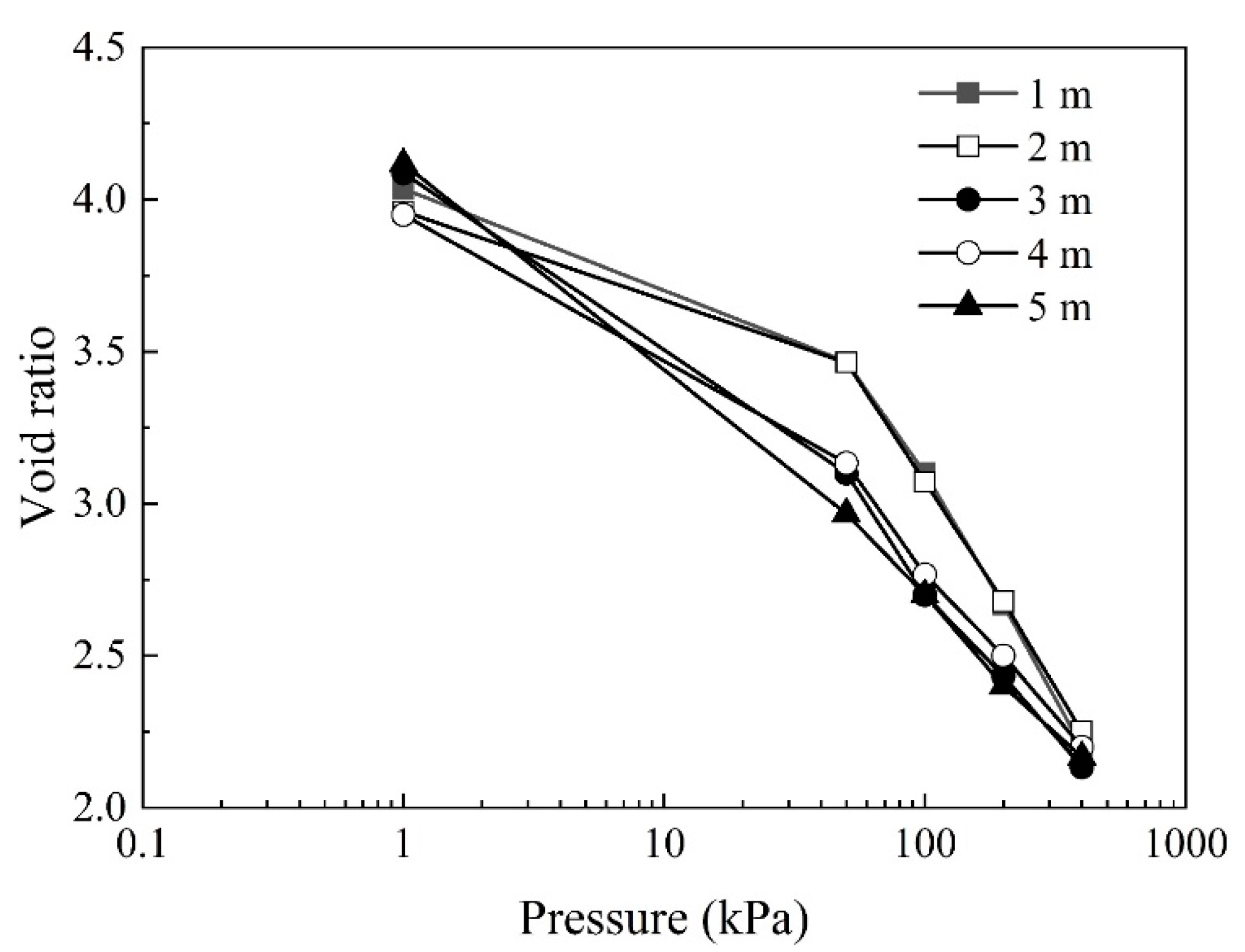

3.3. Compression Characteristics

4. Settlement Prediction of Landfill Waste

5. Conclusions

- According to the test results, the content of kitchen waste was reduced to 0.1% after more than three years of biochemical degradation of MSW with high kitchen waste content. In developing countries (e.g., China), the content of kitchen waste in fresh MSW is high (generally higher than 50%). The impact of rapid degradation of kitchen waste should be considered in landfill settlement prediction and site reuse design (such as expansion). As for landfills with high-kitchen-waste-content MSW, it is recommended that the reuse project of the landfill sites after the kitchen waste is degraded be considered.

- The moisture content of the aged MSW generally increased with depth, and the average moisture content at a depth of 5 m was 97%. Moreover, there might be a perched water table in the landfill due to the influence of the intermediate cover layer and the heterogeneity of the MSW, which was not conducive to the collection of leachate.

- The void ratio of the aged MSW decreased from 4.0 to 2.2 with an increase in vertical load from 1 kPa to 400 kPa. The modified primary compression index of the aged MSW ranged from 0.22 to 0.27, and generally decreased with depth.

- Under the load caused by fly ash, the thickness of the aged MSW after settlement can be reduced by approximately 15% to 20% compared to the initial thickness. The compaction of landfill waste could increase the landfill capacity of fly ash by about 3 years. The influence of aged MSW settlement must be considered in the capacity expansion design of existing landfills.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.M. A fundamental theory of environmental geotechnics and its application. Chin. J. Geotech. Eng. 2014, 36, 1–46. [Google Scholar]

- Hjelmar, O. Disposal strategies for municipal solid waste incineration residues. J. Hazard. Mater. 1996, 47, 345–368. [Google Scholar] [CrossRef]

- Tang, Q.; Liu, Y.; Gu, F.; Zhou, T. Solidification/stabilization of fly ash from a municipal solid waste incineration facility using Portland cement. Adv. Mater. Sci. Eng. 2016, 2016, 7101243. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, J.; Shi, S.; Li, B.; Mo, J.; Tang, Q. Mechanical Properties of Municipal Solid Waste Incinerator (MSWI) Bottom Ash as Alternatives of Subgrade Materials. Adv. Civ. Eng. 2020, 2020, 9254516. [Google Scholar] [CrossRef]

- Tang, Q.; Gu, F.; Chen, H.; Lu, C.; Zhang, Y. Mechanical evaluation of bottom ash from municipal solid waste incineration used in roadbase. Adv. Civ. Eng. 2018. [Google Scholar] [CrossRef]

- Jing, X.; Chang, W. Review for treatment and application of municipal solid waste incineration fly ash. J. Zhejiang Univ. Technol. 2015, 43, 7. [Google Scholar]

- André, F.J.; Cerdá, E. Landfill construction and capacity expansion. Environ. Resour. Econ. 2004, 28, 409–434. [Google Scholar] [CrossRef]

- Rong, F.; Zhaogui, G.; Tugen, F. Analysis of stability and control in landfill sites expansion. Procedia Eng. 2011, 24, 667–671. [Google Scholar] [CrossRef]

- Zhan, L.T.; Xu, H.; Chen, Y.M.; Lü, F.; Lan, J.W.; Shao, L.M.; Lin, W.A.; He, P.J. Biochemical, hydrological and mechanical behaviors of high food waste content msw landfill: Preliminary findings from a large-scale experiment. Waste Manag. 2017, 63, 27–40. [Google Scholar] [CrossRef]

- Ke, H.; Hu, J.; Xu, X.B.; Wang, W.F.; Chen, Y.M.; Zhan, L.T. Evolution of saturated hydraulic conductivity with compression and degradation for municipal solid waste. Waste Manag. 2017, 65, 63–74. [Google Scholar] [CrossRef]

- Shi, J.; Qian, X.; Liu, X.; Sun, L.; Liao, Z. The behavior of compression and degradation for municipal solid waste and combined settlement calculation method. Waste Manag. 2016, 55, 154–164. [Google Scholar] [CrossRef] [PubMed]

- Hettiarachchi, H.; Meegoda, J.; Hettiaratchi, P. Effects of gas and moisture on modeling of bioreactor landfill settlement. Waste Manag. 2009, 29, 1018–1025. [Google Scholar] [CrossRef] [PubMed]

- AHudson, P.; White, J.K.; Beaven, R.P.; Powrite, W. Modelling the compression behaviour of landfilled domestic waste. Waste Manag. 2004, 24, 259–269. [Google Scholar] [CrossRef] [PubMed]

- Tahmoorian, F.; Khabbaz, H. Performance comparison of a MSW settlement prediction model in Tehran landfill. J. Environ. Manag. 2020, 254, 109809. [Google Scholar] [CrossRef]

- Yan, N.; Yu, W.; Shen, B. The Investigation of the Landfill Settlement Prediction Method. Geotech. Eng. Tech. 2015, 29, 24–28. [Google Scholar]

- Park, H.I.; Lee, S.R.; Do, N.Y. Evaluation of decomposition effect on long-term settlement prediction for fresh municipal solid waste landfills. J. Geotech. Geoenviron. Eng. 2002, 128, 107–118. [Google Scholar] [CrossRef]

- Sowers, G.F. Settlement of waste disposal fills. In Proceedings of the International Conference on Soil Mechanics and Foundation Engineering (ICSMFE), Moscow, Russia, 2 August 1973. [Google Scholar]

- Edil, T.B.; Ranguette, V.J.; Wuellner, W.W. Settlement of municipal refuse. In Geotechnics of Waste Fills—Theory and Practice; ASTM International: West Conshohocken, PA, USA, 1990. [Google Scholar]

- Ling, H.I.; Leshchinsky, D.; Mohri, Y.; Kawabata, T. Estimation of municipal solid waste landfill settlement. J. Geotech. Geoenviron. Eng. 1998, 124, 21–28. [Google Scholar] [CrossRef]

- Gourc, J.P.; Staub, M.J.; Conte, M. Decoupling MSW settlement into mechanical and biochemical processes–Modelling and validation on large-scale setups. Waste Manag. 2010, 30, 1556–1568. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.M.; Ke, H.; Fredlund, D.G.; Zhan, L.T.; Xie, Y. Secondary compression of municipal solid wastes and a compression model for predicting settlement of municipal solid waste landfills. J. Geotech. Geoenviron. Eng. 2010, 136, 706–717. [Google Scholar] [CrossRef]

- Chen, Y.M.; Guo, R.Y.; Li, Y.C.; Liu, H.; Zhan, L.T. A degradation model for high kitchen waste content municipal solid waste. Waste Manag. 2016, 58, 376–385. [Google Scholar] [CrossRef]

- China Architecture and Building Press. Technical Specification for Soil Test of Landfilled Municipal Solid Waste CJJ/T204–2013; China Architecture and Building Press: Beijing, China, 2013. [Google Scholar]

- Wang, G.Q.; Zhang, H.Y.; Wang, D.; Zhang, L.; Sun, W. Physical composition and characteristics analysis of the municipal solid waste (MSW) in Beijing. Environ. Eng. 2018, 36, 132–136. [Google Scholar]

- China Architecture and Building Press. Technical Code for Geotechnical Engineering of Municipal Solid Waste Sanitary Landfill CJJ 176–2012; China Architecture and Building Press: Beijing, China, 2012. [Google Scholar]

- Zhang, Z.H.; Sun, B.W.; Ji, H.; Qu, B. Properties of simple waste landfill in Beijing area. J. Beijing Univ. Technol. 2013, 39, 1116–1120. [Google Scholar]

- Zhang, W.J.; Qiu, Q.W.; Qiu, Z.H. Reliability analysis of stability of a municipal solid waste landfill. Chin. J. Rock Mech. Eng. 2010, 29, 12958–12963. [Google Scholar]

- Zekkos, D.; Bray, J.D.; Kavazanjian, E., Jr.; Matasovic, N.; Rathje, E.M.; Riemer, M.F.; Stokoe, K.H. Unit weight of municipal solid waste. J. Geotech. Geoenviron. Eng. 2006, 132, 1250–1261. [Google Scholar] [CrossRef]

- Ke, Q.J.; Tu, F.; Jie, Z.M.; Xiao, C.J. Compression parameters of landfill municipal solid wastes sampled at different depths. Chin. J. Environ. Eng. 2010, 4, 199–203. [Google Scholar]

- Zhan, L.T.; Wei, H.Y.; Chen, Y.M.; Zhu, S.Y.; Ke, H. Mechanical compressibility of in-site municipal solid wastes and its relationship to fill ages. J. Zhejiang Univ. (Eng. Sci.) 2008, 42, 353–358. [Google Scholar]

| Layer | Elevation | Thickness | Modified Primary Compression Index | Modified Secondary Compression Index |

|---|---|---|---|---|

| unit | m | m | / | / |

| LW3 | >29 | 3~5 | 0.254 | 0.035 |

| LW2 | 26~29 | 3 | 0.238 | |

| LW1 | <26 | 7~10 | 0.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, H.; Wu, T.; Wang, X.; Qiu, Z.; Lan, J. Study on Compressibility and Settlement of a Landfill with Aged Municipal Solid Waste: A Case Study in Taizhou. Sustainability 2021, 13, 4831. https://doi.org/10.3390/su13094831

He H, Wu T, Wang X, Qiu Z, Lan J. Study on Compressibility and Settlement of a Landfill with Aged Municipal Solid Waste: A Case Study in Taizhou. Sustainability. 2021; 13(9):4831. https://doi.org/10.3390/su13094831

Chicago/Turabian StyleHe, Haijie, Tao Wu, Xiaogang Wang, Zhanhong Qiu, and Jiwu Lan. 2021. "Study on Compressibility and Settlement of a Landfill with Aged Municipal Solid Waste: A Case Study in Taizhou" Sustainability 13, no. 9: 4831. https://doi.org/10.3390/su13094831

APA StyleHe, H., Wu, T., Wang, X., Qiu, Z., & Lan, J. (2021). Study on Compressibility and Settlement of a Landfill with Aged Municipal Solid Waste: A Case Study in Taizhou. Sustainability, 13(9), 4831. https://doi.org/10.3390/su13094831