Abstract

The agriculture sector produces significant amounts of organic residues and the choice of the management strategy of these flows affects the environmental sustainability of the sector. The scientific literature is rich with innovative processes for the production of bio-based products (BBP) from agriculture residues, aimed at the implementation of circular economy principles. Based on literature data, the present paper performed a life cycle assessment and assessed the environmental sustainability of five processes for the exploitation of rice and wheat straw, tomato pomace, and orange peel. The analysis identified as significant issues the high energy demand and the use of high impact organic solvent. The comparison of BBP with conventional products showed higher environmental loads for the innovative processes that used organic residues (except for rice straw case). The obtained results do not want to discourage the circular strategy in the agriculture sector, but rather to draw the attention of all stakeholders to the environmental sustainability aspects, focusing on the necessity to decrease the electricity demand and identify ecological agents to use in BBP manufacturing, in agreement with the most recent European policies.

1. Introduction

1.1. State of the Art of Exploitation of Agriculture Residues

The agricultural production is genuinely diverse; nevertheless, it focuses on some central species fundamental for human diet, such as cereals, but also fruits and vegetables, whose quantities exceed billions of tons of biomass produced [1]. Italian agriculture has a significant role in Europe, being the 3rd country based on its production value in 2019 [2]. From the ISTAT database, it appears to be dominated by fodder plants, but cereals are another important role in every regional production; besides these main species, horticulture and fruit growing have another important role to play [3]. Due to the world population growth in the current century, food demand has increased worldwide and consequently the residues that food production generates too [4]. This biomass can reach huge quantities and sometimes its disposal might create environmental or health issues. For this reason, a further exploitation can be pursued to reduce these negative effects and enhance the underused potential; in this context, the bio-based products (BBP) can be a viable option [5]. In the scientific literature, several studies have been conducted about agricultural residues and byproducts exploitation. As shown in Table 1, many studies propose solutions for the exploitation of residues from species actually produced in Italy (but not only), i.e., cereals to horticultural species, but also fruits and fodder plants. As reported in the literature, the BBP manufacturing can start from both residual biomass, collected during harvesting stage, and industrial processes. The BBP from agriculture residues can be classified on the basis of the levels of residue manipulation. The first level of manipulation is the lowest (mainly mechanical, physical treatments, and mixing with other components), e.g., composite panels used in the building sector made from sunflower or maize lignocellulosic fibers [6,7]. A greater manipulation level allows the extraction of molecules used in their unaltered state, such as antioxidants and vitamins [8,9]. A third level of transformation consists of more complex processes, creating nanoparticles or functional polymers [10,11]. As an alternative, they can be categorized as chemicals and composites. Acids, enzymes, and coloring substances are chemicals used in pharmaceutical and textile industries, as well as food and biomedical sectors [12]. Among these molecules, there are also the functional ingredients that improve or provide more value to other products of food and cosmetic industries [13]. Examples of these substances are vitamins, fibers, antioxidants, and pigments derived from fruits and vegetables peels [8,9]. On the other hand, composite materials are made of two main elements, a matrix and a filler [14]. Among composite materials, polymers, e.g., hydrogel [15] or plastic films [5], have great importance and they can have several structures, e.g., adsorbent polymers for metal particles [16] or packaging materials. This second type of products includes the smart polymers that can react to some parameter variations to point out the initial deterioration, preventing food loss [17]. Moreover, nanoparticles (NPs) have gained great attraction due to their submicronic dimensions that make them more performing than macro and micro composites for nanocomposites production [14]. In this regard, lignin molecule is used as capping and reducing agent on the surface of silver nanoparticles. Possible applications can be in the textile industry and in biomedical and electronic fields [18,19].

Table 1.

Selected exploitation processes for the use of agricultural residues.

Several articles carried out a comparison between traditional products on the market (produced by conventional manufacturing chain, from raw materials different from byproducts) and bio-based alternatives from organic residues, identifying as the most common benefit the use of low value residual biomass available in huge quantities, for example wheat, rice, and maize [16,20,21,22,23,24]. A common goal of the processes presented by the scientific literature about organic residue exploitation is the green production, meaning low energy consumption and nontoxic agent applications [15,19,23,25]. To complete the current overview about BBP, mainly in an Italian context, the SPRING cluster deserves to be mentioned. It is an Italian cluster that involves bio-refineries and innovation stakeholder with the common goal of enhancing the circular and sustainable economy in the green chemistry sector [26]. Despite the several advantages of BBP manufacturing, the use of organic byproducts shows some relevant challenges. The first one is due to the residue availability, concentrated in a short time span [7], which makes the stocking methods essential [9]. There are also mechanical-physical observations to do about these materials. In this regard, the advantage of the use of bio-based polymers, mainly lignocellulosic materials, is their performance, also as far as it concerns the flammability behavior [7,27]. Nevertheless, they show some disadvantages as the scarce mechanical properties that can be improved by mixing different polymers [11,28]. Furthermore, the literature underlines the necessity to combine studies of BBP production with the analysis of the specific aspects of these products; for example, for human health applications, by clinical tests of the real physiological action [8,18]. Last but definitely not least, the environmental performance of manufacturing processes should be assessed, supported by tools able to implement a life cycle approach.

1.2. The GRASCIARI RIUNITI Project

The present paper is part of a preliminary analysis of the environmental sustainability within the GRASCIARI RIUNITI project (within the European plan to support the Regional development FEASR-PSR MARCHE 2014–2020). Several farms on the Marche territory have identified a relevant problem due to the management of the organic residue from their agriculture activity. This problem is mainly due to the growing specialization of the crops, which has ensured high production levels but it has changed the way of considering the agriculture residues: from a biomass resource of the past to a waste to dispose of the present. This practice has disrupted the balance of agriculture in many Italian regions. The founded project, which combines local farms and research partners, has the ambition to create a virtuous management system of waste and byproduct, suitable for a real scale implementation. With this aim many possibilities of agriculture residue exploitation will be considered (e.g., production of BB materials, active principles with specific action, fertilizers, biostimulants, energy recovery) in order to combine the best options for the most sustainable result. Starting from the byproduct criticality, really highlighted by the local farms, the present manuscript analyzed many papers from the scientific literature addressed to the BBP production (Table 1) and it selected five case studies (focused on the exploitation of residues of the main Italian agricultural productions) for an environmental sustainability analysis. The research did not have the presumption to find a single answer but to critically observe some possibilities of agriculture residue exploitation, to verify the effective implementation of the circular economy pillars. With this aim, the environmental sustainability analysis was carried out by a life cycle assessment (LCA) approach.

2. Materials and Methods

2.1. Methods and Software

The quantification of the environmental impact represents an essential step for the development of processes for agriculture residue management, consistent with the circular economy principles [37]. Therefore, the present paper assesses five exploitation processes of four different types of agriculture residue, from Table 1: rice and wheat straw, tomato pomace, and orange peel. These species were included among the most common of the Italian agriculture with the consequent production of huge quantities of byproducts. Therefore, they have been considered relevant for the national scenario. The analysis, according to the attributional LCA methodology, has been performed in agreement with the LCA ISO standard 14040 and 14044:2006 [38,39]. The assessment aims at answering at two main research questions, inspired by [40]:

- -

- What are the environmental hotspots in the considered exploitation processes of agriculture residues? What is the environmental impact of these innovative processes?

- -

- What is the environmental impact of these processes compared with the most common manufacture of comparable products (using conventional raw materials)?

The system boundaries considered for the present paper focused on the byproduct exploitation (from gate to gate), starting with the produced agricultural residue, excluding the use phase and the end of life, because they are considered equal between the conventional and the biobased product. The environmental burden of byproduct is considered 0, since it has been assumed its simple use, in animal husbandry field, in the case of avoided use in BBP [41,42,43]. Furthermore, the use of the zero-burden assumption for agricultural residues is common for attributional-LCA studies [44]. All LCA steps have been realized, including the optional normalization and weighing, to assess the most affected impact categories and the most critical steps of each process. The software used for data collection is thinkstep Gabi software 9.5, combined with the Database for Life Cycle Engineering (compilation 7.3.3.153; DB version 6.115). The method selected for the analysis is EF 3.0, including all the environmental categories, recommended models at midpoint, together with their indicators, units and sources [45,46]. The functional unit selected for the process analysis is 1 kg of agricultural residue to produce selected bio-based products (with emerging technologies). To answer to the second research question, the functional unit is a specific amount (reported in Figure 1, Figure 2, Figure 3 and Figure 4) of bio-based products, resulting from the treatment of 1 kg of agricultural residue, in order to facilitate a comparison with a conventional production process (baseline scenario). The processes considered for the present assessment were developed at lab scale (maximum TRL4). The literature reports that in a higher technology development stage environmental and economic impacts are usually lower than a lab scale [47]. Therefore, some sensible assumptions are made to realize this analysis, hypothesizing the further scale-up:

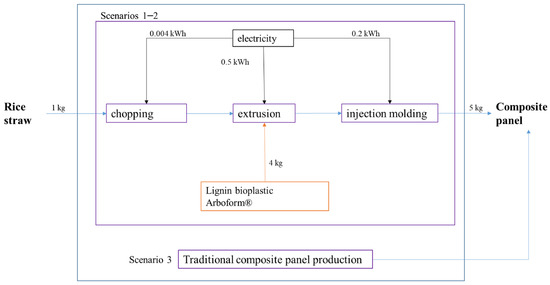

Figure 1.

System boundaries and mass and energy balance of rice straw exploitation (scenario 1) and traditional process (scenario 3); scenario 2 includes the same conditions of scenario 1 with electricity from renewable energy. Functional unit: 1 kg of organic residue.

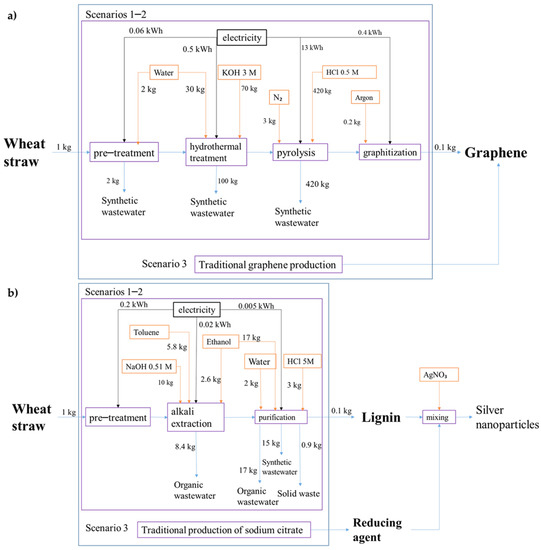

Figure 2.

System boundaries and mass and energy balance of two wheat straw exploitation processes as graphene ((a), scenario 1) and reducing agent ((b), scenario 1) and traditional processes (scenarios 3); in both (a) and (b) options, scenarios 2 include the same conditions of scenarios 1 with electricity from renewable energy. Functional unit: 1 kg of organic residue.

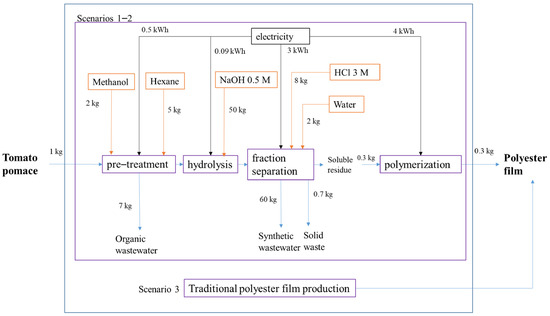

Figure 3.

System boundaries and mass and energy balance of tomato pomace exploitation (scenario 1) and traditional process (scenario 3); scenario 2 includes the same conditions of scenario 1 with electricity from renewable energy. Functional unit: 1 kg of organic residue.

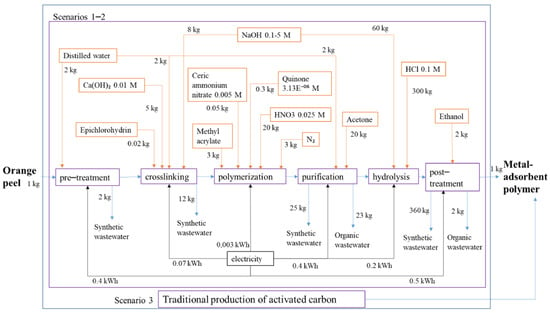

Figure 4.

System boundaries and mass and energy balance of orange peel exploitation (scenario 1) and traditional process (scenario 3); scenario 2 includes the same conditions of scenario 1 with electricity from renewable energy. Functional unit: 1 kg of organic residue.

- The electricity consumption reported within the datasheet of real industrial machineries is considered to calculate the energy environmental load of mechanical-physical steps (e.g., grinding, sieving, mixing, heating); the further implementation of a renewable energy production system by a photovoltaic panel system is considered as an alternative to supply the energy to the machineries [47]. This possibility is not considered for the traditional processes (from raw materials) since it is more likely that a new technology invests in a renewable technology.

- The recirculation of 90% of organic solvents for extraction and washing treatments is applied. This assumption, consistent with the real-scale conditions, makes the processes more efficient and environmentally sustainable, thanks to both the reduction of raw material consumptions and waste flow [47,48].

- The conditions selected for the washing operations have been the residue and the washing solution ratio: 1:2 ratio and the time: 1 h, if not specified elsewhere.

- Considering the low electricity demand, compared to the other process steps (<0.002 kWh/kg residue), the filtration energy demand is considered negligible [49].

Further assumptions, specific for each process, are reported in the supporting materials (Table S1).

2.2. Exploitation Processes

In this section, the five processes (selected among the options in Table 1) are described and showed through mass and energy balances flow charts. The choice of these processes has been determined by the will of the authors to prove the possible use of BBP in a wide range of application fields (e.g., building field of the composite panel and the medical sector of silver nanoparticles).

Currently, rice straw is separated from rice after harvesting and threshing and it is used in animal husbandry, as bedding [41]. As an alternative, the exploitation process in Figure 1 is realized through cutting the residue, mixing with Lignin bioplastic Arboform®, extrusion and injection molding, obtaining 5 kg of composite panel for interior design as final product [27]. On the other hand, the manufacturing of a traditional panel involves wood and polypropylene, by a process comparable to the innovative one [50].

As well as rice straw, wheat straw is produced after harvesting and threshing and it is used in animal husbandry, as bedding [42]. Two processes have been considered as alternative enhancements of this residue and they both represent innovative solutions in electronics and biomedicine, respectively: graphene (Figure 2a) and lignin as reducing agent for silver nanoparticles (Figure 2b). More in detail, the graphene is produced through hydrothermal treatment, pyrolysis and graphitization [23]. Lignin, as reducing agent is extracted from wheat straw, purified, and mixed with silver nitrate [18,51]. There are several techniques currently used for the graphene and lignin productions. The present study considers, as traditional scenario, the electrochemical exfoliation of graphite, which produces graphene monolayer [52] and the production of sodium citrate, as reducing agent [53,54]. In the reducing agent case, system boundaries exclude the silver nitrate addition for the nanoparticles production, since it is a common step in both innovative and traditional scenarios and does not affect the comparison results.

Tomato pomace is a byproduct of the transformation industry and it is currently used in animal feed composition [43]. In the study taken into account (Figure 3), this residue is exploited through the extraction of fatty acids that are used to produce a polyester polymer, after hydrolysis and fraction separation. The product shows many promising qualities, it is insoluble, nontoxic, biodegradable, and waterproof, which are optimal features resulting from the chemical composition of the initial biomass matrix [5]. The comparison has been carried out with a traditional polyester production described in the Gabi database [55].

Orange peel is a byproduct of the juice industry [16] and it is currently used as animal feed, as some of the previous agriculture scraps analyzed [43]. In the innovative scenario (Figure 4), this residue undergoes several steps: it is cut into small pieces, washed and dried, crushed and sieved during the pre-treatment. Thereafter, it is crosslinked with epichlorohydrine [16,56], a crosslinking agent that, owing to covalent bonds with the polymer, makes it more stable in acid conditions improving its adsorbing capacity [57]. The polymerization is realized with methyl acrylate and the following steps aim at the product purification. The process produces 1 kg of polymer characterized by a high adsorbent capacity, useful in wastewater treatment. This purification mechanism can be achieved with different techniques, mainly with activated carbons [16]. This material is selected for the comparison with the innovative proposed adsorbent; in detail, the manufacture of activated carbons includes a chemical activation with potassium hydroxide and pyrolysis of biomass [58].

3. Results

3.1. Classification and Characterization

The step of the analysis including classification and characterization steps has been performed (by thinkstep Gabi software 9.2.1, Database for Life Cycle Engineering, Sphera, Chicago, IL, USA) with the aim to identify both the strengths and weaknesses of the considered processes. The total results for the considered impact categories (referred to the functional unit) are reported in Table 2; the detail of each process is reported in the supporting materials.

Table 2.

Results of classification and characterization. Functional unit: 1 kg of organic residue.

3.1.1. From Rice Straw to Composite Panel

Figure S1 in Supplementary Materials shows the results of classification and characterization steps of LCA carried out on the rice straw treatment for the manufacturing of the composite panel. Overall, it can be observed that the lignin bioplastic Arboform causes the most relevant impact, irrespective of the impact category with a minimum contribution of 55%, which reaches values higher than 95% of the total results. This result is explained by the energy demand and the extraction phase included within the production process of lignin bioplastic Arboform [59,60]. On the other hand, the extrusion step has a non-negligible impact on ionizing radiation-human health effect, land use, and ozone depletion categories due to its high-energy demand. The effect of electricity consumption on the land use category can be justified by the electricity grid mix considered for the analysis (supplied by Gabi database) composed of energy from: 44% of natural gas, 15% hydroelectric, and 12% hard coal (and other lower contributions from additional resources). Instead, the chopping step and has no substantial influence, with a contribution lower than 1% overall, thanks to the low energy demand.

3.1.2. From Wheat Straw to Graphene and Nanoparticles

Considering the availability of two processes for the exploitation of wheat straw, a double result is shown in Supplementary Materials (Figure S2) the contribution of every step on the environmental load of each treatment and the comparison between the two options in all the impact categories. The results show that graphene production has a higher impact than lignin production for most of categories. The pyrolysis step explains this result, due to the energy demand to reach high temperature, around 800 °C for three hours. The effect of the pyrolysis operative conditions is mainly highlighted in the categories of ozone depletion and water scarcity with a contribution of pyrolysis phase around 87% for each of them (Figure S2 (m) and (r)). On the other hand, the pre-treatment stage results as not significant, since its share does not exceed 2% in any category. Even if it is the least influencing process, the lignin production shows as main critical point the purification step. This stage represents the most significant share in most of the categories, affecting by 67% the whole enhancement process and the reason can be identified in the ethanol use. In addition, alkali extraction has an impact due to the use of toluene. This organic compounds use makes the graphene production the best choice mainly in the categories connected to the human health aspects in Supplementary Materials (Figure S2 (l) and (n)). The environmental credit (the negative value) achieved in the water scarcity category (Figure S2 (r)) is obtained by the treated wastewater that has been discharged in the environment.

3.1.3. From Tomato Pomace to Polyester

The results of the tomato pomace exploitation for the polyester film production are presented in Supplementary Materials (Figure S3). The impact of the different steps depends on the impact category; therefore, the further normalization and weighting steps are essential to identify the significant issues of the process. The fraction separation step is the most influencing phase because of the 72 h-vacuum thermic treatment, whose impact is higher than 37%. However, in the water scarcity category (Figure S3 (r)), the fraction separation step has a negative share, an environmental credit derived from the water recovery from the wastewater treatment. In the same category, the most significant step is the hydrolysis due to the high request of water. Overall, pre-treatment and polymerization phases are not negligible with variable contribution to the different categories, between 3% and 48% and between 9% and 40%, respectively. The reasons are the energy demand in the polymer synthesis and the use of organic solvents (hexane and methanol) in the pre-treatment. This information suggests the relevance of the organic agents recirculation to enhance the environmental sustainability of the process.

3.1.4. From Orange Peel to Metal-Adsorbent Polymer

As concern the orange peel exploitation for metal-adsorbent polymer manufacturing, the highest environmental load of polymerization is shown in Supplementary Materisls (Figure S4). The main reason of this impact, starting from 35% up, is the use of methyl acrylate that is an organic compound, essential for the reaction. In agreement to what has been observed in the tomato pomace exploitation process, the hydrolysis phase causes the main contribution (85%) in the water scarcity category (Figure S4 (r)). In addition, the wastewater treatment included in the post-treatment phase produces an environmental credit in the water scarcity category, even though this step has the highest contribution in eutrophication freshwater category. On the other hand, pre-treatment is a negligible phase in almost each category, with a low contribution, steady under 1%, due to the low energy and water consumption.

3.2. Normalization and Weighing

The classification and characterization steps showed relevant information to identify the most critical steps in each process. Nevertheless, the normalization and weighting phases were necessary to assess the whole magnitude of each phase of the treatments and to estimate the environmental performance index (EPI), able to include all the impact categories. In agreement with the selected method, this value is expressed as person equivalent (p.e.), i.e., the number of people (average citizens) that generates the same effect in one year [61].

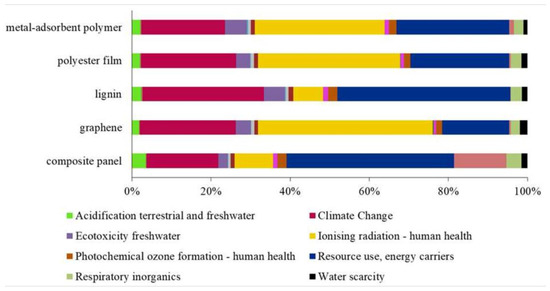

Overall, Figure 5 shows that the most affected categories in the five processes are resource use-energy carriers (in dark blue), ionizing radiation-human health (in yellow) (both connected to energy issue [62]) and climate change (in plum). More in detail, the effect on ionizing radiation-human health is due to the radionuclides (potentially toxic for humans) resulting from both the nuclear energy production, and the mineral oil and gas extraction, used as energy carriers [63,64]. Moreover, greenhouse gas emissions (e.g., CO2, CH4, and more) are the main drivers of climate change, whose biggest contribution stems from energy and industrial activities [65]. From these observations, it is evident that the main criticalities in the innovative processes are the huge energy demand (e.g., pyrolysis in graphene production) and the organic solvents use (e.g., methyl acrylate in orange peel exploitation and ethanol in wheat straw enhancement as lignin). The further detail of impact category loads for all the assessed scenarios is reported in Supplementary Material (Table S2).

Figure 5.

Normalization and weighing graphic of the five exploitation processes. Functional unit: 1 kg of organic residue. The impact categories mentioned in the legend are the most relevant only.

More in detail, the assessed EPI for rice straw exploitation for the production of the composite panel is 0.05 person equivalent. Even though the resource use-energy carrier is the most affected category, 31% of the whole impact is equally distributed between climate change and resource use-minerals and metals categories. The most critical step is Lignin bioplastic Arboform® production that, coherently with the characterization phase, creates the biggest impact on resource use-minerals and metals. The normalization and weighting phases confirm the exploitation of wheat straw for lignin production as the best environmental performance choice, if compared to graphene production. Indeed, the EPI resulting from the assessment of the second process is two times lower than the first one. If graphene production has its biggest impact on ionizing radiation-human health, lignin production largely influences resource use-energy carriers. Particularly, pyrolysis weighs 71% on the graphene production process; moreover, the category ionizing radiation-human health is the main affected, as well as it happens in other stages of the process. Instead, during lignin production process the most influencing step is purification; in this case, resource use-energy carriers is the most critical category, even though there is a significant impact to climate change category too. The tomato pomace exploitation has an environmental performance index of 0.06 person equivalent and the ionizing radiation-human health category is the most affected category. The most important step is hydrolysis that constitutes 31% of the total process impact; the three remaining steps of the process have a significant impact as well and they affect ionizing radiation-human health and resource use-energy carriers more than any other categories. Finally, the orange peel EPI is 0.2 p.e. and the process has the highest effect on ionizing radiation-human health category, as shown in Figure 5. Similarly, to the characterization phase, the most significant step is polymerization, with a contribution of 51% compared to the others and it generates its biggest impact on ionizing radiation-human health and resource use-energy carriers categories.

3.3. Comparison with Traditional Production Processes

In this section, the results of the comparison between the innovative methods based on agricultural residues and traditional methods are shown, considering the normalization phase only and the functional unit equal to the quantity of final product generated by each process, with an initial residue biomass of 1 kg.

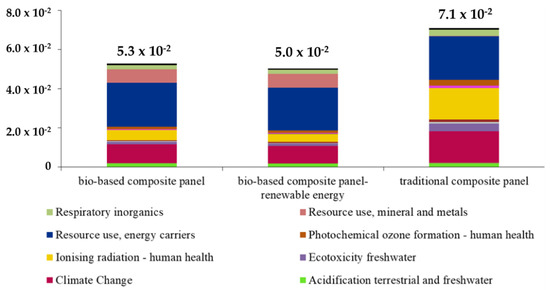

The composite panel produced through the enhancement of rice straw is compared in Figure 6 with a traditional composite panel, made of wood and polypropylene. It is evident that the innovative option allows a relevant decrease of the environmental load (from 0.07 to 0.05 p.e.) thanks to the non-use of polypropylene that is necessary in the traditional process. In the same figure, the production of bio-based composite panel with renewable energy is shown and its impact value is comparable to the EPI of the bio-based composite panel made with mixed energy, since the electricity production is not a critical issue.

Figure 6.

Normalization and weighing graphics of three different composite panel production scenarios, expressed as person equivalent (p.e.). The impact categories mentioned in the legend are the most relevant only. Functional unit: 5 kg of product.

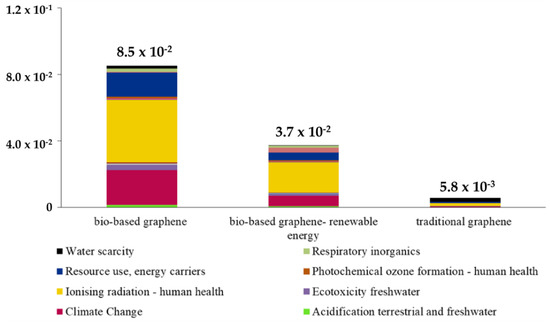

The wheat straw as graphene monolayers is compared to electrochemical exfoliation of graphite [52], obtaining the results in Figure 7. In this case, the residue exploitation does not show advantages for the environment, if compared to the traditional graphene manufacturing. This difference is due to the higher energy demand of the bio-based graphene production. This aspect is confirmed by the possibility of green energy use, which reduces EPI of about 50%, even though it still has a higher impact than traditional graphene.

Figure 7.

Normalization and weighing graphics of three different graphene production scenarios, expressed as p.e. The impact categories mentioned in the legend are the most relevant only. Functional unit: 0.1 kg of product.

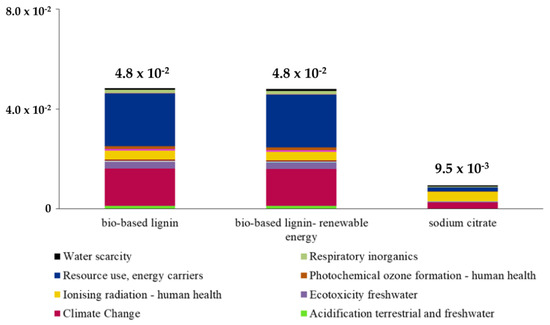

In the second exploitation option, lignin production is compared to sodium citrate production [53,54], which is a reducing agent as well. The comparison between these two processes is visible in Figure 8 with a resulting EPI five times higher than the traditional choice: lignin production has a higher value, because of the use of organic agents, missing in the sodium citrate production. In the same graphic, it can be observed the impact of the production of lignin using renewable energy. The index is comparable to that of lignin made with mixed energy, since the electricity production is not a critical issue of this process.

Figure 8.

Normalization and weighing graphics of three different reducing agents production scenarios, expressed as p.e. The impact categories mentioned in the legend are the most relevant only. Functional unit: 0.1 kg of product.

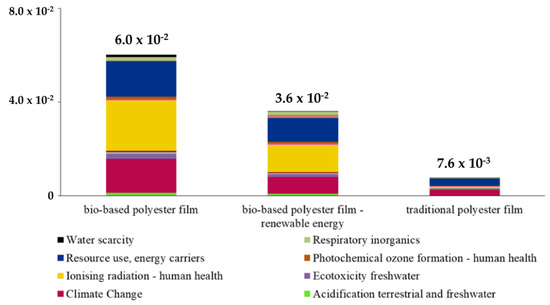

Tomato pomace is used to produce a polyester film. Therefore, the comparison is made with traditional polyester [55]. As shown in Figure 9, innovative polyester film has a bigger impact and its EPI is one order of magnitude higher than classic polyester film. Specifically, both the use of caustic soda and the energy demand are the penalizing factors of the bio-based polyester film production, making it more disadvantageous compared to current production methods. In order to reduce this impact, the alternative of bio-based polyester film made with renewable energy is analyzed and it actually has a smaller value than bio-based polyester film, but still higher than traditional polyester.

Figure 9.

Normalization and weighing graphics of three different polyester production scenarios, expressed as p.e. The impact categories mentioned in the legend are the most relevant only. Functional unit: 0.3 kg of product.

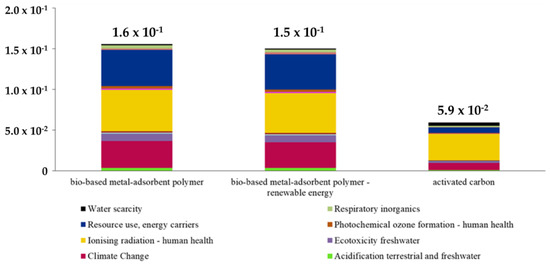

From orange peel, a metal-adsorbent polymer is produced, whose equivalent on the market is activated carbon [58] (Figure 10). The adsorbent polymer has an EPI almost three times higher than the activated carbon production due to the use of organic solvents in the polymer production. The bio-based polymer made with green energy has a comparable impact to the bio-based polymer made with mixed energy: in fact, as well as for the wheat straw exploitation as lignin, the impact of the bio-based alternative is generated by the solvents use and the impact is not significantly reduced by changing the energy source.

Figure 10.

Normalization and weighing graphics of three different metal-adsorbents production scenarios, expressed as p.e. The impact categories mentioned in the legend are the most relevant only. Functional unit: 1 kg of product.

This comparison with the traditional methods shows that the bio-based alternative is more impacting than traditional processes; this result is mainly due to relatively high-energy demand and organic solvents use (as proved by the energy and raw material balances in Figure 2, Figure 3 and Figure 4). Therefore, even though bio-based products are accessible and desirable alternatives, experimentation must proceed further to make these processes as beneficial as actual production methods.

4. Discussion and Limitation of the Study

The present study implemented an environmental sustainability assessment of innovative processes for the use of common Italian byproducts from agriculture sector. The assessed case studies were extracted from the scientific literature, implemented at lab-scale. Nevertheless, they were considered interesting for their proposal to use organic residues in a wide range of application fields. The data used for the implementation of the analysis can be considered of good quality since they were extracted from an international peer-reviewed journal. The additional assumptions implemented for the hypothesis of upscaling followed the literature methods. Comparable observations are carried out for the traditional products. The possibility to use data from wood handbook (for composite panel from rice straw) and from the average value of the Gabi database (for polyester film from tomato pomace) ensured high levels of representativity.

The present assessment shows some limitations:

- Zero burden approach for agricultural residues was used, effects of redirection of residue from today’s application is not included.

- The effect of using other impact assessment methods or normalization sets was not evaluated. Nevertheless, the authors selected the updated method EF 3.0 (recommended by European Commission), which ensured the result validity.

5. Conclusions

The circular economy represents one of the main pillars that drive the choices of countries, all over the world, towards a sustainable development. As confirmed by the detailed study of the scientific literature and the GRASCIARI RIUNITI project, the development of circular strategies within the agriculture field is a primary concern. Nevertheless, this analysis proved that there is still a necessity to evaluate the proposed solutions combining technical/experimental aspects with environmental sustainability issues. More in detail, the LCA of five case studies highlighted some significant issues due to both the significant energy demand and the high impact organic solvents, despite the reduced organic agent demand assumed for the upscaling. The obtained results had not the target to discourage the development of alternatives for the agriculture residue enhancement, but rather to draw the attention to the environmental sustainability aspects. Indeed, an effective implementation of circular economy strategy should have a holistic view, able to consider the effect of the technologies in different environmental categories (as well as in social and economic spheres). In this regard, many aspects play an essential role (as also discussed in the European circular economy action plan and the European Green Deal), as the avoided use of toxic (for both human and environmental health) agents and the low energy demand. Overall, the implemented LCA proved the significant effect of the renewable energy transition and the current necessity to identify ecological agents for an effective environmentally sustainable production of BBP.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/su13073990/s1, Figure S1: Classification and characterization graphics of rice straw exploitation process. Functional unit: 1 kg of organic residue, Figure S2: Classification and characterization graphics of two wheat straw exploitation processes. Functional unit: 1 kg of organic residue, Figure S3: Classification and characterization graphics of tomato pomace exploitation process. Functional unit: 1 kg of organic residue, Figure S4: Classification and characterization graphics of orange peel exploitation process. Functional unit: 1 kg of organic residue, Table S1: Specific assumptions: comparable raw materials chosen to substitute the raw materials missing in the database, Table S2: Weight of each impact category on the normalization and weighing results. Functional unit: 1 kg of organic residue. References [66,67,68,69,70,71,72,73,74,75,76] are cited in the Supplementary Materials.

Author Contributions

Conceptualization, A.A. and F.B.; methodology, A.A.; software, A.A.; validation, M.M. and A.A.; formal analysis, M.M. and A.B.; investigation, M.M.; resources, F.B.; data curation, A.A. and M.M.; writing—original draft preparation, A.A. and M.M.; writing—review and editing, A.A.; visualization, A.B.; supervision, A.A. and F.B.; project administration, F.B.; funding acquisition, F.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

With the support of European funds for the Regional development FEASR-PSR MARCHE 2014–2020 within the project GRASCIARI RIUNITI.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ritchie, H.; Roser, M. Agricultural Production. Available online: https://ourworldindata.org/agricultural-production (accessed on 30 July 2020).

- ISTAT. Andamento dell’Economia Agricola. Available online: https://www.istat.it/it/archivio/243183#:~:text=L’agricoltura%20in%20senso%20stretto,%2C7%25%20del%20valore%20aggiunto.&text=Nel%202019%20%C3%A8%20proseguita%20la,2%2C0%25%20in%20volume (accessed on 30 July 2020).

- ISTAT. Istituto Nazionale di Statistica. Available online: https://www.istat.it/it/agricoltura?dati (accessed on 20 November 2019).

- Food and Agriculture Organization of the United Nations (FAO). The Future of Food and Agriculture—Trends and Challenges; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2017. [Google Scholar]

- Benítez, J.J.; Castillo, P.M.; Del Río, J.C.; León-Camacho, M.; Domínguez, E.; Heredia, A.; Guzmán-Puyol, S.; Athanassiou, A.; Heredia-Guerrero, J.A. Valorization of tomato processing by-products: Fatty acid extraction and production of bio-based materials. Materials 2018, 11, 2211. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. Bio-based composites from waste agricultural residues. Waste Manag. 2010, 30, 680–684. [Google Scholar] [CrossRef]

- Mahieu, A.; Alix, S.; Leblanc, N. Properties of particleboards made of agricultural by-products with a classical binder or self-bound. Ind. Crop. Prod. 2019, 130, 371–379. [Google Scholar] [CrossRef]

- Larrosa, M.; Llorach, R.; Espìn, J.C.; Tomás-Barberán, F.A. Increase of antioxidant activity of tomato juice upon functionalisation with vegetable by-product extracts. LWT Food Sci. Technol. 2002, 35, 532–542. [Google Scholar] [CrossRef]

- Plazzotta, S.; Ibarz, R.; Manzocco, L.; Martín-Belloso, O. Optimizing the antioxidant biocompound recovery from peach waste extraction assisted by ultrasounds or microwaves. Ultrason. Sonochem. 2020, 63, 104954. [Google Scholar] [CrossRef]

- Zhang, J.; Hori, N.; Takemura, A. Optimization of agricultural wastes liquefaction process and preparing biobased polyurethane foams by the obtained polyols. Ind. Crop. Prod. 2019, 138, 111455. [Google Scholar] [CrossRef]

- Gheribi, R.; Habibi, Y.; Khwaldia, K. Prickly pear peels as a valuable resource of added-value polysaccharide: Study of structural, functional and film forming properties. Int. J. Biol. Macromol. 2018, 126, 238–245. [Google Scholar] [CrossRef]

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Review of high-value food waste and food residues biorefineries with focus on unavoidable wastes from processing. Resour. Conserv. Recycl. 2019, 149, 413–426. [Google Scholar] [CrossRef]

- Petruccioli, M.; Raviv, M.; Di Silvestro, R.; Dinelli, G. Agriculture and agro-industrial wastes, by-products, and wastewaters: Origin, characteristics, and potential in bio-based-compounds production. In Comprehensive Biotechnology; Murray, M.Y., Ed.; Environmental Biotechnology and Safety; Elsevier Inc.: Amsterdam, The Netherlands, 2011; Volume 6, pp. 531–545. [Google Scholar] [CrossRef]

- Sharma, R.; Jafari, S.M.; Sharma, S. Antimicrobial bio-nanocomposites and their potential applications in food packaging. Food Control 2020, 112, 107086. [Google Scholar] [CrossRef]

- Heise, K.; Kirsten, M.; Schneider, Y.; Jaros, D.; Keller, H.; Rohm, H.; Kalbitz, K.; Fischer, S. From agricultural by-products to value-added materials: Wheat straw-based hydrogels as soil conditioners? ACS Sustain. Chem. Eng. 2019, 7, 8604–8612. [Google Scholar] [CrossRef]

- Feng, N.; Guo, X.; Liang, S. Adsorption study of copper (II) by chemically modified orange peel. J. Hazard. Mater. 2009, 164, 1286–1292. [Google Scholar] [CrossRef]

- Nešic, A.; Cabrera-Barjas, G.; Dimitrijevic-Brankovic, S.; Davidovic, S.; Radovanovic, N.; Delattre, C. Prospect of polysaccharide-based materials as advanced food packaging. Molecules 2019, 25, 135. [Google Scholar] [CrossRef] [PubMed]

- Saratale, R.G.; Saratale, G.D.; Ghodake, G.; Cho, S.K.; Kadam, A.; Kumar, G.; Jeon, B.H.; Pant, D.; Bhatnagar, A.; Shin, H.S. Wheat straw extracted lignin in silver nanoparticles synthesis: Expanding its prophecy towards antineoplastic potency and hydrogen peroxide sensing ability. Int. J. Biol. Macromol. 2019, 128, 391–400. [Google Scholar] [CrossRef] [PubMed]

- Ullah, H.; Ullah, Z.; Fazal, A.; Irfan, M. Use of vegetable waste extracts for controlling microstructure of CuO nanoparticles: Green synthesis, characterization, and photocatalytic applications. J. Chem. 2017. [Google Scholar] [CrossRef]

- Tabasso, S.; Mariatti, F.; Grillo, G.; Boffa, L.; Tibaldi, P.S.; Cravotto, G. Sustainable microwave-assisted aerobic oxidation of tomato plant waste into bioaromatics and organic acids. Ind. Eng. Chem. Res. 2019, 58, 8578–8584. [Google Scholar] [CrossRef]

- Choi, H.J. Agricultural bio-waste for adsorptive removal of crude oil in aqueous solution. J. Mater. Cycles Waste Manag. 2018, 21, 356–364. [Google Scholar] [CrossRef]

- Li, Y.; Liu, X.; Cai, W.; Cao, Y.; Sun, Y.; Tan, F. Preparation of corn straw based spongy aerogel for spillage oil capture. Korean J. Chem. Eng. 2018, 35, 1119–1127. [Google Scholar] [CrossRef]

- Chen, F.; Yang, J.; Bai, T.; Long, B.; Zhou, Z. Facile synthesis of few-layer graphene from biomass waste and its application in lithium ion batteries. J. Electroanal. Chem. 2016, 768, 18–26. [Google Scholar] [CrossRef]

- Narayanan, A.; Kumar, V.A.S.; Ramana, K.V. Production and characterization of poly (3-Hydroxybutyrateco-3-Hydroxyvalerate) from Bacillus mycoides DFC1 using rice husk hydrolysate. Waste Biomass Valorization 2013, 5, 109–118. [Google Scholar] [CrossRef]

- Chi, W.; Cao, L.; Sun, G.; Meng, F.; Zhang, C.; Li, J.; Wang, L. Developing a highly pH-sensitive k-carrageenan-based intelligent film incorporating grape skin powder via a cleaner process. J. Clean. Prod. 2019, 244, 118862. [Google Scholar] [CrossRef]

- Spring. Available online: http://www.clusterspring.it/home/ (accessed on 30 July 2020).

- Dahy, H. Efficient fabrication of sustainable building products from annually generated non-wood cellulosic fibres and bioplastics with improved flammability resistance. Waste Biomass Valorization 2017, 10, 1167–1175. [Google Scholar] [CrossRef]

- Xie, Y.; Niu, X.; Yang, J.; Fan, R.; Shi, J.; Ullah, N.; Feng, X.; Chen, L. Active biodegradable films based on the whole potato peel incorporated with bacterial cellulose and curcumin. Int. J. Biol. Macromol. 2020, 150, 480–491. [Google Scholar] [CrossRef]

- Guzmán, Á.; Delvasto, S.; Sánchez, E. Valorization of rice straw waste: An alternative ceramic raw material. Cerâmica 2015, 61, 126–136. [Google Scholar] [CrossRef]

- Dos Santos, P.A.; Caliari, M.; Júnior, M.S.S.; Silva, K.S.; Viana, L.F.; Garcia, L.G.C.; De Lima, M.S. Use of agricultural by-products in extruded gluten-free breakfast cereals. Food Chem. 2019, 297, 124956. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Barczewski, M.; Szostak, M. Injection molding of highly filled polypropylene-based biocomposites. buckwheat husk and wood flour filler: A comparison of agricultural and wood industry waste utilization. Polymers 2019, 11, 1881. [Google Scholar] [CrossRef]

- Bastos-Arrieta, J.; Florido, A.; Pérez-Ràfols, C.; Serrano, N.; Fiol, N.; Poch, J.; Villaescusa, I. Green synthesis of Ag nanoparticles using grape stalk waste extract for the modification of screen-printed electrodes. Nanomaterials 2018, 8, 946. [Google Scholar] [CrossRef] [PubMed]

- Crizel, T.D.M.; Jablonski, A.; Rios, A.D.L.; Rech, R.; Flôres, S.H. Dietary fiber from orange byproducts as a potential fat replacer. LWT Food Sci. Technol. 2013, 53, 9–14. [Google Scholar] [CrossRef]

- Cinelli, P.; Mallegni, N.; Gigante, V.; Montanari, A.; Seggiani, M.; Coltelli, M.B.; Bronco, S.; Lazzeri, A. Biocomposites based on polyhydroxyalkanoates and natural fibres from renewable by-products. Appl. Food Biotechnol. 2018, 6, 35–43. [Google Scholar] [CrossRef]

- Rhim, J.W.; Reddy, J.P.; Luo, X. Isolation of cellulose nanocrystals from onion skin and their utilization for the preparation of agar-based bio-nanocomposites films. Cellulose 2014, 22, 408–420. [Google Scholar] [CrossRef]

- Verónica, F.M.; Bengardino, M.; Jagus, R.J.; Agüero, M.V. Enrichment and preservation of a vegetable smoothie with an antioxidant and antimicrobial extract obtained from beet by-products. LWT 2019, 117, 108622. [Google Scholar] [CrossRef]

- Schott, A.B.S.; Wenzel, H.; la Cure Jansen, J. Identification of decisive factors for greenhouse gas emissions in comparative life cycle assessments of food waste management—An analytical review. J. Clean. Prod. 2016, 119, 13–24. [Google Scholar] [CrossRef]

- Ekvall, T.; Weidema, B.P. System boundaries and input data in consequential life cycle inventory analysis. Int. J. LCA 2004, 9, 161–171. [Google Scholar] [CrossRef]

- ISO Valutazione del Ciclo di Vita, Definizione e Linee Guida. 2018. Available online: https://www.uni.com/index.php?option=com_content&view=article&id=6978%3Avalutazione-del-ciclo-di-vita&catid=170&Itemid=2612 (accessed on 30 July 2020).

- Ahlgren, S.; Björklund, A.; Ekman, H.; Berlin, J.; Börjesson, P.; Ekvall, T.; Finnveden, G.; Jansenn, M.; Strid, I. Review of methodological choices in LCA of biorefinery systems-key issues and recommendations. Biofuels Bioprod. Biorefin. 2015, 9, 606–619. [Google Scholar] [CrossRef]

- CIA Lombardia. Available online: http://www.cialombardia.org/fattoriascuola/C-r-lavorazione.htm#:~:text=In%20funzione%20della%20variet%C3%A0%2C%20dell,usate%20per%20gli%20altri%20cereali (accessed on 30 July 2020).

- Perozzi, D. PROGETTO GLUME Ricerca Sperimentale per la Valorizzazione Degli Scarti di Molitura. Caso Studio: Mulino Marino (PROGETTO GLUME Experimental Research to Valorize Milling Waste. Case Study: Mulino Marino). Ph.D. Thesis, Politecnico di Torino, Torino, Italy, 2019. [Google Scholar]

- Rossi, L.; Piccinini, S. Sottoprodotti agroindustriali, un potenziale da sfruttare. Inf. Agrar. 2007, 63, 67. [Google Scholar]

- Espadas-Aldana, G.; Vialle, C.; Belaud, J.P.; Vaca-Garcia, C.; Sablayrolles, C. Analysis and trends for Life Cycle Assessment of olive oil production. Sustain. Prod. Consum. 2019, 19, 216–230. [Google Scholar] [CrossRef]

- European Commission-Joint Research Centre (JRC). Characterisation Factors of the ILCD Recommended Life Cycle Impact Assessment Methods; European Commission-Joint Research Centre—Institute for Environment and Sustainability: Ispra, Italy, 2012. [Google Scholar] [CrossRef]

- European Commission. The Development of the PEF and OEF Methods. Available online: https://ec.europa.eu/environment/eussd/smgp/dev_methods.htm (accessed on 8 March 2021).

- Van der Hulst, M.K.; Huijbregts, M.A.; van Loon, N.; Theelen, M.; Kootstra, L.; Bergesen, J.D.; Hauck, M. A systematic approach to assess the environmental impact of emerging technologies: A case study for the GHG footprint of CIGS solar photovoltaic laminate. J. Ind. Ecol. 2020, 24, 1234–1249. [Google Scholar] [CrossRef]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. Predicting the environmental impact of a future nanocellulose production at industrial scale: Application of the life cycle assessment scale-up framework. J. Clean. Prod. 2018, 174, 283–295. [Google Scholar] [CrossRef]

- Adiansyah, J.S.; Haque, N.; Rosano, M.; Biswas, W. Application of a life cycle assessment to compare environmental performance in coal mine tailings management. J. Environ. Manag. 2017, 199, 181–191. [Google Scholar] [CrossRef] [PubMed]

- Stark, N.M.; Cai, Z.; Carll, C. Wood-based composite materials-panel products, glued-laminated timber, structural composite lumber, and wood-nonwood composite materials. In Wood Handbook: Wood as an Engineering Material; General technical report FPL.; GTR-190; Centennial, Ed.; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; Chapter 11; pp. 11.1–11.28. [Google Scholar]

- Aadil, K.R.; Barapatre, A.; Sahu, S.; Jha, H.; Tiwary, B.N. Free radical scavenging activity and reducing power of Acacia nilotica wood lignin. Int. J. Biol. Macromol. 2014, 67, 220–227. [Google Scholar] [CrossRef]

- Cossutta, M.; McKechnie, J.; Pickering, S.J. A comparative LCA of different graphene production routes. Green Chem. 2017, 19, 5874–5884. [Google Scholar] [CrossRef]

- Pourzahedi, L.; Eckelman, M.J. Comparative life cycle assessment of silver nanoparticle synthesis. Environ. Sci. Nano 2015, 2, 361–369. [Google Scholar] [CrossRef]

- Rivas, B.; Torrado, A.; Torre, P.; Converti, A.; Domínguez, J.M. Submerged citric acid fermentation on orange peel autohydrolysate. J. Agric. Food Chem. 2008, 56, 2380–2387. [Google Scholar] [CrossRef] [PubMed]

- GABI Process Data Eet: Polyester Resin Unsaturated (UP); Esterification and Polymerization, from Propylene Glycol, Phthalic Anhydride and Styrene; Single Route, at Plant; 1.22 to 1.38 g/cm3 (en). Available online: http://gabi-documentation-2019.gabi-software.com/xml-data/processes/b6801f51-3d8e-47d1-96bb-dbbea7b14e16.xml (accessed on 30 July 2020).

- Liu, Y.; Cao, Q.; Luo, F.; Chen, J. Biosorption of Cd2+, Cu2+, Ni2+ and Zn2+ ions from aqueous solutions by pretreated biomass of brown algae. J. Hazard. Mater. 2008, 163, 931–938. [Google Scholar] [CrossRef]

- Jóźwiak, T.; Filipkowska, U.; Szymczyk, P.; Rodziewicz, J.; Mielcarek, A. Effect of ionic and covalent crosslinking agents on properties of chitosan beads and sorption effectiveness of Reactive Black 5 dye. React. Funct. Polym. 2017, 114, 58–74. [Google Scholar] [CrossRef]

- Loya-Gonzalez, D.; Loredo-Cancino, M.; Soto-Regalado, E.; Rivas-García, P.; Cerino-Cordova, F.D.J.; García-Reyes, R.B.; Bustos-Martínez, D.; Estrada-Baltazar, A. Optimal activated carbon production from corn pericarp: A life cycle assessment approach. J. Clean. Prod. 2019, 219, 316–325. [Google Scholar] [CrossRef]

- Bernier, E.; Lavigne, C.; Robidoux, P.Y. Life cycle assessment of kraft lignin for polymer applications. Int. J. LCA 2012, 18, 520–528. [Google Scholar] [CrossRef]

- Nägele, H.; Pfitzer, J.; Nägele, E.; Inone, E.R.; Eisenreich, N.; Eckl, W.; Eyerer, P. Arboform®—A thermoplastic, processable material from lignin and natural fibers. In Chemical Modification, Properties, and Usage of Lignin; Springer: Boston, MA, USA, 2002; pp. 101–119. [Google Scholar] [CrossRef]

- Schmidt, A.; Frydendal, J. Methods for calculating the environmental benefits of “green” products. In Buying into the Environment; Routledge: Oxfordshire, UK, 2003. [Google Scholar]

- Van Oers, L.; Guinée, J. The abiotic depletion potential: Background, updates, and future. Resources 2016, 5, 16. [Google Scholar] [CrossRef]

- Amato, A.; Becci, A.; Birloaga, I.; Michelis, I.D.; Ferella, F.; Innocenzi, V.; Ippolito, N.; Gomez, C.P.J.; Vegliò, F.; Beolchini, F. Sustainability analysis of innovative technologies for the rare earth elements recovery. Renew. Sustain. Energy Rev. 2019, 106, 41–53. [Google Scholar] [CrossRef]

- Frischknecht, R.; Braunschweig, A.; Hofstetter, P.; Suter, P. Human health damages due to ionizing radiation in life cycle impact assessment. Environ. Impact Assess. Rev. 2000, 20, 159–189. [Google Scholar] [CrossRef]

- Stocker, T.; Qin, D.; Plattner, G.K.; Tignor, M.; Allen, S.; Boschung, J.; Nauels, A.; Xia, Y.; Bex, V.; Midgley, P. Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. In Proceedings of the Intergovernmental Panel on Climate Change, Batumi, GA, USA, 14–17 October 2013. [Google Scholar]

- Hung, N.V.; Maguyon-Detras, M.C.; Migo, M.V.; Quilloy, R.; Balingbing, C.; Chivenge, P.; Gummert, M. Rice straw overview: Availability, properties, and management practices. In Sustainable Rice Straw Management; Springer: Cham, Switzerland, 2020; pp. 1–13. [Google Scholar]

- Chevanana, N.; Womac, A.R.; Bitra, V.S.P.; Igathinathene, C.; Yang, Y.T.; Miu, P.I.; Sokhansanj, S. Bulk density and compaction behavior of knife mill chopped switchgrass, wheat straw, and corn stover. Bioresour. Technol. 2009, 101, 207–214. [Google Scholar] [CrossRef] [PubMed]

- Sin, E.H.K. The Extraction and Fractionation of Waxes from Biomass. Ph.D. Thesis, University of York, York, UK, 2012. [Google Scholar]

- Jahanbakhshi, A.; Sharabiani, V.R.; Heidarbeigi, K.; Kaveh, M.; Taghinezhad, E. Evaluation of engineering properties for waste control of tomato during harvesting and postharvesting. Food Sci. Technol. 2019, 7, 1473–1481. [Google Scholar] [CrossRef]

- Stelte, W.; Clemons, C.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B.; Sanadi, A.R. Fuel pellets from wheat straw: The effect of lignin glass transition and surface waxes on pelletizing properties. Bioenergy Res. 2011, 5, 450–458. [Google Scholar] [CrossRef]

- Cuccolini, S.; Aldini, A.; Visai, L.; Daglia, M.; Ferrari, D. Environmentally friendly lycopene purification from tomato peel waste: Enzymatic assisted aqueous extraction. J. Agric. Food Chem. 2012, 61, 1646–1651. [Google Scholar] [CrossRef]

- Olabinjo, O.O.; Ogunlowo, A.S.; Ajayi, O.O.; Olalusi, A.P. Analysis of physical and chemical composition of sweet orange (Citrus sinensis) peels. Int. J. Environ. Agric. Biotechnol. 2017, 2, 238892. [Google Scholar] [CrossRef]

- Munagapati, V.S.; Kim, D.S. Adsorption of anionic azo dye Congo Red from aqueous solution by cationic modified orange peel powder. J. Mol. Liq. 2016, 220, 540–548. [Google Scholar] [CrossRef]

- National Library of Medicine. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/1_4-Benzoquinone#section=Solubility (accessed on 30 July 2020).

- Ahmed, M.; Mashkoor, F.; Nasar, A. Development, characterization, and utilization of magnetized orange peel waste as a novel adsorbent for the confiscation of crystal violet dye from aqueous solution. Groundw. Sustain. Dev. 2019, 10, 100322. [Google Scholar] [CrossRef]

- Cai, J.; Gao, Y.; Zhu, X.; Su, Q. Matrix solid phase dispersion–Soxhlet simultaneous extraction clean-up for determination of organochlorine pesticide residues in tobacco. Anal. Bioanal. Chem. 2005, 383, 869–874. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).