Effects of Lighter Dose of Oxytetracycline on the Accumulation and Degradation of Volatile Fatty Acids in the Process of Thermophilic Anaerobic Digestion of Swine Manure

Abstract

:1. Introduction

2. Materials and Methods

2.1. Manure Sampling and Activated Sludge

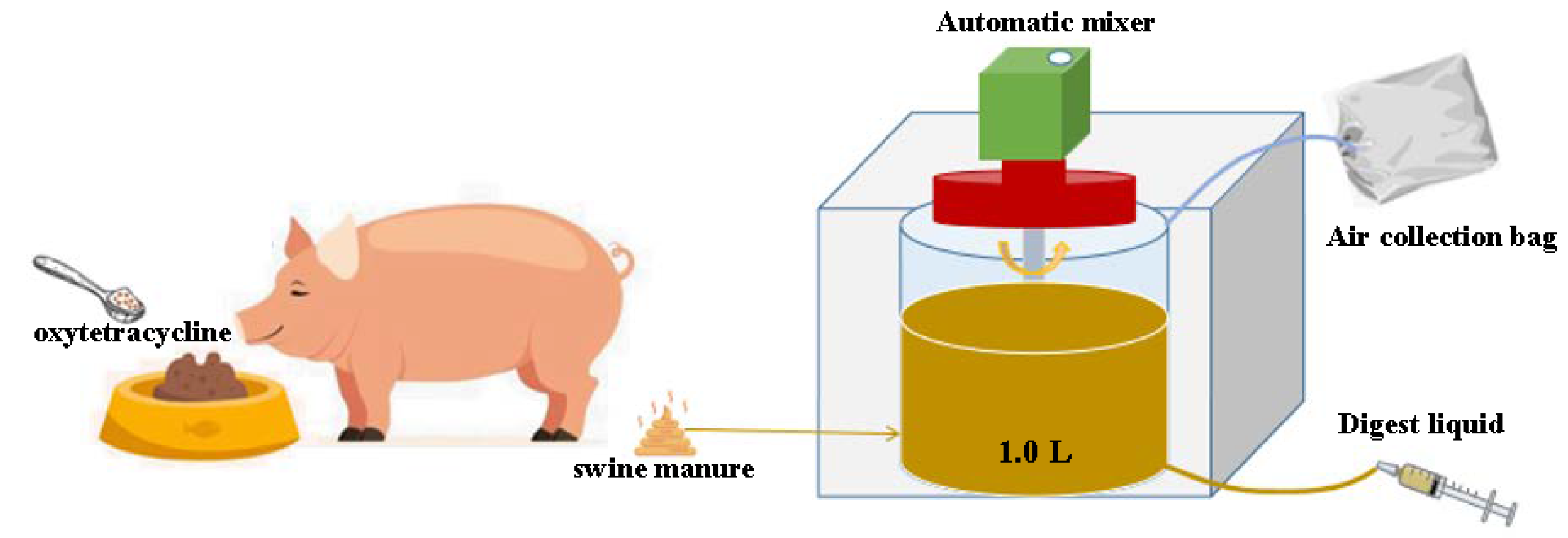

2.2. Experimental Design and Procedure

2.3. Analytical Methods

2.3.1. Basic Indicators

2.3.2. Biogas Measurement

2.3.3. Ultra-Performance Liquid Chromatography–Tandem Mass Spectrometry

2.4. Statistical Analysis

3. Results

3.1. Effects of OTC on Methane Production

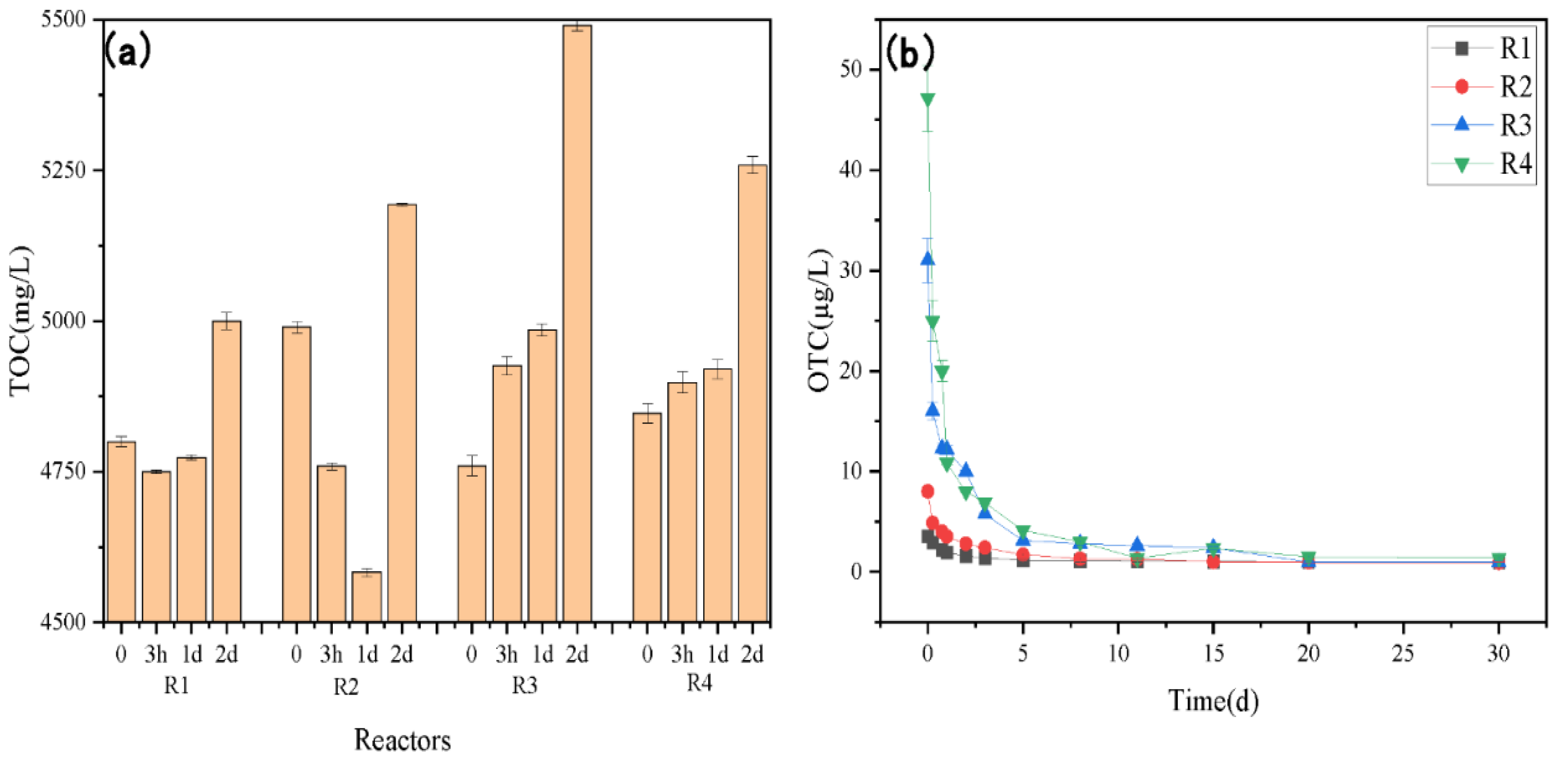

3.2. Effect of OTC on pH and VFA Production from Anaerobic Digestion

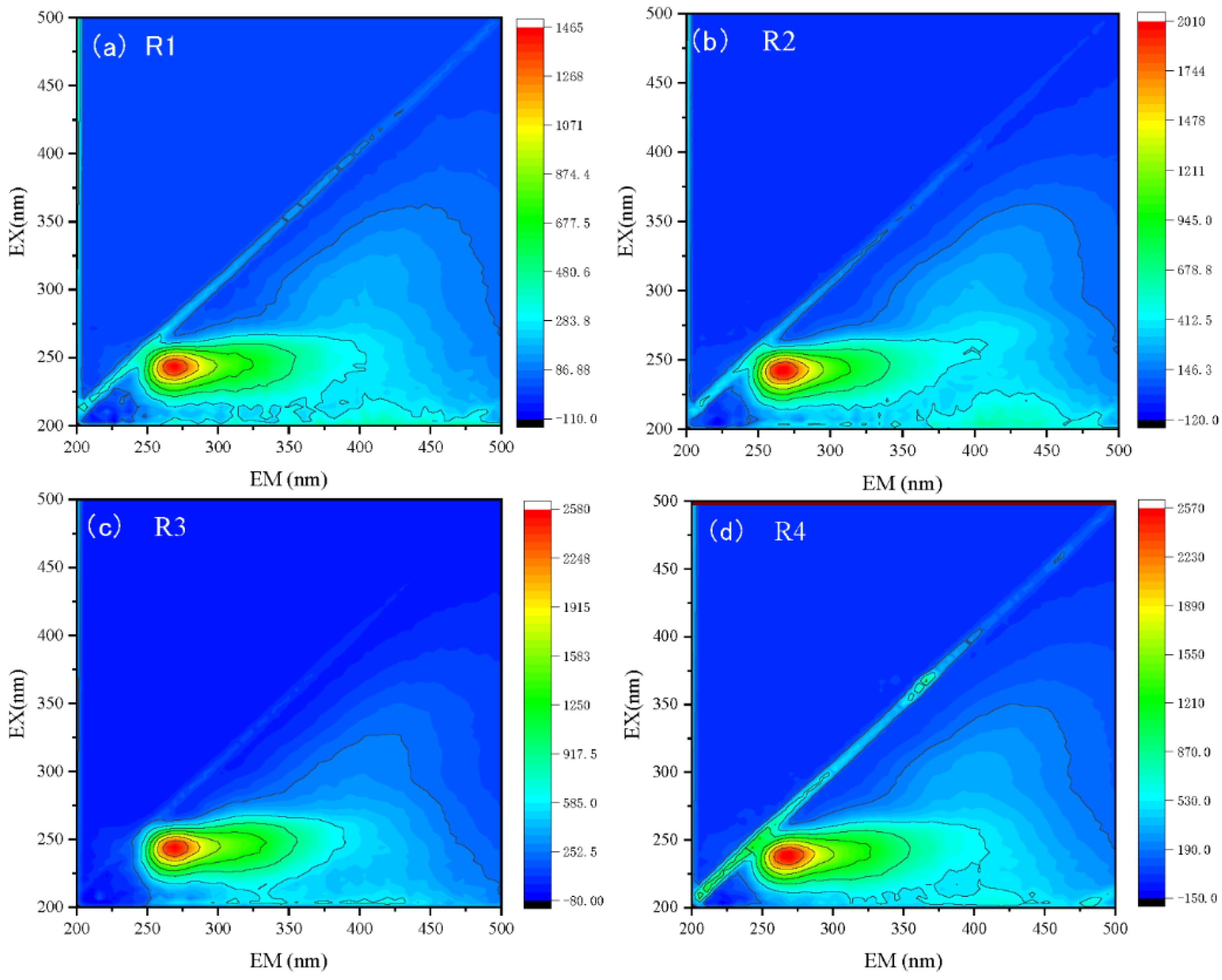

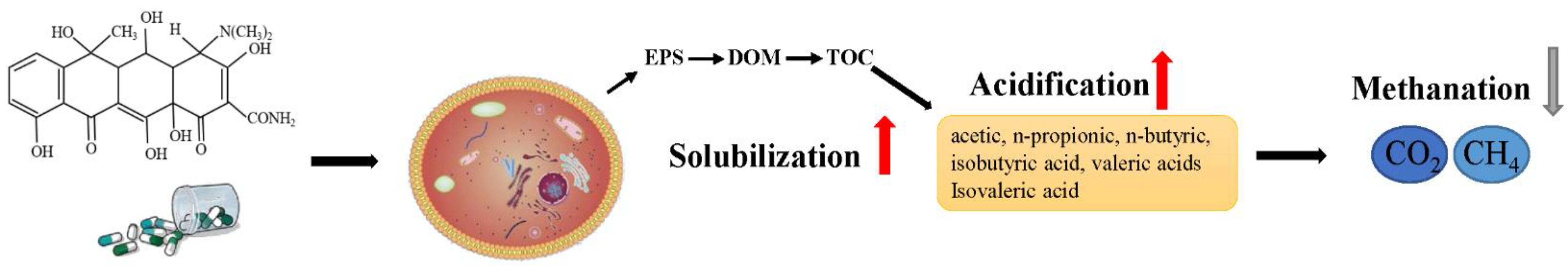

3.3. Effects of OTC on the Solubilization Process and the Entire Anaerobic Reaction

3.4. Degradation of OTC during Anaerobic Digestion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Liguoro, M.; Cibin, V.; Capolongo, F.; Halling-Sørensen, B.; Montesissa, C. Use of oxytetracycline and tylosin in intensive calf farming: Evaluation of transfer to manure and soil. Chemosphere 2003, 52, 203–212. [Google Scholar] [CrossRef]

- Alvarez, J.A.; Otero, L.; Lema, J.M.; Omil, F. The effect and fate of antibiotics during the anaerobic digestion of pig manure. Bioresour. Technol. 2010, 101, 8581–8586. [Google Scholar] [CrossRef]

- Zheng, W.; Zhang, Z.; Liu, R.; Lei, Z. Removal of veterinary antibiotics from anaerobically digested swine wastewater using an intermittently aerated sequencing batch reactor. J. Environ. Sci. 2018, 65, 8–17. [Google Scholar] [CrossRef]

- Ke, X.; Wang, C.; Li, R.; Zhang, Y. Effects of Oxytetracycline on Methane Production and the Microbial Communities During Anaerobic Digestion of Cow Manure. J. Integr. Agric. 2014, 13, 1373–1381. [Google Scholar] [CrossRef]

- Jiang, J.; Sui, J.; Wu, S.; Yang, Y.; Wang, L. Prospects of anaerobic digestion technology in China. Tsinghua Sci. Technol. 2007, 12, 435–440. [Google Scholar] [CrossRef]

- Kardos, L.; Juhasz, A.; Palko, G.; Olah, J.; Zaray, G. Comparing of mesophilic and thermophilic anaerobic fermented sewage sludge based on chemical and biochemical tests. Appl. Ecol. Environ. Res. 2011, 9, 293–302. [Google Scholar] [CrossRef]

- Watanabe, H.; Kitamura, T.; Ochi, S.; Ozaki, M. Inactivation of pathogenic bacteria under mesophilic and thermophilic conditions. Water Sci. Technol. 1997, 36, 25–32. [Google Scholar] [CrossRef]

- Lins, P.; Reitschuler, C.; Illmer, P. Impact of several antibiotics and 2-bromoethanesulfonate on the volatile fatty acid degradation, methanogenesis and community structure during thermophilic anaerobic digestion. Bioresour. Technol. 2015, 190, 148–158. [Google Scholar] [CrossRef]

- Beneragama, N.; Lateef, S.A.; Iwasaki, M.; Yamashiro, T.; Umetsu, K. The combined effect of cefazolin and oxytertracycline on biogas production from thermophilic anaerobic digestion of dairy manure. Bioresour. Technol. 2013, 133, 23–30. [Google Scholar] [CrossRef]

- Cetecioglu, Z.; Ince, B.; Gros, M.; Rodriguez-Mozaz, S.; Barcelo, D.; Ince, O.; Orhon, D. Biodegradation and reversible inhibitory impact of sulfamethoxazole on the utilization of volatile fatty acids during anaerobic treatment of pharmaceutical industry wastewater. Sci. Total Environ. 2015, 536, 667–674. [Google Scholar] [CrossRef]

- Garcia-Sanchez, L.; Garzon-Zuniga, M.A.; Buelna, G.; Estrada-Arriaga, E.B. Tylosin effect on methanogenesis in an anaerobic biomass from swine wastewater treatment. Water Sci. Technol. 2016, 73, 445–452. [Google Scholar] [CrossRef]

- Akyol, Ç.; Ince, O.; Cetecioglu, Z.; Alkan, F.U.; Ince, B. The fate of oxytetracycline in two-phase and single-phase anaerobic cattle manure digesters and its effects on microbial communities. J. Chem. Technol. Biotechnol. 2016, 91, 806–814. [Google Scholar] [CrossRef]

- Aydin, S.; Cetecioglu, Z.; Arikan, O.; Ince, B.; Ozbayram, E.G.; Ince, O. Inhibitory effects of antibiotic combinations on syntrophic bacteria, homoacetogens and methanogens. Chemosphere 2015, 120, 515–520. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association: Washington, DC, USA, 1998. [Google Scholar]

- He, C.; Zhao, J.; Wang, S.; Guan, S.; Zhang, Z.; Zhang, Q.; Pan, X.; Jiao, Y. Ammonium bicarbonate pretreatment of corn stalk for improved methane production via anaerobic digestion: Kinetic modeling. Bioresour. Technol. 2019, 292, 122052. [Google Scholar] [CrossRef]

- Dorival-García, N.; Zafra-Gómez, A.; Cantarero, S.; Navalón, A.; Vílchez, J.L. Simultaneous determination of 13 quinolone antibiotic derivatives in wastewater samples using solid-phase extraction and ultra performance liquid chromatography-tandem mass spectrometry. Microchem. J. 2013, 106, 323–333. [Google Scholar] [CrossRef]

- Yin, F.; Dong, H.; Ji, C.; Tao, X.; Chen, Y. Effects of anaerobic digestion on chlortetracycline and oxytetracycline degradation efficiency for swine manure. Waste Manag. 2016, 56, 540–546. [Google Scholar] [CrossRef]

- Yin, F.; Dong, H.; Zhang, W.; Zhu, Z.; Shang, B. Antibiotic degradation and microbial community structures during acidification and methanogenesis of swine manure containing chlortetracycline or oxytetracycline. Bioresour. Technol. 2018, 250, 247–255. [Google Scholar] [CrossRef]

- Arikan, O.A.; Sikora, L.J.; Mulbry, W.; Khan, S.U.; Rice, C.; Foster, G.D. The fate and effect of oxytetracycline during the anaerobic digestion of manure from therapeutically treated calves. Process Biochem. 2006, 41, 1637–1643. [Google Scholar] [CrossRef]

- Lay, J.J.; Li, Y.Y.; Noike, T.; Endo, J.; Ishimoto, S. Analysis of environmental factors affecting methane production from high-solids organic waste. Water Sci. Technol. 1997, 36, 493–500. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef]

- Eryildiz, B.; Taherzadeh, M.J. Effect of pH, substrate loading, oxygen, and methanogens inhibitors on volatile fatty acid (VFA) production from citrus waste by anaerobic digestion. Bioresour. Technol. 2020, 302, 122800. [Google Scholar] [CrossRef]

- Cheng, D.L.; Ngo, H.H.; Guo, W.S.; Chang, S.W.; Nguyen, D.D.; Kumar, S.M.; Du, B.; Wei, Q.; Wei, D. Problematic effects of antibiotics on anaerobic treatment of swine wastewater. Bioresour. Technol. 2018, 263, 642–653. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Liu, X.; Fu, Y.; Li, Y.; Wang, D.; Wang, Q.; Liu, Y.; An, H.; Zhao, J.; Wu, Y.; et al. Feasibility of enhancing short-chain fatty acids production from waste activated sludge after free ammonia pretreatment: Role and significance of rhamnolipid. Bioresour. Technol. 2018, 267, 141–148. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zeng, X.; Zhou, Y.; Yang, X.; Lam, S.S.; Wang, D. Influence of roxithromycin as antibiotic residue on volatile fatty acids recovery in anaerobic fermentation of waste activated sludge. J. Hazard. Mater. 2020, 394, 122570. [Google Scholar] [CrossRef] [PubMed]

- Xie, J.; Duan, X.; Feng, L.; Yan, Y.; Wang, F.; Dong, H.; Jia, R.; Zhou, Q. Influence of sulfadiazine on anaerobic fermentation of waste activated sludge for volatile fatty acids production: Focusing on microbial responses. Chemosphere 2019, 219, 305–312. [Google Scholar] [CrossRef]

- Khan, M.A.; Ngo, H.H.; Guo, W.S.; Liu, Y.; Nghiem, L.D.; Hai, F.I.; Deng, L.J.; Wang, J.; Wu, Y. Optimization of process parameters for production of volatile fatty acid, biohydrogen and methane from anaerobic digestion. Bioresour. Technol. 2016, 219, 738–748. [Google Scholar] [CrossRef]

- Kong, X.; Yu, S.; Xu, S.; Fang, W.; Liu, J.; Li, H. Effect of Fe(0) addition on volatile fatty acids evolution on anaerobic digestion at high organic loading rates. Waste Manag. 2018, 71, 719–727. [Google Scholar] [CrossRef]

- Han, Y.; Green, H.; Tao, W. Reversibility of propionic acid inhibition to anaerobic digestion: Inhibition kinetics and microbial mechanism. Chemosphere 2020, 255, 126840. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, Q.; Zhao, J.; Wu, Y.; Wu, L.; Li, H.; Tang, M.; Sun, Y.; Guo, W.; Feng, Q.; et al. Potential influences of exogenous pollutants occurred in waste activated sludge on anaerobic digestion: A review. J. Hazard. Mater. 2020, 383, 121176. [Google Scholar] [CrossRef]

- Huang, X.; Xu, Q.; Wu, Y.; Wang, D.; Zhong, Q. Effect of clarithromycin on the production of volatile fatty acids from waste activated sludge anaerobic fermentation. Bioresour. Technol. 2019, 288, 121598. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Y.; Liu, X.; Xu, Q.; Yang, Q.; Li, X.; Zhang, Y.; Liu, Y.; Wang, Q.; Ni, B.J.; et al. Heat pretreatment assists free ammonia to enhance hydrogen production from waste activated sludge. Bioresour. Technol. 2019, 283, 316–325. [Google Scholar] [CrossRef]

- Sheng, G.P.; Yu, H.Q.; Li, X.Y. Extracellular polymeric substances (EPS) of microbial aggregates in biological wastewater treatment systems: A review. Biotechnol. Adv. 2010, 28, 882–894. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Jia, Y.; Khanal, S.K.; Lu, H.; Fang, H.; Zhao, Q. Understanding the Role of Extracellular Polymeric Substances on Ciprofloxacin Adsorption in Aerobic Sludge, Anaerobic Sludge, and Sulfate-Reducing Bacteria Sludge Systems. Environ. Sci. Technol. 2018, 52, 6476–6486. [Google Scholar] [CrossRef] [PubMed]

- Coban, H.; Ertekin, E.; Ince, O.; Turker, G.; Akyol, C.; Ince, B. Degradation of oxytetracycline and its impacts on biogas-producing microbial community structure. Bioprocess Biosyst. Eng. 2016, 39, 1051–1060. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Wei, Y.; Zheng, J.; Zhao, X.; Zhong, W. The behavior of tetracyclines and their degradation products during swine manure composting. Bioresour. Technol. 2011, 102, 5924–5931. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Unit | Inoculum Sludge | Swine Manure | Inoculum Sludge + Swine Manure + Rinse Solution |

|---|---|---|---|---|

| Total solids (TS) | % | 22.92 | 23.54 | 7.00 |

| Volatile solids (VS) | % | 54.42 | 74.59 | 66.87 |

| Total organic carbon (TOC) | mg/L | 52.36 | 6901.21 | 4964.81 |

| Total nitrogen (TN) | mg/L | 178.04 | 1201.02 | 358.48 |

| C/N | - | <1 | 5.75 | 13.85 |

| pH | - | 7.41 | 7.53 | 7.62 |

| Key Parameters | R1 (0 mg/L) | R2 (0.1 mg/L) | R3 (0.5 mg/L) | R4 (1.0 mg/L) |

|---|---|---|---|---|

| Mm (mL) | 1501.92 ± 13.07 | 1523.78 ± 14.02 | 1450.83 ± 20.01 | 1306.06 ± 14.02 |

| Rm (mL/d) | 122.99 ± 3.90 | 119.64 ± 3.99 | 103.29 ± 4.09 | 104.41 ± 4.01 |

| R2 | 0.998 | 0.998 | 0.997 | 0.997 |

| λ (d) | 3.51 ± 0.19 | 3.25 ± 0.21 | 4.20 ± 0.26 | 3.87 ± 0.23 |

| Mm (mL) | 1501.92 ± 13.07 | 1523.78 ± 14.02 | 1450.83 ± 20.01 | 1306.06 ± 14.02 |

| Rm (mL/d) | 122.99 ± 3.90 | 119.64 ± 3.99 | 103.29 ± 4.09 | 104.41 ± 4.01 |

| Key Parameters | R1 (0 mg/L) | R2 (0.1 mg/L) | R3 (0.5 mg/L) | R4 (1.0 mg/L) |

|---|---|---|---|---|

| k (d−1) | / | 0.65 | 0.98 | 1.37 |

| R2 | / | 0.70 | 0.82 | 0.91 |

| Degradation efficiency | 0.73 | 0.89 | 0.97 | 0.97 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Z.; Zhang, M.; Chen, X.; Hu, Z.; Shu, Q.; Jing, C.; Luo, X. Effects of Lighter Dose of Oxytetracycline on the Accumulation and Degradation of Volatile Fatty Acids in the Process of Thermophilic Anaerobic Digestion of Swine Manure. Sustainability 2021, 13, 4014. https://doi.org/10.3390/su13074014

Fan Z, Zhang M, Chen X, Hu Z, Shu Q, Jing C, Luo X. Effects of Lighter Dose of Oxytetracycline on the Accumulation and Degradation of Volatile Fatty Acids in the Process of Thermophilic Anaerobic Digestion of Swine Manure. Sustainability. 2021; 13(7):4014. https://doi.org/10.3390/su13074014

Chicago/Turabian StyleFan, Zijing, Mei Zhang, Xiaxia Chen, Zhongda Hu, Qihang Shu, Chaosen Jing, and Xingzhang Luo. 2021. "Effects of Lighter Dose of Oxytetracycline on the Accumulation and Degradation of Volatile Fatty Acids in the Process of Thermophilic Anaerobic Digestion of Swine Manure" Sustainability 13, no. 7: 4014. https://doi.org/10.3390/su13074014

APA StyleFan, Z., Zhang, M., Chen, X., Hu, Z., Shu, Q., Jing, C., & Luo, X. (2021). Effects of Lighter Dose of Oxytetracycline on the Accumulation and Degradation of Volatile Fatty Acids in the Process of Thermophilic Anaerobic Digestion of Swine Manure. Sustainability, 13(7), 4014. https://doi.org/10.3390/su13074014