Life Cycle Assessment of an Integrated Steel Mill Using Primary Manufacturing Data: Actual Environmental Profile

Abstract

1. Introduction

1.1. Steel Production

1.2. Life Cycle Assessment

LCA of Steel: State of the Art

2. Methodology

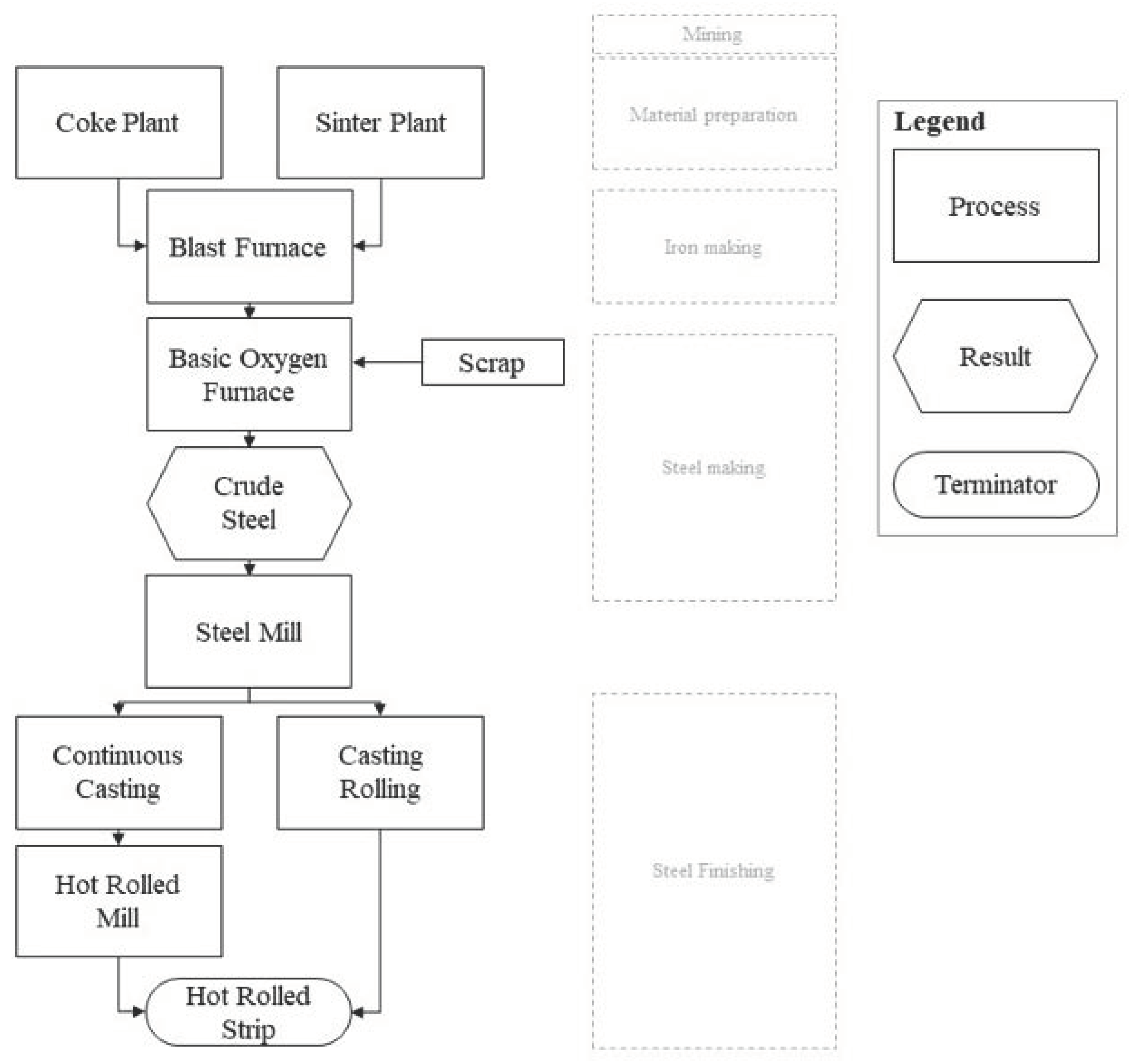

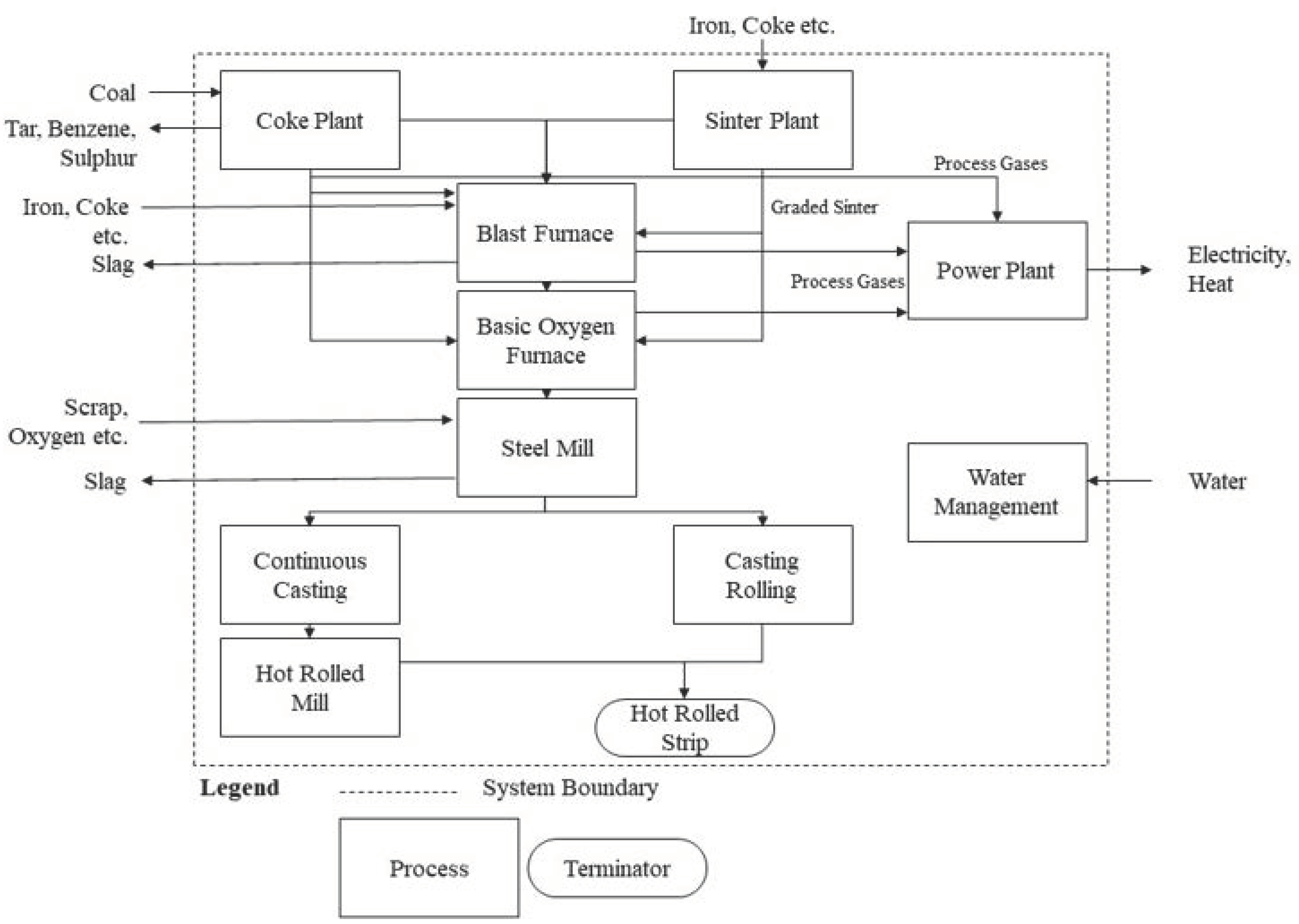

2.1. Goal and Scope

2.2. Life Cycle Inventory

2.3. Life Cycle Impact Assessment

3. Results

3.1. LCI Results

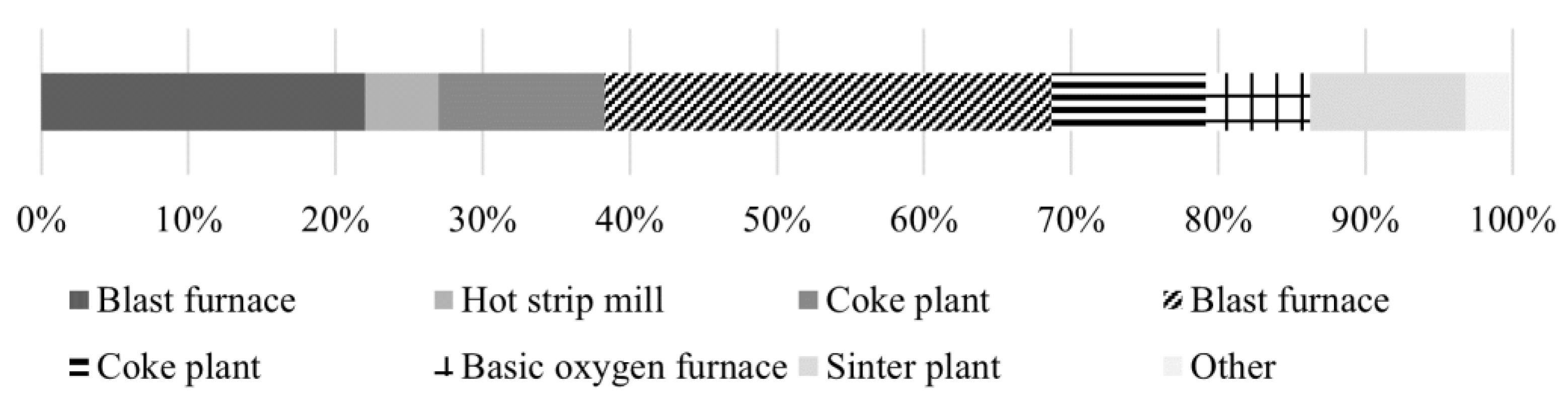

3.2. LCIA Results

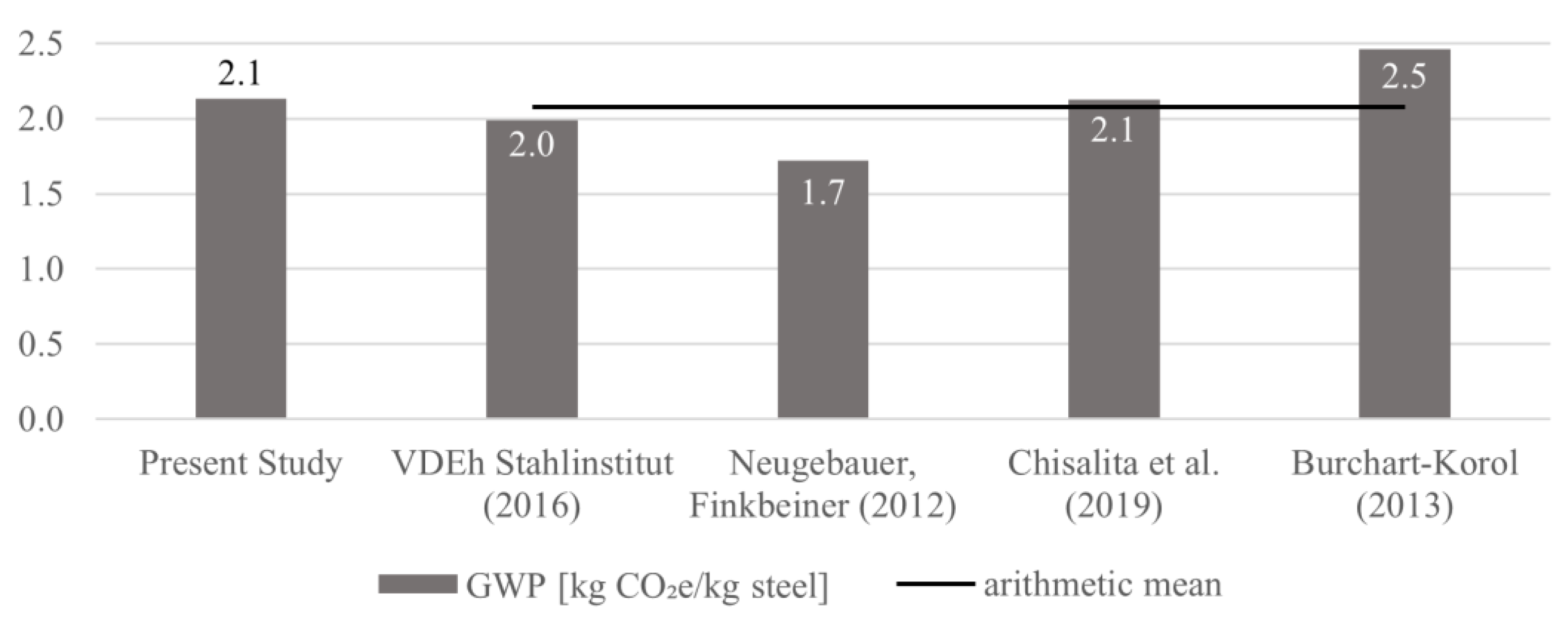

Comparability with Other Study Results

4. Discussion and Data Verification

5. Limitations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chisalita, D.A.; Petrescu, L.; Cobden, P.; van Dijk, H.E.; Cormos, A.M.; Cormos, C.C. Assessing the environmental impact of an integrated steel mill with post-combustion CO2 capture and storage using the LCA methodology. J. Clean. Prod. 2019, 211, 1015–1025. [Google Scholar] [CrossRef]

- Olmez, G.M.; Dilek, F.B.; Karanfil, T.; Yetis, U. The environmental impacts of iron and steel industry: A life cycle assessment study. J. Clean. Prod. 2016, 130, 195–201. [Google Scholar] [CrossRef]

- Ryberg, M.W.; Wang, P.; Kara, S.; Hauschild, M.Z. Prospective Assessment of Steel Manufacturing Relative to Planetary Boundaries: Calling for Life Cycle Solution. Procedia CIRP 2018, 69, 451–456. [Google Scholar] [CrossRef]

- SETIS. Energy Efficiency and CO2 Reduction in the Iron and Steel Industry; 2014. Available online: https://setis.ec.europa.eu/system/files/Iron_and_Steel.pdf (accessed on 2 July 2020).

- World Steel Association. Life Cycle Inventory Methodology Report; World Steel Association: Brussels, Belgium, 2017. [Google Scholar]

- Yoro, K.O.; Daramola, M.O. CO2 Emission Sources, Greenhouse Gases, and the Global Warming Effect; Elsevier Inc.: Amsterdam, The Netherlands, 2020. [Google Scholar]

- García, S.G.; Montequín, V.R.; Fernández, R.L.; Fernández, F.O. Evaluation of the synergies in cogeneration with steel waste gases based on Life Cycle Assessment: A combined coke oven and steelmaking gas case study. J. Clean. Prod. 2019, 217, 576–583. [Google Scholar] [CrossRef]

- European Commission. EU Energy-Intensive Industries’ 2050 Masterplan BECOMING CLIMATE-NEUTRAL WHILE STAYING COMPETITIVE. 2019. Available online: https://ec.europa.eu/docsroom/documents/38402 (accessed on 6 July 2020).

- Burchart-Korol, D. Life cycle assessment of steel production in Poland: A case study. J. Clean. Prod. 2013, 54, 235–243. [Google Scholar] [CrossRef]

- European Commission. The European Green Deal. COM (2019) 640 Final. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52019DC0640&from=EN (accessed on 6 July 2020).

- ISO 14040. Environmental Management–Life Cycle Assessment–Principles and Framework; 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 4 March 2020).

- ISO 14044. Environmental Management–Life Cycle Assessment–Requirements and Guidelines; DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 2018. [Google Scholar]

- Pardo, N.; Moya, J.A. Prospective scenarios on energy efficiency and CO2 emissions in the European Iron & Steel industry. J. Energy 2013, 54, 113–128. [Google Scholar]

- Thyssenkrupp AG. Unsere Klimastrategie Zur Nachhaltigen Stahlproduktion. 2020. Available online: https://www.thyssenkrupp-steel.com/de/unternehmen/nachhaltigkeit/klimastrategie/ (accessed on 6 July 2020).

- Stahlinstitut VDEh. ÖKOBILANZ-Stahlerzeugnisse der Deutschsprachigen Stahlindustrie; VDEh Stahlinstitut: Düsseldorf, Germany, 2016. [Google Scholar]

- Bartos, R.; Stahl-Institut VDEh. Stahlfibel; Verlag Stahleisen GmbH: Düsseldorf, Germany, 2015. [Google Scholar]

- Kloepffer, W. Introducing Life Cycle Assessment and its presentation in ‘LCA Compendium’. In Background and Future Prospects in Life Cycle Assessment; Kloepffer, W., Ed.; Springer Science + Business Media: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Kloepffer, W.; Grahl, B. Life Cycle Assessment-A Guide to Best Practice; Wiley-VCH: Weinheim, Germany, 2014. [Google Scholar]

- Finkbeiner, M. The International Standards as the Constitution of Life Cycle Assessment: The ISO 14040 Series and its Offspring. In Background and Future Prospects in Life Cycle Assessment; Klöpffer, W., Ed.; Springer Science + Business Media: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Neugebauer, S.; Finkbeiner, M. Ökobilanz Nach ISO 14040/44 Für Das Multirecycling von Stahl; Wirtschaftsvereinigung Stahl: Düsseldorf, Germany, 2012; Available online: https://www.stahl-online.de/wp-content/uploads/2013/10/120621_Finkbeiner_Multi-Recycling_von_Stahl.pdf (accessed on 1 March 2020).

- Neugebauer, S.; Finkbeiner, M.; Volkhausen, W.; Mecke, S.; Endemann, G. Environmental evaluation of steel-Advanced life cycle assessment considers multiple recycling of steel. Stahl Und Eisen 2013, 133, 49–55. [Google Scholar]

- Ma, X.; Ye, L.; Qi, C.; Yang, D.; Shen, X.; Hong, J. Life cycle assessment and water footprint evaluation of crude steel production: A case study in China. J. Environ. Manag. 2018, 224, 10–18. [Google Scholar] [CrossRef] [PubMed]

- Cui, L.; Ba, K.; Li, F.; Wang, Q.; Ma, Q.; Yuan, X.; Mu, R.; Hong, J.; Zuo, J. Life cycle assessment of ultra-low treatment for steel industry sintering flue gas emissions. Sci. Total Environ. 2020, 725, 138292. [Google Scholar] [CrossRef] [PubMed]

- Yellishetty, M.; Mudd, G.M.; Ranjith, P.G. The steel industry, abiotic resource depletion and life cycle assessment: A real or perceived issue? J. Clean. Prod. 2011, 19, 78–90. [Google Scholar] [CrossRef]

- Althaus, H.J.; Classen, M. Life cycle inventories of metals and methodological aspects of inventorying material resources in ecoinvent. Int. J. LCA 2005, 10, 43–49. [Google Scholar] [CrossRef]

- Fujita, K.; Harada, T.; Michisita, H.; Tanaka, H. CO2 Emission Comparison between Coal-based Direct Reduction Process and Conventional Blast Furnace Process. Fuel 2010, 19, 19. [Google Scholar]

- Price, L.; Phylipsen, D.; Worrell, E. Energy Use and Carbon Dioxide Emissions in the Steel Sector in Key Developing Countries; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2001.

- Liu, Y.; Li, H.; Huang, S.; An, H.; Santagata, R.; Ulgiati, S. Environmental and economic-related impact assessment of iron and steel production. A call for shared responsibility in global trade. J. Clean. Prod. 2020, 269, 122239. [Google Scholar] [CrossRef]

- Sphera. GaBi Software. 2020. Available online: http://www.gabi-software.com/deutsch/index/ (accessed on 29 June 2020).

- Circular Ecology. Environmental Glossary of Terms and Definitions. 2020. Available online: https://circularecology.com/glossary-of-terms-and-definitions.html#.XvnbJkBuKUl (accessed on 29 June 2020).

- Forschungsgesellschaft für Energiewirtschaft mbH. Merit Order der konventionellen Kraftwerke in Deutschland (2018). 2018. Available online: https://www.ffegmbh.de/aktuelles/veroeffentlichungen-und-fachvortraege/828-merit-order-der-konventionellen-kraftwerke-in-deutschland-2018 (accessed on 29 June 2020).

- Ternium, S.A. Sustainability Report 2018; Ternium: Luxembourg, Luxembourg, 2018; Available online: https://amcen.ternium.com/media/1jlhv5se/sustainability-report-2018.pdf (accessed on 27 September 2020).

- World Steel Association. Life Cycle Assessment Methodology Report; World Steel Association: Brussels, Belgium, 2011; Available online: https://www.worldsteel.org/en/dam/jcr:6a222ba2-e35a-4126-83ab-5ae5a79e6e46/LCA+Methodology+Report.pdf (accessed on 30 October 2020).

- Sphera. GaBi LCA Database Documentation. 2020. Available online: http://www.gabi-software.com/international/support/gabi/ (accessed on 29 June 2020).

- European Parliament and the Council of the European Union. Directive 2009/29/EC of the European Parliament and of the council of 23 april 2009 ammending Directive 2003/87/EC so as to improve and extend the greenhouse gas emission allowance trading scheme of the Community. OJEU 2009, 140, 63–87. [Google Scholar]

- Dehs. Umwelt Bundesamt, Deutsche Emissionshandelsstelle-Emissions Trading. 2020. Available online: https://www.dehst.de/EN/national-emissions-trading/national-emissions-trading_node.html (accessed on 27 October 2020).

- Guinée, J.B.; Lindeijer, E. Handbook on Life Cycle Assessment-Operational Guide to the ISO Standards; Springer Netherlands: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Bach, V.; Finkbeiner, M. Approach to qualify decision support maturity of new versus established impact assessment methods—demonstrated for the categories acidification and eutrophication. Int. J. LCA 2017, 22, 387–397. [Google Scholar] [CrossRef]

- Guinée, J. Life Cycle Sustainability Assessment: What Is It and What Are Its Challenges. In Taking Stock of Industrial Ecology; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Jolliet, O.; Brent, A.; Goedkoop, M.; Itsubo, N.; Mueller-Wenk, R.; Peña, C. Life Cycle Impact Assessment Definition Study: Background Document III Analysis of Midpoint Categories; Life Cycle Initiative: Paris, France, 2003; Available online: https://lca-net.com/files/LCIA_defStudy_final3c.pdf (accessed on 6 July 2020).

- Busch, M.; Vogt, R.; Fehrenbach, H. Wirkungsabschätzung. ifeu-Institut. 2020. Available online: https://www.ifeu.de/methoden/wirkungsabschaetzung/ (accessed on 30 June 2020).

- Kortmann, J.; Kopf, F.; Hillemann, L.; Jehle, P. Recycling von Carbonbeton-Aufbereitung im großtechnischen Maßstab gelungen! Bauingenieur 2018, 2019, 38–44. [Google Scholar]

- Bribián, I.Z.; Capilla, A.V.; Usón, A.A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Habert, G. Assessing the environmental impact of conventional and “green” cement production. In Eco-Efficient Construction and Building Materials; Woodhead Publishing: Philadelphia, PA, USA, 2014. [Google Scholar]

- Nunez, P.; Jones, S. Cradle to gate: Life cycle impact of primary aluminium production. Int. J. LCA 2016, 21, 1594–1604. [Google Scholar] [CrossRef]

- Norgate, T.E.; Jahanshahi, S.; Rankin, W.J. Assessing the environmental impact of metal production processes. J. Clean. Prod. 2007, 15, 838–848. [Google Scholar] [CrossRef]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. LCA 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Thyssenkrupp AG. Verantwortungsvolle Beschaffung. 2020. Available online: https://www.thyssenkrupp.com/de/unternehmen/einkauf/verantwortungsvolle-beschaffung (accessed on 14 July 2020).

- LKAB, SSAB AB, and Vattenfall AB. Hybrit-Towards Fossil-Free Steel. 2016. Available online: http://www.hybritdevelopment.com/ (accessed on 6 July 2020).

- VERBUND Solutions GmbH. H2FUTURE Green Hydrogen. 2020. Available online: https://h2future-project.eu/ (accessed on 6 July 2020).

- Salzgitter, A.G. Salzgitter Low CO2 Steel Making; Salzgitter AG: Salzgitter, Germany, 2019. [Google Scholar]

| Author | Neugebauer and Finkbeiner | Burchart-Korol | VDEh Stahlinstitut | Chisalita et al. |

|---|---|---|---|---|

| Publication Year | 2012 | 2013 | 2016 | 2018 |

| Data Reference Year | 2010/2011 | 2010 | 2012/2013 | n.d. |

| Country | Germany | Poland | Germany | Netherlands |

| System Boundaries | Cradle-to-gate | Cradle-to-gate | Cradle-to-gate | Cradle-to-gate |

| FU | 1000 kg of hot-rolled coil | 1 ton of cast steel produced | 1 kg of steel | 1 metric ton of hot-rolled coil |

| Integrated Steel Mill | x | x | x | x |

| Software | GaBi | SimaPro | GaBi | GaBi |

| Database | GaBi | Ecoinvent | GaBi | GaBi |

| Number Midpoint Indi. | 7 | 2 | 5 | 10 |

| By-Product (Source) | Function Outside the Plant | Used GaBi Data Sets |

|---|---|---|

| Blast furnace slag (Blast furnace) | Cement production | |

| Road building Landfill | EU-28: Gravel 2/32 ts 1 DE: Landfill for inert matter (Steel) PE 1 | |

| Converter slag (Converter) | Road building Fertilizer | EU-28: Gravel 2/32 ts DE: Lime (CaO; finelime) (EN 15804 A1-A3) |

| Process gases (Blast furnace, coke plant, converter) | The process gases produced are primarily used internally. Excess process gases are converted into electricity and heat in the power plant. Produced electricity is internally used. Excess electricity is fed into the power grid. | DE: Electricity grid mix ts |

| District heating (Blast furnace, hot-rolled mill) | District heating | EU-28: District heating mix ts |

| Tar (Coke plant) | Tar | EU-28: Bitumen at refinery ts |

| Sulfur (Coke plant) | Sulfur | DE: Sulfur (elemental) at refinery ts |

| Benzene (Coke plant) | Benzene | DE: Benzene mix ts |

| Material/Energy Flows | Used GaBi Data Sets (SP 29) |

|---|---|

| Aluminum | DE: Aluminum ingot mix ts |

| Argon | DE: Argon (gaseous) ts |

| Bauxite | EU-28: Bauxite ts |

| Quicklime | DE: Lime (CaO; quicklime lumpy) ts |

| Calcium hydroxide | DE: Calcium hydroxide (Ca(OH)2; dry; slaked lime) ts |

| Calcium silicate | EU-28: Calcium silicate ts |

| Chrome | DE: Ferro chrome mix ts |

| Landfill | DE: Landfill for inert matter (steel) PE |

| Iron ore | DE: Iron ore mix PE |

| Iron pellets | DE: Pellet feed mix PE |

| Groundwater | EU-28: Tap water from groundwater ts |

| Limestone, dolomite | DE: Limestone (CaCO3; washed) ts |

| Copper | DE: Copper mix (99.999% from electrolysis) ts |

| Manganese | ZA: Ferro manganese ts |

| Molybdenum | RER: Molybdenum, at regional storage |

| Sodium chloride | EU-28: Sodium chloride (rock salt) ts |

| Nickel | DE: Ferro nickel PE |

| Process water (desalinated; deionized) | EU-28: Process water ts; DE: Water (desalinated; deionized) ts |

| Quartz sand | DE: Silica sand (Excavation and processing) ts |

| Oxygen | DE: Oxygen (gaseous) ts |

| Lubricating oil | DE: Lubricants at refinery ts |

| Sulfuric acid | DE: Sulfuric acid mix (96%) ts |

| Silicon | GLO: Ferro silicon mix ts |

| Nitrogen | DE: Nitrogen (gaseous) ts |

| Synthetic graphite | DE: Synthetic graphite (via petrol coke) PE |

| Titanium | GLO: Titanium ts |

| Water (desalinated; deionized) | DE: Water (desalinated; deionized) ts |

| Tin | GLO: Tin ts |

| Steam | DE: Process steam from natural gas 95% ts |

| Natural gas | DE: Natural gas mix ts |

| Coal | DE: Project hard coal mix |

| Coke | DE: Coke mix ts |

| District heating mix | EU-28: District heating mix ts |

| Electricity mix | DE: Electricity grid mix ts |

| Direct Emissions | Upstream Chain | By-Products | |

|---|---|---|---|

| CO | 99% | 5% | −4% |

| CO₂ | 95% | 25% | −21% |

| CH₄ | 1% | 107% | −8% |

| NMVOC | 1% | 116% | −17% |

| NOₓ | 31% | 80% | −11% |

| SO₂ | 45% | 62% | −7% |

| Share of Total Emissions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Total Emissions | Direct Emissions | Blast Furnace | Hot Strip Mill | Coke Plant | Power Plant | Sinter Plant | Upstream | By- Product | |

| GWP (kg CO₂ₑ) | 2.1 | 90% | 20% | 4% | 10% | 43% | 9% | 27% | −17% |

| AP (kg SO₂ₑ) | 4.8 × 10 3 | 40% | 3% | 3% | 4% | 7% | 23% | 69% | −9% |

| EP (kg PO₄ₑ) | 5.1 × 104 | 28% | 1% | 4% | 5% | 5% | 12% | 85% | −13% |

| POCP (kg C₂H₄ₑ) | 6.5 × 104 | 71% | 5% | 1% | 2% | 2% | 55% | 36% | −6% |

| ADPf (MJ) | 20.7 | 1% | 0% | 0% | 0% | 0% | 0% | 110% | −11% |

| ADPe (kg Sbₑ) | 1.4 × 106 | 3% | 0% | 0% | 0% | 0% | 0% | 115% | −19% |

| ODP (kg R11ₑ) | 1.6 × 1011 | 0% | 0% | 0% | 0% | 0% | 0% | 111% | −11% |

| % of Direct Emissions | % of Upstream Emissions | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Blast Furnace | Hot Strip Mill | Coke Plant | Power Plant | Sinter Plant | Iron Ore Mix | Hard Coal Mix | Pellet Feed Mix | Alloying Elements | |

| GWP ((kg CO2 e) | 22% | 5% | 11% | 48% | 11% | 11% | 26% | 14% | 16% |

| AP (kg SO₂ e) | 9% | 7% | 9% | 17% | 58% | 30% | 26% | 23% | 13% |

| EP (kg PO₄ e) | 4% | 13% | 17% | 17% | 44% | 28% | 29% | 18% | 16% |

| POCP (kg C₂H4 e) | 7% | 1% | 2% | 3% | 79% | 26% | 33% | 20% | 13% |

| ADPf (MJ) | 0% | 0% | 0% | 0% | 0% | 3% | 73% | 4% | 4% |

| ADPe (kg Sb e) | 0% | 0% | 0% | 0% | 0% | 3% | 1% | 2% | 91% |

| ODP (kg R11 e) | 0% | 0% | 0% | 0% | 0% | 18% | 0% | 18% | 64% |

| Impact Category | Upstream—Δ | Total Emission Result—Δ |

|---|---|---|

| ADPe | 10% | 11.5% |

| ADPf | 10% | 11.0% |

| AP | 10% | 6.9% |

| EP | 10% | 8.5% |

| GWP | 10% | 2.7% |

| ODP | 10% | 11.1% |

| POCP | 10% | 3.6% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Backes, J.G.; Suer, J.; Pauliks, N.; Neugebauer, S.; Traverso, M. Life Cycle Assessment of an Integrated Steel Mill Using Primary Manufacturing Data: Actual Environmental Profile. Sustainability 2021, 13, 3443. https://doi.org/10.3390/su13063443

Backes JG, Suer J, Pauliks N, Neugebauer S, Traverso M. Life Cycle Assessment of an Integrated Steel Mill Using Primary Manufacturing Data: Actual Environmental Profile. Sustainability. 2021; 13(6):3443. https://doi.org/10.3390/su13063443

Chicago/Turabian StyleBackes, Jana Gerta, Julian Suer, Nils Pauliks, Sabrina Neugebauer, and Marzia Traverso. 2021. "Life Cycle Assessment of an Integrated Steel Mill Using Primary Manufacturing Data: Actual Environmental Profile" Sustainability 13, no. 6: 3443. https://doi.org/10.3390/su13063443

APA StyleBackes, J. G., Suer, J., Pauliks, N., Neugebauer, S., & Traverso, M. (2021). Life Cycle Assessment of an Integrated Steel Mill Using Primary Manufacturing Data: Actual Environmental Profile. Sustainability, 13(6), 3443. https://doi.org/10.3390/su13063443