Organizational Commitment and Lean Sustainability: Literature Review and Directions for Future Research

Abstract

1. Introduction

Methodological Note

- Choosing a review topic: This first step is the most difficult because the topic must be of interest to both the author and the reader [15,16]. To focus on the topic of interest, it was necessary in our case to initially identify broad topics in our discipline, scan the area to account for other literature reviews that already exist, estimate the number of research studies to be evaluated, and then clearly formulate and define the purpose and scope of the research [15,16].

- Searching and selecting appropriate articles: Once the topic is selected, the next step consists of identifying appropriate and relevant literature [15]. Literature searches are most often conducted using electronic databases that provide access to vast amounts of information related to a research topic [15]. To ensure that the majority of relevant studies on our topic have been identified, references were searched in numerous popular databases including Scopus, Web of Science, Springer Link, JSTOR, and Science Direct. Although the primary focus has been on published sources, such as peer-reviewed journal articles and book chapters, we have also integrated some websites and conference papers on Lean sustainability, found mainly through Google, Google Scholar, and Research Gate.Authors stipulate that keyword search is the appropriate method for identifying literature and they emphasize that these keywords must be directly related to the subject of research in order to generate the data sought [15,17]. In this sense, the string of keywords used in this study includes (“Lean production” OR “Lean manufacturing” OR “Lean management”) AND (sustainability OR sustainable*) AND (“organizational commitment” OR “employee engagement”).

- Analyzing and synthesizing the literature: After identifying and gathering the appropriate literature, the next step is to analyze, synthesize, and discuss the results and conclusions of the selected sources [15]. To do so, a first reading of the articles was undertaken by referring mainly to the summary, and then a classification was made by the type of source, as recommended by Ramdhani [15]. After the initial overview, it was essential to return to the articles to conduct a more systematic and critical examination of the content. Researchers recommend adopting a structure during this process such as that proposed by Cohen [18]. Cohen’s PQRS (Preview, Question, Read, Summarize) method was used to keep focused and consistent with the purpose of the article, and it facilitated the identification and analysis of relevant material.

2. Lean Approach

2.1. Lean Origin

2.2. Lean Definition

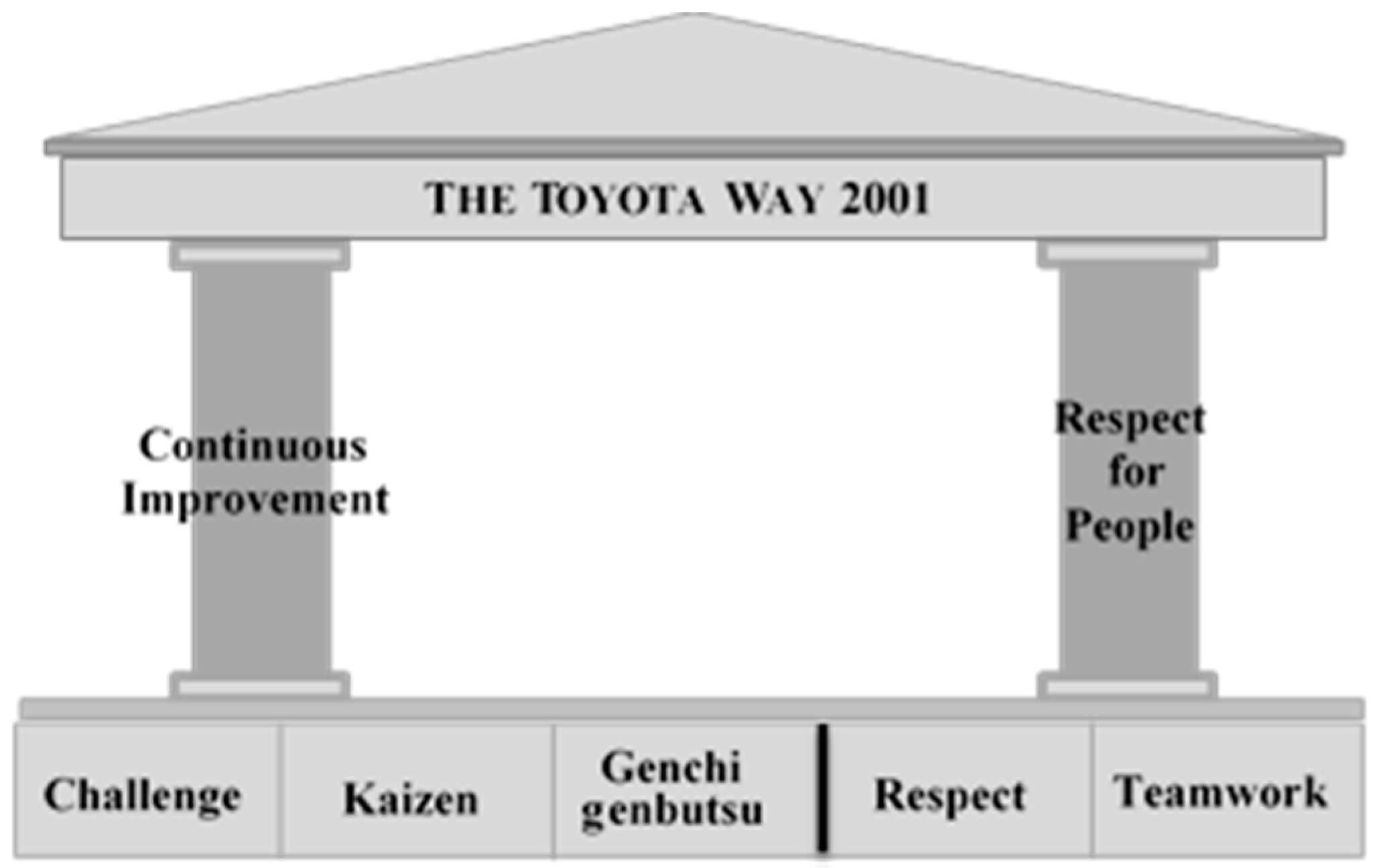

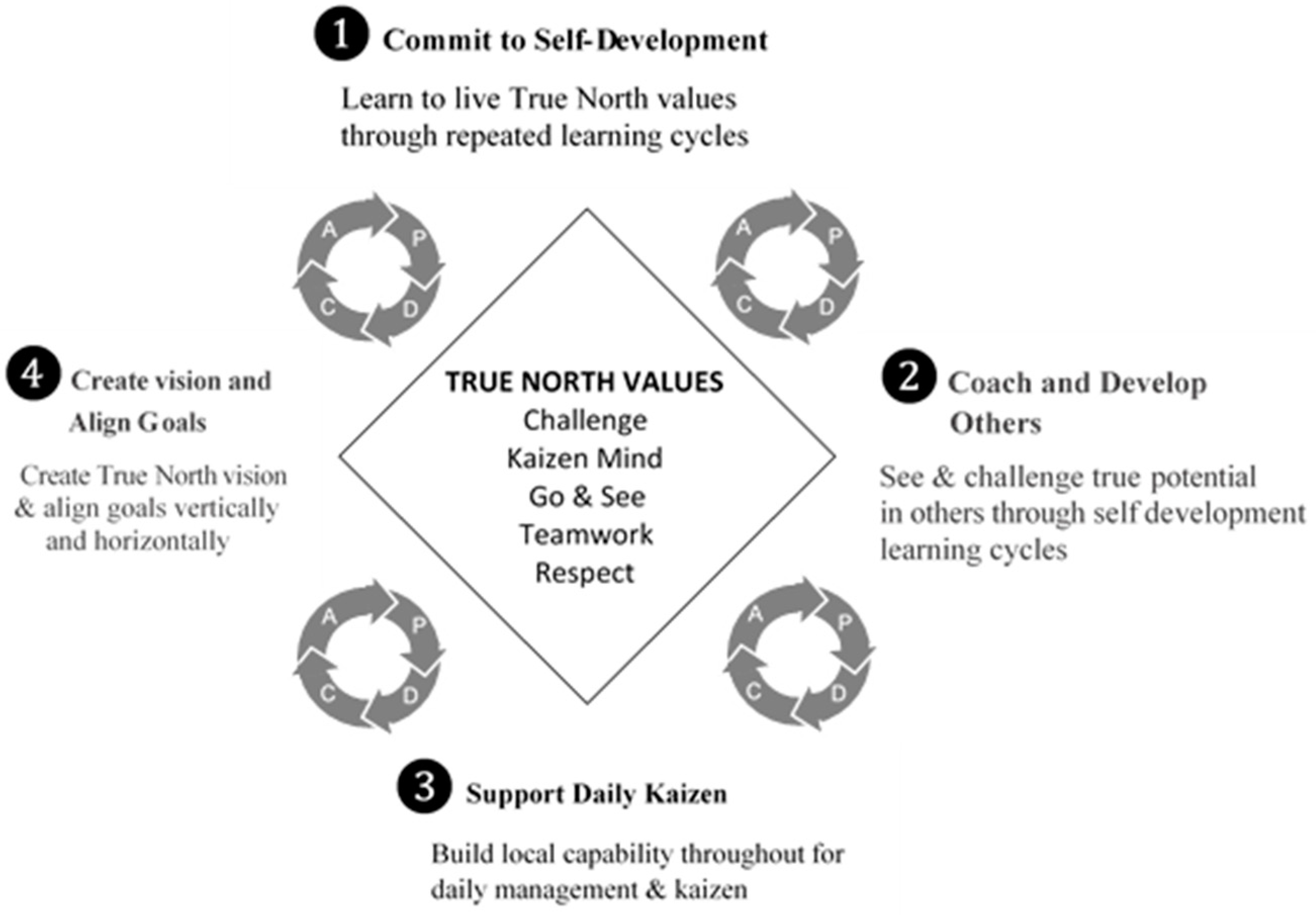

2.3. The Main Pillars of Lean

2.3.1. Pillar 1: Continuous Improvement

- Challenge: Basically, it is about forming a long-term vision and meeting challenges with courage and creativity [33] (p. 15). More specifically, in its internal document “The Toyota Way,” Toyota expresses it as follows: “We accept challenges with a creative spirit and the courage to realize our own dreams without losing drive or energy. We approach our work vigorously, with optimism and a sincere belief in the value of our contribution” [4] (p. 25). Toyota incentivizes the creativity and initiative of its employees by continually challenging them to learn and experiment [4].

- Genchi Genbutsu: It is about going to the source to find the facts in order to make correct decisions, build consensus, and achieve goals at the best speed [33] (p. 15). Genchi Genbutsu, also known as “go and see,” encourages leaders to go directly to workplaces to thoroughly understand the situation or the problem [4]. With this principle, Toyota shows that all leaders must be aware of any issue that is in their charge and make decisions based on facts in order to avoid unproductive situations [20]. Genchi Genbutsu helps employees acquire more awareness about daily events and a better understanding of the root causes of problems [40].

- Kaizen: It is the essence of continuous improvement and literally means “change for the better.” Kaizen aims to improve the business continuously while always driving for innovation and evolution [33]. In the words of Toyota: “We are relentless in our pursuit of improvement, never easily satisfied, constantly making improvement efforts and steadily encouraging innovation” [33] (p. 324). Even though Kaizen is considered by the Toyota Way as one of the aspects of continuous improvement, the two terms, “Kaizen” and “continuous improvement,” are often used interchangeably [11,33,41].

2.3.2. Pillar 2: Respect for People

- Respect: Toyota describes respect as follows: “We respect others, make every effort to understand each other, take responsibility and do our best to build mutual trust” [33] (p. 15). At Toyota, all employees are respected regardless of who they are or what they do, and everyone matters in the contribution to the pursuit and the achievement of goals [50]. In this context, respect goes beyond its conventional definition to also encompass the employees’ ideas, contributions, and personal beliefs [51].

- Teamwork: It is defined by Toyota as follows: “We stimulate personal and professional growth, share the opportunities of development, and maximize individual and team performance” [33] (p. 15). Toyota considers teamwork as the foundation of the organization and aims to ensure that all systems are there to support teams doing value-added work [4]. In this way, it encourages them to be committed to making the organization successful [4]. This vision was supported by Marksberry [52], who stated that to have professional employees work together, each one of them must feel as though he matters to the organization.

3. Organizational Commitment

3.1. Definition of Organizational Commitment

3.2. Models of Organizational Commitment

3.2.1. Angle and Perry’s Two-Dimensional Model

3.2.2. The Three-Dimensional Model of Meyer and Allen

3.2.3. Cohen’s Model

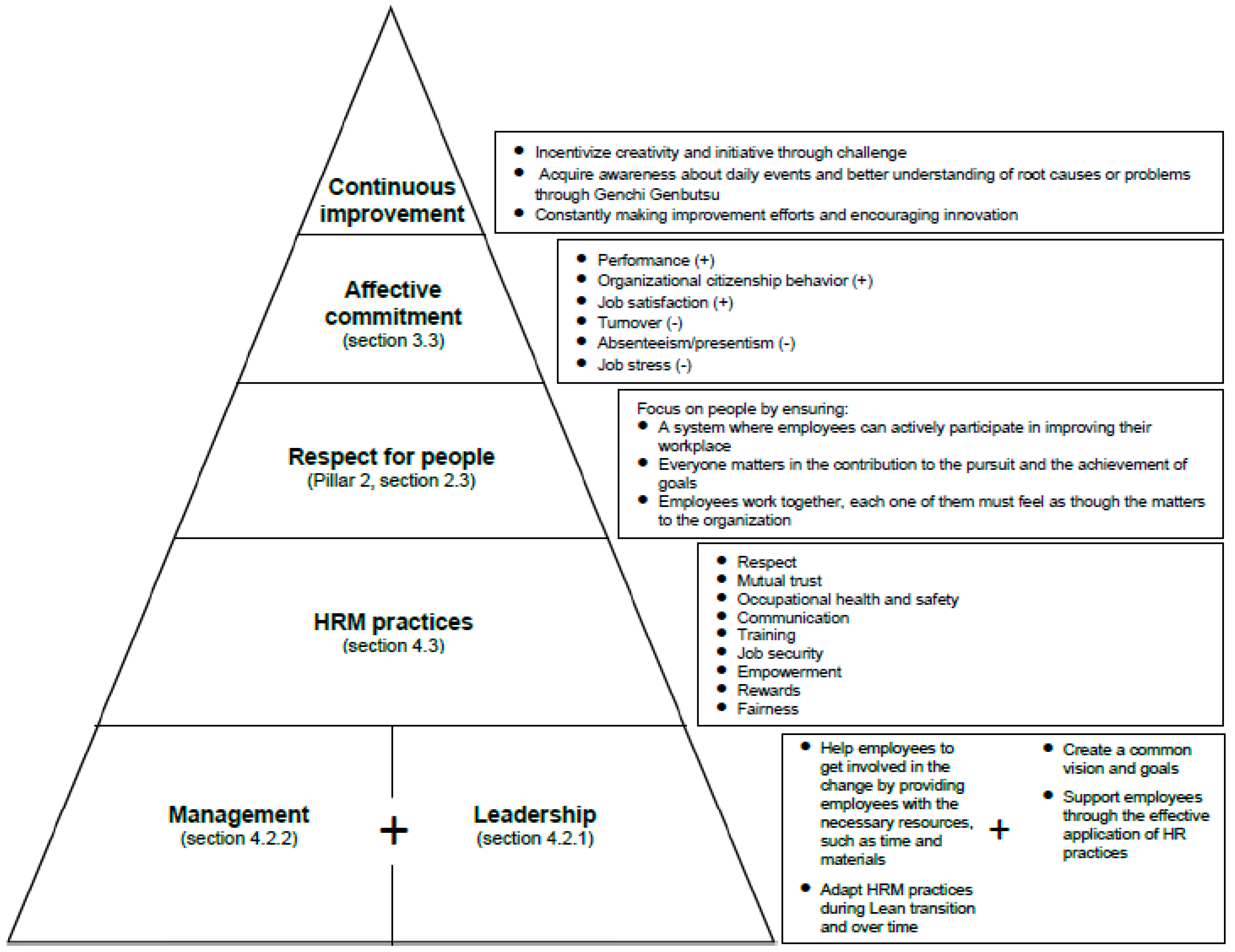

3.3. The Interest in Affective Commitment

- Performance: It refers to the achievement of organizational goals regardless of their nature and variety [77]. Several studies stated that there is a significant relationship between affective commitment and performance (e.g., [64,78]). This correlation could be explained by the fact that employees with high affective commitment are motivated by the achievement of organizational objectives.

- Organizational citizenship behavior: This concept refers to the innovative and spontaneous behaviors of employees and their willingness to cooperate [79,80]. The literature confirms the existence of a positive association between affective commitment and organizational citizenship behaviors [81,82,83]. In a recent study, Danish et al. [82] showed this positive relationship and stated that employees’ affective commitment is a factor that improves their organizational citizenship behaviors.

- Job satisfaction: Affective commitment is positively associated with job satisfaction [78,84,85]. The notion of job satisfaction is defined by Locke [86] as “a pleasurable or positive emotional state resulting from the appraisal of one’s job or job experiences” (p. 1300). This satisfaction is partly due to the sense of involvement and belonging to the organization. The higher the employees’ involvement in the organization, the more satisfied they are. That is, as affective commitment increases, the level of job satisfaction increases too [87].

- Turnover: Several studies found the existence of a negative correlation between affective commitment and turnover (e.g., [88,89]). This negative relationship is explained by the fact that employees who exhibit strong commitment are least likely to leave the organization [89]. This means that improving the level of affective commitment could help reduce the turnover rate within an organization. In fact, according to its definition, affective commitment reflects the willingness to remain within the organization. It is, therefore, evident that it is negatively related to turnover, which reflects the desire to voluntarily leave the organization.

- Presenteeism: Affective commitment is also negatively linked to presenteeism [92,93]. The concept of presenteeism refers to the situation where an employee is at work but is not fully functional and productive because of illness, injury, or other health conditions [94]. Multiple reasons may explain the negative association between affective commitment and presenteeism. First, according to their definitions, the concept of presenteeism is the opposite of affective commitment. The former hinders the achievement of organizational goals [95], whereas the latter prioritizes them. According to Yang et al. [93], employees who exhibit strong affective commitment tend to adopt behaviors that are beneficial to the organization (e.g., increasing performance and decreasing presenteeism). Finally, affectively committed employees have a low presenteeism rate.

- Job stress: It is defined by the National Institute for Occupational Safety and Health (NIOSH) as “the harmful physical and emotional responses that occur when the requirements of the job do not match the capabilities, resources, or needs of the worker” [96]. It has been shown that affective commitment is negatively associated with job stress [78]. This negative correlation was discussed by several authors. For example, Schmidt and Diestel [97] argued that affective commitment creates a sense of emotional stability and belonging in employees, which strengthens their ability to resist work stressors such as workload and lack of social support. For Setti et al. [98], affective commitment is an important resource for protecting against stressful situations.

4. Relationship between Lean Sustainability and Organizational Commitment

4.1. The Relationship between Lean and Employees’ Affective Commitment

4.2. Human Resources According to Lean Philosophy

4.2.1. The Role of Leadership

4.2.2. The Role of Management

4.3. The Practices of Human Resource Management (HRM) in Promoting Employee Commitment in Lean

5. Discussion and Directions for Future Work

Research Limitations

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Foris, D.; Florescu, A.; Foris, T.; Barabas, S. Improving the Management of Tourist Destinations: A New Approach to Strategic Management at the DMO Level by Integrating Lean Techniques. Sustain. J. Rec. 2020, 12, 10201. [Google Scholar] [CrossRef]

- Florescu, A.; Barabaş, B. Integrating the Lean concept in sustainable manufacturing development. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kuala Lumpur, Malaysia, 13–14 August 2018; IOP Publishing: Bristol, UK, 2018; Volume 399, p. 012018. [Google Scholar]

- Emiliani, B.; Stec, D.J.; Grasso, L.; Stodder, J. Better Thinking, Better Results: Case Study and Analysis of an Enterprise-Wide Lean Transformation, 2nd ed.; Center for Lean Business Management: Kensington, CT, USA, 2007; p. 313. ISBN 0972259120. [Google Scholar]

- Liker, J.K. The 14 Principles of the Toyota Way: An Executive Summary of the Culture Behind TPS; McGraw-Hill Education: New York, NY, USA, 2004; pp. 35–41. ISBN 0071392319. [Google Scholar]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; CRC Press: Portland, OR, USA, 1988; ISBN 978-0-915299-14-0. [Google Scholar]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine that Changed the World; Rawson Associates: New York, NY, USA, 1990; pp. 273–287. ISBN 9780743299794. [Google Scholar]

- Liker, J.K.; Morgan, J.M. The Toyota Way in Services: The Case of Lean Product Development. Acad. Manag. Perspect. 2006, 20, 5–20. [Google Scholar] [CrossRef]

- Hines, P. How to Lead a Global Lean Transformation and Make It Stick. Available online: https://theleadershipnetwork.com/article/how-to-lead-a-global-lean-transformation-and-make-it-stick (accessed on 25 February 2020).

- Ingaldi, M.; Dziuba, S.T.; Cierniak-Emerych, A. Analysis of problems during implementation of Lean Manufacturing elements. In Proceedings of the MATEC Web of Conferences, Amsterdam, The Netherlands, 27–29 November 2018; EDP Sciences: Les Ulis, France, 2018; Volume 183, p. 01004. [Google Scholar]

- Rose, A.; Ab Rashid, M.; Mohamed, N.N.; Ahmad, H. Similarities of lean manufacturing approaches implementation in SMEs towards the success: Case study in the automotive component industry. In Proceedings of the MATEC Web of Conferences, Amsterdam, The Netherlands, 23–25 March 2016; EDP Sciences: Les Ulis, France, 2016; Volume 87, p. 02024. [Google Scholar]

- Liker, J.K. Le Modèle Toyota: 14 Principes qui Feront la Réussite de Votre Entreprise; Pearson Education: Paris, France, 2009; ISBN 9782744073908. [Google Scholar]

- Wincel, J.P.; Kull, T.J. People, Process, and Culture: Lean Manufacturing in the Real World; Productivity Press: New York, NY, USA, 2016. [Google Scholar] [CrossRef]

- Madsen, D.Ø.; Berg, T.; Stenheim, T.; Moum, J.V.; Bordewich, I.O.; Storsveen, M. The Long-term Sustainability of Lean as a Management Practice: Survey Evidence on Diffusion and Use of the Concept in Norway in the Period 2015–2017. Sustain. J. Rec. 2019, 11, 3120. [Google Scholar] [CrossRef]

- Jørgensen, F.; Matthiesen, R.; Nielsen, J.; Johansen, J. Lean Maturity, Lean Sustainability; Springer: Boston, MA, USA, 2007. [Google Scholar]

- Ramdhani, A.; Ramdhani, M.A.; Amin, A.S. Writing a Literature Review Research Paper: A step-by-step approach. Int. J. Basic Appl. Sci. 2014, 3, 47–56. [Google Scholar]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Cronin, P.; Ryan, F.; Coughlan, M. Undertaking a literature review: A step-by-step approach. Br. J. Nurs. 2008, 17, 38–43. [Google Scholar] [CrossRef] [PubMed]

- Cohen, P.A. Bringing research into practice. New Dir. Teach. Learn. 1990, 1990, 123–132. [Google Scholar] [CrossRef]

- Kilpatrick, J. Lean principles. Utah Manuf. Ext. Partnersh. 2003, 68, 1–5. [Google Scholar]

- Liker, J.K.; Convis, G.L. Toyota Way to Lean Leadership: Achieving and Sustaining Excellence through Leadership Development; McGraw-Hill Education: New York, NY, USA, 2012; ISBN 9780071780780. [Google Scholar]

- Holweg, M. The genealogy of lean production. J. Oper. Manag. 2006, 25, 420–437. [Google Scholar] [CrossRef]

- Shah, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Hines, P.; Holweg, M.; Rich, N. Learning to evolve. Int. J. Oper. Prod. Manag. 2004, 24, 994–1011. [Google Scholar] [CrossRef]

- Lodgaard, E.; Ingvaldsen, J.A.; Gamme, I.; Aschehoug, S. Barriers to Lean Implementation: Perceptions of Top Managers, Middle Managers and Workers. Procedia CIRP 2016, 57, 595–600. [Google Scholar] [CrossRef]

- Emiliani, M.L. Lean behaviors. Manag. Decis. 1998, 36, 615–631. [Google Scholar] [CrossRef]

- Liker, J.K.; Wu, Y.C. Japanese automakers, US suppliers and supply chain superiority. Sloan Manag. Rev. 2000, 24, 177–196. [Google Scholar]

- Toussaint, J.S.; Berry, L.L. The Promise of Lean in Health Care. Mayo Clin. Proc. 2013, 88, 74–82. [Google Scholar] [CrossRef]

- Brännmark, M.; Langstrand, J.; Johansson, S.; Halvarsson, A.; Abrahamsson, L.; Winkel, J. Researching Lean: Methodological Implications of Loose Definitions. Qual. Innov. Prosper. 2012, 16, 35–48. [Google Scholar] [CrossRef][Green Version]

- Kaltenbrunner, M.; Bengtsson, L.; Mathiassen, S.E.; Engström, M. A questionnaire measuring staff perceptions of Lean adoption in healthcare: Development and psychometric testing. BMC Health Serv. Res. 2017, 17, 235. [Google Scholar] [CrossRef]

- Hohmann, C. Lean Management: Outils, Méthodes, Retours d’Expériences, Questions/Réponses; Editions Eyrolles: Paris, France, 2012; ISBN 978-2-212-55381-9. [Google Scholar]

- Pettersen, J. Defining lean production: Some conceptual and practical issues. TQM J. 2009, 21, 127–142. [Google Scholar] [CrossRef]

- Marodin, G.A.; Saurin, T.A. Classification and relationships between risks that affect lean production implementation. J. Manuf. Technol. Manag. 2015, 26, 57–79. [Google Scholar] [CrossRef]

- Liker, J.K.; Hoseus, M. Toyota Culture: The Heart and Soul of the Toyota Way, 1st ed.; McGraw-Hill Education: New York, NY, USA, 2008; p. 562. ISBN 9780071492171. [Google Scholar]

- Pearce, A.; Pons, D.J. Implementing Lean Practices: Managing the Transformation Risks. J. Ind. Eng. 2013, 2013, 1–19. [Google Scholar] [CrossRef]

- Bicheno, J.; Holweg, M. The Lean Toolbox: A Handbook for Lean Transformation; PICSIE Books: Buckingham, UK, 2016. [Google Scholar]

- Kariuki, B.M.; Mburu, D.K. Role of Lean manufacturing on organization competitiveness. Ind. Eng. Lett. 2013, 3, 81–82. [Google Scholar]

- Liker, J.K.; Ogden, T. Toyota under Fire, 1st ed.; McGraw-Hill Education: New York, NY, USA, 2011; p. 237. ISBN 978-0071762991. [Google Scholar]

- Bhamu, J.; Sangwan, K.S. Lean manufacturing: Literature review and research issues. Int. J. Oper. Prod. Manag. 2014, 34, 876–940. [Google Scholar] [CrossRef]

- Khan, H.U. Impact of Continuous Improvement on Organization Performance Insight from Pakistan: An Empirical Study. Int. J. Innov. Manag. Technol. 2018, 9, 7–14. [Google Scholar] [CrossRef]

- Chiarini, A.; Baccarani, C.; Mascherpa, V. Lean production, Toyota Production System and Kaizen philosophy. TQM J. 2018, 30, 425–438. [Google Scholar] [CrossRef]

- Coetzee, R.; Van Der Merwe, K.; Van Dyk, L. Lean implementation strategies: How are the toyota way principles addressed? S. Afr. J. Ind. Eng. 2016, 27, 79–91. [Google Scholar] [CrossRef]

- Patel, P.M.; Deshpande, V.A. Application of plan-do-check-act cycle for quality and productivity improvement-A review. Studies 2015, 2, 23–34. [Google Scholar]

- Bond, T. The role of performance measurement in continuous improvement. Int. J. Oper. Prod. Manag. 1999, 19, 1318–1334. [Google Scholar] [CrossRef]

- Lodgaard, E.; Gamme, I.; Aasland, K.E. Success factors for PDCA as continuous improvement method in product development. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Berlin, Germany, 24–26 September 2012. [Google Scholar]

- Liker, J.K. Jeff Liker: The Essence of the Toyota Way Is Respect for People and Continuous Improvement; The Lean Edge: New York, NY, USA, 2011. [Google Scholar]

- Emiliani, M. Origins of lean management in America. J. Manag. Hist. 2006, 12, 167–184. [Google Scholar] [CrossRef]

- Emiliani, M. Music as a framework to better understand Lean leadership. Leadersh. Organ. Dev. J. 2013, 34, 407–426. [Google Scholar] [CrossRef]

- Emiliani, B. Lean Is Not Mean: 68 Practical Lessons in Lean Leadership; The CLBM, LLC.: Wethersfield, CT, USA, 2015. [Google Scholar]

- Graban, M. Lean Hospitals: Improving Quality, Patient Safety, and Employee Engagement, 3rd ed.; Productivity Press: New York, NY, USA, 2016. [Google Scholar]

- Dahl, J. Leading Lean: Ensuring Success and Developing a Framework for Leadership; O’Reilly Media, Inc.: Newton, MA, USA, 2019; 225p, ISBN 978-1492046295. [Google Scholar]

- Orzen, M.A.; Paider, T.A. The Lean IT Field Guide: A Roadmap for Your Transformation; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Marksberry, P. The Toyota Way—A quantitative approach. Int. J. Lean Six Sigma 2011, 2, 132–150. [Google Scholar] [CrossRef]

- Meyer, J.P.; Allen, N.J.; Smith, C.A. Commitment to organizations and occupations: Extension and test of a three-component conceptualization. J. Appl. Psychol. 1993, 78, 538. [Google Scholar] [CrossRef]

- Becker, H.S. Notes on the Concept of Commitment. Am. J. Sociol. 1960, 66, 32–40. [Google Scholar] [CrossRef]

- Grusky, O. Career Mobility and Organzational Commitment. Adm. Sci. Q. 1966, 10, 488. [Google Scholar] [CrossRef]

- Kiesler, C.A.; Sakumura, J. A test of a model for commitment. J. Pers. Soc. Psychol. 1966, 3, 349–353. [Google Scholar] [CrossRef]

- Kanter, R.M. Commitment and Social Organization: A Study of Commitment Mechanisms in Utopian Communities. Am. Sociol. Rev. 1968, 33, 499. [Google Scholar] [CrossRef]

- Blau, G.J.; Boal, K.B. Conceptualizing how job involvement and organizational commitment affect turnover and absenteeism. Acad. Manag. Rev. 1987, 12, 288–300. [Google Scholar] [CrossRef]

- Mathieu, J.E.; Zajac, D.M. A review and meta-analysis of the antecedents, correlates, and consequences of organizational commitment. Psychol. Bull. 1990, 108, 171–194. [Google Scholar] [CrossRef]

- Meyer, J.P.; Herscovitch, L. Commitment in the workplace: Toward a general model. Hum. Resour. Manag. Rev. 2001, 11, 299–326. [Google Scholar] [CrossRef]

- Morin, E.M.; Audebrand, L.K. L’Engagement Organisationnel et le Sens du Travail; Cahier de Recherche, Ecole des Hautes Etudes Commerciales, Service de l’Enseignement du Management: Montréal, QC, Canada, 2003. [Google Scholar]

- Mercurio, Z.A. Affective Commitment as a Core Essence of Organizational Commitment. Hum. Resour. Dev. Rev. 2015, 14, 389–414. [Google Scholar] [CrossRef]

- Angle, H.L.; Perry, J.L. An Empirical Assessment of Organizational Commitment and Organizational Effectiveness. Adm. Sci. Q. 1981, 26, 1–14. [Google Scholar] [CrossRef]

- Meyer, J.P.; Allen, N.J. A three-component conceptualization of organizational commitment. Hum. Resour. Manag. Rev. 1991, 1, 61–89. [Google Scholar] [CrossRef]

- Jaros, S. Meyer and Allen model of organizational commitment: Measurement issues. The Icfai Journal of Organizational Behavior 2007, 6, 7–25. [Google Scholar]

- Johnson, R.E.; Chang, C.-H. “I” is to continuance as “We” is to affective: The relevance of the self-concept for organizational commitment. J. Organ. Behav. 2006, 27, 549–570. [Google Scholar] [CrossRef]

- Mowday, R.T.; Porter, L.W.; Steers, R.M. Employee–Organization Linkages; Elsevier BV: Amsterdam, The Netherlands, 1982; p. 264. [Google Scholar]

- Gouldner, A.W. The Norm of Reciprocity: A Preliminary Statement. Am. Sociol. Rev. 1960, 25, 161. [Google Scholar] [CrossRef]

- Cohen, A. Commitment before and after: An evaluation and reconceptualization of organizational commitment. Hum. Resour. Manag. Rev. 2007, 17, 336–354. [Google Scholar] [CrossRef]

- Charles-Pauvers, B.; Peyrat-Guillard, D. L’implication (ou l’engagement?) au travail: Quoi de neuf? In Proceedings of the Actes du 22 e Congrès de l’AGRH, Nancy, France, 12–14 September 2012. [Google Scholar]

- Cheng, Y.; Stockdale, M.S. The validity of the three-component model of organizational commitment in a Chinese context. J. Vocat. Behav. 2003, 62, 465–489. [Google Scholar] [CrossRef]

- Solinger, O.N.; Van Olffen, W.; Roe, R.A. Beyond the three-component model of organizational commitment. J. Appl. Psychol. 2008, 93, 70–83. [Google Scholar] [CrossRef]

- Odoardi, C.; Battistelli, A.; Montani, F.; Peiró, J.M. Affective Commitment, Participative Leadership, and Employee Innovation: A Multilevel Investigation. Rev. Psicol. Trab. Organ. 2019, 35, 103–113. [Google Scholar] [CrossRef]

- McKay, K.; Kuntz, J.R.; Näswall, K. The effect of affective commitment, communication and participation on resistance to change: The role of change readiness. N. Zeal. J. Psychol. 2013, 42, 29. [Google Scholar]

- Gao-Urhahn, X.; Biemann, T.; Jaros, S.J. How affective commitment to the organization changes over time: A longitudinal analysis of the reciprocal relationships between affective organizational commitment and income. J. Organ. Behav. 2016, 37, 515–536. [Google Scholar] [CrossRef]

- Jussila, I.; Byrne, N.; Tuominen, H. Affective Commitment in Co-operative Organizations: What Makes Members Want to Stay? Int. Bus. Res. 2012, 5, p1. [Google Scholar] [CrossRef]

- Bourguignon, A. Définir la performance: Une simple question de vocabulaire. In Performances et Ressources Humaines; Fericelli, A.-M., Sire, B., Eds.; Economica: Paris, France, 2019; pp. 18–31. [Google Scholar]

- Meyer, J.P.; Stanley, D.J.; Herscovitch, L.; Topolnytsky, L. Affective, Continuance, and Normative Commitment to the Organization: A Meta-analysis of Antecedents, Correlates, and Consequences. J. Vocat. Behav. 2002, 61, 20–52. [Google Scholar] [CrossRef]

- Barnard, C. The Functions of the Executive; Harvard University Press: Cambridge, MA, USA, 1938; pp. 3–323. [Google Scholar]

- Katz, D. The motivational basis of organizational behavior. Syst. Res. Behav. Sci. 1964, 9, 131–146. [Google Scholar] [CrossRef]

- Allen, R.S.; Evans, W.R.; White, C.S. Affective organizational commitment and organizational citizenship behavior: Examining the relationship through the lens of equity sensitivity. Organ. Manag. J. 2011, 8, 218–228. [Google Scholar] [CrossRef]

- Danish, R.Q.; Shahid, A.U.; Humayon, A.A.; Nawaz, M.M. Association of Affective Commitment with Organizational Citizenship Behaviour and Task Performance of Employees in Banking Sector. J. Yaşar Univ. 2015, 10, 56. [Google Scholar] [CrossRef]

- Grego-Planer, D. The Relationship between Organizational Commitment and Organizational Citizenship Behaviors in the Public and Private Sectors. Sustain. J. Rec. 2019, 11, 6395. [Google Scholar] [CrossRef]

- Donald, M.F.; Lucia, M.E.; Victor, N.M. The Relationship between Job Satisfaction and Organizational Commitment among Academic Staff Members in a Selected Higher Education. J. WEI Bus. Econ. 2016, 5, 38–47. [Google Scholar]

- Ampofo, E.T. Mediation effects of job satisfaction and work engagement on the relationship between organisational embeddedness and affective commitment among frontline employees of star–rated hotels in Accra. J. Hosp. Tour. Manag. 2020, 44, 253–262. [Google Scholar] [CrossRef]

- Locke, E.A. The nature and causes of job satisfaction. In Handbook of Industrial and Organizational Psychology; Rand McNally College Pub. Co.: Chicago, IL, USA, 1976; Volume 1, pp. 1297–1343. [Google Scholar]

- Saha, S.; Kumar, S.P. Organizational culture as a moderator between affective commitment and job satisfaction. Int. J. Public Sect. Manag. 2018, 31, 184–206. [Google Scholar] [CrossRef]

- Gillet, N.; Forest, J.; Benabou, C.; Bentein, K. The effects of organizational factors, psychological need satisfaction and thwarting, and affective commitment on workers’ well-being and turnover intentions. Le Trav. Hum. 2015, 78, 119–140. [Google Scholar] [CrossRef]

- Allen, N.J.; Meyer, J.P. The measurement and antecedents of affective, continuance and normative commitment to the organization. J. Occup. Psychol. 1990, 63, 1–18. [Google Scholar] [CrossRef]

- Kim, M.; Beehr, T.A. Empowering leadership: Leading people to be present through affective organizational commitment? Int. J. Hum. Resour. Manag. 2018, 31, 2017–2044. [Google Scholar] [CrossRef]

- Drucker, P. A Primer on Organizational Commitment; ASQ, American Society for Quality: Milwaukee, WI, USA, 2005. [Google Scholar]

- Taifor, N.A.; Abdullah, H.S.; Hashim, R. Incidence and antecedents of presenteeism: The case of a federal government ministry in Malaysia. In Proceedings of the 2011 IEEE Colloquium on Humanities, Science and Engineering, Penang, Malaysia, 5–6 December 2011; IEEE: New York, NY, USA, 2011; pp. 654–659. [Google Scholar]

- Yang, T.; Guo, Y.; Ma, M.; Li, Y.; Tian, H.; Deng, J. Job Stress and Presenteeism among Chinese Healthcare Workers: The Mediating Effects of Affective Commitment. Int. J. Environ. Res. Public Health 2017, 14, 978. [Google Scholar] [CrossRef]

- Hemp, P. Presenteeism: At work-but out of it. Harv. Bus. Rev. 2004, 82, 49–58. [Google Scholar] [PubMed]

- De Beer, L.T. The effect of presenteeism-related health conditions on employee work engagement levels: A comparison between groups. SA J. Hum. Resour. Manag. 2014, 14, 8. [Google Scholar] [CrossRef]

- Caruso, C.; Bushnell, T.; Eggerth, D. Overtime and Extended Work Shifts; National Institute for Occupational Safety and Health: Washington, DC, USA, 2004. [Google Scholar]

- Schmidt, K.-H.; Diestel, S. The Relation of Self-Control Demands to Job Strain: The Moderating Role of Organisational Commitment. Appl. Psychol. 2011, 61, 479–497. [Google Scholar] [CrossRef]

- Setti, I.; Lourel, M.; Argentero, P. The role of affective commitment and perceived social support in protecting emergency workers against burnout and vicarious traumatization. Traumatology 2016, 22, 261–270. [Google Scholar] [CrossRef]

- Hines, P. How to create and sustain a lean culture. Dev. Learn. Organ. Int. J. 2010, 24, 24. [Google Scholar] [CrossRef]

- Lucey, J.J. The Concept Of A Lean Sustainability Zone-The final part of a series of articles by Dr. John J Lucey. Manag. Serv. 2009, 53, 8. [Google Scholar]

- Jaaron, A.; Backhouse, C. Lean Manufacturing in Public Services: Prospects for Value Creation; Lecture Notes in Business Information, Processing; Metzler, J.B., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 45–57. [Google Scholar]

- Angelis, J.; Conti, R.; Cooper, C.L.; Gill, C. Building a high-commitment lean culture. J. Manuf. Technol. Manag. 2011, 22, 569–586. [Google Scholar] [CrossRef]

- Morin, J.H.; Ralyté, J.; Snene, M. Exploring Services Science. In Proceedings of the First International Conference, IESS 2010, Geneva, Switzerland, 17–19 February 2010. [Google Scholar]

- Meyer, K.L.; Waddell, W.H. Evolving Excellence: Thoughts on Lean Enterprise Leadership; iUniverse: New York, NY, USA, 2007. [Google Scholar]

- Cardon, N.; Bribiescas, F. Respect for people: The forgotten principle in lean manufacturing implementation. Eur. Sci. J. 2015, 11, 45–61. [Google Scholar]

- Dinero, D. Training within Industry: The Foundation of Lean; Productivity Press: New York, NY, USA, 2005. [Google Scholar]

- Veech, D.S. A Person-Centered Approach to Sustaining a Lean Environment—Job Design for Self-Efficacy. Def. Acquis. Rev. J. 2004, 11, 159–171. [Google Scholar]

- Dibia, I.K. Implementation of the Leadership, People, Process and Outcome Model of Lean Using Soft Systems Methodology in Triangulation. Ph.D. Thesis, University of Portsmouth, Portsmouth, UK, 2012. [Google Scholar]

- Beale, J. Employee motivation to adopt Lean behaviours: Individual-level antecedents. Rev. Adm. FACES J. 2007, 6, 11–31. [Google Scholar]

- Dibia, I.K.; Onuh, S. Lean revolution and the human resource aspects. In Proceedings of the World Congress on Engineering, London, UK, 30 June–2 July 2010. [Google Scholar]

- Martínez-Jurado, P.J.; Moyano-Fuentes, J.; Gómez, P.J. HR management during lean production adoption. Manag. Decis. 2013, 51, 742–760. [Google Scholar] [CrossRef]

- Vanichchinchai, A. Assessing lean satisfaction and its enablers: A care provider perspective. Oper. Manag. Res. 2021, 1–12. [Google Scholar] [CrossRef]

- Marin-Garcia, J.A.; Bonavia, T. Relationship between employee involvement and lean manufacturing and its effect on performance in a rigid continuous process industry. Int. J. Prod. Res. 2014, 53, 3260–3275. [Google Scholar] [CrossRef]

- Swank, C.K. The lean service machine. Harv. Bus. Rev. 2003, 81, 123–130. [Google Scholar]

- Signoretti, A.; Sacchetti, S. Lean HRM practices in work integration social enterprises: Moving towards social lean production. Evidence from Italian case studies. Ann. Public Coop. Econ. 2020, 91, 545–563. [Google Scholar] [CrossRef]

- Alagaraja, M.; Egan, T. The Strategic Value of HRD in Lean Strategy Implementation. Hum. Resour. Dev. Q. 2013, 24, 1–27. [Google Scholar] [CrossRef]

- Sisson, J.; Elshennawy, A.K. Achieving success with Lean. Int. J. Lean Six Sigma 2015, 6, 263–280. [Google Scholar] [CrossRef]

- Margulies, N.; Yukl, G.A. Leadership in Organizations. Acad. Manag. Rev. 1982, 7, 314. [Google Scholar] [CrossRef][Green Version]

- Mann, D. Creating a Lean Culture: Tools to Sustain Lean Conversions; Productivity press: New York, NY, USA, 2005. [Google Scholar]

- Emiliani, M. Standardized work for executive leadership. Leadersh. Organ. Dev. J. 2008, 29, 24–46. [Google Scholar] [CrossRef]

- Aij, K.H.; Teunissen, M. Lean leadership attributes: A systematic review of the literature. J. Health Organ. Manag. 2017, 31, 713–729. [Google Scholar] [CrossRef]

- Dombrowski, U.; Mielke, T. Lean Leadership—Fundamental Principles and their Application. Procedia CIRP 2013, 7, 569–574. [Google Scholar] [CrossRef]

- Worley, J.; Doolen, T. The role of communication and management support in a lean manufacturing implementation. Manag. Decis. 2006, 44, 228–245. [Google Scholar] [CrossRef]

- Meyer, K. The Culture Side of Lean Manufacturing. Available online: http://kevinmeyer.com/blog/2007/02/the_culture_sid.html (accessed on 21 February 2020).

- Teich, S.T.; Faddoul, F.F. Lean Management—The Journey from Toyota to Healthcare. Rambam Maimonides Med. J. 2013, 4, e0007. [Google Scholar] [CrossRef] [PubMed]

- Abramson, M.A.; Gardner, N.W. Human Capital; Rowman & Littlefield Pub. Inc.: Lanham, MD, USA, 2002; 424p. [Google Scholar]

- Kotter, J.P. Force for Change: How Leadership Differs from Management, 1st ed.; Free Press: New York, NY, USA, 1990; 192p. [Google Scholar]

- Lee, J.; Sohn, Y.W.; Kim, M.; Kwon, S.; Park, I.-J. Relative Importance of Human Resource Practices on Affective Commitment and Turnover Intention in South Korea and United States. Front. Psychol. 2018, 9, 669. [Google Scholar] [CrossRef]

- Husar, M. Corporate Culture: Toyota’s Secret, Competitive Advantage; General Motors Internal Paper. Available online: http://www.bobemiliani.com/wp-content/uploads/2016/08/husar_nummi.pdf (accessed on 25 February 2020).

- Hafey, R. Lean Safety: Transforming Your Safety Culture with Lean Management; Productivity Press: Boca Raton, FL, USA, 2009; ISBN 9781439816431. [Google Scholar]

- Askenazy, P. Les Désordres du Travail: Enquête sur le Nouveau Productivisme, 3rd ed.; Seuil: Paris, France, 2004; p. 96. ISBN 978-2020629164. [Google Scholar]

- Dibia, C.H. Lean Manufacturing and Employee Working Conditions in Organisations Operating in Nigeria: The Managers’ and Supervisors’ Perspective. Ph.D. Thesis, University of Portsmouth, Portsmouth, UK, 2017. [Google Scholar]

- Koukoulaki, T. The impact of lean production on musculoskeletal and psychosocial risks: An examination of sociotechnical trends over 20 years. Appl. Ergon. 2014, 45, 198–212. [Google Scholar] [CrossRef] [PubMed]

- Imbeau, D.; Aubry, K.; Chiasson, M.-È. Suivi du Déploiement d’un Programme d’Amélioration Continue Augmenté d’un Volet SST/Ergonomie dans une Entreprise Manufacturière au Québec: Recherche-Action 2003–2010; École Polytechnique de Montréal: Montreal, QC, Canada, 2012. [Google Scholar]

- Conti, R.; Angelis, J.; Cooper, C.; Faragher, B.; Gill, C. The effects of lean production on worker job stress. Int. J. Oper. Prod. Manag. 2006, 26, 1013–1038. [Google Scholar] [CrossRef]

- Ouellet, S.; Vézina, N. L’implantation de la rotation de postes: Un exemple de démarche préalable. Perspect. Interdiscip. Trav. St. 2003. [Google Scholar] [CrossRef]

- O’Brien, E. Employers’ Benefits from Workers’ Health Insurance. Milbank Q. 2003, 81, 5–43. [Google Scholar] [CrossRef]

- Choi, T.Y.; Liker, J.K. Bringing Japanese Continuous Improvement Approaches to U.S. Manufacturing: The Roles of Process Orientation and Communications. Decis. Sci. 1995, 26, 589–620. [Google Scholar] [CrossRef]

- Gao, S.; Low, S.P. Lean Construction Management, 1st ed.; Springer: New York, NY, USA, 2014; p. 390. ISBN 978-981-287-013-1. [Google Scholar]

- Béndek, P. Beyond Lean; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; p. 126. [Google Scholar]

- McMahon, T. A Lean Journey. Available online: http://www.aleanjourney.com/2014/06/10-ways-to-show-respect-for-people.html (accessed on 25 February 2020).

- Doustar, S.M.; Astaneh, M.R.; Balalami, M.K. Human Resource Empowerment in Lean Manufacturing. Int. J. Innov. Res. Educ. Sci. 2014, 1, 10. [Google Scholar]

- Bai, C.; Satir, A.; Sarkis, J. Investing in lean manufacturing practices: An environmental and operational perspective. Int. J. Prod. Res. 2018, 57, 1037–1051. [Google Scholar] [CrossRef]

- Zhang, B.; Niu, Z.; Liu, C. Lean Tools, Knowledge Management, and Lean Sustainability: The Moderating Effects of Study Conventions. Sustain. J. Rec. 2020, 12, 956. [Google Scholar] [CrossRef]

- Iranmanesh, M.; Zailani, S.; Hyun, S.S.; Ali, M.H.; Kim, K. Impact of Lean Manufacturing Practices on Firms’ Sustainable Performance: Lean Culture as a Moderator. Sustain. J. Rec. 2019, 11, 1112. [Google Scholar] [CrossRef]

- Gaikwad, L.; Sunnapwar, V. The Role of Lean Manufacturing Practices in Greener Production: A Way to Reach Sustainability. Int. J. Ind. Manuf. Syst. Eng. 2020, 5, 1. [Google Scholar] [CrossRef]

- Hines, P.; Taylor, D.; Walsh, A. The Lean journey: Have we got it wrong? Total. Qual. Manag. Bus. Excel. 2020, 31, 389–406. [Google Scholar] [CrossRef]

- Shamila, F. The Impact of Performance Appraisal System on Organizational Commitment in Selected Banks in Puttlam District. In Proceedings of the International Conference on Business and Information, Kelaniya, Sri Lanka, 17 November 2017. [Google Scholar]

- Bess, J.L.; Bess, M. Creative r & d Leadership: Insights from Japan; Greenwood Publishing Group: New York, NY, USA, 1995; p. 359. [Google Scholar]

- Scott-Ladd, B.; Travaglione, A.; Marshall, V. Causal inferences between participation in decision making, task attributes, work effort, rewards, job satisfaction and commitment. Leadersh. Organ. Dev. J. 2006, 27, 399–414. [Google Scholar] [CrossRef]

- Chew, J.; Chan, C.C. Human resource practices, organizational commitment and intention to stay. Int. J. Manpow. 2008, 29, 503–522. [Google Scholar] [CrossRef]

- Lamba, S.; Choudhary, N. Impact of HRM practices on organizational commitment of employees. Int. J. Adv. Res. Technol. 2013, 2, 407–423. [Google Scholar]

- Trudel, J.M.; Saba, T.; Guérin, G. L’influence contrastée des pratiques de gestion des ressources humaines sur l’engagement organisationnel et la performance au travail. Rev. Int. Trav. Société 2005, 3, 1–25. [Google Scholar]

- Bonavia, T.; Marin-Garcia, J.A. Integrating human resource management into lean production and their impact on organizational performance. Int. J. Manpow. 2011, 32, 923–938. [Google Scholar] [CrossRef]

- Ferrari, R. Writing narrative style literature reviews. Med. Writ. 2015, 24, 230–235. [Google Scholar] [CrossRef]

| Date | Lean Evolution |

|---|---|

| Before 1945 |

|

| Birth and evolution of the TPS in Japan 1945–1978 |

|

| The arrival of TPS in North America 1973–1988 |

|

| Academic progress 1988–2000 |

|

| 2000-present |

|

| Authors | Definitions |

|---|---|

| Becker [54] | Employee’s need to pursue working in an organization because of costs associated with leaving it. |

| Grusky [55] | The strength of an individual’s attachment to an organization. The factors that influence this strength are the rewards received from the organization and the required experiences to receive them. |

| Kiesler et Sakumura [56] | The link that binds an individual to behavioral acts. |

| Kanter [57] | Employee’s willingness to invest their energy and loyalty in a given organization. |

| Angle and Perry [63] | Meyer and Allen [64] | Cohen [69] |

|---|---|---|

| Value commitment Commitment to stay | Affective commitment Continuance commitment Normative commitment | Instrumental commitment propensity Normative commitment propensity Instrumental commitment Affective commitment |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benkarim, A.; Imbeau, D. Organizational Commitment and Lean Sustainability: Literature Review and Directions for Future Research. Sustainability 2021, 13, 3357. https://doi.org/10.3390/su13063357

Benkarim A, Imbeau D. Organizational Commitment and Lean Sustainability: Literature Review and Directions for Future Research. Sustainability. 2021; 13(6):3357. https://doi.org/10.3390/su13063357

Chicago/Turabian StyleBenkarim, Amal, and Daniel Imbeau. 2021. "Organizational Commitment and Lean Sustainability: Literature Review and Directions for Future Research" Sustainability 13, no. 6: 3357. https://doi.org/10.3390/su13063357

APA StyleBenkarim, A., & Imbeau, D. (2021). Organizational Commitment and Lean Sustainability: Literature Review and Directions for Future Research. Sustainability, 13(6), 3357. https://doi.org/10.3390/su13063357