Abstract

End-of-life tires (ELTs) represent a great source of readily available, low-cost and sustainable construction materials having excellent engineering properties. Their reuse (in the form of granulated rubber mixed with soils) in large-volume recycling civil (geotechnical) engineering applications would be beneficial and should be encouraged. It is estimated that at present worldwide only less than 10% of ELTs are reused in geotechnical applications, while nearly 40% are recycled as tire-derived fuel. Although many studies have focused on the material characterization of soil-rubber mixtures (SRMs), it appears that the results of such investigations have not been properly compiled and compared, making it difficult to fully understand the potential applicability of SRMs. In an attempt to provide useful insights facilitating the use of SRMs as geotechnical construction materials, this review paper presents a comprehensive review of published research on the engineering properties of granular soils (i.e., mainly sand and gravel) blended with various recycled rubber inclusions. Available experimental data are scrutinized, and the results of the analyses are presented and discussed primarily in terms of effects of rubber content and aspect ratio (ratio of rubber to gravel median particle sizes) on compaction, permeability, strength and compression properties along with dynamic and cyclic deformation characteristics of SRMs. This review paper may help to alleviate the concerns of designers and consumers and encourage and further promote the use of recycled rubber tires on a larger scale in civil engineering projects.

1. Introduction

End-of-life tires (ELTs) are non-reusable tires in their original form. They enter a waste management system based on product/material recycling, energy recovery or go to disposal [1]. The current rate of ELT production worldwide is over 1 billion per year, including passenger vehicle tires and truck tires [2], and is expected to grow over time with increased population and number of vehicles on roads. Annually, more than half of one billion ELTs is estimated to be discarded and destined in landfills worldwide without any treatment [2]. For the sake of completeness, Table 1 provides some statistics about the production of ELTs (in terms of quantity and per capita), the recovery rate and main application in different countries.

In many countries, ELTs are a controlled waste under environmental regulations, which places a duty of care on waste producers to ensure safe disposal through licensed carriers to approved sites. For instance, since 2003 in Europe, under the European Union Landfill Directive, waste tires are prohibited from being used for landfill [3]. Even shredded tires are not accepted by landfill facilities. However, in many other countries, at present no national regulations are in place to efficiently manage waste tire recycling, and with the ever-growing volume of ELTs, environmental and health concerns are urging the reuse of waste tires through large-scale recycling engineering projects.

Waste tire recycling may be challenging, but it is not impossible to achieve. In Europe, Canada, USA, Japan and many other countries where strategic waste marketing, collection and management procedures have been put in place to effectively make use of recycled ELTs, the disposal of waste tires has been reduced to 20% or less [1,3,4]. While ELTs have excellent engineering properties (i.e., strength, dynamic properties, durability, etc.) making them ideal construction materials, the majority of ELTs is currently used as tire-derived fuel, which is arguably the most environmentally friendly way to reuse tires, and only 10% or less is sheared into various sizes to be used in different civil (geotechnical) engineering applications.

Table 1.

Generation and recovery rate of ELTs in different countries.

Table 1.

Generation and recovery rate of ELTs in different countries.

| Country | ELTs Generation per Year | Recovery Rate (%) | Main Application | Reference | ||

|---|---|---|---|---|---|---|

| By Weight (Million Tons) | By Number (Million) | ELTs/Person 1 | ||||

| US | 4.2 | 250 | 0.77 | 84 | Tire-derived Fuel | [4] |

| Europe | 3.3 | 270 | 0.53 | 92 | Energy generation | [5] |

| Japan | 1.034 | 97 | 0.77 | 93 | Thermal recycling | [6] |

| UK | 0.436 | 40 | 0.62 | 98 | Energy generation | [5] |

| Australia | 0.41 | 20 | 0.80 | 38 | Export (Energy generation) | [7] |

| Canada | 0.42 | 28 | 0.74 | 98 | Tire crumbs and molded | [8] |

| New Zealand | 0.04 | 5 | 1.25 | 30 | Energy generation | [9] |

1 Population data (Source: https://www.worldometers.info/world-population/ accessed on 25 March 2020).

The reuse of granulated rubber derived from ELTs on its own or to be mixed with soil has been found suitable in applications such as light-weight embankment fill, drainage layer, conventional fill, retaining wall back-fill, etc. [10,11,12]. However, statistics suggest that to date only less than 10% of ELTs-derived rubber is currently being used for this purpose worldwide. More in-depth and coordinated investigations are certainly required to be carried out to broaden the available database that could include a wider range of soil types, rubber type and sizes and also refer to new promising applications such as geotechnical seismic isolation systems for residential buildings [13,14,15,16,17,18,19], countermeasures against soil liquefaction [20,21] and railways applications [22,23].

In an attempt to provide useful insights facilitating the use of soil-rubber mixtures (SRMs), this paper presents a comprehensive review of published research studies on the geotechnical engineering properties of ELT inclusions blended with different granular soils (i.e., sand and gravel), the main focus being on the effects of rubber content and relative rubber/soil size on compaction and permeability properties, compressibility and strength behavior, as well as dynamic and cyclic deformation characteristics.

2. Geotechnical Properties of Soil-Rubber Mixtures (SRMs)

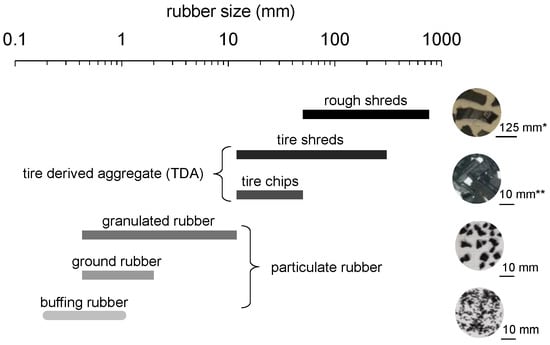

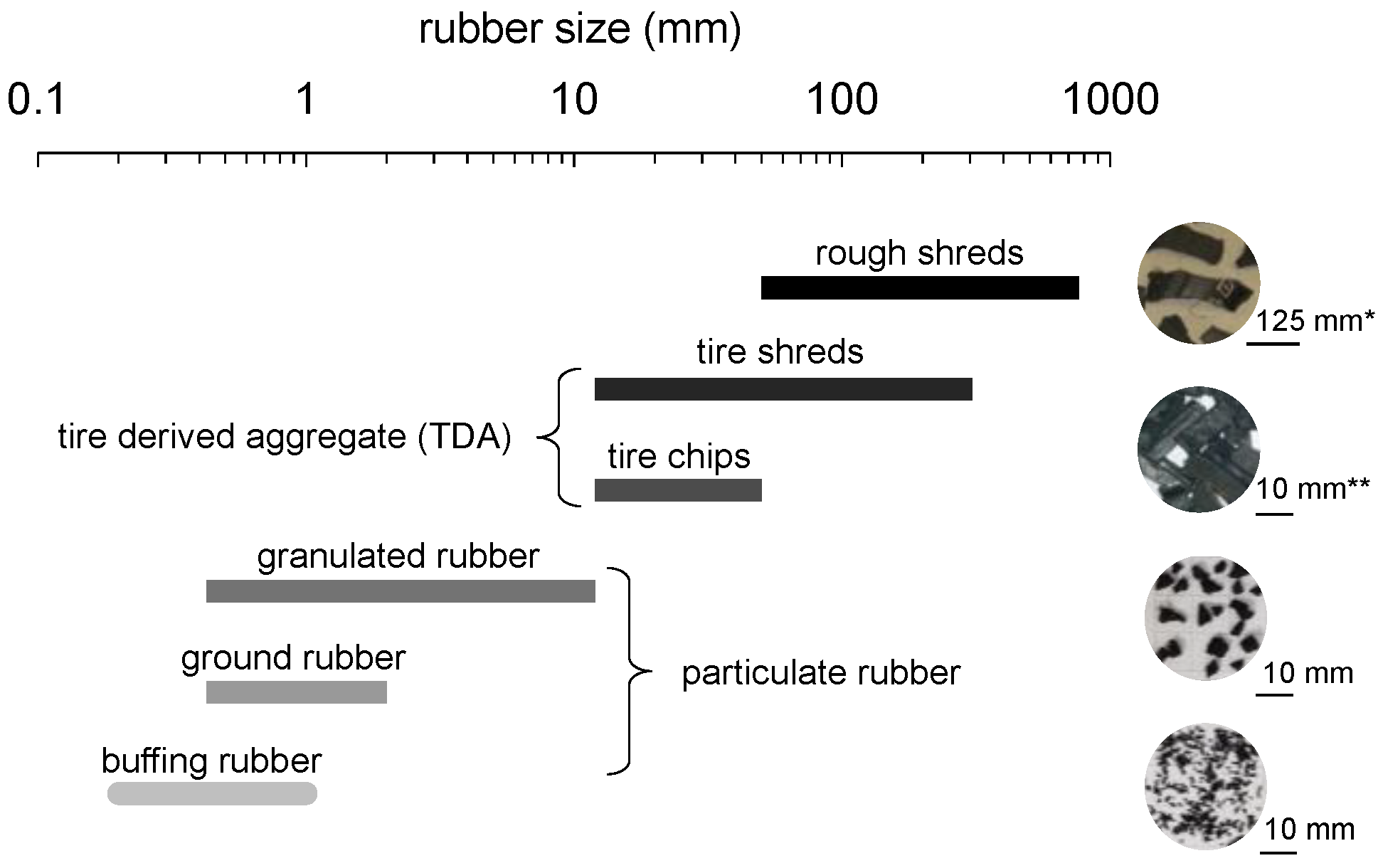

Tires have a mixed composition of carbon black, elastomer compounds and steel wire, in addition to several other organic and inorganic components (Table 2). From a geotechnical engineering viewpoint, ELTs can be recycled under the form of granulated rubber and mixed with granular soils and, therefore, represent a great source of low-cost, environmentally friendly and sustainable construction materials having excellent engineering properties. As shown in Figure 1, according to the American Standard for Testing and Material ASTM D6270-17 [24], granulated tires can be categorized based on their sizes.

Table 2.

Typical composition of tires as reported by US Tires [4] and ETRMA [5].

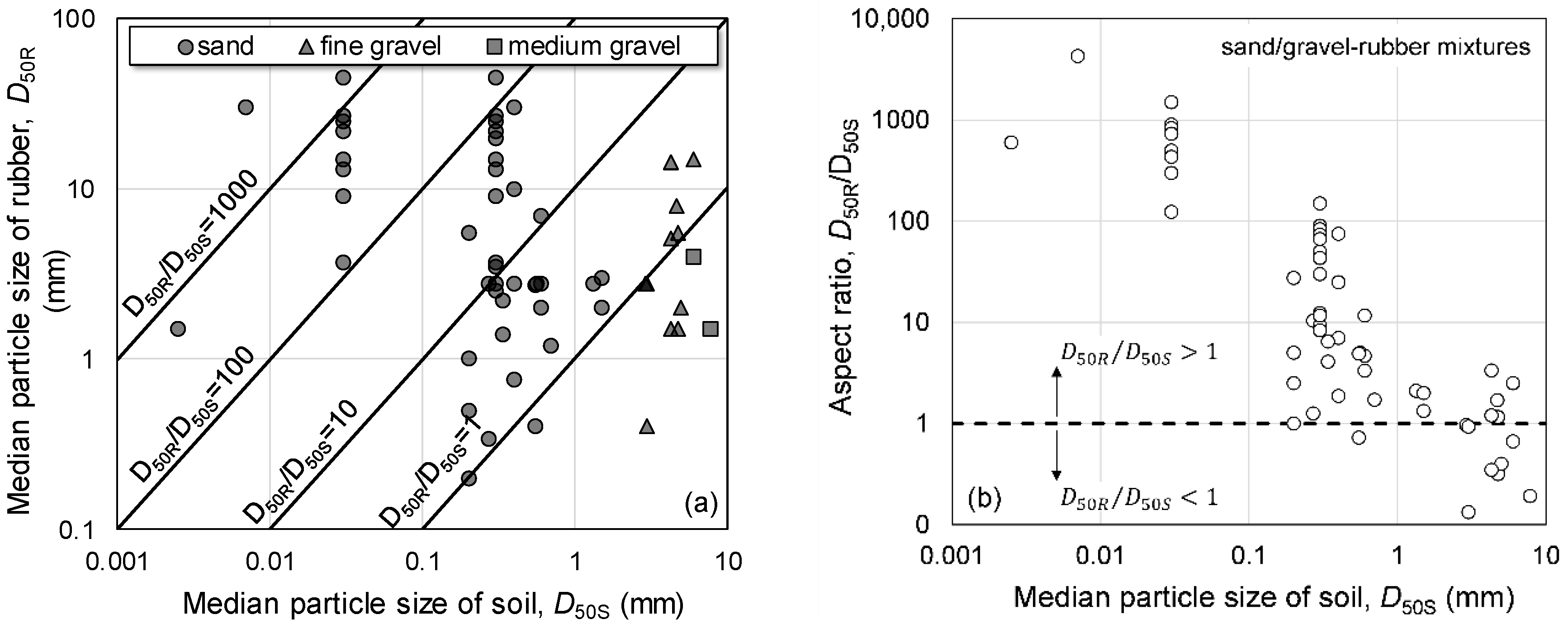

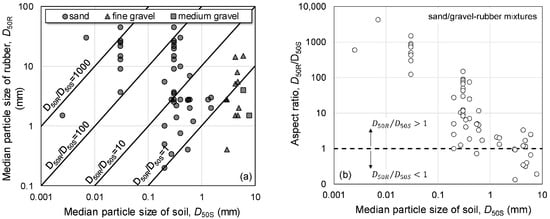

When mixed with soils, the relative grain size between rubber particles and soil grains (i.e., aspect ratio or the ratio of median particle sizes; D50R/D50S) plays an important role in the overall mechanical behavior of SRMs [25,26,27]. Hence, various scrap tire sizes and soil mixtures have been considered in previous studies as summarized in Figure 2. It is evident that the majority of research is focused on the use of fine-medium sand blended with various rubber sizes, mainly 1 < D50R/D50S < 100. Granulated rubber-gravel mixtures, on the other hand, have been poorly characterized.

Figure 2.

Rubber and soil mixtures investigated in previous studies: (a) relationship between median particle size of rubber and soil and (b) aspect ratio against median particle size of soil (Data points from: [11,25,26,27,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47]).

Figure 1.

Granulated tire sizes according to ASTM D6270-17 [24]. * Balunaini [28], ** Mashiri [29].

Figure 1.

Granulated tire sizes according to ASTM D6270-17 [24]. * Balunaini [28], ** Mashiri [29].

Hereafter, findings from previous relevant studies are summarized and experimental data available from the literature are scrutinized. The results of the analyses focusing on the compaction and permeability properties, mechanical behavior, dynamic and cyclic deformation characteristics of SRMs are presented and discussed primarily in terms of effects of gravimetric (GRC) or volumetric (VRC) rubber content and aspect ratio of rubber to gravel median particle sizes. It is worth noticing that in this study GRC and VRC are defined as follows:

where MRubber and VRubber are the mass and the volume of the rubber particle fraction in the mixture, respectively; and MSoil and VSoil are the mass and the volume of soil fraction in the mixture.

2.1. Packing States and Matrix Materials for SRMs

SRMs are essentially binary granular mixtures consisting of rigid and soft particles of different sizes and shapes. Their packing density (i.e., void ratio) and mechanical behavior (i.e., compressibility and strength) are influenced by the inherent properties of the materials (i.e., size and shape), the proportion of large/small and soft/rigid particles in the total volume of solids as well as the size ratio of large/small (D50large/D50small) and soft/rigid (D50R/D50S) particles.

Previous studies [33,40,48,49] have indicated that three packing states exist for a binary mixture of two-size particles. These states reflect the amount of small and large particles present in the mixture: floating state (large-particle dominated), non-floating state (small-particle dominated) and transitional state. In the floating state, small particles inhibit contact between large particles. In the non-floating state, the large particles are in contact with each other and the small particles mainly fill the voids between large particles. In the transitional state, small particles partially fill the gaps between large particles and large particles are only partially disconnected. It has been shown that the densest state possible, where there is the minimum number of voids in the binary mixture, is obtained in the transitional state [16,40].

The packing properties of the SRMs described earlier may provide useful information regarding the expected mechanical behavior of the mixtures. However, the way the load is transferred within the mixtures depends primarily on the skeleton material [25,50]. According to the concept of skeleton material, a skeleton is formed when particles of the same material are in contact with each other and are able to transfer loads. The material forming the skeleton becomes the matrix material that governs the overall mechanical behavior of a mixture. In the case of SRMs, two well-defined matrix materials can be expected: (i) a soil matrix characterized by stiff soil-like behavior for mixtures with low VRC; and (ii) a rubber matrix that will produce a soft rubber-like response for mixtures with higher VRC. Depending on the aspect ratio, however, transition matrixes can also be formed as described later. In Table 3, a schematic summary of rubber-soil interaction in mixtures with different VRC and aspect ratios is reported. Distinct skeleton materials, particle level phenomena and macroscale responses are identified.

Table 3.

Schematic summary of rubber-soil interaction in mixtures with different VRC and aspect ratios (modified from [25]).

In the case of D50R << D50S mixtures (i.e., soil grains larger than rubber particles), rubber particles tend to fill the voids between soil grains in mixtures with low VRC, but then eventually separate and replace soil particles as VRC increases [50]. Mixtures with intermediate VRC values may experience the development of soil-to-soil contacts as the confining pressure increases, so that transition mixtures behave like rubber-like at low confining pressure and soil-like at high confining pressure.

In the case of D50R >> D50S mixtures (i.e., soil grains smaller than rubber particles), rubber particles tend to float within the soil skeleton in mixtures with low VRC. For intermediate values of VRC, mixtures exhibit consistent behavior at all stress levels and there is no transition from rubber-like to soil-like with increasing confining pressure [25].

In the case of D50R ≈ D50S mixtures (i.e., soil grains the same size as rubber particles), mixtures behave like D50R >> D50S mixtures for VRC ≤ 50%, where rubber forms peculated structures and soil-soil grain interaction exists. On the other hand, for VRC > 50%, D50R ≈ D50S mixtures behave like D50R << D50S mixtures, where soil forms peculated structures and rubber-rubber particle interaction takes place.

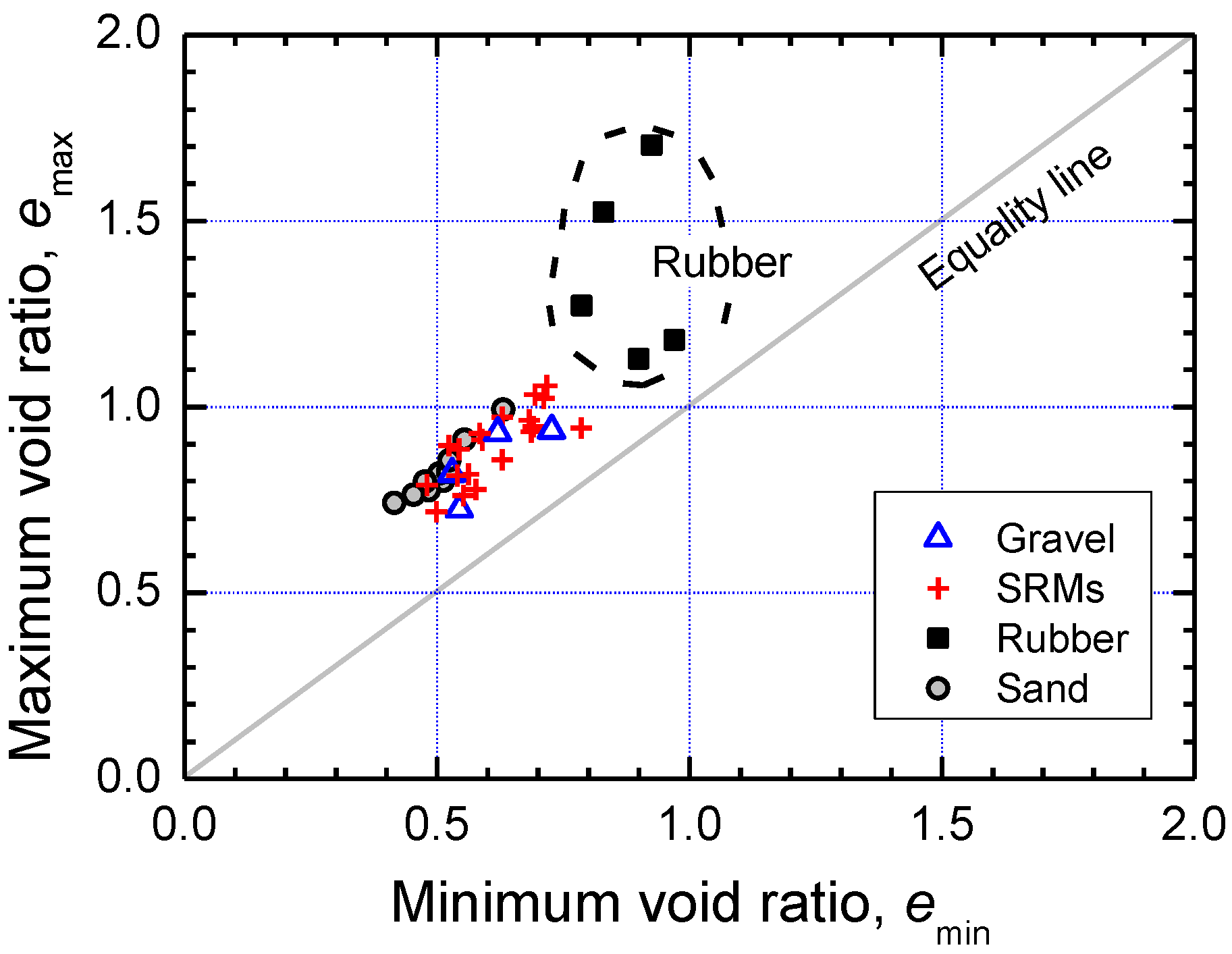

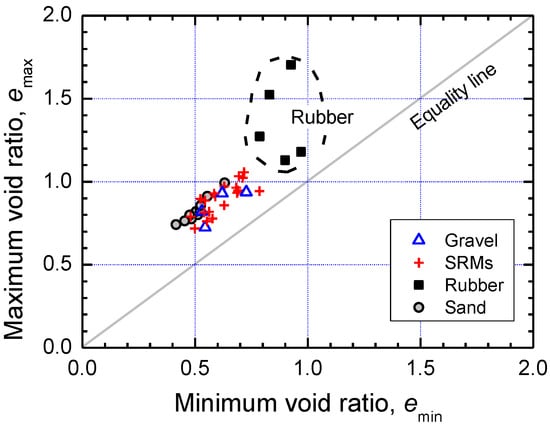

2.2. Maximum and Minimum Void Ratios of SMRs

Typical values of maximum and minimum void ratios (emax and emin, respectively) for pure sand, gravel and granulated rubber are shown in Figure 3. For completeness, typical values for SRMs are also reported. It is evident that the void ratio values of rubber are higher than those of granular soils. This is due mainly to the higher angularity of rubber particles and the lower specific gravity (Gs). It is worth mentioning that the smaller the rubber particles are, the higher the emax value of the pure rubber is.

Figure 3.

Typical maximum and minimum void ratios for rubber, sand and rubber ([Data points form: [27,40,51]).

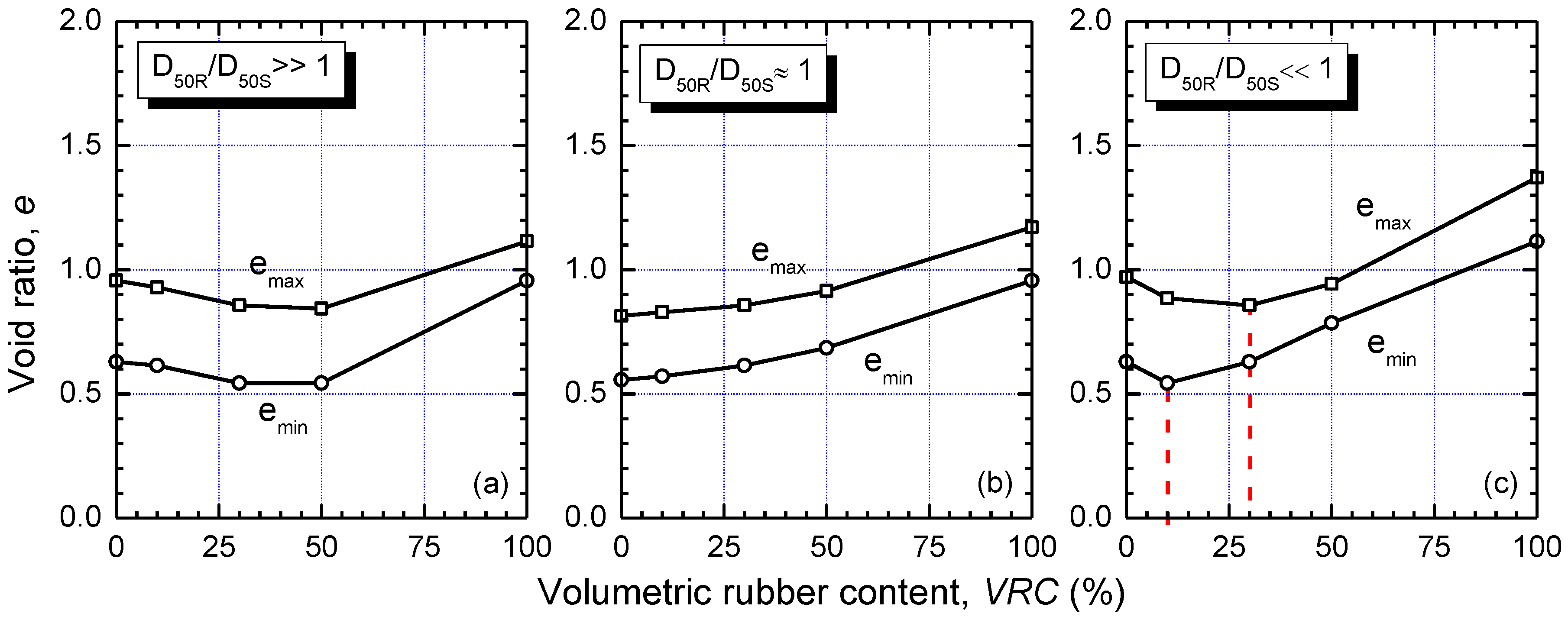

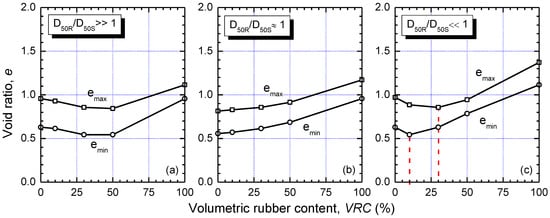

The variation of emax and emin of SRMs can be better described by looking at the packing density that depends on the aspect ratio. As shown in Figure 4a, in the case of D50R >> D50S mixtures, the minimum values of the emax and emin (densest states) typically occur at VRC ≈ 50% [25,40,41,52]. Alternatively, for mixtures with aspect ratio D50R ≈ D50S, the emax and emin values increase with increasing VRC (Figure 4b). Because rubber and soil have a similar particle size, no packing phenomenon takes place [40,41,53]. On the other hand, as shown in Figure 4c, in the case of D50R << D50S mixtures, the minimum values of the emax and emin takes place for VRC ≈ 10-30% [40,41,53,54].

Figure 4.

Variation of maximum and minimum void ratios for SRMs with different VRC and aspect ratios (a) D50R >> D50S, (b) D50R ≈ D50S, and (c) D50R << D50S (Data points from: [26,40,54]).

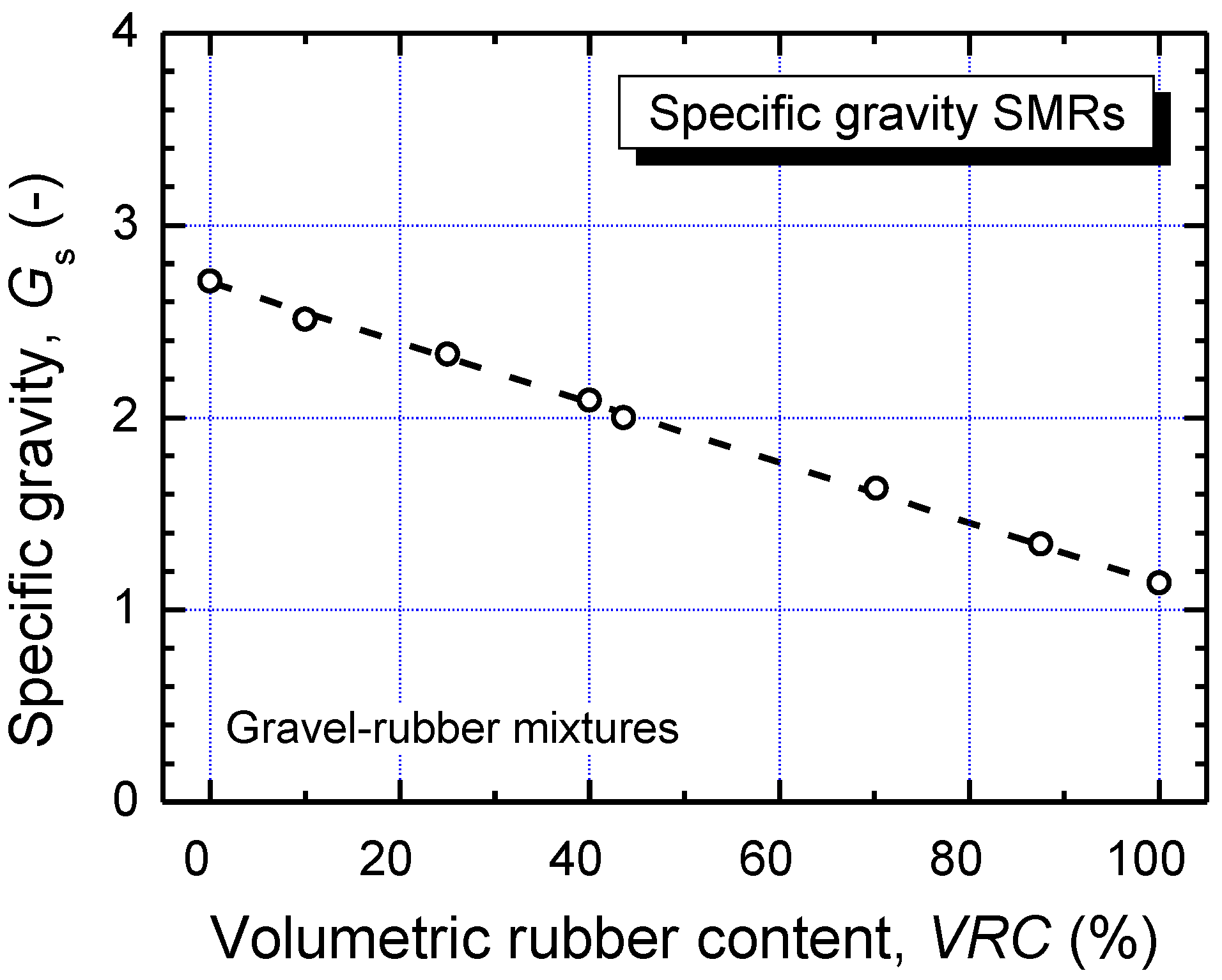

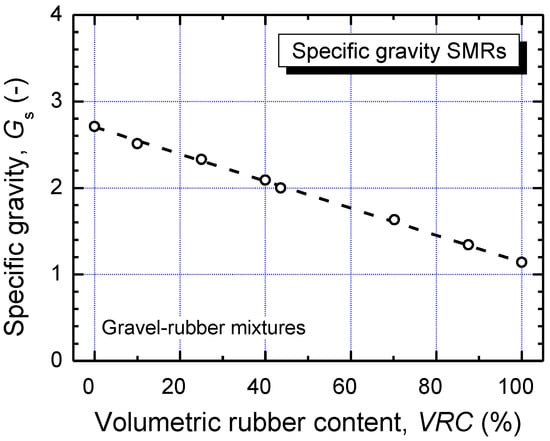

2.3. Specific Gravity for SRMs

Granulated rubber is a lightweight material. Its specific gravity (Gs) may vary between 1.02 and 1.27 [10,11,55] (the higher Gs being for rubber inclusive of steel wires and textile reinforcement), which is half of that of typical soils (Gs = 2.5–2.8).

In the case of SRMs, experimental evidence has shown that, generally, the Gs decreases linearly with increasing VRC. For the sake of completeness, an example of Gs for gravel-rubber mixtures is reported in Figure 5 [26,27].

Figure 5.

Specific gravity of gravel-rubber mixtures (Data points from: [26,27]).

2.4. Compaction Properties of SRMs

For the satisfactory performance of SRM structures, it is necessary to properly control the compaction and correctly evaluate the physical properties of compacted SRMs. Similar to conventional soils, laboratory compaction tests represent the best method to understand the sensitivity of compaction to the properties of SRMs (shape and distribution of grains, mineralogy, water content, etc.) and to the given actions (compaction methodology and energy). Hereafter, therefore, a summary of key findings from previous studies on the compaction properties of SRMs is reported.

2.4.1. Compactability of Pure Granulated Rubber

The dry unit weight (γdry) of different types of compacted granulated rubber ranges from approximately 4 to 9 kN/m3 [25,26,27,37,42,47,50,56,57] and typically increases with increasing rubber size and steel wire content in the rubber [57]. Experimental investigations, however, have shown that moisture content [55] and energy level [55,57] have little or negligible effects on the compactibility of granulated rubber evaluated by conventional Proctor compaction tests. On the other hand, [42] reported that vibratory compaction is not suitable for pure granulated rubber.

2.4.2. Compactability of Granular Soil-Rubber Mixtures

Much research has been conducted on sand-rubber mixtures to assess their compactibility. The addition of rubber results in a decrease in γdry proportional to the added percentage of rubber [11,56], which provides the lightweight advantage compared to using pure soils [58].

Edil and Bosscher [10] reported that the rubber content is the main factor influencing the γdry of sand-tire chip mixtures, whereas water content and compaction energy effects are insignificant. Also, vibratory compaction is mostly ineffective for compacting sand-tire chip mixtures [10,42]. Lee et al. [56] pointed out that the γdry values may differ depending on the aspect ratio D50R/D50S. Specifically, for any given VRC, the minimum value of γdry is attained for the D50R/D50S = 1 because for other values of the aspect ratio, smaller particles can easily fill the voids between larger particles resulting in a higher density [56]. Lee et al. [50] and Kim and Santamarina [25] showed that for the case of D50R/D50S = 4 and 10, the γdry decreases almost linearly with the increasing of the rubber content. Similar trends were recently reported by Tasalloti et al. [27] for gravel-rubber mixtures with D50R/D50S = 4.

2.4.3. Dry Unit Weight of SRMs

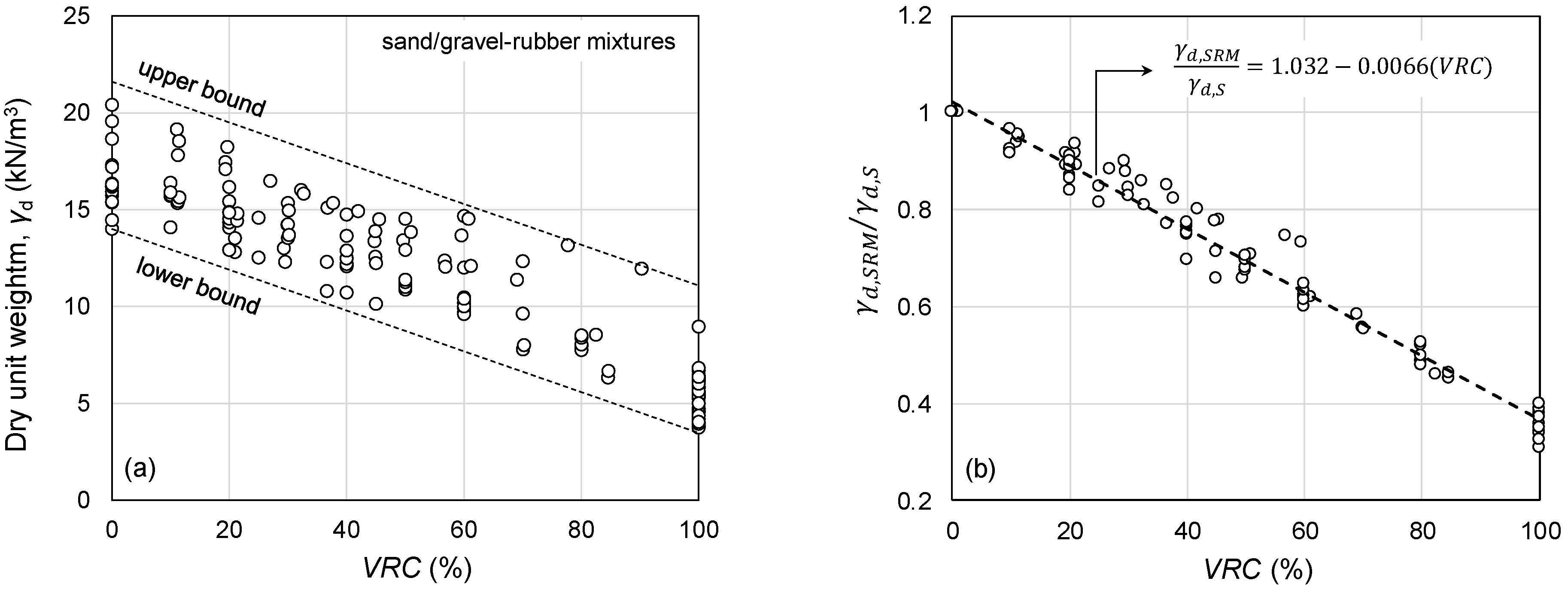

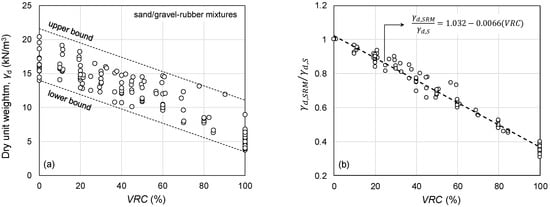

A compilation of compaction test results reported by various studies [25,27,37,42,47,50,56,59] showing the effect of the VRC and aspect ratio on the γdry and void ratio of SRMs, is presented in Figure 6.

Figure 6.

Effect of rubber content on (a) dry unit weight and (b) normalized unit weight of SRMs (Data points from: [25,27,37,42,47,50,56,59]).

The γdry of pure soils (γdry,soil) typically varies between 14 to 21 kN/m3, while that of pure rubber (γdry,rubber) ranges between 4 and 9 kN/m3. The γdry of SRMs (γdry,SRM) has intermediate values and decreases with increasing VRC. Overall, the data points appear to be largely scattered across the entire range of VRC (Figure 6a) reflecting the fact that both the soil and the rubber may have different intrinsic properties (e.g., specific gravity, particle size and shape, etc.). However, it can be seen that the addition of rubber to soil results in a decrease of γdry proportional to the added percentage of rubber.

In Figure 6b, the same data points are replotted as the ratio of γdry of SRMs (γdry,SRM) to γdry of the parent soil (γdry,soil) vs. VRC relationship. The normalized data are much less scattered, regardless of the type and size of rubber used in the investigations. If a linear mixing model is superimposed on the data, it can be seen that for VRC > 60% the data points are mostly coincident; while, for rubber fractions with 20% < VRC < 60%, some of the data are slightly above or below the linear model because, in the case of SRMs with higher aspect ratio, small particles fill the gaps between large particles [25,41,50].

2.5. Permeability of SRMs

Many geotechnical and geo-environmental problems may require consideration of water flow through SRMs. This involves the evaluation of the coefficient of permeability within the SRMs, which due to the granular nature of SRMs is usually determined by constant head permeability test.

2.5.1. Permeability of Granulated Rubber

Humphrey and Sandford [55] performed large scale permeability test on various tire chips (particle size in a range of 13 to 76 mm) at different applied deformation. The result showed that permeability decreased by increasing deformation (i.e., decreasing volume or void ratio). Also, the permeability of pure tire chips was in the range of 1.5 to 15 cm/s which is similar to that of clean gravels.

Moo-Young et al. [57] conducted permeability tests on various pure tire shred sizes compacted at modified proctor energy and results showed that the hydraulic conductivity increased with the tire shred size. The permeability was reported to be 0.2 cm/s and 0.82 cm/s for tire shred sizes of <50 mm and 200–300 mm, respectively. In similar studies, Ahmed and Lovell [42] reported the permeability of pure rubber in the order of 0.54 to 0.65 cm/s for rubber size of 25.4 mm, while Edinçliler et al. [60] found the permeability of compacted tire shreds in the range from 0.75 to 2.0 cm/s (similar to gravelly soil).

2.5.2. Permeability of Sand-Rubber Mixtures

Masad et al. [11] performed permeability tests on pure Ottawa sand, pure tire chips (<4.75 mm) and SRMs with VRC = 50% on compacted samples to 90% relative density at various confining pressures. The experimental results showed that by increasing the confining pressure, the permeability of pure tire chips decreased more rapidly than pure sand and SRMs. Also, at any given confining pressure (σ3), the permeability of pure tire chips was lower than other tested materials. For instance, the permeability at σ3 = 200 kPa for pure sand, pure tire chips and SRMs was 2.7 × 10−3, 1.5 × 10−3 and 2.4 × 10−3 cm/s, respectively.

According to Edil and Bosscher [10], the permeability of pure tire chips, pure sand, and VRC = 50% at a hydraulic gradient of 0.6 was 0.8, 0.07 and 0.05 cm/s, respectively. They also mentioned that permeability decreased by increasing applied normal stress on the specimen. This is, under larger stresses, due to the high compressibility of the rubber, smaller voids between particles are expected leading to a reduced hydraulic conductivity.

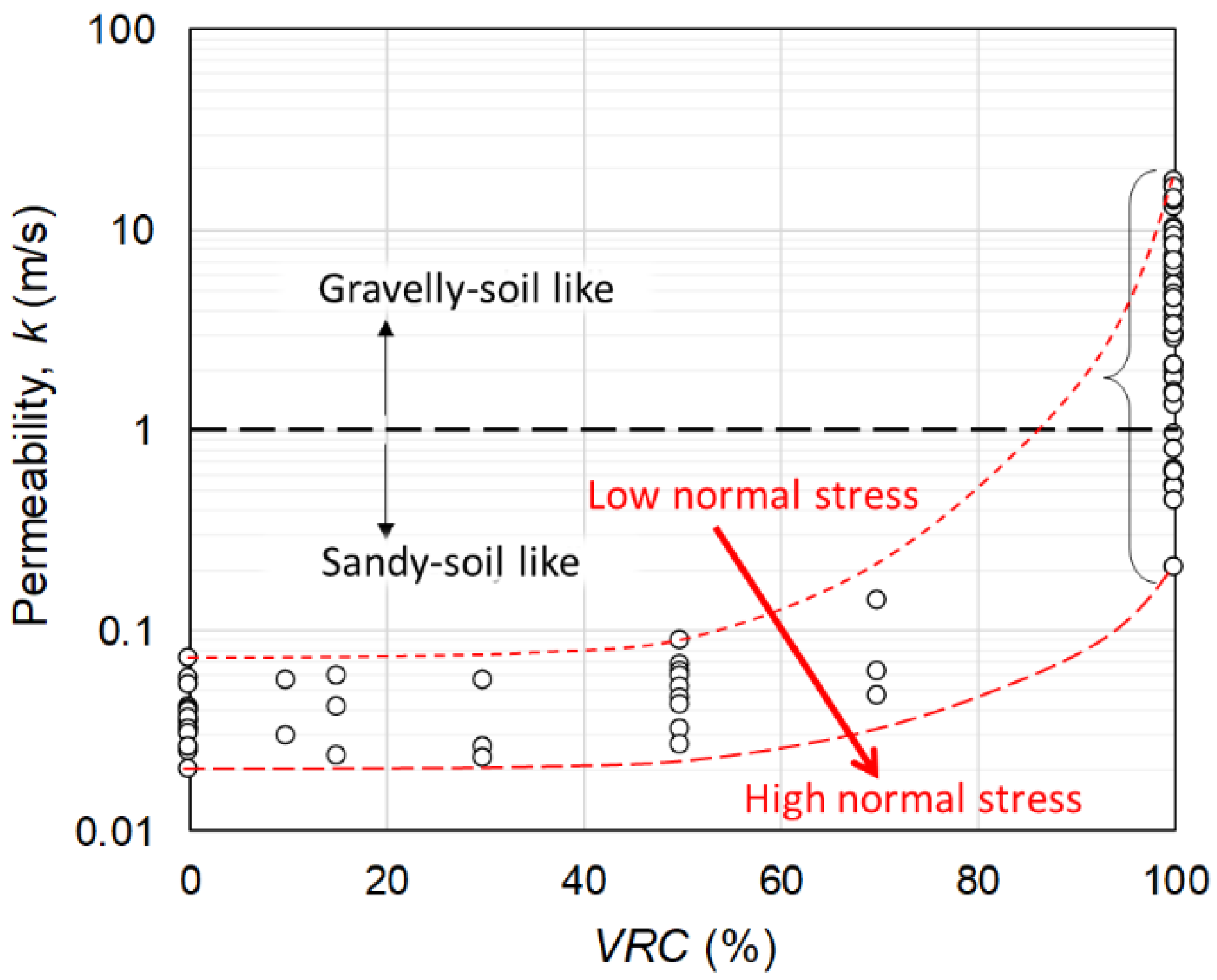

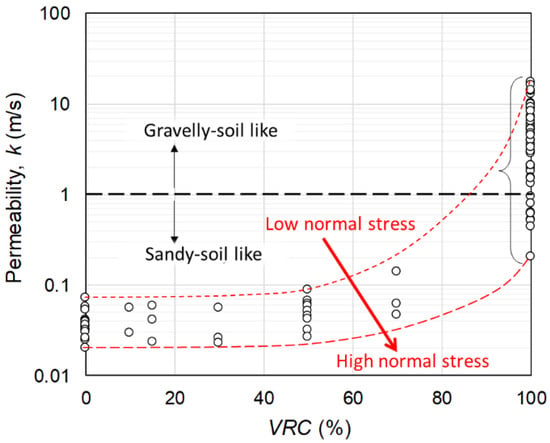

Figure 7 presents a summary of permeability values for SRMs reported in various studies. It is evident that for the majority of mixtures (i.e., 0 < VRC < 60%), the effect of VRC on permeability is minimal and the permeability is similar to that of sandy soil. However, for pure rubber, the permeability is much higher and typically is comparable to that of gravelly soil.

Figure 7.

Variation of SRM permeability with VRC and normal stress (Data points from: [10,53,55]).

2.6. Compressibility Characteristics of SRMs

Compressibility or the capability of SRMs to decrease in volume when subjected to an applied load is one of the most important parameters required in design considerations. For conventional soils having rigid particles such as sand and gravel, any change in volume is due to the movement, rotation and rearrangement of non-compressible particles [56]. The compressibility of SRMs, however, is completely different than that of granular soils, due to significant differences in the elastic modulus of the rigid particles of the host soil and that of the soft rubber particles. Moreover, under normal stress, not much volume change is associated with individual particles of rubber (Poisson’s ratio of pure rubber ν ≈ 0.5; for comparison, that of granulated rubber is found to be between 0.20 and 0.32 [55]) and distortion is the main phenomenon that occurs in pure rubber specimens while being loaded [55,57,61].

Pure rubber. Humphrey and Sandford [55] investigated the one-dimensional compression (1DC) of pure tire chips with and without steel wires and reported higher compressibility for tire chips with steel wires. Moo-Young et al. [57] also performed 1DC and indicated that the compressibility of pure tire shreds increased with increasing rubber size. For instance, the vertical settlement at 100 kPa stress for tire shred <50 mm and 200–300 mm was 22% and 45%, respectively.

Yang et al. [61] conducted 1DC and isotropic compression (IC) tests on pure tire chips (poorly graded with grain size of 2–10 mm). Both tests showed strain hardening against increasing stress, and more volumetric strain was observed in IC because the average stress was greater than 1DC.

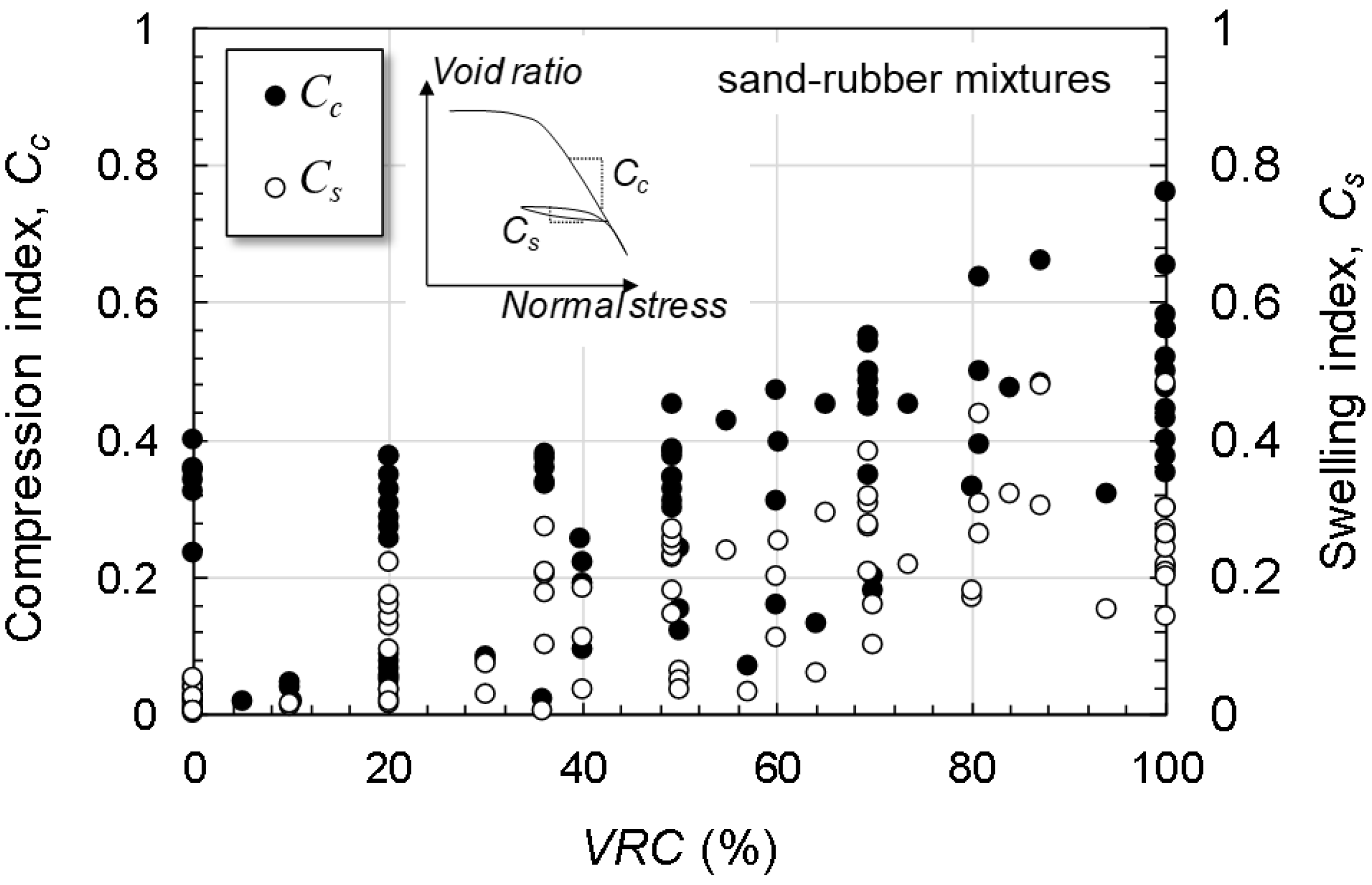

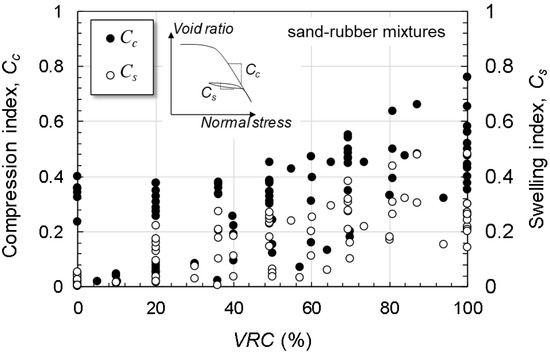

Sand-rubber mixtures. 1DC tests on sand-rubber mixtures have indicated that typically the compressibility increases with increasing GRC [10,25,34,35,42,50,56,62,63]—which is due to the more rubber-rubber contact and higher compressibility of tire chips compared to sand grains, but it could be reduced by increasing the confining and overburden pressures [42]. Moreover, in such mixtures, the majority of strain accumulation happens within the first cycle of load [10,35]. As shown in Figure 8, an increase in compression index (Cc) and swelling index (Cs) is detected for mixtures with rubber inclusions compared to pure sand due to the lower shear modulus of rubber [35,46,64].

Figure 8.

Effect of rubber content on the compression index (Cc) and swelling index (Cs) (Data points from: [10,25,34,35,42,46,50,55,56,61,63]).

It has been reported by Rao and Dutta [62] that under repetitive loading between 0 and 225 kPa, permanent deformation for pure sand and sand with 20% rubber at 1000 load-cycles was 0.45% and 2.04%, respectively. Further load-cycles did not increase permanent deformation. In addition, rubber size had no influence on the compressibility of mixtures in repeated loading.

Ngo and Valdes [65] investigated the creep behavior of sand-rubber mixture in 1DC apparatus and reported that both the initial strain and the creep strain increased with increasing VRC. More importantly, the strain rate did not decrease noticeably after 55 days of applied stress, thus, the time-dependent behavior of sand-rubber mixtures is required to be considered in practical application. They also reported that the creep behavior of sand-rubber mixtures was temperature independent.

Comparison between 1DC and IC tests on sand blended with granulated tire rubber indicated that residual strain increased as VRC increased, and it was greater in 1DC compared to IC. This is mainly due to the interlocking effect and side-wall friction with rubber particles and rigid boundary in 1DC [63].

Lee et al. [56] reported that in 1DC tests, by increasing D50R/D50S, the compressibility of the mixture decreased for a given rubber content and applied stress because generally larger rubber particles have less angularity and irregularity compared to the smaller size. Nevertheless, no effect of D50R/D50S was observed for the mixture with VRC < 20%.

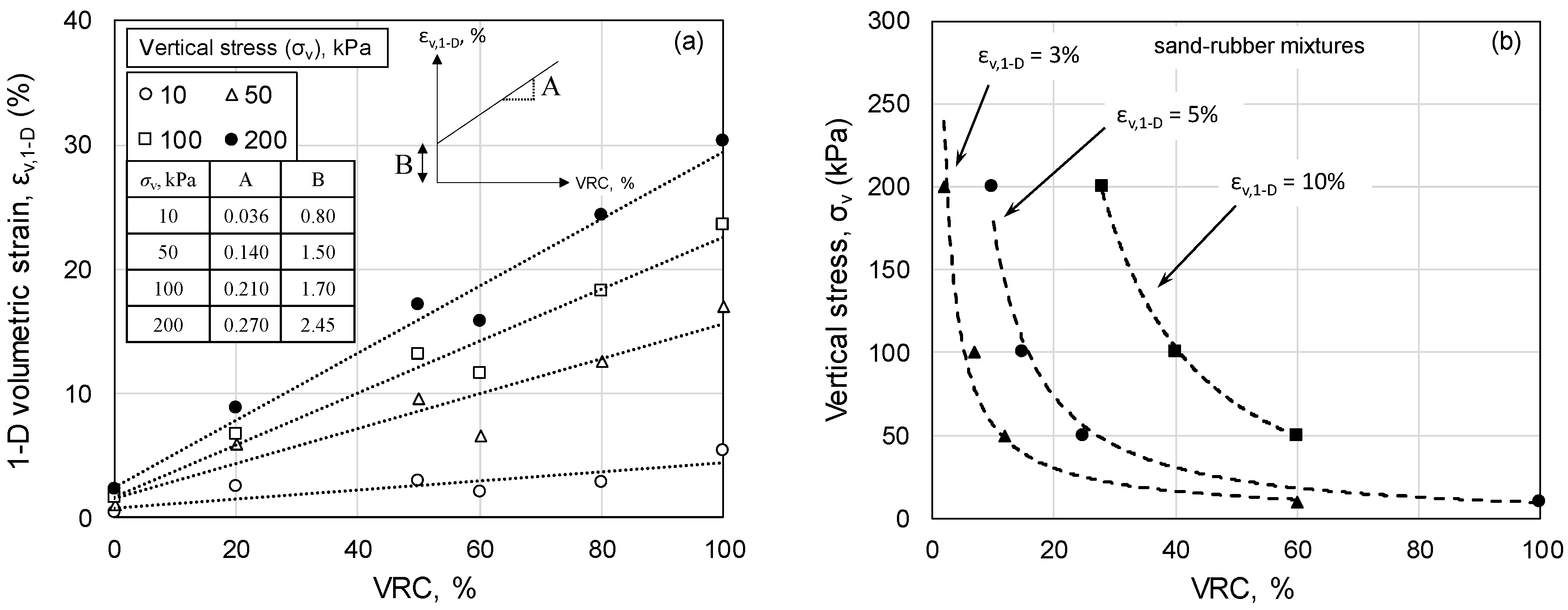

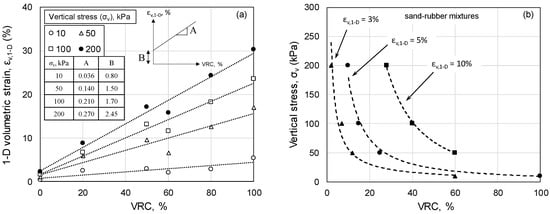

Volumetric Strain and Constrained Modulus of SRMs

The effect of the VRC on the 1DC volumetric behavior reported in the literature is illustrated in Figure 9a. It is evident that at any given vertical stress, by increasing VRC, the 1DC volumetric strain increases linearly from a minimum value for pure granular soils to a maximum value for pure rubber). At lower vertical stress levels (i.e., 10 kPa) the effect of VRC on 1DC volumetric strain is marginal, while at higher vertical stresses (i.e., 100 and 200 kPa) is more pronounced. Trends for volumetric strains of 3%, 5% and 10% for various VRC and vertical tress are reported in Figure 9b for completeness.

Figure 9.

1-D compressibility of SRMs (a) effect of VRC on 1-D volumetric strain and (b) variation of vertical stress against VRC at different level of volumetric strain (Data points from: [46]).

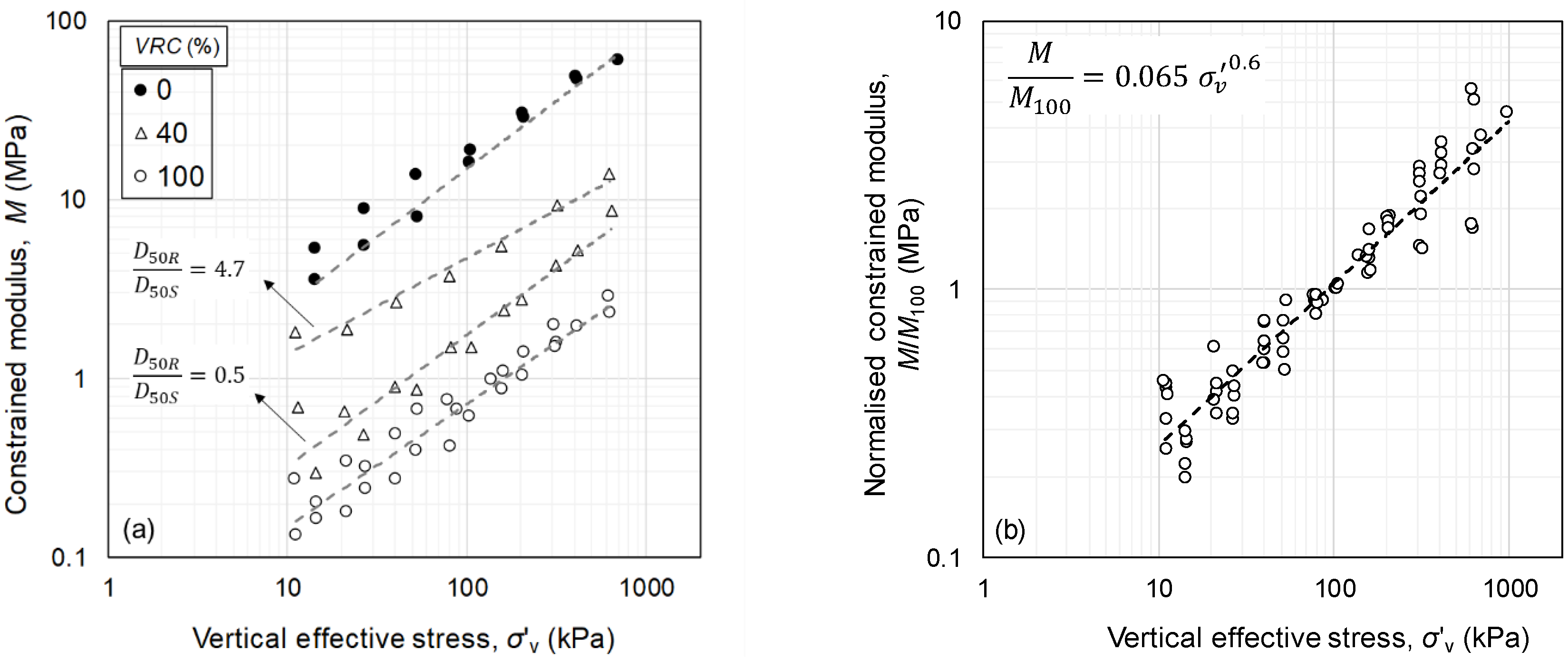

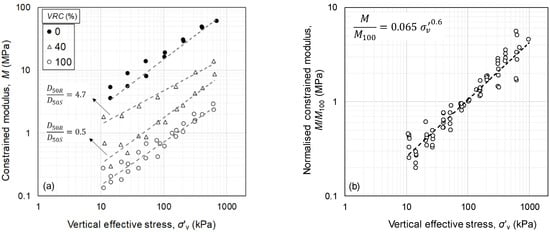

Figure 10 and Figure 11 present the constrained modulus (M) calculated from 1DC tests available in the literature for pure soil, pure rubber and SRMs with VRC = 40%. The difference between the constrained modulus of pure soil and pure rubber is in the order of 1000 times. By increasing rubber in the mixture, constraint modulus decreases. In addition, the effect of vertical effective stress () on constrained modulus is more significant for mixtures with higher VRC. Moreover, it appears that the aspect ratio also plays an important part. The higher the aspect ratio, the lower the constrained modulus as shown by the data points reported for VRC = 40% and D50R/D50G = 4.7 and 0.5. Yet, as shown in this paper, if the constraint modulus of SRMs at any is normalized with the constraint modulus at 100 kPa (M100), it appears that the normalized constrained modulus () yields a linear trend with for various VRC in a log-log scale (Figure 10b).

Figure 10.

Effect of VRC and on (a) constrained modulus for pure soil, pure rubber and SRM (VRC = 40%) and (b) normalized constrained modulus (Data points from: [25,50,56]).

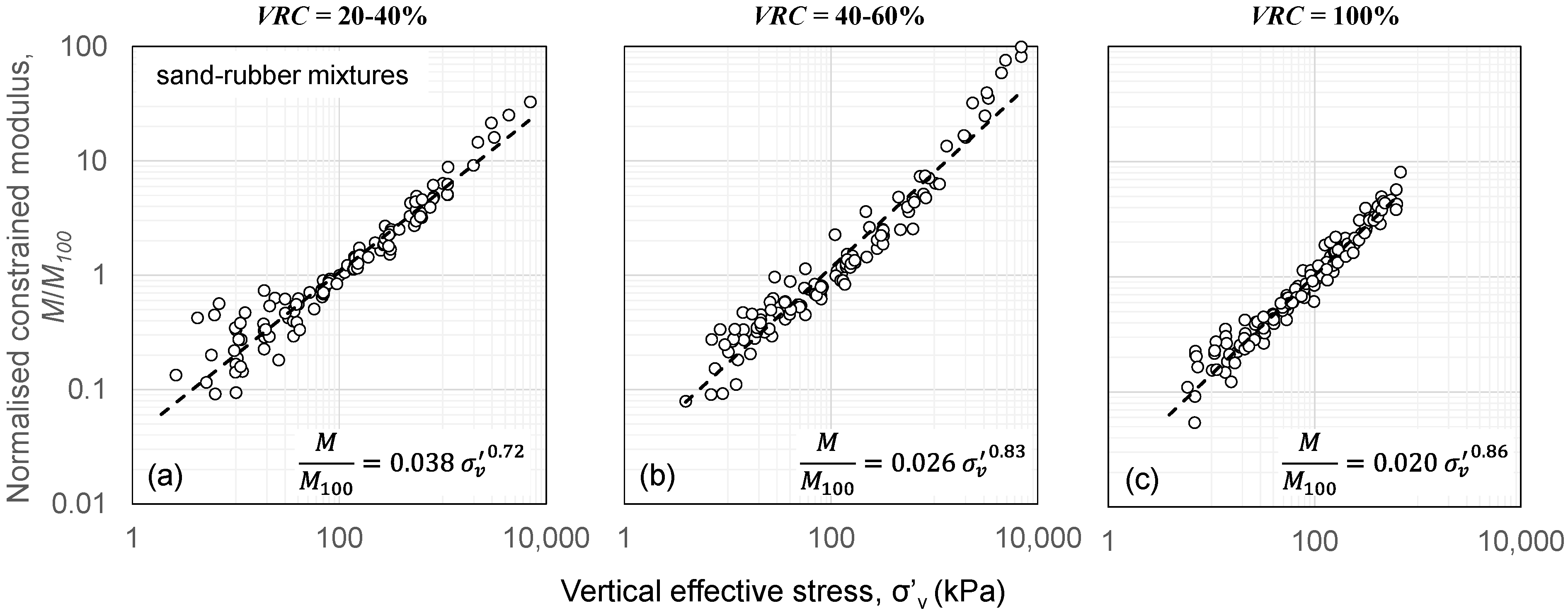

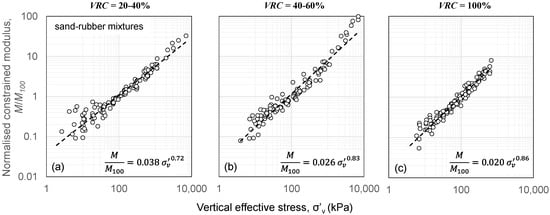

Figure 11.

Effect of VRC and on normalized constrained modulus for (a) VRC = 20–40% (b) VRC = 40–60% and (c) VRC = 100% (Data points from: [10,25,34,35,42,46,50,55,56,61,62,63,64]).

2.7. Shear Strength Characteristics

The shear strength of any soil is the result of friction and interlocking between particles, and possibly cementation or bonding at particle contacts. Due to interlocking, particulate materials may expand or contract in volume as they are subject to shear strains. Alike conventional soils, shear strength is one of the most important characteristics contributing to the performance also for SRMs. Various parameters influence the overall mechanical behavior of SRMs which can be divided into three main categories: (i) parameters associated with the parent soil such as particle mineralogy, size, shape, etc. (ii) parameters related to the granulated rubber including size, shape, content by volume or mass, etc. and (iii) test conditions such as confining pressure, strain rate, specimen density, mode of shear, etc. Any combination of these parameters affects the mechanical behavior of the mixtures. Previous studies mainly focused on mixtures of sand with scrap tires (in various shapes). Different percentages of scrap tires (either by weight or volume) were added to sand to assess the shear behavior of sand-rubber mixtures using various apparatus, including direct shear devices and triaxial cells, either on dry or fully saturated specimens. The majority of previous studies focused on a maximum rubber content of 40% by weight. Within this threshold, the behavior of SRMs is mainly governed by rigid particles (i.e., hard-grained parent soil particles), and the overall behavior of mixtures is known as soil-like behavior. In this section, the mechanical behavior of SRMs is described based on reported experimental results of either direct shear or triaxial tests.

2.7.1. Evaluation by Direct Shear Tests

Most of the studies on the shear strength of sand and granulated rubber mixtures have been conducted using direct shear box apparatus.

Pure rubber. Humphrey and Sandford [55] carried out a large-scale direct shear test (square shear box with dimensions of 286 × 286 × 228 mm) on pure tire chips (particle size in the range of 13 to 76 mm). They noticed that even at a 30 mm horizontal displacement, no peak in shear stress was detected, so the friction angle and cohesion were calculated based on the deformation equal to 10% of the length of the shear box. The friction angle and cohesion were reported to be in the range of 19° to 26° and 8 to 11 kPa, respectively. Typically, the shear strength of cubic-shaped tire chips was higher than the flat-shaped ones because better packaging and particle interlocking are associated with cubic-shaped rubber.

Yang et al. [61] also performed a direct shear test on pure tire chips (particle size in the range of 2–10 mm) at normal stress in the range of 0 to 82.7 kPa. Results indicated that most of the tests exhibited no well-defined peak shear stress, thus friction angle and cohesion corresponding to 10, 20 and 30% of horizontal displacement was 32° and 0, 42° and 5.7 kPa and 45° and 8.1 kPa, respectively. Moreover, they suggested that shear strength is independent of the tire chip size.

In a similar study by Moo-Young et al. [57], results of a large direct shear test (610 mm by 610 mm by 305 mm) on various pure tire shred sizes (i.e., from <50 mm to 300 mm) indicated that, generally, shear strength increased with tire shred size. However, tire shred size of 50–100 mm exhibited the highest shear strength that could be due to the steel wire within tire shreds and the highest density (lowest void ratio) among other tire shred sizes. The friction angle for pure tire shred was between 15° to 29°, while cohesion was nearly 12 kPa.

Sand-rubber mixtures. Foose et al. [66] performed a direct shear test (diameter of 279 mm and height of 157 mm) on sand blended with three types of shredded tires (i.e., based on length: <50 mm, 50–100 mm and 100–150 mm) at various VRC equal to 0, 10, 30 and 100%. They mentioned that five factors influenced the sand-shredded tire mixtures including (i) normal stress, (ii) sand matrix density, (iii) rubber shred content, (iv) rubber shred length and v) rubber shred orientation, in which the first three factors had the most effect. A bilinear shear failure envelope was observed for mixtures (ϕ1 for initial friction angle and ϕ2 for the latter portion of failure envelope). By increasing VRC, ϕ1 increased and all mixtures showed higher ϕ1 than pure sand. For instance, ϕ1 for pure sand and VRC = 30% was 35° and 63°, respectively. It was also mentioned that no peak in the shear stress was reached even at a 25 mm horizontal displacement for sand-shredded tire mixtures.

Edil and Bosscher [10] also carried out a direct shear test (shear ring with a diameter of 305 mm) on sand-tire chips mixtures. The shear strength of all mixtures was higher than pure dense sand. However, at elevated normal stress (e.g., σn > 80 kPa), the influence of tire chips was lessened. They mentioned that the orientation and tire chip content especially at the shearing zone were the main factors involved in increasing the shear strength of the mixtures.

The experimental investigation reported by Tatlisoz et al. [36] on mixtures of tire chips (particle size in the range of 30 to 110 mm) and two types of soil (i.e., sand and sandy silt) in a large direct shear ring (280 mm in diameter and 300 mm in height) showed that by increasing tire chip content (up to 30%), the shear strength for both types of sand increased. Friction angle for sand-tire chip increased with increasing VRC, while no change in friction angle was detected for sandy silt-tire chip mixtures. For the latter, the apparent cohesion increased, which resulted in an increase in the shear strength of mixtures.

Ghazavi and Sakhi [30] emphasized that not only normal stress, tire shred content, and density influence the shear strength of sand-rubber mixtures, but also the rubber aspect ratio plays an important role. They conducted extensive tests on various shredded tire sizes (2, 3 and 4 mm in width) and content (15, 30 and 50% by volume) in a large-scale direct shear (300 mm by 300 mm). Results showed that for any given shred width, there is a particular shred length (optimum rubber aspect ratio) that provides the highest shear strength regardless of mixture density and rubber content. The increment in the friction angle at the optimum rubber aspect ratio was approximately 25%. An apparent cohesion was also detected in sand-rubber mixtures. They explained that there would be a possibility of sand grains penetrating the shred tire, thus during shearing, a sand-rubber bridge could form and result in apparent cohesion. Ghazavi [47] also reported similar observations on the shear strength of sand-rubber mixtures tested in a direct shear apparatus (63 mm in diameter and 20 mm in height). It was mentioned that a marginal enhancement of shear strength could be associated with sand-rubber mixtures having up to 20% rubber content. Beyond this threshold, the shear strength was lower than pure sand. The highest shear strength was reported for an optimum GRC = 15%.

Shear strength characteristics of sand blended with one type of tire crumb and two types of rubber buffing (with an aspect ratio of 3 and 7) were assessed through a series of standard direct shear tests (60 mm × 60 mm) by Edinçliler and Ayhan [44]. The GRC varied between 0% and 100% and normal stresses of 25, 50 and 100 kPa were applied. Although the shear strength of sand-rubber mixtures increased with the increasing GRC, the friction angle exhibited a declining trend. The optimum GRC was reported to be 15% and any GRC beyond 30% resulted in a decrease in the shear strength compared to the sand alone.

In a similar study by Edinçliler et al. [60], large-scale direct shear tests (300 mm × 300 mm) were carried out on uniform well-graded medium sand mixed with tire crumb and two types of rubber buffing (with an aspect ratio of 3 and 7) under three different normal stress levels of 20, 40 and 80 kPa. The GRC varied from 0% to 100%. Results showed that the shear strength of sand was enhanced by adding rubber inclusions. In particular, the maximum peak friction angle achieved with GRC = 20% rubber was 42.6° for tire crumb and 45° for tire buffing with a higher aspect ratio. Generally, a higher aspect ratio of rubber particles showed higher shear strength. This could be justified by the greater contact area between tire buffing and sand particles. The apparent cohesion was insensitive to the rubber type and it was in a range of 8 to 14 kPa. Also, the initial slope of shear stress-horizontal displacement increased with the inclusion of rubber to sand. The effect of tire crumb inclusion on the shear strength of sand decreased with increasing normal stress.

For mixtures consisting of the same particle sizes of sand and rubber (i.e., D50R/D50S = 1.0), a continuous reduction of the friction angle (or shear strength) with increasing GRC was observed in direct shear tests by Lee et al. [64]. Also, a higher volumetric contraction was reported and associated with mixtures with higher rubber content. However, opposite trends were reported by Attom (2006) performed a direct shear test on mixtures of three types of sand with shredded tires with GRCs of 0, 10, 20, 30 and 40% [67]. The results showed an increase in friction angle with increasing shredded tire content. For example, the friction angle for 100% sand and sand with 40% shredded tire at 100 kPa was 36° and 49°, respectively (i.e., 36% increase in shear strength). This was justified by the contribution of the shredded tires to the shearing zone in which some of the shredded tires may resist the shearing. It was also shown that by increasing the initial dry density, the friction angle increased.

Gravel-rubber mixtures. Tasalloti et al. [27] and Chiaro et al. [17] reported results of medium-size direct shear tests (100 mm × 100 mm × 53 mm) on several mixtures made of angular gravel (D50 = 4), rounded gravels (D50 = 4) mixed with two rubber sizes (D50 = 5 and 2 mm). The VRC was 0, 10, 25, 40 and 100% and the vertical stress level was 6.5, 30, 60 and 100. In all cases, a continuous reduction of the friction angle (or shear strength) with increasing VRC was observed, similar to what was observed by Lee et al. [64] for sand-rubber mixtures with AR = D50R/D50S = 1.0. Moreover, higher volumetric contraction was reported with mixtures with higher rubber content. Also, it was reported that the small-size rubber particles produced slightly smaller friction angle values as well as a higher volumetric contraction compared to the large-size rubber particles when mixed with either the angular or the rounded gravels.

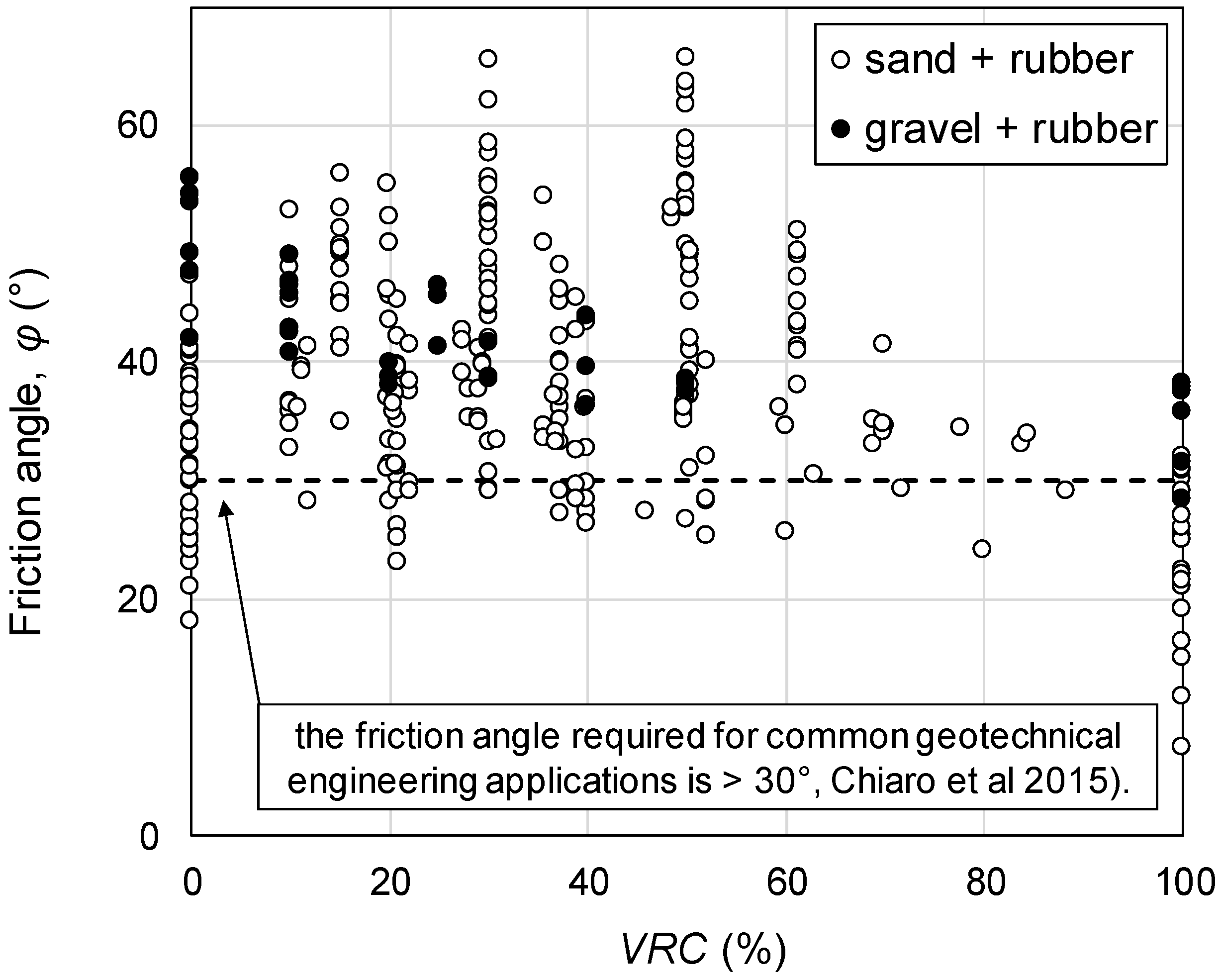

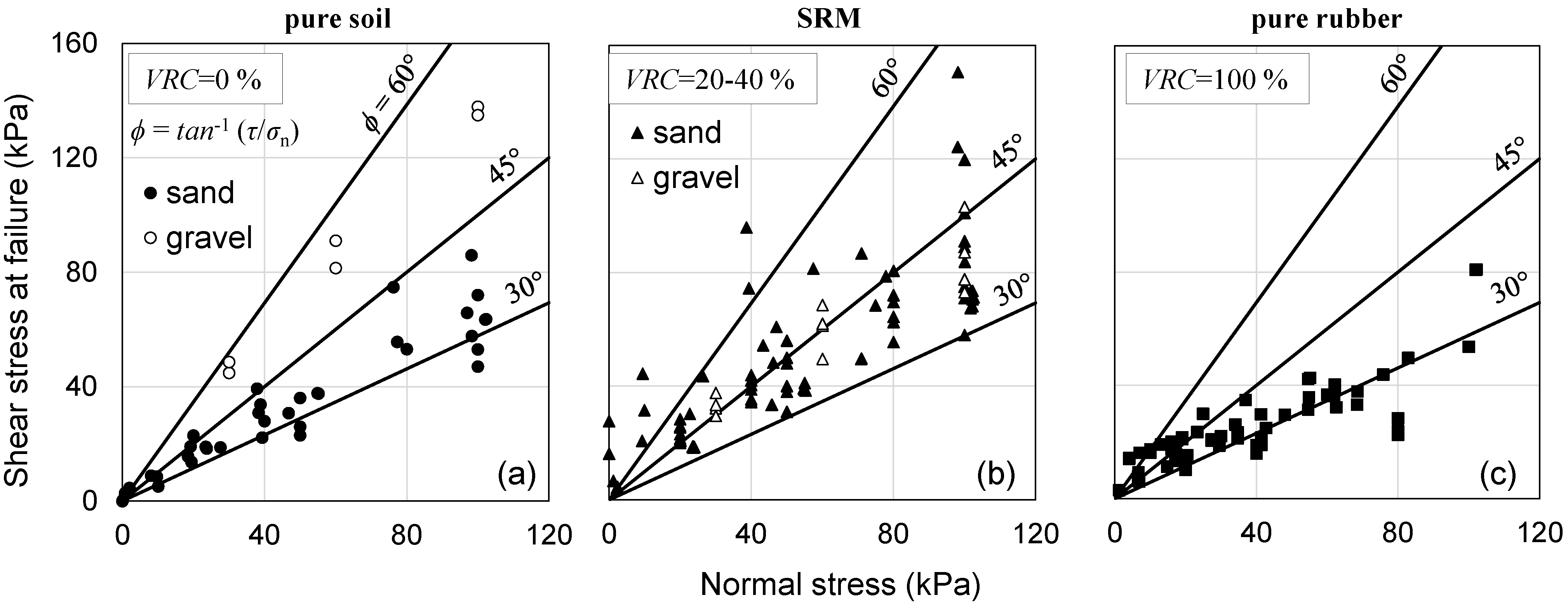

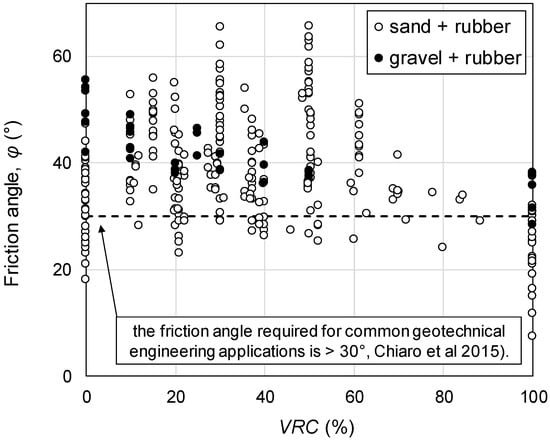

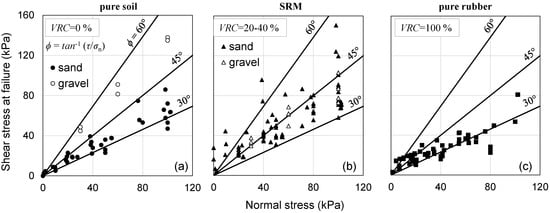

Summary. The friction angle and shear stress at failure in direct shear tests for various SRMs reported in literature are summarized and presented in Figure 12 and Figure 13, respectively. Although the friction angle of pure rubber is generally lower than pure soil, there is a range of VRC (i.e., 20% < VRC < 50%) in which the friction angle of sand-rubber mixtures seems to be higher than pure sand. This means that the shear strength of pure sand can be enhanced by mixing it with rubber. For these mixtures, the friction angle is between 26° and 62°.

Figure 12.

Variation of friction angle of SRMs form direct shear tests (Data points from: [11,27,30,35,36,44,47,54,55,57,60,61,62,64,66,67,68,69,70,71]).

Figure 13.

Shear strength for (a) pure soil, (b) SRM (VRC = 20–24%) and (c) pure rubber (Data points from: [10,17,27,44,47,55,57,61,66,67,72]).

Compared to sand-rubber mixtures, tests on gravel-rubber mixtures are still very limited. Yet, the available data to date suggest that the friction angle of gravel-rubber mixtures generally decreases with increasing rubber content, so that the addition of rubber does not enhance the strength of gravelly soils. Yet, on the other hand, it can be argued that the use of gravelly soils can enhance the mechanical properties of highly compressible and low-strength pure rubber as compared to sand.

2.7.2. Evaluation by Triaxial Tests

In addition to direct shear, many other relevant studies dealing with the shear strength of soil and granulated rubber mixtures have been carried out using the triaxial apparatus, as summarized hereafter.

Pure rubber. Wu et al. [73] investigated the shear strength of five different sizes of pure tire chips (grain size between 2 mm to 38 mm) in triaxial by applying a constant σ1 stress path. The friction angle and Young’s modulus for pure tire chips were reported to be in the range of 45° to 57° and 430 to 820 kPa, respectively. All tire chip sizes illustrated dilative behavior, and no cohesion was detected. They also separated the interparticle friction angle and the dilation angle in order to eliminate the effect of particle size on shear strength using the method proposed by Rowe and Taylor [74] and Taylor [75]. Results indicated that the interparticle friction angle was 44°–56°.

Triaxial tests on pure tire chips (2–10 mm grain size) showed almost a linear stress-strain behavior with up to 15% axial strain and then strain softening was observed. Volumetric contraction was detected during shearing because, at a small strain, tire chip particles move into available voids and then, at large strain, particles start to slide and move over each other (where dilation occurs). The initial modulus within the linear portion was between 720 to 920 kPa for confining pressures in the range of 20 to 60 kPa [61].

Sand-rubber mixtures. Masad et al. [11] performed consolidated drained triaxial tests on pure sand, pure tire chips (<4.75 mm) and SRMs with GRC = 50% at confining pressures between 150 to 350 kPa. Three different behaviors were reported for each specimen. For sand, a distinct peak and strain softening along with dilatation were detected, while a linear deviatoric stress-axial strain was observed for 100% tire chips without any peak (i.e., no failure) and an excessive volumetric contraction. For GRC = 50%, an intermediate behavior was reported. Opposite to natural soils, volume contraction increased with a decrease in confining pressure, and the effect of confining pressure was more pronounced for pure sand. Unlike other studies, a high cohesion (i.e., 82 kPa at 20% axial strain) was reported for pure tire chips, while the friction angle was just 15°. In addition, the elastic modulus decreased drastically for 100% tire chips compared to pure sand from nearly 50 MPa to less than 5 MPa. Lee et al. [31] also performed large-scale triaxial tests (150 mm in diameter by 300 mm in height) on pure tire chips (particle size in the range of 5 to 30 mm) and sand-tire chips (GRC = 40%) at various confining pressures. Linear stress-strain and linear volume contraction behavior were observed for pure tire chips, while an intermediate behavior between pure sand and pure rubber resulted in sand-tire chip mixtures.

Zornberg et al. [76] investigated the effect of tire shred aspect ratio, content and sand matrix relative density on the behavior of sand-tire shred mixtures. A large-scale triaxial apparatus (153 mm in diameter to 305 mm in height) was used. Tire shreds with widths of 12.7 mm and 25.4 mm and aspect ratios of 1, 2, 4 and 8 were mixed with sand at varying GRC between 0% and 100% and confining pressures of 48.3, 103.5 and 200 kPa. Linear stress-strain and contractive behavior were observed for rubber sand while dilative behavior was detected for pure sand. Also, axial strain at peak increased with increasing shred content. The effect of tire shred aspect ratio was minimal at low axial strain (<5%), but its effect at large strain was significant. They mentioned that the peak shear strength of mixtures increased with increasing tire shred up to GRC = 35% (optimum tire shred content) and decreased beyond that. Varying tire shred aspect ratio showed that the increase in shear strength of mixtures was more significant for aspect ratios greater than 4. In addition, no major effect was reported due to the sand matrix relative density on the shear behavior of sand-tire shreds. A shear mechanism for sand-tire shred was proposed, which was mainly composed of (i) shear strength contribution from individual sand and tire shred particles and (ii) reinforcement mechanism due to the tensile strength within tire shred, with the latter being more pronounced at low confining pressure.

Large-scale triaxial tests (300 mm by 600 mm) were conducted on flat rubber tire chips and sand by Bergado et al. [68]. GRC varied from 0 to 100% and σ′3 = 50, 100, 200 kPa. Unlike other studies, the shear strength decreased with increasing GRC, and the axial strain at peak increased significantly for mixture with 30% rubber (from 3% for pure sand to 16% for GRC = 30%). Minimum and maximum shear strengths were identified for pure rubber and pure sand, respectively. Similar results were reported by Youwai and Bergado [37] for sand-rubber mixtures (D50R/D50S ≈ 12) tested in triaxial apparatus. Isotropic consolidated drained tests on sand-rubber mixtures (GRC = 0 to 100%) showed that with increasing GRC, shear strength at the peak decreased, shear strain at the peak and also initial dilatancy increased (due to the higher deformability of rubber compared to sand). The peak friction angle decreased from 34° for pure sand to 30° for pure rubber. Almost a linear increase in shear strength was observed with increasing confining pressure.

Gotteland et al. [70] performed large-scale triaxial tests (150 mm by 300 mm) on sand and rubber (disk shape with a diameter of 28.1 mm and thickness of 10.4 mm with exposed steel wire) and investigated the effect of rubber disk orientation and GRC on the shear strength. Results indicated that the optimum rubber percentage was in the range of 20% to 40% with maximum shear strength at 34% and the horizontal orientation of rubber disks provides the highest shear strength followed by mixtures with alternately horizontal and vertical orientations. The behavior of mixtures was sand-like for specimens with GRC < 34% and rubber-like for GRC > 34%. Also, in terms of volumetric strain, similar to other studies, less dilation and more contractive behavior were observed with increasing GRC.

Sheikh et al. [35] carried out monotonic triaxial tests on sand mixed with 0% to 40% (by mass) of two types of rubber crumbs (D50R/D50S = 4.0 and 6.5). The test results indicated that peak deviatoric stress (qpeak) decreased by increasing rubber content (RC), while the axial strain corresponding to qpeak increased with increasing RC irrespective of the confining pressures applied. For instance, at the confining pressure of 207 kPa, qpeak decreased by 22% and 45% for RC = 10% and 30% (D50R/D50S = 4.0), respectively. Similar results were observed by Lee et al. (2007) for D50R/D50S = 0.25 in which the friction angle increased with decreasing VRC. Also, no peak and softening behavior was detected for mixtures with VRC > 40% [50]. On the other hand, Rao and Dutta [62] reported an almost marginal effect on the shear strength of sand-tire chips tested in triaxial apparatus. They used three sizes of tire chips (i.e., 10 mm × 20 mm, 20 mm × 20 mm and 20 mm × 10 mm) with up to 20% content by mass and indicated that friction angle remained almost constant while a small increase in cohesion was observed with rubber inclusion (around 14–19 kPa with 20% tire chips). However, initial tangent modulus and secant modulus decreased with the increase in RC (the reduction was minor at low confining pressure and substantial at a high confining pressure of around 270 kPa).

Fu et al. [77] also carried out monotonic triaxial tests on sand-rubber mixtures. Two types of rubber (i.e., granules and fibers) with 10% and 30% by mass were mixed with crushable sand (completely decomposed granite). Results showed that negligible improvement in the shear strength was observed by adding 10% rubber in the form of either granules or fibers. However, 30% rubber in the form of fibers increased the shear strength noticeably and decreased dilation. Later, Fu et al. [46] conducted triaxial tests on mixtures of rubber and sand and observed that the stiffness of sand decreases with the inclusion of rubber. In addition, a large strain (nearly 40%) was required for the ultimate strength of mixtures to be fully mobilized. More importantly, the effect of rubber type (rubber granules or buffing) was pronounced in shear strength since rubber buffing provided a reinforcing effect on the mixture. In a series of monotonic triaxial tests reported by Mashiri et al. [33] on sand-rubber mixtures with GRC between 0% and 40%, the peak deviator stress increased with the increase in GRC up to 35% and then decreased with further increase in GRC. However, the axial strain corresponding to peak deviatoric stress constantly increased with increasing GRC. The dilation of sand was also reduced by rubber inclusions. Based on the void ratio of mixture, Mashiri et al. [33] suggested three behavioral zones, including sand-like (GRC < 18%), sand-rubber-like (18% < GRC < 35%) and rubber-like (GRC > 35%). A dilatancy model was also proposed for rubber-sand mixtures. The model is based on the three-phase behavior including minimum volumetric strain, peak deviatoric stress and constant stress ratio.

Gravel-rubber mixtures. More recently, the effect of various rubber sizes on the mechanical behavior of gravel-rubber mixtures was studied by Pasha et al. [40]. Two types of gravel (i.e., sub-angular and sub-rounded) were mixed with three tire chips (D50R/D50S = 0.35, 1.2, 3.35). Results showed that irrespective of types of rubber or gravel, by increasing VRC shear strength decreased. However, mixtures with D50R/D50S = 3.35 exhibited greater shear strength at failure compared to the other aspect ratios because more gravel-gravel contact was formed, which resulted in higher shear strength. In addition, various rubber sizes yielded approximately the same shear strength for VRC = 100%. Effect of relative density of specimens on the mechanical behavior of gravel-rubber mixtures decreased with the increasing VRC, and no relative density effect was observed for VRC = 100%.

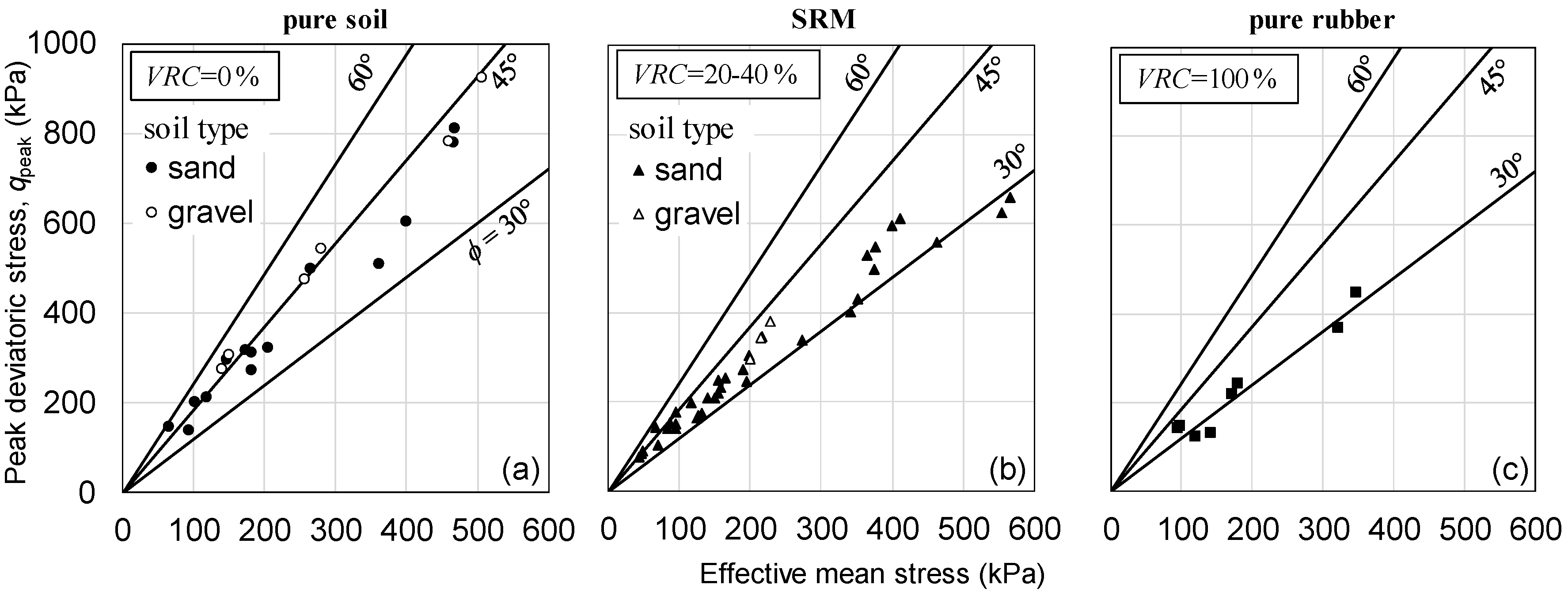

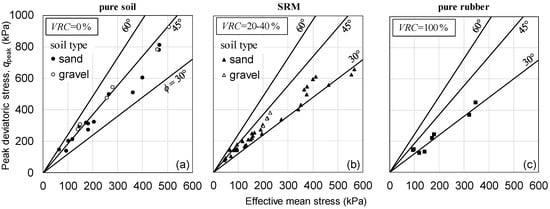

Summary. A summary of previous research on the strength properties of SRMs evaluated by triaxial tests is given in Figure 14 for pure soil, pure rubber and SRMs with VRC = 20–40%. Results indicated that the friction angle of SRMs is in the range of 25 to 45°.

Figure 14.

Shear strength from triaxial tests for (a) pure soil, (b) SRMs (VRC = 20–40%) and (c) pure rubber in triaxial tests (Data points from: [33,35,37,40,50,68,77]).

2.8. Dynamic Behaviour

The design of many geotechnical structures such as retaining walls, foundations and slopes subjected to cyclic shear loading conditions (e.g., earthquake or traffic loads) require the evaluation of the dynamic and cyclic response of SRMs, such as the small-strain shear stiffness (Gmax), shear modulus (G) degradation with increasing shear strain and damping ratio (D).

Small-strain shear stiffness. An experimental investigation was carried out on sand-rubber mixtures with D50R/D50S = 10 by Kim and Santamarina [25] using an oedometer cell equipped with bender element sensors. VRC varied between 0% and 100%. Results showed that due to the arching effect and incompressibility of rubber particles, the mean stress in sand particles increased for VRC = 20% compared to the pure sand; therefore, the shear velocity (Vs) was maximum for VRC = 20%. A significant reduction in Vs was observed for mixtures with VRC > 40%. In a similar study conducted by Lee et al. [50] on sand-rubber mixtures with D50R/D50S = 0.25, two distinct behaviors were observed for Gmax in k0 condition which were (1) rubber-like behavior for VRC > 60% and (2) sand-like behavior for VRC < 30%. For VRC = 40%, at low stress and high stress, the overall behavior was rubber-like and sand-like, respectively. At low confinement, sand particles are not in contact with each other, and rubber particles form the primary chain to transfer shear waves, while at high stress, rubber particles deform and consequently, sand particles form a chain which resulted an increase in Gmax.

The effect of D50R/D50S on Gmax in k0-loading condition (i.e., oedometer cell with bender elements) was discussed in detail by Lee et al. [56]. Six types of rubber were mixed with a uniform sand to consider a variety of aspect ratios (i.e., D50R/D50S = 0.35, 0.5, 0.7, 1.0, 2.0 and 4.7) with VRC of 0% to 100%. Results indicated that Gmax showed no change with D50R/D50S for VRC > 80% because these mixtures reproduce a rubber-like behavior. In addition, Gmax reached a minimum value for D50R/D50S = 1.0 (for any given normal stress) because, under this condition, the density was minimum.

Senetakis et al. [78] and Senetakis and Anastasiadis [79] reported that the initial moisture content of sand-rubber (i.e., dry, moist, or fully saturated) influenced damping ratio but not Gmax. More water content resulted in a higher damping ratio because water acts as a viscous damping component compared to the fully dried specimens. They carried out various tests using a resonant column apparatus on two types of sand and three types of rubber (GRC = 0 to 35% and D50R/D50S = 0.7, 5, 6) and observed that an increase in GRC results in a decrease in Gmax and an increase in damping ratio. In this investigation, a wide range of shear strain (γ) were considered (from 5 × 10−4 % to 6 × 10−1). They observed that a more linear-like trend of G/Gmax-log γ curves was associated with the higher GRC. Moreover, at a larger shear strain, G/Gmax increased with GRC. Additionally, a model to predict Gmax based on void ratio and confining pressure was proposed. In this model, the volume of rubber was considered as an addition to the volume of voids, which is referred to as equivalent void ratio (i.e., ). Also, two models to predict G/G0 and damping ratio as a function of shear strain amplitude, confining pressure, GRC and D50R/D50S were proposed for sand-rubber and gravel-rubber mixtures.

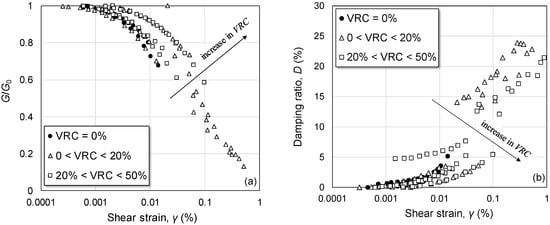

Anastasiadis et al. [43], Anastasiadis et al. [59] and Senetakis et al. [80] evaluated the effect of rubber type and content and confining pressure on the Gmax and D for different soils (i.e., sand and gravel) using a torsional resonant column apparatus. Seven granular soils with various particle size distributions and four uniform-sized rubbers were used to create synthetic blends. The test results showed that generally, by increasing RC and confining pressure, a more linear trend of G/Gmax-log γ curves was attained. By increasing the confining pressure (σ3), the normal stress at soil-soil and soil-rubber particle contacts increased yielding to higher shear moduli. The damping ratio of mixtures increased with increasing RC. They also showed that the variation both in G and D can be better explained by . In a study by Lee et al. [64], for sand-rubber mixtures with the same particle size (i.e., D50R/D50S = 1.0), it was found that the degradation of G/Gmax against shear strain decreased by increasing VRC. Moreover, for mixtures with VRC > 80% a constant G was observed up to shear strain of 0.1% which is mainly due to the high elasticity and low stiffness of rubber particles.

Experimental results conducted by Li et al. [53] on sand-rubber mixtures using resonant column and cyclic triaxial tests showed that not only does the rubber content influence the small strain shear modulus, but also rubber size (in comparison to sand size) affects the behavior. In this investigation, two types of rubber (i.e., D50R/D50S = 0.25 and 1.0) were mixed with uniform sand at different VRC (0% to 20%). For the case of D50R/D50S = 0.25, Gmax increased with VRC and reached the peak for VRC = 10%. This is mainly due to the voids being filled by rubber particles that can provide higher lateral support. Also, the damping ratio generally increased with the inclusion of rubber in sand but the effect was insignificant for VRC < 20%.

Shear modulus and damping ratio. Feng and Sutter [81] performed the torsional resonant column test on sand-granulated rubber (D50R/D50S = 5.0) with VRC between 0 and 100% and σ′3 = 69, 207, 345 and 483 kPa. Two sample preparation methods were used: (1) hand spooning (fully dried) and (2) under-compaction (moist specimen). Results showed that by increasing VRC, the shear modulus decreased, the damping ratio increased and more elastic behavior was observed because granulated rubber is highly elastic. For instance, at a confining pressure of 345 kPa, the shear modulus at a shear strain of 0.01% decreased from 205 MPa for pure sand to less than 10 MPa for pure rubber, while the damping ratio increased from 1% to 6%, respectively. Unlike natural soil, the damping ratio of pure rubber increased slightly with increasing confining pressure. This was justified with the energy dissipation of rubber associated with particle deformation and more particle interaction in elevated confining pressure. Due to the presence of water in sample preparation using the under-compaction method, the shear modulus was slightly lower than the hand spooning method. However, no effect of the preparation method was observed on the damping ratio.

A large-scale undrained cyclic triaxial test (150 mm in diameter by 300 mm in height) was employed to evaluate the effect of rubber and confining pressure on shear modulus and damping ratio of gravel-rubber mixtures by Nakhaei et al. [39]. Specifically, well-graded gravel was mixed with granulated rubber with D50R/D50S ≈ 0.4 and GRC of 0% to 14%. Results illustrated that by increasing GRC, the shear modulus decreased, while by increasing confining pressure, the shear modulus increased. This behavior is due to the soft nature of rubber particles relative to hard gravel. Also, interparticle frictional forces increased with increasing confining pressure. The effect of rubber on shear modulus gradually decreased with increasing confining pressure. In terms of damping ratio, a higher GRC resulted in a decrease of the damping ratio at low confining pressures (σ3 < 100 kPa) and an increase of the damping ratio at σ3 < 200 kPa. At confining great than > 200 kPa, the damping ratio increased for gravel-rubber mixtures but decreased for pure gravel.

Mashiri et al. [29] presented the results of bender element tests on various sand-tire chip mixtures at different confining pressures. The shear modulus of sand-tire chips decreased with the increase in tire chip content, but elevated confining pressure resulted in higher shear modulus. Mashiri et al. [52] also performed undrained cyclic triaxial tests on sand-tire chip mixtures and indicated that rubber content, shear strain amplitude and the number of cycles were the main factors influencing the shear modulus and damping ratio of sand-tire chips mixtures. Generally, increasing rubber content decreased shear modulus and increased the damping ratio of the mixtures.

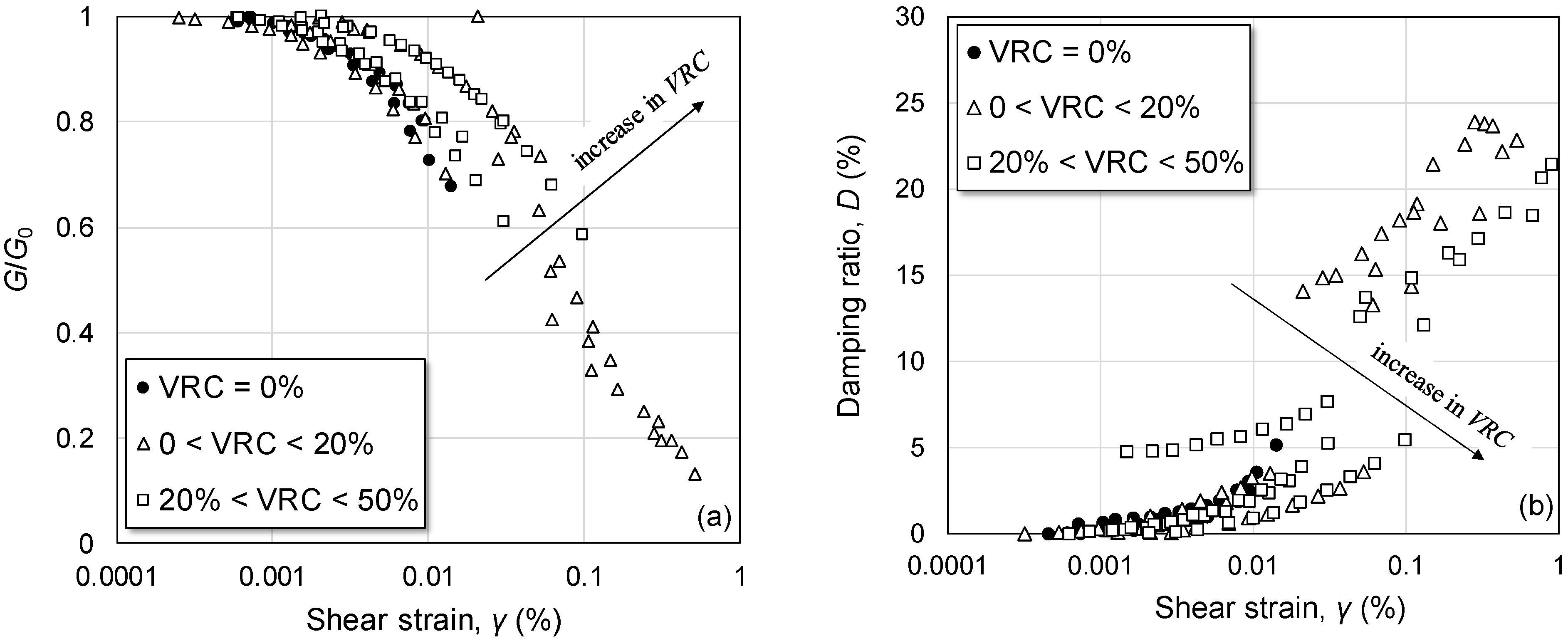

Summary. Normalized shear modulus (G/Gmax) and damping ratio of SRMs against shear strain from previous research are presented in Figure 15. It appears that at any given shear strain level, G/Gmax increases with increasing VRC (Figure 15a). In contrast, as shown in Figure 15b, the experimental results indicate that the damping ratio decreases by increasing VRC at any shear strain amplitude. This behavior is mainly due to the high elastic deformation capacity of rubber particles especially at low confining pressure (σ′3 < 100 kPa). Therefore, more rubber in SRMs results in higher elastic strains that decrease the damping ratio. However, at higher confining pressure, rubber particles exhibited less elastic deformation, hence a higher damping ratio is attained at higher VRC [39].

Figure 15.

Dynamic behavior of SRM (a) normalized shear modulus degradation versus strain and (b) damping ratio versus strain at σ′3 = 100 kPa (Data points from [78]).

2.9. Cyclic Response and Liquefaction Characteristics

As discussed so far, diverse practical applications may be considered for SRMs. Therefore, not only the dynamic response of SRMs is important, but also the behavior of these mixtures under cyclic undrained and drained loading should be evaluated. The resilient modulus, permanent settlement (or plastic deformations), the effect of shear strain amplitude against the number of cycles and liquefaction potential are among the most important characteristics that have been previously studied.

Resilient modulus. A series of strain-controlled cyclic triaxial tests on crushed rock and granulated rubber mixtures by Arulrajah et al. [38] indicated that the addition of 1% and 2% of rubber resulted in an insignificant effect on the resilient modulus, while 3% of rubber caused a decrease of the resilient modulus. Also, larger rubber aggregates influenced more significantly the behavior of the mixtures. This is due to the changes in the load-bearing mechanism from more rigid particles (i.e., crushed rock) to relatively soft particles (i.e., rubber). Therefore, an optimum mixture consists of 2% rubber mixed with crushed rock was suggested to be suitable for pavement base/subbase layers. Edil and Bosscher [10] also indicated that the resilient modulus of sand-tire chips decreased with an increase in VRC. The reduction of resilient modulus was pronounced for the mixture with VRC > 30%. At 100 kPa bulk stress, the resilient modulus of pure sand, VRC = 30% and VRC = 50% was 60, 10 and 5 MPa, respectively.

Liquefaction resistance. Promputthangkoon and Hyde [34] performed an undrained cyclic triaxial test with sand-rubber mixtures (D50R/D50S ≈ 1.7) and VRC of 0, 1, 2.5, 5 and 15%. They mentioned that the cyclic stress ratio (CSR) for all sand-rubber mixture at 20 cycles were lower than pure sand except for VRC = 1% at 10 and 15 cycles. This means minor liquefaction improvement was observed by mixing sand with rubber but only a particular rubber size and shape were considered in their investigation and these findings cannot be generalized.

Mashiri et al. [52] carried out undrained cyclic triaxial tests on sand-tire chips mixtures and the results indicated that the liquefaction potential decreases significantly by the inclusion of tire chips in the sand and the optimum rubber content was reported to be 30% to 33% by mass. Kaneko et al. [32] also mentioned that the inclusion of rubber chips in sand significantly influenced the seismic response of the specimen due to the lower stiffness and higher deformability of tire chips. Results of simple shear test on sand-rubber chips (D50R/D50S ≈ 2.0) with VRC of 30% and 50% showed that by increasing VRC, the liquefaction resistance and ground acceleration decreased remarkably. The effect is more pronounced if the rubber is placed as a full layer compared to be mixed with sand, especially if the rubber layer was placed at deeper location. However, static settlement would be greater for the later situation.

3. Discussions

3.1. Gravel-Rubber Mixtures vs. Sand-Rubber Mixtures: What to Use and Why?

Hazarika and Adbullah [82] pointed out that in the selection of the soil and recycled rubber to form soil-rubber mixtures for use in geotechnical applications, the availability and the cost efficiency of both materials should be carefully considered. In actual fact, to avoid segregation, the recycled rubber should be cut into smaller pieces when mixed with sandy soils, which will inevitably increase the implementation costs. To address this issue, it was therefore proposed to replace the gravel with sand. A following study by Hazarika et al. [20] demonstrated that using gravel-rubber layers underneath the foundation of residential buildings may provide sufficient bearing capacity and reduce earthquake-induced settlements. Furthermore, due to a high permeability compared to sand-rubber mixtures, gravel-rubber mixtures are able to confine the development of pore water pressure during cyclic loading, hence improving the structural stability of the foundation and the superstructure.

Gravel-rubber mixtures appear to be a promising replacement for sand-rubber mixtures in many geotechnical engineering applications and understanding their physical and mechanical properties is essential to correctly evaluate their performance. To date, however, very limited studies have focused on the geotechnical characterization of gravel-rubber mixtures [20,40,78,82], making their physical properties and mechanical behavior largely unknown.

3.2. Environmental Aspects

The introduction of new or alternative (recycled waste) materials in geotechnical engineering applications may have benefits in terms of cost reductions and increased mechanical performance. However, it is essential to ensure that such innovations do not result in long-term negative impacts on the environment, for example, through the leaching of toxic chemicals into the surrounding soil environment, groundwater and surface water [83].

While tire rubber itself, which makes up 75–80% of the weight of car and truck tires [84], can be considered inert under ambient foundation conditions [85], tires contain ~ 1.5% by weight of hazardous compounds. Additives used in the manufacture of tires are potentially harmful to the environment (e.g., organohalogen compounds, acidic solutions) and the steel fibers within the tires can leach heavy metals (e.g., zinc, manganese, lead, cadmium) [84]. A review of the leachate characteristics of tires [86] showed that depending on if the steel components of the tires are exposed, there may be elevated manganese and iron levels within the leachate and in groundwater (although at levels below relevant environmental standards). Levels of aluminum, zinc and organic compounds may be elevated in groundwater; however, the majority of the studies reported negligible levels. While these results were based on field and laboratory investigations, the risk of groundwater and soil contamination through tire leachate is related to a number of different factors (tire size, amount of exposed steel, distance to groundwater, permeability and chemistry of the soil, contact time with water, vertical water flow through soil, horizontal groundwater flow, leachate control systems [86] and these results cannot be directly related to specific sites. As far as the authors are aware, no previous test results are available from the literature on the leaching properties of tire rubber mixed with gravelly soils. These issues should be addressed by in-depth investigations.

4. Summary, Conclusions and Recommendations

To date, many studies have focused on the geotechnical characterization of soil-rubber mixtures (SRMs). Yet, because the results of such studies have not been properly compiled and compared, it is still difficult to fully understand the potential applicability of SRMs in many geotechnical applications. In an attempt to provide useful insights facilitating the use of SRMs as geotechnical materials, this paper presents a detailed review of published research studies on the geotechnical engineering properties of SRMs. Available experimental data were scrutinized in terms of effects of rubber content (by mass or volume) on the key engineering properties of SRMs, including (i) dry density, compaction and permeability, (ii) compressibility and shear strength and (iii) dynamic and cyclic deformation characteristics. The following main conclusions can be drawn from this review:

- The geotechnical characteristics of SRMs depend not only on the rubber content (by mass or volume) in the mixtures but also on host soil type (i.e., sand or gravel), rubber particle size and shape, aspect ratio between rubber particles and soil grains (AR = D50R/D50S), as well as density state (packing) and applied stress level.

- Due to the smaller specific gravity values of rubber (Gs = 1.14–1.27) compared to granular soils (Gs = 2.5–2.7) the addition of rubber in the mixtures produces materials with lower dry density (or higher void ratios). Different from granulated soils, the maximum dry density of SRMs is better evaluated by Proctor impact compaction tests rather than the vibratory compaction technique. This is due to the elastic and damping properties of the rubber particles. In other words, vibratory compaction is mostly ineffective for compacting SMRs.

- For SRMs consisting of two different particle sizes (either D50R/D50S < 1 or D50R/D50S > 1) three packaging states can be defined during compaction depending on the percentage of smaller-sized material in the mixture: floating state, non-floating state and transitional state. This also greatly affects the mechanical response of SRMs.

- The inclusion of rubber particles in the SRMs drastically increases the compressibility of the compound materials. At any given vertical stress, a linear increase of 1-D volumetric strain can be observed with increasing VRC.

- The permeability of SRMs reported in previous investigations is almost constant up to VRC = 50% (similar to the permeability of sandy soil) and then increases with further increase in VRC. The permeability of pure rubber is usually similar to that of gravely soils.

- The majority of studies on sand-rubber mixtures indicated that there is a range of rubber content (VRC ≈ 20–50%) that enhance the shear strength of SRMs, and further rubber inclusion will result in a reduction in shear strength. In contrast, for gravel-rubber mixtures, a continuous reduction in shear strength (friction angle) can be observed by increasing rubber content.

- The main beneficial aspect of adding rubber particles in granular soil is the improvement of the dynamic properties and cyclic characteristics of the parent soil. Some investigations showed that even a small amount of rubber (for instance VRC < 10%) could increase Gmax especially for D50R/D50S < 1 as rubber fills the voids between soil particles. However, higher VRC values usually result in a reduction of Gmax (due to the soft nature of rubber), as well as an increase in the damping ratio (due to the energy absorption nature of the rubber).

- While strength and compressibility of SRMs have been characterized in many studies, further research on the dynamic and cyclic behavior of SMRs is still necessary (in particular gravel-rubber mixtures).

- The load-transmission concept between hard and soft grains is still poorly understood and studies focusing on the micro-scale mechanical behavior of SRMs (e.g., using DEM software) are encouraged.

- Previous studies on SRMs have mainly focused on sandy soils mixed with various rubber sizes. Yet, recent studies, have pointed out that to avoid inherent segregation of two-size sand-rubber mixtures, AR = 1 should be used, resulting in high costs from a practical viewpoint. Thus, gravel-rubber mixtures should be considered as a more suitable host soil to create more cost-effective SRMs. Yet, more studies are deemed necessary to facilitate the use of grave-rubber mixtures in many geotechnical applications.

- Finally, while SRMs are excellent construction materials from a geotechnical viewpoint, their ultimate adoption should be based also on environmental investigations to make sure that any harm to the environment is prevented.

Funding

This research was funded by Ministry of Business, Innovation and Employment of New Zealand (MBIE Smart Ideas Research Grant No. 56289). This study was also (partially) supported by QuakeCoRE (Research Grant No. QC53), a New Zealand Tertiary Education Commission-funded Centre.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors are grateful for discussion and support of Alessandro Palermo, Gabriele Granello and Kevin Chew in the course of presented research.

Conflicts of Interest

The authors declare no conflict of interest. The funding organizations had no role in the collec-tion, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Abbreviations

| Cc | compression index |

| Cs | swelling index |

| CSR | cyclic stress ratio |

| D | damping ratio |

| D50R | median particle size of rubber |

| D50S | median particle size of soil |

| DEM | discrete element model |

| ELTs | end-of-life tires |

| void ratio of soil-rubber mixture | |

| void ratio of soil | |

| equivalent void ratio | |

| G | small-strain shear modulus |

| Gmax | maximum shear modulus |

| GRC | Gravimetric Rubber Content |

| Gs | specific gravity |

| k | permeability |

| M | constraint modulus |

| M100 | constraint modulus at vertical effective stress of 100 kPa |

| MDD | maximum dry density |

| OMC | optimum moisture content |

| q | deviatoric stress |

| qpeak | peak deviatoric stress |

| RC | rubber content |

| SRMs | soil-rubber mixtures |

| VRC | Volumetric Rubber Content |

| Vs | shear wave velocity |

| εv,1-D | one dimensional volumetric strain |

| φ | friction angle |

| γ | shear strain |

| dry unit weight of soil-rubber mixture | |

| dry unit weight of soil | |

| σn | normal stress |

| vertical effective stress | |

| vertical stress | |

| confining pressure | |

| σ′3 | effective confining pressure |

References

- Pehlken, A.; Essadiqi, E. Scrap Tire Recycling in Canada; CANMET Materials Technology Laboratory: Hamilton, ON, Canada, 2005. [Google Scholar]

- WBCSD. Managing End-of-Life Tires; WBCSD: Geneva, Switzerland, 2008. [Google Scholar]

- Torretta, V.; Rada, E.C.; Ragazzi, M.; Trulli, E.; Istrate, I.A.; Cioca, L.I. Treatment and disposal of tyres: Two EU approaches. A review. Waste Manag. 2015, 45, 152–160. [Google Scholar] [CrossRef]

- USTMA. 2017 U.S. Scrap Tire Management Summary; U.S. Tire Manufacturers Association: Washington, DC, USA, 2018. [Google Scholar]

- ETRMA. Annual Report 2017, Moving Innovation that Cares; ETRMA: Brussels, Belgium, 2017. [Google Scholar]

- JATMA. Tyre Industry of Japan; JATMA: Tokyo, Japan, 2018. [Google Scholar]

- Mountjoy, E.; Hasthanayake, D.; Freeman, T. Stocks and Fate of End-of-Life Tyres-2013–14 Study; National Environmental Protection Council: Washington, DC, USA, 2015.

- CATRA. Annual Report; CATRA: Rixheim, France, 2018. [Google Scholar]

- Ministry for the Environment. Environement New Zealand 2007; Ministry for the Environment: Wellington, New Zealand, 2015.

- Pincus, H.; Edil, T.; Bosscher, P. Engineering Properties of Tire Chips and Soil Mixtures. Geotech. Test. J. 1994, 17, 453. [Google Scholar] [CrossRef]

- Chaney, R.; Demars, K.; Masad, E.; Taha, R.; Ho, C.; Papagiannakis, T. Engineering Properties of Tire/Soil Mixtures as a Lightweight Fill Material. Geotech. Test. J. 1996, 19, 297–304. [Google Scholar] [CrossRef]

- Bosscher, P.J.; Edil, T.B.; Kuraoka, S. Design of Highway Embankments Using Tire Chips. J. Geotech. Geoenviron. Eng. 1997, 123, 295–304. [Google Scholar] [CrossRef]

- Tsang, H.-H. Seismic isolation by rubber–soil mixtures for developing countries. Earthq. Eng. Struct. Dyn. 2007, 37, 283–303. [Google Scholar] [CrossRef]

- Tsang, H.-H.; Lo, S.H.; Xu, X.; Sheikh, M.N. Seismic isolation for low-to-medium-rise buildings using granulated rubber-soil mixtures: Numerical study. Earthq. Eng. Struct. Dyn. 2012, 41, 2009–2024. [Google Scholar] [CrossRef]

- Hernández, E.; Palermo, A.; Granello, G.; Chiaro, G.; Banasiak, L.J. Eco-rubber Seismic-Isolation Foundation Systems: A Sustainable Solution for the New Zealand Context. Struct. Eng. Int. 2020, 30, 192–200. [Google Scholar] [CrossRef]

- Chiaro, G.; Palermo, A.; Granello, G.; Tasalloti, A.; Stratford, C.; Banasiak, L.J. Eco-rubber seismic-isolation foundation systems: A cost-effective way to build resilience. In Proceedings of the 2019 Pacific Conference on Earthquake Engineering, Auckland, New Zealand, 4–6 April 2019; pp. 1–8. [Google Scholar]

- Chiaro, G.; Tasalloti, A.; Palermo, A.; Granello, G.; Banasiak, L. Reuse of Waste Tires to Develop Eco-Rubber Seismic-Isolation Foundation Systems: Preliminary Results-Advances in Sustainable Construction and Resource Management; Hazarika, H., Madabhushi, G.S.P., Yasuhara, K., Bergado, D.T., Eds.; Springer: Singapore, 2021; pp. 159–169. [Google Scholar]

- Tsiavos, A.; Alexander, N.A.; Diambra, A.; Ibraim, E.; Vardanega, P.J.; Gonzalez-Buelga, A.; Sextos, A. A sand-rubber deformable granular layer as a low-cost seismic isolation strategy in developing countries: Experimental investigation. Soil Dyn. Earthq. Eng. 2019, 125, 105731. [Google Scholar] [CrossRef]

- Pitilakis, D.; Anastasiadis, A.; Vratsikidis, A.; Kapouniaris, A.; Massimino, M.; Abate, G.; Corsico, S. Large-Scale Field Testing of Geotechnical Seismic Isolation of Structures Using Gravel-Rubber Mixtures; Aristotle University of Thessaloniki: Thessaloniki, Greece, 2021. [Google Scholar]

- Hazarika, H.; Pasha, S.M.K.; Ishibashi, I.; Yoshimoto, N.; Kinoshita, T.; Endo, S.; Karmokar, A.K.; Hitosugi, T. Tire-chip reinforced foundation as liquefaction countermeasure for residential buildings. Soils Found. 2020, 60, 315–326. [Google Scholar] [CrossRef]

- Paramasivam, B.; Dashti, S.; Liel, A.B. In-Ground Gravel–Rubber Panel Walls to Mitigate and Base Isolate Shallow-Founded Structures on Liquefiable Ground. J. Geotech. Geoenviron. Eng. 2020, 146, 04020087. [Google Scholar] [CrossRef]

- Yujie, Q.; Buddhima, I. Energy-Based Approach to Assess the Performance of a Granular Matrix Consisting of Recycled Rubber, Steel-Furnace Slag, and Coal Wash. J. Mater. Civ. Eng. 2020, 32, 04020169. [Google Scholar] [CrossRef]

- Indraratna, B.; Qi, Y.; Ngo, T.N.; Rujikiatkamjorn, C.; Neville, T.; Ferreira, F.B.; Shahkolahi, A. Use of Geogrids and Recycled Rubber in Railroad Infrastructure for Enhanced Performance. Geosciences 2019, 9, 30. [Google Scholar] [CrossRef]

- ASTM. Standard Practice for Use of Scrap Tires in Civil Engineering Applications; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Kim, H.-K.; Santamarina, J.C. Sand-rubber mixtures (large rubber chips). Can. Geotech. J. 2008, 45, 1457–1466. [Google Scholar] [CrossRef]

- Tasalloti, A.; Chiaro, G.; Palermo, A.; Banasiak, L. Effect of Rubber Crumbs Volumetric Content on the Shear Strength of Gravelly Soil in Direct Shear Apparatus. Geo-Congress 2020, 259–266. [Google Scholar] [CrossRef]

- Tasalloti, A.; Chiaro, G.; Banasiak, L.; Palermo, A. Experimental investigation of the mechanical behaviour of gravel-granulated tyre rubber mixtures. Constr. Build. Mater. 2021, 273, 121749. [Google Scholar] [CrossRef]