1. Introduction

Industry 4.0 is a strategy for being competitive in global markets providing the integration of lean production systems with efficient and dynamic solutions, and enhancing process flows and effectiveness, as well as the efficiency of machinery. In such a competitive environment, the product design process (PDP) is characterized by multiple intertwined factors ranging from product characteristics to organizational capabilities. Thus, in order to compete successfully in global markets, products should be produced on time, within budget, meeting customer requirements, and meeting organizational requirements [

1]. The major problem which leads particularly to decrease in sales despite implementation of statistical quality control techniques and quality improvements is failure to satisfy customer requirements [

2]. According to recent product design research, late introduction of new products is the single largest contributor to the loss of companies’ potential profit in industrial countries such as the UK [

3]. In addition, recent statistics on new products worldwide have shown that for every ten ideas three will be developed, 1.3 will be launched and only one will make any profit [

4]. This is backed by two facts regarding the profitability equation, the quotient of the total revenue minus the cost of goods sold: (i) the revenue component of the profitability equation is significantly determined by the market competitiveness condition and supply-demand equilibrium, (ii) the design and manufacturing operations significantly influence and shape the cost component of this equation [

5]. Thus, the criticality of the design process should be analyzed in context.

The design process and product life cycle are inter-linked. The product life cycle reflects how a product progresses from introduction, through growth and maturity to decline. Although designers become involved before the introduction stage, the impact of the design process affects the stages of introduction, growth and maturity. Designers become involved again when a product is in decline to decide either to extend its life cycle or to move on to a new product/project. The need for design processes for realizing efficient management of the product lifecycle has been investigated by Panchal et al. [

6], who highlighted the importance of leveraging the design process in addressing the product lifecycle considerations. Challenges were identified that are inherent in the design process. Panchal also identified key elements for enabling the integrated design of products and their underlying design processes in a systematic fashion pointing out the importance of modeling the design process. In accord with these studies, Bernard et al. [

7], pointed out that the design process is a critical stage in the product lifecycle. Decisions taken in the design process impact 80% of the overall cost and performance of products throughout the entire lifecycle.

Another critical emphasis in the design process is maintainability. For complex products, improper design can result in making operation and maintenance costs as high as the initial costs. Thus, incorporating maintainability planning within the design process is critical for ensuring a successful product. The operational engineering availability and maintainability should therefore be considered not only in the detailed design phase but also well before that, in the preliminary design phase. In fact, designing for reliability is a top-down approach that starts from the level of system design in the design process. Yu et al. [

8] proposed a maintainability layout design for complex equipment. They pointed out that with the increase in equipment complexity, the probability of equipment failure is dramatically increased. They indicated that most of the currently existing maintainability designs are qualitative. The authors thus used a quantitative method of maintainability design for guidance. Ding et al. [

9] pointed out that maintainability is an important characteristic that is totally enabled by the product design process. They summarized maintainability design criteria and the measurement index used in product maintainability analysis, and proposed a product maintainability design method by integrating the product feature model, maintainability design criteria and measurement index.

A further critical emphasis in the design process is recyclability. Recyclability is another important aspect that significantly affects the management of the development process of complex products sustainably. Product recyclability is too significant to be enforced by law in industry. In fact, the European “Take-Back Law” requires vehicles’ manufacturers and other manufacturers to take back their products which do not comply with recyclability standards. This becomes more significant when the product contains advanced materials, such as thermoset polymeric composite materials, whose recyclability is a challenge. Thus, design for recycling has become a goal of manufacturers in industry [

10]. Peters et al. [

11] pointed out that most products are not designed with recycling taken into consideration. They proposed a tool to be used in the design process for assessing the design concept at an early stage with respect to recyclability, indicating that the Design for Recyclability method has three main components: a set of design guidelines, a recycling performance evaluation method, and prioritized improvement suggestions. Li et al. [

12] indicated the importance of recyclability and proposed the evaluation of product recyclability in the design process using a time-series forecasting methodology. This proposed tool provides designers with decision support for enabling recyclability at an early stage in the product life cycle.

The current challenge in the design process (DP) is thus to improve the value added to customers while shortening the product development time [

4]. This is particularly true in light of what Browning et al. [

13] reported that determining how and when value is added in the product development process (PDevP) is problematic. Therefore, this research starts by investigating the relationship between return on product development (PD) and product performance (PP) level in the PDevP (

Section 5.1). It then investigates risk management (RM) in the PDevP since the returns on PD are influenced by risk (

Section 5.2). Next, the paper investigates the key approaches to understanding and to managing the PDevP since the RM plan can help in realizing the sought harmony between design activities and strategies (

Section 5.3). Finally, case studies for validation (

Section 6) and the statistical analysis of the results of validation then follow (

Section 7). The present paper is an exploratory study that involves case studies for investigating these research objectives.

2. Materials and Methods

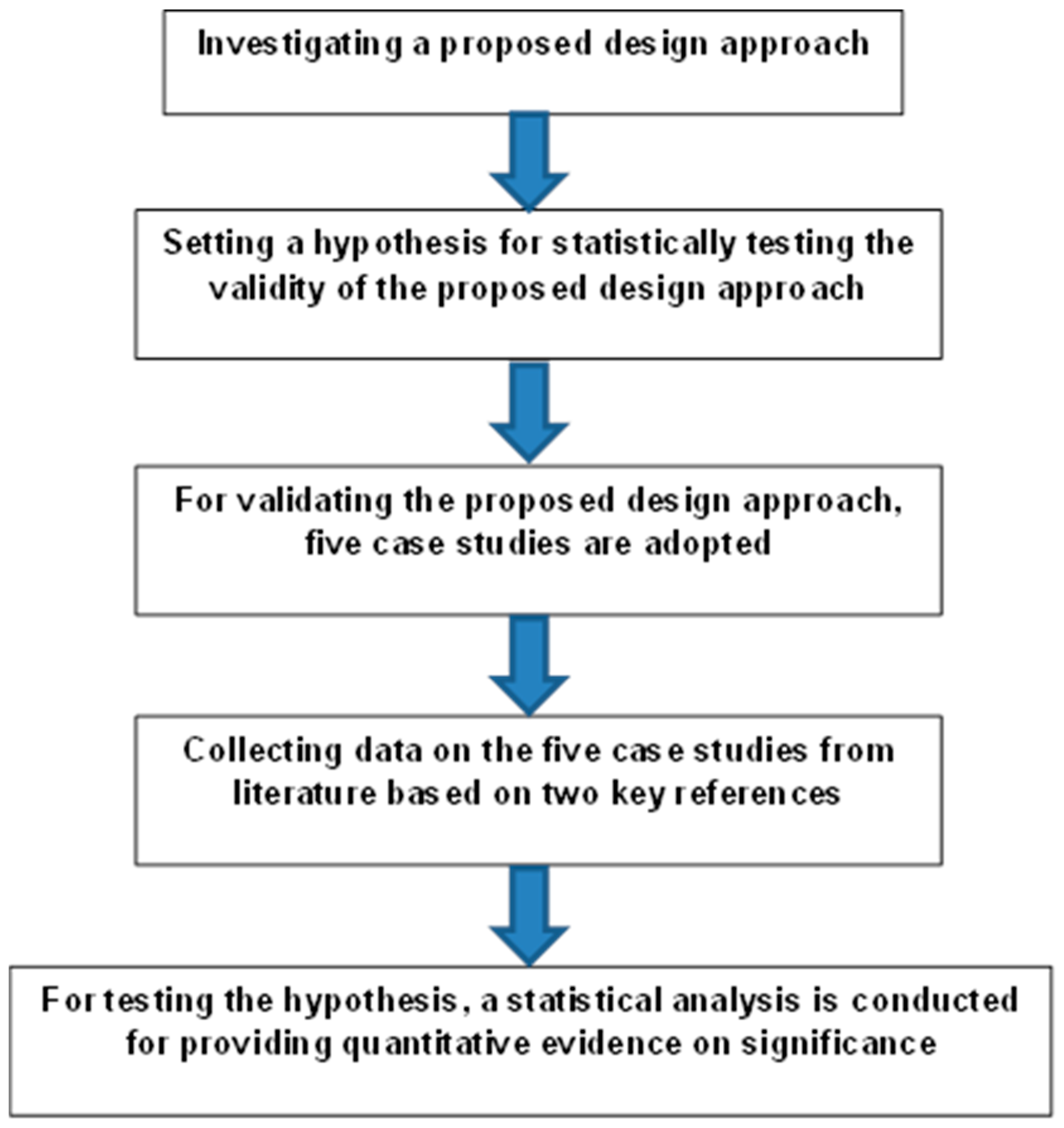

This research is an exploratory study that involves five case studies for investigating and validating a proposed design approach. To investigate the truth of the objectives of this research mentioned in the previous section, the following hypothesis is statistically tested in the present paper: “When most companies adopt the hybrid lean-agile approach, the aggregate performance of companies becomes closer to best performance”. To examine a limited number of variables, the case study research method involves a longitudinal examination of a case. It provides a systematic way of looking at events, collecting data, and analyzing information. Case studies provide an empirical inquiry that investigates a phenomenon within its real-life context. In the present paper, a statistical analysis follows the case study in order to test a hypothesis and to further provide quantitative evidence on significance. Such a quantitative case-study provides a statistical framework for making inferences.

In the present research paper, the basis of the case study-based analysis is deductive research and it includes the following steps: (1) determining the research question, (2) selecting the cases and determining the techniques of data gathering and analysis, (3) collecting data, (4) evaluating and analyzing the data, (5) reporting the result of the analysis.

Figure 1 provides a block diagram for describing this research approach.

As to the first step in the present paper, the research question is set based on a literature review. This question is related to the hybrid approach that hybridizes attributes of both the lean and agile design paradigms. This question is indicated in the hypothesis formulated in this section and in “

Section 7”. A research gap has been identified for investigating whether companies that adopt the hybrid approach in the DP become more successful than those companies that do not. In the second step, five companies are studied regarding the approaches adopted in managing the DP. These five companies are a representative sample of key manufacturing sectors in industry, since statistically the minimum representative sample size is 5 [

14]. Data were collected through questionnaires and open interviews using a semi-structured script, with R&D managers and employees from each of these companies. The participants were selected to represent the stakeholders and those who influence the observed events. As to the third step, the data are collected from empirical case studies conducted on industrial companies and reported in the literature [

15,

16]. Two key referenced papers on case studies that suit the specific focus of the present paper, that are related to each other, that are highly cited and that are authored by leading research authorities, are adopted and utilized in the present paper:

(I) On the total quality management (TQM) practices in R&D-based companies [

15]. This study validated the questionnaire on TQM practices in a sample of R&D-based companies;

(II) On the remaining practices in R&D-based companies [

16]. This study focused on all practices in a smaller sample of R&D-based companies and adopted the validated questionnaire on TQM practices in the sample of R&D-based companies used by [

15].

These two key referenced papers addressed all relevant practices in R&D-based companies. The focus of the statistical validation of the present study is to utilize the results of these two referenced, related and highly cited papers in order to test the hypothesis of the present paper. It is scientifically acceptable to take data from literature on the companies that suit the scope of the present study, i.e., companies that invest in R&D and that produce tangible products in key manufacturing sectors in industry. Therefore, not all of the 11 firms presented in the referenced case study [

16] are eligible to be included in the present paper.

In the fourth step, the collected data are analyzed statistically. There were 632 R&D units to which the questionnaire was sent via postal mail. There were 112 received questionnaires that were identified as valid, which constitute the backbone of the sample in the statistical analysis for validation [

15]. This indicates about a 20% response rate which is reasonable. The respective number of validly answered questionnaires received from this sample of R&D units in industry is given in

Table 1. The industrial sectors adopted in the present paper as key sectors in industry are also the focus of the two referenced papers [

15,

16].

It is noteworthy that an example of such complex products is robots, as implied in

Table 1 in the Mechanical industry in the Machinery industrial sector. The present paper is not intended to be a proof of the generalization of the results, but rather is exploratory research that provides evidence towards establishing a framework for inference. It is noteworthy that randomization in this regard is a randomized controlled sampling method, i.e. simple random sampling. This randomization gives items of particular characteristics the same probability of selection over all trials. Thus, this is in accord with the definition of the technical term “randomization”, which is “making no difference in selection from a group of things”. This applies to the research data gathered and presented in the key referenced paper [

16] in the sense that the authors made no difference in selection among the companies that met the basic criterion of being “R&D-based companies”. The authors of this key referenced paper indicated this random selection by stating that these companies operate in different key manufacturing sectors in industry [

16]. When the authors of the key referenced paper [

16] mentioned that the goal of their paper was not generalization statistically is true in the sense that their data and results do not cover all companies in all industrial sectors. In addition, adopting the criterion that the companies from which the selection is made must be “R&D-based companies” makes the study more focused. This does not contradict randomization, i.e. making no difference in selection, which has been implemented onto the companies that met the basic criterion of being “R&D-based companies”. For instance, there was no difference in selection based on religion or color. The research aim of “not a generalization” mentioned in the key referenced paper [

16] makes the present research paper complementary by integratively adding a further value to the gathered research data and case studies. The statistical analysis made in the present paper based on the data gathered by Bigliardi & Galati makes the present paper a continuation of their highly cited research work, filling a research gap.

4. Sustainability and Product Development Process: A Brief Review

Managing the development process of complex products sustainably is significantly important, not only from the engineering, quality, manufacture, and operational perspectives but also from the economical, managerial, and environmental perspectives. The sustainability of the design process of complex products is the development process that is supported at every stage in the value chain of the product.

Improved sustainability is expected to be realized in this regard in terms of longer service life with maintainability and serviceability, less power consumption, an environmentally friendly product with small emissions footprint, maintainability and recyclability. Improved sustainability would, in an environmentally friendly manner, strengthen competitiveness and growth of the organization that adopts and implements this framework. Sustainability has two aspects to be addressed in the product development process: in the supply chain and in the demand chain.

In the supply chain, Al-Zabidi et al. [

17] proposed an approach to assess sustainable agility in a manufacturing organization. They highlighted the relationships between sustainable supply-chain capabilities, enablers, and attributes. They reported that in order to maintain sustainability in the supply chain, priority should be given to: (1) enhancing maintainability and serviceability for enabling flexibility and low cost, (2) development and integration of the core competencies for dealing with cross-functional and cross-enterprise issues in the supply chain. They reported that the design and fabrication process is one of the key factors that shape the decision making criteria for maintaining a sustainable supply chain. Emovon et al. backed this conclusion [

18]. Al-Zabidi et al. [

17] pointed out that digitalization in product design is one of the sustainable attributes that enable the realization of a sustainable supply chain. Al-Zabidi et al. [

17] also pointed out that quality design is a key attribute that is implemented in the design process in order to enable a sustainable supply chain. Several studies have seconded this conclusion [

19,

20,

21].

In the supply chain, the relationship between the environmental footprint and the United Nations’ Sustainable Development Goals has been investigated by Vanham, et al. [

22]. They identified a family of environmental footprints that can be used for the assessment of environmental sustainability. They suggested a methodology for assessing how the family of environmental footprints can comply with the United Nations’ Sustainable Development Goals. They also proposed a quantification of the environmental pressures along the supply chain and to relate these to the water–energy–food ecosystem.

In the demand chain, Zimon et al. [

23] identified the drivers of sustainable supply chain management that comply with the sustainable development goals. They reported that there are three drivers of sustainable supply chain management implementation: (1) internal drivers within the company including management commitment, organizational involvement, supportive culture, productivity improvement, and waste elimination; (2) demand chain drivers related to customers such as reverse logistics, business social compliance, environmental regulation compliance, customer and supplier involvement; (3) demand chain drivers related to third parties such as regulatory requirements, institutional pressures, international environmental regulations and green warehouses requirements, industrial competition, corporate reputation, and social responsibility. Rosati et al. [

24] identified the institutional factors that lead to complying with the United Nations’ Sustainable Development Goals. They reported that the organizations complying with these goals are more likely to have their value chain located in countries with higher levels of climate change vulnerability, national corporate social responsibility, and spending on tertiary education. Fonseca et al. [

25] defined the Circular Economy (CE) as an economic system that aims to conciliate economic and environmental performance, by adopting an innovative approach to address the relationship between business and the environment. They investigated a CE model that has been advocated and supported in Europe, proving that this economic system leads to profitability and value creation throughout the value chain. They pointed out that successful implementation of CE activities faces the challenge of the need for both strongly supportive supply chain agents and demand chain customers. In the interest of adding to the advancement of knowledge in this field, the results of the present research on the key approaches, risks and product performance in managing the sustainably of the development process for complex products are presented in the following section.

6. Case Studies for Validation

In this case study, five companies have been analyzed regarding each of the above-mentioned approaches. These five companies have been considered since they met the basic criterion which is to be a “R&D-based company” in the key manufacturing sectors in industry. There was no difference in selection, for instance based on religion or color. The description of these companies is presented in

Table 8 [

16].

For each of these companies, the events that were observed on the strategic, resource-based and sustainability-oriented approach include: Setting and Implementing R & D Strategy, Conforming to quality specifications, and Entering new markets. The events that were observed on the cost-oriented approach include: Employees flexibility, and Adhering to financial standards. The events that were observed on the time duration-oriented approach include: Speed of PD, and Number of new products. The events that were observed on the technical and problem solving approach include: Partnering with suppliers to identify needs and requirements, Involving customers in PDevPs, and Performance of products. The events that were observed on the social science and knowledge-based approach include: Availability of up-to-date data and information, Implementing effective reporting practices, “Fool-proof” process design, Maintaining a close relationship with customers, Involving employees in R&D decision making, and Use of latest technologies.

Data were collected through questionnaires and open interviews using a semi-structured script, with R&D management from each of the five companies. In the first part of the interviews with the management of the R & D units in this sample of companies, respondents were asked to answer verbal questions on the aspects mentioned in

Table 9,

Table 10,

Table 11,

Table 12 and

Table 13. In the second part, respondents were asked to answer a series of questions dealing with the TQM factors and practices [

15,

16]. “Success” herein means the market success of the firm and that is based on product quality and customer focus. The level of adoption that each of these companies has reached regarding each of the above-mentioned approaches is presented in

Table 9,

Table 10,

Table 11,

Table 12 and

Table 13. The scale of evaluation of adoption of each practice within each of the above-mentioned approaches is a 5-point scale, i.e., level 5 is the highest level that can be ultimately reached.

Table 9,

Table 10,

Table 11,

Table 12 and

Table 13 present these levels of adoption.

Table 9 presents the level of adoption of the strategic, resource-based and sustainability-oriented approach in these five companies. The level of adoption of the cost-oriented approach in these five companies is shown in

Table 10. The level of adoption of the time duration-oriented approach is presented in

Table 11. The level of adoption of the technical and problem solving approach is shown in

Table 12. The level of adoption of the social science and knowledge-based approach is presented in

Table 13.

The key referenced papers in these highly cited case studies used the arithmetical mean and the statistically significant test [

15,

16]. It is noteworthy that the arithmetical mean is a statistical method in this regard for measuring the central tendency of the level of meeting the ultimate targeted performance by these companies. The arithmetical mean is a suitable statistical method in this regard, for several reasons: (i) it is insensitive to the order of companies in the dataset, (ii) it is the most efficient method of averaging for representing the central tendency in the present dataset in comparison with the median, mid-range and mode. The present paper is focused on tangible complex products that are processed in R&D-based companies in key manufacturing sectors. It is thus reasonable to compute the mean in this regard. It is also reasonable to use the statistical significance test in this regard.

Based on the Mean value of adopting Practices,

Table 9,

Table 10,

Table 11,

Table 12 and

Table 13 imply that companies I, II, and III are much more successful than companies IV and V.

Table 9,

Table 10,

Table 11,

Table 12 and

Table 13 show that only the companies that have adopted the hybrid approach have been successful in all of the five aspects. The next section presents the statistical analysis of the results of this validation.

7. Statistical Analysis of the Results of Validation

The case studies have been conducted in order to test the hypothesis that: “When most of the companies adopt the hybrid lean-agile approach, the aggregate performance of companies becomes closer to the best performance”. In order to test the significance of the results of the case studies, an inferential statistics-based analysis is conducted in this section. It is assumed that the interval variable is a random variable that is normally distributed (x

i) and represents the average of the adoption of the approaches presented in

Table 9,

Table 10,

Table 11,

Table 12 and

Table 13 as shown in

Table 14.

The hypothesis is now formulated mathematically comparing the mean of the dataset (

) with the ultimate corresponding value of performance (μ

o), which is the ultimate value of performance corresponding to the ultimate adoption of the approaches presented in

Table 9,

Table 10,

Table 11,

Table 12 and

Table 13. This hypothesis is mathematically formulated as follows:

Moderate departure from normality should not significantly affect the results. The test statistic,

tx, is hence evaluated as follows:

where:

is the standard deviation of the dataset of the interval variable xi,

ᴧ is the number of records in the sample.

The standard deviation of the dataset of the interval variable

xi,

, is formulated as [

83]:

Thus, using

Table 14 and for ᴧ equals 5, the standard deviation,

sx, is equal to “0.917” following from Equation (4). Hence, following from Equation (3),

tx is equal to “−2.78”. At the most conservative level of significance, α

o, is equal to “0.01”, since this is a two-sided test, and both the mean and variance are estimated, from the t-distribution we find that

equals “4.6” for ᴧ equals 5. Therefore,

is greater than

tx. Therefore, we cannot reject the null hypothesis. Thus, the null hypothesis, Equation (1), is significant at the level of confidence of 99%. The result of statistically testing this hypothesis therefore proves that when companies adopt the hybrid lean-agile approach, the aggregate performance of the companies becomes closer to best performance.

8. Discussion

While other studies in the NDP literature, such as [

84], investigated the characteristics of innovative firms, such as their size and financial resources, the present research has identified the level of PP that yields maximum return on PD in such a competitive environment as Industry 4.0. The study has also identified the six key approaches to understanding and to managing the PDevP. These key approaches are (1) strategic, resource-based and sustainability-oriented perspective; (2) cost accounting and financial perspective; (3) PD time duration-oriented perspective; (4) social sciences and knowledge-based perspective; (5) technical and problem solving perspective; (6) hybrid approach of the aforementioned five approaches.

Following the social science and knowledge-based approach, many organizations have implemented enterprise-wide knowledge management initiatives with the aim of transforming organizational knowledge assets into core competencies in order to gain competitive advantage [

85,

86]. Therefore, business-critical tacit knowledge has become more visible, more appropriately distributed, and adequately codified [

87]. The adopted approach in this study enables business-critical tacit knowledge to be shared efficiently.

Following the strategic, resource-based and sustainability-oriented approach, organizations are increasingly recognizing that intangible assets are the key strategic resources and that tangible assets have frequently become transient commodities. Organizations thus need to efficiently manage their intellectual resources in order to gain and sustain a competitive advantage [

86]. Since it is critical for organizations to recognize whether they are using their intangible resources efficiently for value creation, an increasing number of researchers have been addressing the assessment of intellectual capital [

88,

89,

90,

91,

92,

93,

94]. This assessment should be followed by the determination of which KM activities are required to obtain the desired intellectual capital results [

88]. Among the key means for firms to acquire knowledge-assets is via intra-organizational processes [

92]. This is particularly true in light of the fact that researchers analyzed the NPD by moving from the traditional approach of considering the NPD as a planning process of strategic and organizational aspects to a cognitive approach which handles NPD as a process and relies on learning and strategic knowledge management [

95,

96,

97]. In addition, numerous studies have investigated the role of specific knowledge assets in the NPD process, such as the relationships a company has [

98]. The adopted approach in this study enables intra-organizational processes based on learning. In addition, it enables efficient utilization of the available resources, such as energy consumption.

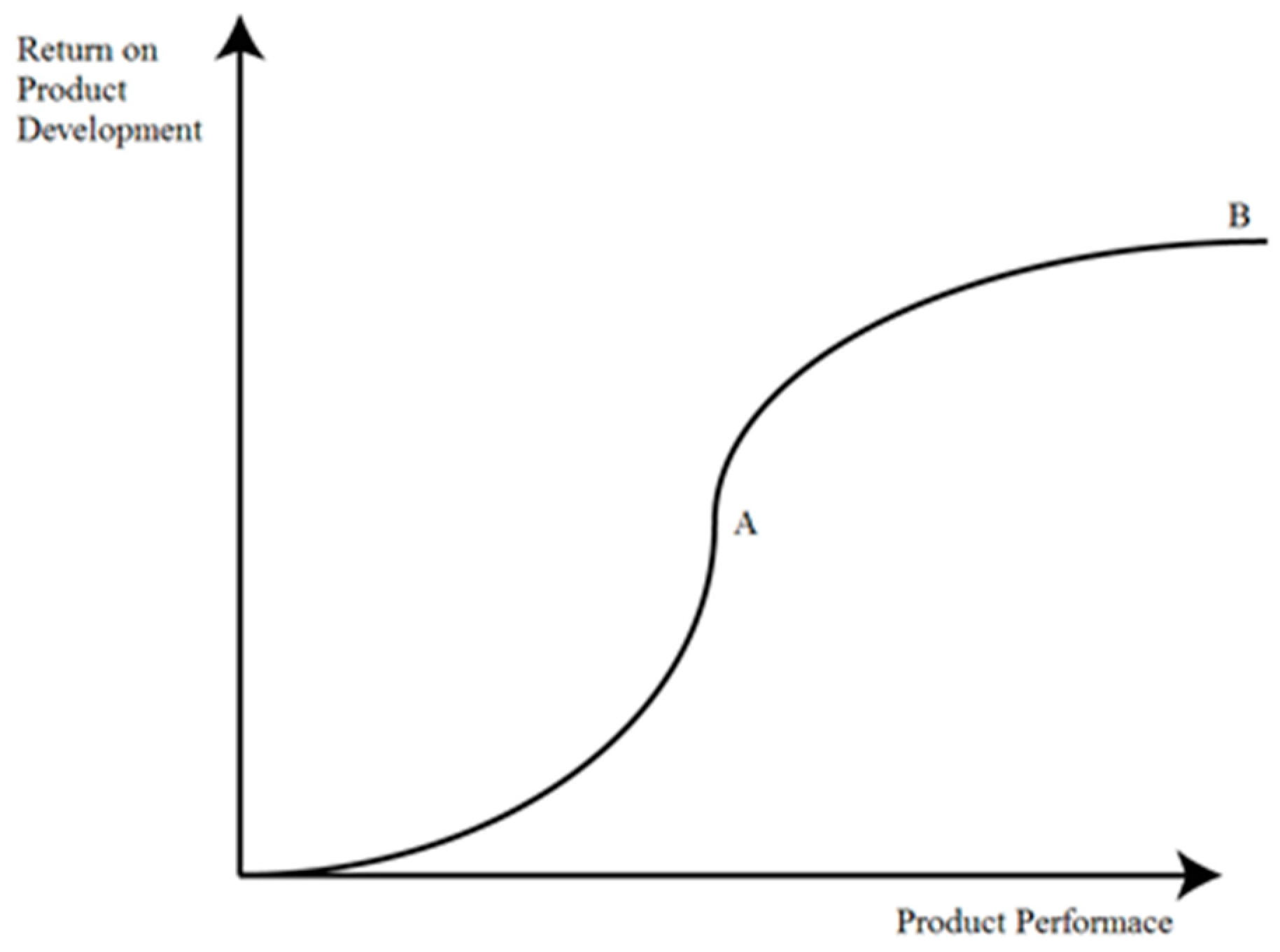

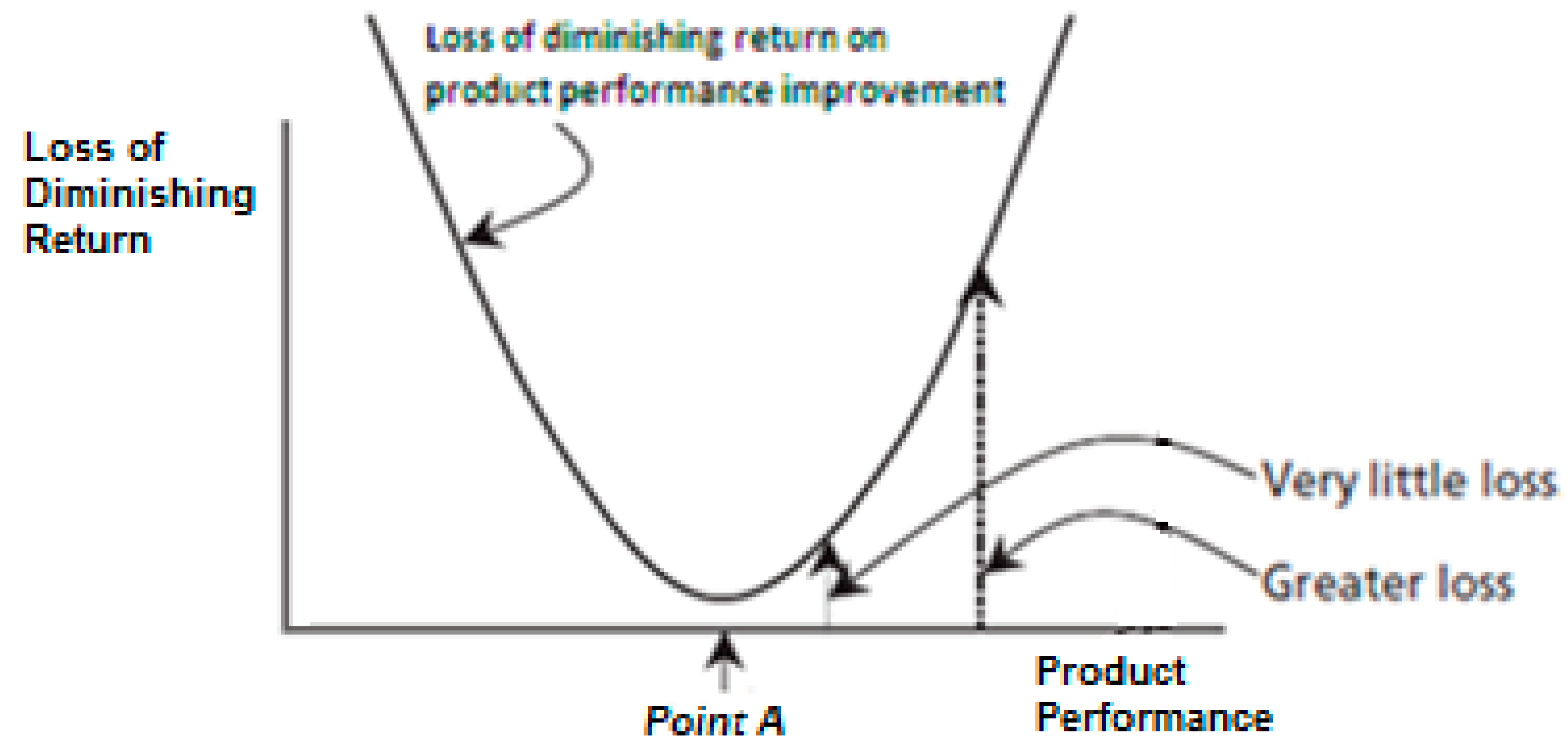

The present study has identified the PP level in the PDevP that yields maximum return on PD as indicated in

Figure 2. The study has indicated that point A in

Figure 2 is the optimum point to be targeted by designers for minimizing the loss of diminishing return on PP improvement as depicted in

Figure 3. The idealized model presented in

Figure 2 and

Figure 3 and supported by evidence from the literature paves the way for further investigation in future research papers. In the five case studies presented herein: (i) performance has been measured in terms of “Performance of Products” in

Table 12, (ii) returns have been measured in terms of “Financial Performance” in

Table 10. It is scientifically acceptable to use data from a published case study available in the literature to validate the results of another research work, such as the highly cited research published in top scientific research journals [

99]. Extracting the dataset from a highly cited paper to validate the research results of another research work is even more reliable than creating our own dataset from our own experiments, because no bias in this regard exists since the authors are not the source of the dataset. This research methodology is particularly useful in NPD research.

The task of NPD becomes increasingly complex as it has to satisfy and integrate the preferences of stakeholders to formulate an optimal set of specifications in a competitive arena and a turbulent environment [

100]. Thus, it requires not only knowledge from various disciplines such as marketing and manufacturing [

101] but also an integration of various functions such as R&D and planning [

32]. The task becomes more challenging as companies are increasingly placing an emphasis on their core competencies and outsourcing non-core competencies to third parties [

102]. On the one hand, where these partners along the supply chain bring improvements and further business opportunities in the NPD process, they present additional complexities and risks on the other [

102]. Although NPD is considered a source of competitive advantage [

35], these complexities and risks render it a risky endeavor [

103,

104]. The adopted approach in this study tackles these complexities and mitigates these risks [

105,

106,

107].

The first phase of the RM proposed action plan takes place before the beginning of the PDP in which SWOT analysis is conducted. The second phase of this plan is during the PDevP in which the design managers should ensure that the product satisfies the customer, satisfies its functional requirement, has reliable quality, and is cost-effective, which reflects the technological aspect of RM. The third and last phase of this plan is after the end of the PDP in which FMEA is conducted and ultimately products which do not meet the objective are killed off as soon as possible, which reflects the marketing aspect of RM. The RM plan proposed in the present paper is an extension of the RM plan proposed by Baxter [

4].

It is noteworthy that randomized controlled sampling was applicable to the research data gathered and presented in the paper [

16] in the sense that the authors made no difference in selection among the companies that met the basic criterion of their research, which is to be “R&D-based companies”. Adopting the criterion that the companies from which the selection is made must be “R&D-based companies”, is scientifically acceptable in the sense that it makes the study more focused. The claim of the research approach of “not a generalization” mentioned in [

16] makes the present research paper a complementary piece of research that integratively adds further value to the research data gathered by Bigliardi & Galati and the case study. The statistical analysis made in the present paper based on the data gathered by Bigliardi & Galati makes the present research paper a continuation of their research work filling a research gap. The results of the present study would expectedly help in enabling the paradigm shift from Industry 4.0 to Industry 5.0, which is driven by being environmentally friendly, to realize the United Nations’ Sustainable Development Goals.