Mechanical Performance of Lime Mortar Coatings for Rehabilitation of Masonry Elements in Old and Historical Buildings

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Compressive and Flexural Strength

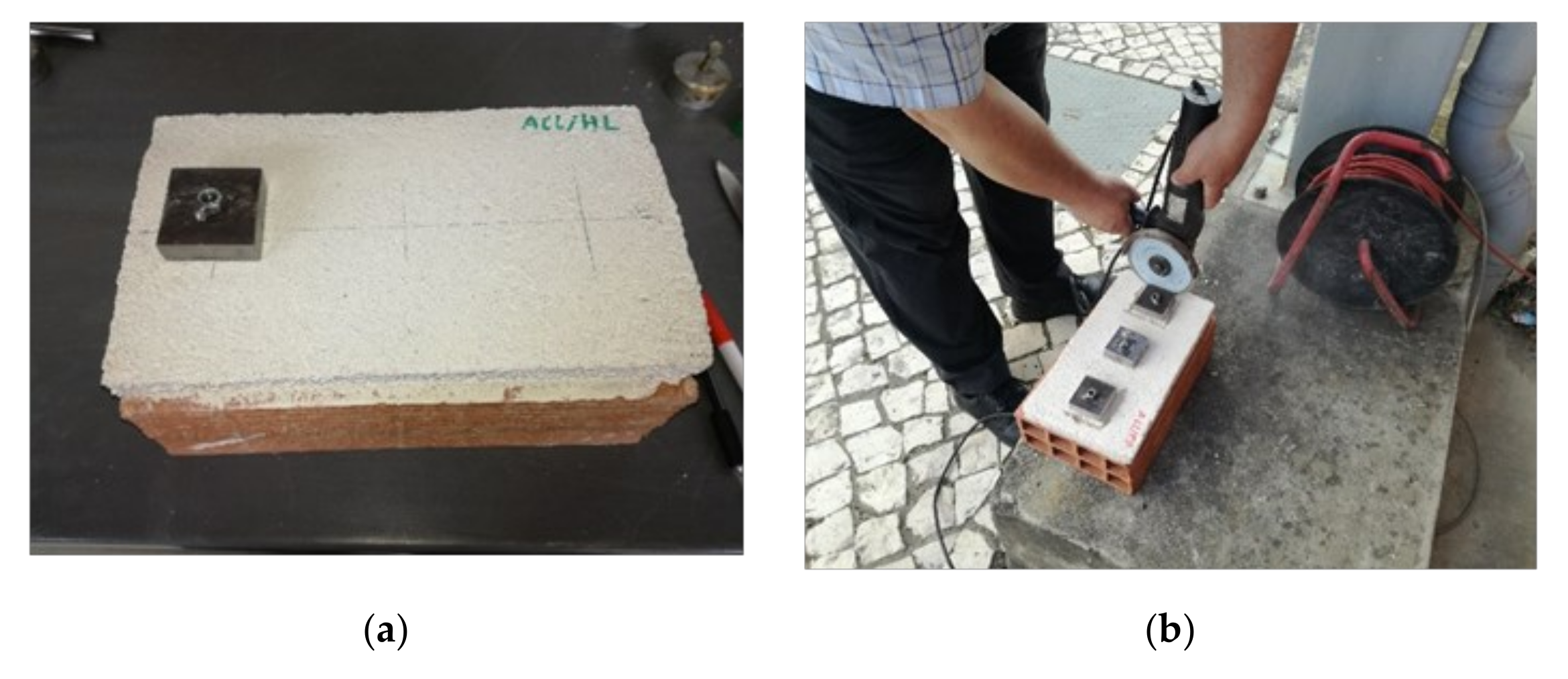

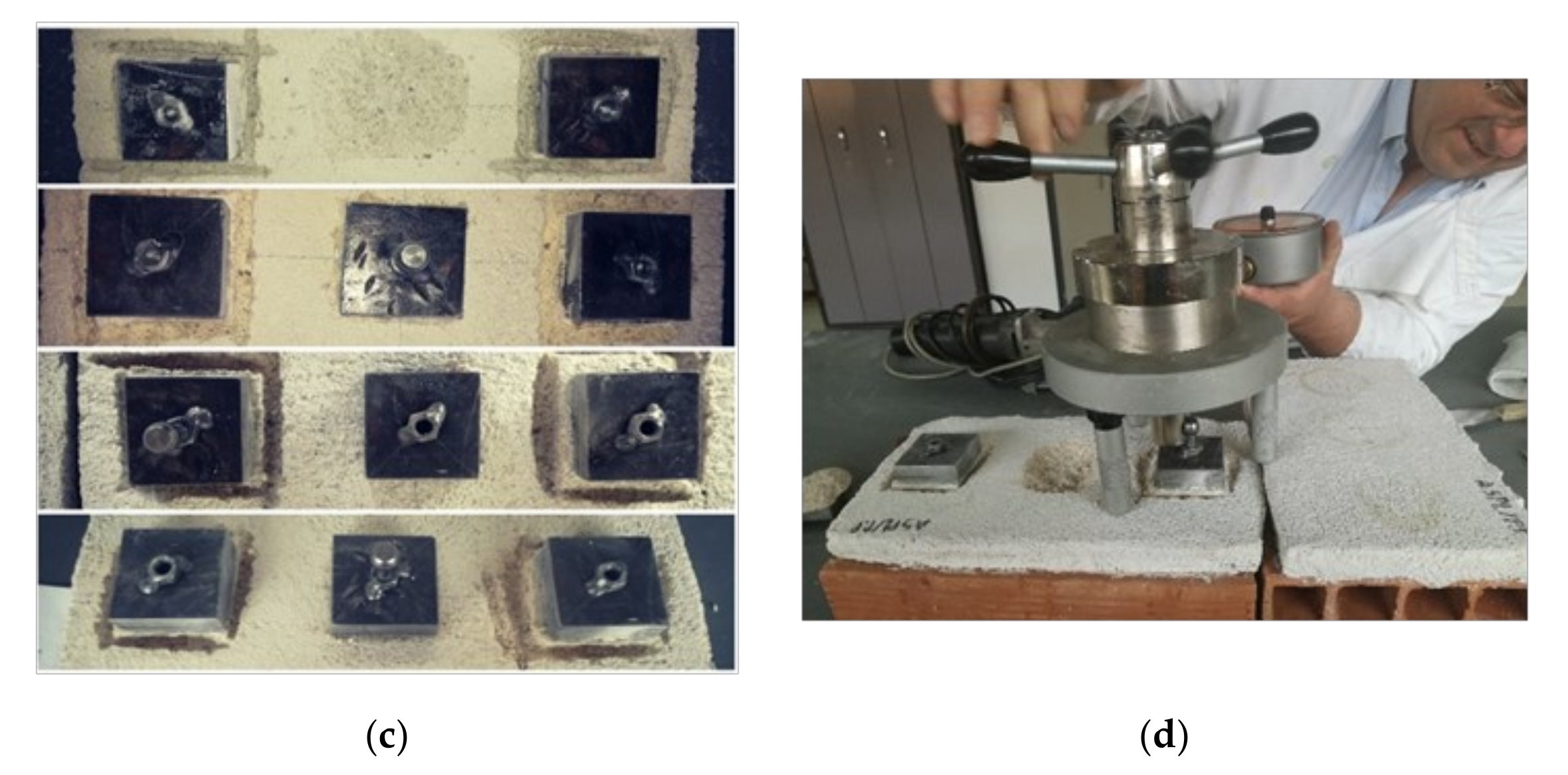

2.4. Pull-Off Test

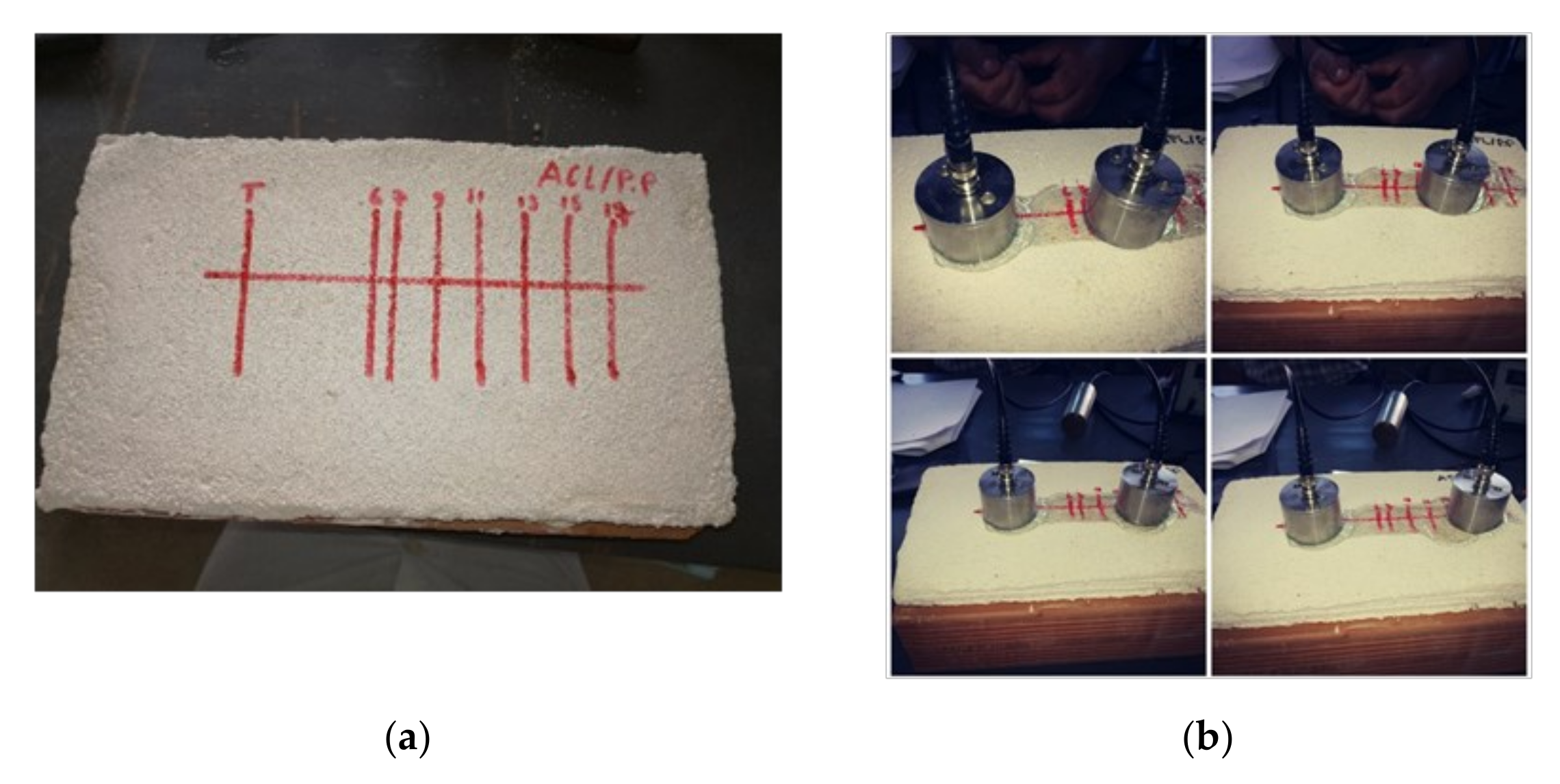

2.5. Ultrasonic Pulse Velocity

2.6. Water Penetration under Low Pressure Test (Karsten Method)

2.7. Shrinkage Cracking

3. Results

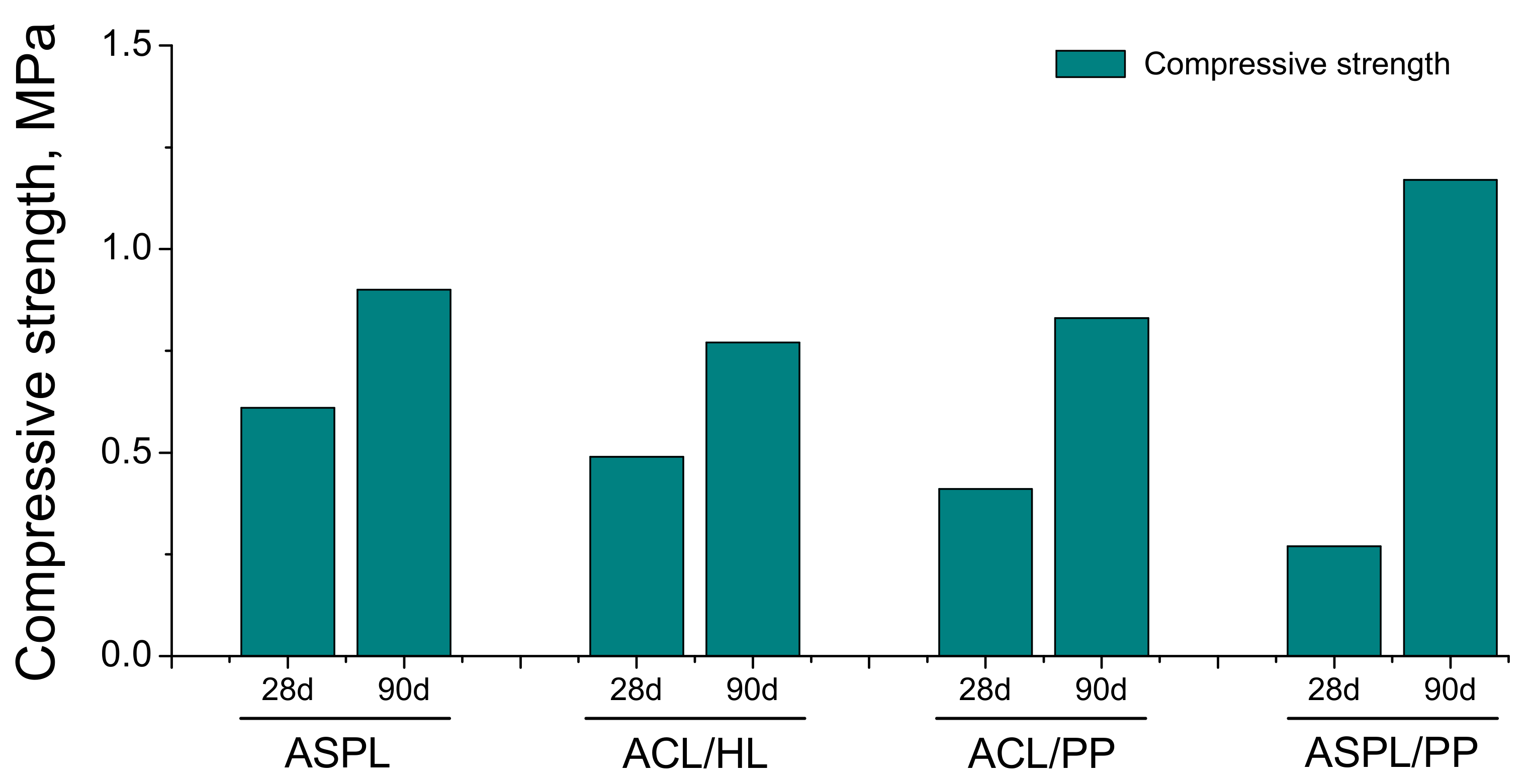

3.1. Compressive and Flexural Strength

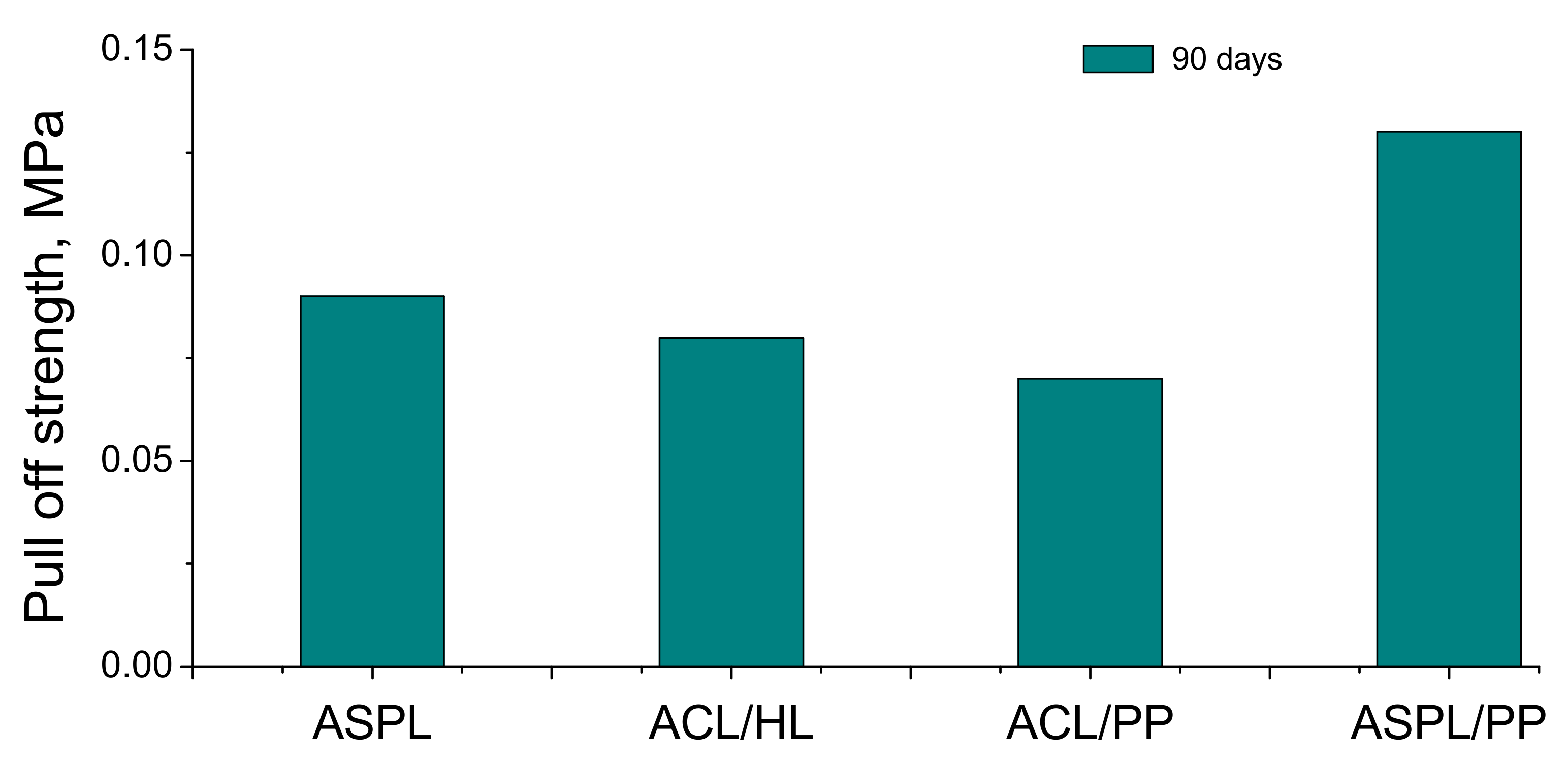

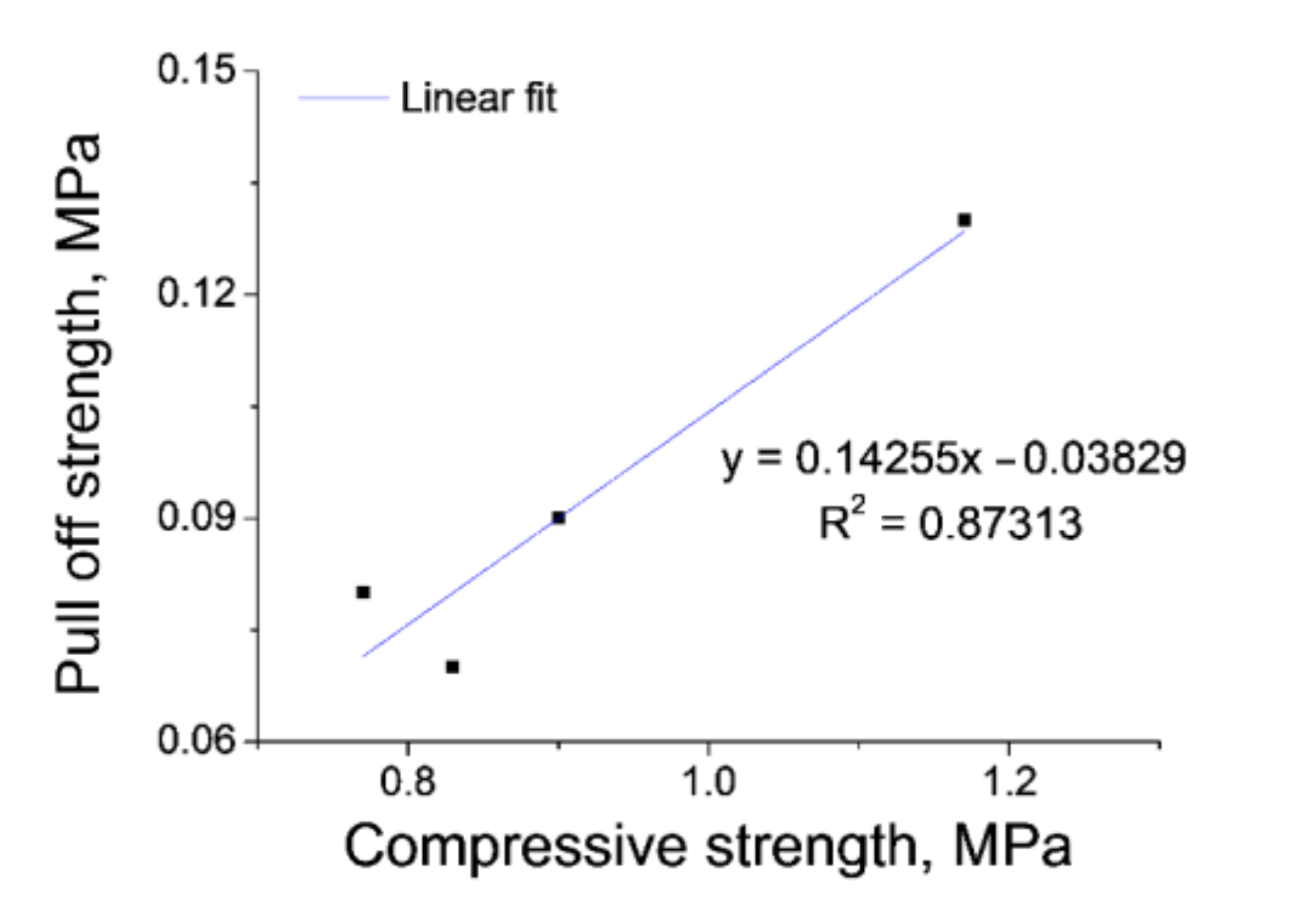

3.2. Pull-off Strength

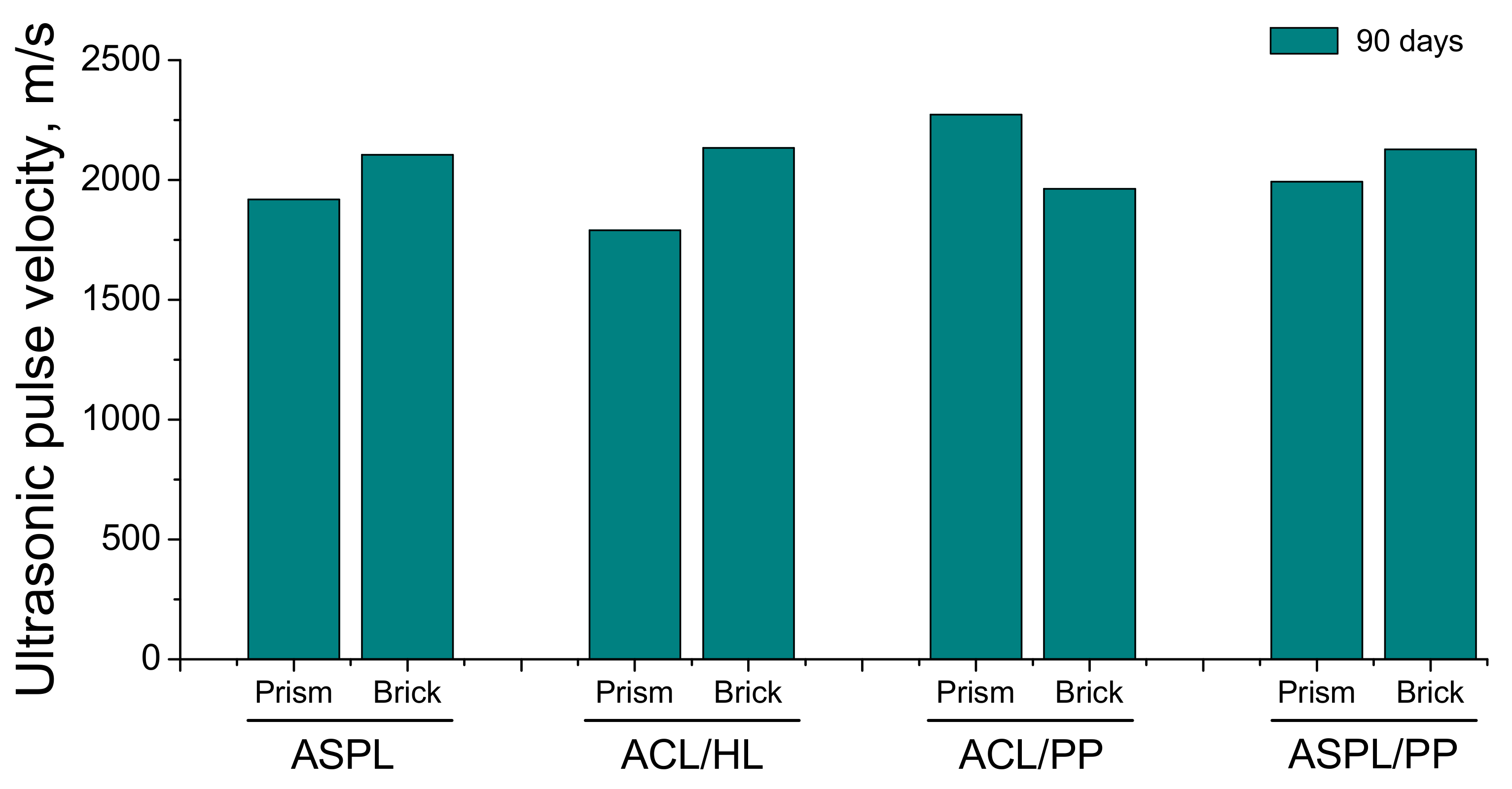

3.3. Ultrasonic Pulse Velocity

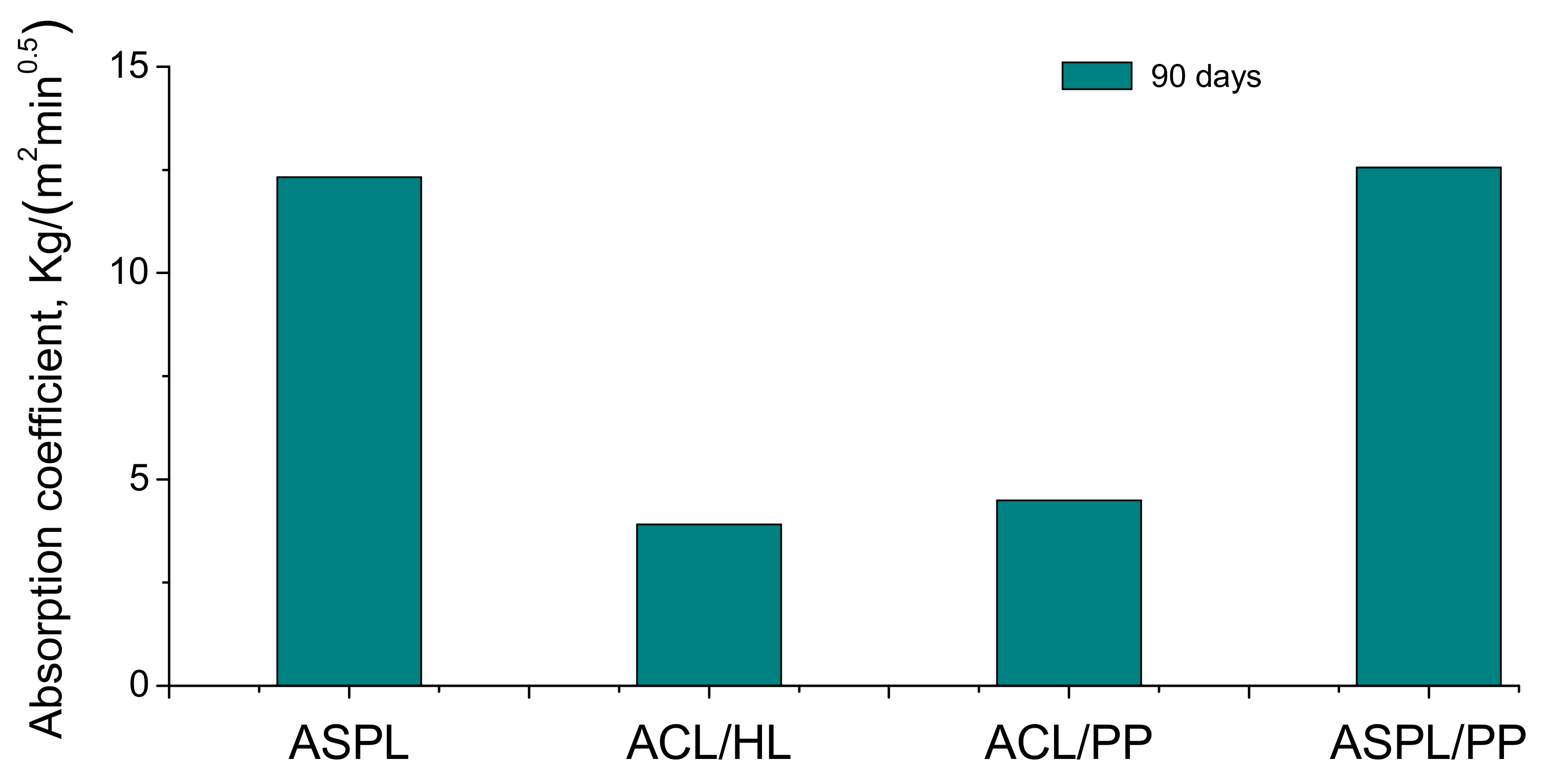

3.4. Water Penetration under Low Pressure

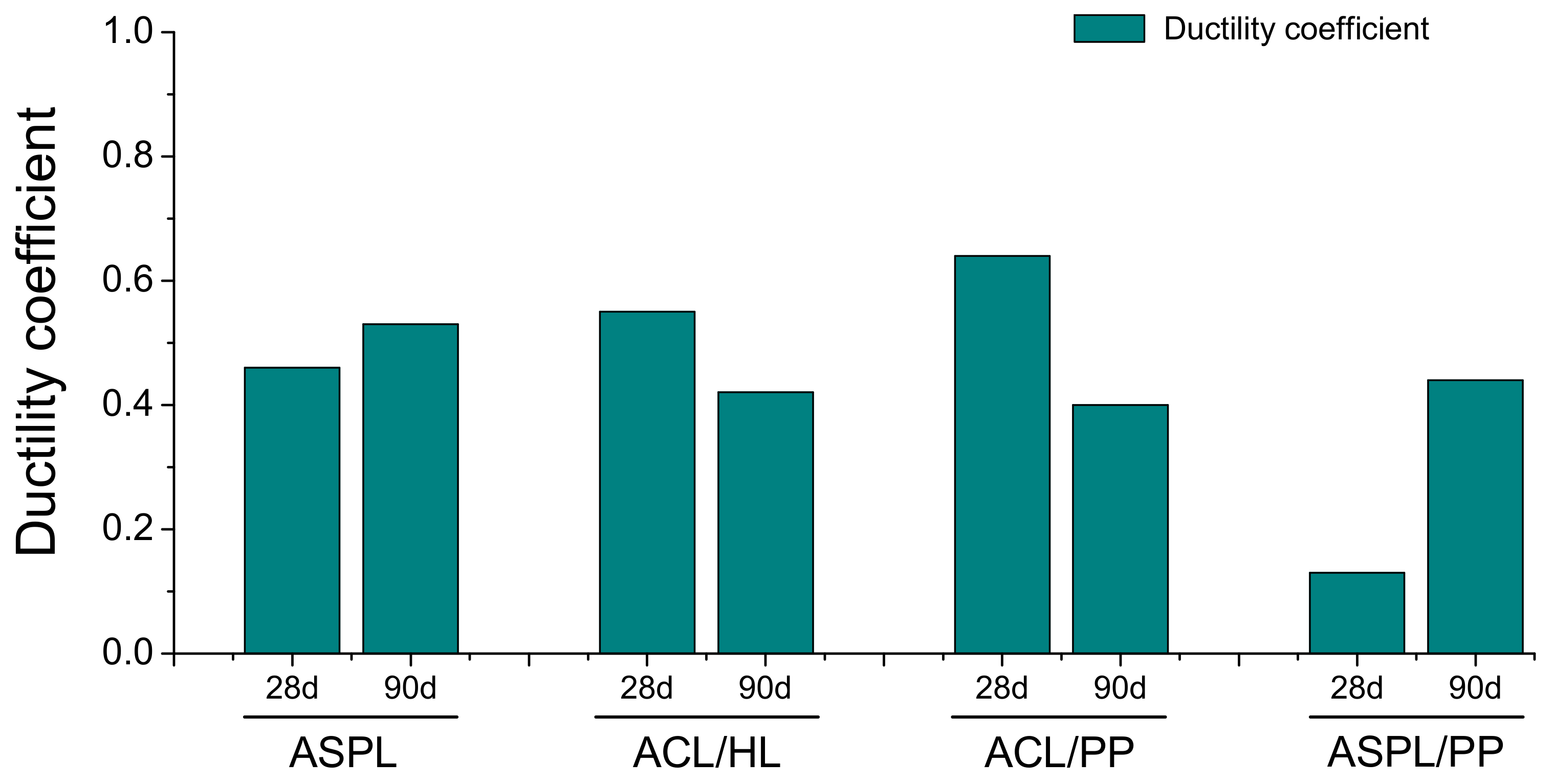

3.5. Shrinkage Cracking

4. Discussion

5. Conclusions

- The compressive and flexural strengths increased with time for all the studied mortars, being this rise more noticeable for mortars made using lime putty and both sand and crushed rock powder as aggregates (ASPL/PP series). At 90 hardening days, higher values of both mechanical strengths were noted for mortars with lime putty (ASPL and ASPL/PP series) compared to aerial lime ones (ACL/HL and ACL/PP series).

- In view of the results of compressive and flexural strengths, the incorporation of rock crushed powder as an aggregate would produce a reduction of these parameters in the short-term (28 days), although it has a beneficial effect in the middle-term (90 days), increasing both mechanical strengths, especially when it is combined with lime putty.

- Regarding the different types of limes studied, the incorporation of lime putty in the binder would generally produce higher compressive and flexural strengths after 90 days.

- With respect to pull-off strength, all the studied mortars showed a cohesive fracture. The results of this parameter were overall in keeping with those noted for compressive and flexural strength, showing the ASPL/PP and ASPL series higher pull-off strength than ACL/HL and ACL/PP ones.

- The ultrasonic pulse velocity was similar for all the studied mortars, which would indicate that they would have a similar global porosity, with slight differences between them.

- The highest absorption coefficients were noted for mortars with lime putty (ASPL and ASPL/PP series). This could be related to the possible presence of pores with higher diameters in these mortars, in spite of having similar or even less global porosity compared to aerial lime mortars (ACL/HL and ACL/PP series), as suggested by the ultrasonic pulse velocity results. These pores with higher diameters would facilitate the penetration of water under pressure in the microstructure of the mortars with lime putty.

- Mortars that incorporated aerial lime (ACL/HL and ACL/PP series) showed the lowest absorption coefficient. This would reveal a finer porosity in these mortars which would make the water penetration more difficult.

- The formation of shrinkage cracks in the surface of the mortar coatings was not detected at 28 and 90 hardening days.

- As a general conclusion, mortar coatings with lime putty (ASPL and ASPL/PP series) showed better mechanical properties, while the mortar coatings with aerial lime (ACL/HL and ACL/PP series) had better behavior regarding water absorption under pressure. Despite that, considering the results obtained in this research, the overall performance of all the studied mortars is adequate for being used in the rehabilitation of masonry elements in old and historical buildings.

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Vinagre, A.I.B. Estudo Comparativo Entre Argamassas de cal Calcítica e de cal Dolomítica: Características Mecânicas, Físicas, Mineralógicas e Microestruturais. Master’s Thesis, Universidade de Évora, Évora, Portugal, 2015. [Google Scholar]

- Margalha, M.G.; Veiga, M.R.; Brito, J. Algumas vantagens do uso da cal em pasta em revestimentos. In Proceedings of the 2° Encontro sobre Patologia e Reabilitação de Edifícios—PATORREB, Porto, Portugal, 20–21 March 2006. [Google Scholar]

- Coelho, A.Z.G.; Torgal, F.P.; Jalali, S. A Cal na Construção; TecMinho: Guimarães, Portugal, 2009. [Google Scholar]

- Veiga, R. Air lime mortars: What else do we need to know to apply them in conservation and rehabilitation interventions? A review. Constr. Build. Mater. 2017, 157, 132–140. [Google Scholar] [CrossRef]

- Veiga, R.; Santos Silva, A. Mortars. In Long-term Performance and Durability of Masonry Structures; Ghiassi, B., Lourenço, P.B., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Duxford, UK, 2019; pp. 169–208. [Google Scholar]

- Moropoulou, A.; Maravelaki-Kalaitzaki, P.; Borboudakis, M.; Bakolas, A.; Michailidis, P.; Chronopoulos, M. Historic mortars technologies in Crete and guidelines for compatible restoration mortars. In PACT, Revue du Groupe Europeen d’etudes pour les Techniques Physiques, Chimiches, Biologiques et Mathematiques Applique´s a L’archeologie, Compatible Materials for the Protection of European Cultural Heritage; Biscontin, G., Moropoulou, A., Erdik, M.J.D.R., Eds.; Technical Chamber of Greece: Athens, Greece, 1998; Volume 55, pp. 55–72. [Google Scholar]

- Aalil, I.; Badreddine, D.; Beck, K.; Brunetaud, X.; Cherkaoui, K.; Chaaba, A.; Al-Mukhtar, M. Valorization of crushed bricks in lime-based mortars. Constr. Build. Mater. 2019, 226, 555–563. [Google Scholar] [CrossRef]

- Thirumalini, S.; Ravi, R.; Rajesh, M. Experimental investigation on physical and mechanical properties of lime mortar: Effect of organic addition. J. Cult. Herit. 2018, 31, 97–104. [Google Scholar] [CrossRef]

- Maravelaki-Kalaitzaki, P.; Bakolas, A.; Karatasios, I.; Kilikoglou, V. Hydraulic lime mortars for the restoration of historic masonry in Crete. Cem. Concr. Res. 2005, 35, 1577–1586. [Google Scholar] [CrossRef]

- Aggelakopoulou, E.; Bakolas, A.; Moropoulou, A. Lime putty versus hydrated lime powder: Physicochemical and mechanical characteristics of lime based mortars. Constr. Build. Mater. 2019, 225, 633–641. [Google Scholar] [CrossRef]

- Garijo, L.; Zhang, X.; Ruiz, G.; Ortega, J.J. Age effect on the mechanical properties of natural hydraulic and aerial lime mortars. Constr. Build. Mater. 2020, 236, 117573. [Google Scholar] [CrossRef]

- Faria, P.; Henriques, F.; Rato, V. Comparative evaluation of lime mortars for architectural conservation. J. Cult. Herit. 2008, 9, 338–346. [Google Scholar] [CrossRef]

- Silva, B.A.; Ferreira Pinto, A.P.; Gomes, A. Natural hydraulic lime versus cement for blended lime mortars for restoration works. Constr. Build. Mater. 2015, 94, 346–360. [Google Scholar] [CrossRef]

- Gulbe, L.; Vitina, I.; Setina, J. The Influence of Cement on Properties of Lime Mortars. Procedia Eng. 2017, 172, 325–332. [Google Scholar] [CrossRef]

- Silva, B.A.; Ferreira Pinto, A.P.; Gomes, A. Influence of natural hydraulic lime content on the properties of aerial lime-based mortars. Constr. Build. Mater. 2014, 72, 208–218. [Google Scholar] [CrossRef]

- Grilo, J.; Faria, P.; Veiga, R.; Santos Silva, A.; Silva, V.; Velosa, A. New natural hydraulic lime mortars—Physical and microstructural properties in different curing conditions. Constr. Build. Mater. 2014, 54, 378–384. [Google Scholar] [CrossRef]

- Grilo, J.; Santos Silva, A.; Faria, P.; Gameiro, A.; Veiga, R.; Velosa, A. Mechanical and mineralogical properties of natural hydraulic lime-metakaolin mortars in different curing conditions. Constr. Build. Mater. 2014, 51, 287–294. [Google Scholar] [CrossRef]

- Santos, A.R.; Veiga, M.D.R.; Santos Silva, A.; de Brito, J.; Álvarez, J.I. Evolution of the microstructure of lime based mortars and influence on the mechanical behaviour: The role of the aggregates. Constr. Build. Mater. 2018, 187, 907–922. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Liu, J.B.; Li, B.; Yu, G.X.; Li, L. Experimental study on factors affecting the physical and mechanical properties of shell lime mortar. Constr. Build. Mater. 2019, 228. [Google Scholar] [CrossRef]

- Gameiro, A.; Santos Silva, A.; Faria, P.; Grilo, J.; Branco, T.; Veiga, R.; Velosa, A. Physical and chemical assessment of lime-metakaolin mortars: Influence of binder:aggregate ratio. Cem. Concr. Compos. 2014, 45, 264–271. [Google Scholar] [CrossRef]

- Garijo, L.; Zhang, X.; Ruiz, G.; Ortega, J.J.; Wu, Z. The effects of dosage and production process on the mechanical and physical properties of natural hydraulic lime mortars. Constr. Build. Mater. 2018, 169, 325–334. [Google Scholar] [CrossRef]

- Instituto Português da Qualidade. NP EN 933–1. Ensaios das Propriedades Geométricas dos Agregados—Parte 1: Análise Granulométrica, Método da Peneiração; Instituto Português da Qualidade: Lisboa, Portugal, 2014. [Google Scholar]

- Instituto Português da Qualidade. NP EN 1097–6. Ensaios das Propriedades Mecânicas e Físicas dos Agregados, Parte 6: Determinação da Massa Volúmica e da Absorção de Água; Instituto Português da Qualidade: Lisboa, Portugal, 2016. [Google Scholar]

- Instituto Português da Qualidade. NP EN 1097–3. Ensaios das Propriedades Mecânicas e Físicas dos Agregados, Parte 3: Determinação da Baridade e do Volume de Vazios; Instituto Português da Qualidade: Lisboa, Portugal, 2002. [Google Scholar]

- Instituto Português da Qualidade. NP EN 459–1. Cal de Construção—Parte 1: Definições, Especificações e Critérios de Conformidade; Instituto Português da Qualidade: Lisboa, Portugal, 2015. [Google Scholar]

- European Committee for Standardization. EN 1015–2. Methods of Test for Mortar for Masonry—Part 2: Bulk Sampling of Mortars and Preparation of test Mortars; Instituto Português da Qualidade: Brussels, Belgium, 1999. [Google Scholar]

- European Committee for Standardization. EN 1015–3. Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table); Instituto Português da Qualidade: Brussels, Belgium, 2000. [Google Scholar]

- European Committee for Standardization. EN 1015–11. Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; Instituto Português da Qualidade: Brussels, Belgium, 1999. [Google Scholar]

- Pavão, J.M. Estudo da Influência da Dosagem de Ligante no Desempenho de Rebocos para Edifícios Antigos. Master’s Thesis, Universidade Técnica de Lisboa, Lisboa, Portugal, 2010. [Google Scholar]

- European Committee for Standardization. EN 1015–12. Methods of Test for Mortar for Masonry—Part 12: Determination of Adhesive Strength of Hardened Rendering and Plastering Mortars on Substrates; European Committee for Standardization: Brussels, Belgium, 2000. [Google Scholar]

- da Encarnação Ferreira, M.J. Análise das Características Mecânicas de Amostras de Argamassas Pré-Doseadas. Master’s Thesis, Técnico de Lisboa, Lisboa, Portugal, 2012. [Google Scholar]

- de Viveiros Mendonça, B. Estudo do Desempenho das Argamassas Hidráulicas—Influência do Ligante. Master’s Thesis, Universidade Técnica de Lisboa, Lisboa, Portugal, 2007. [Google Scholar]

- Instituto Português da Qualidade. NP EN 12504-4. Ensaios do Betão nas Estruturas, Parte 4: Determinação da Velocidade de Propagação dos Ultra-Sons; Instituto Português da Qualidade: Lisboa, Portugal, 2007. [Google Scholar]

- RILEM Commision 25-PEM. Measurement of Water Absorption Under Low Pressure; Rilem Test Method No. II.4; RILEM Commision: Bagneux, France, 1980. [Google Scholar]

- Gomes, F.A.C.M. Argamassas Pré-Doseadas para Rebocos de Edificios Antigos. Master’s Thesis, Universidade Técnica de Lisboa, Lisboa, Portugal, 2009. [Google Scholar]

- Agostinho, C.S.A. Estudo da Evolução do Desempenho no Tempo de Argamassas de cal Aérea. Master’s Thesis, Universidade Técnica de Lisboa, Lisboa, Portugal, 2008. [Google Scholar]

| Aggregate | Dmax (mm) | dmin (mm) | Density (kg/m3) | Bulk Density (kg/m3) |

|---|---|---|---|---|

| Sand | 2 | 0.250 | 2609 | 1494 |

| Crushed rock powder | 4 | <0.063 | 2725 | 1534 |

| Mortar Type | Aerial Lime | Hydraulic Lime | Lime Putty | Crushed Rock Powder | Sand |

|---|---|---|---|---|---|

| ASPL | - | - | 1 | - | 3 |

| ACL/HL | 0.5 | 0.5 | - | - | 3 |

| ACL/PP | 1 | - | - | 1 | 2 |

| ASPL/PP | - | - | 1 | 1 | 2 |

| Mortar Type | Aerial Lime (g) | Hydraulic Lime (g) | Lime Putty (g) | Crushed Rock Powder (g) | Sand (g) | Water (mL) |

|---|---|---|---|---|---|---|

| ASPL | - | - | 370 | - | 1380 | 88.58 |

| ACL/HL | 92 | 128 | - | - | 1400 | 300 |

| ACL/PP | 182 | - | - | 475 | 920 | 280 |

| ASPL/PP | - | - | 370 | 475 | 920 | 87.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Branco, F.G.; Belgas, M.d.L.; Mendes, C.; Pereira, L.; Ortega, J.M. Mechanical Performance of Lime Mortar Coatings for Rehabilitation of Masonry Elements in Old and Historical Buildings. Sustainability 2021, 13, 3281. https://doi.org/10.3390/su13063281

Branco FG, Belgas MdL, Mendes C, Pereira L, Ortega JM. Mechanical Performance of Lime Mortar Coatings for Rehabilitation of Masonry Elements in Old and Historical Buildings. Sustainability. 2021; 13(6):3281. https://doi.org/10.3390/su13063281

Chicago/Turabian StyleBranco, Fernando G., Maria de Lurdes Belgas, Cátia Mendes, Luís Pereira, and José Marcos Ortega. 2021. "Mechanical Performance of Lime Mortar Coatings for Rehabilitation of Masonry Elements in Old and Historical Buildings" Sustainability 13, no. 6: 3281. https://doi.org/10.3390/su13063281

APA StyleBranco, F. G., Belgas, M. d. L., Mendes, C., Pereira, L., & Ortega, J. M. (2021). Mechanical Performance of Lime Mortar Coatings for Rehabilitation of Masonry Elements in Old and Historical Buildings. Sustainability, 13(6), 3281. https://doi.org/10.3390/su13063281