Corn Stover Removal Responses on Soil Test P and K Levels in Coastal Plain Ultisols

Abstract

1. Introduction

2. Methods and Materials

2.1. Site Description and Experimental Setup

2.2. Corn Grain and Stover Analysis

2.3. Statistical Analysis

3. Results and Discussion

3.1. Agronomic Practices

3.2. Stover Harvest Rates

3.3. Grain and Stover P and K Concentrations and Removal

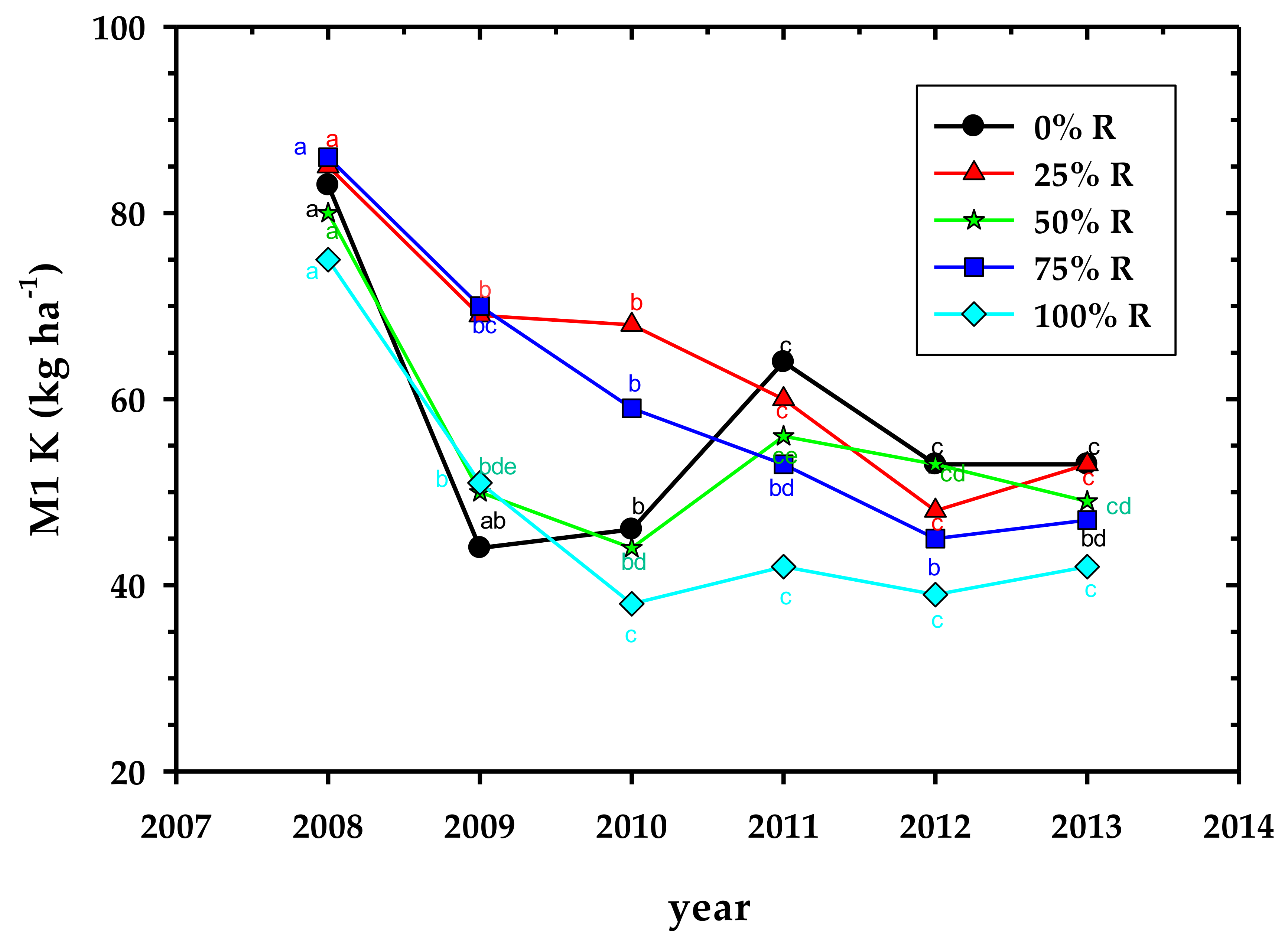

3.4. Soil Test P and K

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Berndes, G.; Hoogwijk, M.; van den Brock, R. The contribution of biomass in the future of global energy supply: A review of 17 studies. Biomass Bioenergy 2003, 25, 1–28. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change [IPCC]. Climate Change 2007: The Physical Science Basis. Summary for POLICYMAKERS. Intergovernmental Panel on Climate Change, Geneva, Switzerland. Available online: http://www.ipcc.ch (accessed on 12 March 2021).

- National Academy of Sciences (NAS). Liquid Transportation Fuels from Coal and Biomass: Technological Status, Costs, and Environmental Impacts; The National Academies Press: Washington, DC, USA, 2009. [Google Scholar]

- Naik, S.N.; Vaibhav, V.G.; Rout, P.K.; Dalai, A.K. Production of first and second generation biofuels: A comprehensive review. Renew. Sustain. Energy 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Lee, J.W. Introduction: An overview of advanced biofuels and bioproducts. In Advanced Biofuels and Bioproducts; Springer: New York, NY, USA, 2013. [Google Scholar] [CrossRef]

- Demirbas, A.; Gönenç, A. An overview of biomass pyrolysis. Energy Sources 2002, 24, 471–482. [Google Scholar] [CrossRef]

- Lv, D.; Xu, M.; Liu, X.; Zhan, Z.; Li, Z.; Yao, H. Effects of cellulose, lignin, alkali and alkaline earth metallic species on biomass pyrolysis and gasification. Fuel Process. Technol. 2010, 91, 903–909. [Google Scholar] [CrossRef]

- Perlack, R.D.; Wright, L.L.; Turnhollow, A.F.; Graham, R.L.; Stokes, B.J.; Erbach, D.C. Biomass as a Feedstock for a Bioenergy and Bioproducts Industry: The Technical Feasibility of a Billion-Ton Annual Supply. 2005; DOE/GO-102005-2135 and ORNL/TM-2005/66. Available online: http://feedstockreview.ornl.gov/pdf/billion_ton_vision.pdf (accessed on 12 March 2021).

- Biomass Research and Development Board. Increasing Feedstock Production for Biofuels. In Economic Drivers, Environmental Implications, and the Role of Research; USDA: Washington, DC, USA, 2008; Available online: http://www.brdisolutions.com/site%20DOCs/increasing%20Feedstock_revised.pdf (accessed on 12 March 2021).

- Karlen, D.L.; Johnson, J.M.F. Crop residue considerations for sustainable bioenergy feedstock supplies. Bioenergy Res. 2014, 7, 465–467. [Google Scholar] [CrossRef][Green Version]

- Langholtz, M.H.; Stokes, B.J.; Eaton, L.M. 2016 Billion-Ton Report: Advancing Domestic Resources for a Thriving Bioeconomy; Office of Scientific and Technical Information (OSTI); US Department of Energy, Forrestal Building: Washington, DC, USA, 2016; p. 448. [Google Scholar] [CrossRef]

- Wilhelm, W.W.; Hess, J.R.; Karlen, D.L.; Johnson, J.M.F.; Muth, D.J.; Baker, J.M.; Gollany, H.T.; Novak, J.M.; Stott, D.E.; Varvel, G.E. Review: Balancing limiting factors and economic drivers for sustainable Midwestern US agricultural residue feedstock supplies. Ind. Biotechnol. 2010, 6, 271–287. [Google Scholar] [CrossRef]

- Karlen, D.L.; Birrell, S.J.; Hess, J.R. A five-year assessment of corn stover harvest in central Iowa, USA. Soil Tillage Res. 2011, 115–116, 47–55. [Google Scholar] [CrossRef]

- Zhao, G.; Bryan, B.A.; King, D.; Luo, Z.; Wang, E.; Yu, Q. Sustainable limits to crop residue harvest for bioenergy: Maintaining soil carbon in Australia’s agricultural lands. GCB Bioenergy 2015, 7, 479–487. [Google Scholar] [CrossRef]

- Cherubin, M.R.; Oliveria, D.M.; Feigl, B.J.; Pimental, L.G.; Lisboa, I.P.; Gmach, M.R.; Varanda, L.L.; Morais, M.C.; Satiro, L.S.; Popin, G.V.; et al. Crop residue harvest for bioenergy production and its implication on soil functioning and plant growth: A review. Sci. Agric. 2018, 75, 255–272. [Google Scholar] [CrossRef]

- Blanco-Canqui, H.; Lal, R. Soil and crop response to harvesting corn residues for biofuel production. Geoderma 2007, 141, 355–362. [Google Scholar] [CrossRef]

- Blanco-Canqui, H.; Lal, R. Crop residue removal impacts on soil productivity and environmental quality. Crit. Rev. Plant Sci. 2009, 28, 139–163. [Google Scholar] [CrossRef]

- Birrell, S.J.; Karlen, D.L.; Wirt, A. Development of sustainable corn stover harvest strategies for cellulosic ethanol production. Bioenergy Res. 2014, 7, 516–590. [Google Scholar] [CrossRef]

- Kenny, I.; Blanco-Canqui, H.; Presley, D.R.; Rice, C.W.; Janssen, K.; Olson, B. Soil and crop responses to stover removal from rainfed and irrigated corn. GCB Bioenergy 2015, 7, 219–230. [Google Scholar] [CrossRef]

- Jin, V.L.; Schmer, M.R.; Wienhold, B.J.; Stewart, C.E.; Varvel, G.E.; Sindelar, A.J.; Follett, R.F.; Mitchell, R.B.; Vogel, K.P. Twelve years of stover removal increases soil erosion potential without impacting yield. Soil Sci. Soc. Am. J. 2015, 79, 1169–1178. [Google Scholar] [CrossRef]

- Adler, P.R.; Rau, B.M.; Roth, G.W. Sustainability of corn stover harvest strategies in Pennsylvania. Bioenergy Res. 2015, 8, 1310–1320. [Google Scholar] [CrossRef]

- Karlen, D.L.; Birrell, S.J.; Johnson, J.M.F.; Osborne, S.L.; Schumacher, T.E.; Varvel, G.E.; Ferguson, R.B.; Novak, J.M.; Frederick, J.R.; Baker, J.M.; et al. Multilocation corn stover harvest effects on crop yields and nutrient removal. Bioenergy Res. 2014, 7, 528–539. [Google Scholar] [CrossRef]

- Tan, Z.; Liu, S. Soil nutrient budgets following projected corn stover harvest for biofuel production in the conterminous United States. GCB Bioenergy 2014, 71, 1–19. [Google Scholar] [CrossRef]

- Karlen, D.L.; Flannery, R.L.; Sadler, E.J. Aerial accumulation and portioning of nutrients by corn. Agron. J. 1988, 80, 232–242. [Google Scholar] [CrossRef]

- Johnson, J.M.F.; Papiernik, S.K.; Mikha, M.M.; Spokas, K.; Tomer, M.D.; Weyers, S.L. Soil Processes and Residue Harvest Management. In Soil Quality and Biofuel Production; Lal, R., Stewart, B.A., Eds.; CRC Press: Boca Raton, FL, USA, 2010; pp. 1–44. [Google Scholar]

- Setiyono, T.D.; Walters, D.T.; Cassman, K.G.; Witt, C.; Dobermann, A. Estimating maize nutrient uptake requirements. Field Crop. Res. 2010, 118, 158–168. [Google Scholar] [CrossRef]

- Novak, J.M.; Watts, D.W.; Bauer, P.J.; Karlen, D.L.; Hunt, P.G.; Mishra, U. Loamy sand soil approaches organic carbon saturation after 37 years of conservation tillage. Agron. J. 2020, 112, 3152–3162. [Google Scholar] [CrossRef]

- Karlen, D.L. Corn stover feedstock trials to predictive modeling. GCB Bioenergy 2010, 2, 235–247. [Google Scholar] [CrossRef]

- Owens, V.N.; Karlen, D.L.; Lacey, J.A. Regional Feedstock Partnership Summary Report: Enabling the Billion-Ton Vision. In Regional Feedstock Partnership Summary Report: Enabling the Billion-Ton Vision; US Department of Energy: Washington, DC, USA, 2016. [Google Scholar] [CrossRef][Green Version]

- Daniels, R.B.; Buol, S.W.; Kleiss, H.J.; Ditzler, C.A. Soil Systems in North Carolina; Technical Bulletin 314; North Carolina State University: Raleigh, NC, USA, 1999. [Google Scholar]

- Gray, L.C. History of Agriculture in the Southern United States to 1860; Carnegie Institute: Washington, DC, USA, 1933. [Google Scholar]

- Trimble, S.W. Man-Induced Soil Erosion of the Southern Piedmont: 1700–1970; Soil Conservation Society of America: Ankeny, IA, USA, 1974. [Google Scholar]

- Grossmann, R.B.; Reinsch, T.G. Bulk density and linear extensibility. In Methods of Soil Analysis. Part 4; Dane, J.H., Topp, G.C., Eds.; SSSA: Madison, WI, USA, 2002; pp. 201–228. [Google Scholar]

- Busscher, W.J.; Bauer, P.J.; Frederick, J.R. Recompaction of a coastal loamy sand after deep tillage as a function of subsequent cumulative rainfall. Soil Tillage Res. 2002, 68, 49–57. [Google Scholar] [CrossRef]

- Mills, H.A.; Jones, J. Plant Analysis Handbook II: Practical Sampling, Preparation, Analysis, and Interpretation Guide; Micro-Macro Publisher: Athens, GA, USA, 1996. [Google Scholar]

- Novak, J.M.; Frederick, J.R.; Bauer, P.J.; Watts, D.W. Rebuilding organic carbon contents in coastal plain soils using conservation tillage systems. Soil Sci. Soc. Am. J. 2009, 73, 622–629. [Google Scholar] [CrossRef]

- Novak, J.M.; Sigua, G.C.; Ducey, T.F.; Watts, D.W.; Stone, K.C. Designer biochar impact on corn grain yields, biomass production, and fertility properties of a highly-weathered Ultisol. Environments 2019, 6, 64. [Google Scholar] [CrossRef]

- Karlen, D.L.; Hunt, P.G.; Campbell, R.B. Crop residue removal effects on corn yield and fertility of a Norfolk sandy loam. Soil Sci. Soc. Am. J. 1984, 48, 868–872. [Google Scholar] [CrossRef]

- Odum, E.P.; Pinder, J.E., III; Christiansen, T.A. Nutrient losses from sandy soils during old-field succession. Am. Midl. Nat. 1984, 111, 148–154. [Google Scholar] [CrossRef]

- Karlen, D.L.; Kovar, J.; Birrell, S. Corn stover nutrient removal estimates for central Iowa. Sustainability 2015, 7, 8621–8634. [Google Scholar] [CrossRef]

- Lindstrom, M.J. Effects of residue harvesting on water runoff, soil erosion, and nutrient loss. Agric. Ecosyst. Environ. 1986, 16, 103–112. [Google Scholar] [CrossRef]

- Kolahchi, Z.; Jalali, M. Effect of water quality on the leaching of potassium from sandy soil. J. Arid. Environ. 2007, 68, 624–639. [Google Scholar] [CrossRef]

- Wulff, F.; Schulz, V.; Jungk, A.; Claassen, N. Potassium fertilization on sandy soils in relation to soil test, crop yields and K-leaching. Z. Pflanz. Bodenkd. 2011, 161, 591–599. [Google Scholar] [CrossRef]

- Rao, C.S.; Rupa, T.R.; Rao, A.S.; Bansal, S.K. Subsoil potassium availability in twenty-two benchmark soil series of India. Commun. Soil Sci. Plant Anal. 2007, 32, 863–876. [Google Scholar] [CrossRef]

- Johnson, J.M.F. A “Soil Lorax” perspective on corn stover for advanced biofuels. Agron. J. 2018, 110, 59–62. [Google Scholar] [CrossRef]

| Fertilizer Applied (kg ha−1) | Planting Rate | ||||

|---|---|---|---|---|---|

| Year | N | P | K | Corn Cultivar | Plants ha−1 |

| 2008 | 140 | 0 | 0 | DeKalb C69-71 | 49,505 |

| 2009 | 140 | 20 | 50 | DeKalb C69-71 | 49,505 |

| 2010 | 140 | 20 | 50 | DeKalb C69-71 | 54,455 |

| 2011 | 99 | 17 | 42 | DeKalb C69-71 | 54,340 |

| 2012 | 135 | 34 | 83 | DeKalb C69-71 | 54,450 |

| Stover Removed (%) | Annual Mean Corn Stover (kg ha−1) | ||

|---|---|---|---|

| Year | Removed | Returned | |

| 0 | 2008 | 0 | 6712 |

| 2009 | 0 | 8543 | |

| 2010 | 0 | 6676 | |

| 2011 | 0 | 4274 | |

| 2012 | 0 | 7996 | |

| mean | 0 | 6820 | |

| 25 | 2008 | 1657 | 4970 |

| 2009 | 1919 | 5758 | |

| 2010 | 1624 | 4871 | |

| 2011 | 1138 | 3415 | |

| 2012 | 1754 | 5263 | |

| mean | 1618 | 4851 | |

| 50 | 2008 | 3196 | 3197 |

| 2009 | 4056 | 4056 | |

| 2010 | 3107 | 3107 | |

| 2011 | 2393 | 2393 | |

| 2012 | 3924 | 3924 | |

| mean | 3335 | 3335 | |

| 75 | 2008 | 4814 | 1618 |

| 2009 | 5839 | 1947 | |

| 2010 | 5081 | 1693 | |

| 2011 | 3528 | 1176 | |

| 2012 | 5944 | 1981 | |

| mean | 5041 | 1683 | |

| 100 | 2008 | 6408 | 0 |

| 2009 | 8295 | 0 | |

| 2010 | 6494 | 0 | |

| 2011 | 4931 | 0 | |

| 2012 | 7508 | 0 | |

| mean | 6757 | 0 | |

| % Corn Stover Removed (kg ha−1) † | |||||

|---|---|---|---|---|---|

| Nutrients in Corn Grain | 0 | 25 | 50 | 75 | 100 |

| P | 14 (7) a | 14 (6) a | 13 (6) a | 15 (7) a | 14 (6) a |

| K | 17 (9) a | 17 (7) a | 15 (7) a | 18 (7) a | 18 (7) a |

| Stover P | |||||

| removed | 0 (0) a | 2 (0) b | 4 (1) c | 5 (1) cd | 6 (2) d |

| returned | 8 (2) a | 6 (1) b | 4 (1) c | 2 (0.5) d | 0 (0) e |

| Stover K | |||||

| removed | 0 (0) a | 20 (5) b | 40 (10) c | 60 (15) d | 79 (17) e |

| returned | 84 (22) a | 61 (14) b | 40 (10) c | 20 (5) d | 0 (0) e |

| Nutrient Mass Balance (kg ha−1) Estimate for Each % Stover Removal Amount † | |||||

|---|---|---|---|---|---|

| Nutrient | 0 | 25 | 50 | 75 | 100 |

| P | 12.6 (11.9) a | 8.4 (11.5) a | 5.5 (11.6) a | −0.4 (12.6) a | −2.5 (11.7) a |

| K | 116.5 (51.6) a | 68.9 (35) ac | 30.1 (28.4) bc | −12.5 (25) bd | −51.2 (25.3) d |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Novak, J.M.; Frederick, J.R.; Watts, D.W.; Ducey, T.F.; Karlen, D.L. Corn Stover Removal Responses on Soil Test P and K Levels in Coastal Plain Ultisols. Sustainability 2021, 13, 4401. https://doi.org/10.3390/su13084401

Novak JM, Frederick JR, Watts DW, Ducey TF, Karlen DL. Corn Stover Removal Responses on Soil Test P and K Levels in Coastal Plain Ultisols. Sustainability. 2021; 13(8):4401. https://doi.org/10.3390/su13084401

Chicago/Turabian StyleNovak, Jeffrey M., James R. Frederick, Don W. Watts, Thomas F. Ducey, and Douglas L. Karlen. 2021. "Corn Stover Removal Responses on Soil Test P and K Levels in Coastal Plain Ultisols" Sustainability 13, no. 8: 4401. https://doi.org/10.3390/su13084401

APA StyleNovak, J. M., Frederick, J. R., Watts, D. W., Ducey, T. F., & Karlen, D. L. (2021). Corn Stover Removal Responses on Soil Test P and K Levels in Coastal Plain Ultisols. Sustainability, 13(8), 4401. https://doi.org/10.3390/su13084401