Toward Life Cycle Sustainability in Infrastructure: The Role of Automation and Robotics in PPP Projects

Abstract

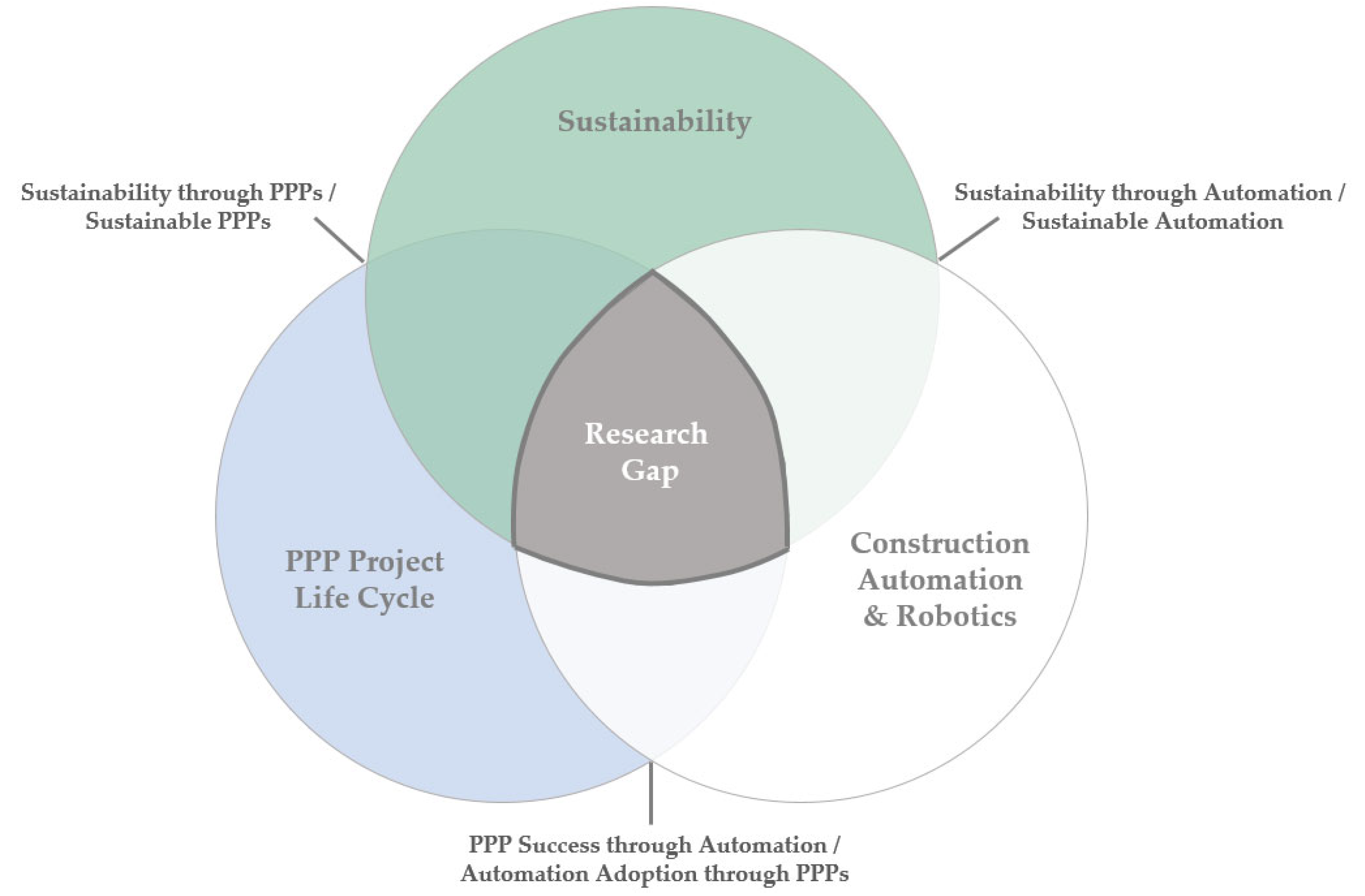

1. Introduction

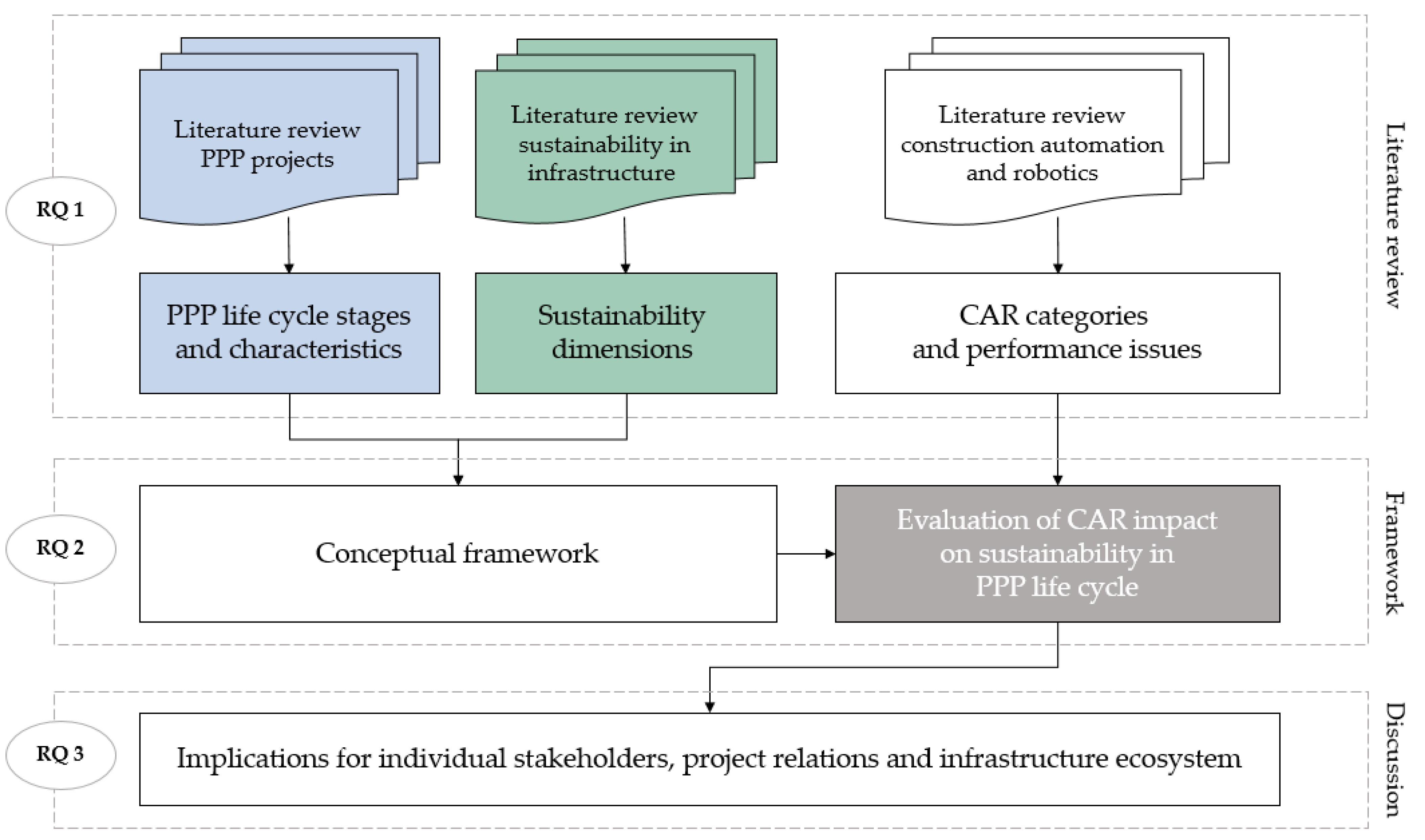

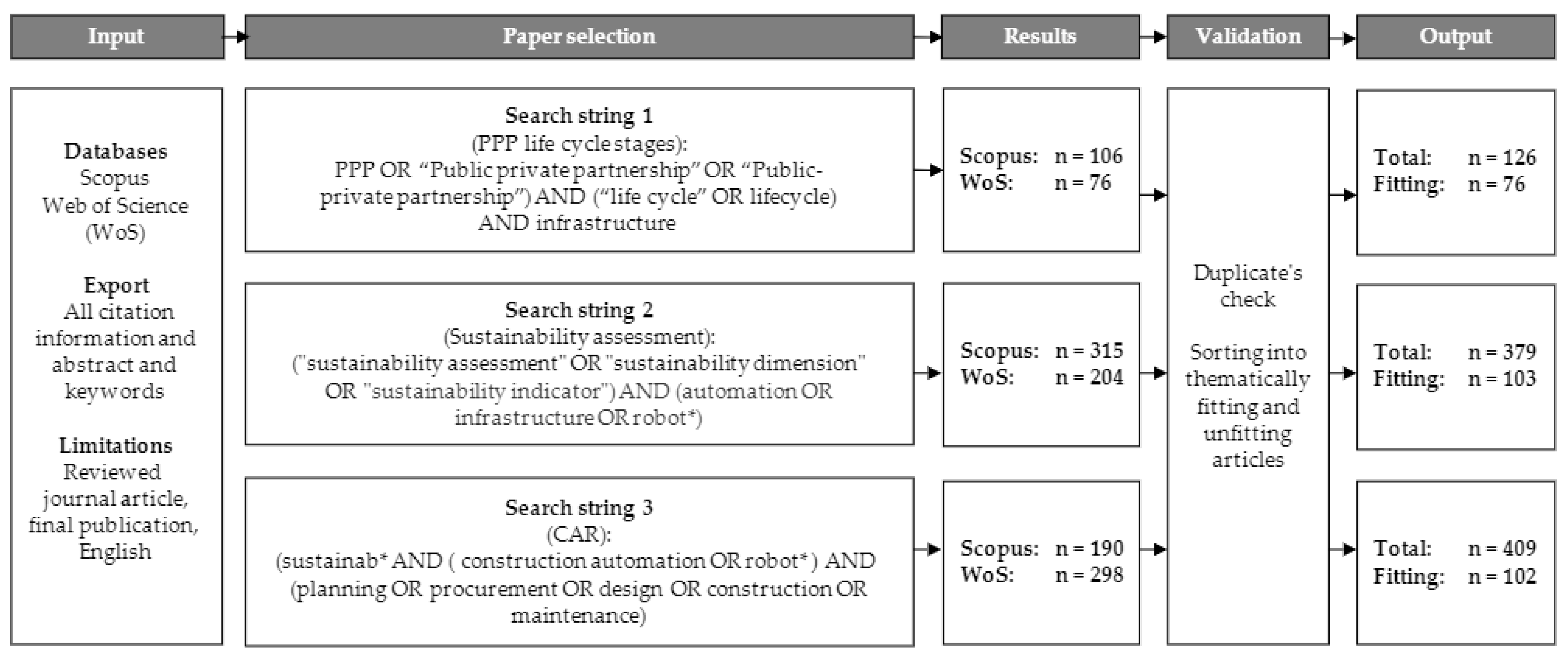

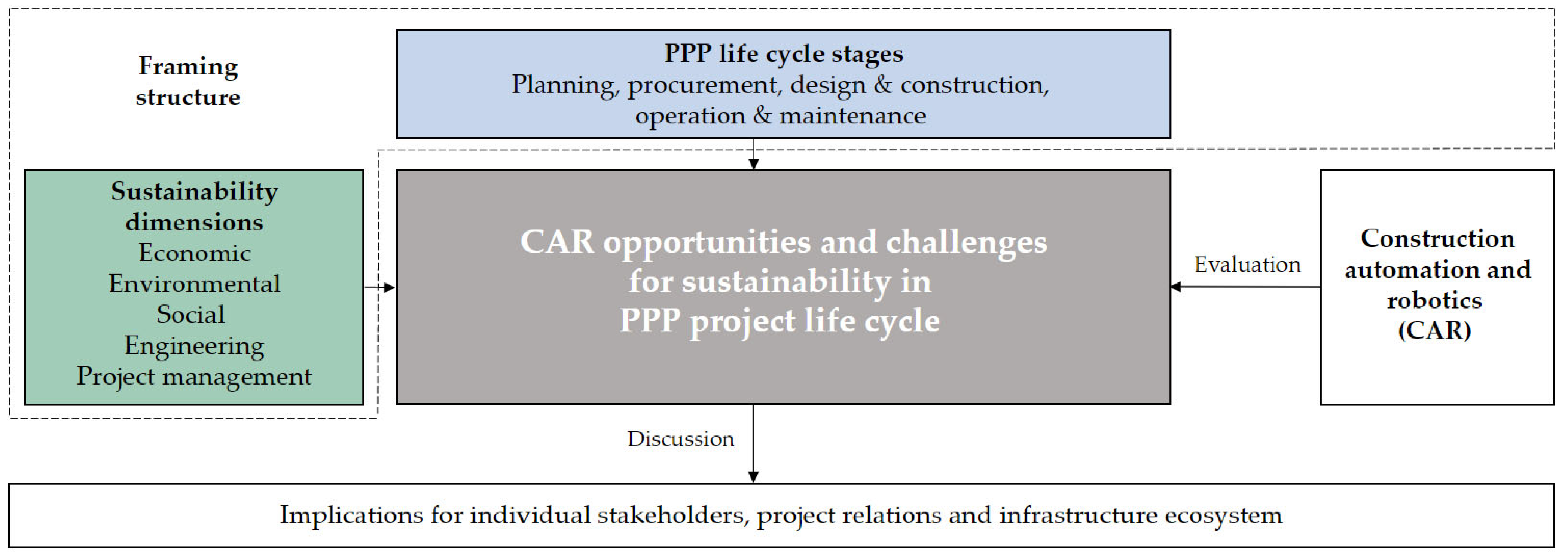

2. Materials and Methods

3. Results

3.1. Literature Review

3.1.1. PPP Project Life Cycle Stages

Planning

Procurement

Design and Construction

Operation and Maintenance

3.1.2. Sustainability Assessment

3.1.3. Automation and Robotics

Design and Project Management Technologies

Off-Site Technologies

On-Site Technologies

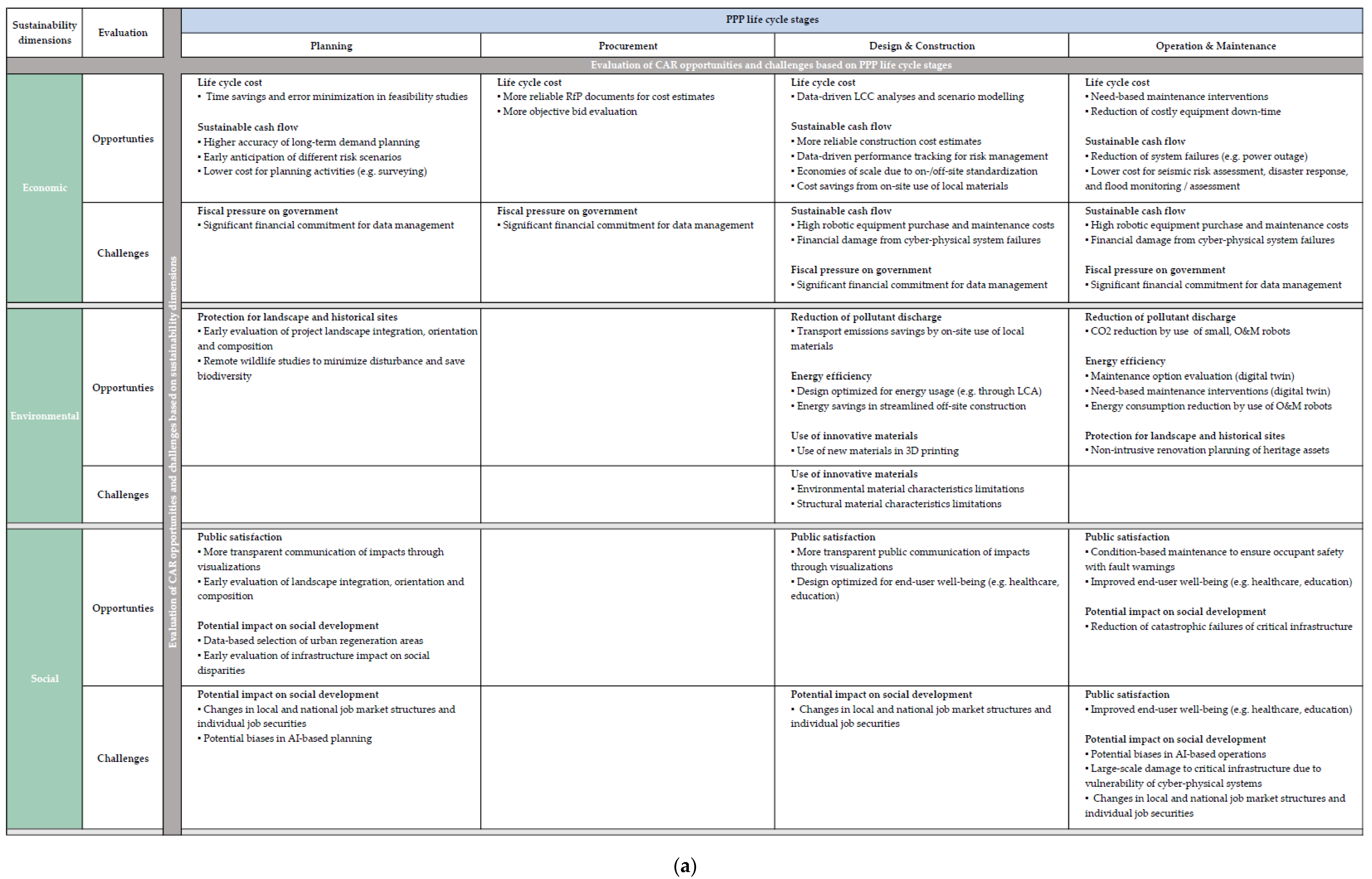

3.2. Evaluation Framework

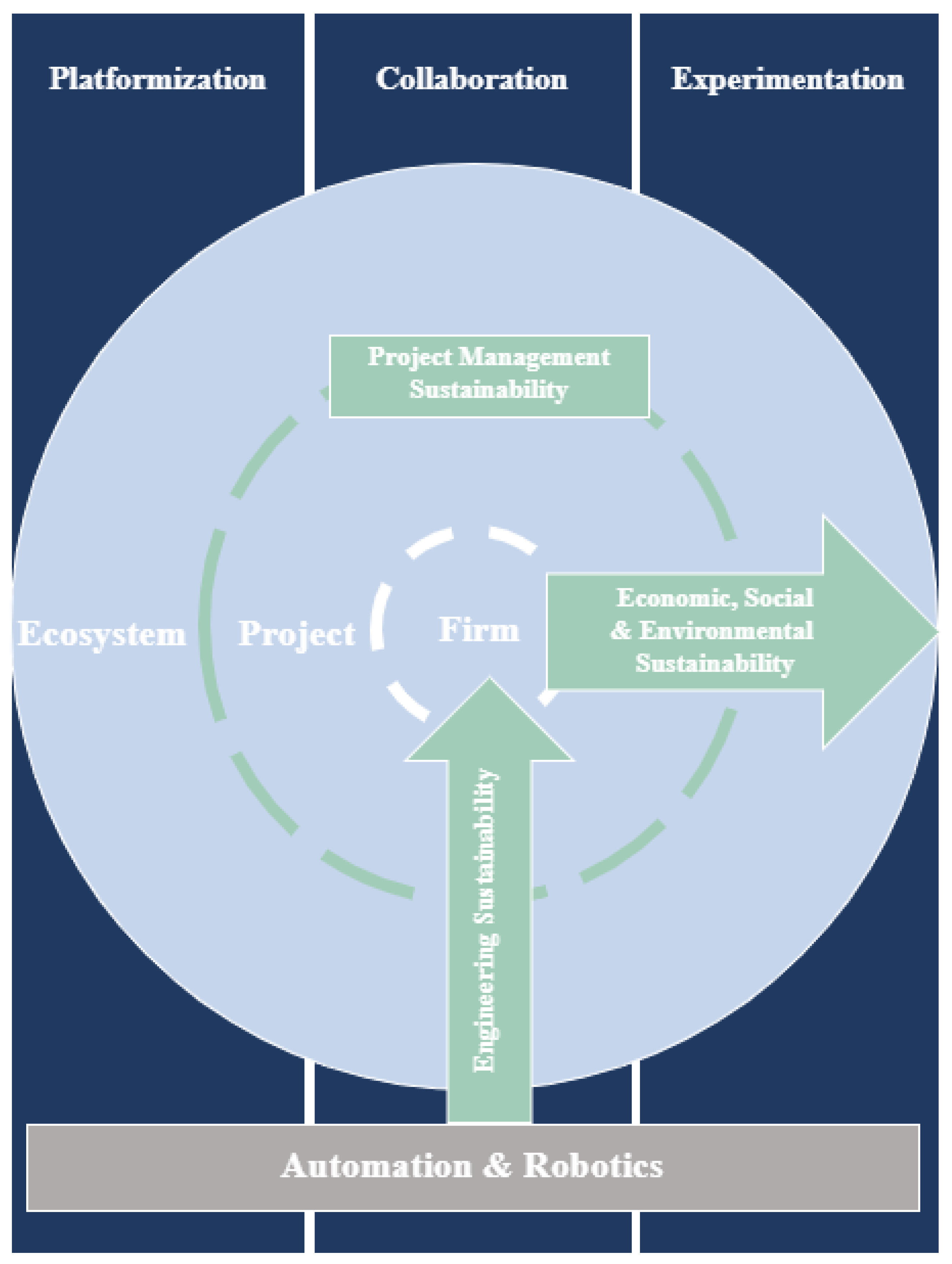

4. Discussion

4.1. Firm-Level Implications

4.2. Project-Level Implications

4.3. Ecosystem Implications

5. Conclusions

6. Research Agenda

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Ma, L.; Li, J.; Jin, R.; Ke, Y.; Yuan, J. A holistic review of public-private partnership literature published between 2008 and 2018. Adv. Civ. Eng. 2019, 2019. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, H.; Xiong, W.; Zhu, D.; Cheng, L. Public–private partnership as a driver of sustainable development: Toward a conceptual framework of sustainability-oriented PPP. Environ. Dev. Sustain. 2020. [Google Scholar] [CrossRef]

- Casady, C.B.; Eriksson, K.; Levitt, R.E.; Scott, W.R. (Re)defining public-private partnerships (PPPs) in the new public governance (NPG) paradigm: An institutional maturity perspective. Public Manag. Rev. 2020, 22, 161–183. [Google Scholar] [CrossRef]

- Kim, T.; Lee, D.; Lim, H.; Lee, U.; Cho, H.; Cho, K. Exploring research trends and network characteristics in construction automation and robotics based on keyword network analysis. J. Asian Archit. Build. Eng. 2020. [Google Scholar] [CrossRef]

- Chen, Q.; de Soto, B.G.; Adey, B.T. Construction automation: Research areas, industry concerns and suggestions for advancement. Autom. Constr. 2018, 94, 22–38. [Google Scholar] [CrossRef]

- Kim, M.J.; Chi, H.L.; Wang, X.; Ding, L. Automation and Robotics in Construction and Civil Engineering. J. Intell. Robot. Syst. Theory Appl. 2015, 79, 347–350. [Google Scholar] [CrossRef]

- Pan, M.; Linner, T.; Pan, W.; Cheng, H.; Bock, T. A framework of indicators for assessing construction automation and robotics in the sustainability context. J. Clean. Prod. 2018, 182, 82–95. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Davis, S.R.; Li, H.; Luo, X.R. Modeling the Implementation Process for New Construction Technologies: Thematic Analysis Based on Australian and US Practices. J. Manag. Eng. 2018, 34, 12. [Google Scholar] [CrossRef]

- Bock, T. The future of construction automation: Technological disruption and the upcoming ubiquity of robotics. Autom. Constr. 2015, 59, 113–121. [Google Scholar] [CrossRef]

- ISO 15392:2019 Sustainability in Buildings and Civil Engineering Works - General Principles; International Organization for Standardization: Geneva, Switzerland, 2019.

- Cui, C.; Liu, Y.; Hope, A.; Wang, J. Review of studies on the public–private partnerships (PPP) for infrastructure projects. Int. J. Proj. Manag. 2018, 36, 773–794. [Google Scholar] [CrossRef]

- Wang, N.; Ma, M. Public–private partnership as a tool for sustainable development—What literatures say? Sustain. Dev. 2020. [Google Scholar] [CrossRef]

- Hueskes, M.; Verhoest, K.; Block, T. Governing public–private partnerships for sustainability: An analysis of procurement and governance practices of PPP infrastructure projects. Int. J. Proj. Manag. 2017, 35, 1184–1195. [Google Scholar] [CrossRef]

- Yuan, J.; Zhang, L.; Tan, Y.; Skibniewski, M.J. Evaluating the regional social sustainability contribution of public-private partnerships in China: The development of an indicator system. Sustain. Dev. 2020, 28, 259–278. [Google Scholar] [CrossRef]

- Villalba-Romero, F.; Liyanage, C.; Roumboutsos, A. Sustainable PPPs: A comparative approach for road infrastructure. Case Stud. Transp. Policy 2015, 3, 243–250. [Google Scholar] [CrossRef]

- Love, P.E.D.; Liu, J.; Matthews, J.; Sing, C.P.; Smith, J. Future proofing PPPs: Life-cycle performance measurement and Building Information Modelling. Autom. Constr. 2015, 56, 26–35. [Google Scholar] [CrossRef]

- Lember, V.; Petersen, O.H.; Scherrer, W.; Ågren, R. Understanding the relationship between infrastructure public‒Private partnerships and innovation. Ann. Public Coop. Econ. 2019, 90, 371–391. [Google Scholar] [CrossRef]

- Liu, Z.; Stephens, V. Exploring innovation ecosystem from the perspective of sustainability: Towards a conceptual framework. J. Open Innov. Technol. Mark. Complex. 2019, 5, 48. [Google Scholar] [CrossRef]

- Jaakkola, E. Designing conceptual articles: Four approaches. AMS Rev. 2020, 10, 18–26. [Google Scholar] [CrossRef]

- Gilson, L.L.; Goldberg, C.B. Editors’ Comment. Group Organ. Manag. 2015, 40, 127–130. [Google Scholar] [CrossRef]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Ward, V.; House, A.; Hamer, S. Developing a framework for transferring knowledge into action: A thematic analysis of the literature. J. Health Serv. Res. Policy 2009, 14, 156–164. [Google Scholar] [CrossRef] [PubMed]

- South, A.; Eriksson, K.; Levitt, R. How Infrastructure Public–Private Partnership Projects Change Over Project Development Phases. Proj. Manag. J. 2018, 49, 62–80. [Google Scholar] [CrossRef]

- Liu, J.; Love, P.E.D.; Davis, P.R.; Smith, J.; Regan, M. Conceptual framework for the performance measurement of public-private partnerships. J. Infrastruct. Syst. 2015, 21. [Google Scholar] [CrossRef]

- Devkar, G.; Palliyaguru, R.; Oyegoke, A.S. The effects of institutional frameworks on implementation of PPP projects: A comparative perspective in Australia and India. Int. J. Constr. Manag. 2020, 20, 720–736. [Google Scholar] [CrossRef]

- Bao, F.; Martek, I.; Chen, C.; Chan, A.P.C.; Yu, Y. Lifecycle performance measurement of public-private partnerships: A case study in China’s water sector. Int. J. Strateg. Prop. Manag. 2018, 22, 516–531. [Google Scholar] [CrossRef]

- Buso, M.; Stenger, A. Public-private partnerships as a policy response to climate change. Energy Policy 2018, 119, 487–494. [Google Scholar] [CrossRef]

- Liu, J.; Love, P.E.D.; Smith, J.; Regan, M.; Davis, P.R. Life cycle critical success factors for public-private partnership infrastructure projects. J. Manag. Eng. 2015, 31. [Google Scholar] [CrossRef]

- Zou, P.X.W.; Wang, S.; Fang, D. A life-cycle risk management framework for PPP infrastructure projects. J. Financ. Manag. Prop. Constr. 2008, 13, 123–142. [Google Scholar] [CrossRef]

- Simon, L.; Jefferies, M.; Davis, P.; Newaz, M.T. Developing a theoretical success factor framework for the tendering phase of social infrastructure PPPs. Int. J. Constr. Manag. 2020, 20, 613–627. [Google Scholar] [CrossRef]

- Soomro, M.A.; Zhang, X. Evaluation of the Functions of Public Sector Partners in Transportation Public-Private Partnerships Failures. J. Manag. Eng. 2016, 32. [Google Scholar] [CrossRef]

- Alexander, J.; Ackermann, F.; Love, P.E.D. Taking a Holistic Exploration of the Project Life Cycle in Public–Private Partnerships. Proj. Manag. J. 2019, 50, 673–685. [Google Scholar] [CrossRef]

- Antillon, E.I.; Molenaar, K.R.; Javernick-Will, A. Evaluating the Effect of Contract Timing on Lifecycle-Design Innovation in Public-Private Partnerships: Comparative Case Study of Highway Projects. J. Constr. Eng. Manag. 2017, 143. [Google Scholar] [CrossRef]

- Tariq, S.; Zhang, X. Critical Failure Drivers in International Water PPP Projects. J. Infrastruct. Syst. 2020, 26. [Google Scholar] [CrossRef]

- Bao, F.Y.; Chan, A.P.C.; Chen, C.; Darko, A. Review of Public-Private Partnership Literature from a Project Lifecycle Perspective. J. Infrastruct. Syst. 2018, 24. [Google Scholar] [CrossRef]

- Páez-Pérez, D.; Sánchez-Silva, M. A dynamic principal-agent framework for modeling the performance of infrastructure. Eur. J. Oper. Res. 2016, 254, 576–594. [Google Scholar] [CrossRef]

- Trangkanont, S.; Charoenngam, C. Critical failure factors of public-private partnership low-cost housing program in Thailand. Eng. Constr. Archit. Manag. 2014, 21, 421. [Google Scholar] [CrossRef]

- Hasheminasab, H.; Gholipour, Y.; Kharrazi, M.; Streimikiene, D.; Hashemkhani, S. A dynamic sustainability framework for petroleum refinery projects with a life cycle attitude. Sustain. Dev. 2020, 28, 1033–1048. [Google Scholar] [CrossRef]

- Boz, M.A.; El-Adaway, I.H. Creating a holistic systems framework for sustainability assessment of civil infrastructure projects. J. Constr. Eng. Manag. 2015, 141. [Google Scholar] [CrossRef]

- Gharehbaghi, K.; McManus, K.; Hurst, N.; Robson, K.; Myers, M. Complexities in mega rail transportation projects: “Sydney metro” and “Melbourne metro rail” insight. J. Eng. Des. Technol. 2020, 18, 973–990. [Google Scholar] [CrossRef]

- Spoann, V.; Fujiwara, T.; Seng, B.; Lay, C.; Yim, M. Assessment of public-private partnership in municipal solid waste management in Phnom Penh, Cambodia. Sustainability 2019, 11, 1228. [Google Scholar] [CrossRef]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. An overview of sustainability assessment methodologies. Ecol. Indic. 2009, 9, 189–212. [Google Scholar] [CrossRef]

- Li, H.; Xia, Q.; Wen, S.; Wang, L.; Lv, L. Identifying Factors Affecting the Sustainability of Water Environment Treatment Public-Private Partnership Projects. Adv. Civ. Eng. 2019, 2019, 7234. [Google Scholar] [CrossRef]

- Ferrarez, R.P.F.; Vargas, R.V.; Alvarenga, J.C.; Chinelli, C.K.; Costa, M.A.; Oliveira, B.L.; Haddad, A.N.; Soares, C.A.P. Sustainability indicators to assess infrastructure projects: Sector disclosure to interlock with the global reporting initiative. Eng. J. 2020, 24, 43–61. [Google Scholar] [CrossRef]

- Navarro, I.J.; Yepes, V.; Martí, J.V. A Review of Multicriteria Assessment Techniques Applied to Sustainable Infrastructure Design. Adv. Civ. Eng. 2019, 2019. [Google Scholar] [CrossRef]

- Aboushady, A.M.; El-Sawy, S.A.R. Qualitative assessment framework to evaluate sustainability indicators affecting infrastructure construction projects in developing countries using the analytical hierarchy process (AHP). Wit Trans. Ecol. Environ. 2013, 179, 1309–1320. [Google Scholar] [CrossRef]

- Hallin, A.; Karrbom-Gustavsson, T.; Dobers, P. Transition towards and of sustainability—Understanding sustainability as performative. Bus. Strategy Environ. 2021, 10.1002/bse.2726. [Google Scholar] [CrossRef]

- Raouf, A.M.I.; Al-Ghamdi, S.G. Building information modelling and green buildings: Challenges and opportunities. Archit. Eng. Des. Manag. 2019, 15, 1–28. [Google Scholar] [CrossRef]

- Mansouri, S.; Castronovo, F.; Akhavian, R. Analysis of the Synergistic Effect of Data Analytics and Technology Trends in the AEC/FM Industry. J. Constr. Eng. Manag. 2020, 146. [Google Scholar] [CrossRef]

- Tibaut, A.; Rebolj, D.; Nekrep Perc, M. Interoperability requirements for automated manufacturing systems in construction. J. Intell. Manuf. 2016, 27, 251–262. [Google Scholar] [CrossRef]

- Sanhudo, L.P.N.; Martins, J. Building information modelling for an automated building sustainability assessment. Civ. Eng. Environ. Syst. 2018, 35, 99–116. [Google Scholar] [CrossRef]

- Paiva, G.; Agra, R.; de Tomi, G. Application challenges for information and automation technologies in an underground mine in Brazil. Rev. Esc. De Minas 2017, 70, 93–97. [Google Scholar] [CrossRef][Green Version]

- Khairulzaman, H.A.; Usman, F. Automation in civil engineering design in assessing building energy efficiency. Int. J. Eng. Technol. 2018, 7, 722–727. [Google Scholar] [CrossRef]

- Starynina, J.; Ustinovichius, L. A multi-criteria decision-making synthesis method to determine the most effective option for modernising a public building. Technol. Econ. Dev. Econ. 2020, 26, 1237–1262. [Google Scholar] [CrossRef]

- Ismail, N.A.A.; Idris, N.H.; Ramli, H.; Sahamir, S.R.; Rooshdi, R.R.R.M. Sustainable BIM-based cost estimating for quantity surveyors. Chem. Eng. Trans. 2018, 63, 235–240. [Google Scholar] [CrossRef]

- Zhang, L.; Balangé, L.; Braun, K.; Di Bari, R.; Horn, R.; Hos, D.; Kropp, C.; Leistner, P.; Schwieger, V. Quality as driver for sustainable construction-Holistic quality model and assessment. Sustainability 2020, 12, 7874. [Google Scholar] [CrossRef]

- Rea, P.; Pelliccio, A.; Ottaviano, E.; Saccucci, M. The Heritage Management and Preservation Using the Mechatronic Survey. Int. J. Arch. Herit. 2017, 11, 1121–1132. [Google Scholar] [CrossRef]

- Yang, X.; Loh, P.; Leggett, D. Robotic variable fabric formwork. J. Comput. Des. Eng. 2019, 6, 404–413. [Google Scholar] [CrossRef]

- Wagner, H.J.; Alvarez, M.; Kyjanek, O.; Bhiri, Z.; Buck, M.; Menges, A. Flexible and transportable robotic timber construction platform-TIM. Autom. Constr. 2020, 120, 17. [Google Scholar] [CrossRef]

- Kromoser, B.; Ritt, M.; Spitzer, A.; Stangl, R.; Idam, F. Design concept for a greened timber truss bridge in city area. Sustainability 2020, 12, 3218. [Google Scholar] [CrossRef]

- Yang, L.; Fu, C.; Li, Y.; Su, L. Survey and study on intelligent monitoring and health management for large civil structure. Int. J. Intell. Robot. 2019, 3, 239–254. [Google Scholar] [CrossRef]

- Myung, H.; Wang, Y.; Kang, S.C.J.; Chen, X.Q. Survey on robotics and automation technologies for civil infrastructure. Smart. Struct. Syst. 2014, 13, 891–899. [Google Scholar] [CrossRef]

- Rizo-Maestre, C.; González-Avilés, Á.; Galiano-Garrigós, A.; Andújar-Montoya, M.D.; Puchol-García, J.A. UAV + BIM: Incorporation of photogrammetric techniques in architectural projects with building information modeling versus classical work processes. Remote Sens. 2020, 12, 2329. [Google Scholar] [CrossRef]

- Rivera, R.G.; Alvarado, R.G.; Martínez-Rocamora, A.; Cheein, F.A. A comprehensive performance evaluation of different mobile manipulators used as displaceable 3D printers of building elements for the construction industry. Sustainability 2020, 12, 4378. [Google Scholar] [CrossRef]

- Ayman, R.; Alwan, Z.; McIntyre, L. BIM for sustainable project delivery: Review paper and future development areas. Archit. Sci. Rev. 2020, 63, 15–33. [Google Scholar] [CrossRef]

- Hack, N.; Lauer, W.V. Mesh-mould: Robotically fabricated spatial meshes as reinforced concrete formwork. Archit. Des. 2014, 84, 44–53. [Google Scholar] [CrossRef]

- Rea, P.; Ottaviano, E. Design and development of an Inspection Robotic System for indoor applications. Robot. Comput. Integr. Manuf. 2018, 49, 143–151. [Google Scholar] [CrossRef]

- Nagarajan, B.; Li, Y.; Sun, Z.Y.; Qin, R.W. A routing algorithm for inspecting grid transmission system using suspended robot: Enhancing cost-effective and energy efficient infrastructure maintenance. J. Clean. Prod. 2019, 219, 622–638. [Google Scholar] [CrossRef]

- Mascaro, R.; Wermelinger, M.; Hutter, M.; Chli, M. Towards automating construction tasks: Large-scale object mapping, segmentation, and manipulation. J. Field Robot. 2020, 16. [Google Scholar] [CrossRef]

- Nisar, N.; Bhat, J.A. Effect of Rice Husk Ash on the Carbonation Depth of Concrete under Different Curing Ages and Humidity Levels. J. Mater. Civ. Eng. 2021, 33. [Google Scholar] [CrossRef]

- García-Alvarado, R.; Martínez, A.; González, L.; Auat, F. Projections of 3D-printed construction in Chile. Rev. Ing. Constr. 2020, 35, 60–72. [Google Scholar] [CrossRef]

- Konietzko, J.; Bocken, N.; Hultink, E.J. Circular ecosystem innovation: An initial set of principles. J. Clean. Prod. 2020, 253. [Google Scholar] [CrossRef]

- Azcárate-Aguerre, J.F.; Den Heijer, A.; Klein, T. Integrated faades as a Product-Service System -Business process innovation to accelerate integral product implementation. J. Facade Des. Eng. 2018, 6, 41–56. [Google Scholar] [CrossRef]

- Truby, J. Governing Artificial Intelligence to benefit the UN Sustainable Development Goals. Sustain. Dev. 2020, 28, 946–959. [Google Scholar] [CrossRef]

- Saeed, T.U.; Alabi, B.N.T.S.m.a.; Labi, S. Preparing Road Infrastructure to Accommodate Connected and Automated Vehicles: System-Level Perspective. J. Infrastruct. Syst. 2021, 27. [Google Scholar] [CrossRef]

| Dimension | Definition | Indicators (Examples) |

|---|---|---|

| Economic sustainability | “[…] long-term, stable, and reasonable investment returns to the project itself but also the impact on the local economy and development.” | Life cycle cost Sustainable cash flow Fiscal pressures on government |

| Environmental sustainability | “[…] giving a better world to the future generation and protecting ecological balance and natural systems from destruction [...] to achieve energy conservation, emission reduction, and environmental protection.” | Reduction of pollutant discharge Energy efficiency Protection for landscape & historical sites Use of innovation materials |

| Social sustainability | “[…] providing the public with satisfactory goods and services through measures that enhance the social development potential of the project area, provide employment opportunities for local people, and improve the quality of life.” | Public satisfaction Impact on social development |

| Engineering sustainability | “[…] sustainable development of the project itself, specifically, its durability (i.e., engineering quality), operation, and maintenance capability and the sustainability of the technology itself.” | Construction quality Control of pollution sources Adoption of advanced technology Sustainability of technology itself Operation & maintenance capabilities Use of construction waste |

| Project management sustainability | “[…] profitable, fair, transparent, safe, ethical, and environmentally friendly project delivery, which aims at a project deliverable that is socially and environmentally acceptable throughout its life cycle.” | Organization structure Continual improvement of the operation management system Competence & skill of the project team |

| Research Area | Research Question |

|---|---|

| Economic, environmental and social sustainability | What are drivers of infrastructure projects to promote the SDGs and how can CAR technologies leverage them? What do concrete actions and best practices on an organizational, project and ecosystem level look like? How are technological solutions and PPP governance structures addressing the evolving, dynamic nature inherent to the understanding of sustainability? |

| Engineering sustainability | How can CAR use case scenarios in PPP projects be prioritized? What are metrics to evaluate the maturity and risks of technological solutions? |

| Project management sustainability | How can CAR be aligned with project management processes, knowledge management and organizational structures? How can PPP project governance and risk management be designed to account for technology-related risks? How can assessment and selection of project consortia be done in a transparent procurement process, and include metrics beyond purely economic indicators? What attracts innovative, potentially smaller actors to participate in PPP biddings? |

| Collaboration | What are best practices and strategies for multi-disciplinary and cross-industry collaboration around infrastructure automation? Which role do political circumstances and systems play in realizing sustainability benefits through infrastructure technology? |

| Experimentation | How can testbeds and minimum viable ecosystems be designed to reduce residual technology risks in actual infrastructure projects? Which incentives exist for public and private actors to engage in experimentation activities? |

| Platformization | How can marketplaces and transactions between stakeholders and projects be structured efficiently to lower the costs of acquiring and maintaining CAR equipment? What are the implications for stakeholder relations, e.g., in terms of platform access and big data management? How can the state, agencies and other government actors facilitate innovative PPP markets that integrate technology, infrastructure and sustainability? |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoeft, M.; Pieper, M.; Eriksson, K.; Bargstädt, H.-J. Toward Life Cycle Sustainability in Infrastructure: The Role of Automation and Robotics in PPP Projects. Sustainability 2021, 13, 3779. https://doi.org/10.3390/su13073779

Hoeft M, Pieper M, Eriksson K, Bargstädt H-J. Toward Life Cycle Sustainability in Infrastructure: The Role of Automation and Robotics in PPP Projects. Sustainability. 2021; 13(7):3779. https://doi.org/10.3390/su13073779

Chicago/Turabian StyleHoeft, Madeleine, Marianne Pieper, Kent Eriksson, and Hans-Joachim Bargstädt. 2021. "Toward Life Cycle Sustainability in Infrastructure: The Role of Automation and Robotics in PPP Projects" Sustainability 13, no. 7: 3779. https://doi.org/10.3390/su13073779

APA StyleHoeft, M., Pieper, M., Eriksson, K., & Bargstädt, H.-J. (2021). Toward Life Cycle Sustainability in Infrastructure: The Role of Automation and Robotics in PPP Projects. Sustainability, 13(7), 3779. https://doi.org/10.3390/su13073779