Integrating Regionalized Socioeconomic Considerations onto Life Cycle Assessment for Evaluating Bioeconomy Value Chains: A Case Study on Hybrid Wood–Concrete Ceiling Elements

Abstract

1. Introduction

2. Materials and Methods

2.1. Definition of the Case Study

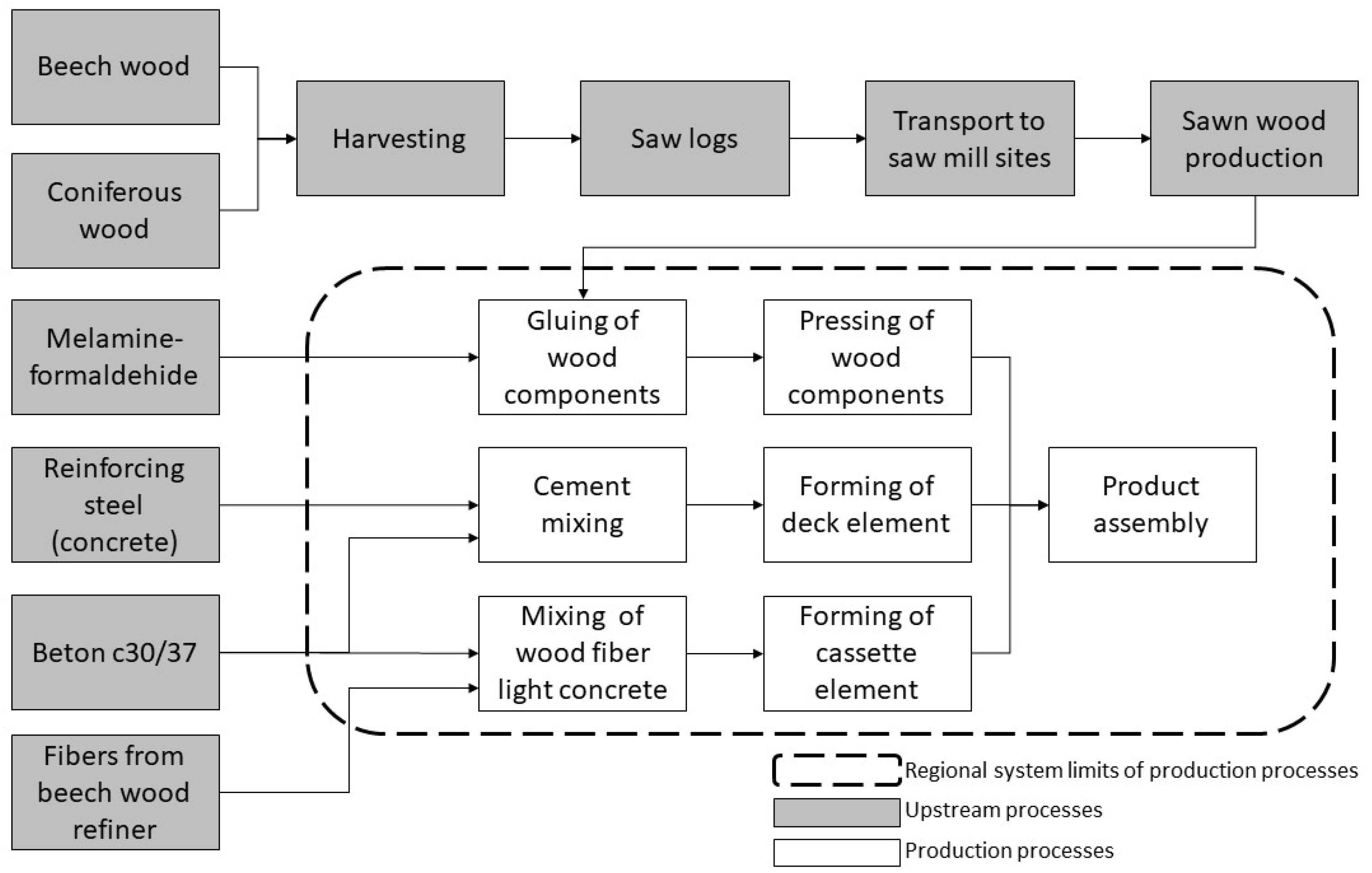

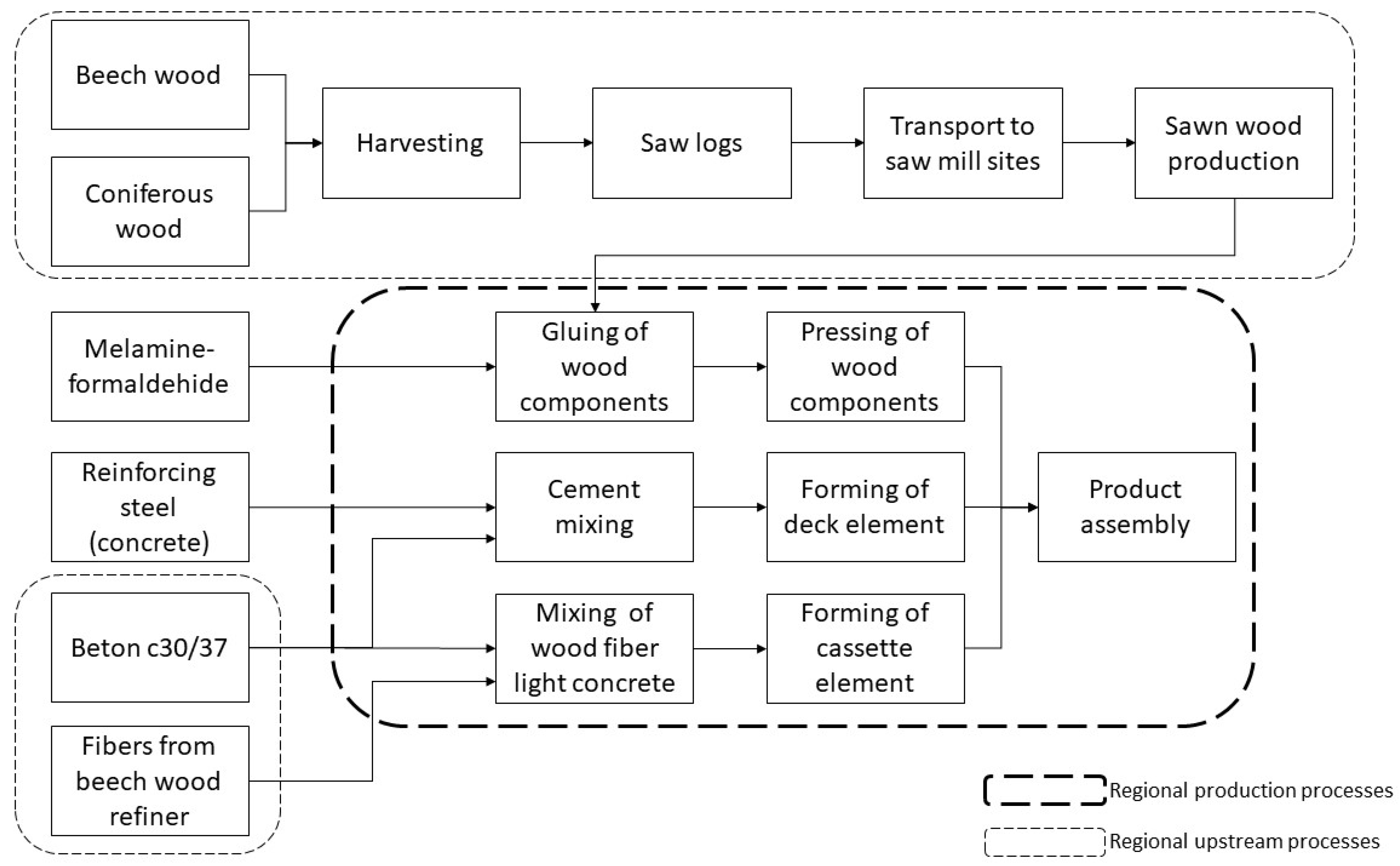

2.2. Systems Definition for the Case Study

2.3. Life Cycle Assessment

2.3.1. Goal and Scope Definition

2.3.2. System Definition

2.3.3. Specification of Demonstrator Compositions and Definition of a Functional Unit

2.3.4. Data Collection and Life Cycle Inventories

2.3.5. Life Cycle Impact Assessment

2.4. Regionalized Social Life Cycle Assessment

2.4.1. Definition of Goal and Scope

2.4.2. Inventory Analysis

2.4.3. Impact Assessment

3. Results

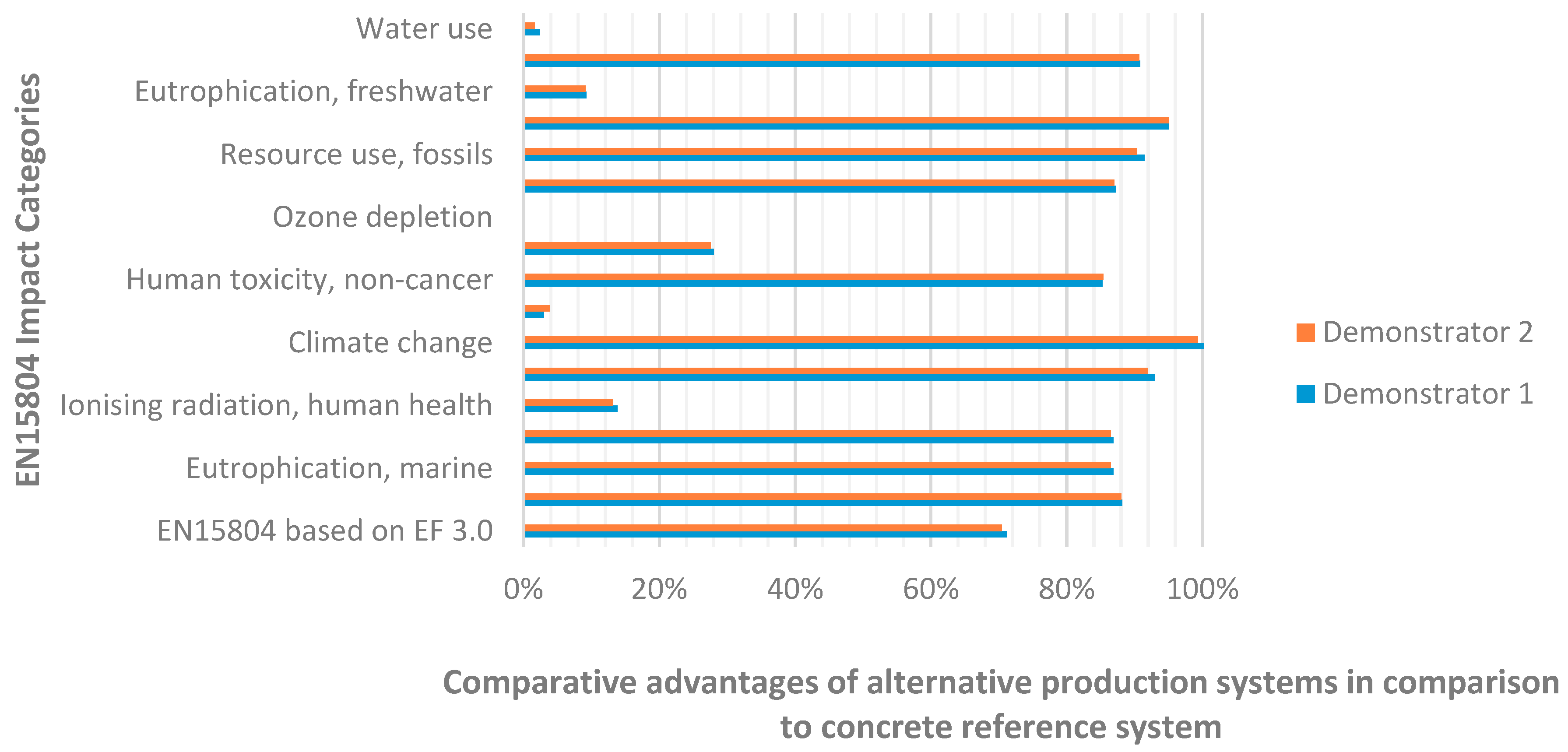

3.1. Life Cycle Assessment

3.2. Regionalized Social Life Cycle Assessment

4. Discussion

4.1. Life Cycle Assessment

4.2. Regionalized Social Life Cycle Assessment

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thrän, D. Einführung in das system bioökonomie. In Das System Bioökonomie; Thrän, D., Moesenfechtel, U., Eds.; Springer Spektrum: Berlin, Germany, 2020; pp. 1–19. [Google Scholar]

- Hildebrandt, J.; Hagemann, N.; Thran, D. The contribution of wood-based construction materials for leveraging a low carbon building sector in europe. Sustain. Cities Soc. 2017, 34, 405–418. [Google Scholar] [CrossRef]

- Bezama, A. Let us discuss how cascading can help implement the circular economy and the bio-economy strategies. Waste Manag. Res. 2016, 34, 593–594. [Google Scholar] [CrossRef]

- Directorate-General for Research and Innovation (European Commission). A Sustainable Bioeconomy for Europe—Strengthening the Connection between Economy, Society and the Environment: Updated Bioeconomy Strategy; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Directorate-General for Research and Innovation (European Commission). Bioeconomy—the European Way to Use Our Natural Resources: Action Plan 2018; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Ingrao, C.; Bacenetti, J.; Bezama, A.; Blok, V.; Goglio, P.; Koukios, E.G.; Lindner, M.; Nemecek, T.; Siracusa, V.; Zabaniotou, A.; et al. The potential roles of bio-economy in the transition to equitable, sustainable, post fossil-carbon societies: Findings from this virtual special issue. J. Clean Prod. 2018, 204, 471–488. [Google Scholar] [CrossRef]

- Ingrao, C.; Arcidiacono, C.; Bezama, A.; Ioppolo, G.; Winans, K.; Koutinas, A.; Gallego-Schmid, A. Sustainability issues of by-product and waste management systems, to produce building material commodities: A comprehensive review of findings from a virtual special issue. Resour. Conserv. Recy. 2019, 146, 358–365. [Google Scholar] [CrossRef]

- Bezama, A. Understanding the systems that characterise the circular economy and the bioeconomy. Waste Manag. Res. 2018, 36, 553–554. [Google Scholar] [CrossRef] [PubMed]

- Charles, D.; Davies, S.; Miller, S.; Clement, E.K.; Hoes, A.-C.; Hasenheit, M.; Kiresiewa, Z.; Kah, S.; Bianchini, C. Case studies of regional bioeconomy strategies across europe. BIOSTEP 2016. Available online: https://www.ecologic.eu/14079 (accessed on 10 April 2021).

- Dubois, O.; Gomez San Juan, M. How Sustainability is Addressed in Official Bioeconomy Strategies at International, National and Regional Levels—an Overview; Food and Agriculture Organization of the United Nations: Rome, Italy, 2016. [Google Scholar]

- Siebert, A.; Bezama, A.; O’Keeffe, S.; Thran, D. Social life cycle assessment: In pursuit of a framework for assessing wood-based products from bioeconomy regions in germany. Int. J. Life Cycle Ass. 2018, 23, 651–662. [Google Scholar] [CrossRef]

- O’Keeffe, S.; Majer, S.; Bezama, A.; Thran, D. When considering no man is an island-assessing bioenergy systems in a regional and lca context: A review. Int. J. Life Cycle Ass. 2016, 21, 885–902. [Google Scholar] [CrossRef]

- Balkau, F.; Bezama, A. Life cycle methodologies for building circular economy in cities and regions. Waste Manag. Res. 2019, 37, 765–766. [Google Scholar] [CrossRef]

- Riala, M.; Ilola, L. Multi-storey timber construction and bioeconomy—barriers and opportunities. Scand. J. For. Res. 2014, 29, 367–377. [Google Scholar] [CrossRef]

- Strogies, M.; Gniffke, P. Berichterstattung unter der Klimarahmenkonvention der Vereinten Nationen und dem kyoto-Protokoll 2017—Nationaler Inventarbericht zum deutschen Treibhausgasinventar 1990–2015; Umweltbundesamt: Dessau-Roßlau, Germany, 2017. [Google Scholar]

- Huang, L.Z.; Krigsvoll, G.; Johansen, F.; Liu, Y.P.; Zhang, X.L. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- Chen, Z.J.; Gu, H.M.; Bergman, R.D.; Liang, S.B. Comparative life-cycle assessment of a high-rise mass timber building with an equivalent reinforced concrete alternative using the athena impact estimator for buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- Guo, A.F.; Sun, Z.H.; Qi, C.Q.; Sathitsuksanoh, N. Hydration of portland cement pastes containing untreated and treated hemp powders. J. Mater. Civ. Eng. 2020, 32, 04020148. [Google Scholar] [CrossRef]

- Jaaranen, J.; Fink, G. Frictional behaviour of timber-concrete contact pairs. Constr. Build. Mater. 2020, 243, 118273. [Google Scholar] [CrossRef]

- Munoz-Ruiperez, C.; Olivan, F.F.; Carpintero, V.C.; Santamaria-Vicario, I.; Saiz, A.R. Mechanical behavior of a composite lightweight slab, consisting of a laminated wooden joist and ecological mortar. Materials 2020, 13, 13. [Google Scholar] [CrossRef] [PubMed]

- Villas-Boas, B.T.; Iwakiri, S.; Parchen, C.F.A. Production and evaluation of low-density cast-wood-cement blocks for civil construction. Science 2020, 48. [Google Scholar]

- Giesekam, J.; Tingley, D.D.; Cotton, I. Aligning carbon targets for construction with (inter)national climate change mitigation commitments. Energ. Build. 2018, 165, 106–117. [Google Scholar] [CrossRef]

- Giergiczny, Z.; Krol, A.; Talaj, M.; Wandoch, K. Performance of concrete with low co(2)emission. Energies 2020, 13, 4328. [Google Scholar] [CrossRef]

- Karlsson, I.; Rootzen, J.; Toktarova, A.; Odenberger, M.; Johnsson, F.; Goransson, L. Roadmap for decarbonization of the building and construction industry-a supply chain analysis including primary production of steel and cement. Energies 2020, 13, 4136. [Google Scholar] [CrossRef]

- Koh, C.H.; Kraniotis, D. A review of material properties and performance of straw bale as building material. Constr. Build. Mater. 2020, 259, 120385. [Google Scholar] [CrossRef]

- Mata, E.; Korpal, A.K.; Cheng, S.H.; Navarro, J.P.J.; Filippidou, F.; Reyna, J.; Wang, R. A map of roadmaps for zero and low energy and carbon buildings worldwide. Environ. Res. Lett. 2020, 15, 113003. [Google Scholar] [CrossRef]

- Mercader-Moyano, P.; Esquivias, P.M. Decarbonization and circular economy in the sustainable development and renovation of buildings and neighbourhoods. Sustainability 2020, 12, 7914. [Google Scholar] [CrossRef]

- Zeug, W.; Bezama, A.; Thrän, D. Towards a Holistic and Integrated Life Cycle Sustainability Assessment of the Bioeconomy—Background on Concepts, Visions and Measurements; Helmholtz-Zentrum für Umweltforschung—UFZ: Leipzig, Germany, 2020; p. 35. [Google Scholar]

- Bos, U.; Maier, S.D.; Horn, R.; Leistner, P.; Finkbeiner, M. A gis based method to calculate regionalized land use characterization factors for life cycle impact assessment using lanca (r). Int. J. Life Cycle Ass. 2020, 25, 1259–1277. [Google Scholar] [CrossRef]

- Crenna, E.; Marques, A.; La Notte, A.; Sala, S. Biodiversity assessment of value chains: State of the art and emerging challenges. Environ. Sci. Technol. 2020, 54, 9715–9728. [Google Scholar] [CrossRef] [PubMed]

- Ita-Nagy, D.; Vazquez-Rowe, I.; Kahhat, R.; Chinga-Carrasco, G.; Quispe, I. Reviewing environmental life cycle impacts of biobased polymers: Current trends and methodological challenges. Int. J. Life Cycle Ass. 2020, 25, 2169–2189. [Google Scholar] [CrossRef]

- Lee, M.; Lin, Y.L.; Chiueh, P.T.; Den, W. Environmental and energy assessment of biomass residues to biochar as fuel: A brief review with recommendations for future bioenergy systems. J. Clean. Prod. 2020, 251, 119714. [Google Scholar] [CrossRef]

- Balkau, F.; Massari, S.; Sonnemann, G. Sustainable regional development in a life cycle context. In Life Cycle Approaches to Sustainable Regional Development; Massari, S., Sonnemann, G., Balkau, F., Eds.; Routledge: New York, NY, USA, 2016; pp. 9–14. [Google Scholar]

- Bezama, A.; Ingrao, C.; O’Keeffe, S.; Thran, D. Resources, collaborators, and neighbors: The three-pronged challenge in the implementation of bioeconomy regions. Sustainability 2019, 11, 7235. [Google Scholar] [CrossRef]

- Albrecht, M. (Re-)producing bioassemblages: Positionalities of regional bioeconomy development in finland. Local Environ. 2019, 24, 342–357. [Google Scholar] [CrossRef]

- Petig, E.; Choi, H.S.; Angenendt, E.; Kremer, P.; Grethe, H.; Bahrs, E. Downscaling of agricultural market impacts under bioeconomy development to the regional and the farm level-an example of baden-wuerttemberg. Gcb. Bioenergy 2019, 11, 1102–1124. [Google Scholar] [CrossRef]

- Befort, N. Going beyond definitions to understand tensions within the bioeconomy: The contribution of sociotechnical regimes to contested fields. Technol. Soc. 2020, 153, 119923. [Google Scholar] [CrossRef]

- Siebert, A.; O’Keeffe, S.; Bezama, A.; Zeug, W.; Thran, D. How not to compare apples and oranges: Generate context-specific performance reference points for a social life cycle assessment model. J. Clean. Prod. 2018, 198, 587–600. [Google Scholar] [CrossRef]

- Siebert, A.; Bezama, A.; O’Keeffe, S.; Thran, D. Social life cycle assessment indices and indicators to monitor the social implications of wood-based products. J. Clean. Prod. 2018, 172, 4074–4084. [Google Scholar] [CrossRef]

- Jarosch, L.; Zeug, W.; Bezama, A.; Finkbeiner, M.; Thran, D. A regional socio-economic life cycle assessment of a bioeconomy value chain. Sustainability 2020, 12, 1259. [Google Scholar] [CrossRef]

- Gonzalez, O.M.; Garcia, A.; Guachambala, M.; Navas, J.F. Innovative sandwich-like composite biopanels—towards a new building biomaterials concept for structural applications in nonconventional building systems. Wood Mater. Sci. Eng. 2020, 16, 132–148. [Google Scholar] [CrossRef]

- Mirdad, M.A.H.; Chui, Y.H. Strength prediction of mass-timber panel concrete-composite connection with inclined screws and a gap. J. Struct. Eng. 2020, 146. [Google Scholar] [CrossRef]

- Molina, J.C.; Oliveira, C.A.B.; Christoforo, A.L.; Boas, D.V.; Calil, C. Influence of the bonding of rebar dowel with adhesive on wood-concrete composite specimens. Proc. Inst. Civ. Eng.-Str. Build. 2020, 173, 904–913. [Google Scholar] [CrossRef]

- Orlowski, K. Verified and validated design curves and strength reduction factors for post-tensioned composite steel-timber stiffened wall systems. Eng. Struct. 2020, 204, 110053. [Google Scholar] [CrossRef]

- Shi, B.K.; Liu, W.Q.; Yang, H.F.; Ling, X. Long-term performance of timber-concrete composite systems with notch-screw connections. Eng. Struct. 2020, 213, 110585. [Google Scholar] [CrossRef]

- Tannert, T.; Gerber, A.; Vallee, T. Hybrid adhesively bonded timber-concrete-composite floors. Int. J. Adhes Adhes 2020, 97, 102490. [Google Scholar] [CrossRef]

- Keilholz, M.; Rüther, N. Schlussbericht für die öffentlichkeit. Vp 1.13, “Entwicklung eines leichbetons aus buchenholz”; Fraunhofer-Institut für Holzforschung, Wilhelm-Klauditz-Institut (WKI); Universalbeton Heringen GmbH & Co. KG: Braunschweig/Heringen, Germany, 2017. [Google Scholar]

- Krug, D. Einfluss der Faserstoff-Aufschlussbedingungen und des Bindemittels auf die Eigenschaften von Mitteldichten Faserplatten (MDF) für eine Verwendung im Feucht- und Außenbereich. Ph.D. Thesis, Universität Hamburg, Hamburg, Germany, 2010. [Google Scholar]

- Paulitsch, M.; Barbu, M.C. Holzwerkstoffe der Moderne. 1, Aufl. ed.; DRW-Verlag: Leinfelden-Echterdingen, Germany, 2015. [Google Scholar]

- Siebert, A. Socio-Economic Assessment of Wood-Based Products from German Bioeconomy Regions: A Social Life Cycle Assessment Approach. Dissertation’ s Thesis, University of Leipzig, Leipzig, Germany, 2019. [Google Scholar]

- Jarosch, L. A Social Life Cycle Assessment in Context of the Bioeconomy: The Example of Social Aspects of the Timber Processing Industry in Central Germany. B.Sc. Thesis, Technische Universität Berlin, Berlin, Germany, 2019. [Google Scholar]

- Zhou, C.; Shi, S.Q.; Chen, Z.; Cai, L.; Smith, L. Comparative environmental life cycle assessment of fiber reinforced cement panel between kenaf and glass fibers. J. Clean. Prod. 2018, 200, 196–204. [Google Scholar] [CrossRef]

- Wu, T.; Gong, M.; Xiao, J. Preliminary sensitivity study on an life cycle assessment (lca) tool via assessing a hybrid timber building. J. Bioresour. Bioprod. 2020, 5, 108–113. [Google Scholar] [CrossRef]

- Nikolić Topalović, M.; Stanković, M.; Ćirović, G.; Pamučar, D. Comparison of the applied measures on the simulated scenarios for the sustainable building construction through carbon footprint emissions—case study of building construction in serbia. Sustainability 2018, 10, 4688. [Google Scholar] [CrossRef]

- Gámez-García, D.C.; Gómez-Soberón, J.M.; Corral-Higuera, R.; Saldaña-Márquez, H.; Gómez-Soberón, M.C.; Arredondo-Rea, S.P. A cradle to handover life cycle assessment of external walls: Choice of materials and prognosis of elements. Sustainability 2018, 10, 2748. [Google Scholar] [CrossRef]

- Caruso, M.; Pinho, R.; Bianchi, F.; Cavalieri, F.; Lemmo, M.T. A life cycle framework for the identification of optimal building renovation strategies considering economic and environmental impacts. Sustainability 2020, 12, 10221. [Google Scholar] [CrossRef]

- Scope, C.; Guenther, E.; Schütz, J.; Mielecke, T.; Mündecke, E.; Schultze, K.; Saling, P. In Aiming for Life Cycle Sustainability Assessment of Cement-Based Composites: A Trend Study for Wall Systems of Carbon Concrete; Dresden nexus conference 2020—session 4—circular economy for building with secondary construction materials to minimise resource use and land use. Civ. Eng. Des. 2020, 2, 143–158. [Google Scholar] [CrossRef]

- Falcone, P.M.; Imbert, E. Social life cycle approach as a tool for promoting the market uptake of bio-based products from a consumer perspective. Sustainability 2018, 10, 1031. [Google Scholar] [CrossRef]

- Falcone, P.M.; González García, S.; Imbert, E.; Lijó, L.; Moreira, M.T.; Tani, A.; Tartiu, V.E.; Morone, P. Transitioning towards the bio-economy: Assessing the social dimension through a stakeholder lens. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 1135–1153. [Google Scholar] [CrossRef]

- Valente, C.; Brekke, A.; Modahl, I.S. Testing environmental and social indicators for biorefineries: Bioethanol and biochemical production. Int. J. Life Cycle Assess. 2018, 23, 581–596. [Google Scholar] [CrossRef]

- Mandegari, M.A.; Farzad, S.; van Rensburg, E.; Görgens, J.F. Multi-criteria analysis of a biorefinery for co-production of lactic acid and ethanol from sugarcane lignocellulose. Nat. Sci. 2017, 11, 971–990. [Google Scholar] [CrossRef]

- Mair-Bauernfeind, C.; Zimek, M.; Asada, R.; Bauernfeind, D.; Baumgartner, R.J.; Stern, T. Prospective sustainability assessment: The case of wood in automotive applications. Int. J. Life Cycle Assess. 2020, 25, 2027–2049. [Google Scholar] [CrossRef]

- Rafiaani, P.; Kuppens, T.; Thomassen, G.; Van Dael, M.; Azadi, H.; Lebailly, P.; Van Passel, S. A critical view on social performance assessment at company level: Social life cycle analysis of an algae case. Int. J. Life Cycle Assess. 2020, 25, 363–381. [Google Scholar] [CrossRef]

- Hildebrandt, J.; Bezama, A.; Thran, D. Insights from the sustainability monitoring tool suministro applied to a case study system of prospective wood-based industry networks in central germany. Sustainability 2020, 12, 3896. [Google Scholar] [CrossRef]

- Hildebrandt, J.; O’Keeffe, S.; Bezama, A.; Thran, D. Revealing the environmental advantages of industrial symbiosis in wood-based bioeconomy networks: An assessment from a life cycle perspective. J. Ind. Ecol. 2019, 23, 808–822. [Google Scholar] [CrossRef]

- UNEP. Guidelines for Social Life Cycle Assessment of Products and Organizations 2020; United Nations Environment Programme (UNEP): Paris, France, 2020. [Google Scholar]

| Parameters of Material Composition | Value | Unit | Source |

|---|---|---|---|

| Specific weight of a demonstrator element | 10,710 | kg per element | Own calculations |

| Possible range of solid concrete density | 1250–1400 | kg/m3 | Leading-edge cluster bioeconomy and parameters from [47] |

| Length | 9300 | mm | Leading-edge cluster bioeconomy/Fraunhofer WKI |

| Width | 3000 | mm | Leading-edge cluster bioeconomy/Fraunhofer WKI |

| Thickness | 250 | mm | Leading-edge cluster bioeconomy/Fraunhofer WKI |

| Fraction of flakes of fibers in relation to solid concrete density | 15–250 | % by weight related to solid concrete | Leading-edge cluster bioeconomy/Fraunhofer WKI and parameters from [47] |

| Bulk density of wood flakes | 230 | kg/m3 | Leading-edge cluster bioeconomy/Fraunhofer WKI |

| Density of wood flakes in the element production process | Approx. 280 | kg/m3 | Leading-edge cluster bioeconomy/Fraunhofer WKI |

| Subnet/Intermediates | Unit Processes | Source |

|---|---|---|

| Production of beech wood fibers for wood-based lightweight concrete system demonstrator type 1 | Natio: refiner <e-ep> Natio: fiber drying <e-ep> RER: wood chips, deciduous wood, u = 80%, stationary chipper <e-ep> RER: chipping of pulp/fiber wood, stationary chipper electric, at the gate RER: deciduous wood, allocation factor, 1 RER: deciduous wood DE: electricity mix PE DE: thermal energy from natural gas PE | - Results of own modeling and using data sources from [47] - Generic energy demands for refiners [48], adapted to beech wood - Life Cycle Inventories of Wood as Fuel and Construction Material. In: Final report ecoinvent data v2.0 Dübendorf, CH 2007. - PE International, GaBi database 2008–2013 |

| Production of beech wood flakes for wood-based lightweight concrete system demonstrator type 2 | RER: wood chips, deciduous wood, u = 80%, stationary chipper <e-ep> RER: chipping of pulp/fiber wood, stationary chipper electric, at the gate RER: deciduous wood, allocation factor, 1 RER: deciduous wood DE: electricity Mix PE DE: thermal energy from natural gas PE Disc Flaker process, self-specified | - Results of own modeling - Life Cycle Inventories of Wood as Fuel and Construction Material. In: Final report ecoinvent data v2.0 Dübendorf, CH 2007. - PE International, GaBi database 2008–2013 - Datasheets |

| Production of load-bearing reinforced concrete element as the outer part of the cassette systems | Natio: ceiling element-reinforced concrete <e-ep> GLO: reinforcing steel World Steel CN: concrete C30/37 ts | ThinkStep data set 2018: mixing of cement, water and aggregates such as gravel, production mix, at plant, Ökologische Bilanzierung von Baustoffen und Gebäuden, 2000, Eyerer, P.; Reinhardt, H.-W.: Ökologische Bilanzierung von Baustoffen und Gebäuden, Birkhäuser, Zürich 2000, data valid until 2021 ThinkStep data set 2018: blast furnace route and electric arc furnace route, production mix, at plant, World Steel Association 2015–2017 |

| Natio: product mixer Nation: wood fiber lightweight concrete for a cassette system | Results of own modeling based on inventory and material composition and [47] |

| Index | Indicator | Unit | Description | Indicator ID |

|---|---|---|---|---|

| Sub-Index | ||||

| 1. Health and safety | ||||

| Sick-leave | Preventive health measures | Cat. | Health measures (e.g., sick-leave analysis, health activities) | I1.1 |

| 2. Adequate remuneration | ||||

| Payment | Payment according to basic wage Average remuneration level | y/n € | Payment off basic wage Average payment per month per full-time employee per total employees | I2.1 I2.2 |

| 3. Adequate working time | ||||

| Working time | Contractual working hours | h | Average contractual working hours per week per full-time employee | I3.1 |

| Work–life-balance | Access to flexible working time agreements Rate of part-time employees | % % | Percentage of employees with access to flexible working agreements Number of part-time employees per total employees | I3.2 I3.3 |

| 4. Employment | ||||

| Job conditions | Rate of qualified employees Rate of marginal employees (max 450€) | % % | Percentage of employees with professional training per total employees Percentage of employees earning max. 450€ per total employees | I4.1 I4.2 |

| Duration of employment | Rate of fixed-term employees Rate of employees provided by temporary work agencies | % % | Number of fixed-term employees in relation to total employees Number of employees provided by temporary work agencies per total employees | I4.3 I4.4 |

| 5. Knowledge capital | ||||

| On-the-job training | Employees/unity participated in training Support for professional qualification | % y/n | (Qualified) employees/unity participated in training per total employees Assumption of cost or exemption for training programs | I5.1 I5.2 |

| Vocational training | Rate of vocational trainees | % | Trainees/total employees | I5.3 |

| 6. Equal opportunities | ||||

| Gender equality | Rate of female employees in management positions Rate of female employees | % % | Percentage of female employees in management positions in relation to all employees in management positions Percentage of female employees in relation to total employees | I6.1 I6.2 |

| Indicator | PRP | PRP | PRP |

|---|---|---|---|

| ID | O1 | O2 | O3 |

| I1.1 | 94% yes, 6% no | 94% yes, 6% no | 50% yes, 50% no |

| I2.1 I2.2 | 22% yes, 78% no 1016.34 | 21% yes, 79% no 1619.05 | 60% yes, 40% no 2115.34 |

| I3.1 | 40.85 | 38.8 | 40.6 |

| I3.2 I3.3 | 14% yes, 86% no 42.70% | 52% yes, 48% no 16.67% | 38% yes, 62% no 8.89% |

| I4.1 I4.2 | 53.11% 14.29% | 63.39% 5.23% | 75% 0% |

| I4.3 I4.4 | 1.62% No data | 6.48% 5.31% | 15.03% 5.64% |

| I5.1 I5.2 | 33.44% 39% yes, 61% no | 29.31% 76% yes, 24% no | 17.89% 77% yes, 23% no |

| I5.3 | 0.00% | 0.00% | 0.5% |

| I6.1 I6.2 | 21% yes, 79% no 39.50% | 21% yes, 79% no 47.62% | No data 41.67% |

| Indicator | Values | Values | Values | Scores | Scores | Scores |

|---|---|---|---|---|---|---|

| ID | O1 | O2 | O3 | O1 | O2 | O3 |

| I1.1 | Yes | Yes | Yes | 5.6 | 5.6 | 7.5 |

| I2.1 | Yes | No | No | 8.9 | 2.2 | 2.5 |

| I2.2 | 4105 | 1641 | 2192 | 10 | 4.1 | 7.5 |

| I3.1 | 40.0 | 38.8 | 37.6 | 6.6 | 9.2 | 10 |

| I3.2 | Yes | No | Yes | 9.7 | 2.1 | 10 |

| I3.3 | 4.34% | 18.23% | 4.18% | 9.5 | 4.0 | 8.51 |

| I4.1 | 96% | 61.7% | 72.2% | 5.4 | 4.3 | 5.36 |

| I4.2 | 0.23% | 7.69% | 0% | 9.7 | 4.2 | 10 |

| I4.3 | 1.55% | 24.7% | 15.78% | 10 | 1.6 | 5.54 |

| I4.4 | 0% | 46.55% | 0 | 5 | 0.3 | 10 |

| I5.1 | No data | 40.63% | 13.63% | 7.7 | 2.06 | |

| I5.2 | No | Yes | Yes | 3.1 | 6.21 | 6.5 |

| I5.3 | 3.25% | 0.00% | 0.2% | 7.7 | 4.8 | 3.82 |

| I6.1 | Yes | No | Yes | 9.0 | 4.1 | 7.5 |

| I6.2 | 18.28% | 50.0% | 33.33% | 2.0 | 5.3 | 5.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bezama, A.; Hildebrandt, J.; Thrän, D. Integrating Regionalized Socioeconomic Considerations onto Life Cycle Assessment for Evaluating Bioeconomy Value Chains: A Case Study on Hybrid Wood–Concrete Ceiling Elements. Sustainability 2021, 13, 4221. https://doi.org/10.3390/su13084221

Bezama A, Hildebrandt J, Thrän D. Integrating Regionalized Socioeconomic Considerations onto Life Cycle Assessment for Evaluating Bioeconomy Value Chains: A Case Study on Hybrid Wood–Concrete Ceiling Elements. Sustainability. 2021; 13(8):4221. https://doi.org/10.3390/su13084221

Chicago/Turabian StyleBezama, Alberto, Jakob Hildebrandt, and Daniela Thrän. 2021. "Integrating Regionalized Socioeconomic Considerations onto Life Cycle Assessment for Evaluating Bioeconomy Value Chains: A Case Study on Hybrid Wood–Concrete Ceiling Elements" Sustainability 13, no. 8: 4221. https://doi.org/10.3390/su13084221

APA StyleBezama, A., Hildebrandt, J., & Thrän, D. (2021). Integrating Regionalized Socioeconomic Considerations onto Life Cycle Assessment for Evaluating Bioeconomy Value Chains: A Case Study on Hybrid Wood–Concrete Ceiling Elements. Sustainability, 13(8), 4221. https://doi.org/10.3390/su13084221