Enhancing the Microstructure and Sustainability of Ultra-High-Performance Concrete Using Ultrafine Calcium Carbonate and High-Volume Fly Ash under Different Curing Regimes

Abstract

1. Introduction

2. Materials and Methods

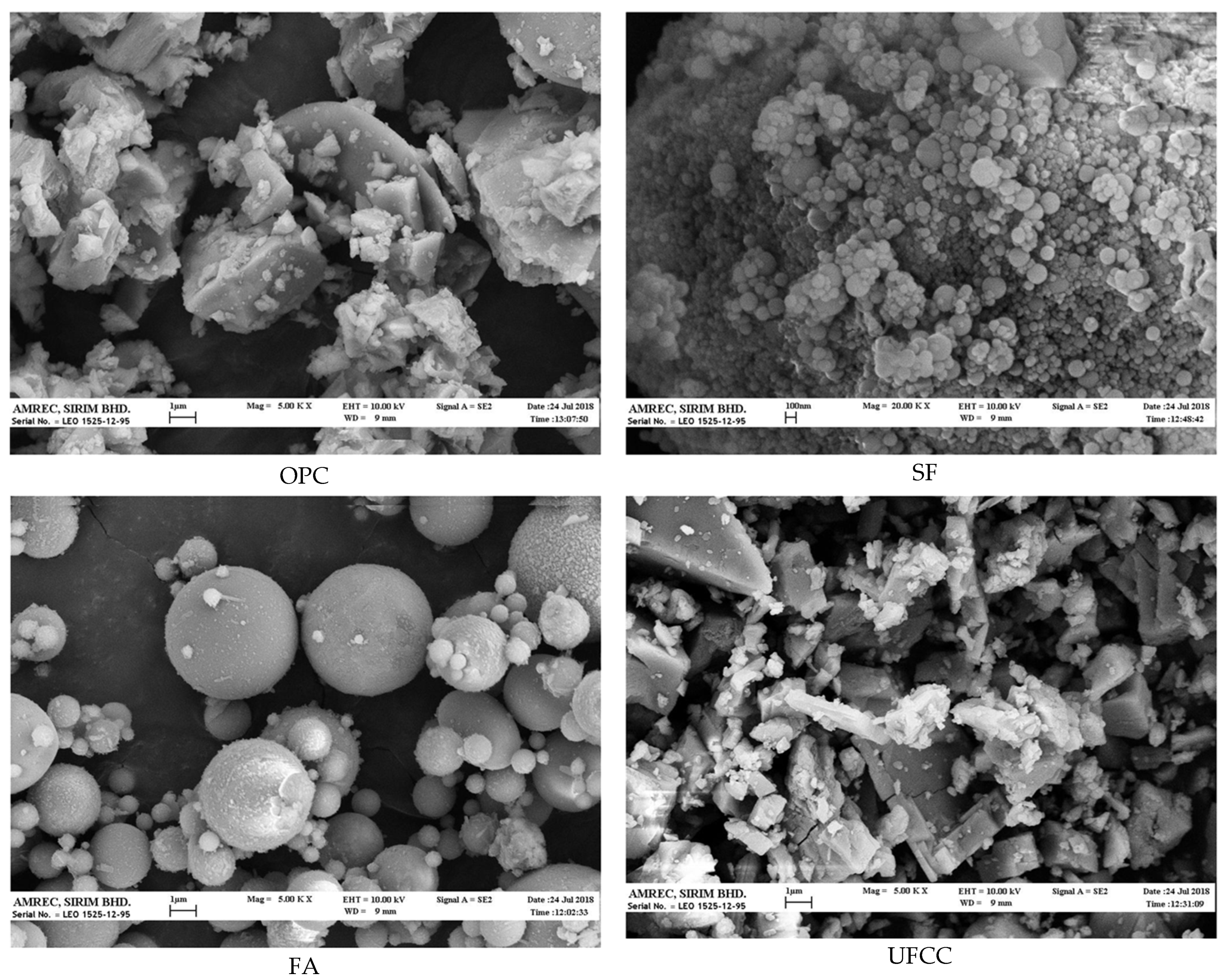

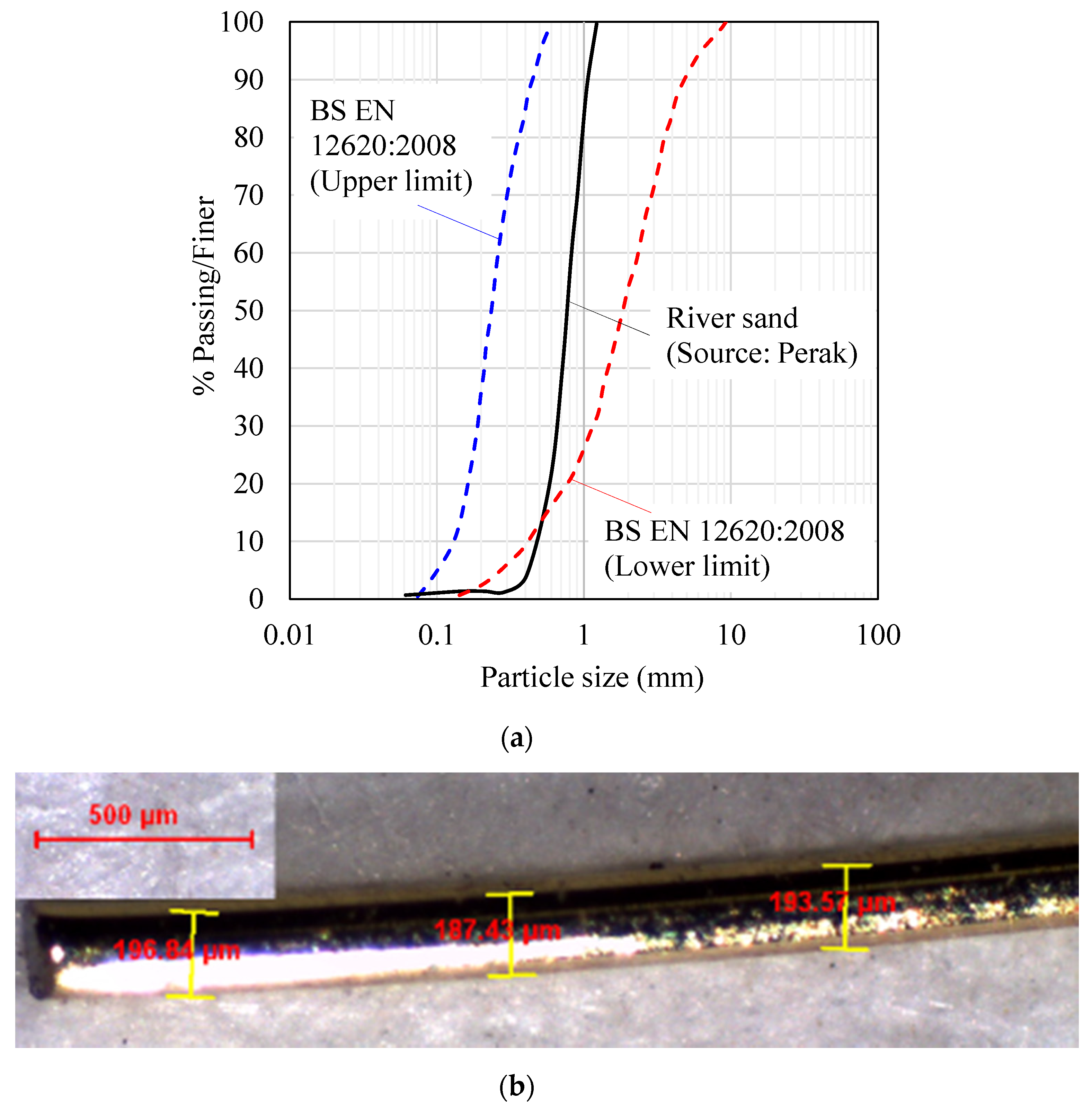

2.1. Material Properties

2.2. Concrete Mix Proportions, Specimen Casting, and Curing

2.3. Preparation for Compressive Strength and Microstructure Analysis

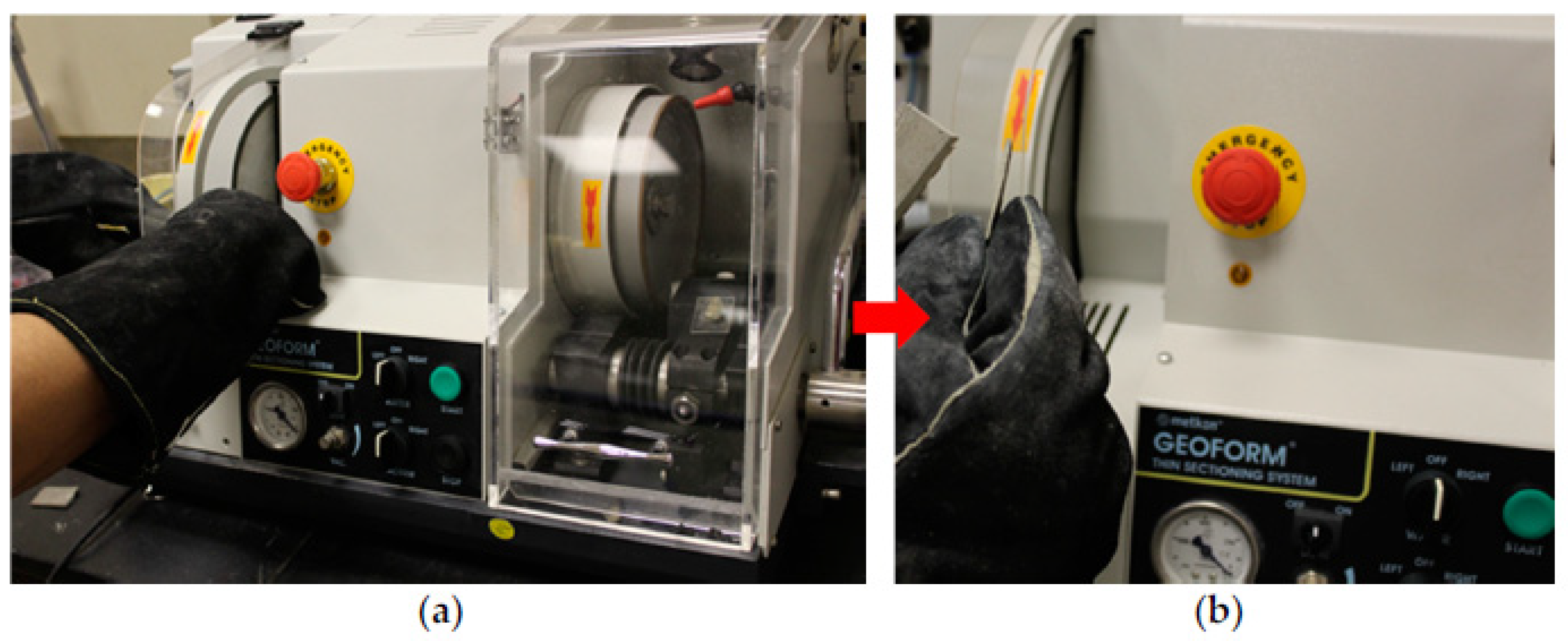

2.4. Preparation of Paste Samples for Multispectral SEM Analysis

2.5. Direct Tensile and Flexural Strengths Testing Methods

3. Results and Discussion

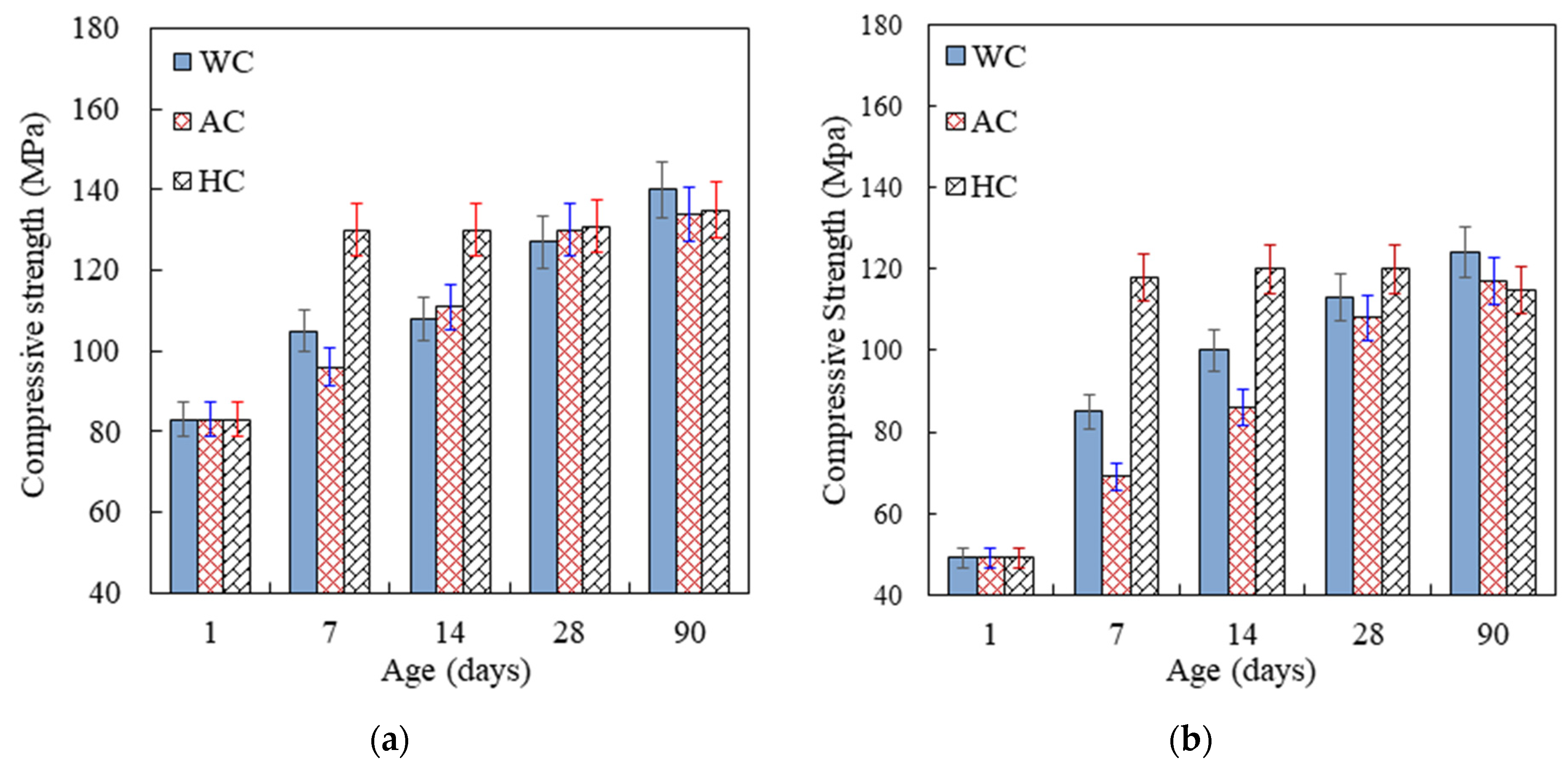

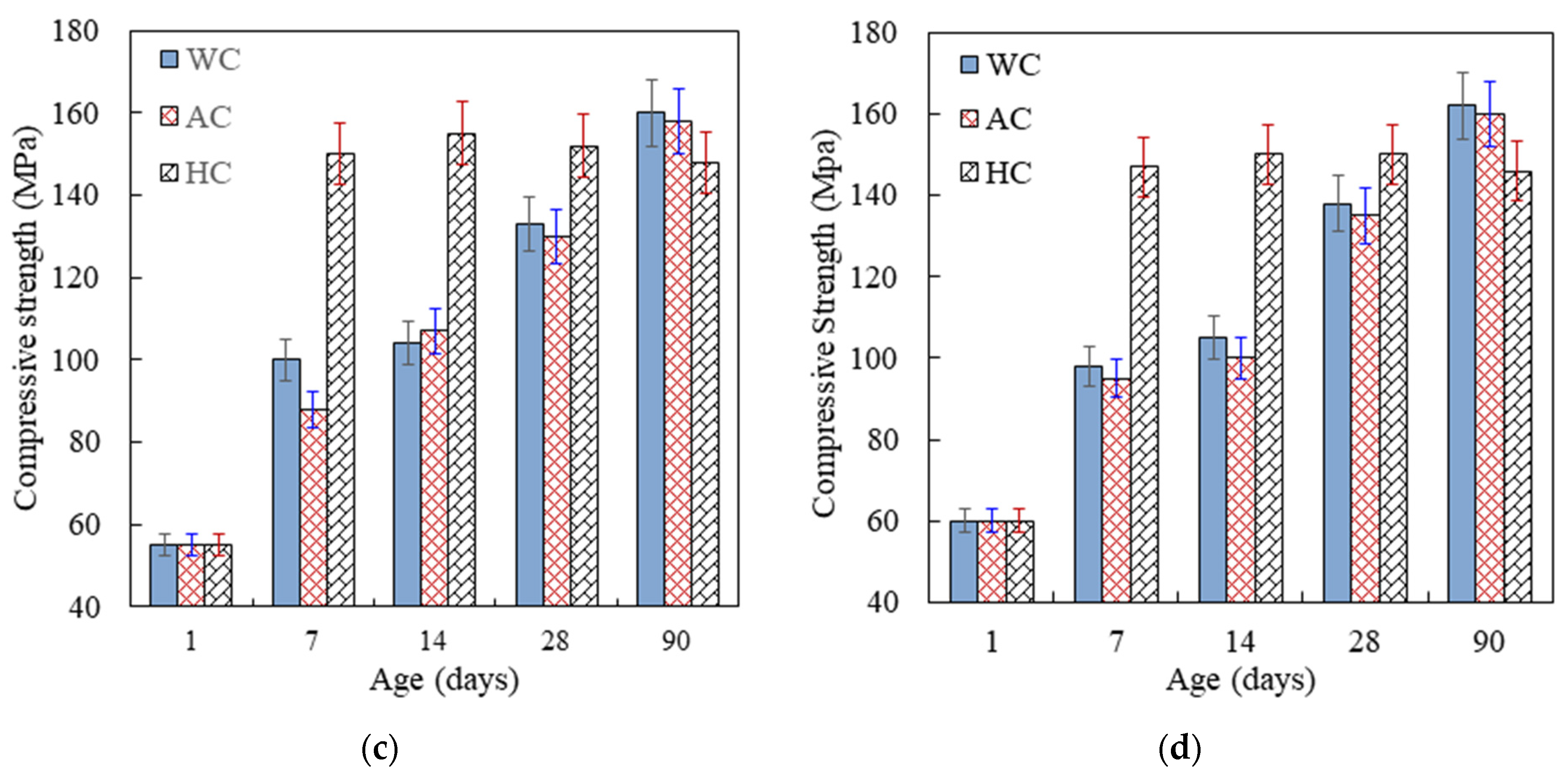

3.1. Investigation of the Effects of SCM and Curing Method on the Compressive Strength

3.2. Efficiency of SCM Combinations in Concrete

3.3. Microstructure Properties of Concrete with Different SCM Combinations

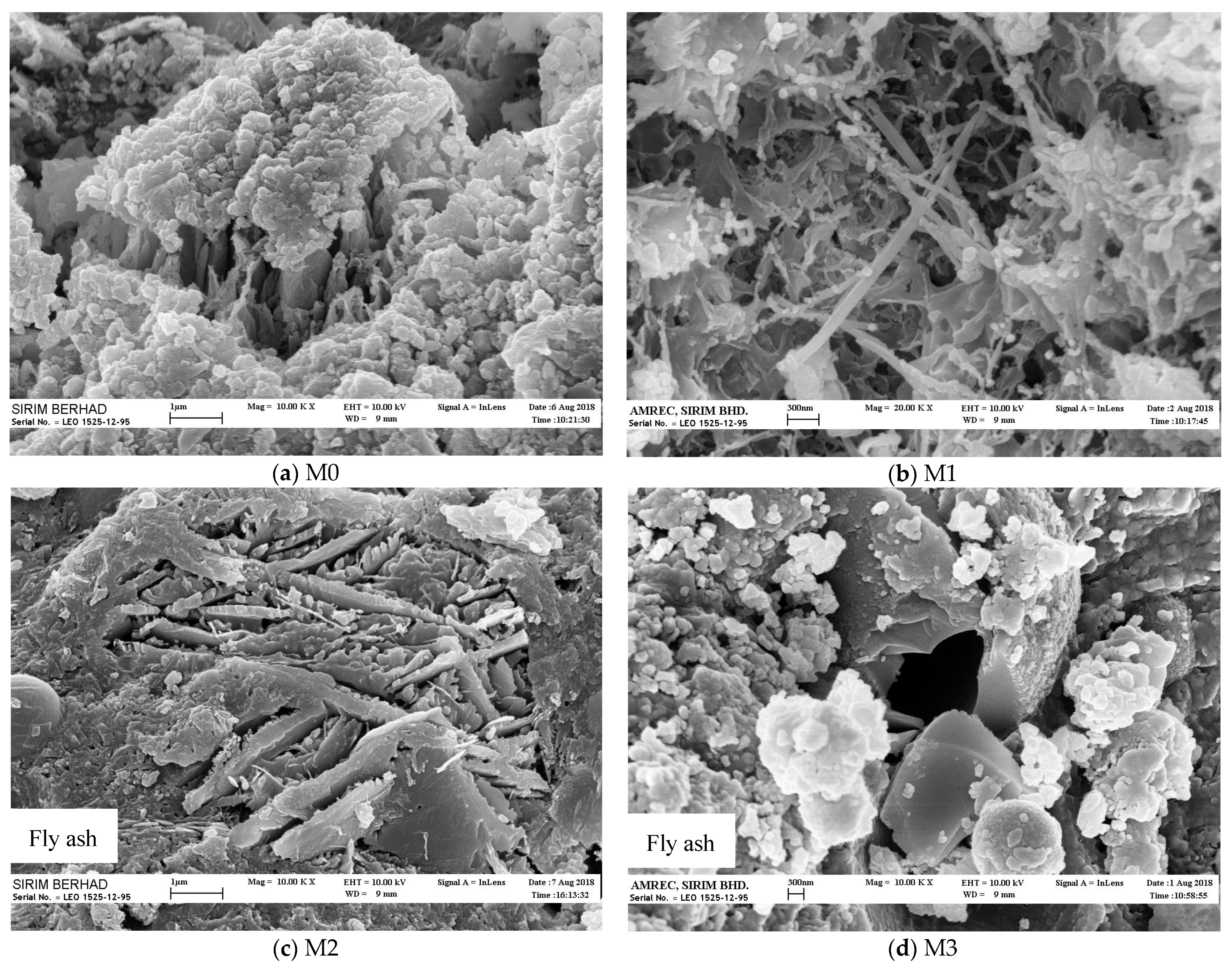

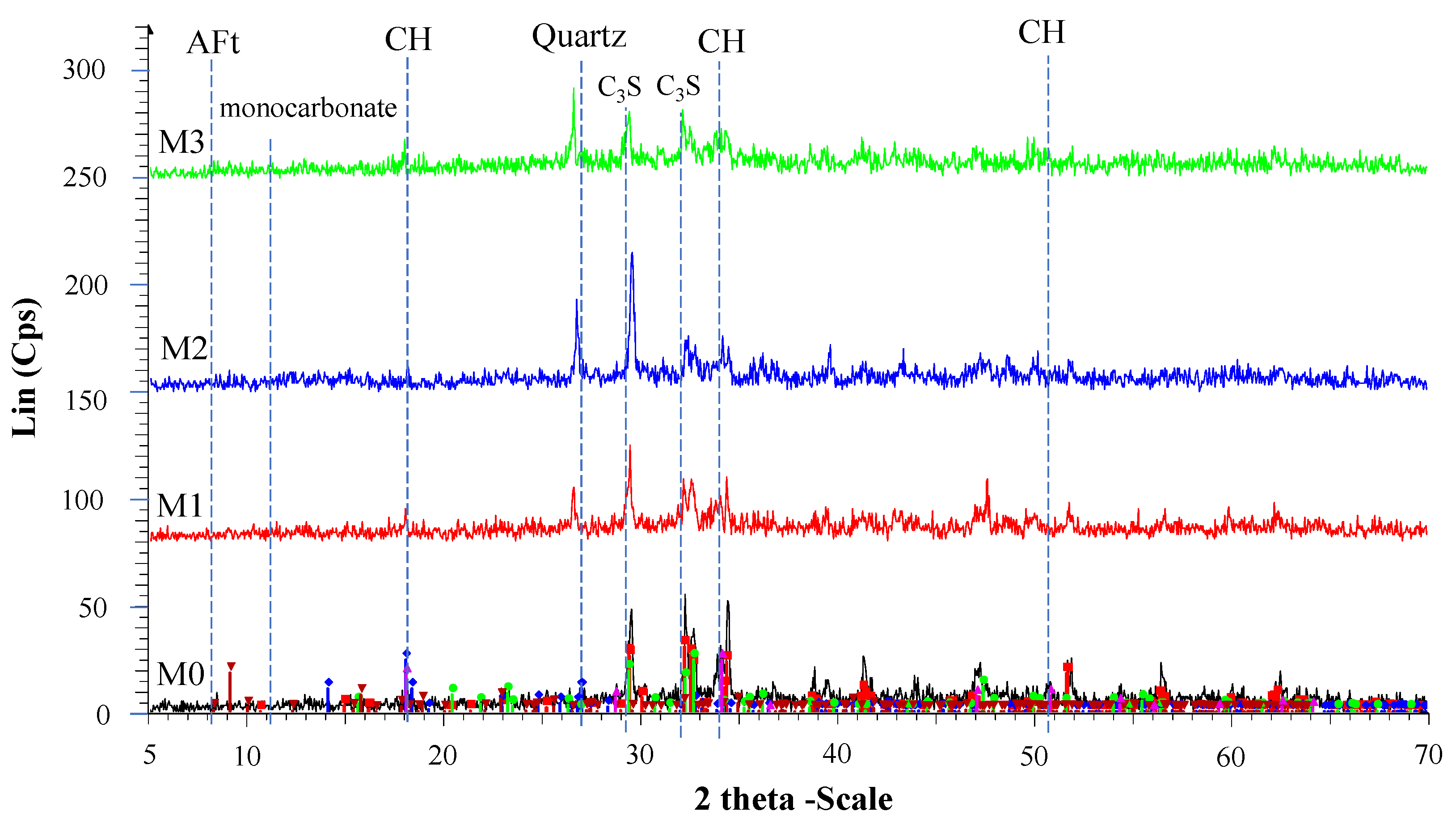

3.4. Multispectral SEM Analysis

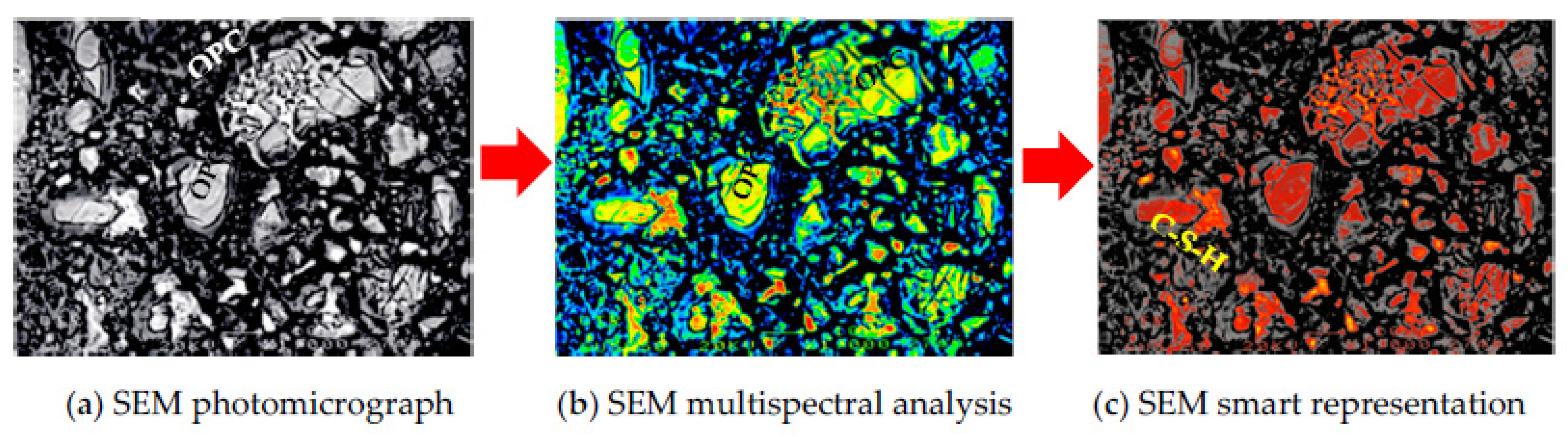

3.5. Tensile and Flexural Strengths

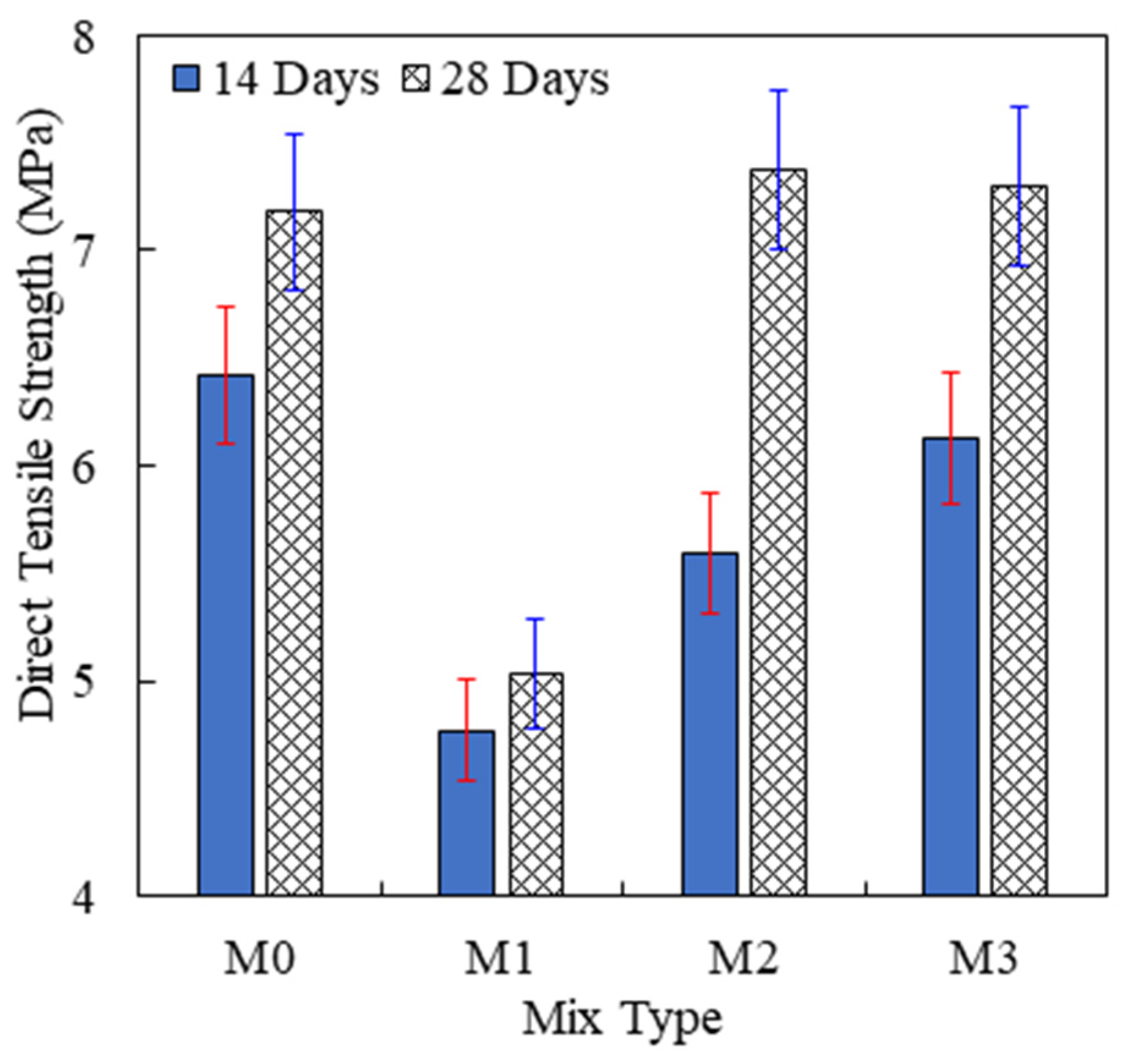

3.5.1. Direct Tensile Strength

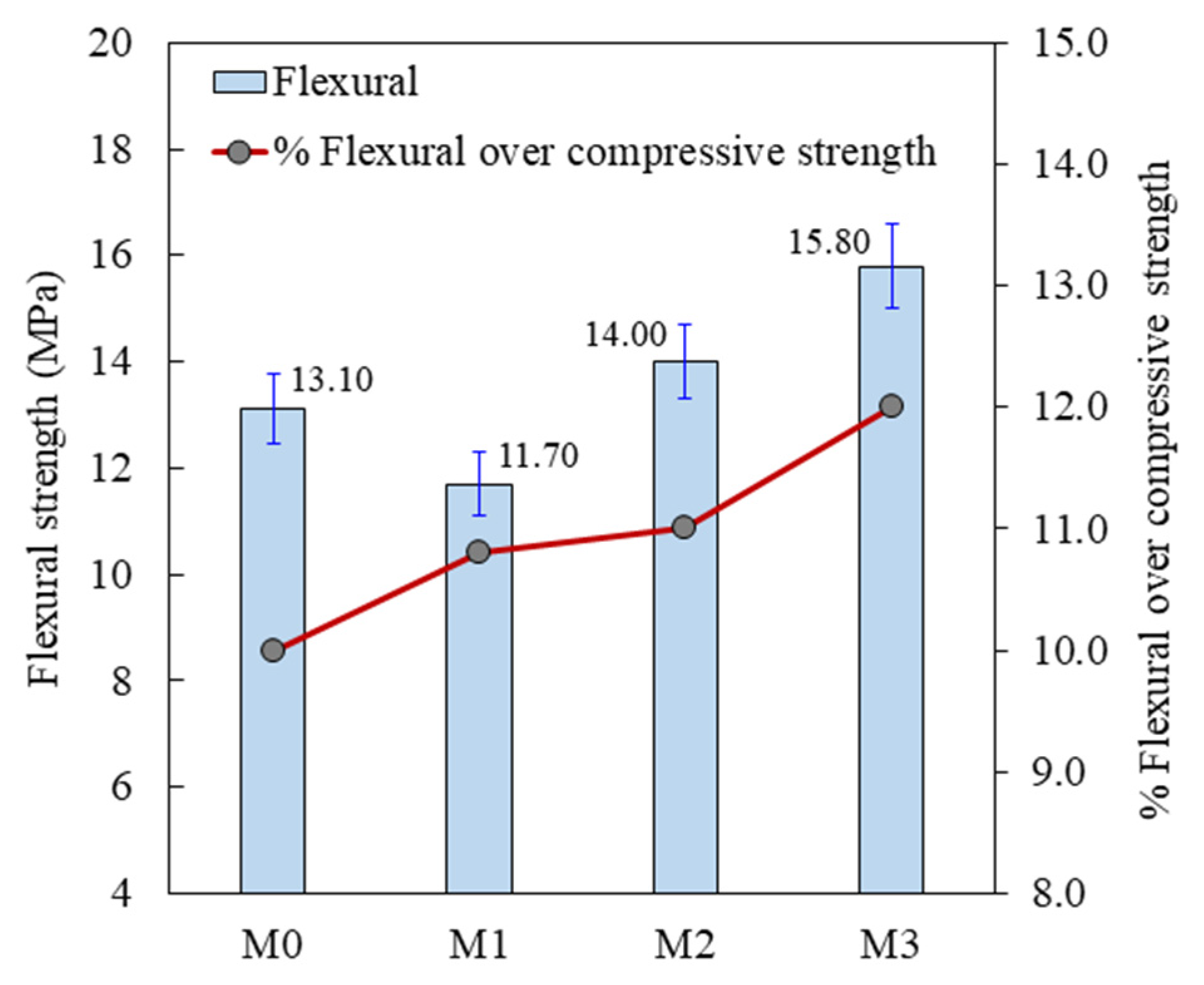

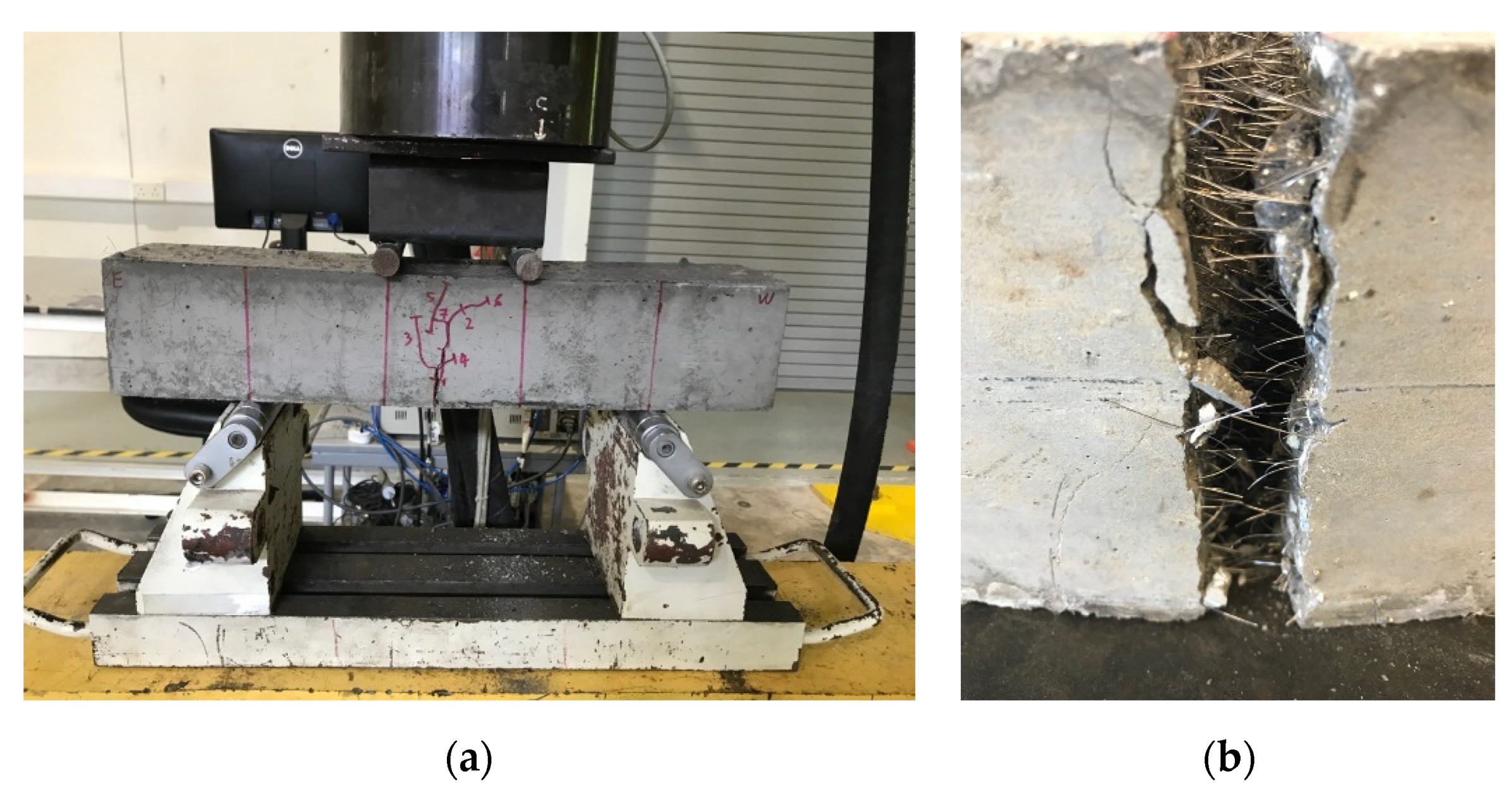

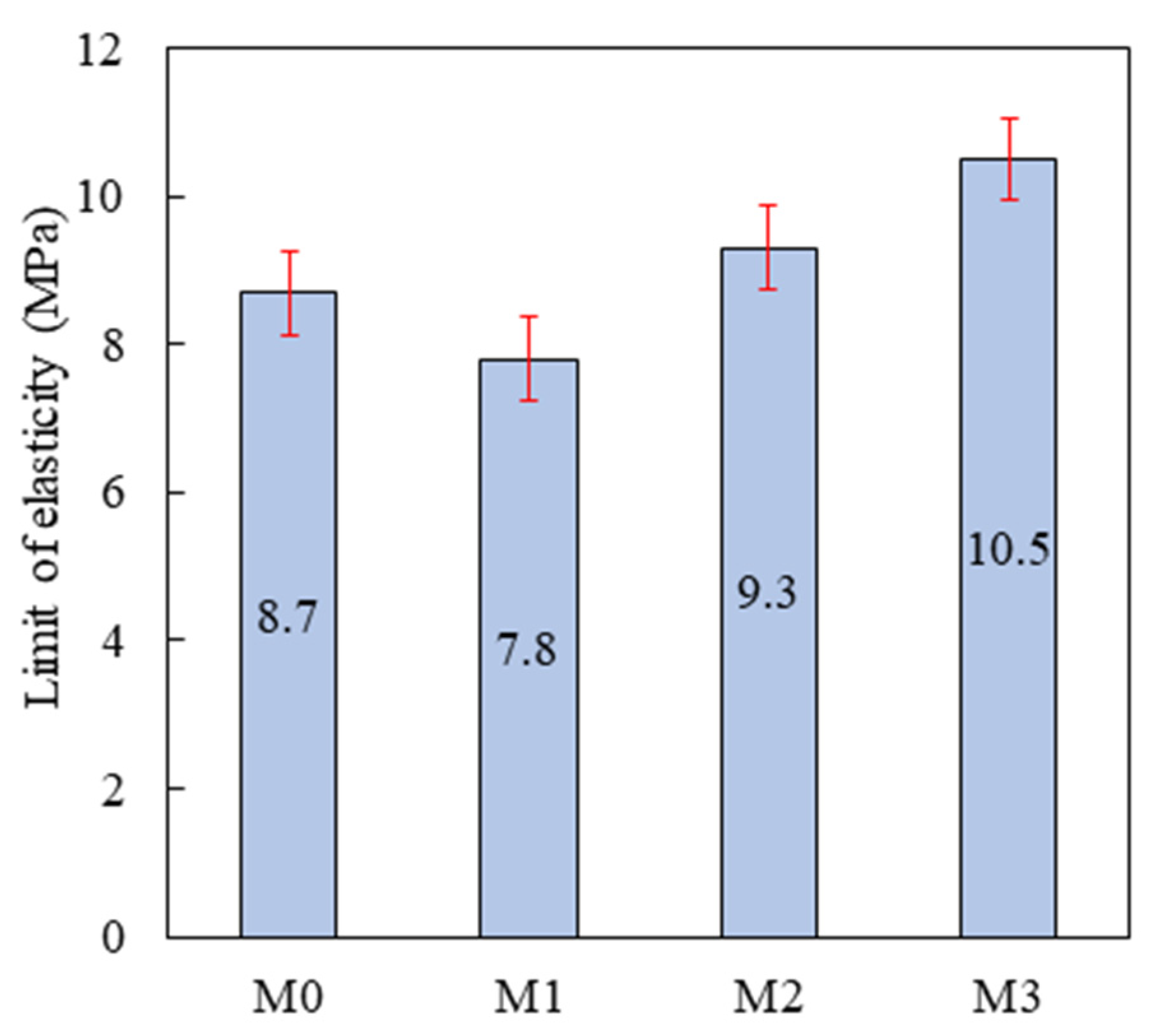

3.5.2. Flexural Strength

4. Conclusions

- Up to 50% of cement can be optimally replaced with the combination of FA and UFCC using a W/B of 0.16 without heat treatment.

- The HC treatment significantly improved the seven-day concrete compressive strength by up to 50%. However, the strength was reduced after 28 days owing to weak pozzolanic reaction and relaxation phenomena. Both WC and AC methods showed a slower rate of strength development compared to the HC. AC treatment was useful at 14 and 28 days for the OPC–FA–UFCC concrete system. The concrete achieved the target strength under AC, which eliminated the need for WC and HC.

- HPC can be produced using a high-amount FA replacement and the addition of 10% UFCC with an average particle size of 3.5 µm. The seven-day compressive strength of concrete was improved by 25% with the addition of UFCC in the OPC–FA–UFCC system, surpassing that of the concrete containing FA only. The synergic effect of efficiency (k value) for ternary blend concrete containing OPC–FA–UFCC showed the highest values at all ages, with k = 1.06 at 28 days and k = 1.39 at 90 days.

- SEM observations showed that the use of UFCC improved the microstructure and ITZ of concrete containing HVFA. The dense matrix was attributed to the possible filling effect, pozzolanic phenomena, and the synergic reaction of FA–UFCC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Patel, V.; Shah, N. A Survey of High Performance Concrete Developments in Civil Engineering Field. 2013. Available online: https://www.researchgate.net/publication/269791432_A_Survey_of_High_Performance_Concrete_Developments_in_Civil_Engineering_Field (accessed on 1 November 2020).

- Balaji, M.; Dhilip Sharma, S.; Vigneshwaran, A.; Fayaz Ahamed, K. Experimental Study on the Behavior of Self-Compacting Self Cured Concrete Using Chemical Admixtures and Metakaolin. In Proceedings of the International Conference on Emerging Trends in Engineering, Science and Sustainable Technology (ICETSST-2017), Erode, India, 16 January 2017. [Google Scholar]

- Schmidt, M.; Fehling, E. Ultra-high-performance concrete: Research, development and application in Europe. ACI Spec. Publ. 2005, 228, 51–78. [Google Scholar]

- Azmee, N.M.; Shafiq, N. Ultra-high performance concrete: From fundamental to applications. Case Stud. Constr. Mater. 2018, 9, e00197. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Reactive Powder Concrete with High Ductility and 200–800 MPa Compressive Strength, Concrete Technology: Past, Present and Future. Mater. Sci. 1994. [Google Scholar] [CrossRef]

- Mehta, P.K. Concrete technology for sustainable development. Concr. Int. 1999, 21, 47–53. [Google Scholar]

- Poon, C.S.; Lam, L.; Wong, Y. A study on high strength concrete prepared with large volumes of low calcium fly ash. Cem. Concr. Res. 2000, 30, 447–455. [Google Scholar] [CrossRef]

- Ferdosian, I.; Camões, A. Eco-efficient ultra-high performance concrete development by means of response surface methodology. Cem. Concr. Compos. 2017, 84, 146–156. [Google Scholar] [CrossRef]

- Mehta, P.K. High-performance, high-volume fly ash concrete for sustainable development. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2004; Marquardt Printing: Ottawa, ON, Canada, 2012; pp. 3–14. [Google Scholar]

- Nm, A.; Mf, N. Effect of High Volume of Fly Ash in Ultra-High-Performance Concrete on Compressive Strength. In Engineering Challenges for Sustainable Future; Taylor and Francis Group: London, UK, 2016; pp. 463–466. [Google Scholar]

- UNSTAT. Greenhouse Gas Emissions by Sector (Absolute Values); United Nation Statistics Division: New York, NY, USA, 2010. [Google Scholar]

- Friendlingstein, P.; Houghton, R.; Marland, G.; Hackler, J.; Boden, T.; Conwat, T. Uptake on CO2 Emission. Nat. Geosci. 2010, 3, 811–812. [Google Scholar] [CrossRef]

- Habert, G.; Denarié, E.; Šajna, A.; Rossi, P. Lowering the global warming impact of bridge rehabilitations by using Ultra High Performance Fibre Reinforced Concretes. Cem. Concr. Compos. 2013, 38, 1–11. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E.; El-Tawil, S.; Parra-Montesinos, G.J. Ultra-high performance concrete and fiber reinforced concrete: Achieving strength and ductility without heat curing. Mater. Struct. 2012, 45, 309–324. [Google Scholar] [CrossRef]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete; Federal Highway Administration, Office of Infrastructure: West Trenton, NJ, USA, 2006.

- Bentz, D.P.; Stutzman, P.E.; Garboczi, E.J. Experimental and simulation studies of the interfacial zone in concrete. Cem. Concr. Res. 1992, 22, 891–902. [Google Scholar] [CrossRef]

- Chung, D. Improving cement-based materials by using silica fume. J. Mater. Sci. 2002, 37, 673–682. [Google Scholar] [CrossRef]

- Zhang, M.-H.; Gjørv, O.E. Microstructure of the interfacial zone between lightweight aggregate and cement paste. Cem. Concr. Res. 1990, 20, 610–618. [Google Scholar] [CrossRef]

- Berry, E.E.; Hemmings, R.T.; Zhang, M.-H.; Cornelius, B.J.; Golden, D.M. Hydration in high-volume fly ash concrete binders. Mater. J. 1994, 91, 382–389. [Google Scholar]

- Babu, K.G.; Rao, G.S.N. Efficiency of fly ash in concrete with age. Cem. Concr. Res. 1996, 26, 465–474. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.; Poon, C.S. Degree of hydration and gel/space ratio of high-volume fly ash/cement systems. Cem. Concr. Res. 2000, 30, 747–756. [Google Scholar] [CrossRef]

- Wang, C.; Yang, C.; Liu, F.; Wan, C.; Pu, X. Preparation of ultra-high performance concrete with common technology and materials. Cem. Concr. Compos. 2012, 34, 538–544. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.; Poon, C.-S. Effect of fly ash and silica fume on compressive and fracture behaviors of concrete. Cem. Concr. Res. 1998, 28, 271–283. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Su, Y.; Wu, C.; Li, J.; Li, Z.-X.; Li, W. Development of novel ultra-high performance concrete: From material to structure. Constr. Build. Mater. 2017, 135, 517–528. [Google Scholar] [CrossRef]

- Soliman, N.; Tagnit-Hamou, A. Development of ultra-high-performance concrete using glass powder–Towards ecofriendly concrete. Constr. Build. Mater. 2016, 125, 600–612. [Google Scholar] [CrossRef]

- Burroughs, J.F.; Shannon, J.; Rushing, T.S.; Yi, K.; Gutierrez, Q.B.; Harrelson, D.W. Potential of finely ground limestone powder to benefit ultra-high performance concrete mixtures. Constr. Build. Mater. 2017, 141, 335–342. [Google Scholar] [CrossRef]

- Heinz, D.; Ludwig, H.-M. Heat treatment and the risk of DEF delayed ettringite formation in UHPC. In Proceedings of the International Symposium on UHPC, Kassel, Germany, 13–15 September 2004; pp. 717–730. [Google Scholar]

- Graybeal, B.A.; Hartmann, J.L. Strength and durability of ultra-high performance concrete. In Proceedings of the Concrete Bridge Conference, Charlotte, NC, USA, January 2003. [Google Scholar]

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Nowoświat, A.; Gołaszewski, J. Influence of the variability of calcareous fly ash properties on rheological properties of fresh mortar with its addition. Materials 2019, 12, 1942. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, L.; Li, L.; Cheng, B.; Zhang, Y.; Wei, Y. The Study on the Whole Stress–Strain Curves of Coral Fly Ash-Slag Alkali-Activated Concrete under Uniaxial Compression. Materials 2020, 13, 4291. [Google Scholar] [CrossRef] [PubMed]

- AFNOR. Concrete-Ultra-High Performance Fiber-Reinforced Concrete-Specifications, Performance, Production and Conformity; AFNOR NF P18-470 ENG; Association Française de Normalisation (AFNOR): Paris, France, 2016. [Google Scholar]

- British Standards Institution. Testing Hardened Concrete. Compressive Strength of Test Specimens; BS EN 12390-3; British Standards Institution: London, UK, 2009. [Google Scholar]

- Uchida, Y.; Tanaka, Y.; Katagiri, M.; Niwa, J. Recommendations for design and construction of ultra high strength fiber reinforced concrete structure (Draft). Concr. J. 2005. [Google Scholar] [CrossRef]

- Kang, S.-H.; Lee, J.-H.; Hong, S.-G.; Moon, J. Microstructural investigation of heat-treated ultra-high performance concrete for optimum production. Materials 2017, 10, 1106. [Google Scholar] [CrossRef] [PubMed]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Justs, J.; Wyrzykowski, M.; Bajare, D.; Lura, P. Internal curing by superabsorbent polymers in ultra-high performance concrete. Cem. Concr. Res. 2015, 76, 82–90. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, D.; Zhang, Y. Experimental investigation and quantitative calculation of the degree of hydration and products in fly ash-cement mixtures. Adv. Mater. Sci. Eng. 2017, 2017, 2437270. [Google Scholar] [CrossRef]

- Yang, J.; Peng, G.F.; Gao, Y.X.; Zhang, H. Mechanical Properties and Durability of Ultra-High Performance Concrete Incorporating Coarse Aggregate; Key Engineering Materials, 2015; Trans Tech Publications: Stafa-Zurich, Switzerland, 2015; pp. 96–103. [Google Scholar]

- Matschei, T.; Lothenbach, B.; Glasser, F.P. The role of calcium carbonate in cement hydration. Cem. Concr. Res. 2007, 37, 551–558. [Google Scholar] [CrossRef]

- Winter, N.B. Understanding Cement: An Introduction to Cement Production, Cement Hydration and Deleterious Processes in Concrete; Microanalysis Consultants: Saint Ives, UK, 2012. [Google Scholar]

- Schöler, A.; Lothenbach, B.; Winnefeld, F.; Zajac, M. Hydration of quaternary Portland cement blends containing blast-furnace slag, siliceous fly ash and limestone powder. Cem. Concr. Compos. 2015, 55, 374–382. [Google Scholar] [CrossRef]

- Arora, A.; Sant, G.; Neithalath, N. Ternary blends containing slag and interground/blended limestone: Hydration, strength, and pore structure. Constr. Build. Mater. 2016, 102, 113–124. [Google Scholar] [CrossRef]

- Atiş, C.D. Strength properties of high-volume fly ash roller compacted and workable concrete, and influence of curing condition. Cem. Concr. Res. 2005, 35, 1112–1121. [Google Scholar] [CrossRef]

| OPC | FA | SF | UFCC | ||

|---|---|---|---|---|---|

| Chemical composition (%) | SiO2 | 12.38 | 36.41 | 90.4 | 0.19 |

| Al2O3 | 2.86 | 16.95 | 0.71 | 0.07 | |

| Fe2O3 | 5.32 | 20.54 | 1.31 | 0.05 | |

| TiO2 | 0.17 | 1.59 | - | - | |

| MnO | 0.09 | 0.18 | - | - | |

| MgO | 0.99 | 2.26 | - | 0.8 | |

| CaO | 73.50 | 14.4 | 0.45 | 54.6 | |

| Na2O | - | 1.03 | - | - | |

| K2O | 0.80 | 2.23 | - | - | |

| P2O5 | 0.44 | 1.35 | - | - | |

| SO3 | 3.11 | 2.19 | 0.41 | - | |

| L.O.I. | 4.7 | 1.7 | 5.4 | 43 | |

| Physical properties | D50 (µm) | 20.8 | 24.4 | 0.16 | 3.5 |

| Fiber Properties | Straight End |

|---|---|

| Length, mm | 20 |

| Diameter, mm | 0.2 |

| Aspect ratio () | 100 |

| Tensile strength, MPa | >2300 |

| Mix ID | Binder | % Binder | CA | Sand | % Fiber | |||

|---|---|---|---|---|---|---|---|---|

| OPC | FA | SF | UFCC | |||||

| M0 | 900 | 100 | - | - | - | 930 | 620 | 1 |

| M1 | 900 | 50 | 50 | - | - | 930 | 620 | 1 |

| M2 | 900 | 50 | 40 | 10 | - | 930 | 620 | 1 |

| M3 | 900 | 50 | 40 | - | 10 | 930 | 620 | 1 |

| Mixing Procedure | Time (min) |

|---|---|

| Add aggregates + 3% moisture content | 3 |

| Add binder | 5 |

| Add 50% water + 50% SP | 5 |

| Add 50% water + 50% SP | 5 |

| Add steel fiber | 2 |

| Curing Method | Testing (Days) | |

|---|---|---|

| WC | Water curing at room temperature until the date of testing | 1, 7, 14, 28, 90 |

| AC | Ambient curing until the date of testing | |

| HC | Heat curing at 90 °C for 8 h in a water bath, and specimens were formerly relocated in water curing tank at room temperature until the date of testing | |

| Mix | Binder Combinations | Value at 28 Days | Value at 90 Days |

|---|---|---|---|

| M0 | 100% OPC | - | - |

| M1 | 50% OPC + 50% FA | 0.66 | 0.75 |

| M2 | 50% OPC + 40% FA + 10% SF | 1 | 1.36 |

| M3 | 50% OPC + 40% FA + 10% UFCC | 1.08 | 1.39 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azmee, N.; Abbas, Y.M.; Shafiq, N.; Fares, G.; Osman, M.; Iqbal Khan, M. Enhancing the Microstructure and Sustainability of Ultra-High-Performance Concrete Using Ultrafine Calcium Carbonate and High-Volume Fly Ash under Different Curing Regimes. Sustainability 2021, 13, 3900. https://doi.org/10.3390/su13073900

Azmee N, Abbas YM, Shafiq N, Fares G, Osman M, Iqbal Khan M. Enhancing the Microstructure and Sustainability of Ultra-High-Performance Concrete Using Ultrafine Calcium Carbonate and High-Volume Fly Ash under Different Curing Regimes. Sustainability. 2021; 13(7):3900. https://doi.org/10.3390/su13073900

Chicago/Turabian StyleAzmee, Norzaireen, Yassir M. Abbas, Nasir Shafiq, Galal Fares, Montasir Osman, and M. Iqbal Khan. 2021. "Enhancing the Microstructure and Sustainability of Ultra-High-Performance Concrete Using Ultrafine Calcium Carbonate and High-Volume Fly Ash under Different Curing Regimes" Sustainability 13, no. 7: 3900. https://doi.org/10.3390/su13073900

APA StyleAzmee, N., Abbas, Y. M., Shafiq, N., Fares, G., Osman, M., & Iqbal Khan, M. (2021). Enhancing the Microstructure and Sustainability of Ultra-High-Performance Concrete Using Ultrafine Calcium Carbonate and High-Volume Fly Ash under Different Curing Regimes. Sustainability, 13(7), 3900. https://doi.org/10.3390/su13073900