Supply Chain Operations Management in Pandemics: A State-of-the-Art Review Inspired by COVID-19

Abstract

1. Introduction

Problem Statement and Objectives

- Providing a comprehensive operations management review in pandemics and framing the objectives addressed in epidemic outbreaks.

- Exploring and categorizing supply chain operation objectives solved in the context of previous pandemics, solution methodologies, and their associated implications.

- Identifying supply chain sustainability, viability, and industry 4.0 developments from a pandemic perspective.

- Classifying literature gaps and research extension opportunities to support supply chain practitioners during COVID-19-like pandemics.

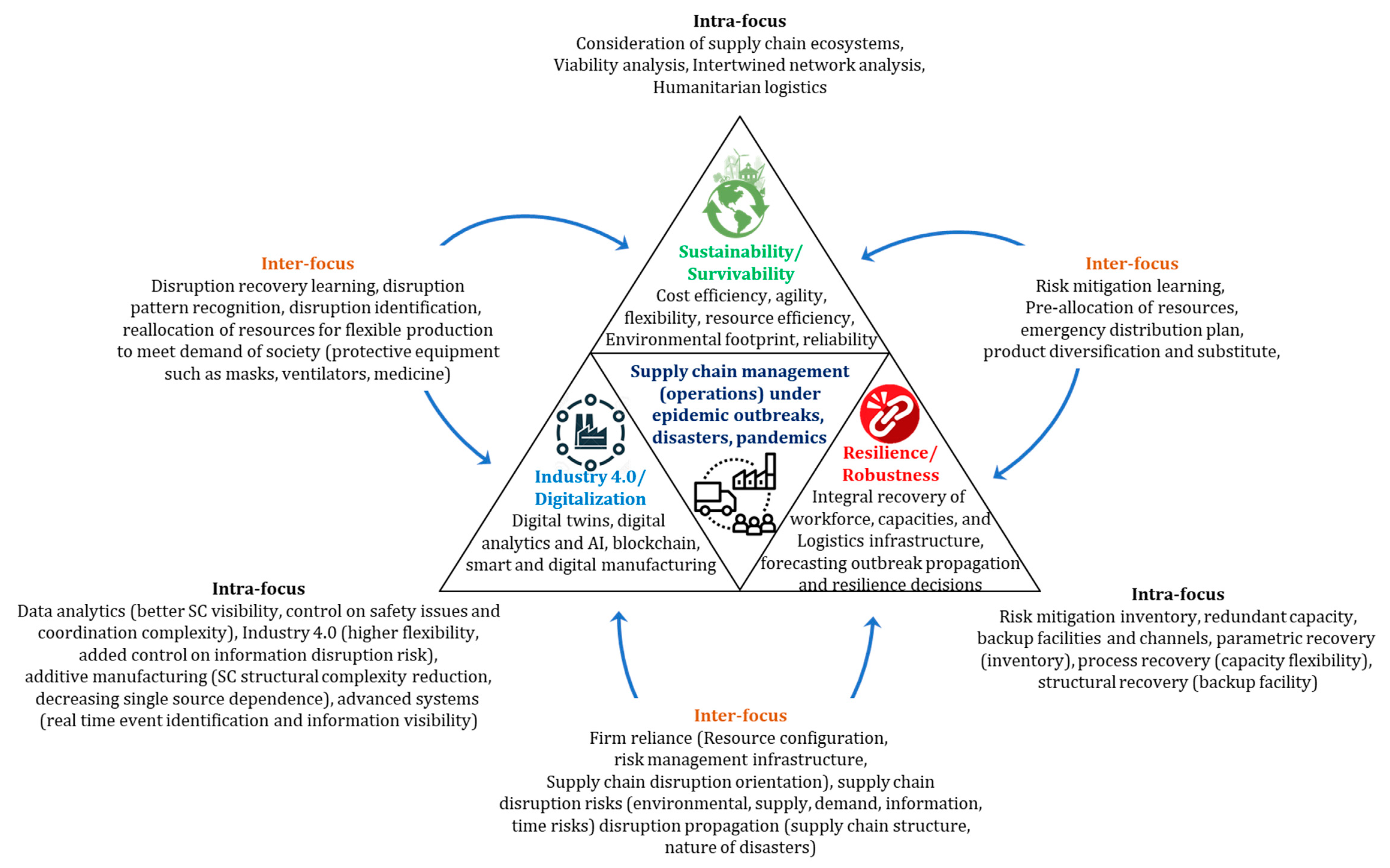

- Developing a conceptual integrated framework of supply chain operations management sustainability preparedness, resilience readiness, and digital vigilance.

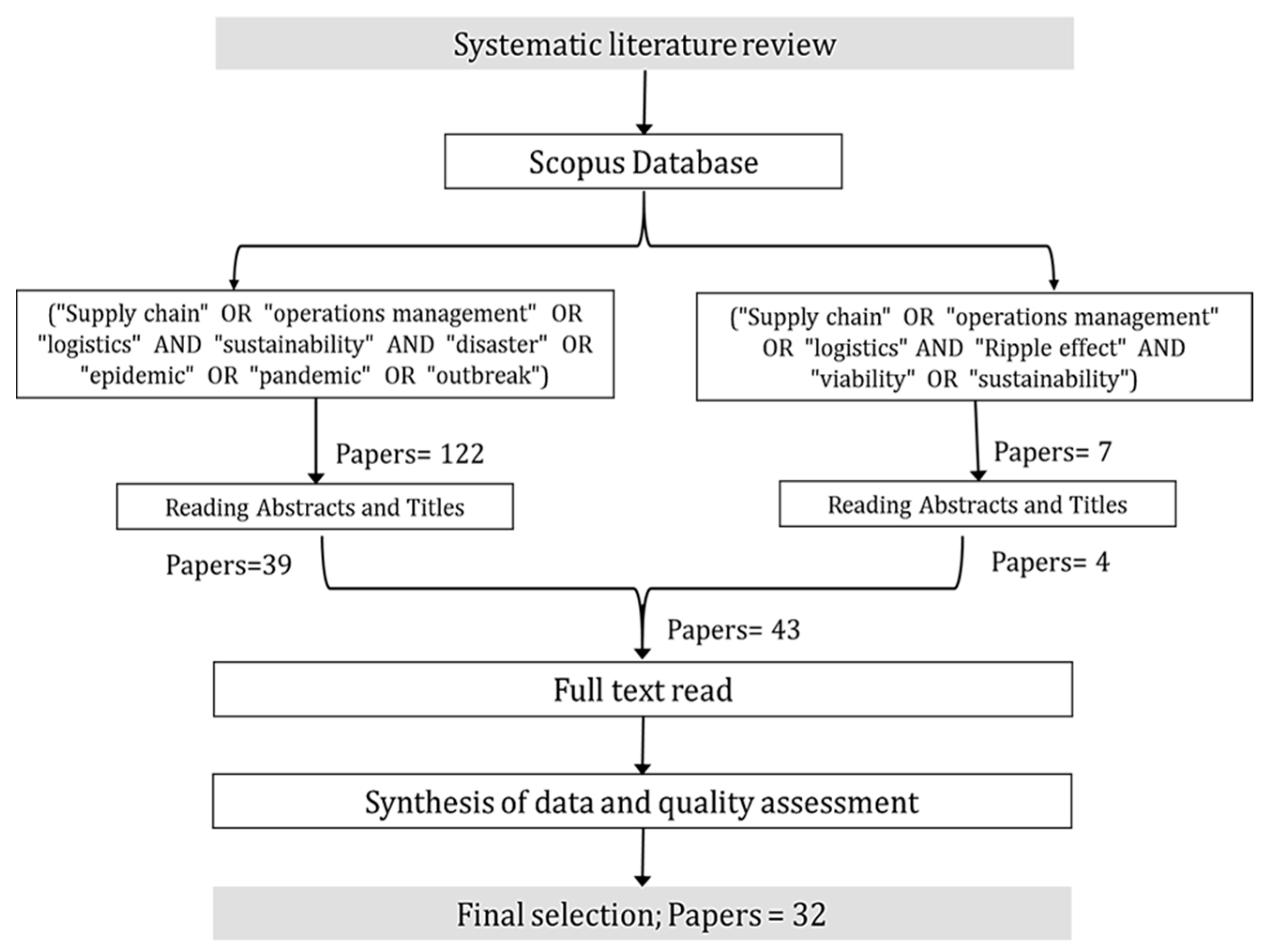

2. Research Methodology

2.1. Planning

- RQ1. What is the state-of-the-art in the existing literature related to SC disruptions, especially during epidemic outbreaks?

- RQ2. What are the unexplored areas and open questions to combat these effects in the field of SC?

2.2. Searching

2.3. Screening

2.3.1. Inclusion

2.3.2. Exclusion

2.4. Extraction

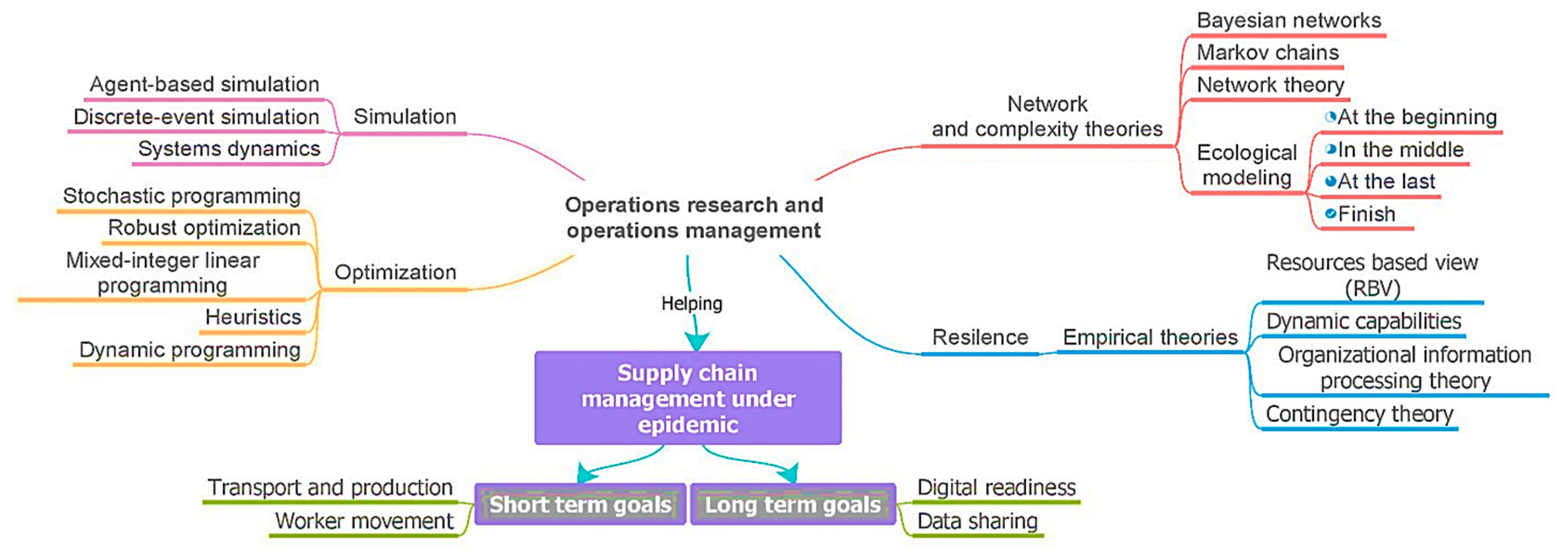

3. Discussion on the Findings

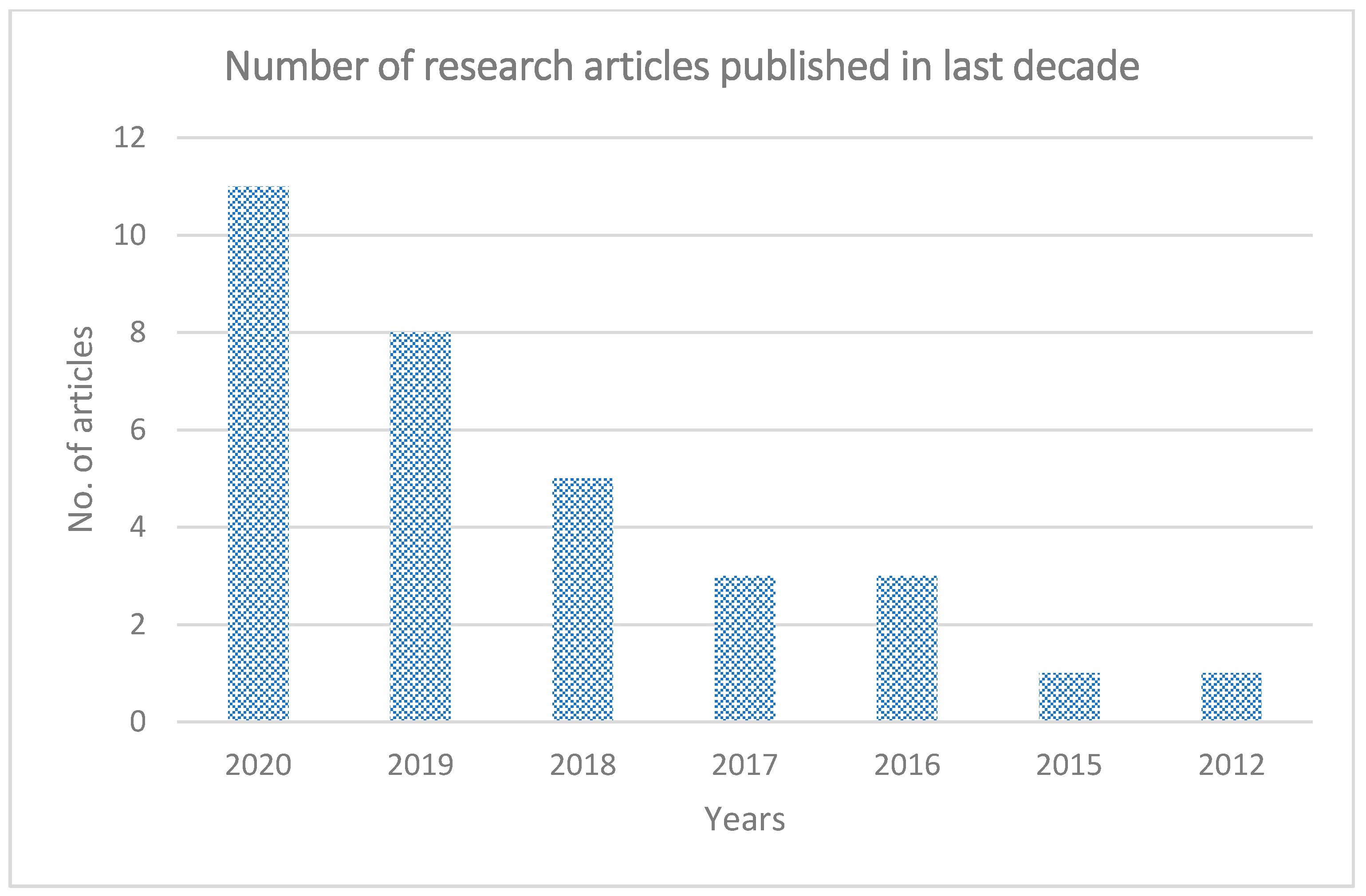

3.1. Publications in Journals

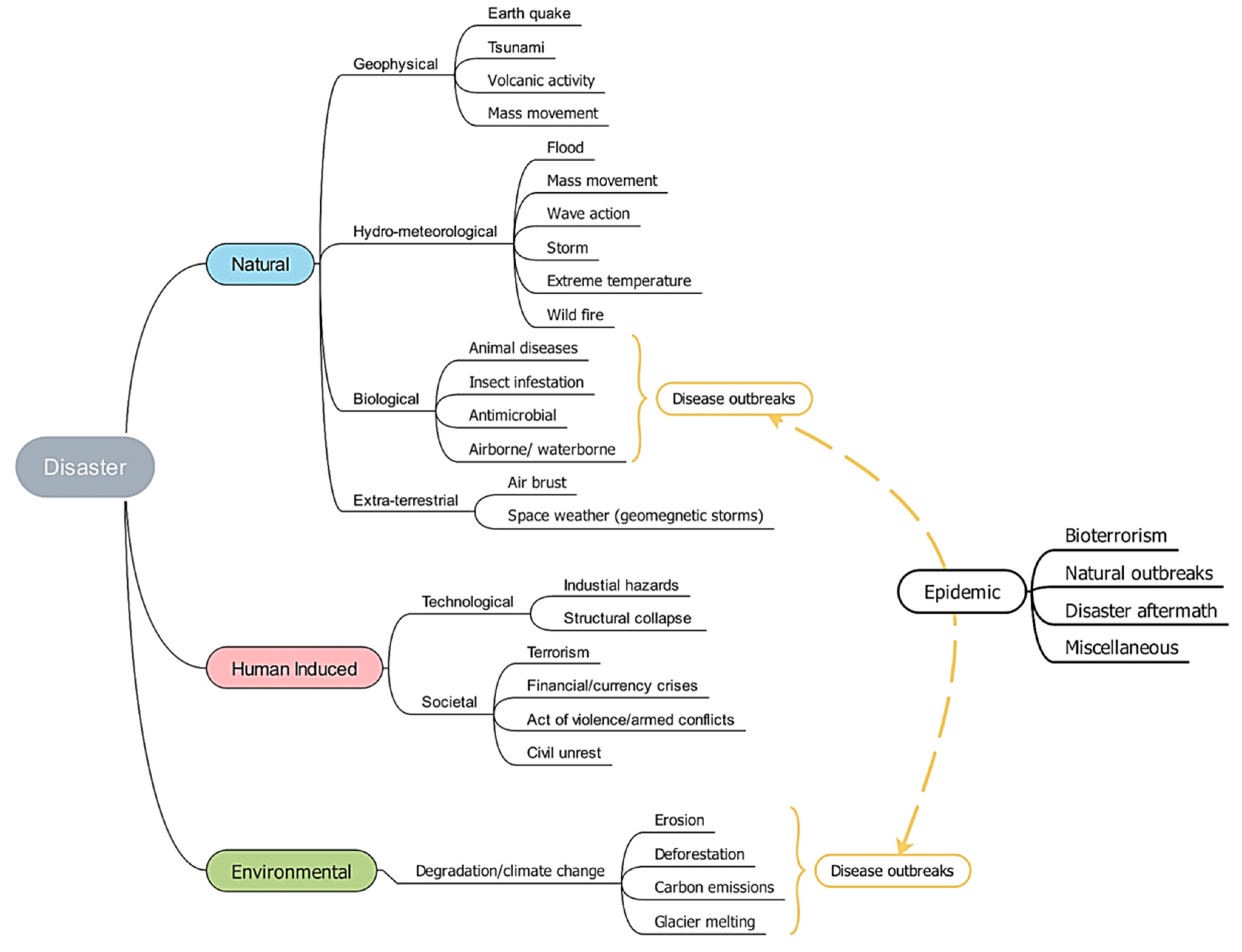

3.2. Categorization of Previous Epidemic/Disease Outbreaks and SC Implications

3.3. Multiple Correspondence Analysis

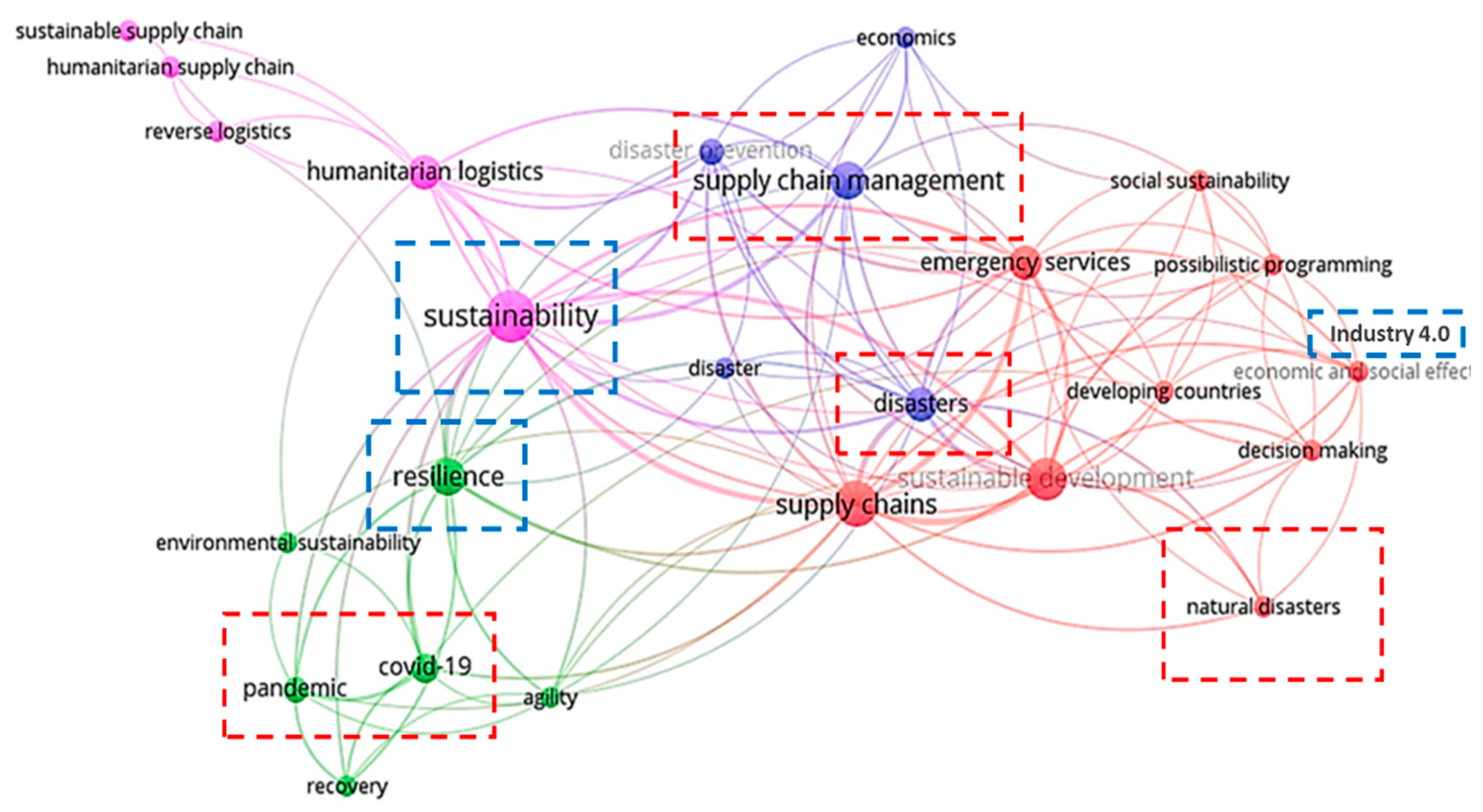

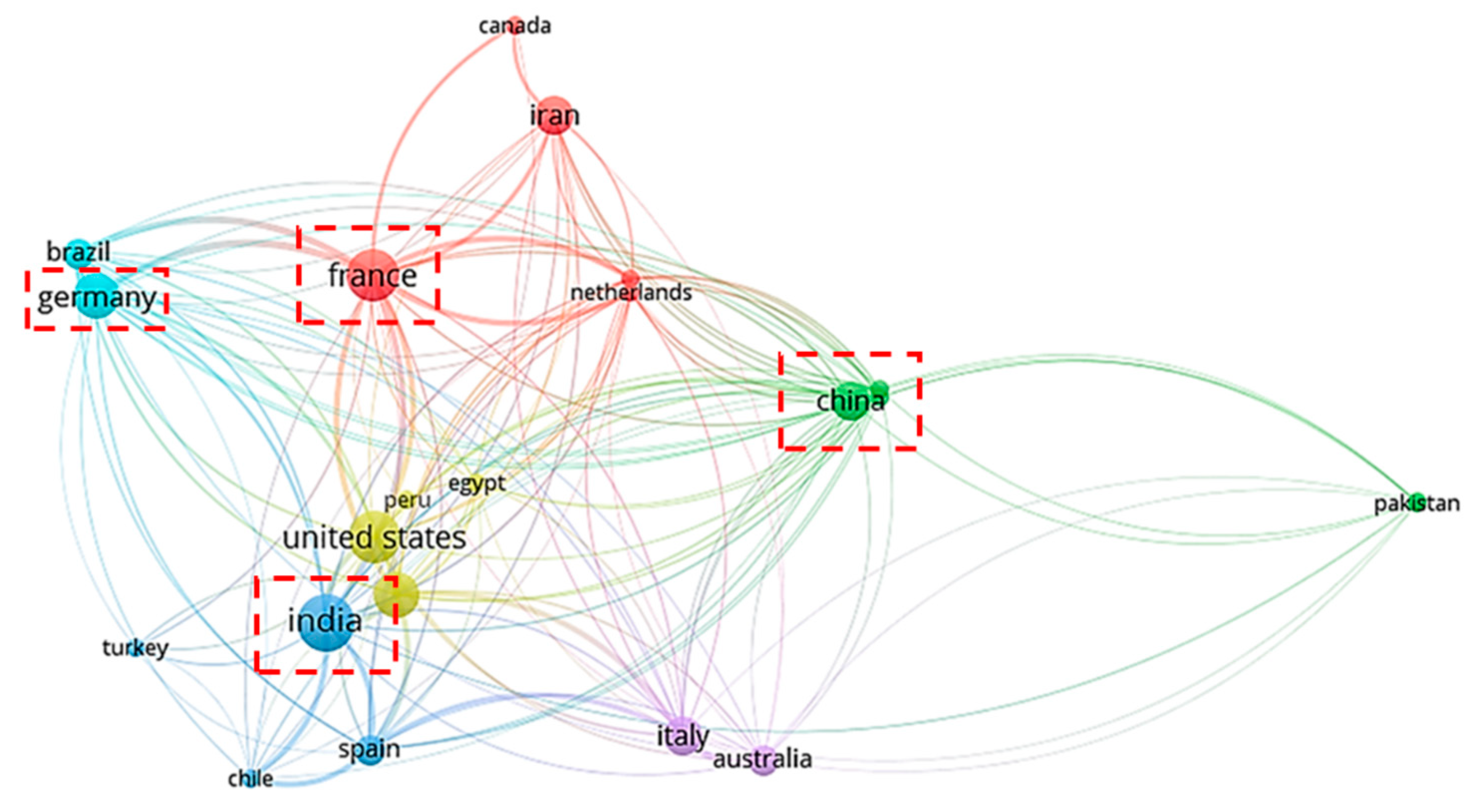

3.4. SC Sustainability and Viability during Disasters/Outbreak Produced Ripple Effects

3.5. Positive Aspects of COVID-19 on Businesses

4. Future Research Avenues

4.1. Sustainability/Survivability Preparedness

4.2. Digital/Industry 4.0 Vigilance

4.3. Resilience/Robustness Readiness

4.4. A Conclusive Insight

Practical Implications for Researchers and Practitioners

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hofmann, H.; Busse, C.; Bode, C.; Henke, M. Sustainability-related supply chain risks: Conceptualization and management. Bus. Strategy Environ. 2014, 23, 160–172. [Google Scholar] [CrossRef]

- Yaghlane, A.B.; Azaiez, M.N. Systems under attack-survivability rather than reliability: Concept, results, and applications. Eur. J. Oper. Res. 2017, 258, 1156–1164. [Google Scholar] [CrossRef]

- Shareef, M.A.; Dwivedi, Y.K.; Mahmud, R.; Wright, A.; Rahman, M.M.; Kizgin, H.; Rana, N.P. Disaster management in Bangladesh: Developing an effective emergency supply chain network. Ann. Oper. Res. 2019, 283, 1463–1487. [Google Scholar] [CrossRef]

- Yu, K.D.S.; Aviso, K.B. Modelling the economic impact and ripple effects of disease outbreaks. Process Integr. Optim. Sustain. 2020, 4, 183–186. [Google Scholar] [CrossRef]

- Ivanov, D. Predicting the impacts of epidemic outbreaks on global supply chains: A simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transp. Res. Part E Logist. Transp. Rev. 2020, 136, 101922. [Google Scholar] [CrossRef]

- Mobula, L.M.; Samaha, H.; Yao, M.; Gueye, A.S.; Diallo, B.; Umutoni, C.; Anoko, J.; Lokonga, J.-P.; Minikulu, L.; Mossoko, M. Recommendations for the COVID-19 Response at the National Level Based on Lessons Learned from the Ebola Virus Disease Outbreak in the Democratic Republic of the Congo. Am. J. Trop. Med. Hyg. 2020, 103, 12–17. [Google Scholar] [CrossRef]

- Olu, O.O.; Lako, R.; Wamala, J.F.; Ramadan, P.O.; Ryan, C.; Udenweze, I.; Berta, K.; Guyo, A.G.; Sokemawu, A.; Tukuru, M. What did we learn from preparing for cross-border transmission of Ebola virus disease into a complex humanitarian setting–The Republic of South Sudan? Infect. Dis. Poverty 2020, 9, 1–7. [Google Scholar] [CrossRef]

- Fernandes, N. Economic Effects of Coronavirus Outbreak (COVID-19) on the World Economy. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3557504 (accessed on 23 February 2021).

- Habib, M.S.; Sarkar, B.; Tayyab, M.; Saleem, M.W.; Hussain, A.; Ullah, M.; Omair, M.; Iqbal, M.W. Large-scale disaster waste management under uncertain environment. J. Clean. Prod. 2019, 212, 200–222. [Google Scholar] [CrossRef]

- WHO | Disasters and Emergencies. Available online: http://www.who.int/surgery/challenges/esc_disasters_emergencies/en/ (accessed on 5 July 2020).

- Mari, S.I.; Lee, Y.H.; Memon, M.S. Sustainable and resilient supply chain network design under disruption risks. Sustainability 2014, 6, 6666–6686. [Google Scholar] [CrossRef]

- Smith, K.F.; Goldberg, M.; Rosenthal, S.; Carlson, L.; Chen, J.; Chen, C.; Ramachandran, S. Global rise in human infectious disease outbreaks. J. R. Soc. Interface 2014, 11, 20140950. [Google Scholar] [CrossRef]

- Sarkis, J.; Cohen, M.J.; Dewick, P.; Schröder, P. A brave new world: Lessons from the COVID-19 pandemic for transitioning to sustainable supply and production. Resour. Conserv. Recycl. 2020, 159, 104894. [Google Scholar] [CrossRef]

- WHO Coronavirus Disease (COVID-19) Outbreak Situation. Available online: https://www.who.int/emergencies/diseases/novel-coronavirus-2019 (accessed on 24 June 2020).

- WHO Director-General’s Opening Remarks at the Media Briefing on COVID-19—11 March 2020. Available online: https://www.who.int/dg/speeches/detail/who-director-general-s-opening-remarks-at-the-media-briefing-on-covid-19---11-march-2020 (accessed on 24 June 2020).

- Cheema-Fox, A.; LaPerla, B.R.; Serafeim, G.; Wang, H.S. Corporate Resilience and Response during COVID-19. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3578167 (accessed on 23 February 2021).

- Gehrie, E.A.; Frank, S.M.; Goobie, S.M. Balancing supply and demand for blood during the COVID-19 pandemic. Anesthesiology 2020, 133, 16–18. [Google Scholar] [CrossRef]

- Govindan, K.; Mina, H.; Alavi, B. A decision support system for demand management in healthcare supply chains considering the epidemic outbreaks: A case study of coronavirus disease 2019 (COVID-19). Transp. Res. Part E Logist. Transp. Rev. 2020, 138, 101967. [Google Scholar] [CrossRef]

- Hobbs, J.E. Food supply chains during the COVID-19 pandemic. Can. J. Agric. Econ. Rev. Can. Agroecon. 2020, 68, 171–176. [Google Scholar] [CrossRef]

- International Journal of Production Research IJPR SI: Production of Healthcare under Epidemic Outbreaks. Available online: https://www.journalconferencejob.com/production-healthcare-epidemic (accessed on 24 June 2020).

- International Journal of Production Research IJPR SI: Viability of Supply Networks & Ecosystems: Lessons Learned from COVID19. Available online: https://www.journalconferencejob.com/viability-supply-networks-ecosystem (accessed on 24 June 2020).

- Ivanov, D. Viable supply chain model: Integrating agility, resilience and sustainability perspectives—Lessons from and thinking beyond the COVID-19 pandemic. Ann. Oper. Res. 2020, 1–21. [Google Scholar] [CrossRef]

- Ivanov, D.; Das, A. Coronavirus (COVID-19/SARS-CoV-2) and supply chain resilience: A research note. Int. J. Integr. Supply Manag. 2020, 13, 90–102. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef]

- Journal of Operations Management Special Issue of the Journal of Operations Management—The Effects of COVID-19 on Global Supply Chains: Responsiveness, Resilience, and Restoration (3Rs). Available online: https://onlinelibrary.wiley.com/pb-assets/assets/18731317/JOMCFP-COVID-19andglobalsupplychains-1585601180383.pdf (accessed on 24 June 2020).

- Park, C.-Y.; Kim, K.; Roth, S. Global Shortage of Personal Protective Equipment Amid COVID-19: Supply Chains, Bottlenecks, and Policy Implications; Asian Development Bank: Mandaluyong, Philippines, 2020. [Google Scholar]

- Medel, K.; Kousar, R.; Masood, T. A Collaboration–Resilience Framework for Disaster Management Supply Networks: A Case Study of the Philippines. J. Humanit. Logist. Supply Chain Manag. 2020, 10, 509–553. [Google Scholar] [CrossRef]

- Masood, T.; So, E.; McFarlane, D. Disaster Management Operations–Big Data Analytics to Resilient Supply Networks. Available online: http://euroma2017.eiasm.org/userfiles/HKJGLML_GDFJMK_AW7YG3VT.pdf (accessed on 24 February 2021).

- Business Insider Coronavirus Business & Economy Impact News | Business Insider. Available online: https://www.businessinsider.com/coronavirus-business-impact (accessed on 25 June 2020).

- Forbes the COVID-19 Problems That will Force Manufacturing to Innovate. Available online: https://www.forbes.com/sites/annashedletsky/2020/05/05/the-covid-19-problems-that-will-force-manufacturing-to-innovate/#7fd49c9230d0 (accessed on 25 June 2020).

- Fortune How Global 500 Companies are Responding to COVID-19. Available online: https://fortune.com/2020/04/13/global-500-companies-coronavirus-response-covid-19-pandemic/ (accessed on 25 June 2020).

- Harvard Business Review How to Manage Coronavirus Layoffs with Compassion. Available online: https://hbr.org/2020/04/how-to-manage-coronavirus-layoffs-with-compassion?ab=hero-main-text (accessed on 25 June 2020).

- Alicke, K.; Azcue, X.; Barriball, E. Supply-Chain Recovery in Coronavirus Times—Plan for Now and the Future. 2020. Available online: https://www.mckinsey.com/business-functions/operations/our-insights/supply-chain-recovery-in-coronavirus-times-plan-for-now-and-the-future (accessed on 25 June 2020).

- Fortune 94% of the Fortune 1000 are Seeing Coronavirus Supply Chain Disruptions. Available online: https://fortune.com/2020/02/21/fortune-1000-coronavirus-china-supply-chain-impact/ (accessed on 2 July 2020).

- Agyepong, L.A. A systems view and lessons from the ongoing Ebola Virus Disease (EVD) outbreak in West Africa. Ghana Med. J. 2014, 48, 168–172. [Google Scholar] [CrossRef] [PubMed]

- Scarpino, S.V.; Petri, G. On the predictability of infectious disease outbreaks. Nat. Commun. 2019, 10, 898. [Google Scholar] [CrossRef]

- Anparasan, A.A.; Lejeune, M.A. Data laboratory for supply chain response models during epidemic outbreaks. Ann. Oper. Res. 2018, 270, 53–64. [Google Scholar] [CrossRef]

- Preciado, V.M.; Zargham, M.; Enyioha, C.; Jadbabaie, A.; Pappas, G. Optimal vaccine allocation to control epidemic outbreaks in arbitrary networks. In Proceedings of the 52nd IEEE Conference on Decision and Control, Firenze, Italy, 10–13 December 2013; pp. 7486–7491. [Google Scholar]

- Dasaklis, T.K.; Pappis, C.P.; Rachaniotis, N.P. Epidemics control and logistics operations: A review. Int. J. Prod. Econ. 2012, 139, 393–410. [Google Scholar] [CrossRef]

- Duijzer, L.E.; van Jaarsveld, W.; Dekker, R. Literature review: The vaccine supply chain. Eur. J. Oper. Res. 2018, 268, 174–192. [Google Scholar] [CrossRef]

- Kumar, S.; Havey, T. Before and after disaster strikes: A relief supply chain decision support framework. Int. J. Prod. Econ. 2013, 145, 613–629. [Google Scholar] [CrossRef]

- Pastor-Satorras, R.; Castellano, C.; Van Mieghem, P.; Vespignani, A. Epidemic processes in complex networks. Rev. Mod. Phys. 2015, 87, 925. [Google Scholar] [CrossRef]

- Dolgui, A.; Ivanov, D.; Sokolov, B. Reconfigurable supply chain: The X-network. Int. J. Prod. Res. 2020, 58, 4138–4163. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod. Plan. Control 2020, 1–14. [Google Scholar] [CrossRef]

- Broekhuizen, T.L.J.; Broekhuis, M.; Gijsenberg, M.J.; Wieringa, J.E. Introduction to the Special Issue—Digital Business Models: A Multi-Disciplinary and Multi-Stakeholder Perspective; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the definition of industry 4.0: Analysis and open questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Ivanov, D.; Dolgui, A.; Wamba, S.F. Impacts of epidemic outbreaks on supply chains: Mapping a research agenda amid the COVID-19 pandemic through a structured literature review. Ann. Oper. Res. 2020, 1–38. [Google Scholar] [CrossRef]

- WEF. The Ongoing Impact of COVID-19 on Global Supply Chains | World Economic Forum. Available online: https://www.weforum.org/agenda/2020/06/ongoing-impact-covid-19-global-supply-chains/ (accessed on 13 July 2020).

- Durach, C.F.; Kembro, J.; Wieland, A. A new paradigm for systematic literature reviews in supply chain management. J. Supply Chain Manag. 2017, 53, 67–85. [Google Scholar] [CrossRef]

- Habib, M.S.; Lee, Y.H.; Memon, M.S. Mathematical models in humanitarian supply chain management: A systematic literature review. Math. Probl. Eng. 2016, 3212095. [Google Scholar] [CrossRef]

- Tachizawa, E.M.; Wong, C.Y. Towards a theory of multi-tier sustainable supply chains: A systematic literature review. Supply Chain Manag. Int. J. 2014, 19, 643–663. [Google Scholar] [CrossRef]

- Wilding, R.; Wagner, B.; Colicchia, C.; Strozzi, F. Supply chain risk management: A new methodology for a systematic literature review. Supply Chain Manag. Int. J. 2012. [Google Scholar]

- de Oliveira, F.N.; Leiras, A.; Ceryno, P. Environmental risk management in supply chains: A taxonomy, a framework and future research avenues. J. Clean. Prod. 2019, 232, 1257–1271. [Google Scholar] [CrossRef]

- de Campos, E.A.R.; de Paula, I.C.; Pagani, R.N.; Guarnieri, P. Reverse logistics for the end-of-life and end-of-use products in the pharmaceutical industry: A systematic literature review. Supply Chain Manag. Int. J. 2017, 22, 375–392. [Google Scholar] [CrossRef]

- van Eck, N.J.; Waltman, L. How to normalize cooccurrence data? An analysis of some well-known similarity measures. J. Am. Soc. Inf. Sci. Technol. 2009, 60, 1635–1651. [Google Scholar]

- Rachaniotis, N.P.; Dasaklis, T.K.; Pappis, C.P. A deterministic resource scheduling model in epidemic control: A case study. Eur. J. Oper. Res. 2012, 216, 225–231. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, D. A dynamic logistics model for medical resources allocation in an epidemic control with demand forecast updating. J. Oper. Res. Soc. 2016, 67, 841–852. [Google Scholar] [CrossRef]

- Mamani, H.; Chick, S.E.; Simchi-Levi, D. A game-theoretic model of international influenza vaccination coordination. Manag. Sci. 2013, 59, 1650–1670. [Google Scholar] [CrossRef]

- Majić, Z.; Jukić, I.; Pavlin, S. Air transport and logistics in pandemic outbreak of influenza A (H1N1) virus. Promet-Traffic Transp. 2009, 21, 441–450. [Google Scholar] [CrossRef]

- Savachkin, A.; Uribe, A. Dynamic redistribution of mitigation resources during influenza pandemics. Socio-Econ. Plan. Sci. 2012, 46, 33–45. [Google Scholar] [CrossRef]

- Liu, M.; Xu, X.; Cao, J.; Zhang, D. Integrated planning for public health emergencies: A modified model for controlling H1N1 pandemic. J. Oper. Res. Soc. 2020, 71, 748–761. [Google Scholar] [CrossRef]

- Khokhar, S.G.; Min, Q.; Su, C. Bird flu (H7N9) outbreak and its implications on the supply chain of poultry meat in China. J. Appl. Poult. Res. 2015, 24, 215–221. [Google Scholar] [CrossRef]

- Hessel, L.; European Vaccine Manufacturers (EVM) Influenza Working Group. Pandemic influenza vaccines: Meeting the supply, distribution and deployment challenges. Influenza Respir. Viruses 2009, 3, 165–170. [Google Scholar] [CrossRef] [PubMed]

- Orenstein, W.A.; Schaffner, W. Lessons learned: Role of influenza vaccine production, distribution, supply, and demand—what it means for the provider. Am. J. Med. 2008, 121, S22–S27. [Google Scholar] [CrossRef] [PubMed]

- Chick, S.E.; Mamani, H.; Simchi-Levi, D. Supply chain coordination and influenza vaccination. Oper. Res. 2008, 56, 1493–1506. [Google Scholar] [CrossRef]

- Cruz, M.A.; Hawk, N.M.; Poulet, C.; Rovira, J.; Rouse, E.N. Public health incident management: Logistical and operational aspects of the 2009 initial outbreak of H1N1 influenza in Mexico. J. Emerg. Manag. 2015, 13, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Ekici, A.; Keskinocak, P.; Swann, J.L. Modeling influenza pandemic and planning food distribution. Manuf. Serv. Oper. Manag. 2014, 16, 11–27. [Google Scholar] [CrossRef]

- Sun, L.; DePuy, G.W.; Evans, G.W. Multi-objective optimization models for patient allocation during a pandemic influenza outbreak. Comput. Oper. Res. 2014, 51, 350–359. [Google Scholar] [CrossRef]

- Enayati, S.; Özaltın, O.Y. Optimal influenza vaccine distribution with equity. Eur. J. Oper. Res. 2020, 283, 714–725. [Google Scholar] [CrossRef]

- Büyüktahtakın, İ.E.; des-Bordes, E.; Kıbış, E.Y. A new epidemics–logistics model: Insights into controlling the Ebola virus disease in West Africa. Eur. J. Oper. Res. 2018, 265, 1046–1063. [Google Scholar] [CrossRef]

- Bogoch, I.I.; Creatore, M.I.; Cetron, M.S.; Brownstein, J.S.; Pesik, N.; Miniota, J.; Tam, T.; Hu, W.; Nicolucci, A.; Ahmed, S. Assessment of the potential for international dissemination of Ebola virus via commercial air travel during the 2014 west African outbreak. Lancet 2015, 385, 29–35. [Google Scholar] [CrossRef]

- Long, E.F.; Nohdurft, E.; Spinler, S. Spatial resource allocation for emerging epidemics: A comparison of greedy, myopic, and dynamic policies. Manuf. Serv. Oper. Manag. 2018, 20, 181–198. [Google Scholar] [CrossRef]

- Anparasan, A.; Lejeune, M. Resource deployment and donation allocation for epidemic outbreaks. Ann. Oper. Res. 2019, 283, 9–32. [Google Scholar] [CrossRef]

- Muggy, L.; Stamm, J.L.H. Decentralized beneficiary behavior in humanitarian supply chains: Models, performance bounds, and coordination mechanisms. Ann. Oper. Res. 2020, 284, 333–365. [Google Scholar] [CrossRef]

- Anparasan, A.; Lejeune, M. Analyzing the response to epidemics: Concept of evidence-based Haddon matrix. J. Humanit. Logist. Supply Chain Manag. 2017, 7, 266–283. [Google Scholar] [CrossRef]

- Parvin, H.; Beygi, S.; Helm, J.E.; Larson, P.S.; Van Oyen, M.P. Distribution of medication considering information, transshipment, and clustering: Malaria in Malawi. Prod. Oper. Manag. 2018, 27, 774–797. [Google Scholar] [CrossRef]

- Dasaklis, T.K.; Rachaniotis, N.; Pappis, C. Emergency supply chain management for controlling a smallpox outbreak: The case for regional mass vaccination. Int. J. Syst. Sci. Oper. Logist. 2017, 4, 27–40. [Google Scholar] [CrossRef]

- Paul, S.; Venkateswaran, J. Designing robust policies under deep uncertainty for mitigating epidemics. Comput. Ind. Eng. 2020, 140, 106221. [Google Scholar] [CrossRef]

- Wang, H.; Wang, X.; Zeng, A.Z. Optimal material distribution decisions based on epidemic diffusion rule and stochastic latent period for emergency rescue. Int. J. Math. Oper. Res. 2009, 1, 76–96. [Google Scholar] [CrossRef]

- Einav, S.; Hick, J.L.; Hanfling, D.; Erstad, B.L.; Toner, E.S.; Branson, R.D.; Kanter, R.K.; Kissoon, N.; Dichter, J.R.; Devereaux, A.V. Surge capacity logistics: Care of the critically ill and injured during pandemics and disasters: CHEST consensus statement. Chest 2014, 146, e17S–e43S. [Google Scholar] [CrossRef] [PubMed]

- Bóta, A.; Gardner, L.M.; Khani, A. Identifying critical components of a public transit system for outbreak control. Netw. Spat. Econ. 2017, 17, 1137–1159. [Google Scholar] [CrossRef]

- Tao, Y.; Shea, K.; Ferrari, M. Logistical constraints lead to an intermediate optimum in outbreak response vaccination. PLoS Comput. Boil. 2018, 14, e1006161. [Google Scholar] [CrossRef]

- Shamsi G., N.; Ali Torabi, S.; Shakouri G., H. An option contract for vaccine procurement using the SIR epidemic model. Eur. J. Oper. Res. 2018, 267, 1122–1140. [Google Scholar] [CrossRef]

- Habib, M.S.; Asghar, O.; Hussain, A.; Imran, M.; Mughal, M.P.; Sarkar, B. A robust possibilistic programming approach toward animal fat-based biodiesel supply chain network design under uncertain environment. J. Clean. Prod. 2021, 278, 122403. [Google Scholar] [CrossRef]

- Habib, M.S.; Sarkar, B. A multi-objective approach to sustainable disaster waste management. Proc. Int. Conf. Ind. Eng. Oper. Manag. 2018, 2018, 1072–1083. [Google Scholar]

- Habib, M.S.; Lee, Y.H.; Memon, S. Mathematical Models and Information Systems in Humanitarian Supply Chain Management: A Systematic Literature Review. 2015. Available online: https://www.dbpia.co.kr/Journal/articleDetail?nodeId=NODE06561326 (accessed on 24 February 2021).

- van Barneveld, K.; Quinlan, M.; Kriesler, P.; Junor, A.; Baum, F.; Chowdhury, A.; Junankar, P.N.; Clibborn, S.; Flanagan, F.; Wright, C.F. The COVID-19 pandemic: Lessons on building more equal and sustainable societies. Econ. Labour Relat. Rev. 2020, 31, 133–157. [Google Scholar] [CrossRef]

- Trautrims, A.; Schleper, M.C.; Cakir, M.S.; Gold, S. Survival at the expense of the weakest? Managing modern slavery risks in supply chains during COVID-19. J. Risk Res. 2020, 23, 1067–1072. [Google Scholar] [CrossRef]

- Yazdani, M.; Gonzalez, E.D.; Chatterjee, P. A multi-criteria decision-making framework for agriculture supply chain risk management under a circular economy context. Manag. Decis. 2019. [Google Scholar] [CrossRef]

- Cao, C.; Li, C.; Yang, Q.; Liu, Y.; Qu, T. A novel multi-objective programming model of relief distribution for sustainable disaster supply chain in large-scale natural disasters. J. Clean. Prod. 2018, 174, 1422–1435. [Google Scholar] [CrossRef]

- Ibrahim, S.E.; El Ebrashi, R. How social entrepreneurship can be useful in long-term recovery following disasters. J. Humanit. Logist. Supply Chain Manag. 2017. [Google Scholar] [CrossRef]

- Yadav, D.K.; Barve, A. Modeling post-disaster challenges of humanitarian supply chains: A TISM approach. Glob. J. Flex. Syst. Manag. 2016, 17, 321–340. [Google Scholar] [CrossRef]

- Zhang, F.; Wu, X.; Tang, C.S.; Feng, T.; Dai, Y. Evolution of Operations Management Research: From Managing Flows to Building Capabilities. Prod. Oper. Manag. 2020, 29, 2219–2229. [Google Scholar] [CrossRef]

- Quayson, M.; Bai, C.; Osei, V. Digital Inclusion for Resilient Post-COVID-19 Supply Chains: Smallholder Farmer Perspectives. IEEE Eng. Manag. Rev. 2020, 48, 104–110. [Google Scholar] [CrossRef]

- Mishra, S.; Singh, S.P. A stochastic disaster-resilient and sustainable reverse logistics model in big data environment. Ann. Oper. Res. 2020, 1–32. [Google Scholar] [CrossRef]

- Kaur, H. Modelling internet of things driven sustainable food security system. Benchmarking Int. J. 2019. [Google Scholar] [CrossRef]

- Papadopoulos, T.; Gunasekaran, A.; Dubey, R.; Altay, N.; Childe, S.J.; Fosso-Wamba, S. The role of Big Data in explaining disaster resilience in supply chains for sustainability. J. Clean. Prod. 2017, 142, 1108–1118. [Google Scholar] [CrossRef]

- Boostani, A.; Jolai, F.; Bozorgi-Amiri, A. Designing a sustainable humanitarian relief logistics model in pre- and postdisaster management. Int. J. Sustain. Transp. 2020, 1–17. [Google Scholar] [CrossRef]

- Zarei, M.H.; Carrasco-Gallego, R.; Ronchi, S. To Greener Pastures: An Action Research Study on the Environmental Sustainability of Humanitarian Supply Chains. Int. J. Oper. Prod. Manag. 2019, 39, 1193–1225. [Google Scholar] [CrossRef]

- Laguna-Salvadó, L.; Lauras, M.; Okongwu, U.; Comes, T. A multicriteria Master Planning DSS for a sustainable humanitarian supply chain. Ann. Oper. Res. 2019, 283, 1303–1343. [Google Scholar] [CrossRef]

- Andalib Ardakani, D.; Soltanmohammadi, A. Investigating and analysing the factors affecting the development of sustainable supply chain model in the industrial sectors. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 199–212. [Google Scholar] [CrossRef]

- Silva, M.E.; Pereira, S.C.; Gold, S. The response of the Brazilian cashew nut supply chain to natural disasters: A practice-based view. J. Clean. Prod. 2018, 204, 660–671. [Google Scholar] [CrossRef]

- Eskandari-Khanghahi, M.; Tavakkoli-Moghaddam, R.; Taleizadeh, A.A.; Amin, S.H. Designing and optimizing a sustainable supply chain network for a blood platelet bank under uncertainty. Eng. Appl. Artif. Intell. 2018, 71, 236–250. [Google Scholar] [CrossRef]

- Peretti, U.; Tatham, P.; Wu, Y.; Sgarbossa, F. Reverse logistics in humanitarian operations: Challenges and opportunities. J. Humanit. Logist. Supply Chain Manag. 2015, 5, 253–274. [Google Scholar] [CrossRef]

- Rabenasolo, B.; Zeng, X. A Risk-Based Multi-criteria Decision Support System for Sustainable Development in the Textile Supply Chain. In Handbook on Decision Making: Vol 2: Risk Management in Decision Making; Lu, J., Jain, L.C., Zhang, G., Eds.; Intelligent Systems Reference Library; Springer: Berlin/Heidelberg, Germany, 2012; pp. 151–170. ISBN 978-3-642-25755-1. [Google Scholar]

- Ivanov, D. Revealing interfaces of supply chain resilience and sustainability: A simulation study. Int. J. Prod. Res. 2018, 56, 3507–3523. [Google Scholar] [CrossRef]

- Ivanov, D.; Das, A.; Choi, T.-M. New Flexibility Drivers for Manufacturing, Supply Chain and Service Operations; Taylor & Francis: Abingdon, UK, 2018. [Google Scholar]

- Kayikci, Y. Stream processing data decision model for higher environmental performance and resilience in sustainable logistics infrastructure. J. Enterp. Inf. Manag. 2020, 34, 140–167. [Google Scholar] [CrossRef]

- Kaur, H.; Singh, S.P. Sustainable procurement and logistics for disaster resilient supply chain. Ann. Oper. Res. 2019, 283, 309–354. [Google Scholar] [CrossRef]

- Das, K. Integrating Lean, Green, and Resilience Criteria in a Sustainable Food Supply Chain Planning Model. Int. J. Math. Eng. Manag. Sci. 2019, 4, 259–275. [Google Scholar] [CrossRef]

- Kunz, N.; Gold, S. Sustainable humanitarian supply chain management—Exploring new theory. Int. J. Logist. Res. Appl. 2017, 20, 85–104. [Google Scholar] [CrossRef]

- Connelly, E.B.; Lambert, J.H.; Thekdi, S.A. Robust investments in humanitarian logistics and supply chains for disaster resilience and sustainable communities. Nat. Hazards Rev. 2016, 17, 04015017. [Google Scholar] [CrossRef]

- Vargas, J.; González, D. Model to assess supply chain resilience. Int. J. Saf. Secur. Eng. 2016, 6, 282–292. [Google Scholar] [CrossRef][Green Version]

- Forbes Which Companies Did Well During The Coronavirus Pandemic? Available online: https://www.forbes.com/sites/rohitarora/2020/06/30/which-companies-did-well-during-the-coronavirus-pandemic/ (accessed on 9 February 2021).

- Forbes How COVID-19 Is Transforming E-Commerce? Available online: https://www.forbes.com/sites/louiscolum-bus/2020/04/28/how-covid-19-is-transforming-e-commerce/ (accessed on 9 February 2021).

- Beltagui, A.; Kunz, N.; Gold, S. The role of 3D printing and open design on adoption of socially sustainable supply chain innovation. Int. J. Prod. Econ. 2020, 221, 107462. [Google Scholar] [CrossRef]

- Wahl, B.; Cossy-Gantner, A.; Germann, S.; Schwalbe, N.R. Artificial intelligence (AI) and global health: How can AI contribute to health in resource-poor settings? BMJ Glob. Health 2018, 3, e000798. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Vaishya, R.; Bahl, S.; Suman, R.; Vaish, A. Industry 4.0 technologies and their applications in fighting COVID-19 pandemic. Diabetes Metab. Syndr. Clin. Res. Rev. 2020, 14, 419–422. [Google Scholar] [CrossRef]

- Mughal, M.P.; Farooq, M.U.; Mumtaz, J.; Mia, M.; Shareef, M.; Javed, M.; Jamil, M.; Pruncu, C.I. Surface Modification for Osseointegration of Ti6Al4V ELI Using Powder Mixed Sinking EDM. J. Mech. Behav. Biomed. Mater. 2021, 113, 104145. [Google Scholar] [CrossRef] [PubMed]

- Umar Farooq, M.; Pervez Mughal, M.; Ahmed, N.; Ahmad Mufti, N.; Al-Ahmari, M.A.; He, Y. On the Investigation of Surface Integrity of Ti6Al4V ELI Using Si-Mixed Electric Discharge Machining. Mater. 2020, 13, 1549. [Google Scholar] [CrossRef] [PubMed]

- Farooq, M.U.; Ali, M.A.; He, Y.; Khan, A.M.; Pruncu, C.I.; Kashif, M.; Ahmed, N.; Asif, N. Curved Profiles Machining of Ti6Al4V Alloy through WEDM: Investigations on Geometrical Errors. J. Mater. Res. Technol. 2020, 9, 16186–16201. [Google Scholar] [CrossRef]

- Shepard, W. COVID-19 Undermines China’s Run as the World’s Factory, but Beijing has a Plan. Available online: https://www.forbes.com/sites/wadeshepard/2020/03/26/covid-19-undermines-chinas-run-as-the-worlds-factory-but-beijing-has-a-plan/ (accessed on 28 July 2020).

- Settanni, E. Those who do not move, do not notice their (supply) chains—Inconvenient lessons from disruptions related to COVID-19. Ai Soc. 2020, 35, 1065–1071. [Google Scholar] [CrossRef]

- Liu, Y.; Lee, J.M.; Lee, C. The challenges and opportunities of a global health crisis: The management and business implications of COVID-19 from an Asian perspective. Asian Bus. Manag. 2020, 19, 277–297. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Bryde, D.J.; Dwivedi, Y.K.; Papadopoulos, T. Blockchain technology for enhancing swift-trust, collaboration and resilience within a humanitarian supply chain setting. Int. J. Prod. Res. 2020, 58, 3381–3398. [Google Scholar] [CrossRef]

- Bag, S.; Wood, L.C.; Mangla, S.K.; Luthra, S. Procurement 4.0 and its implications on business process performance in a circular economy. Resour. Conserv. Recycl. 2020, 152, 104502. [Google Scholar] [CrossRef]

- Malik, A.A.; Masood, T.; Kousar, R. Repurposing factories with robotics in the face of COVID-19. Sci. Robot. 2020, 5, eabc2782. [Google Scholar] [CrossRef]

- Attaran, M. 3D Printing Role in Filling the Critical Gap in the Medical Supply Chain during COVID-19 Pandemic. Am. J. Ind. Bus. Manag. 2020, 10, 988. [Google Scholar] [CrossRef]

- Paul, S.K.; Sarker, R.; Essam, D.; Lee, P.T.-W. A mathematical modelling approach for managing sudden disturbances in a three-tier manufacturing supply chain. Ann. Oper. Res. 2019, 280, 299–335. [Google Scholar] [CrossRef]

- Currie, C.S.; Fowler, J.W.; Kotiadis, K.; Monks, T.; Onggo, B.S.; Robertson, D.A.; Tako, A.A. How simulation modelling can help reduce the impact of COVID-19. J. Simul. 2020, 14, 83–97. [Google Scholar] [CrossRef]

- Pavlov, A.; Ivanov, D.; Werner, F.; Dolgui, A.; Sokolov, B. Integrated detection of disruption scenarios, the ripple effect dispersal and recovery paths in supply chains. Ann. Oper. Res. 2019, 1–23. [Google Scholar] [CrossRef]

- Besiou, M.; Van Wassenhove, L.N. Humanitarian operations: A world of opportunity for relevant and impactful research. Manuf. Serv. Oper. Manag. 2020, 22, 135–145. [Google Scholar] [CrossRef]

- Dubey, R.; Altay, N.; Blome, C. Swift trust and commitment: The missing links for humanitarian supply chain coordination? Ann. Oper. Res. 2019, 283, 159–177. [Google Scholar] [CrossRef]

- Hosseini, S.; Ivanov, D.; Dolgui, A. Review of quantitative methods for supply chain resilience analysis. Transp. Res. Part E Logist. Transp. Rev. 2019, 125, 285–307. [Google Scholar] [CrossRef]

- Hosseini, S.; Ivanov, D. Resilience assessment of supply networks with disruption propagation considerations: A Bayesian network approach. Ann. Oper. Res. 2019. [Google Scholar] [CrossRef]

- Choi, T.-M. Innovative “Bring-Service-Near-Your-Home” Operations under Corona-Virus (COVID-19/SARS-CoV-2) Outbreak: Can Logistics Become the Messiah? Transp. Res. Part E Logist. Transp. Rev. 2020, 140, 101961. [Google Scholar] [CrossRef] [PubMed]

- Dolgui, A.; Ivanov, D.; Rozhkov, M. Does the ripple effect influence the bullwhip effect? An integrated analysis of structural and operational dynamics in the supply chain. Int. J. Prod. Res. 2020, 58, 1285–1301. [Google Scholar] [CrossRef]

- Dolgui, A.; Ivanov, D.; Potryasaev, S.; Sokolov, B.; Ivanova, M.; Werner, F. Blockchain-oriented dynamic modelling of smart contract design and execution in the supply chain. Int. J. Prod. Res. 2020, 58, 2184–2199. [Google Scholar] [CrossRef]

- Reuters. Boeing to Cut 787/777 Production as COVID-19 Hammers Sales. Available online: https://www.reuters.com/article/boeing-results/boeing-to-cut-787-777-production-as-covid-19-hammers-sales-idUKL3N2F03B3 (accessed on 30 July 2020).

- Reuters. COVID-19 Crushes U.S. Economy in Second Quarter; Rising Virus Cases Loom over Recovery. Available online: https://www.reuters.com/article/us-usa-economy-idUSKCN24V0FO (accessed on 30 July 2020).

- Reuters. U.S. Second-Quarter GDP Falls at Steepest Rate since Great Depression. Available online: https://www.reuters.com/article/us-usa-economy-instant-idUSKCN24V2GJ (accessed on 30 July 2020).

- Malik, A.A.; Masood, T.; Kousar, R. Reconfiguring and ramping-up ventilator production in the face of COVID-19: Can robots help? J. Manuf. Syst. 2020, in press. [Google Scholar] [CrossRef]

- Malik, A.A.; Masood, T.; Bilberg, A. Virtual reality in manufacturing: Immersive and collaborative artificial- reality in design of human-robot workspace. Int. J. Comput. Integr. Manuf. 2020, 33, 22–37. [Google Scholar] [CrossRef]

- Elluru, S.; Gupta, H.; Kaur, H.; Singh, S.P. Proactive and reactive models for disaster resilient supply chain. Ann. Oper. Res. 2019, 283, 199–224. [Google Scholar] [CrossRef]

- Masood, T.; Kern, M.; Clarkson, P.J. Characteristics of changeable systems across value chains. Int. J. Prod. Res. 2020. [Google Scholar] [CrossRef]

- Egger, J.; Masood, T. Augmented reality in support of intelligent manufacturing—A systematic literature review. Comput. Ind. Eng. 2020, 140, 106195. [Google Scholar] [CrossRef]

- Masood, T.; Sonntag, P. Industry 4.0: Adoption challenges and benefits for SMEs. Comput. Ind. 2020, 121, 103261. [Google Scholar] [CrossRef]

- Masood, T.; Egger, J. Adopting augmented Reality in the age of Industrial Digitalisation. Comput. Ind. 2020, 115, 103112. [Google Scholar] [CrossRef]

- Masood, T.; Egger, J. Augmented reality in support of Industry 4.0—Implementation challenges and success factors. Robot. Comput. Integr. Manuf. 2019, 58, 181–195. [Google Scholar] [CrossRef]

- Aven, T. How some types of risk assessments can support resilience analysis and management. Reliab. Eng. Syst. Saf. 2017, 167, 536–543. [Google Scholar] [CrossRef]

- Dolgui, A.; Proth, J.-M. Supply Chain Engineering: Useful Methods and Techniques; Springer Science & Business Media: Berlin, Germany, 2010. [Google Scholar]

- Masood, T.; Egger, J.; Kern, M. Future-proofing the through-life engineering service systems. Procedia Manuf. 2018, 16, 179–186. [Google Scholar] [CrossRef]

| Research Protocol | Description | |

|---|---|---|

| Search base plan | Databases | Scopus database |

| Publication type | Peer-reviewed journal articles indexed by Scopus | |

| Language | English | |

| Year range | 2010–2020 (exploring streams of last 10 years) | |

| Directing features | Search terms | Titles, abstracts, keywords |

| Search term in titles, abstracts, keywords | ("Supply chain” OR “operations management” OR “logistics” AND “sustainability” AND “disaster” OR "epidemic" OR "pandemic" OR "outbreak") | |

| ("Supply chain” OR “operations management” OR “logistics” AND “Ripple effect” AND “viability” OR "sustainability") | ||

| Limiting factors | Inclusion criteria | Research articles presented on any disaster, specifically epidemics |

| Exclusion criteria | Research articles with general focus, discussing disasters, outbreaks without the context of supply chain and/or operations management | |

| Analysis | Data extraction, analysis, and synthesis | Supported by VOS viewer to visualize the streams and detailed analysis |

| Sources | Articles |

|---|---|

| Annals of Operations Research | 5 |

| Journal of Cleaner Production | 4 |

| International Journal of Production Research | 3 |

| Journal of Humanitarian Logistics and Supply Chain Management | 2 |

| Transportation Research Part E | 1 |

| Production and Operations Management | 1 |

| International Journal of Operations and Production Management | 1 |

| Management Decision | 1 |

| International Journal of Logistics Research and Applications | 1 |

| International Journal of Mathematical, Engineering and Management Sciences | 1 |

| Engineering Applications of Artificial Intelligence | 1 |

| International Journal of Sustainable Transportation | 1 |

| Global Journal of Flexible Systems Management | 1 |

| Corporate Social Responsibility and Environmental Management | 1 |

| Benchmarking | 1 |

| Journal of Risk Research | 1 |

| IEEE Engineering Management Review | 1 |

| Journal of Enterprise Information Management | 1 |

| Natural Hazards Review | 1 |

| International Journal of Safety and Security Engineering | 1 |

| Intelligent Systems Reference Library | 1 |

| Economic and Labour Relations Review | 1 |

| Ref | Pandemic | Objectives | Problem-Solving Approaches | Developments/Implications |

|---|---|---|---|---|

| [56,57,58,59,60,61,62,63,64,65,66,67,68,69] | Influenza |

|

|

|

| [70,71,72] | Ebola |

|

|

|

| [37,73,74,75] | Cholera |

|

|

|

| [76] | Malaria |

|

|

|

| [77] | Smallpox |

|

|

|

| [5,22,23,24] | COVID-19 |

|

|

|

| [78,79,80,81,82,83,84,85,86] | General epidemic management/control |

|

|

|

| Lines of Research | Ref. | Area of Application | Key Contribution |

|---|---|---|---|

| Sustainability|Survivability | |||

| Examining impacts on the economic and labor market to build sustainable societies | [87] | COVID-19: Humanitarian crises | “Leave no-one behind” agenda is the future, as COVID-19 might be the portal to achieve sustainable development goals more effectively through a greener, ecologically concerned, and sustainable global version. Developed nations are concerned with minimizing the reliance on long transitional supply chains and diversifying the sources of imports, as well as increasing domestic manufacturing capabilities. |

| Operations and supply chain management approaches to support SCs during epidemic outbreaks | [47] | Operations management: Supply chain management | A framework to support SCs in the time of epidemic outbreaks based on digitalization of processes, systems and structures, preparedness and recovery against ripple effects under the sustainable capabilities development goal was proposed. |

| Sustainable humanitarian relief logistics in different stages of disaster | [98] | Operations management | A relief logistics network model considering the strategic and tactical planning issues of facility location, procurement, and resource allocation was proposed, considering the costs of the preparedness and response phases and ensuring social welfare, along with taking care of the ecological impacts of the packaging of relief goods, and CO2 emissions in transportation routes. The proposed model works in pre- and post-disaster phases. |

| Humanitarian supply chains focusing on social sustainability considering the environmental impact | [99] | Green humanitarian logistics and supply chains | A framework for green humanitarian supply chain management was developed which identifies the contingency factors related to stakeholders, the field of activity, and organizational management. |

| Decision support system for a sustainable humanitarian supply chain | [100] | Humanitarian supply chain and logistics | Master planning decision support system for managing a sustainable humanitarianism against key parameters such as effectiveness, efficiency, local empowerment, and pollution reduction. |

| Large scale disaster waste management under uncertain environment | [9] | Disaster management | A model was proposed considering economic objectives (total waste processing cost), environmental objectives (greenhouse gas emissions from waste processing facilities), and social objectives (job opportunities generated). |

| Drivers of sustainable supply chain management in industrial sectors | [101] | Supply chain management | Green product development (reducing waste, recyclable products) is an effective way to manage green supply chains, as well as ecological aspects (carbon management, eco-design, mutual responsibility towards environment, reducing hazardous effects of activities) in a sustainable supply chain management (optimal energy consumption, reduced production and environmental costs). |

| The response of the supply chain to natural disasters | [102] | Supply chain management: Sustainability | It was found that responding to natural disasters requires companies to reorganize their strategies towards sustainability and to develop new practices such as food safety, organic production, and social responsibility |

| Sustainable blood supply chain management under uncertainty | [103] | Supply chain management: Sustainability | A model was proposed for a multi-period and multi-objective sustainable blood supply chain with uncertain data due to an uncertain condition during a disaster and after, considering donor groups, blood collection facilities, distribution centers, and hospitals as the demand points. |

| Reverse logistics in humanitarian operations | [104] | Humanitarian supply chain and logistics | Developing commercial practice in the aftermath of a disaster or emergency is not comprehensively addressed by the reverse logistics based on the triple bottom line. Greenfield opportunities were highlighted for the support of host governments, aid agencies, donors, and most important of all, the affected populations. |

| Risk-based system for a sustainable textile supply chain | [105] | Supply chain management: Sustainability | A multi-criteria decision support system was proposed to evaluate the risks of different textile materials and the corresponding suppliers using sustainable development criteria, such as environmental protection, recycling capacity, energy-savings, human health and safety, and social impacts. |

| Industry 4.0|Digitalization | |||

| Operations management helping to build efficient, resilient, and sustainable capabilities | [93] | Operations management: Transition to Industry 4.0 | Several approaches have been effective to deal with the problems of material, information, and financial flows. To achieve sustainable and reliable performance in the Industry 4.0 epoch, industries must look forward by deploying cutting edge technologies such as digital twins, blockchain, big data analytics, artificial intelligence, virtual reality, and so on to ensure connectivity, clarity, and continuity for building reliable capabilities. |

| Digital inclusion for resilient agriculture supply chains | [94] | Digitization | Digital transformation was proposed to developing countries for building resilient and sustainable post-COVID-19 supply chains. |

| Internet of things (IoT) driven sustainable food supply management | [96] | Industry 4.0; IoT | A structured Fuzzy-TISM model was proposed to ensure sustainability and food security by reducing food loss and wastage across distribution channels. |

| Sustainable supply chain management for disaster resilience with the aid of big data | [97] | Supply chain management: Big data | It was concluded that swift trust, information sharing, and public–private partnerships are critical enablers of resilience in supply chain networks. |

| Reconfigurable supply chain | [43] | Supply chain management: Transition to Industry 4.0 | The framework of a reconfigurable supply chain was introduced to operate in highly vulnerable environments, dynamic supply chain meta-structures, and dynamic autonomous services. |

| Supply chain resilience and sustainability | [106] | Supply chain risk management | A simulation-based model identified that sustainable single-sourcing enhances the ripple effect, whereas facility strengthening mitigates the ripple effect and enhances sustainability. It also builds that a reduction in storage facilities in the supply chain downstream during disruption is risky, as facilities increases sustainability |

| Flexibility in manufacturing for supply chain and service operations | [107] | Supply chain management: Transition to Industry 4.0 | Certain challenges were identified to improve efficiency and resilience in manufacturing, services, and supply chain systems in the context of flexibility drivers, such as disruption risks, digitalization and smart operations, sustainability and closed-loop supply chains, and supplier integration. |

| Resilience|Robustness | |||

| Implications of the COVID-19 pandemic on slavery risks in SCs | [88] | Supply chain risk management | Tightly coupled supply chains, prioritizing short term efficiency goals are more prone to risks. A shift of value-based supply chain management is to be encouraged, away from a short term and arms-length cost focus, paving the way for triple-line approaches. |

| Way forward for viable supply chain management by integrating agility, resilience, and sustainably | [22] | Viable supply chain management | A viable supply chain management helps decision-makers to design structures and processes to adapt to changes positively, and to absorb negative disturbances, recover, and survive during ripple effects. |

| Environmental performance and resilience in sustainable logistics infrastructure | [108] | Logistics management | A hierarchical stream processing data decision and control system model was proposed to get insights about sustainability trade-offs for resilient and sustainable global transport. |

| Disaster resilient and sustainable reverse logistics in big data | [95] | Logistics management: Big data | A hybrid facility network was recommended, having forward as well as reverse logistics facilities for design making through a mixed-integer linear programming model. The model was tested under various man-made and natural disasters. |

| Sustainable procurement and logistics for disaster resilient supply chain | [109] | Supply chain management: logistics management | A model based on environmental sustainability through a cap-and-trade method of carbon emissions was proposed that can be used to design sustainable procurement logistics for disaster-resilient supply chain management |

| Integrating lean, green, and resilient sustainable food supply chain management | [110] | Supply chain management | A model was proposed for selecting the location of warehouses, most suitable plants, grids, in addition to applicable lean tools for the collection, distribution, and processing of food items, optimizing the overall process through waste removal and prevention, to improve economic and environmental sustainability performance. |

| Agriculture supply chain risk management under a circular economy context | [89] | Supply chain risk management | An integrated decision framework was defined to identify essential and sustainable characters of risk drivers in an agricultural production system. It ranks different agricultural crop zones that pretend to mitigate flood risks, and their impacts on crop zones/areas and the related agricultural supply chain. |

| Relief distribution for the sustainable disaster supply chain in large-scale natural disasters | [90] | Supply chain management: disaster management | The proposed model tries to maximize the lowest victims perceived satisfaction, and minimize, respectively, the largest deviation in victims’ perceived satisfaction for all demand points and sub-phases. |

| Sustainable humanitarian supply chain management under disasters | [111] | Humanitarian supply chain management: disaster management | A framework was proposed for supply chain design, integrating it with relief organization enablers, the population’s long-term requirements, along with socio-economic and governmental contingency factors. |

| Social entrepreneurship to recover from disasters | [91] | Disaster management | A conceptual framework was proposed, emphasizing the contributions of social entrepreneurship in planning, development, delivery, and distribution of services in long-term recovery humanitarian and development operations |

| The post-disaster challenge for supply chains | [92] | Supply chain management: disaster management | The developed model suggested that the poor strategic planning and lack of investment in ex-ante measures (limited number and capacity of shelters, and smaller number of in-country warehouses lead to the lack of sustainable relief aid. |

| Humanitarian logistics and supply chains for disaster resilience | [112] | Humanitarian supply chain management: disaster management | The framework aids emergency management agencies in the agility and resilience of emergency supply chains and logistics systems, particularly for the needs of underrepresented populations. |

| Assessing supply chain resilience | [113] | Supply chain management | A model based on three categories of indicators was proposed to assess resilience, such as an organizational resilience in terms of responsiveness, flexibility, and effectiveness, attaining business resilience (to assess by cash-to-cash, days of inventory, days of receivables, and days of payables), and labor resilience, based on capabilities for overcoming vulnerable living conditions. |

| Evaluating impacts of COVID-19 on supply chains | [5] | Supply chain risk management | It was concluded that the timing of the closing and opening of the facilities at different echelons might become a major factor that determines the epidemic outbreak’s impact on SC performance, rather than upstream disruption duration or the speed of epidemic propagation |

| Ref | Literature Gap | Open Questions and Opportunities for Future Research | Potential Solution Approaches |

|---|---|---|---|

| [90,101,103,105] | Optimized and novel models for sustainable operations in disturbed SCs during epidemic/disasters, for resource allocation in a dynamic environment, and for the development of sustainable SCs and smart production systems in smart cities | How can optimized and novel models help in responding to vulnerable SCs and show robust behavior with SC effects such as shortages, delays, and overhead costs? How new facilities can be developed to cater to the requirements of dynamic disruptive situations? How smart cities can help to support epidemic epicenters? | Robust optimization; Stochastic programming; Mixed-integer linear programming; Game theory; Dynamic capability |

| [87,92,98,100,104] | Optimized response to humanitarian logistics (forward and reverse), supply chains, and operations | How can the local and global SCs plan to respond to disasters at a local as well as global scale in terms of humanitarian relief? How to prepare a flexible humanitarian response, to plan for an epidemic anywhere? How parallel operations can help in sustaining reliable and quick humanitarian relief response through digitally supported SCs? | System dynamics Mixed-integer linear programming Socio-technical systems |

| [4,8,23,29,47,87] | Novel and severe disruptions to SCs and how a circular economy can help to sustain production capacities and manage insufficient supply and demand conditions | What are the scenarios that lead to severe ripple effect intensification? Do they cause long-term unremitting bullwhip effects? How can a circular and digitally supported economy help to reduce global shortages and mitigate the effects on production and global supply? | System dynamics Complexity theory Agent-based simulation Discrete event simulation Informational processing theory |

| [53,90,95,99] | Severe effects on the ecology of epidemic outbreaks in SCs | How to restore and take benefit from severely impacted SCs in a societal and organizational context? How can the focus on environmental sustainability be intensified, such as carbon emission reduction, pollution reduction etc.? | Agent-based simulation Discrete event simulation Knowledge-based systems Mixed-integer linear programming |

| [106,109,112,113] | Drastic reduction in the sales of multiple industrial business and global SCs, and coping with the shortages of medical supplies; building resilient capabilities to repurpose operations during disruptions | How can disruptions to global SCs sales affect short- and long-term goals? How can resilience strategies help in this situation? How can immediate transition and repurposing of factories make it possible to meet novel demands? | System dynamics Discrete event simulation Contingency theory Digital twinning |

| [30,122,123,124] | Delocalization of manufacturing facilities and reducing the dependence on others | How to reduce dependence and build inhouse capabilities for manufacturing effectively? What are the potential effects on economies because of relocating major manufacturing facilities? | System dynamics Discrete event simulation Contingency theory |

| [44,83,94,125] | Blockchain as an aid to reduce disruption effects through effective information flow | How blockchain technologies, such as traceability through visibility and security can help to reduce the shortages? How can this help in quickly responding to the disruption? | Complexity theory Reliability theory Dynamic capabilities Convex programming Mixed-integer linear programming |

| [22,43,93,96,103,116,126,127,128] | Artificial intelligence and additive manufacturing to support SCs during epidemic outbreaks | How artificial intelligence can help industries through digital manufacturing and other assistive technologies in the epoch of epidemics? How can artificial intelligence help in making responsive models, and by providing an optimized strategy through heuristics? How to make an assessment of technological readiness, and roadmap the transformation journey to combat future disruptions? How additive manufacturing assistance with artificial intelligence can repurpose manufacturing demand through digital as well as social media data analytics? How can additive manufacturing contribute to meet urgent demand, such as surgical masks, protective equipment, and so on? | System dynamics Discrete event simulation Organizational resilience Complexity theory Heuristics Machine/Deep learning-based models |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farooq, M.U.; Hussain, A.; Masood, T.; Habib, M.S. Supply Chain Operations Management in Pandemics: A State-of-the-Art Review Inspired by COVID-19. Sustainability 2021, 13, 2504. https://doi.org/10.3390/su13052504

Farooq MU, Hussain A, Masood T, Habib MS. Supply Chain Operations Management in Pandemics: A State-of-the-Art Review Inspired by COVID-19. Sustainability. 2021; 13(5):2504. https://doi.org/10.3390/su13052504

Chicago/Turabian StyleFarooq, Muhammad Umar, Amjad Hussain, Tariq Masood, and Muhammad Salman Habib. 2021. "Supply Chain Operations Management in Pandemics: A State-of-the-Art Review Inspired by COVID-19" Sustainability 13, no. 5: 2504. https://doi.org/10.3390/su13052504

APA StyleFarooq, M. U., Hussain, A., Masood, T., & Habib, M. S. (2021). Supply Chain Operations Management in Pandemics: A State-of-the-Art Review Inspired by COVID-19. Sustainability, 13(5), 2504. https://doi.org/10.3390/su13052504